Four-roller downward-pressing-type stone diamond wire cutting machine

A diamond wire and cutting machine technology, which is applied in stone processing equipment, stone processing tools, grinding racks, etc., can solve problems that affect cutting efficiency and cutting stability, diamond wire is prone to breakage, and provide stable tension, etc. , to achieve the effect of improving cutting efficiency and cutting quality, improving cutting quality and efficiency, and facilitating installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to further explain the technical solution of the present invention, the following will be described in detail in conjunction with the examples.

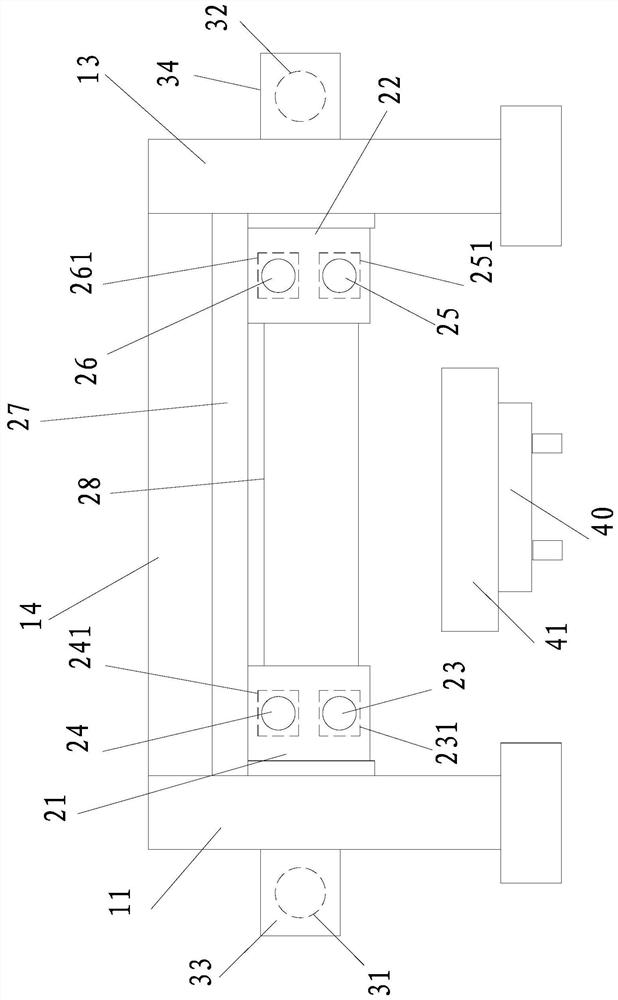

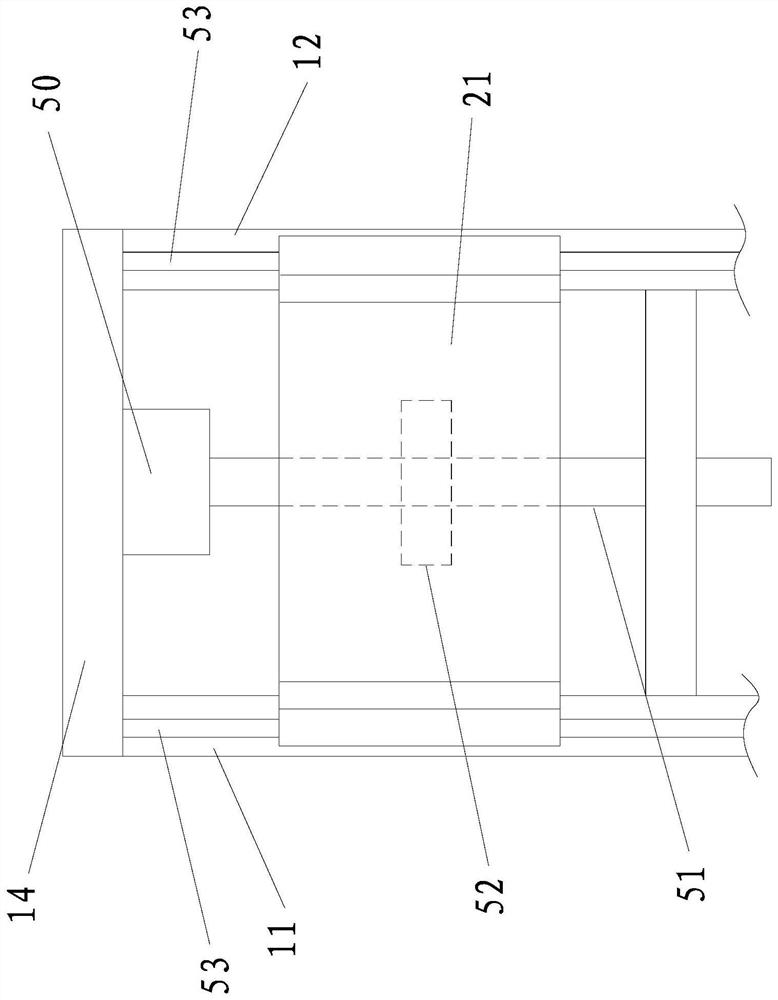

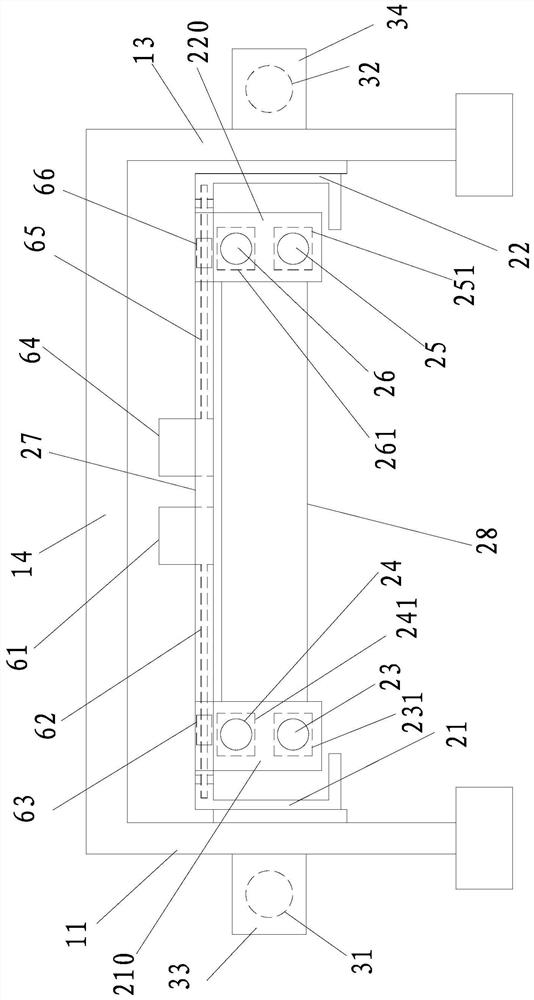

[0057] refer to Figure 1 to Figure 10 , Four-roller down-pressure stone diamond wire cutting machine, including frame 100, diamond wire 28, wire roller and take-up and pay-off device, diamond wire 28 is wound on the wire roller and connected to the take-up and pay-off device. In the present invention, the line rolls include a first line roll 23 arranged horizontally, a second line roll 24 above the first line roll 23, a third line roll 25 and a fourth line roll above the third line roll 25 26. In the embodiment, the four wire rollers are distributed at the four corners of the rectangle. In the present invention, the four wire rollers can also be arranged in a trapezoidal shape.

[0058] The first line roll 23, the second line roll 24, the third line roll 25 and the fourth line roll 26 are rotatably installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com