Patents

Literature

50results about How to "Cutting does not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adhesive tape cutting mechanism and method thereof

ActiveCN106876043ASolve wear and tearCutting effectManufacturing wire harnessesEngineeringMechanical engineering

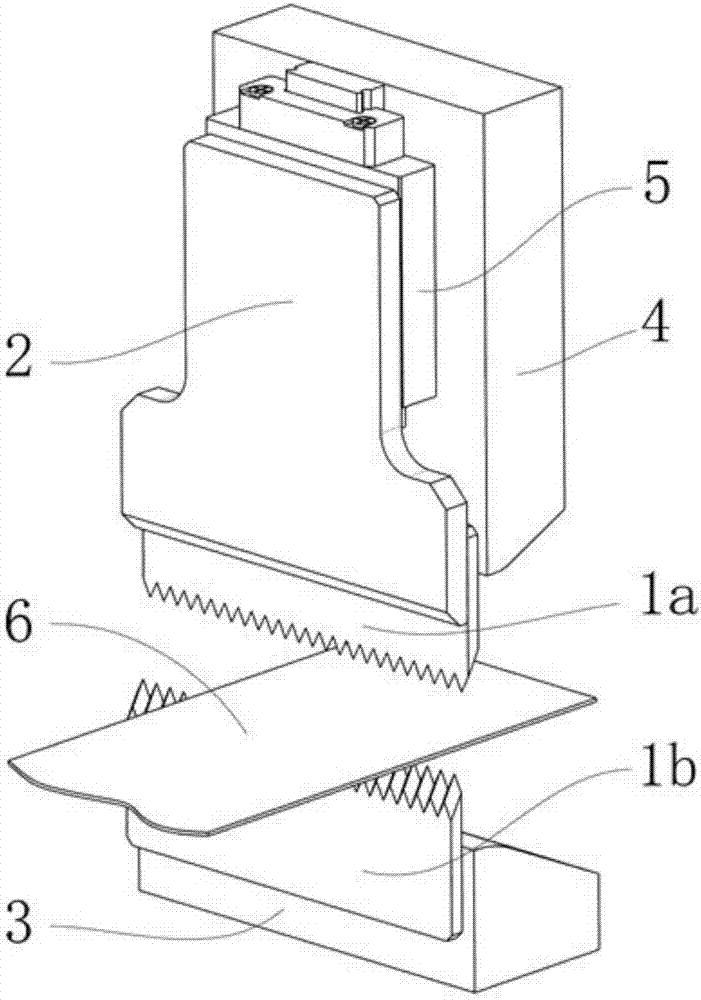

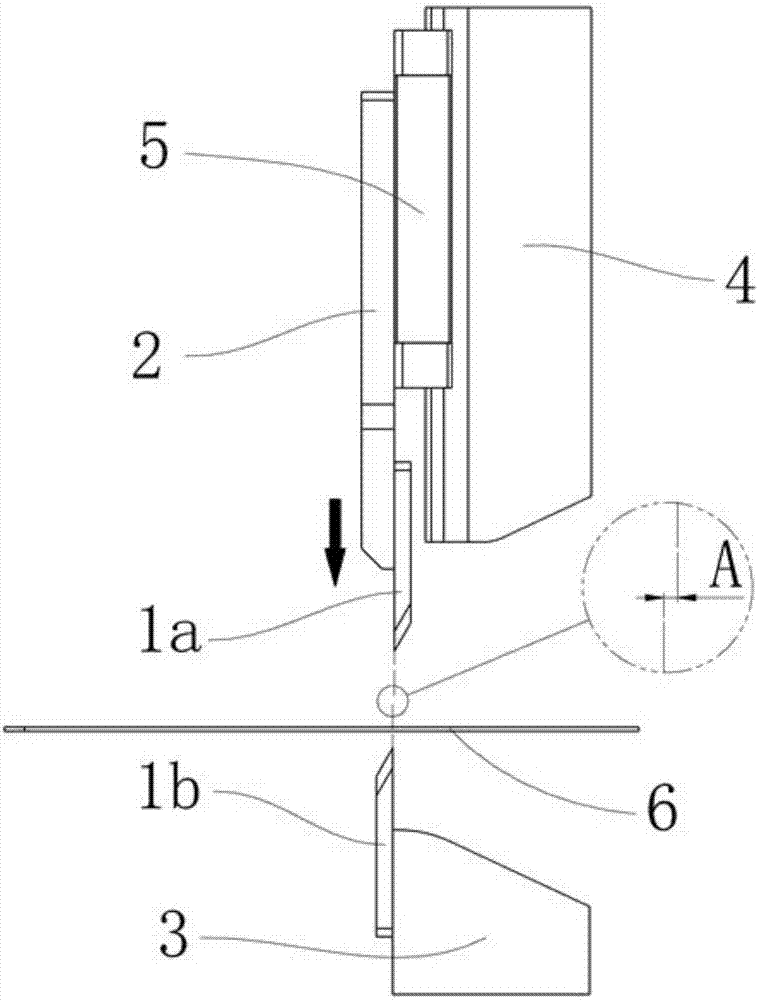

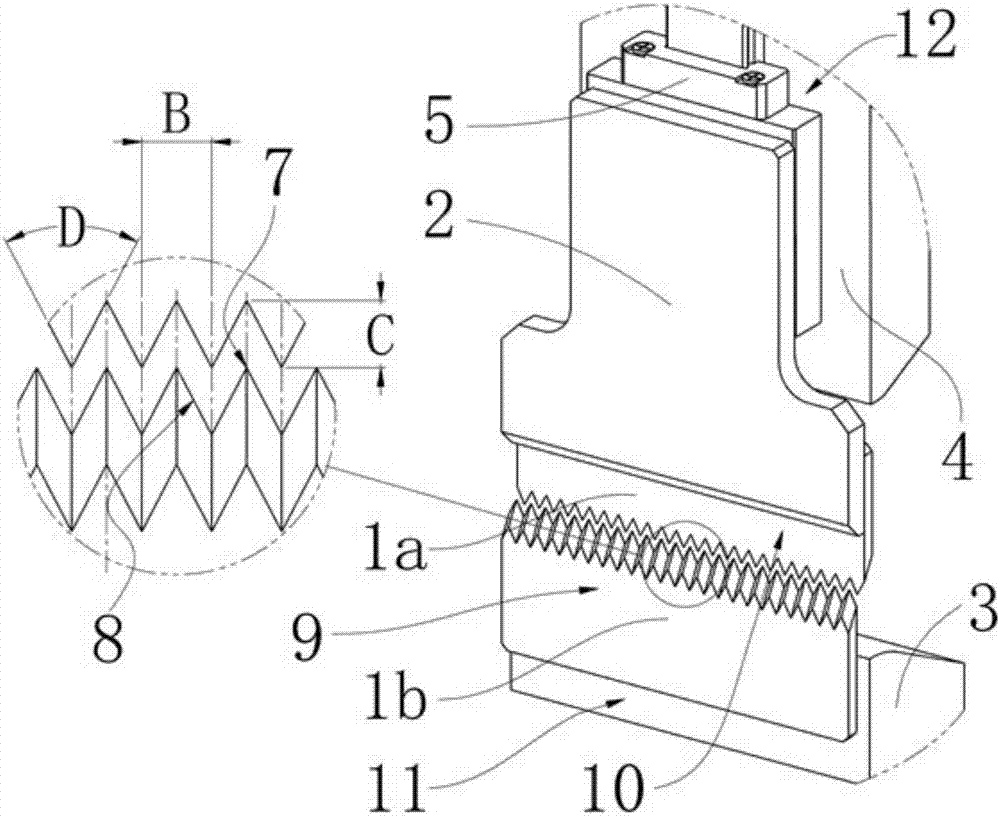

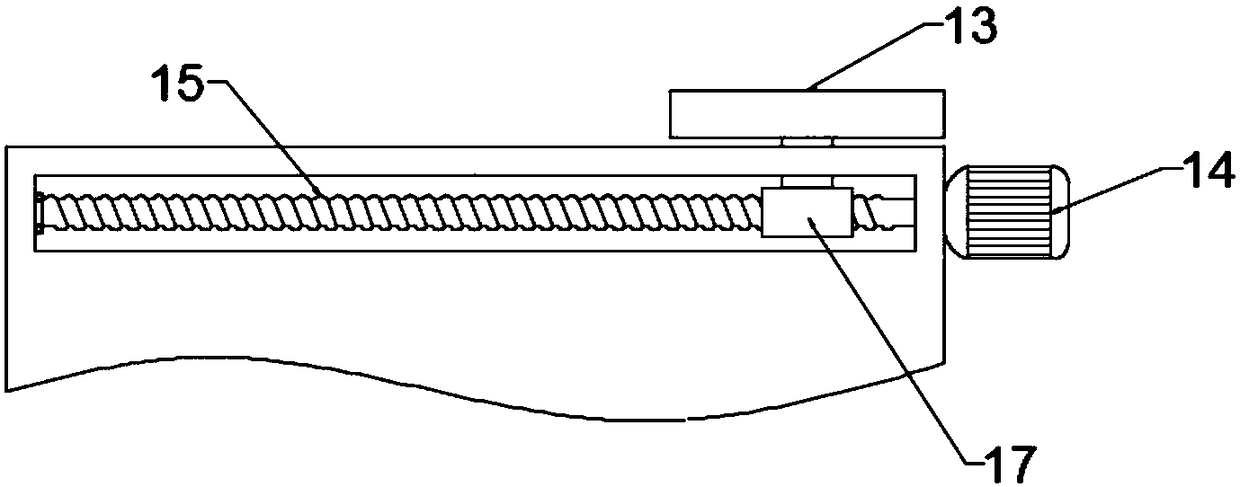

The invention discloses an adhesive tape cutting mechanism and a method thereof, and belongs to the field of automatic devices. The cutting mechanism comprises an upper blade and a lower blade. Each of the edged part of the upper blade part and the lower blade part is in the shape of sawtooth. The sawteeth of the two blades are arranged on two sides where a to-be-cut adhesive tape in the cutting mechanism. A driving device is arranged on the upper blade and / or the lower blade and is used for driving the two blades to oppositely move and pierce the adhesive tape from opposite directions. Moving journeys of the sawtooth parts of the upper blade and the lower blade are overlapped to a certain degree in a position where the to-be-cut adhesive tape is arranged. In the overlapped journey, non-edged parts of the two blades get close to each but keep a certain distance. According to the invention, blades can be prevented from being abraded in actual application; the cutting mechanism and the method are quite suitable for all kinds of highly adhesive cloth-based adhesive tapes; and even if an inevitable adhesion phenomenon exists in a cutting process, cutting of the adhesive tape will not be affected.

Owner:ZHUJI CANU AUTOMATION EQUIP CO LTD

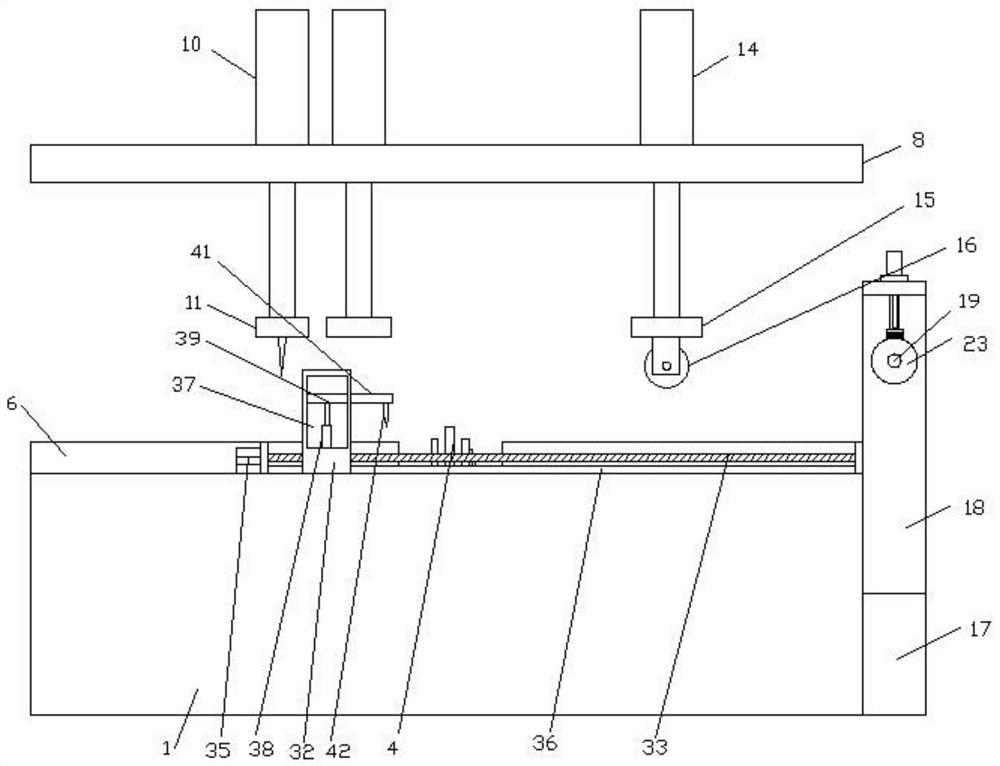

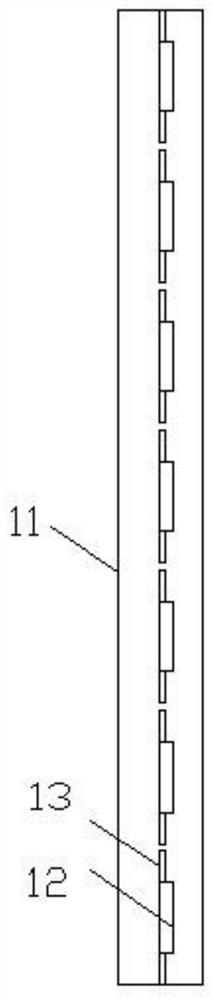

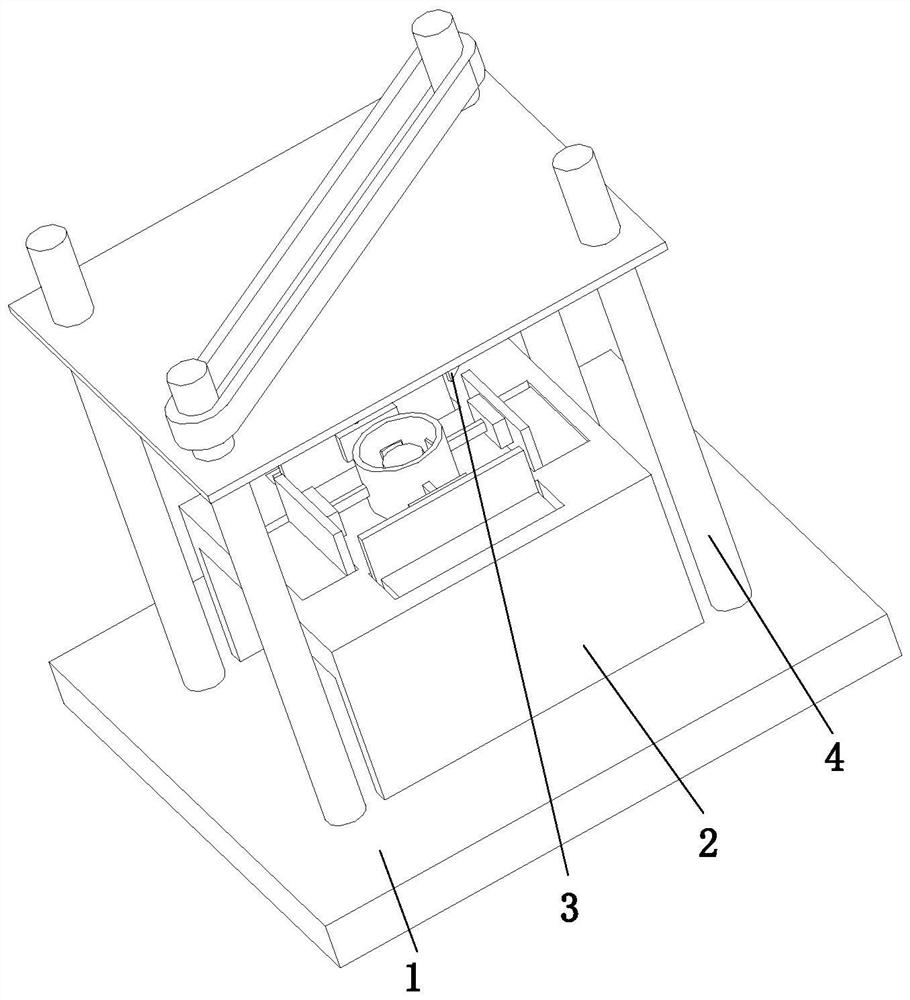

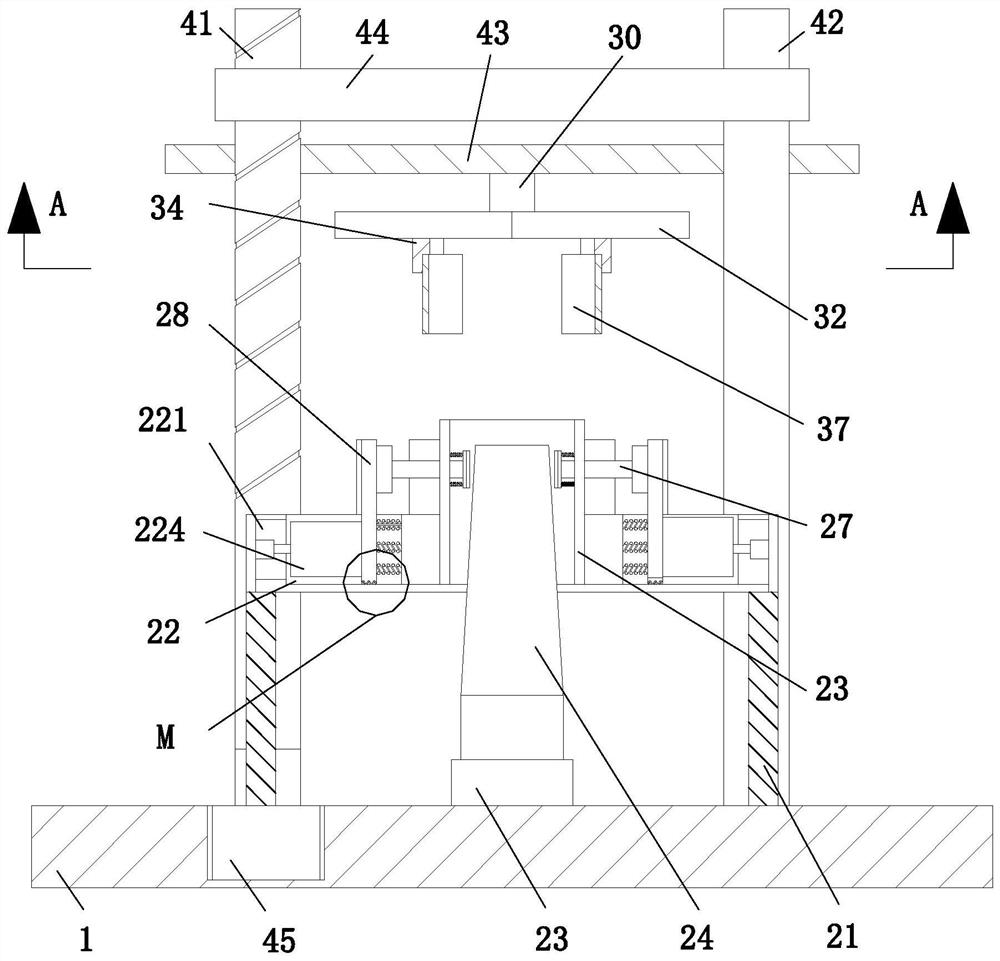

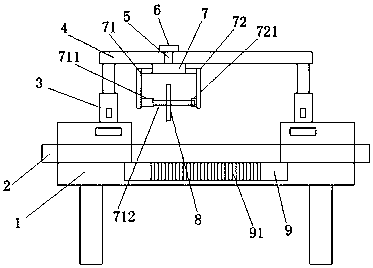

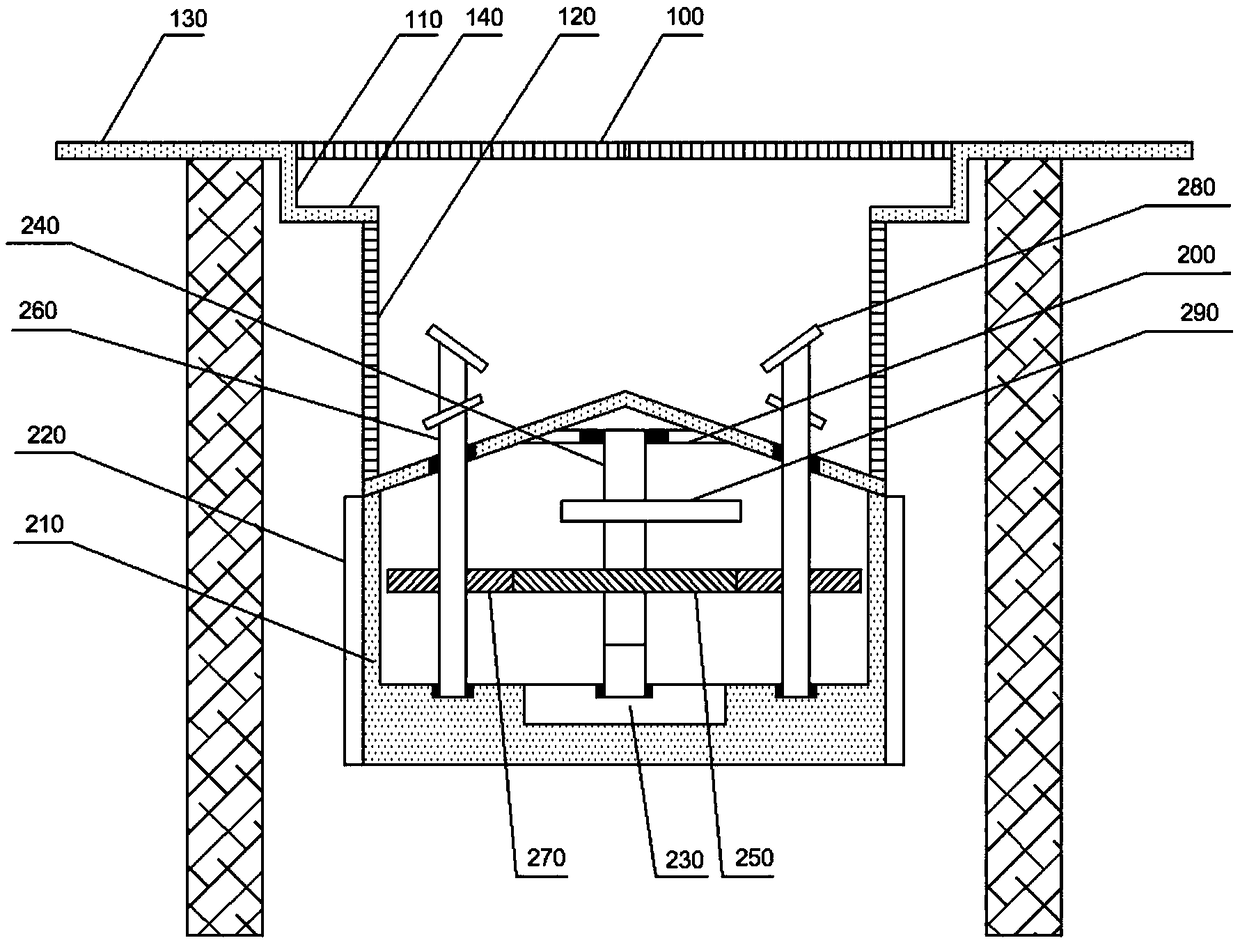

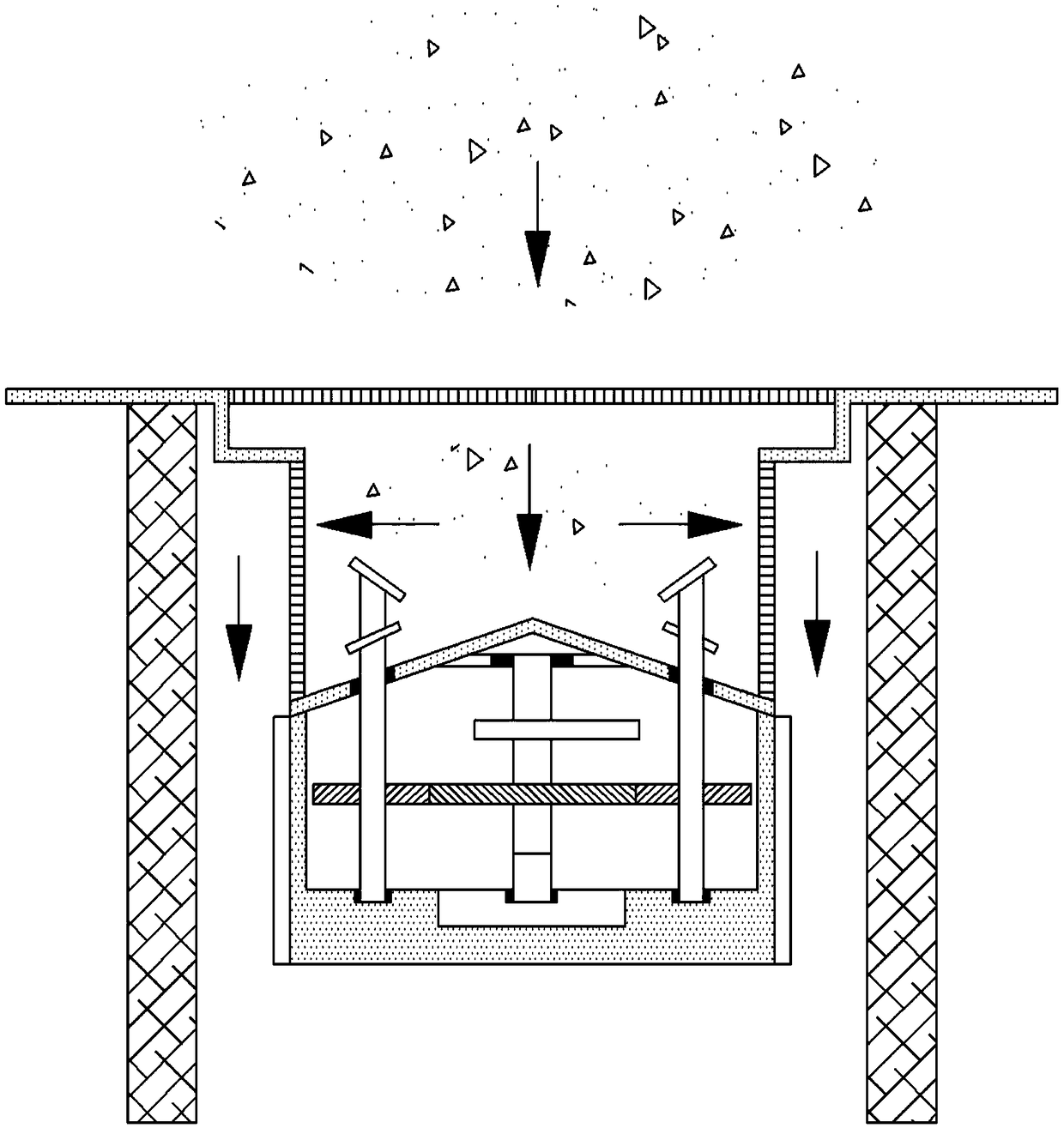

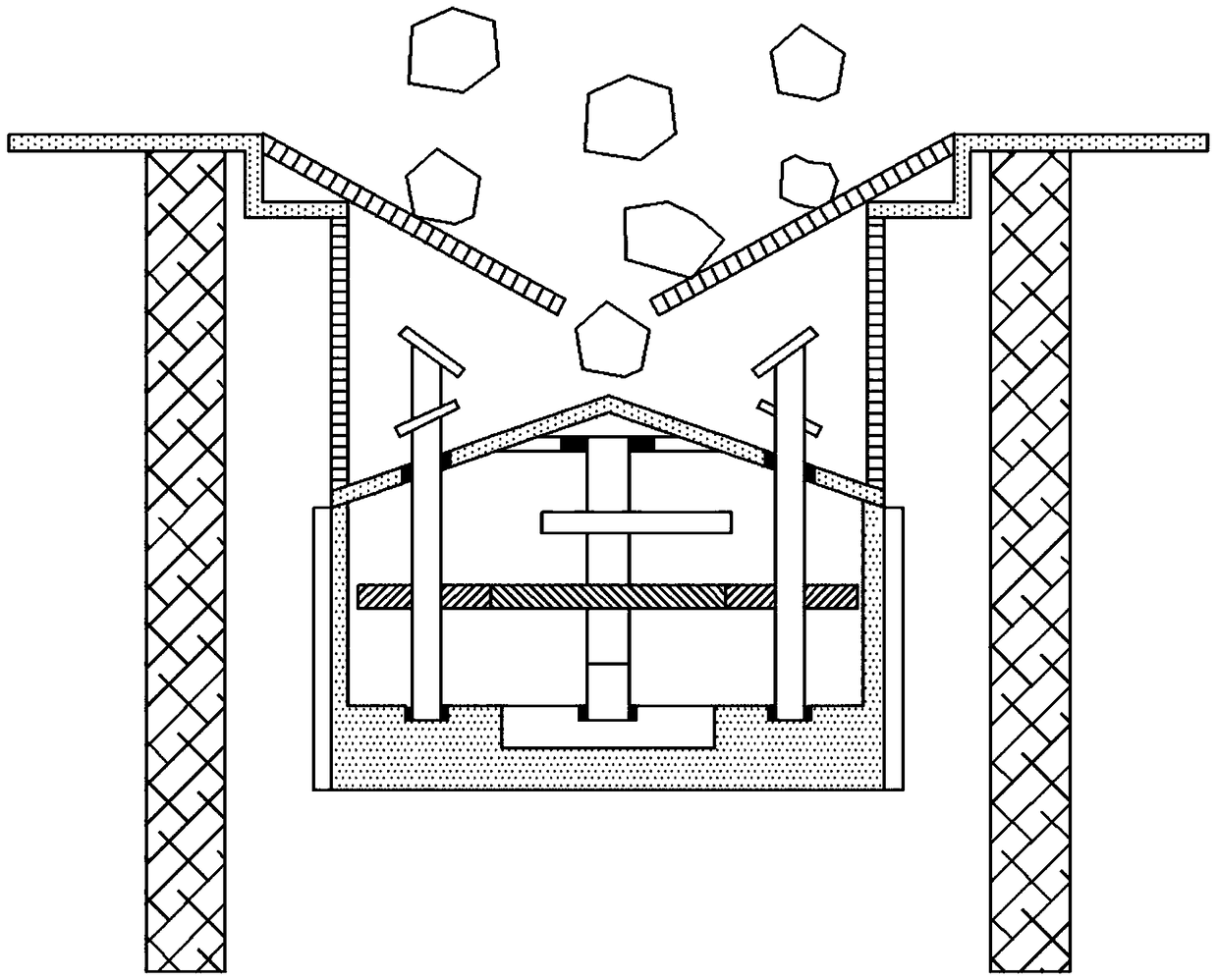

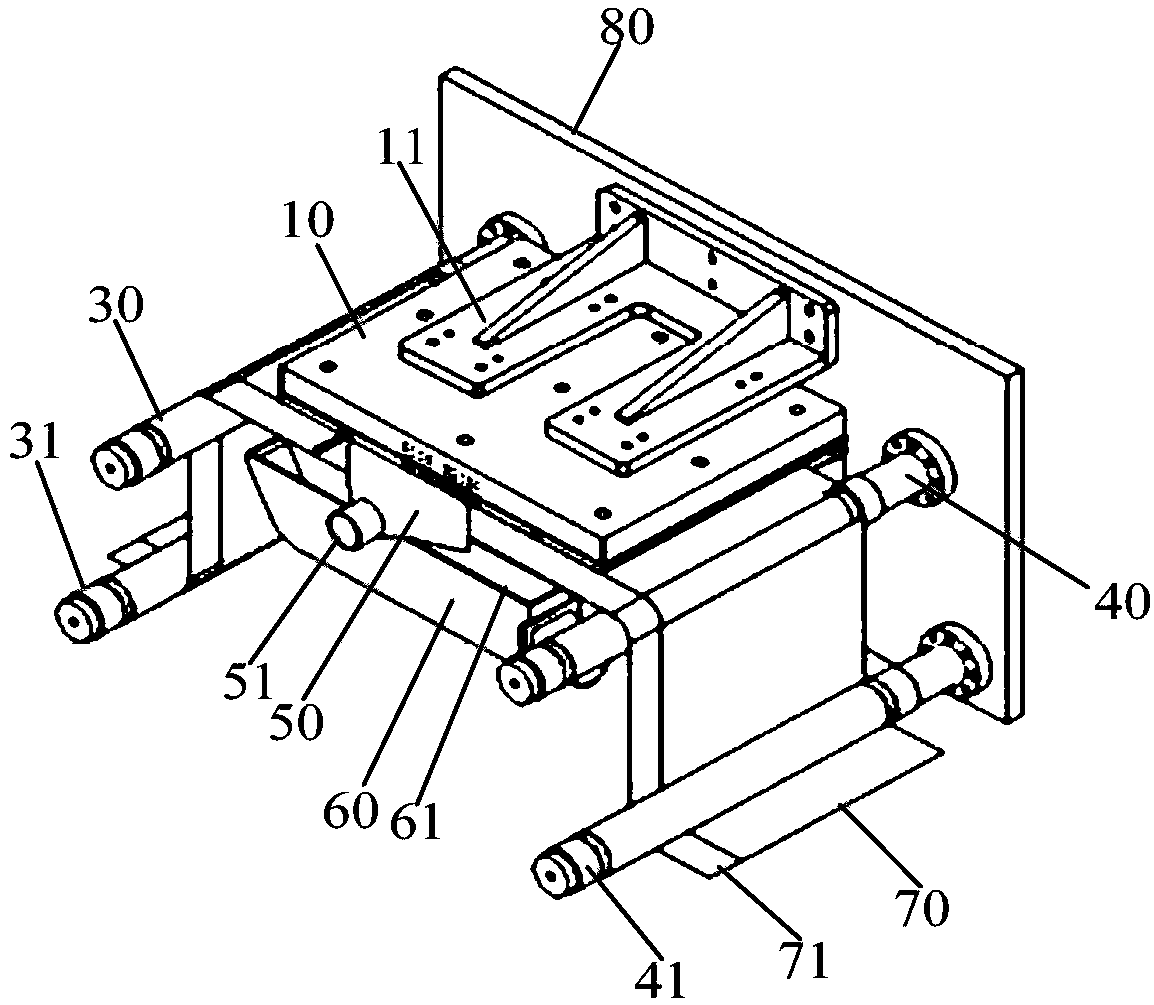

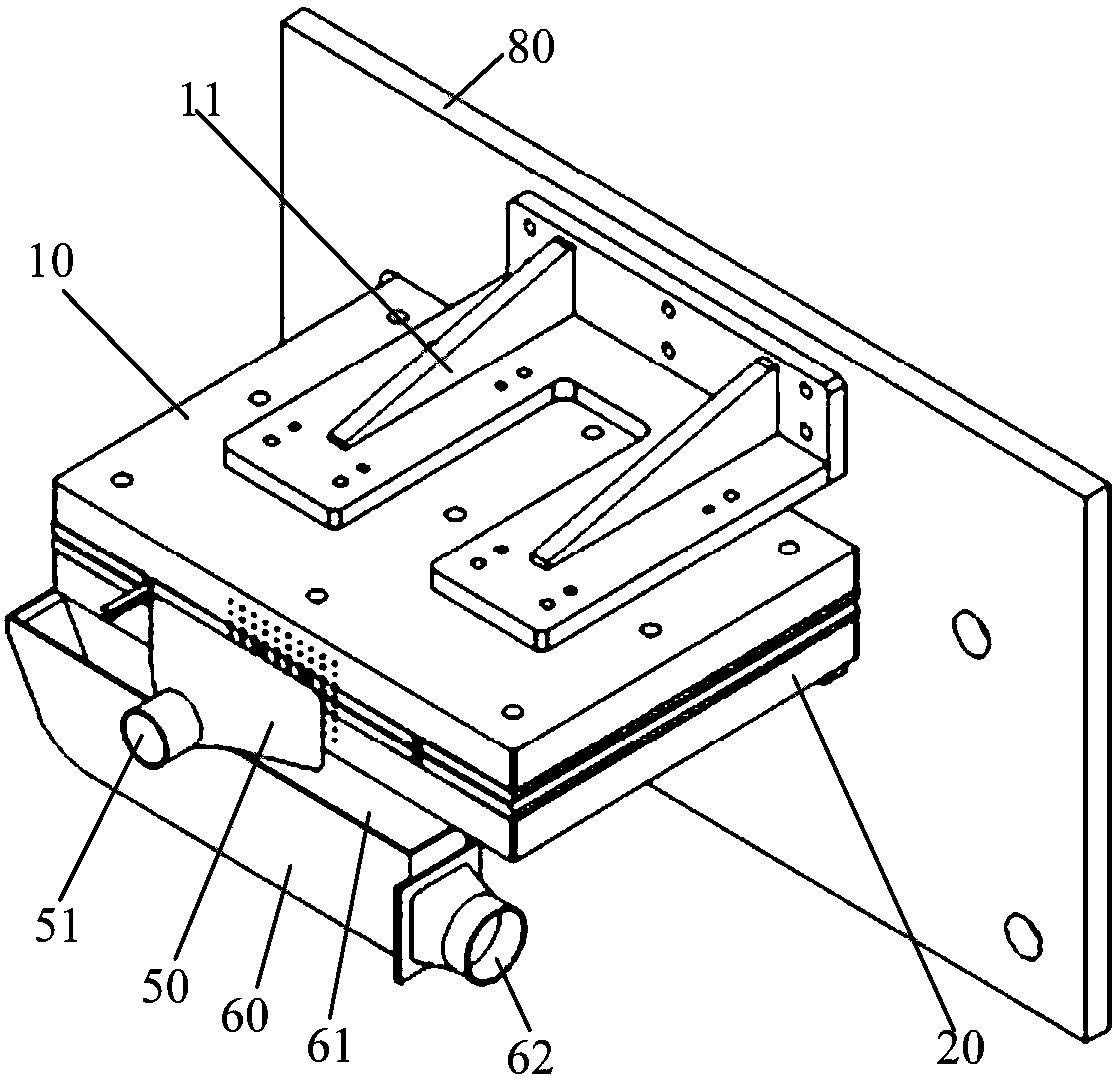

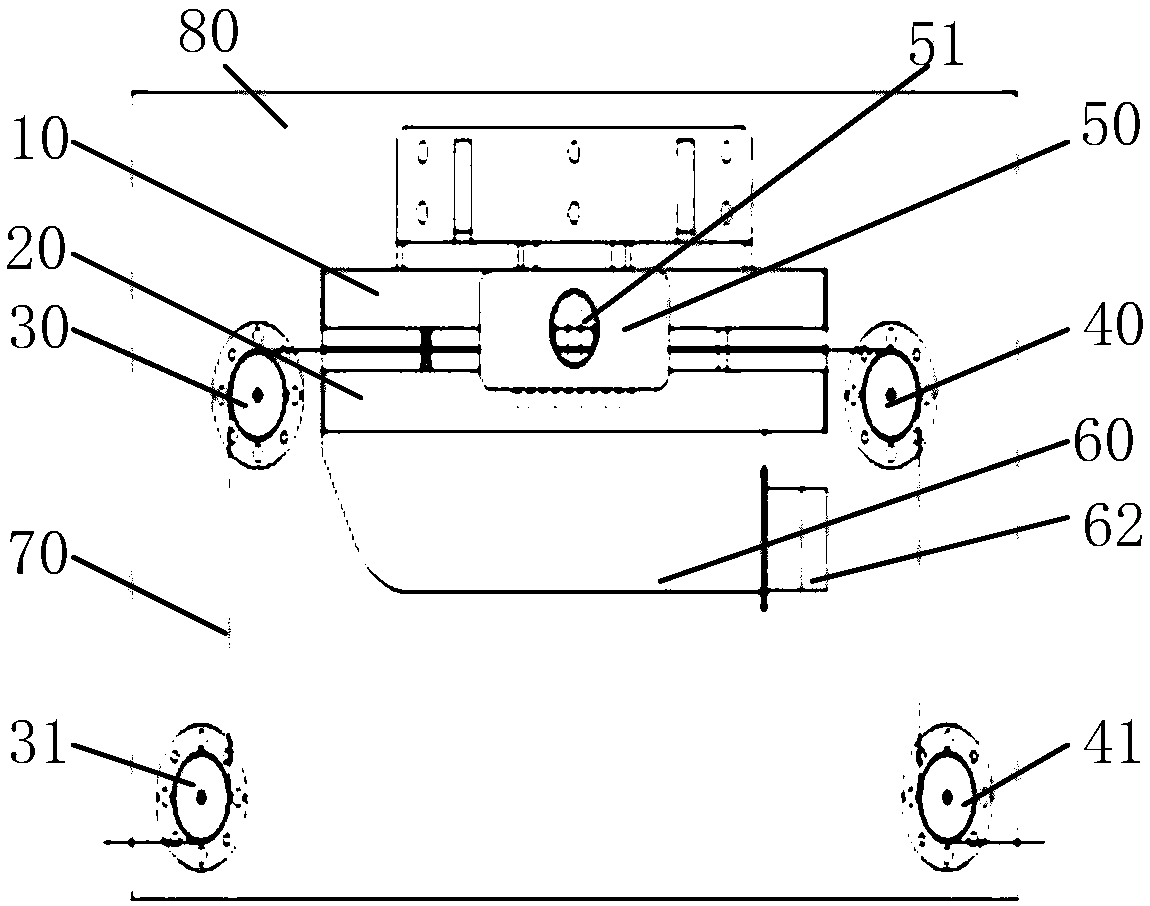

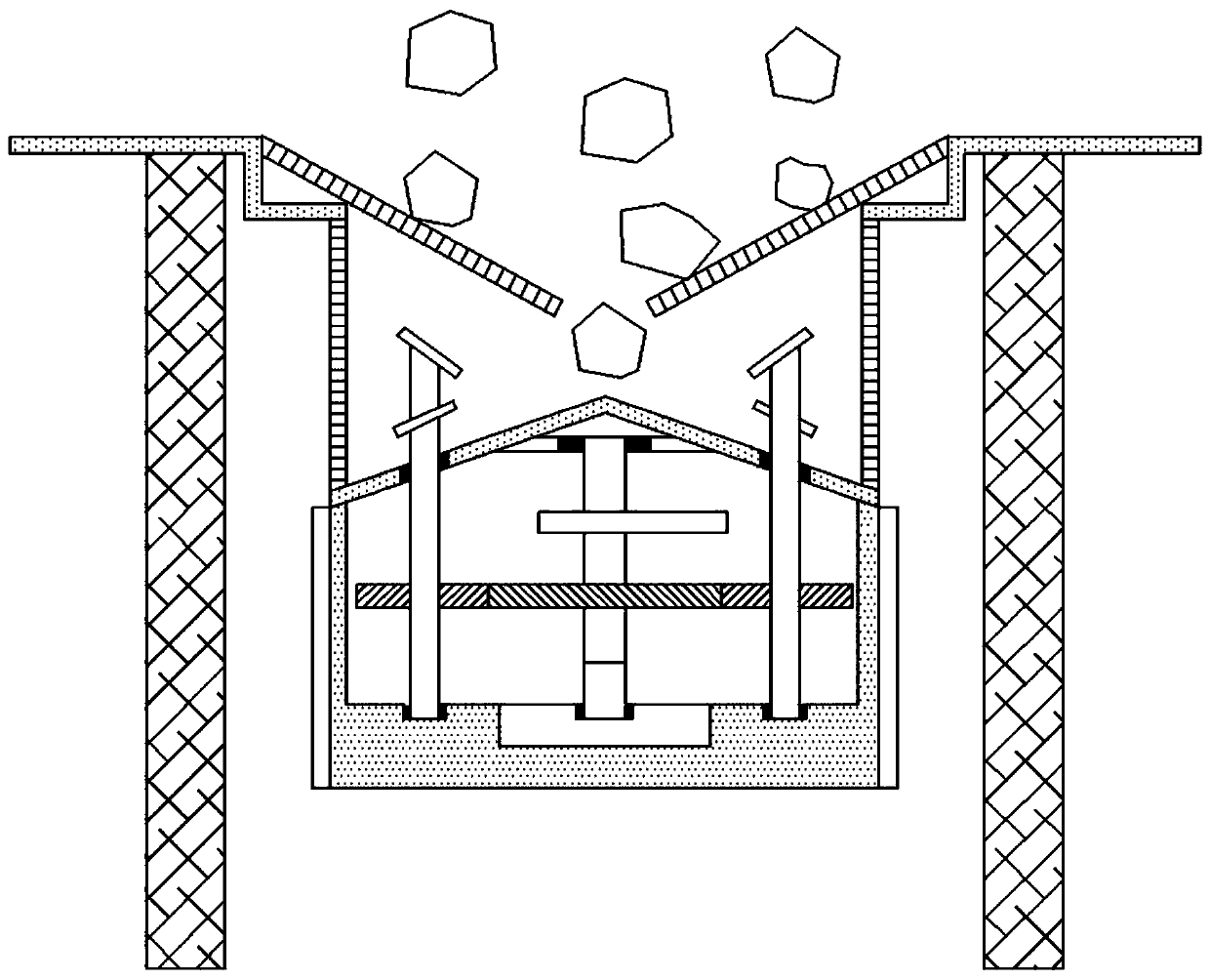

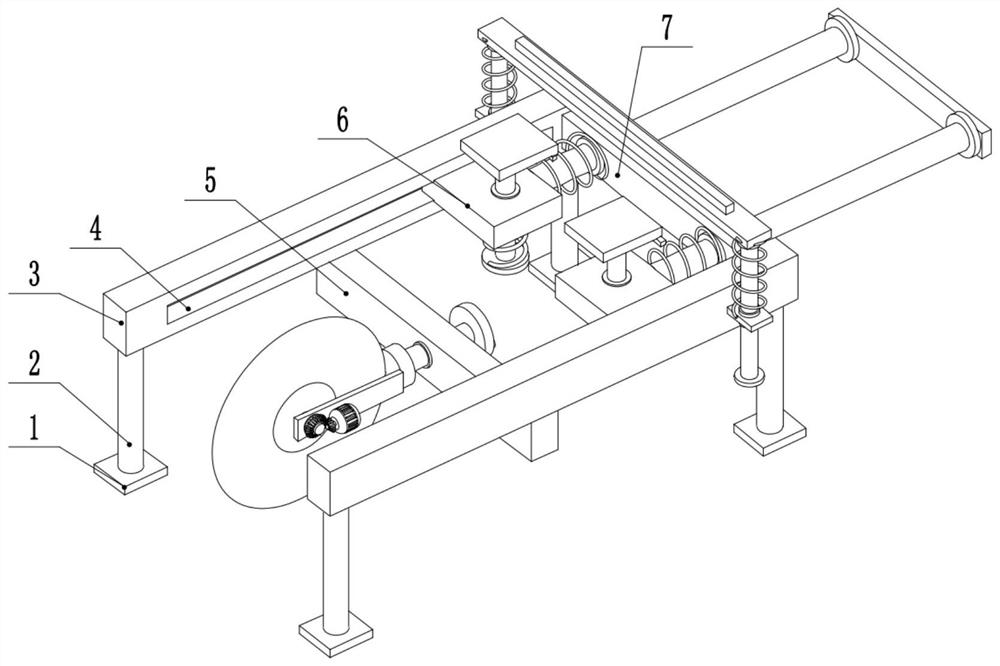

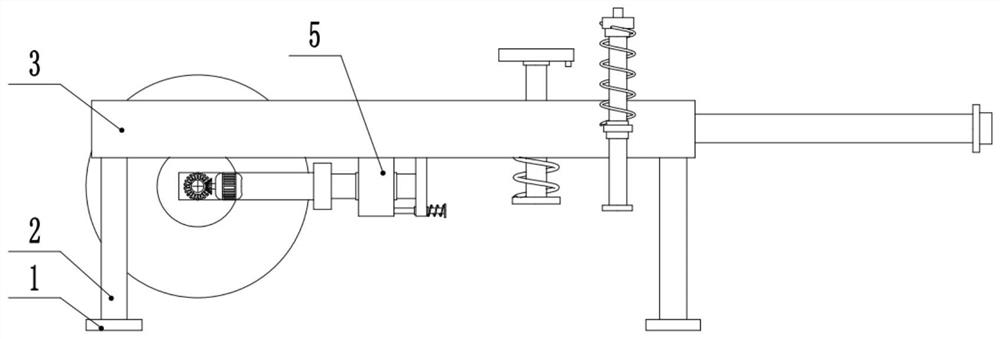

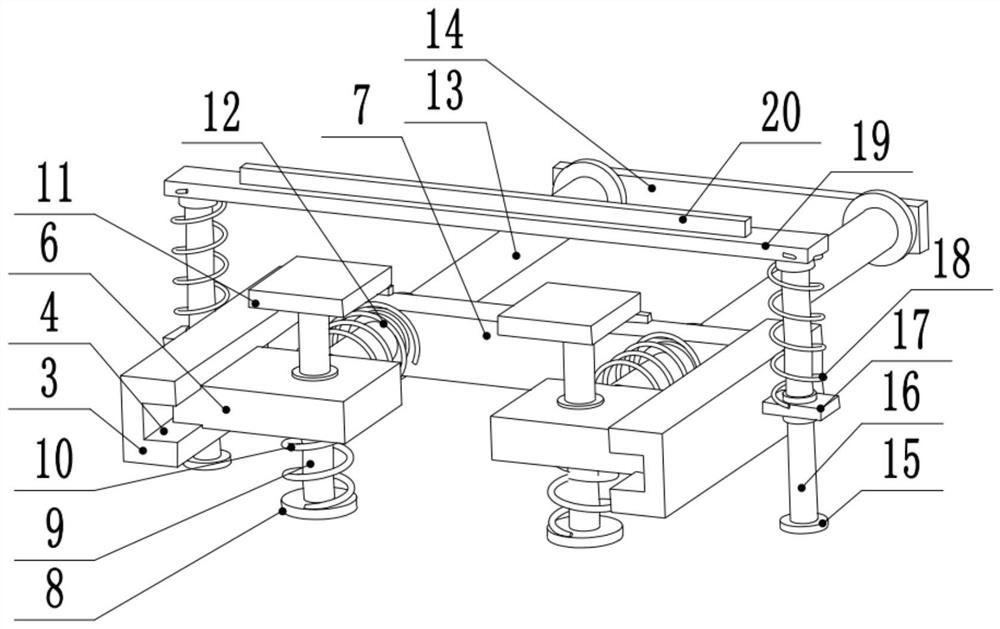

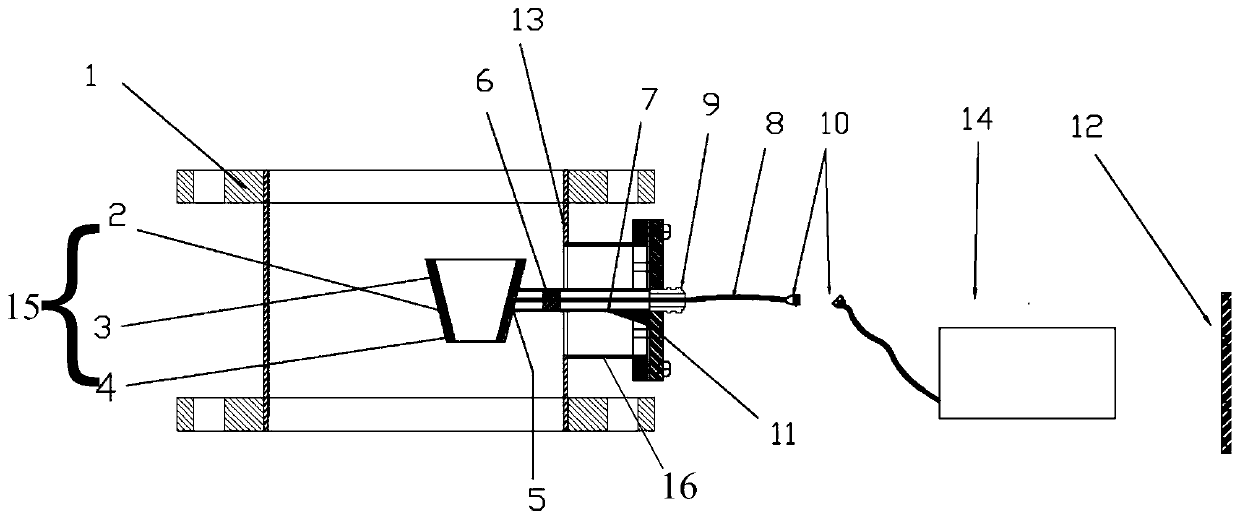

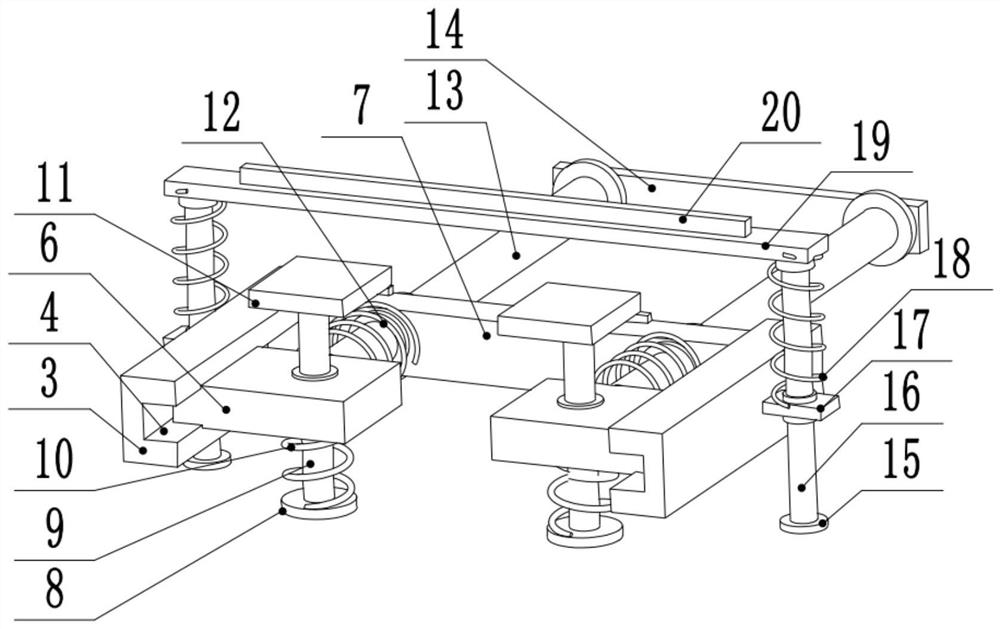

Four-roller downward-pressing-type stone diamond wire cutting machine

PendingCN111745833AEasy to installEasy to debugGrinding carriagesGrinding drivesWire cuttingStructural engineering

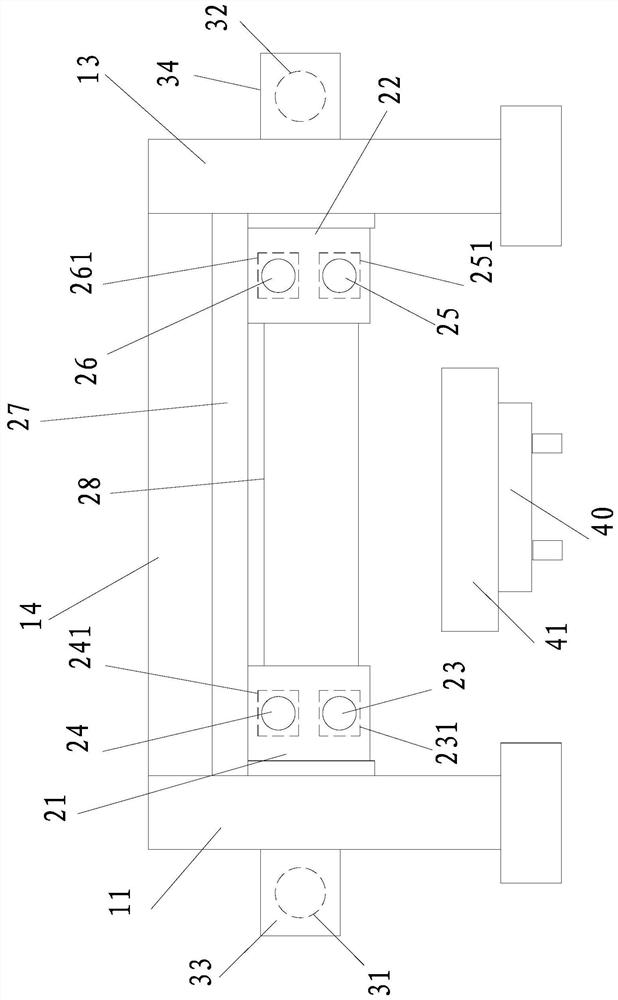

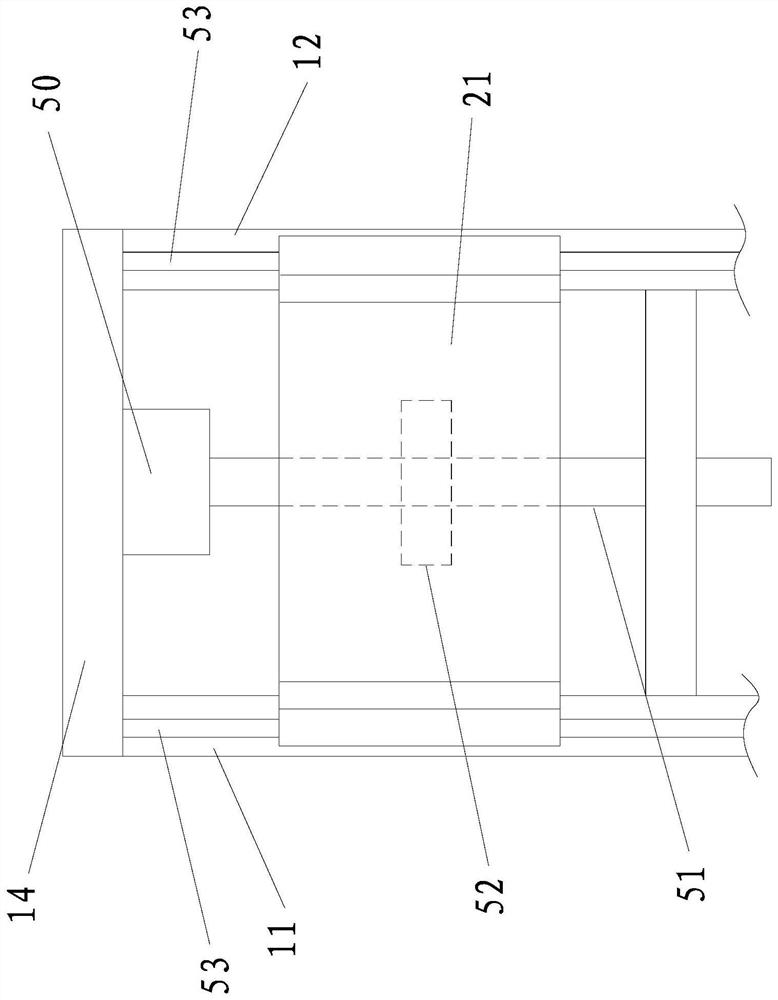

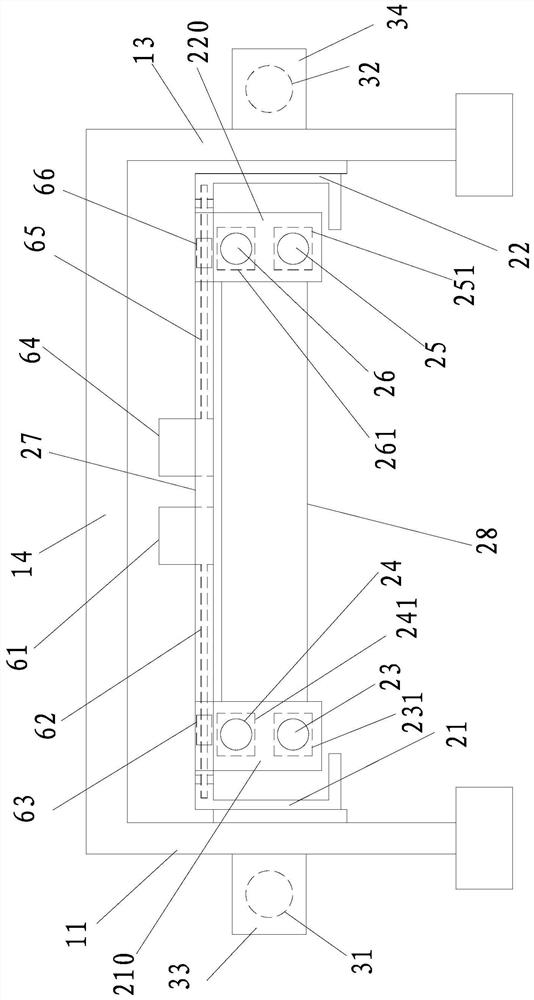

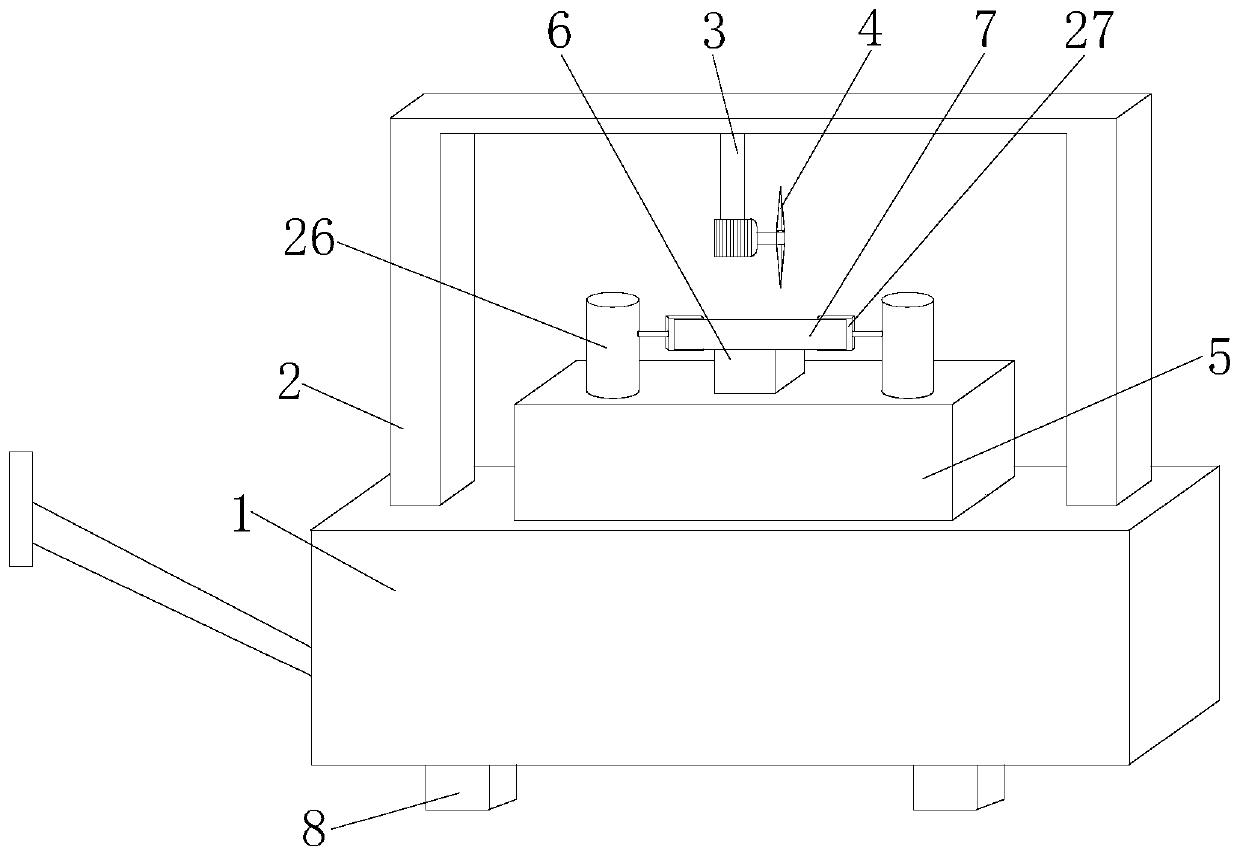

The invention relates to a four-roller downward-pressing-type stone diamond wire cutting machine. The four-roller downward-pressing-type stone diamond wire cutting machine comprises a rack, a diamondwire, wire rollers and a take-up and pay-off device; the diamond wire is wound on the wire rollers and connected to the take-up and pay-off device; the wire rollers comprise a first wire roller, a second wire roller, a third wire roller and a fourth wire roller which are all arranged in the horizontal direction; the first wire roller and the second wire roller are rotatably mounted on a mounting frame, and the third wire roller and the fourth wire roller are rotatably mounted on the mounting frame; the mounting frame can be mounted on the rack in an up-down moving mode; and the four-roller downward-pressing-type stone diamond wire cutting machine further comprises a driving mechanism used for driving the mounting frame to move up and down. The mounting frame is driven to move up and down through the driving mechanism, the diamond wire travels in the take-up and pay-off device and moves downwards along with all the wire rollers to form a reciprocating cutting action, stone is cut and does not need to be lifted, energy consumption is reduced, saw cutting is more stable, in addition, all the wire rollers can ascend and descend, and mounting and debugging of the diamond wire are convenient.

Owner:XIAMEN PINHE PRECISION TECH CO LTD

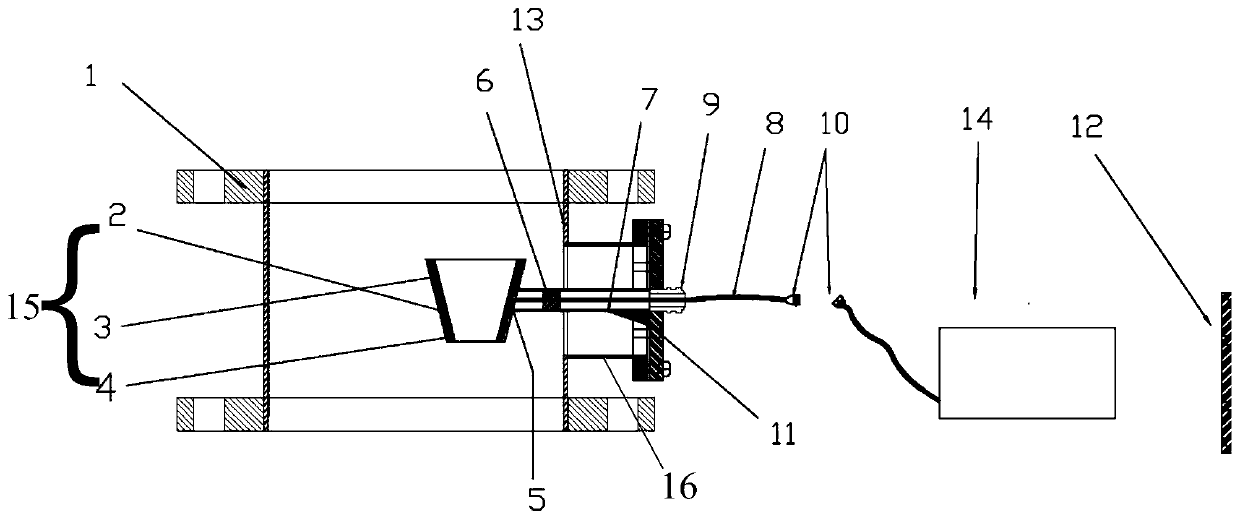

Automatic focusing high-efficiency laser cutting device

ActiveCN107335927AAchieve the role of laser cuttingAchieve the function of automatic adjustment of laser cuttingLaser beam welding apparatusEngineeringLaser cutting

The invention provides an automatic focusing high-efficiency laser cutting device. The automatic focusing high-efficiency laser cutting device comprises a sliding module, a connecting rod, a detection module and an adjusting module. The sliding module comprises a sliding block and a tension spring. The sliding module is provided with a sliding shell. The sliding shell is internally provided with a cavity. A sliding groove is formed in the portion, making contact with a laser cutting head, of the sliding shell. The lower end of the sliding shell is provided with a through hole. The detection module is designed into a circular ring shape. The adjusting module comprises an adjustment lever. An adjustment groove corresponding to the sliding groove is formed in the portion, making contact with the laser cutting head, of the adjusting module. The automatic focusing high-efficiency laser cutting device can automatically change the position of a laser cutting focus according to the thickness of a workpiece and meanwhile adjust the laser cutting strength for more flexible cutting.

Owner:温州市镭诺科技有限公司

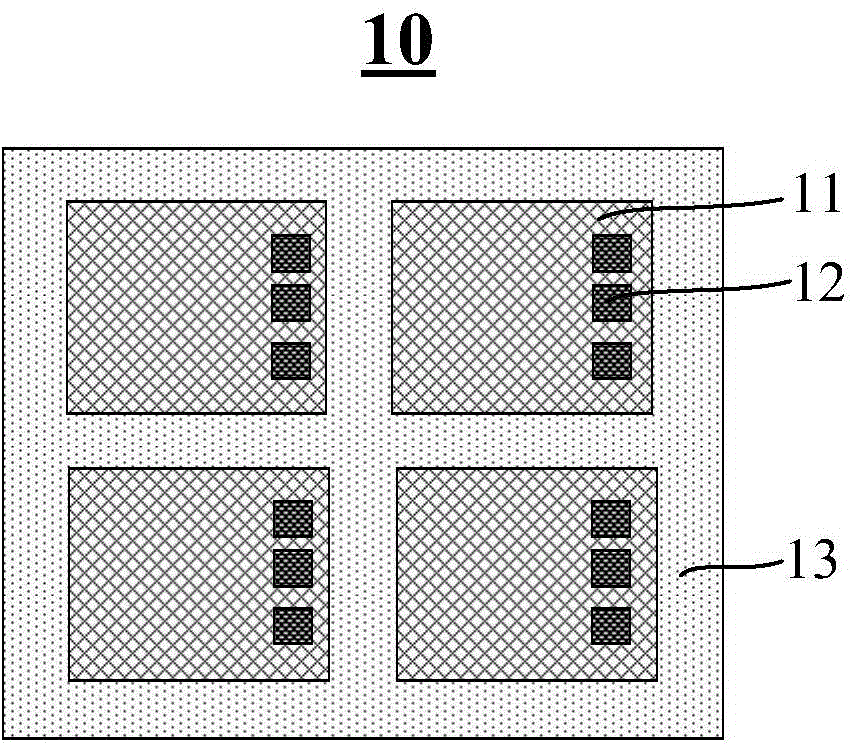

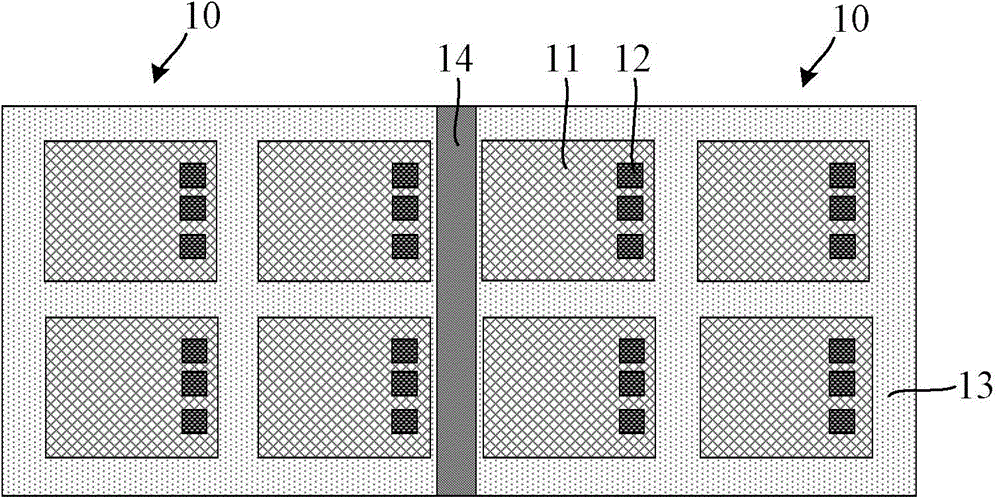

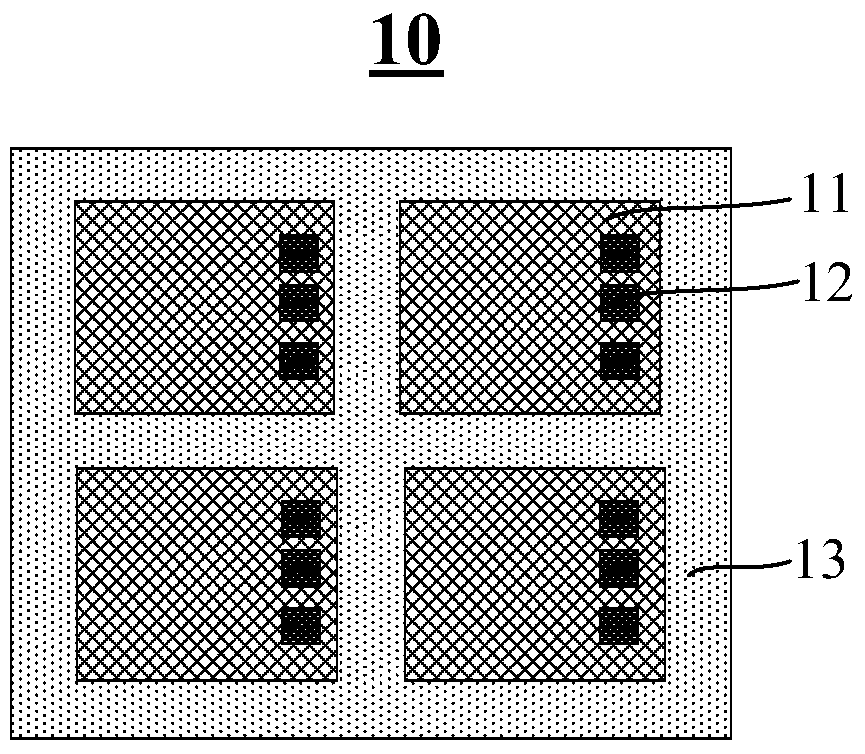

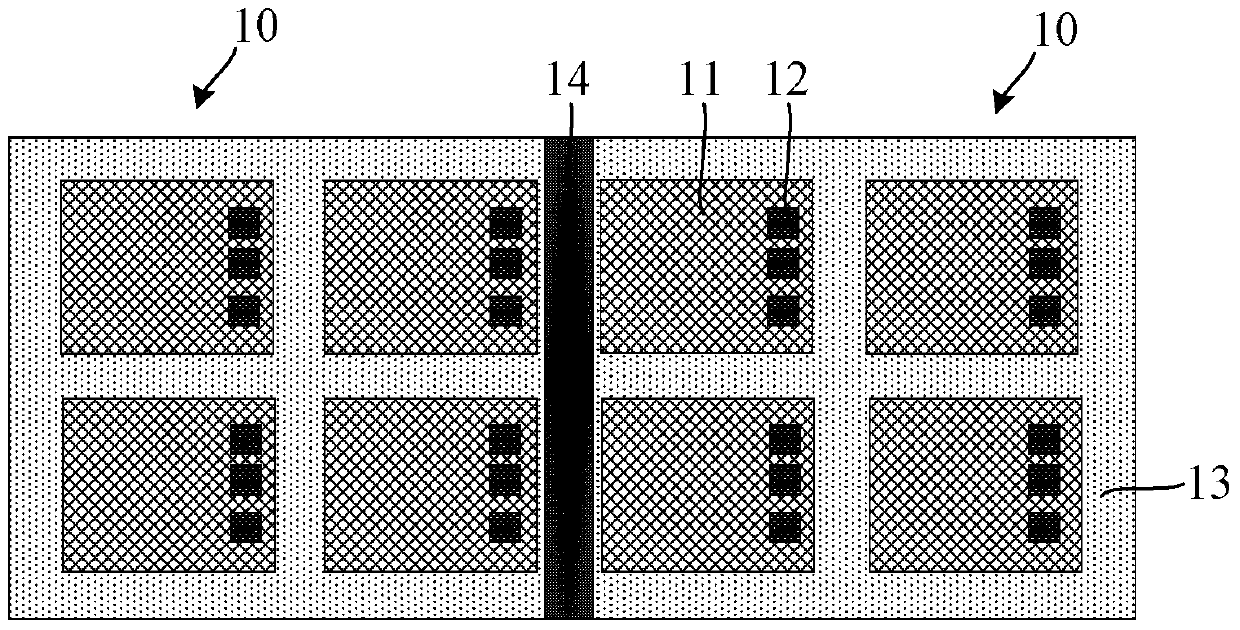

Chip structure and manufacturing method thereof

ActiveCN105826286AWon't hurtQuality assuranceSemiconductor/solid-state device detailsSolid-state devicesEngineeringMetal

The invention provides a chip structure and a manufacturing method thereof. According to the invention, a welding pad is formed on a cutting channel at one side of a first direction of a chip and is connected with the chip through a metal connecting wire, a test probe is pricked into the welding pad located at the cutting channel when a CP test is carried out subsequently, and no damage is imposed on the chip, so that the quality of the chip can be ensured, and the number of available chips of a wafer is increased. In addition, subsequent cutting for the chip structure is not affected after the CP test is completed. Furthermore, the invention provides a manufacturing method of the chip structure. A photomask unit on the cutting channel at the other side of the first direction of the chip is set to be a dark portion, thereby avoiding secondary exposure for the public cutting channel, ensuring the performance of the welding pad on the public cutting channel, and enabling the CP test to be carried out smoothly.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Winding device used in cutting process of fireproof thermal insulation material

The invention discloses a winding device used in the cutting process of a fireproof thermal insulation material. The winding device comprises a workbench, a cutting groove is formed in the upper end of the workbench, conveying belts are arranged at the positions, located on the two sides of the cutting groove, of the upper end of the workbench correspondingly, a first mounting frame is arranged above the workbench, a punching mechanism is fixed to the first mounting frame, a first hydraulic cylinder is fixed to the first mounting frame, the first hydraulic cylinder and the punching mechanism are located on the two sides of the cutting groove correspondingly, a piston rod of the first hydraulic cylinder is fixed to a first mounting plate, a pressing roller is mounted at the lower end of the first mounting plate, a lifting table is arranged on one side of the workbench, a second mounting frame is fixed to the upper end of the lifting table, a winding roller is mounted on the second mounting frame and fixedly sleeved with a winding barrel, a gluing mechanism is arranged on the second mounting frame and used for gluing the upper end face of the winding barrel, and a traction mechanism is installed at the upper end of the workbench and used for pulling cut-off materials to the winding barrel. By means of the winding device, the cut materials can be automatically wound.

Owner:安徽省绩溪县华宇防火滤料有限公司

Formation processing method for foam packaging box

The invention relates to a formation processing method for a foam packaging box. The formation processing method adopts a workbench, a fixing device, a cutting device and a moving device; the fixing device is installed at the top of the workbench; the cutting device is arranged above the fixing device; and the moving device is arranged at the top of the workbench and located above the cutting device. According to the formation processing device provided by the invention, by cooperation of the workbench, the fixing device, the cutting device and the moving device which are arranged, firstly, foam packaging boxes to be chamfered are placed on the fixing device and are then fixed and fixed by the fixing device according to different sizes of the foam packaging boxes; subsequently, the cuttingdevice is correspondingly adjusted according to the sizes of the foam packaging boxes; and finally, the cutting device is pushed by the moving device to cut the foam packaging boxes to be chamfered,so that the applicability of the machine is improved.

Owner:桂煦明

Lathe machining cutting device for hollow slender shaft

InactiveCN111331152AHigh precisionAvoid bendingAuxillary equipmentTurning toolsStructural engineeringMachining

The invention discloses a lathe machining cutting device for a hollow slender shaft. The lathe machining cutting device comprises a control body, wherein an electric sliding sleeve is fixedly arrangedon the bottom surface of the control body, the electric sliding sleeve is arranged on the top surface of a sliding rail in a front-back sliding mode, a connecting cavity with a leftward opening, a moving cavity and a sliding cavity are formed in the control body, the moving cavity and the sliding cavity are located on the front side of the connecting cavity, the moving cavity is located on the upper side of the sliding cavity, and two sliding columns symmetrical up and down are fixedly arranged between the front wall and the rear wall of the connecting cavity. The lathe machining cutting device adopts a mode of middle stable positioning and clamping and along-shaft rotating to solve the problems that when a hollow shaft workpiece is machined by a lathe, the side of the lathe cannot be positioned in the circle center, due to too long length, rotating shaking is caused, and due to too long length, the jumping error is too large during cutting, and can effectively improve the precision during hollow shaft workpiece lathe cutting machining.

Owner:PUJIANG JISHU MASCH TECH CO LTD

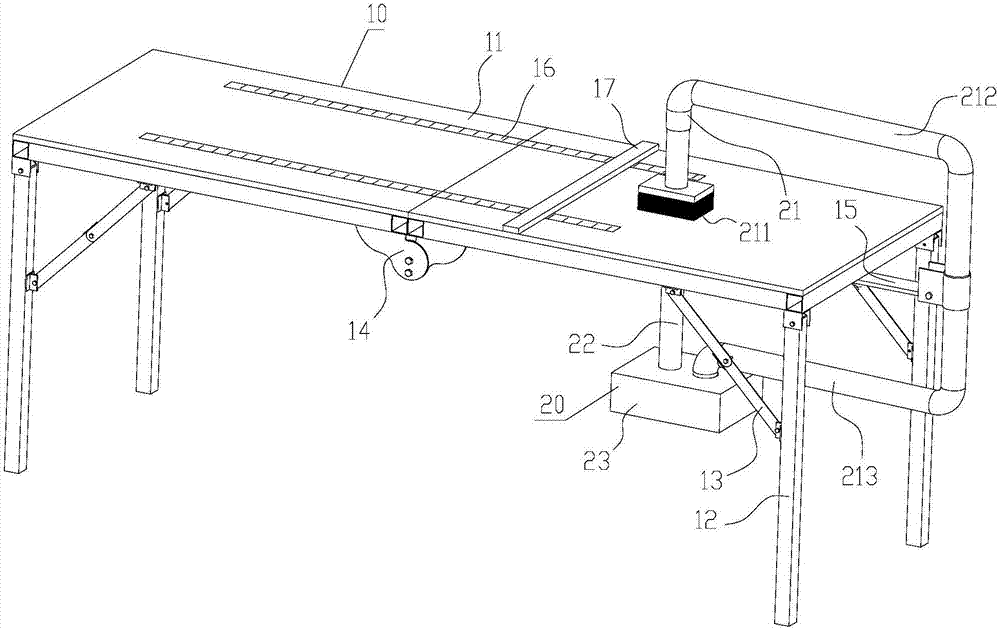

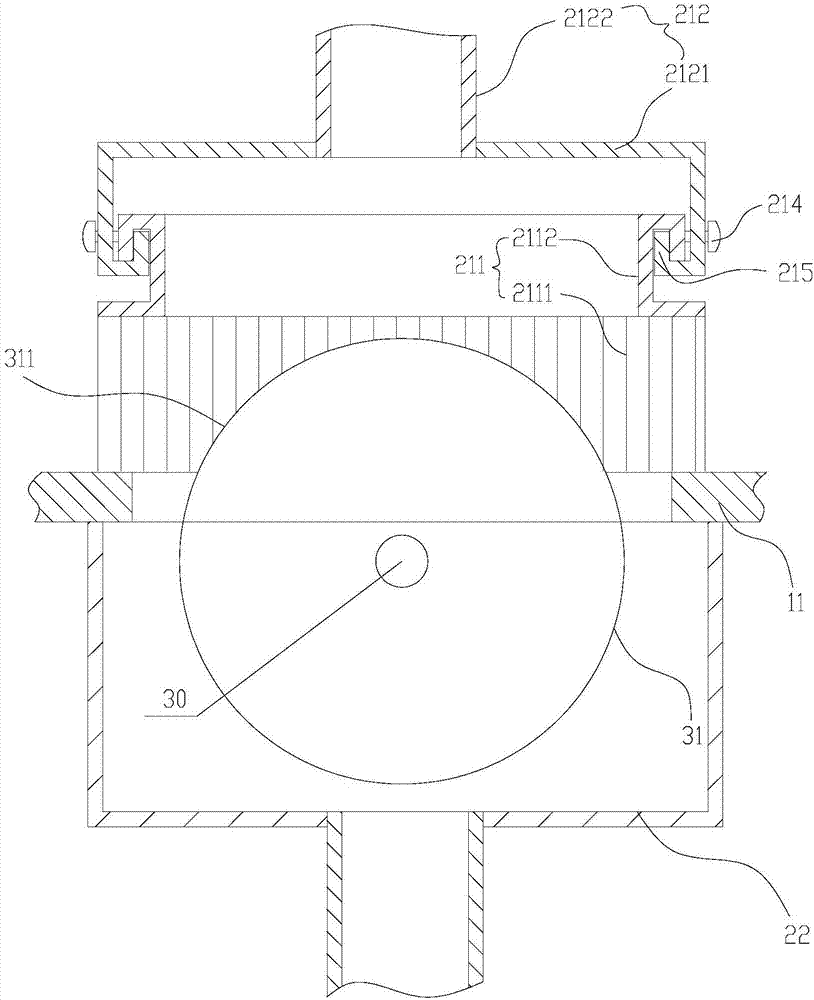

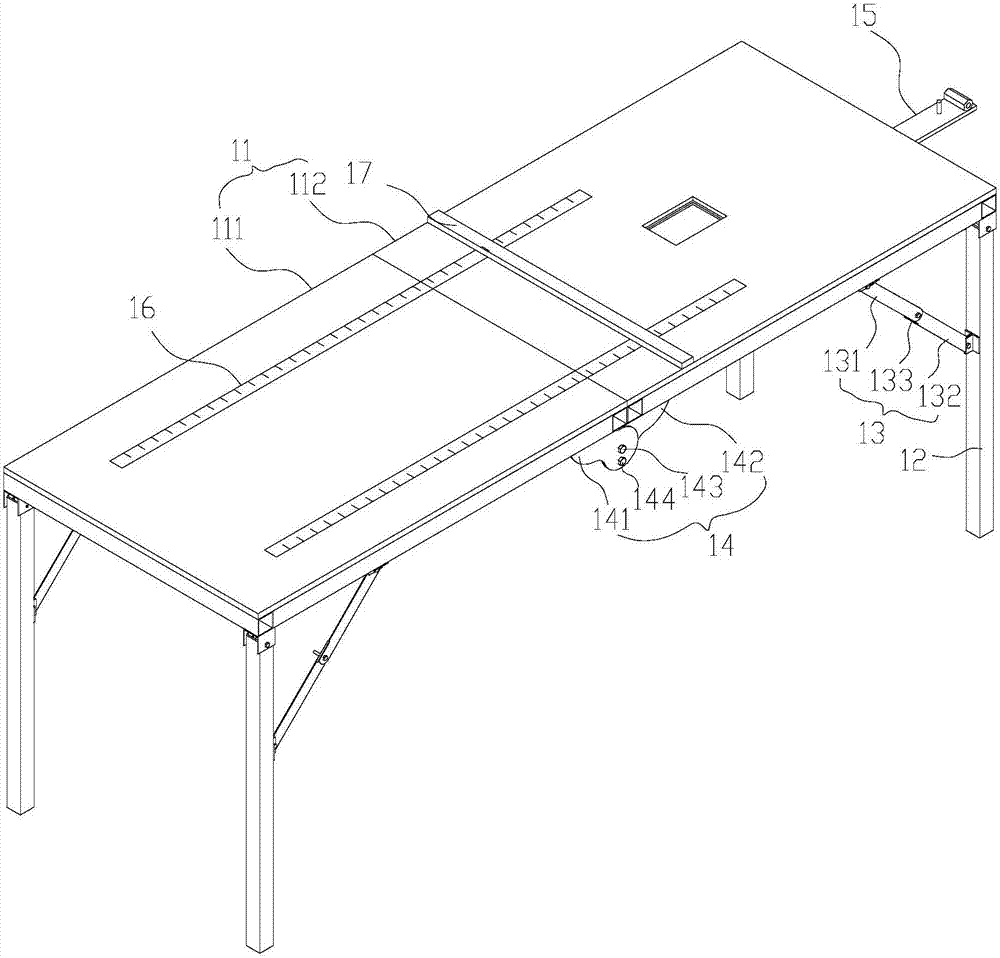

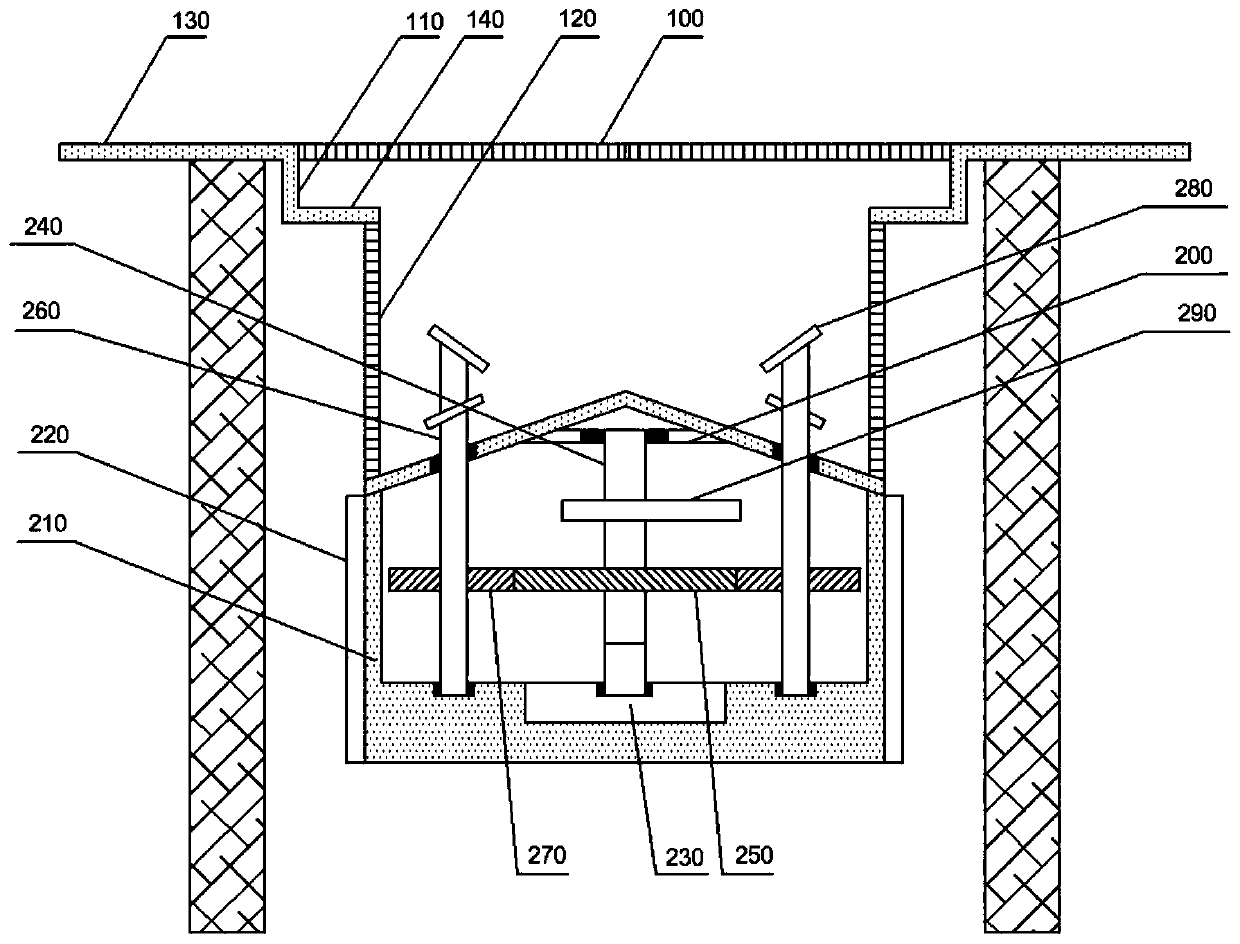

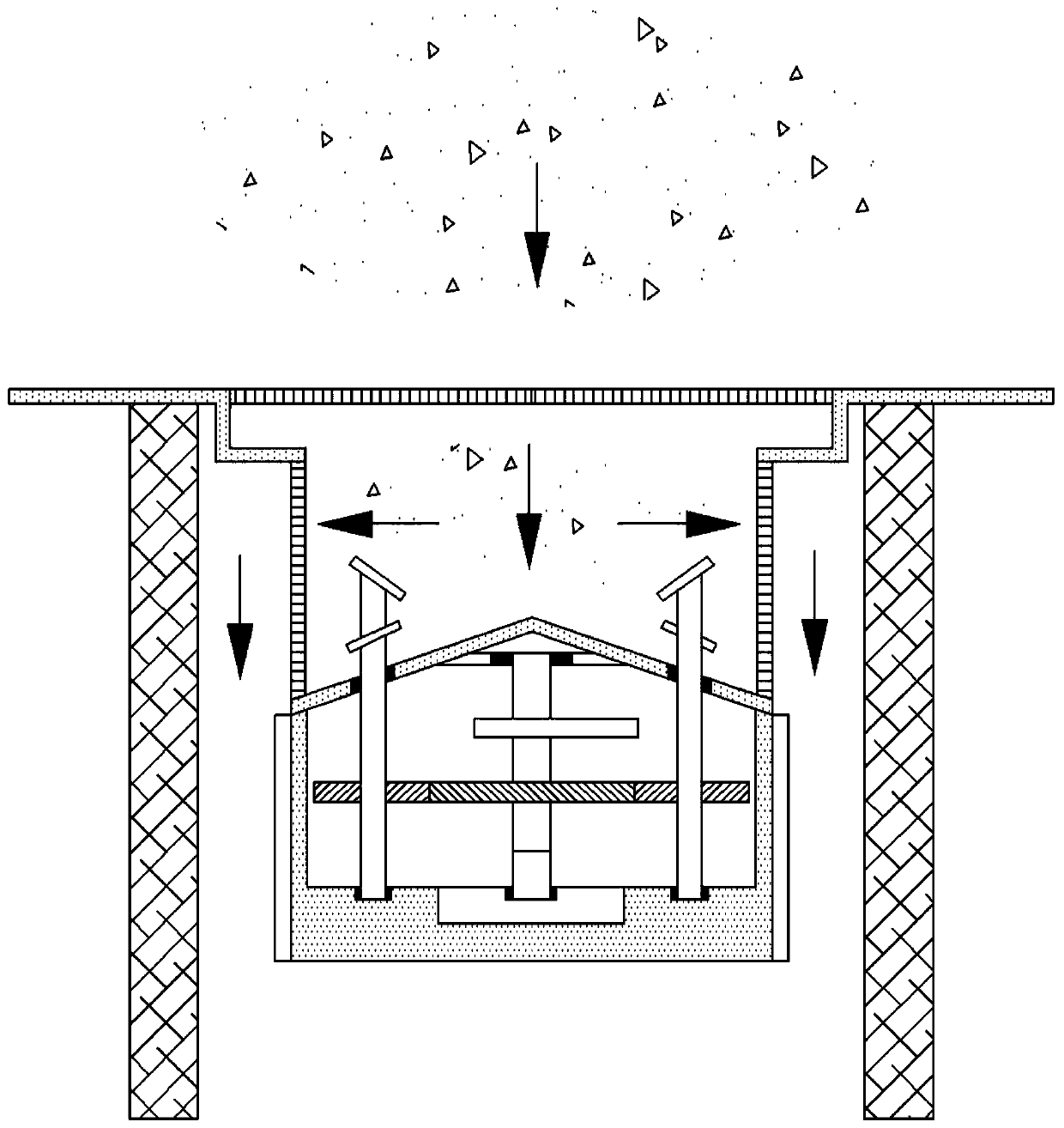

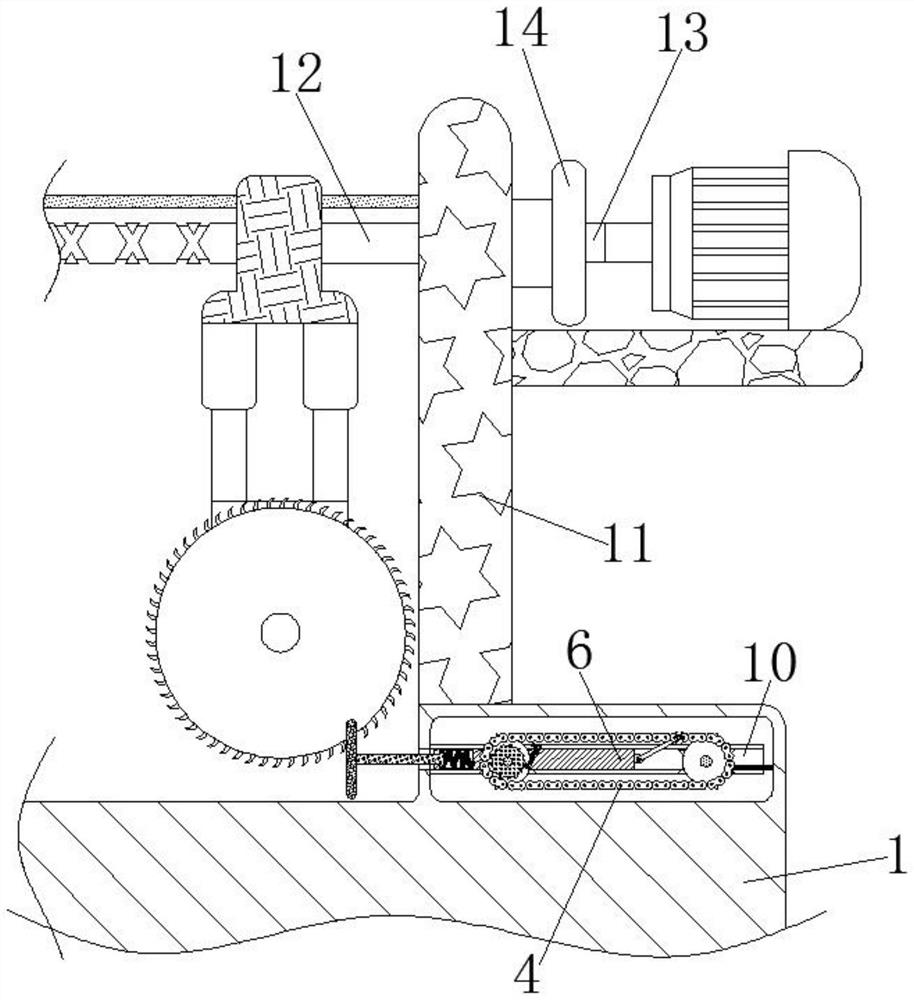

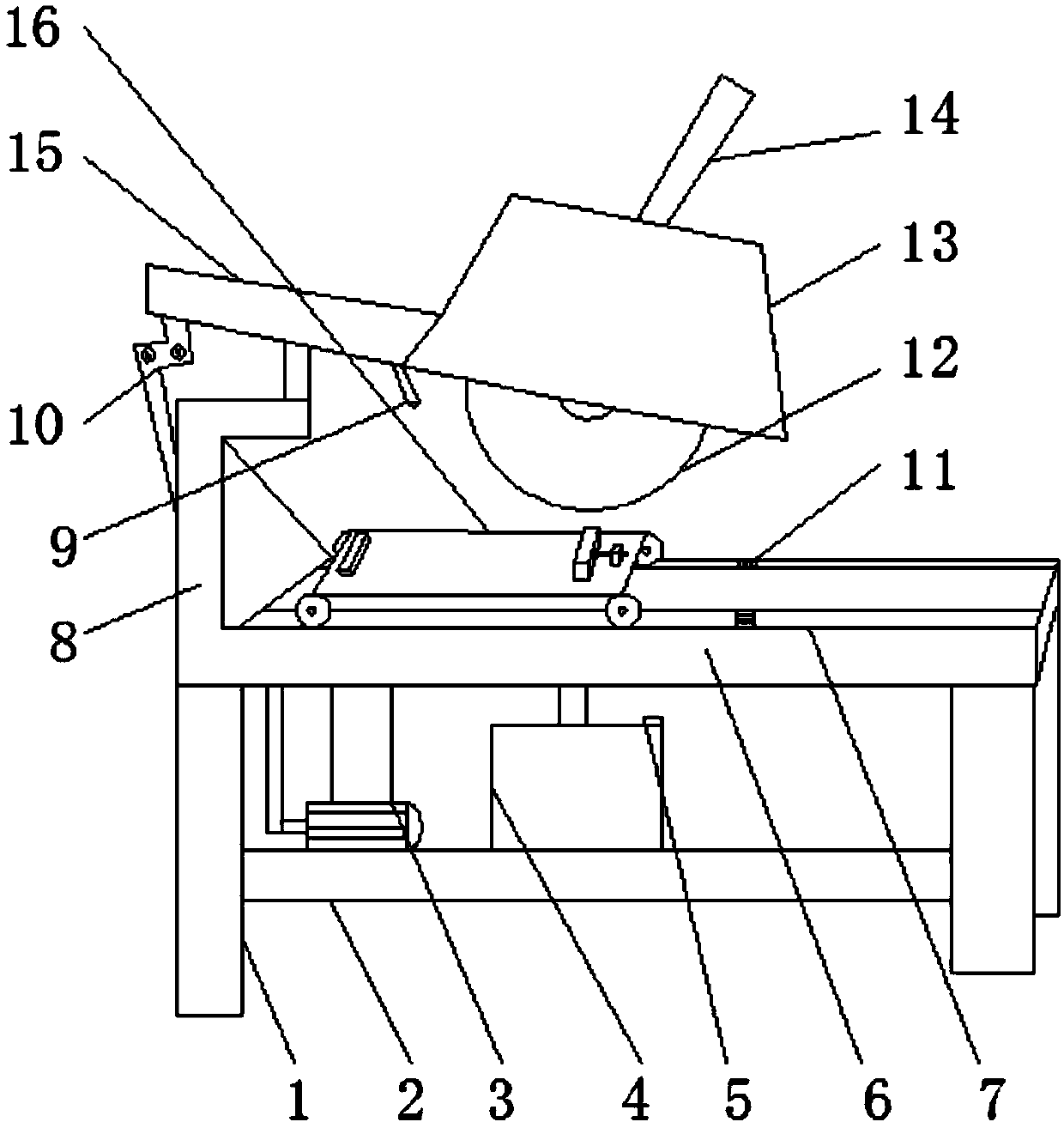

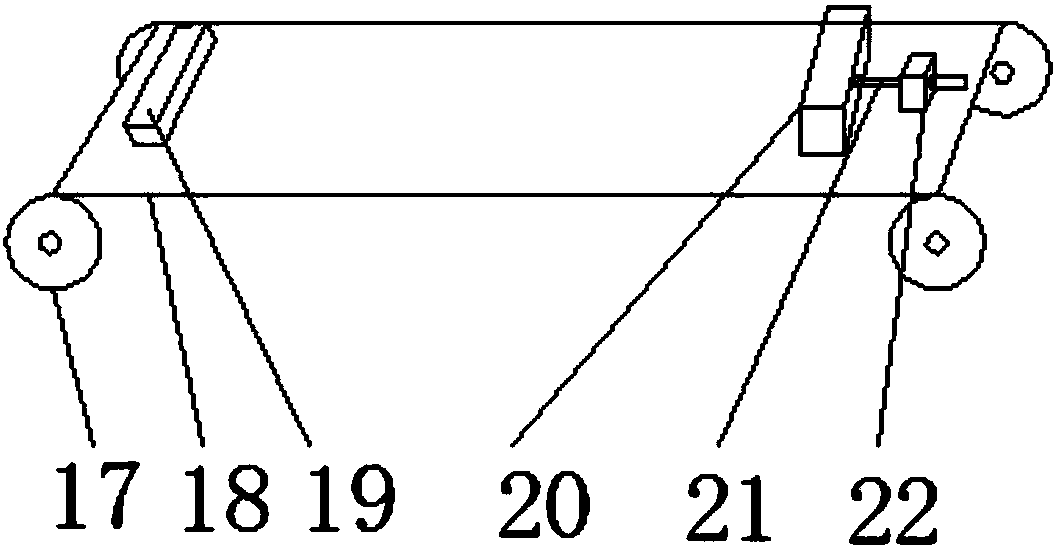

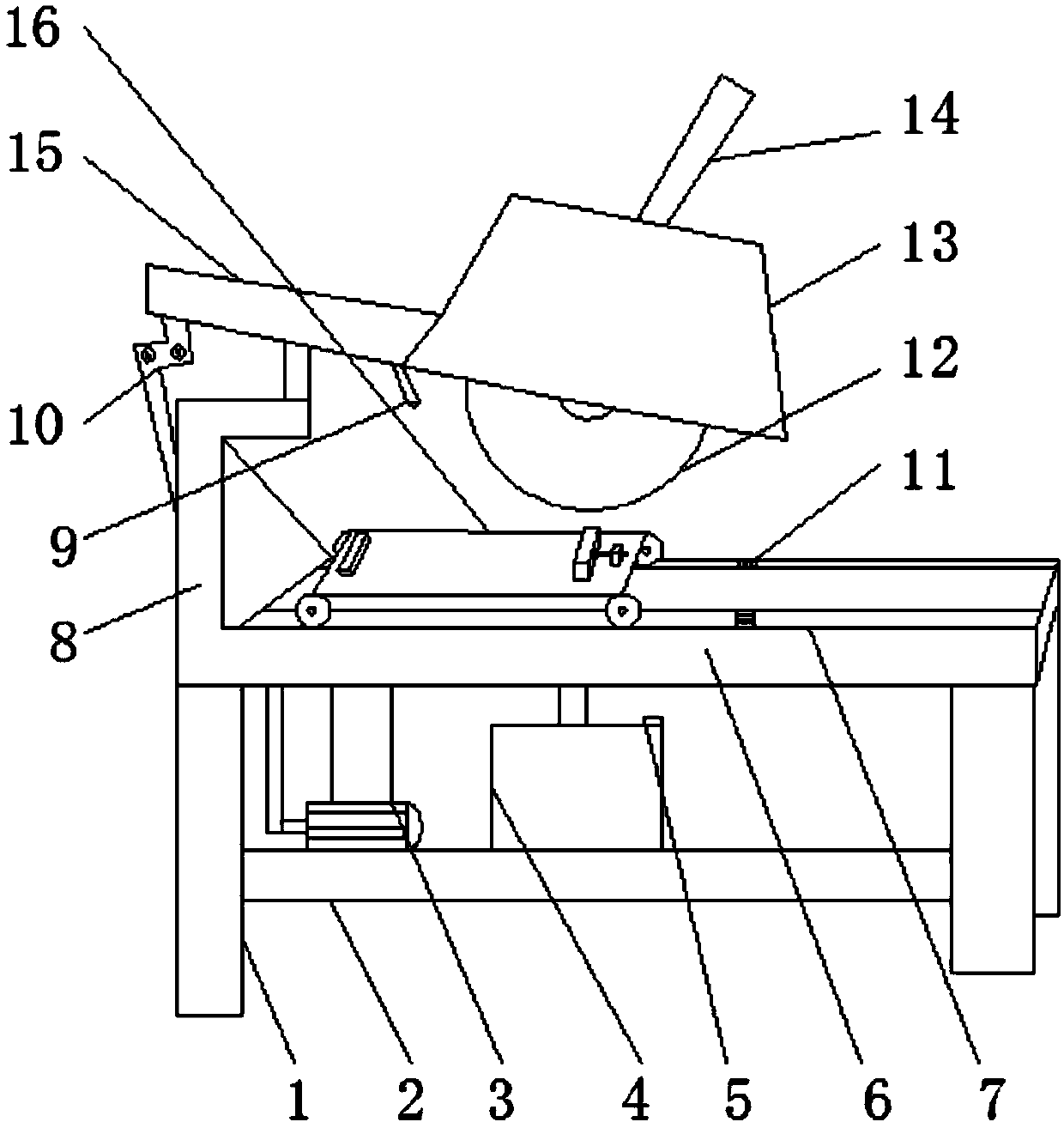

Dustless sawing machine

PendingCN107139270AGood working environmentImprove recycling efficiencyCircular sawsBark-zones/chip/dust/waste removalEngineeringMachine parts

The invention discloses a dustless sawing machine. The dustless sawing machine comprises a frame, a cutting device and a dust sucking device; and the frame comprises a working platform. The cutting device comprises a cutting piece, and is assembled to the working platform to enable the cutting piece to penetrate through the working platform; and one part, projected on the working platform, of the cutting piece forms a machining part. The dust sucking device comprises a bottom dust sucking module, a top dust sucking module, and a dust sucker body respectively connected with the bottom dust sucking module and the top dust sucking module; the bottom dust sucking module covers the cutting piece positioned on one side of the working platform; and the top dust sucking module covers the machining part. Dust generated by cutting boards with the cutting device is recovered by the dust sucking device, and is prevented from falling to bodies of operators, so that the working environment of the operators is good. The top dust sucking module adopts a brush piece to stop floating out of the dust, so that the cutting of the boards is not influenced, and the use is convenient.

Owner:百合盛华建筑科技有限公司

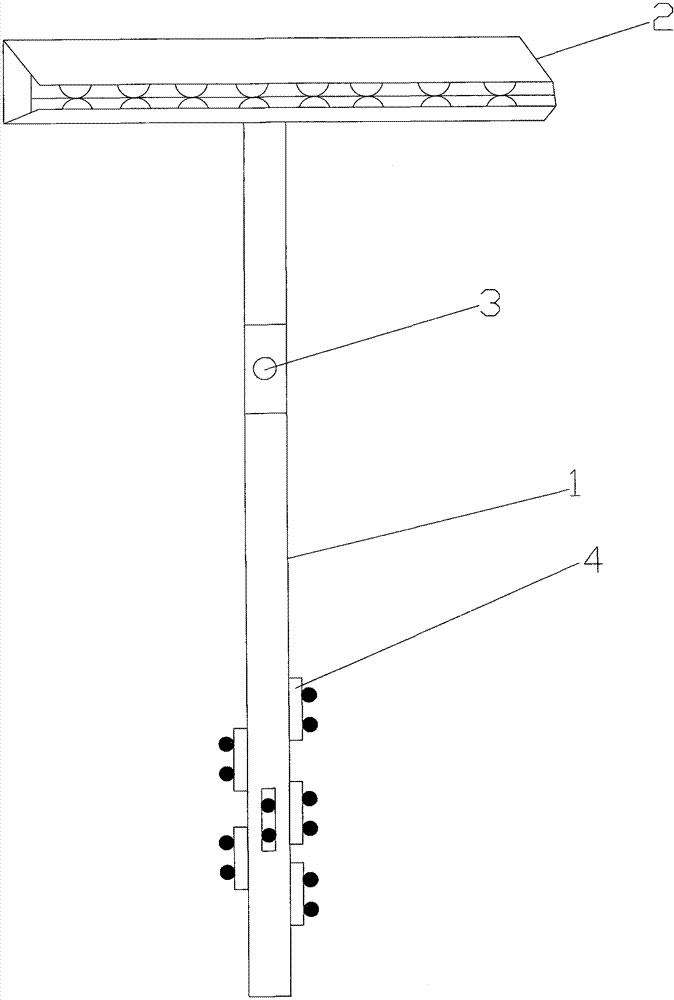

Glass knife with electronic level meter

InactiveCN103708715AHigh precisionImprove work efficiencyGlass severing apparatusEngineeringGlass knife

The invention belongs to a glass cutting tool, and concretely provides a glass knife with an electronic level meter. The glass knife comprises a glass backup plate, a push knife body and an electronic level meter. One end of the push knife body is fixed on the glass backup plate in the vertical direction. The electronic level meter is installed at the bottom surface of the push knife body. Glass levelness is transmitted to the electronic level meter through a sensor installed on the electronic level meter. The push knife body comprises a glass slide rail, a rotating disc and a six-rail knife bar. The glass knife changes the cutting method of a traditional glass knife that only one piece of glass can be cut once. That six pieces of glass with different sizes or the same size can be cut at the same time is achieved through one glass knife. Each knife head is independent, and no influences to glass cutting are generated among the knife heads. In addition, because the glass knife is equipped with an electronic level meter, the glass cutting precision is high, and the working efficiency is raised.

Owner:ZIBO VOCATIONAL INST

Cutting device for plastic tableware production

InactiveCN109202983AImprove cutting efficiencyEasy to operateMetal working apparatusEngineeringMechanical engineering

The invention discloses a cutting device for plastic tableware production. The cutting device includes a device body, and the device body is internally provided with a conveying mechanism, an efficient pressing cutting mechanism located on the upper part of the conveying mechanism and a feeding mechanism matched with the efficient pressing cutting mechanism; the efficient pressing cutting mechanism comprises a cutting platform, a first driving device and a linkage device, the cutting platform is suspended and fixed between the inner walls on both sides through a mounting plate, the cutting platform is internally and slidably provided with a discharging plate, one side of the discharging plate is provided with a fixing plate, one side of the fixing plate is connected with a guiding rod flushing with the discharging plate, and the guiding rod is sleeved with a spring; and a bottom piston rod of the first driving device is provided with a cutting blade, the linkage device is composed of four rotating guiding wheels and a transmission rope, and the transmission rope is connected to the four rotating guiding wheels in series. According to the cutting device for plastic tableware production, design is smart, manual feeding and discharging are not required, the degree of automation is high, the cost is saved, and the cutting efficiency of plastic tableware is effectively improved.

Owner:安徽森德自动化工业股份有限公司

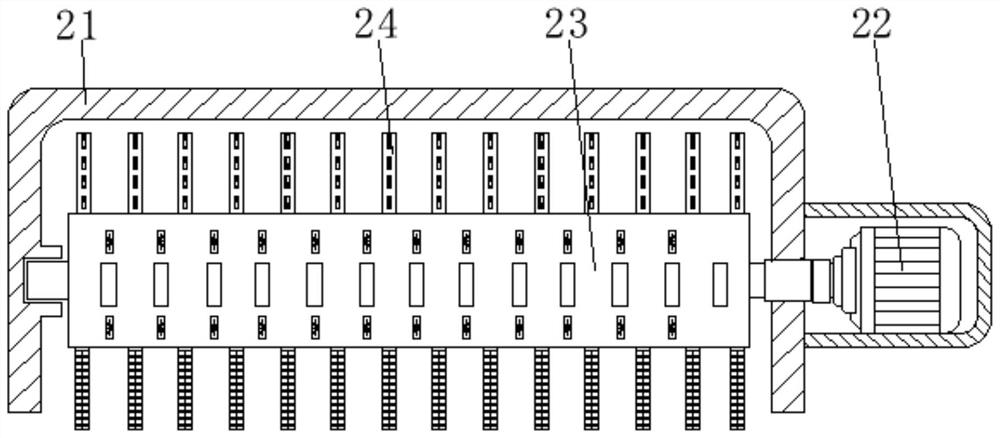

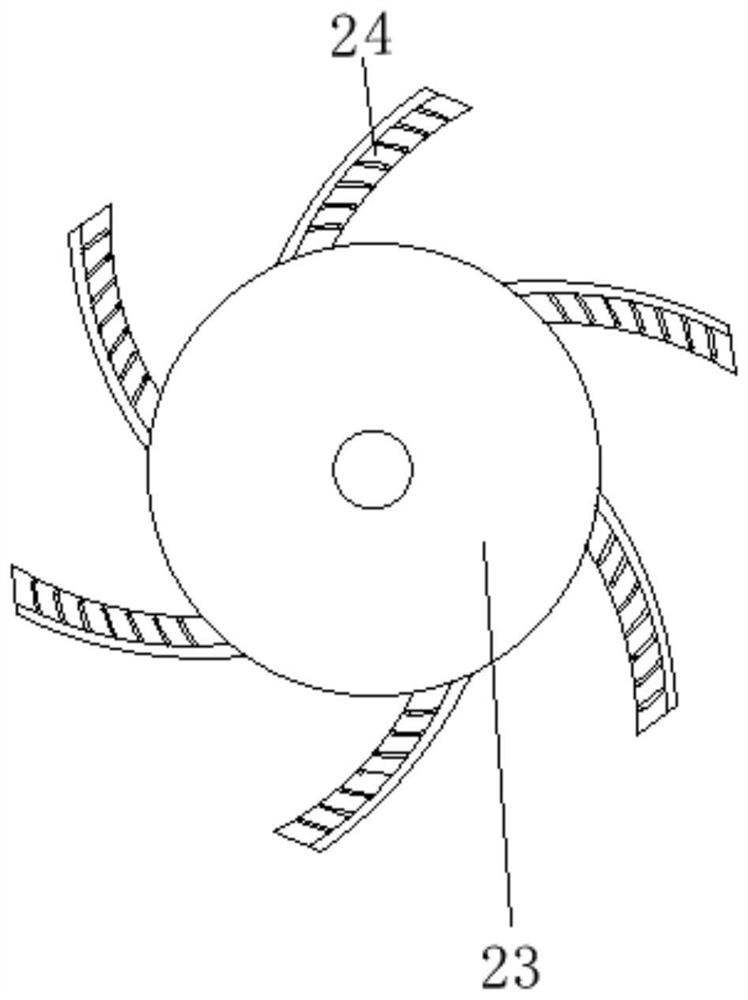

Municipal aquatic plant cutting equipment

PendingCN112369197AAvoid entanglementAvoid blockageAgricultural machinesHarvestersEnvironmental engineeringDrive motor

The invention discloses municipal aquatic plant cutting equipment which comprises a ship body and an aquatic plant cutting device. The aquatic plant cutting device is fixed to the tail of the ship body, a driving motor is fixed to the surface of a fixed housing through a fixing box and located at the end of the fixed housing, and a roller device is arranged between the two corresponding sides of the inner wall of the fixed housing; and the roller device is rotationally connected with the fixed housing, one end of the roller device penetrates through the inner wall of the fixed housing and extends to the exterior of the fixed housing, the end, extending to the exterior of the fixed housing, of the roller device is fixedly connected with an output shaft of the driving motor through a coupler, and the aquatic plant cutter device is fixed to the surface of the roller device. The invention relates to the technical field of aquatic plant cutting. The municipal aquatic plant cutting equipmentachieves the anti-winding purpose, cutting is rapid and uniform, time and labor are saved, winding is avoided, the service life of the machine is prolonged, and the working efficiency and the using performance are improved.

Owner:周晓亮

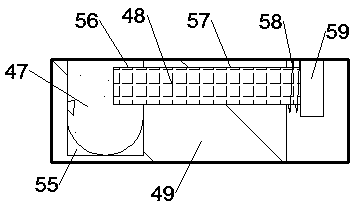

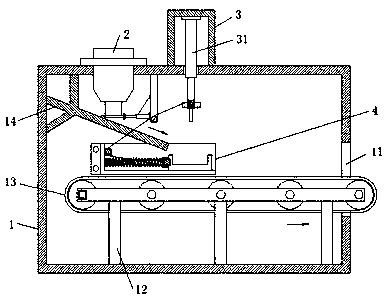

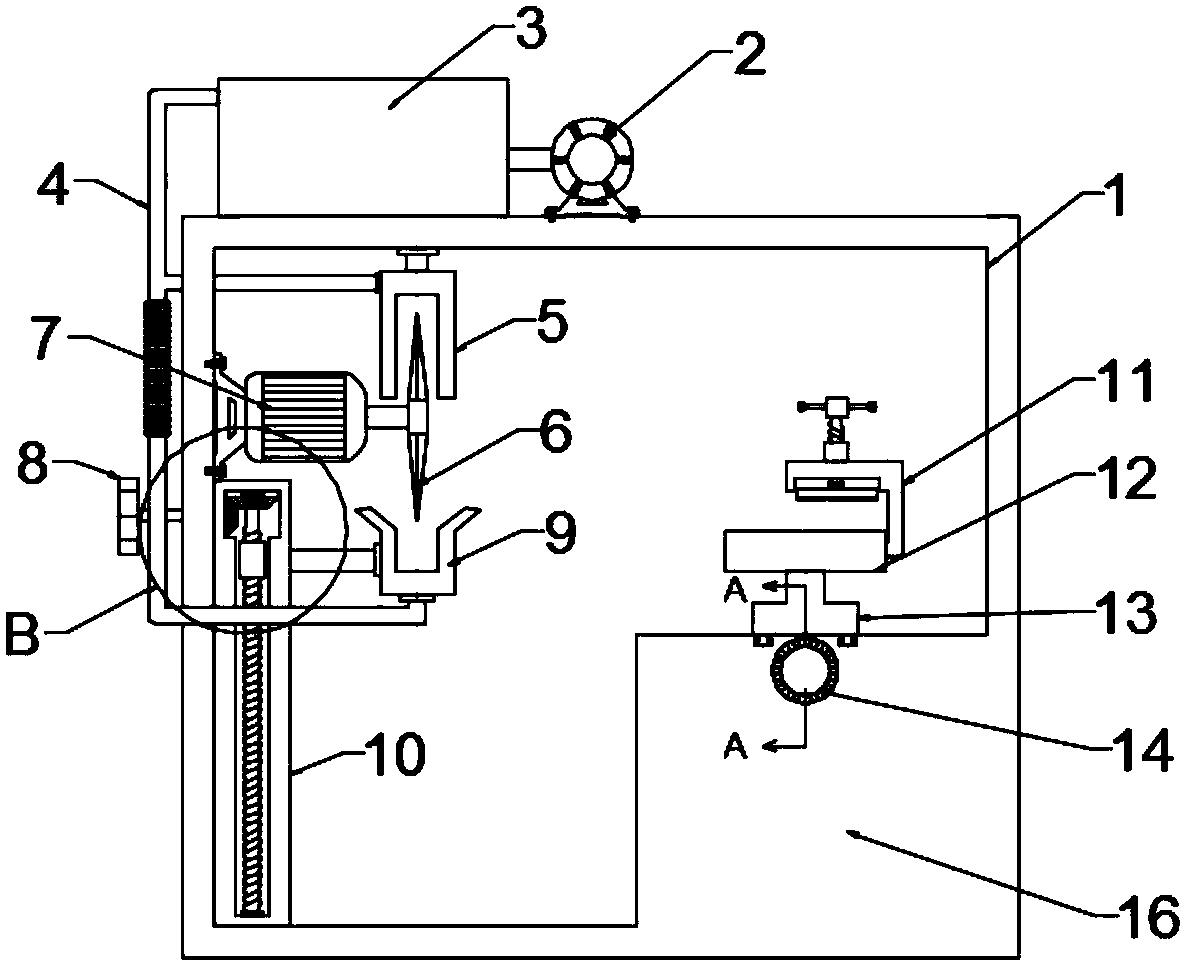

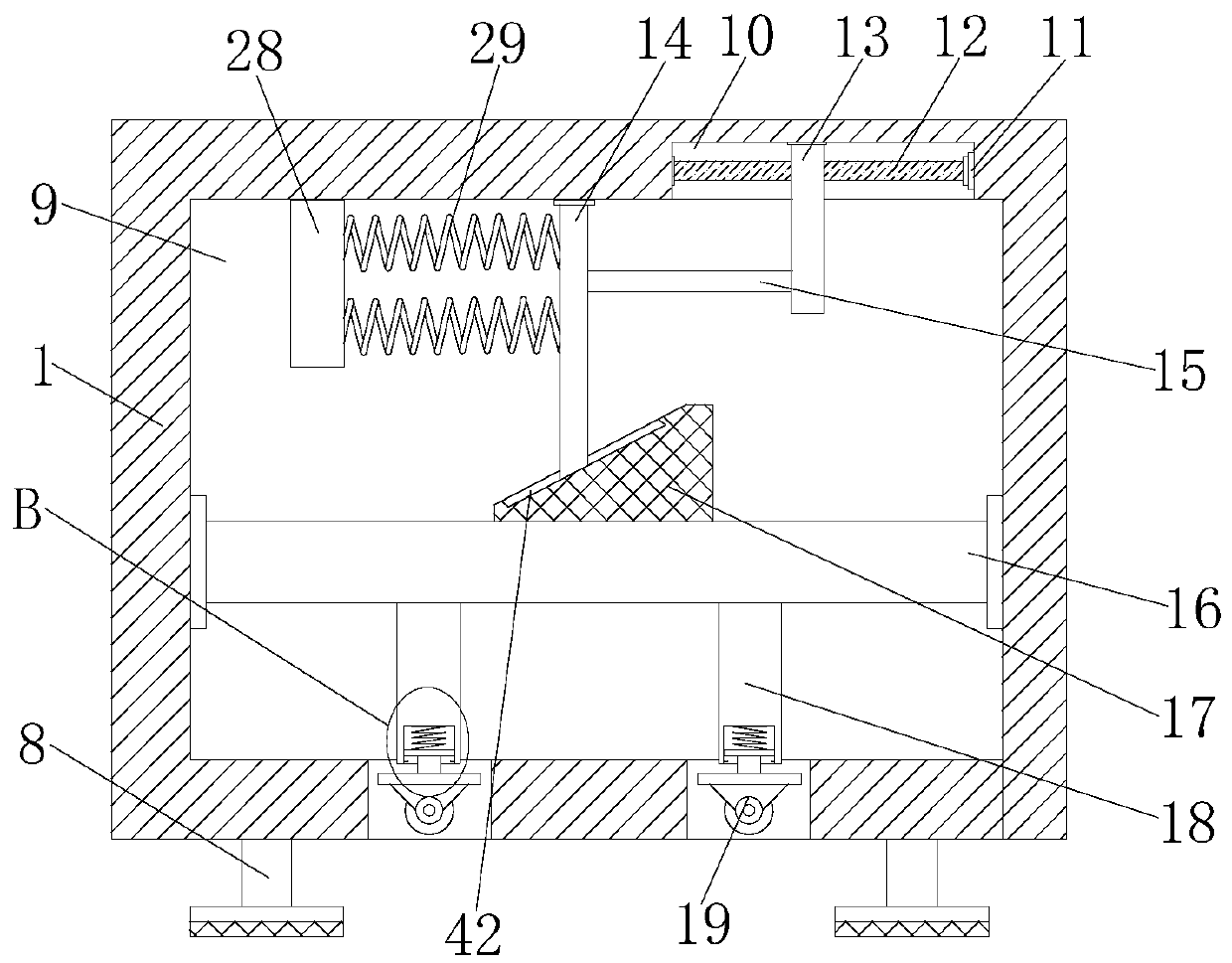

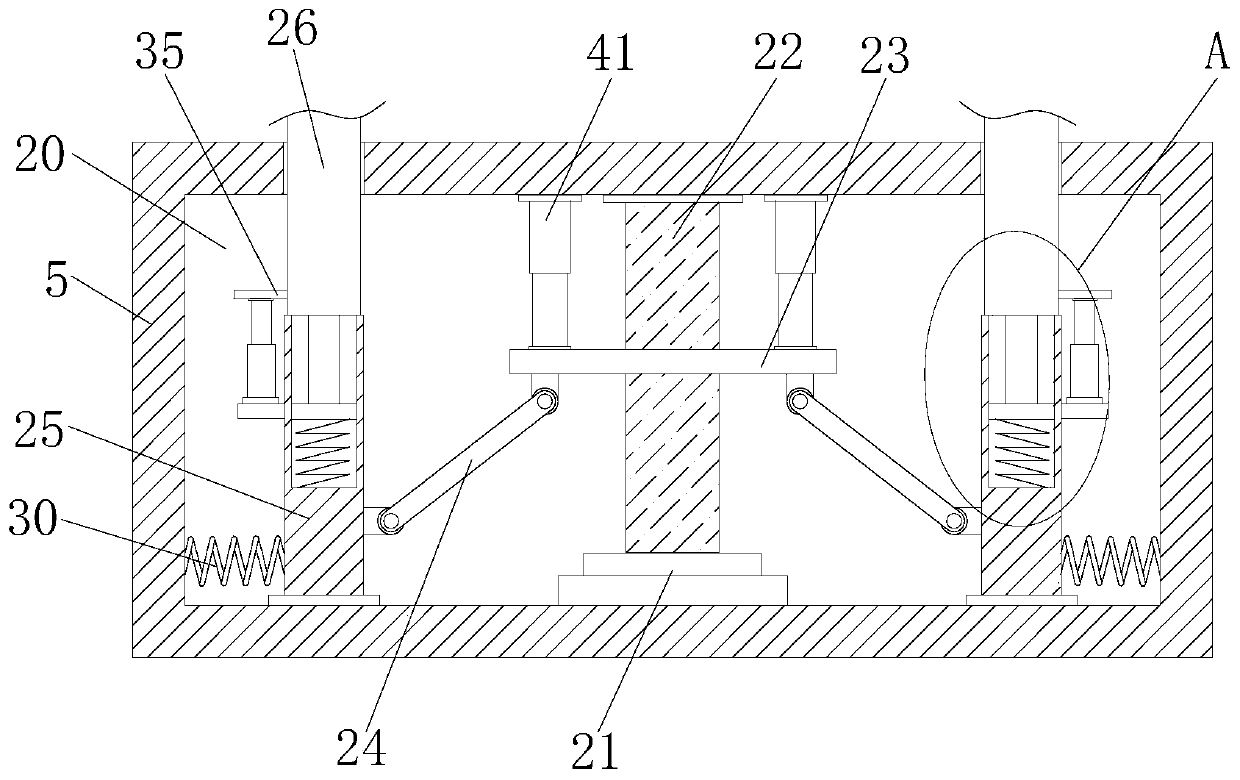

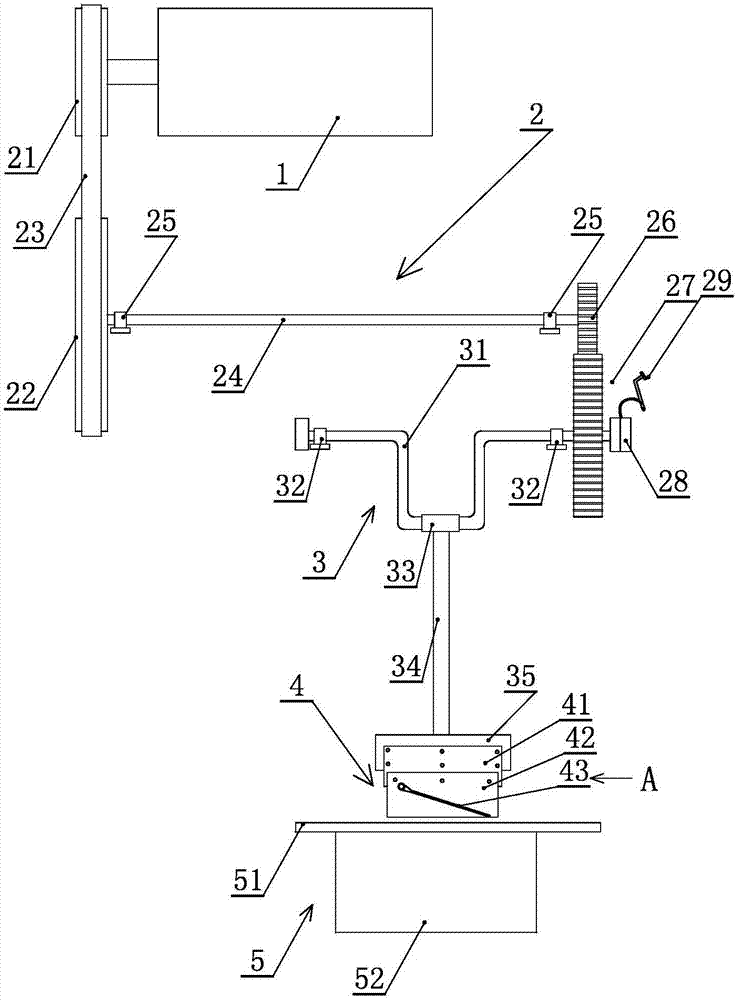

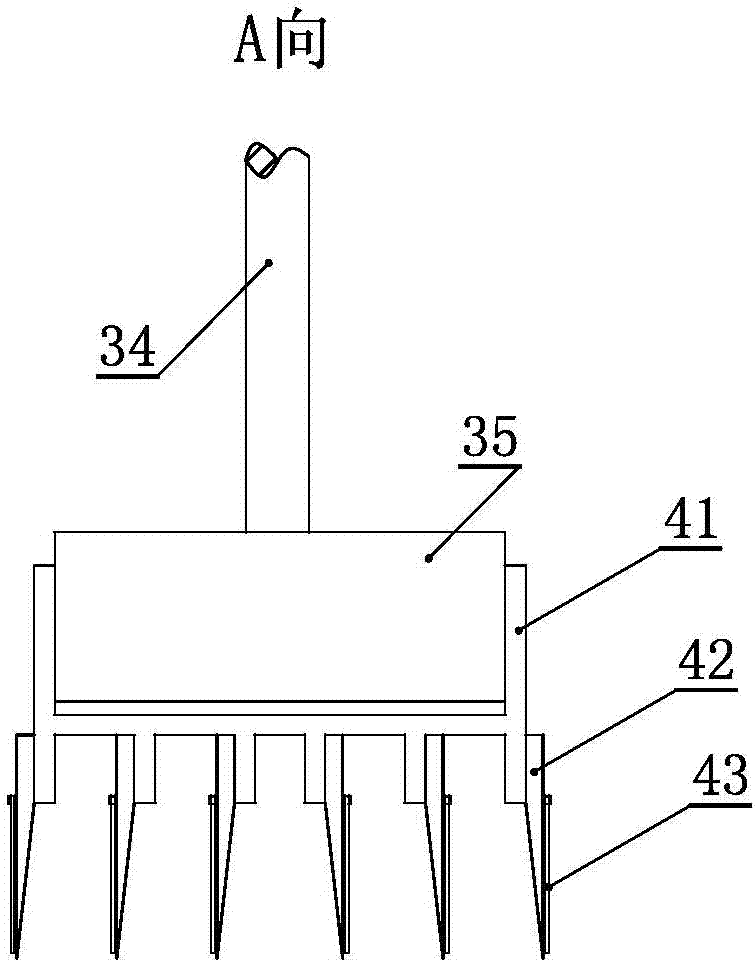

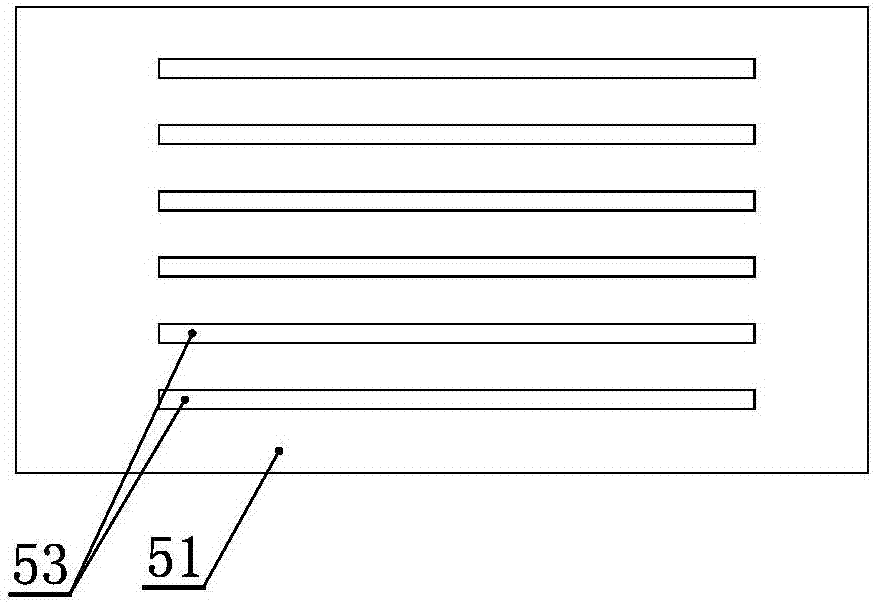

Biomass high molecular material cutting equipment

InactiveCN109203013AInnovative designCutting does not affectMetal working apparatusBiomassEngineering

The invention discloses biomass high molecular material cutting equipment. The equipment comprises an equipment frame, a chip removing mechanism and a cutting motor; the cutting motor is fixed on theinner side of the equipment frame through a motor base; a cutter is fixedly mounted on an output shaft of the cutting motor; the chip removing mechanism is arranged at the side end of the cutter; thechip removing mechanism comprises an air sucking machine, a collecting cavity, an upper cover body and an ash inlet hopper; a cavity is formed in the outer wall of the upper cover body; the cavity communicates with one end of the collecting cavity through a guide pipe; the other end of the collecting cavity communicates with the air sucking machine; and the ash inlet hopper is arranged at the lower end of the cutter, and is fixedly connected with an adjusting mechanism through a mounting block. The equipment is novel in design; through adding of the ash inlet hopper capable of adjusting upperand lower positions, chips generated in the cutting process are totally absorbed without influencing cutting of plates with different thicknesses; and a baffle plate is arranged in the collecting cavity for effectively preventing direct impact on a screen by the chips to damage the screen.

Owner:盐城康鼎机械有限公司

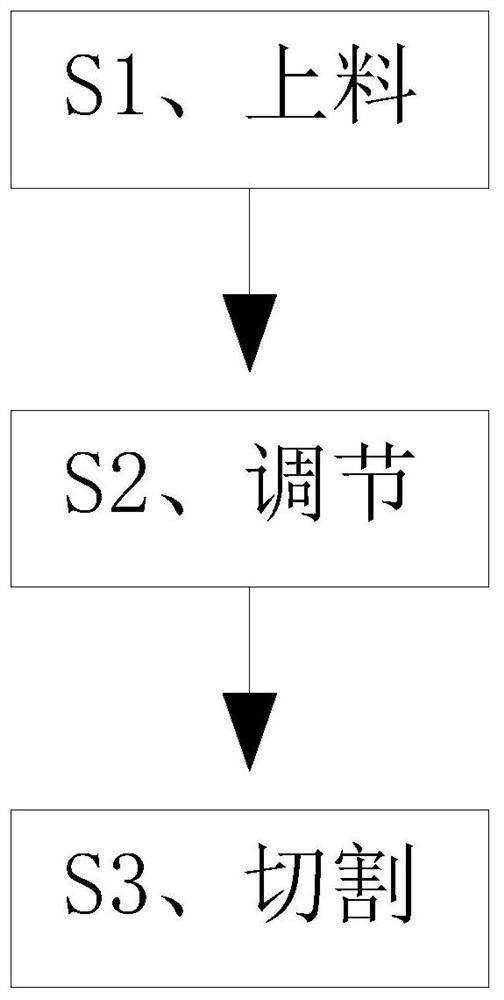

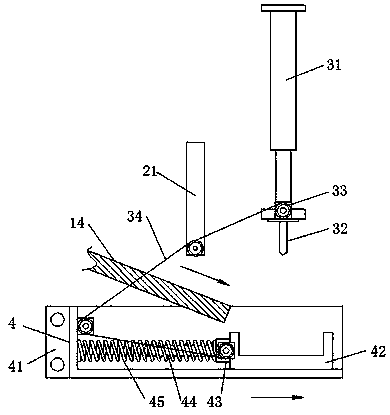

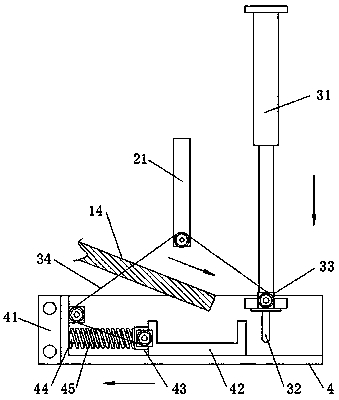

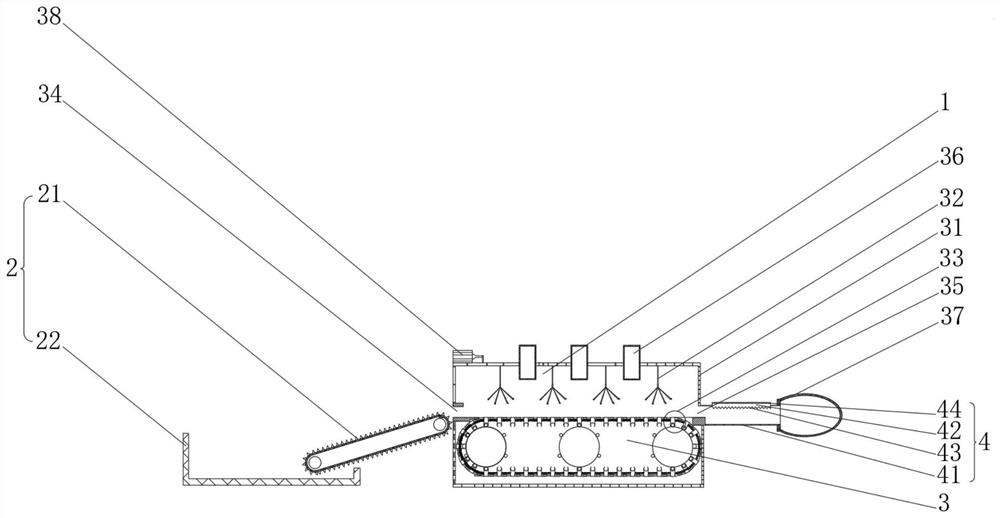

Forming and cutting method of aquatic products

ActiveCN111528264ARealize molding processingCutting does not affectFish cuttingAquatic productMechanical engineering

The invention relates to the technical field of processing of aquatic products, and in particular relates to a forming and cutting method of aquatic products. The forming and cutting method of the aquatic products comprises the steps of: firstly, clamping and fixing an aquatic product to be processed on a support plate surface by selecting an adjustable clamping fixer; then, setting a laser pen onthe support plate surface, so that the cutting size line is conveniently obtained; and finally, setting a formed product transmission toothed belt at the rear of a cutting wheel, so that the cut andformed aquatic product is pulled and transported. By means of the method in the invention, vertically flat, bilaterally uniform and horizontally vertical forming processing is realized; the transmission toothed belt only has the effect of hanging, pulling, cutting and transporting on the cut processed aquatic product above the support plate surface; the aquatic product to be processed is promptedto be appressed to a rear support plate surface to advance; cutting of aquatic products to be processed on other surfaces is not influenced; therefore, the processed aquatic product to be processed isformed better; furthermore, the aquatic product to be processed is regular to cut; forming and processing of the aquatic product to be processed are realized; and the working efficiency is increased.

Owner:漳州市东好水产食品有限公司

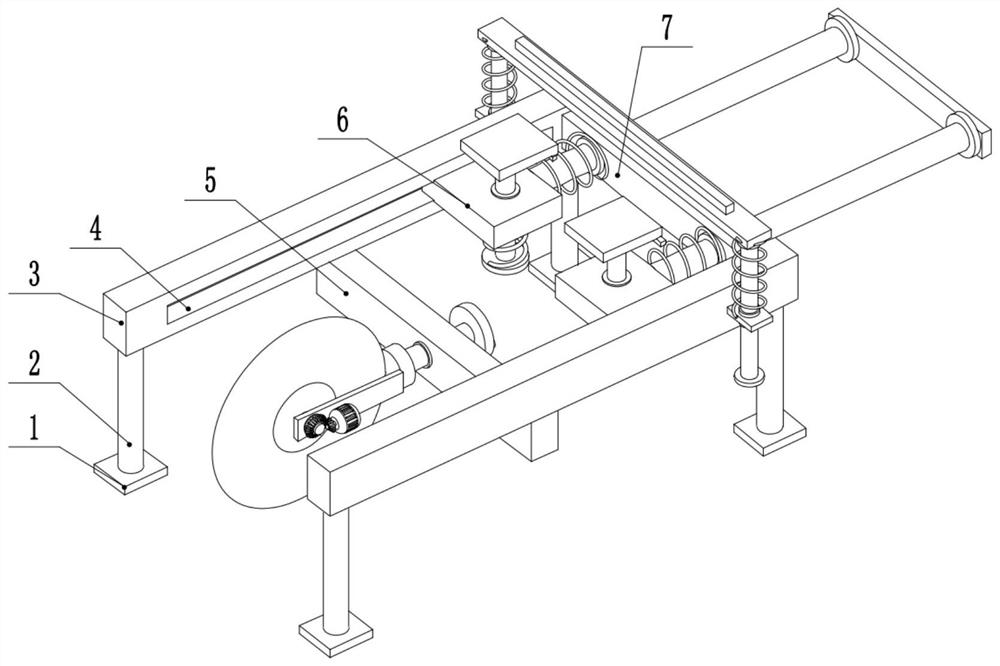

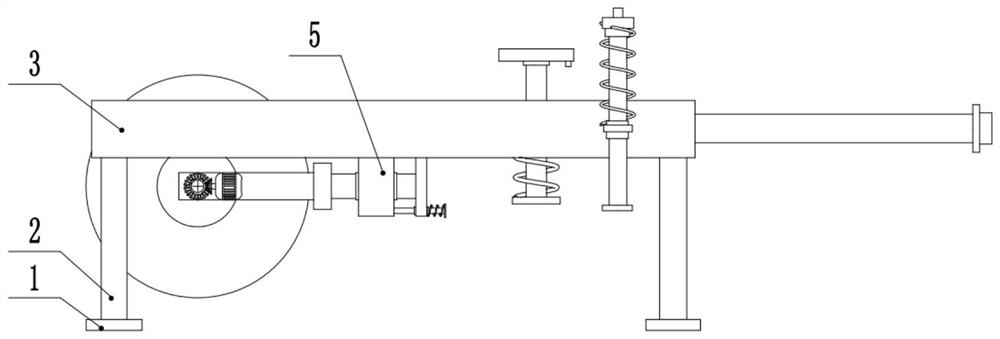

Convenient-to-move rebar cutting machine

The invention belongs to the field of rebar cutting, particularly relates to a convenient-to-move rebar cutting machine, and aims to solve the problems that some of the existing rebar cutting machinesare heavier and more strenuous to move, and rebars are likely to have displacement during the rebar cutting process. According to the scheme, the convenient-to-move rebar cutting machine comprises abase, wherein a handle is fixedly connected with one side of the base; a fixed rack is fixedly connected with the top of the base; a fixed plate is connected with the top interior of the fixed rack; acutting machine main body is connected with the bottom of the fixed plate; a fixed seat is connected with the top of the base; a placing plate is connected with the top of the fixed seat; a driving component is arranged on the fixed seat; two vertical plates are in transmission joint with the driving component; and clamping plates are connected with two sides mutually close to each other of the two vertical plates. The convenient-to-move rebar cutting machine is reasonable in structure and simple to operate to move a cutting machine main body, so that application by a user is facilitated; anda second motor is adopted to clamp and fix the rebar main body, so that during the cutting process, the rebar main body does not move and cutting is not affected.

Owner:河源东江电力线路器材有限公司

Machine capable of cutting integral mutton chop

InactiveCN107410431ABeautiful imageEasy to reprocessMeat shaping/cuttingNeighbor relationEngineering

The invention discloses a machine capable of cutting an integral mutton chop. An electric motor is used as a power source; the electric motor drives a transmission component to transmit power to a driving component; the driving component is fixedly connected with a cutting component, so that the cutting component can be driven to move up and down; the cutting component comprises a plurality of row cutters which are fixedly mounted side by side; the driving component drives the cutting component to move to the lowest position and cut the mutton chop at the same time; an elastic sheet is fixedly arranged on one side of each row cutter; one ends of the elastic sheets are hinged and fixed to one sides of the upper parts of the row cutters, and the other ends naturally oblique and extend downward to the blades of the row cutters; fresh mutton is integrally cut; though the mutton is cut into small cubes conforming to a specification, the neighboring relation of the bones and the mutton is not damaged, the overall shape is still preserved, and the product looks beautiful and tidy; after cutting is completed, the cut mutton chops are pushed onto a mutton chop placement table under the action of the elastic sheets and cannot stick to the row cutters; the condition that the cutters fall down to cut the mutton chop next time cannot be influenced; and mutton residues or bone residues produced by cutting the cut mutton chops again cannot be produced.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

Cutting device for silicon rod production

InactiveCN108772960AImprove convenienceImprove securityWorking accessoriesFine working devicesMachiningSilicon

The invention discloses a cutting device for silicon rod production. The cutting device comprises an operation table, the operation table is provided with an operation chamber, moreover, a storage groove is formed in the bottom of the operation chamber, the storage groove is formed in the operation table, and the storage groove communicates with the operation chamber; and a collecting plate is arranged in the storage groove, a collecting chamber is formed in the collecting plate, a working groove hole is formed in the operating table, and the operation groove hole communicates with the operation chamber. The cutting device for the silicon rod production has the beneficial effects that a silicon rod body is arranged in the operation groove hole, the silicon rod body is placed in the operation groove hole for machining, a pushing device is arranged on the operation table, the operation height of an adjusting plate can be adjusted through the pushing device, so that the height adjustmentduring operation or non-operation is facilitated, and the operation convenience and safety are improved; and an adjusting groove hole is formed in the adjusting plate, a control handle can be manuallypulled, so that the control rod can slide in the adjusting groove hole, then the position of a cutting blade can be adjusted in the horizontal position, and the convenience of cutting operation is facilitated.

Owner:方小玲

Construction reinforcement cutting machine after construction

The invention relates to a cutting machine, in particular to a construction reinforcement cutting machine after construction. The construction reinforcement cutting machine after construction is freeof influencing on cutting of reinforcements, and can prevent smashing of building workers due to downward falling of the reinforcements during cutting. The construction reinforcement cutting machine after construction comprises a hollow handle, a movable handle, a first spring, connecting rods and a connecting plate; the movable handle is arranged in the hollow handle; the first spring is connected between the bottom end of the movable handle and the inner bottom of the hollow handle; and two connecting rods are provided and separately arranged at the left ends of the hollow handle and the movable handle. The cutting machine can be fixed through an arc clamping plate to prevent shaking to influence on cutting of the reinforcements; the cutting machine can be fixed on the reinforcements through a clamping mechanism to prevent smashing of the building workers due to downward falling of the reinforcements during cutting; and through a cooling mechanism, a cutting blade of the cutting machine can be cooled, so that the service life of the cutting blade can be prolonged.

Owner:TAIZHOU ZUANHUANG AUTO PARTS CO LTD

Multi-angle stirring, standing and separating equipment for cake stock solution

InactiveCN112438417AAutomatic cuttingCutting does not affectFood shapingCream preparationElectric machineryProcess engineering

The invention discloses multi-angle stirring, standing and separating equipment for cake stock solution. The multi-angle stirring, standing and separating equipment comprises a cake stock solution processing shell; a U-shaped plate is fixedly installed on the top surface of the cake stock solution processing shell; a motor is fixedly installed on the top surface of the U-shaped plate; the output end of the motor is fixedly connected with a rotating rod rotationally penetrating through the top wall of the U-shaped plate; a cake stock solution discharging box is fixedly installed on the top wallof the cake stock solution processing shell; an automatic cake stock solution discharging mechanism is arranged in the cake stock solution discharging box; and the automatic cake stock solution discharging mechanism is used for automatically discharging cake stock solution. According to the invention, in the process of beating cake stock solution through rotation of the rotating rod, automatic discharging of the cake stock solution can be achieved; furthermore, discharging treatment on beaten waste is carried out while discharging is not affected; the beating purity of the cake stock solutionevery time is higher; manual interference is not needed in the beating process; and automatic discharging and automatic waste treatment are achieved while stirring is carried out.

Owner:合肥企禾信息科技有限公司

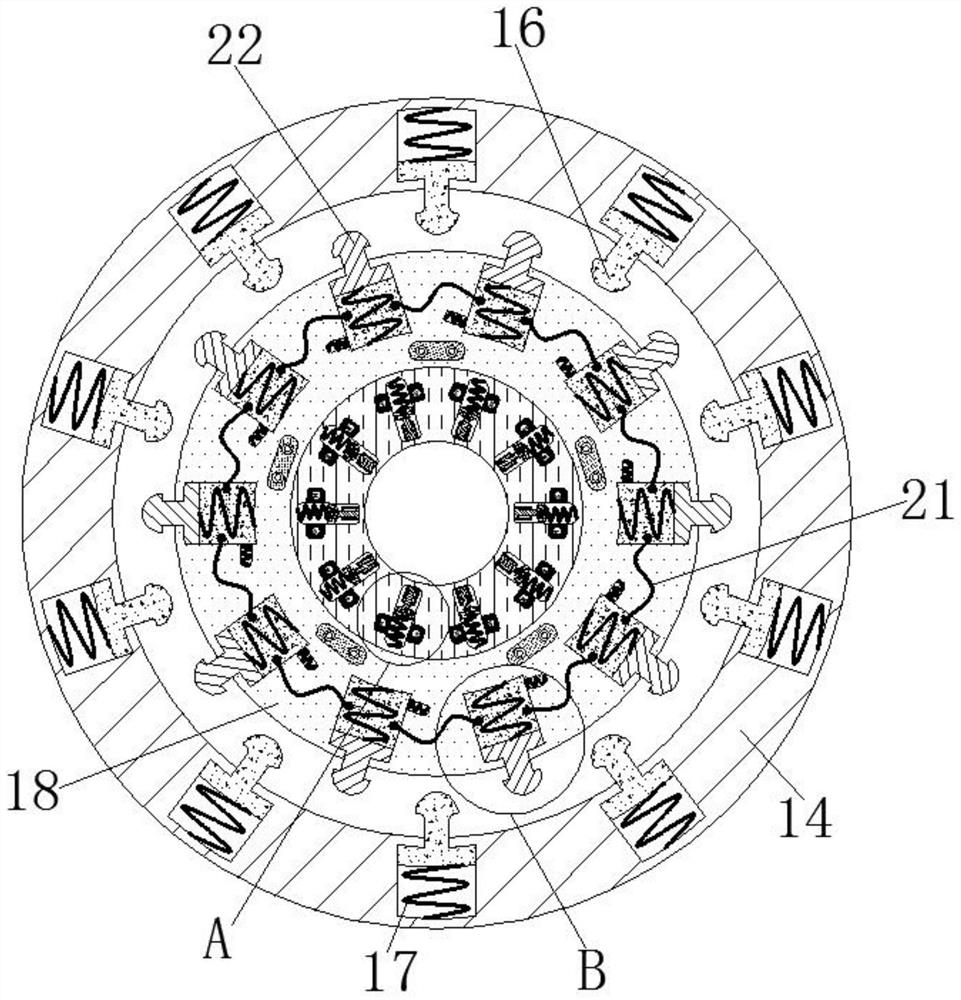

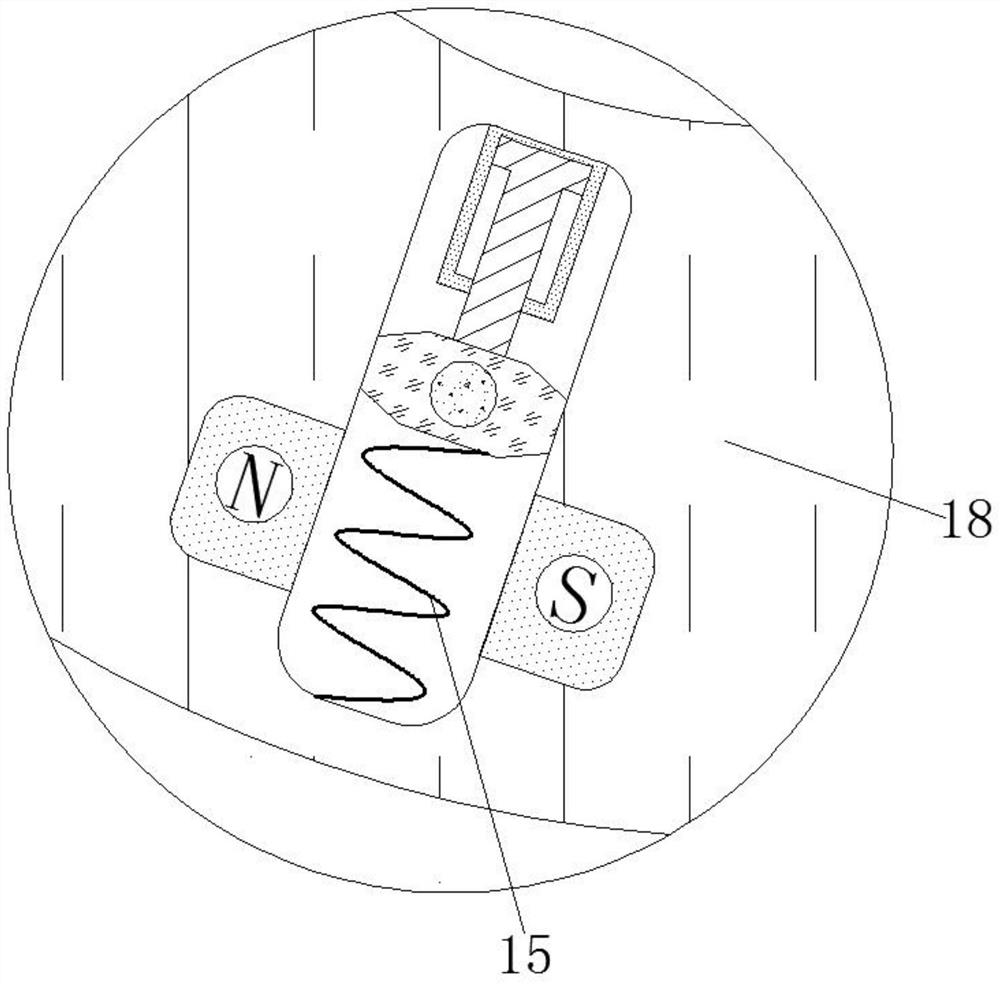

House sewer line protection device

The invention discloses a house sewer line protection device which is matched with a sewer line and comprises a storage portion and a power portion. The storage portion is coaxial with the sewer lineand comprises a first portion with a large diameter and a second portion with a small diameter from top to bottom, the top of the first portion peripherally extends to cover the edge of the sewer lineto form an erection plate, and the power portion is coaxial with the sewer line and positioned below the storage portion and comprises an inner cylinder, an outer cylinder, a motor, a gear assembly and a vibration assembly. Impurity accumulation can be prevented, congestion of the sewer line is avoided, self-cleaning is facilitated, and life of people is greatly facilitated.

Owner:靳职雄

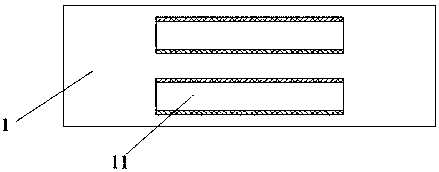

Lug laser cutting device, workbench assembly and lug laser cutting method

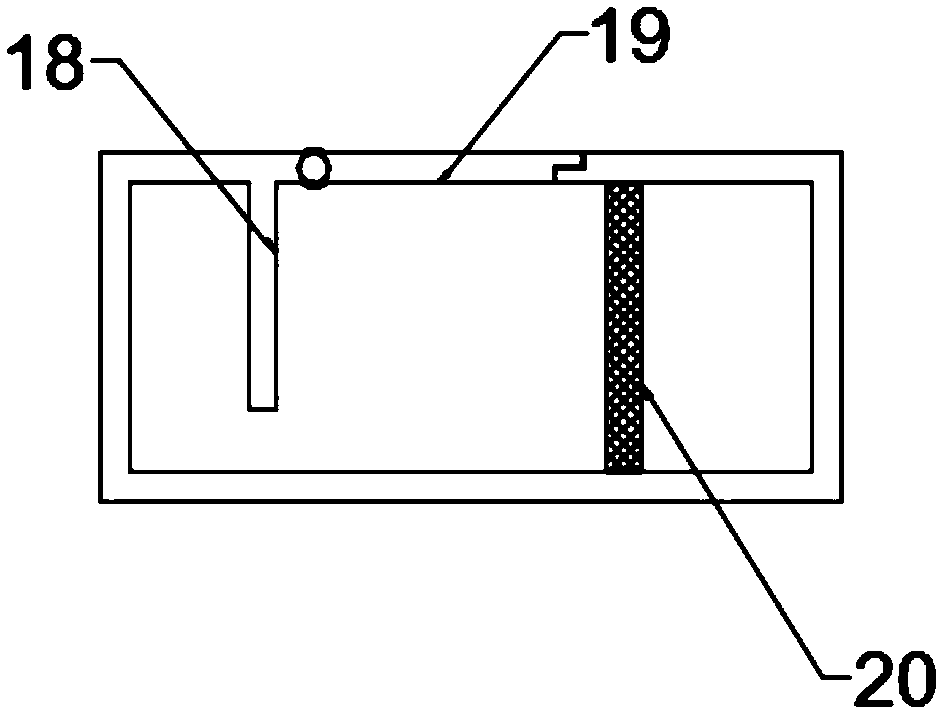

PendingCN108284279ACutting does not affectImprove stabilityLaser beam welding apparatusLaser cuttingEngineering

The invention discloses a lug laser cutting device, a workbench assembly and a lug laser cutting method. The workbench assembly comprises an upper air channel plate and a lower air channel plate. Theupper air channel plate is arranged above the lower air channel plate. An interval space allowing the lug to pass is reserved between the upper air channel plate and the lower air channel plate. The bottom face of the upper air channel plate and the top face of the lower air channel plate are each provided with multiple air holes. The upper air channel plate and the lower air channel plate blow air into the interval space through the multiple air holes so as to remove dust. When the workbench assembly cuts the lug, the upper air channel plate and the lower air channel plate blow air to the interval space so as to remove dust, the stability of a conveyed pole plate in the interval space can be improved at the same time, shake of the pole plate in the cutting process is restrained, and therefore an out-of-focus laser and other phenomena can be avoided.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

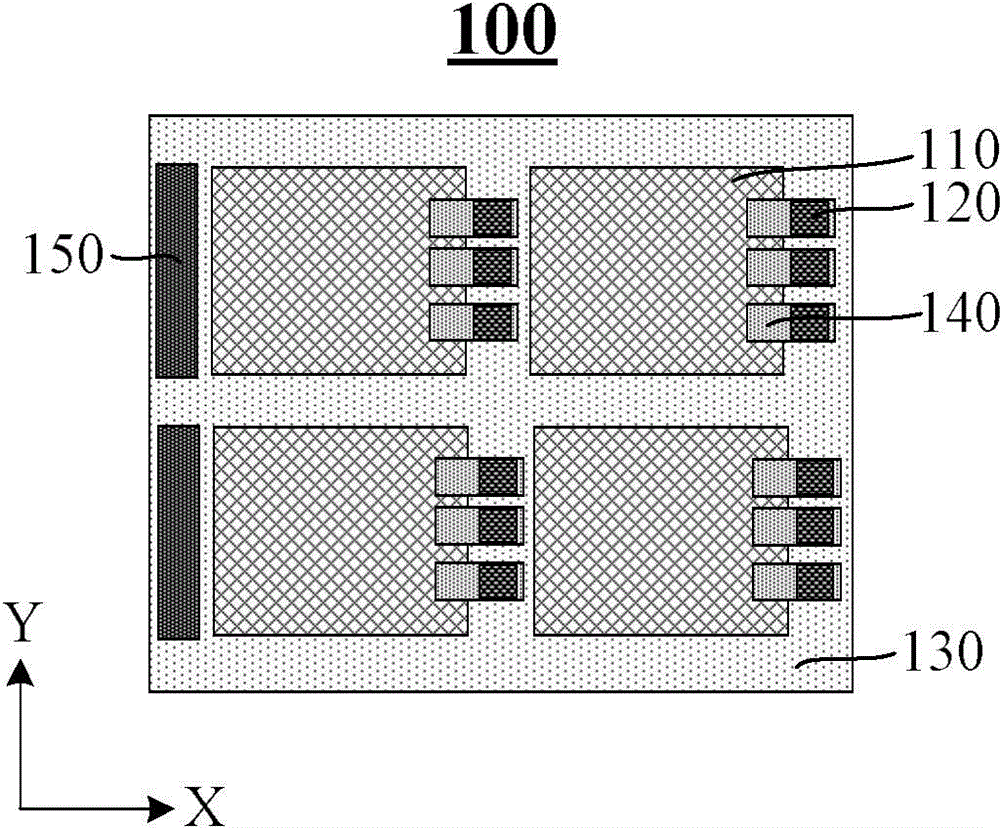

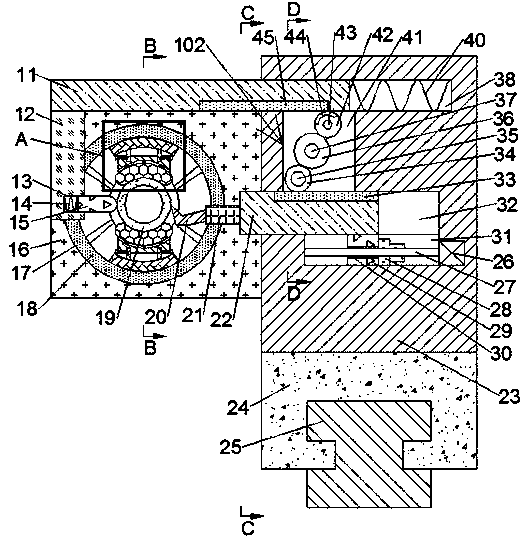

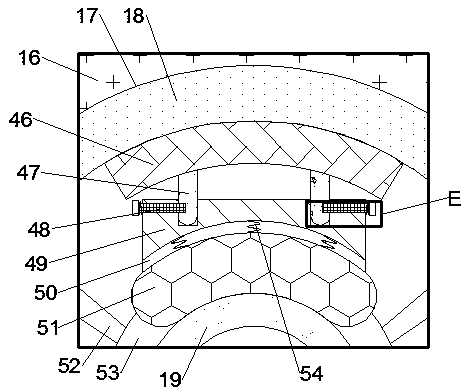

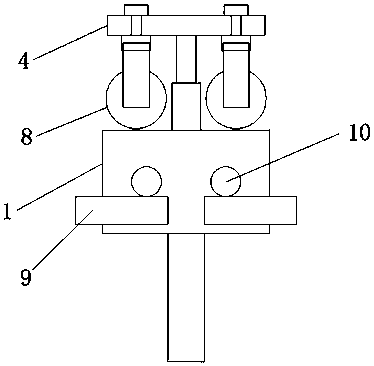

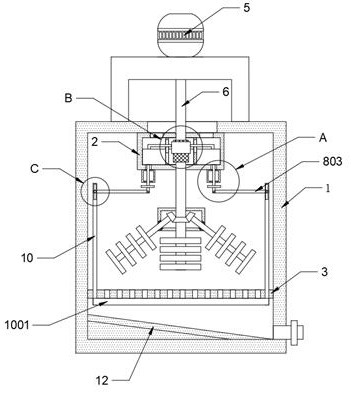

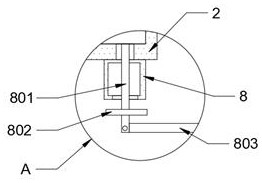

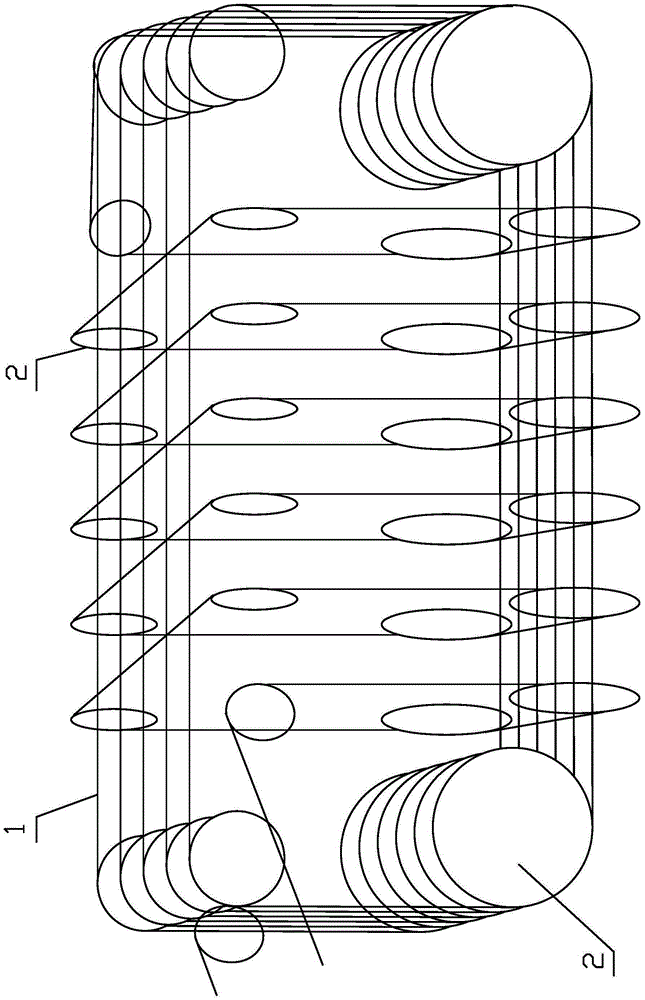

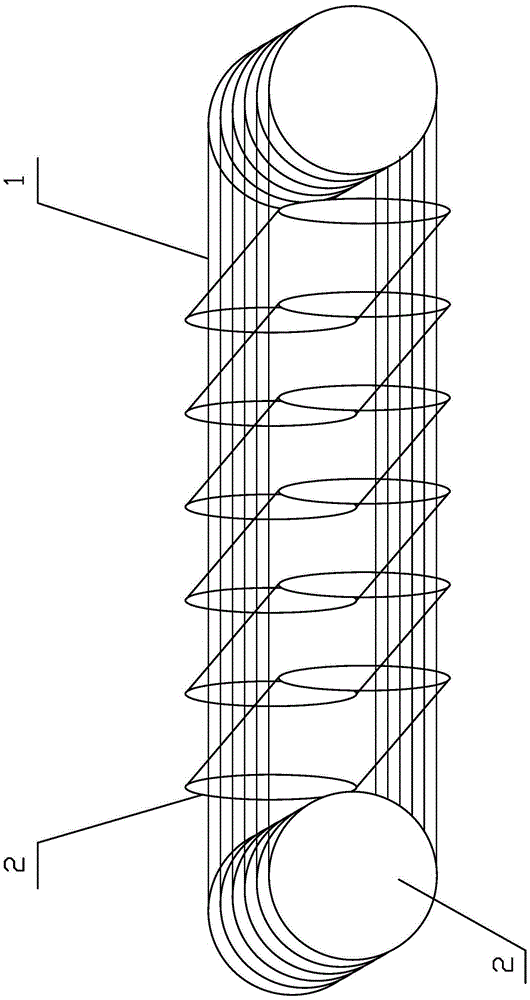

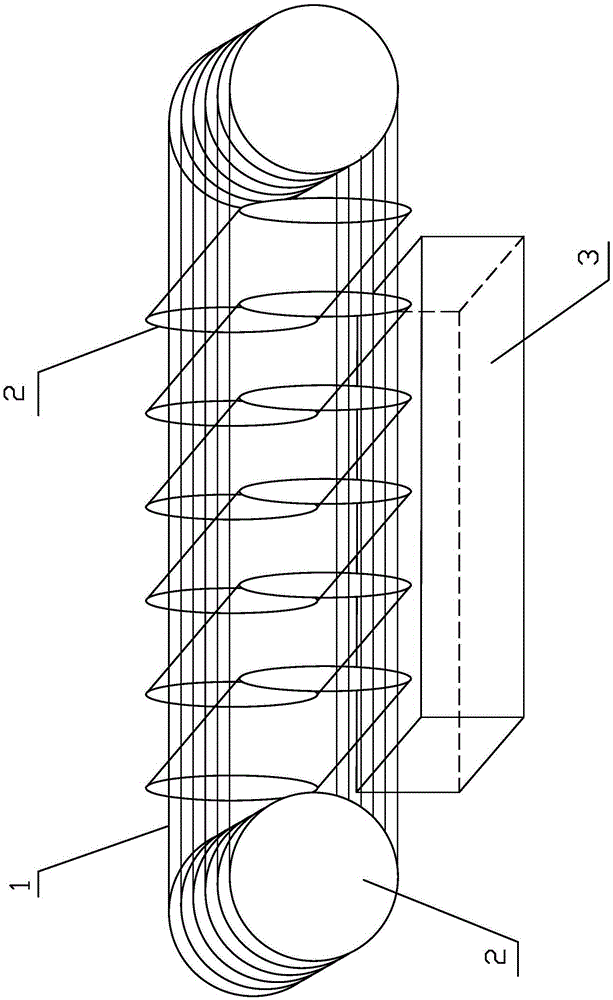

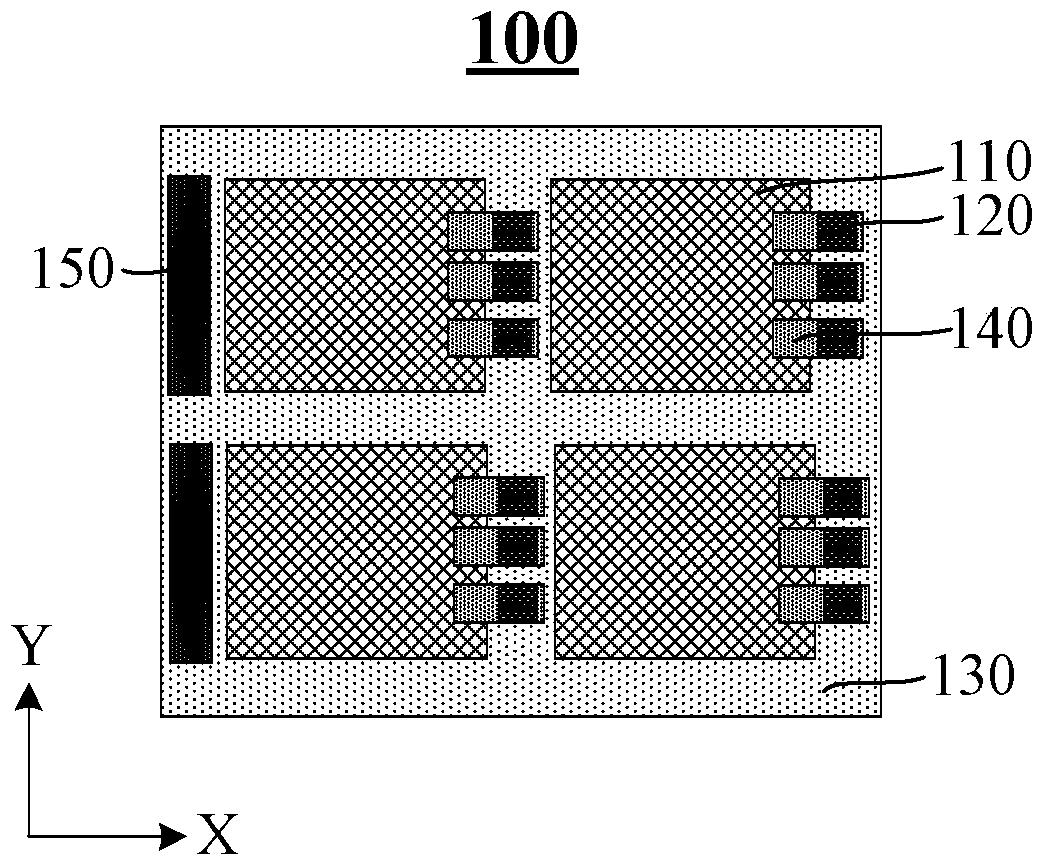

Square diamond wire saw device for polycrystalline silicon ingot

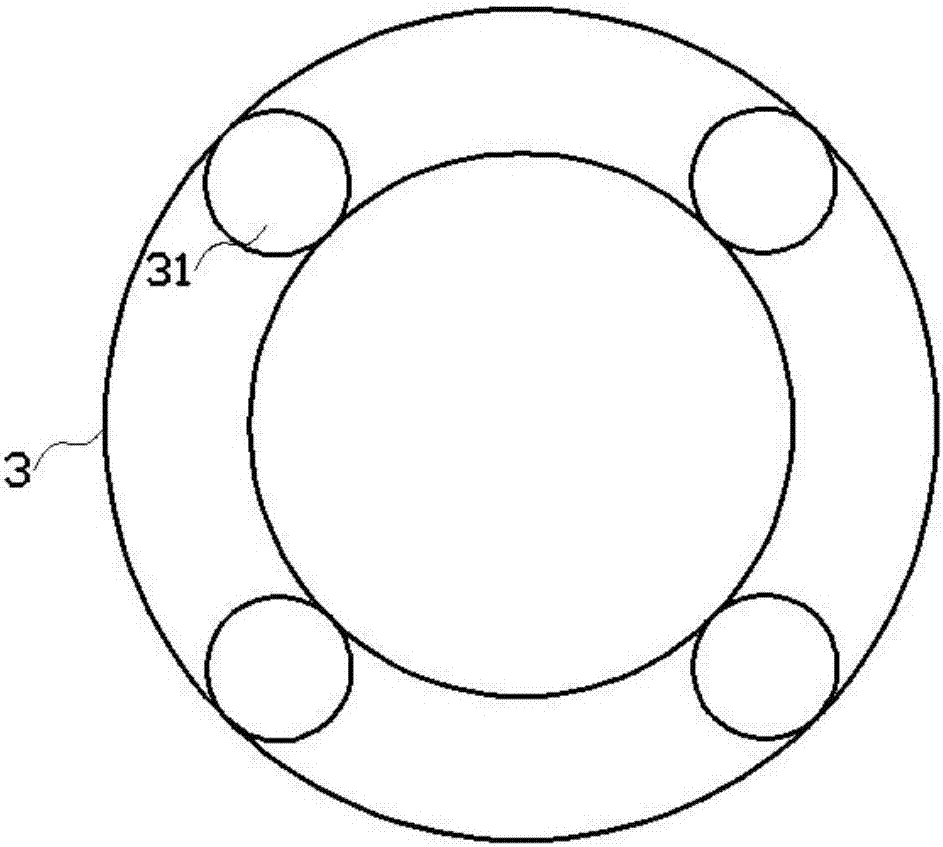

ActiveCN103786274BImprove processing efficiencyImprove flatnessFine working devicesDiamond wire sawIngot

The invention discloses a diamond fretsaw device for polycrystalline silicon ingot squaring. The device comprises a diamond fretsaw used for cutting polycrystalline silicon ingots, wherein the diamond fretsaw comprises annular diamond sawing wires, at least two annular diamond sawing wires are tensioned by guide wheel sets arranged corresponding to the sawing wires respectively to operate to form a set of cutting faces parallel to one another in the X direction, at least two annular diamond sawing wires are tensioned by guide wheel sets arranged corresponding to the sawing wires respectively to operate to form another set of cutting faces parallel to one another in the Y direction, and the X-direction diamond sawing wire set and the Y-direction diamond sawing wire set on the two sets of cutting faces intersect to form a checkered cutting net. According to the device, the multiple annular diamond sawing wires are arranged to form vertical and horizontal netty lines to cut the polycrystalline silicon ingots, the single-direction, inertia-force-free, and high-velocity motion characteristics of the annular diamond sawing wires are effectively utilized, and the machining efficiency is improved by 3-5 times compared with a reciprocating type diamond fretsaw device.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

House sewer protection device

The invention discloses a house sewer line protection device which is matched with a sewer line and comprises a storage portion and a power portion. The storage portion is coaxial with the sewer lineand comprises a first portion with a large diameter and a second portion with a small diameter from top to bottom, the top of the first portion peripherally extends to cover the edge of the sewer lineto form an erection plate, and the power portion is coaxial with the sewer line and positioned below the storage portion and comprises an inner cylinder, an outer cylinder, a motor, a gear assembly and a vibration assembly. Impurity accumulation can be prevented, congestion of the sewer line is avoided, self-cleaning is facilitated, and life of people is greatly facilitated.

Owner:靳职雄

Cutting device for refitting computer

ActiveCN112454475ACutting does not affectMetal working apparatusElectronic waste recyclingEngineeringMechanical engineering

The invention relates to the technical field of computers, and discloses a cutting device for refitting a computer. The cutting device comprises fixing rods, wherein supporting columns are arranged onthe left and right sides of the lower surface of each fixing rod, a sliding groove is formed in the middle of each fixing rod, and the middle of each sliding groove is slidably connected with the end, away from the center of the device, of a corresponding sliding block; a second fixing plate is arranged at the right ends of the fixing rods, second guide rods are slidably connected to the front side and the rear side of the second fixing plate, the left ends of each second guide rod is fixedly connected with the right side of the corresponding sliding block, a first guide rod is slidably connected to the middle of each sliding block, a first limiting block is fixedly connected to the lower end of each first guide rod, and a first spring is arranged between each first limiting block and thecorresponding sliding block; and a pressing plate is fixedly connected to the upper end of each first guide rod, and a first fixing plate is arranged in the middles of the lower surfaces of the fixing rods. The cutting device for refitting the computer is suitable for refitting the computer, a cutting wheel can rotate around a rotating shaft, and the cutting angle can be freely adjusted in a morepersonalized mode.

Owner:费莱(浙江)科技有限公司

Powder electrostatic charge detection and calibration short section

PendingCN111157808AReal-time response to charge statusAccurate and reliableElectrical measurementsCharge detectionEngineering

A powder electrostatic charge detection and calibration short section is composed of a counter flange, a sampling cup, an electric lead-out wire structure, a sealing box, a supporting frame, an electric lead-out wire, an anti-explosion gland, a connector, a detection cover plate, an operation replacement cover plate, an outer cylinder, a charge-to-mass ratio detector and a calibration frame. Two ends of the outer cylinder are fixedly connected with the butt flanges. The calibration frame is a hollow square tubular component, and one end of the calibration frame is hermetically and fixedly connected with the outer cylinder, and the other end of the calibration frame is provided with a flange mounting hole. The sampling cup is taken out of the outer cylinder through the calibration frame. The sampling cup is arranged in the outer cylinder and is close to the inner wall of one side of the outer cylinder, and a sampling outer cup of the sampling cup is fixedly connected with one end of thesupport frame through welding. The other end of the support frame is welded and fixedly connected with the detection cover plate through the calibration frame. An electric leading-out wire structureis arranged on the sampling inner cup and is connected with an electric leading-out wire. The electric leading-out wire penetrates through the sealing box and is arranged in the support frame. The electric leading-out wire penetrates through the explosion-proof gland and is connected with the charge-to-mass ratio detector through a joint, and the explosion-proof gland is fixedly connected to the detection cover plate.

Owner:北京普惠实华科技有限公司

A cutting device for modifying a computer

ActiveCN112454475BCutting does not affectMetal working apparatusElectronic waste recyclingPersonalizationEngineering

Owner:费莱(浙江)科技有限公司

Safety protection device for aluminum alloy plate cutting machining

InactiveCN112518028ACutting does not affectReduce rotation speedMetal sawing devicesElectric machineryEngineering

The invention relates to the technical field of aluminum alloy material machining equipment, and discloses a safety protection device for the aluminum alloy plate cutting machining. The safety protection device comprises a workbench, a rotating shaft is movably connected into the workbench, a first chain wheel fixedly sleeves the rotating shaft, a chain is engaged with the exterior of the first chain wheel, and a connecting rod is movably connected with the exterior of the chain; a sliding rod is movably connected to the outside of the connecting rod, and a sleeve rod is movably connected to the outside of the sliding rod; through interaction among a connection rod, a shell, a limiting block, an electro-rheological body, an electric wire, a movable block, a speed reducing block, a first spring, a second spring and a monitoring assembly, the rotating speed of a lead screw can be limited in time when the rotating speed of the lead screw exceeds a normal speed range due to stall of a motor in the aluminum alloy plate cutting machining process; and the rotating speed of the lead screw is gradually reduced, so that the situation that the cutting blade is broken due to the fact that themoving speed of the lead screw is too high is avoided, and meanwhile continuous cutting of an aluminum alloy plate is not affected.

Owner:李兴东

Chip structure and fabrication method thereof

ActiveCN105826286BWon't hurtQuality assuranceSemiconductor/solid-state device detailsSolid-state devicesEngineeringPhotomask

The invention provides a chip structure and a manufacturing method thereof. According to the invention, a welding pad is formed on a cutting channel at one side of a first direction of a chip and is connected with the chip through a metal connecting wire, a test probe is pricked into the welding pad located at the cutting channel when a CP test is carried out subsequently, and no damage is imposed on the chip, so that the quality of the chip can be ensured, and the number of available chips of a wafer is increased. In addition, subsequent cutting for the chip structure is not affected after the CP test is completed. Furthermore, the invention provides a manufacturing method of the chip structure. A photomask unit on the cutting channel at the other side of the first direction of the chip is set to be a dark portion, thereby avoiding secondary exposure for the public cutting channel, ensuring the performance of the welding pad on the public cutting channel, and enabling the CP test to be carried out smoothly.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Cotton filling machine

ActiveCN112520682ASave manpower and material resourcesImprove work efficiencyUpholstery manufactureDollsTextile technologyAgricultural science

The invention discloses a cotton filling machine which comprises a cotton filling machine body composed of a conveying mechanism, a cotton loosening mechanism and a cotton filling mechanism, the conveying mechanism comprises a conveying belt, the right side of the conveying belt is communicated with the cotton loosening mechanism, a material frame is arranged on the left side of the conveying belt, and the cotton loosening mechanism comprises a shell. A cotton fluffing mechanism and a pulling mechanism are arranged in the shell, a feeding port is formed in the left side of the shell, a discharging port is formed in the right side of the shell, the top of the shell is fixedly connected with a right air blower, and the right end of the discharging port communicates with a cotton filling mechanism. And the right side of the cotton filling mechanism is fixedly connected with a filling product through a clamping and locking mechanism. The invention relates to the technical field of cotton filling machine. According to the cotton filling machine, the problems that various filling cotton bodies cannot be fully and uniformly mixed, the plumpness and the elasticity of products are seriouslyinfluenced due to the fact that the expansion degree of the cotton bodies is not enough, meanwhile, manual cotton filling is uneven, and the working efficiency is low are solved.

Owner:浙江宇立家具有限公司

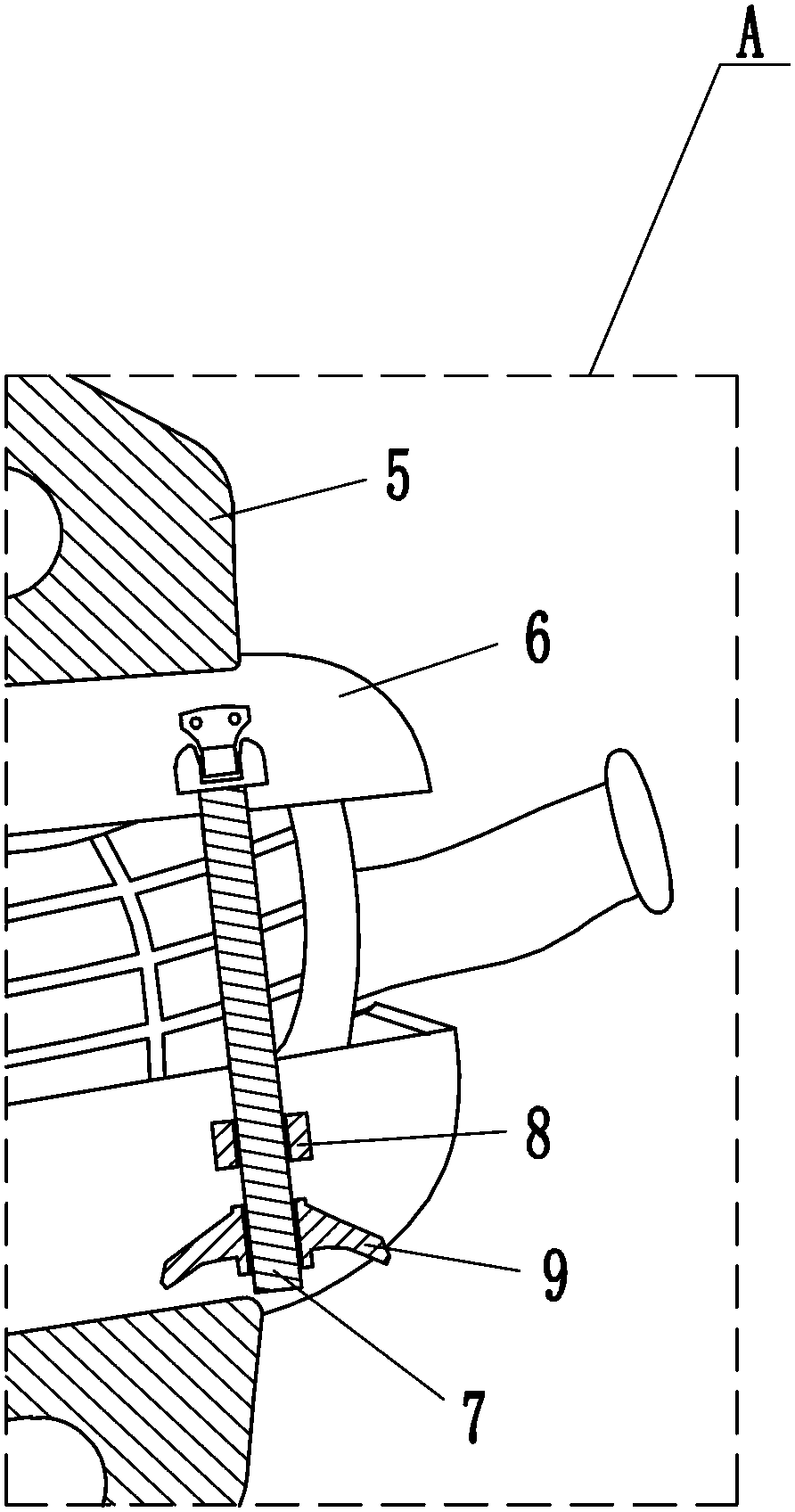

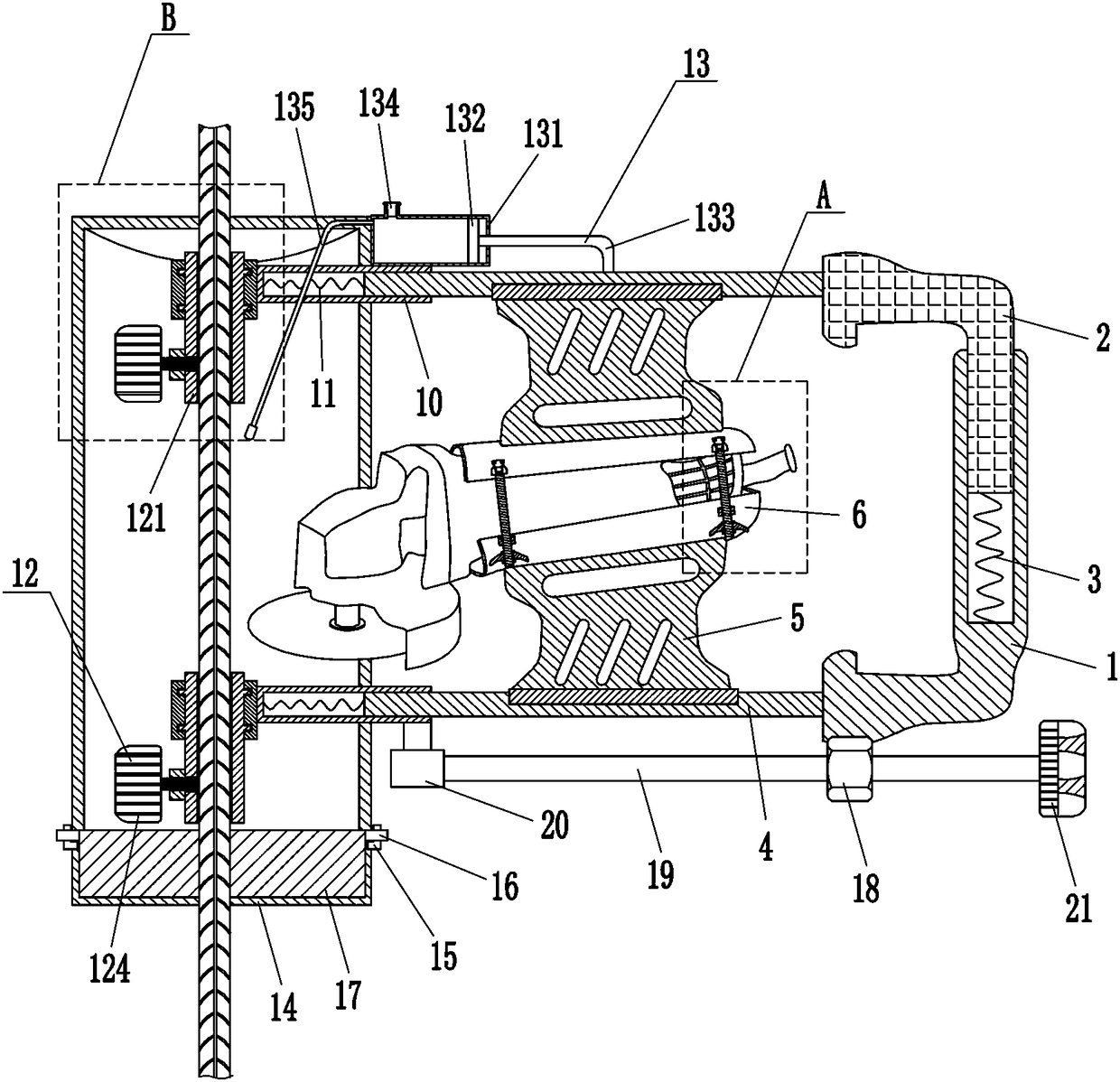

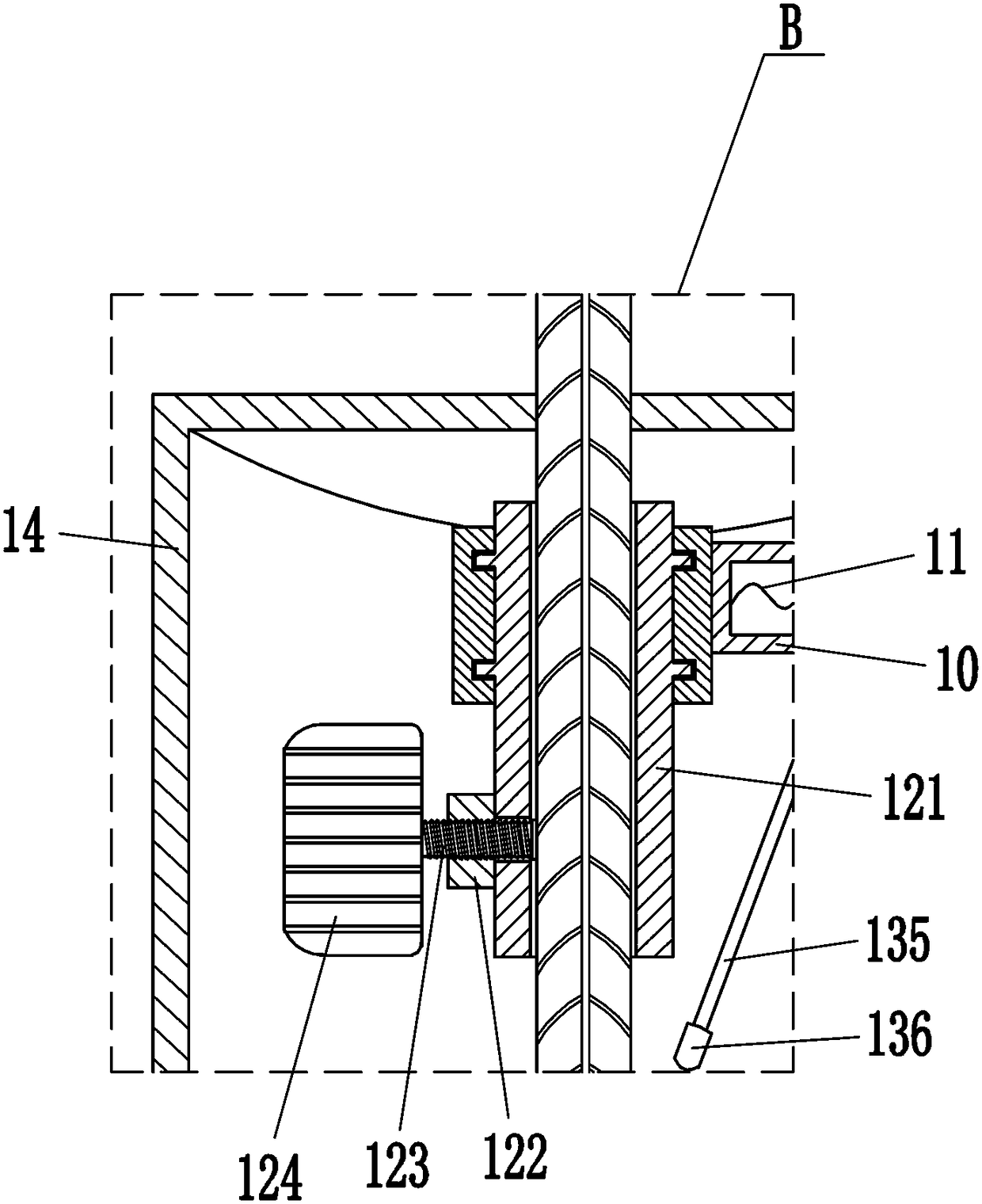

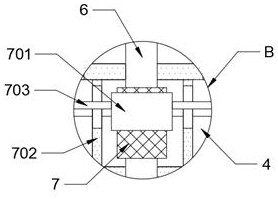

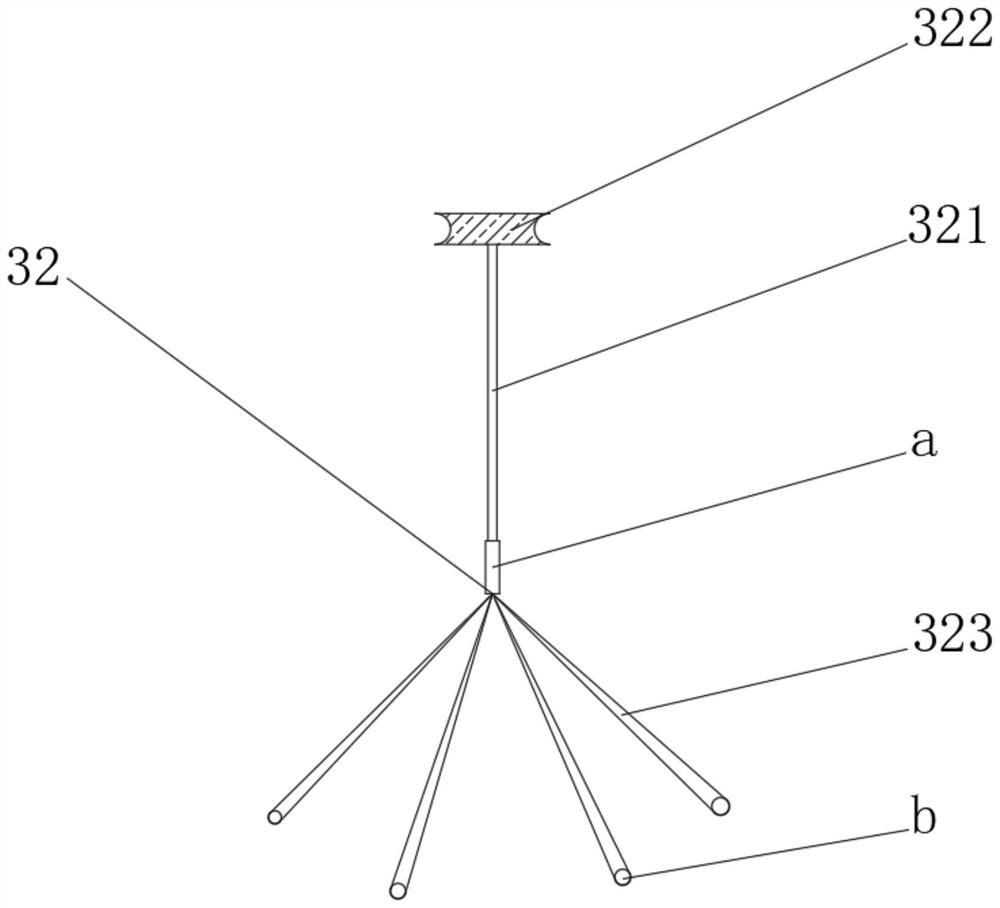

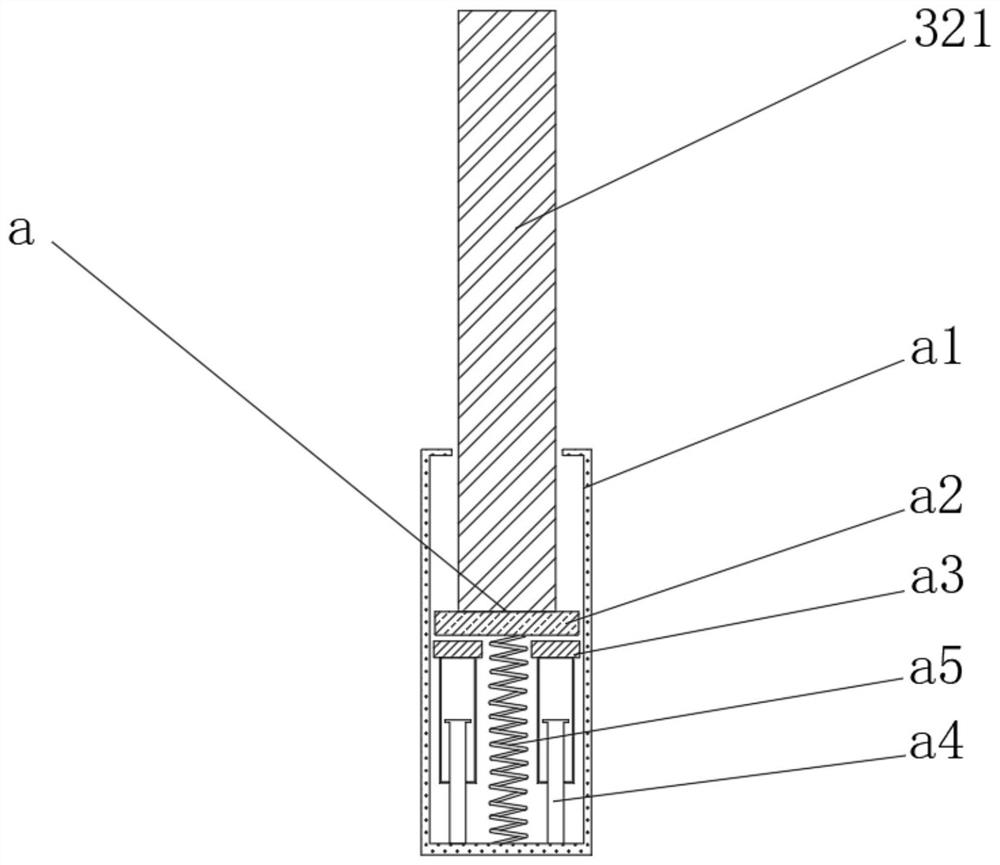

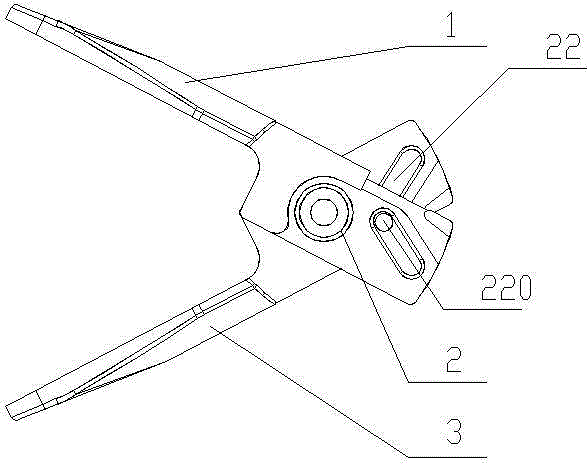

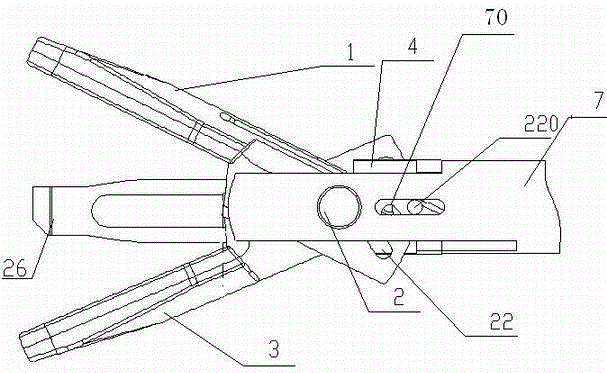

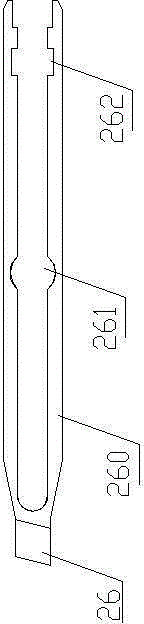

High Frequency Bipolar Closed Cutting Pliers

ActiveCN102178559BImprove closing effectEasy to useSurgical instruments for heatingPush pullOrthopedic department

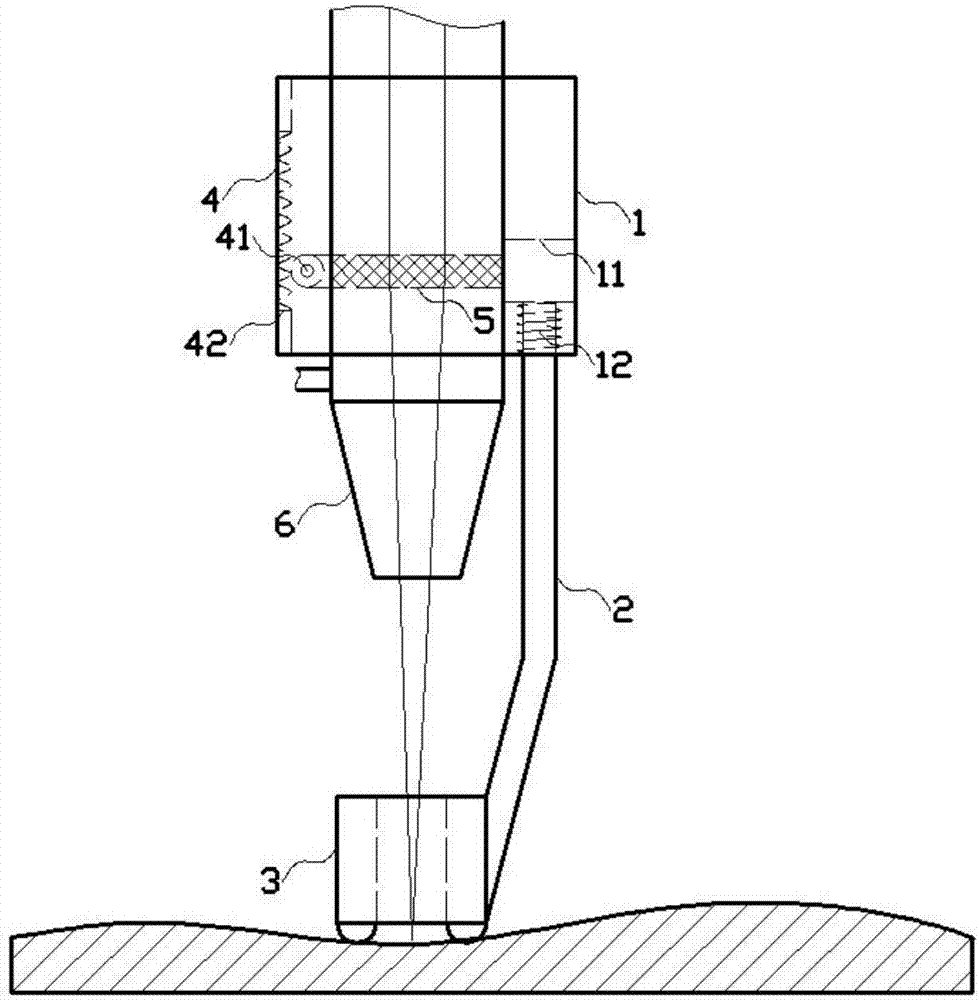

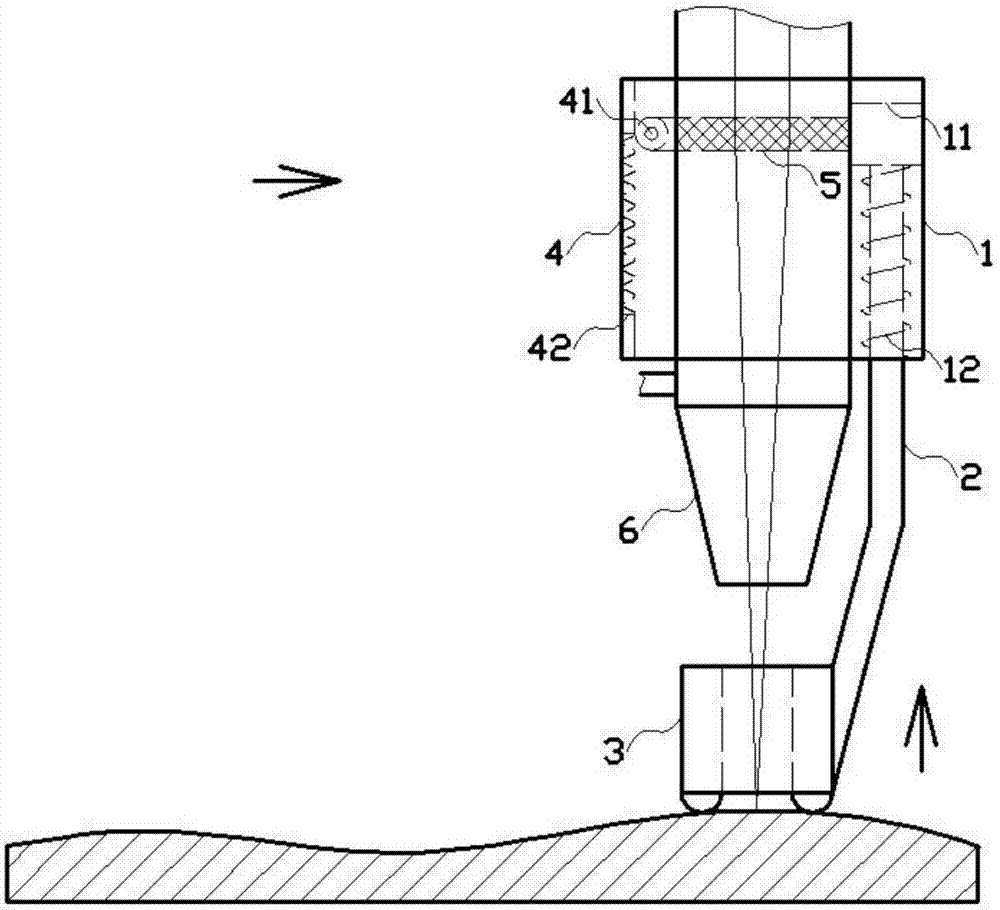

The invention relates to high-frequency bipolar closed cutting forceps. The high-frequency bipolar closed cutting forceps are characterized by comprising a closed cutting forceps head device of the high-frequency bipolar closed cutting forceps, a forceps head opening / closing locking device of the high-frequency bipolar closed cutting forceps and a forceps head cutting precise control device of the high-frequency bipolar closed cutting forceps, wherein the closed cutting forceps head device comprises a first closed forceps head (1), a closed forceps head pin (2), a second closed forceps head (3), a forceps head insulating barrier (4), a forceps head push-pull bar (5), a blade push-pull tube (6), an outer aluminum tube (7) and a cutting blade (26); and the first closed forceps head (1) is rotationally connected with the second closed forceps head (3) through the closed forceps head pin (2). The invention aims to provide a medical high-frequency surgery instrument and relates to monopolar and bipolar mode multifunctional closed cutting forceps. The high-frequency bipolar closed cutting forceps are widely applicable to general surgery, cardiothoracic department, urological department, orthopedic department, coordinate with endoscopic surgery and laparoscopic surgery, and are a closed ring amplitude-regulating and power-regulating electrotome.

Owner:杭州得道医疗设备科技有限公司

Porcelain separator with excellent functions

InactiveCN109877980AEasy to cutImprove qualityWorking accessoriesStone-like material working toolsSurface mountingEngineering

The invention discloses a porcelain separator with excellent functions. The porcelain separator includes a fixed column, a long column, a processing panel, an anti-injury protective sheath, a fixing column and an operating panel, a rotating column is installed on the surface of the long column, a supporting column is installed on the upper side of the fixing column, and the supporting column is connected with the fixing column through a variable fixator; a separation sheet is arranged on the right side of the fixing column, and the anti-injury protective sheath is installed on the upper side of the surface of the separation sheet; and a handle is arranged on the upper side of the anti-injury protective sheath, a cleaning output hole is formed in the lower side of the fixed column, a material cutting and fixing table is installed on the upper side of the processing panel, and a left fixed baffle is installed on the surface of the operating panel. According to the porcelain separator with the excellent functions, the distance of a cutting object is adjusted through an adjustment button on the side face, meanwhile, the cutting object is fixed, deviation and vibration of the cutting object are avoided, and thus the precision of cutting is ensured.

Owner:吴雨桐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com