Axial flow fan

A technology of axial flow fan and diameter reducing part, which is applied to non-variable-capacity pumps, pumps, electrical components, etc., can solve problems such as troublesome cross-sectional shapes of conductive pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

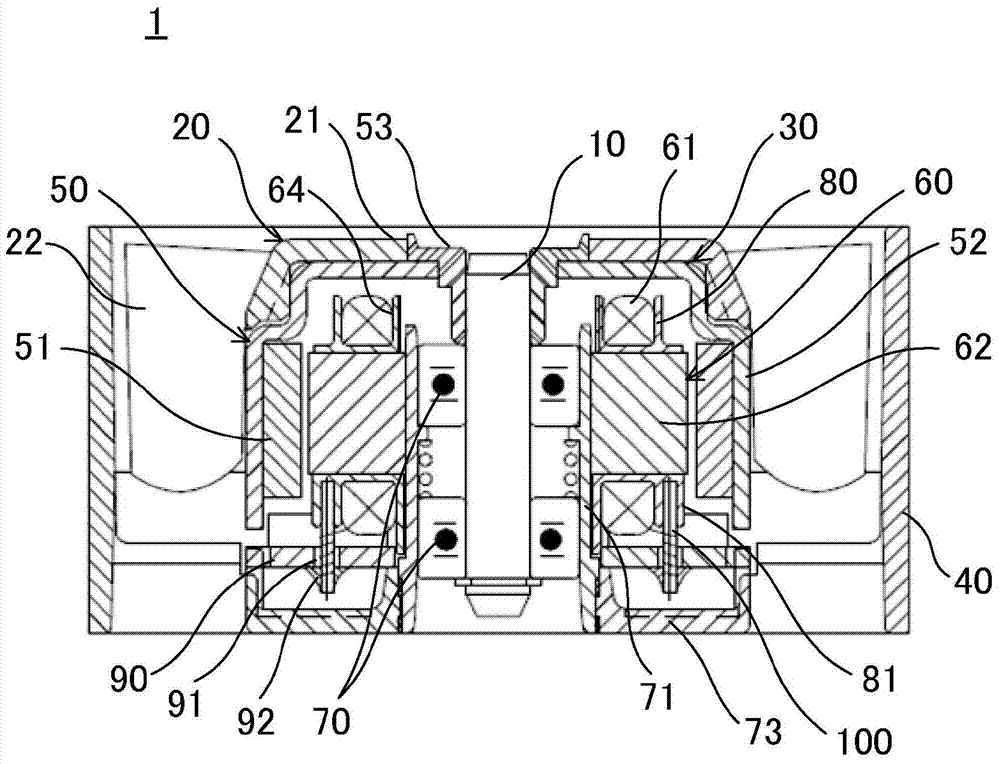

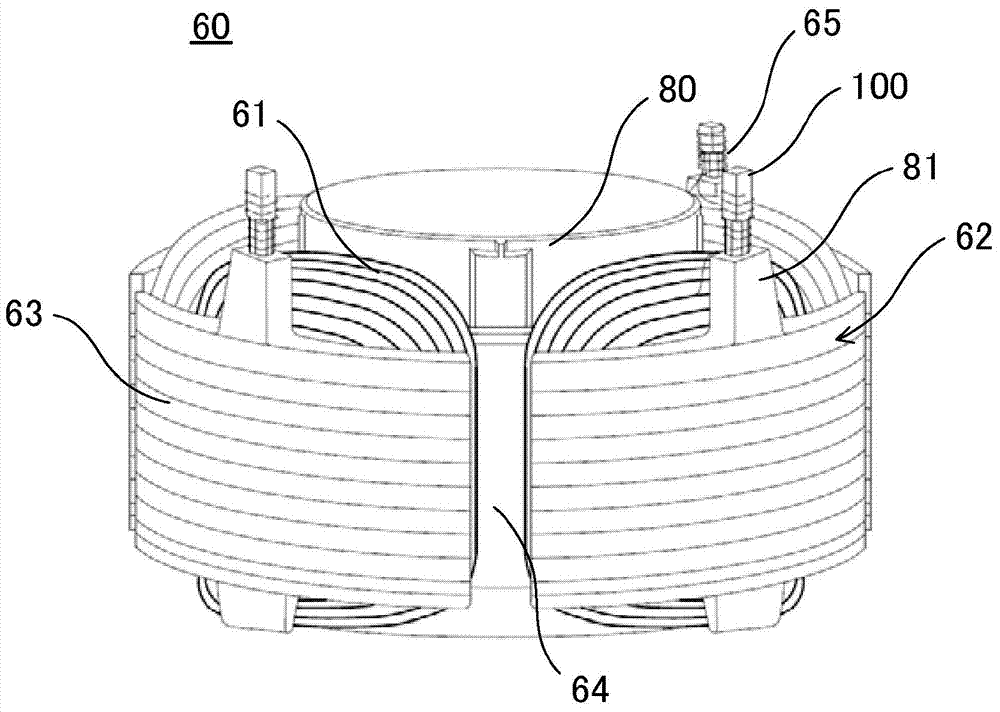

[0047] Next, an axial flow fan according to this embodiment will be described with reference to the drawings.

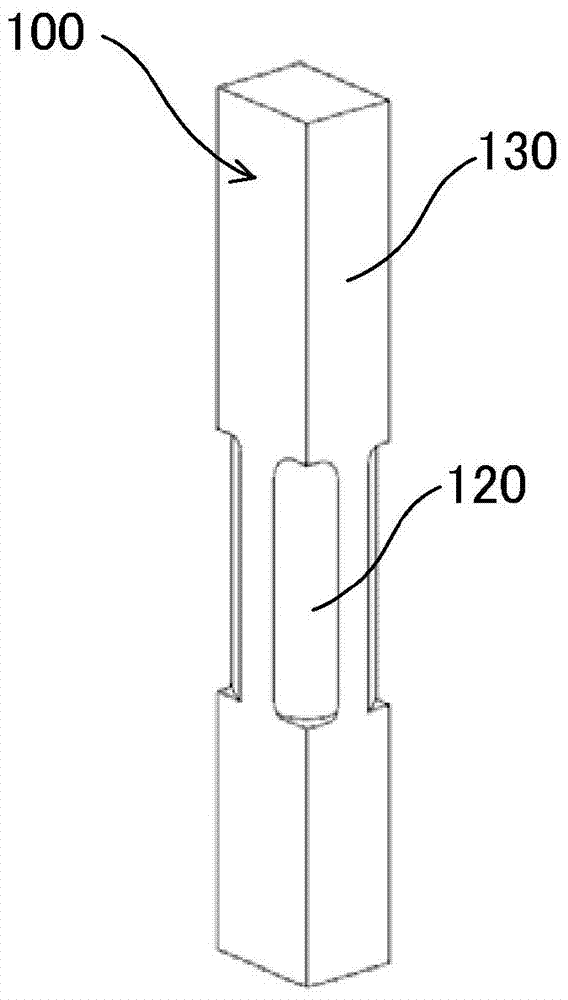

[0048] In the axial flow fan of this embodiment, the shape of the conductive pin is a square prism (square prism pin) as the basic shape, and at least a part of the exposed portion exposed from the electrical insulator has a reduced diameter portion that does not have the corners of the square prism pin. . According to this embodiment, it is possible to realize an axial flow fan having a conductive pin that can reliably hold the film wire of the coil, prevents disconnection even when an unexpected load is applied to the film wire, and can respond to the end of winding. Automatic cut-off of the membrane leads. It should be noted that, in this embodiment, although the basic shape of the conductive pin is set as a quadrangular prism with an internal angle of 90°, the basic shape of the conductive pin may also be a triangular prism with an internal angle of less than 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com