Automatic focusing high-efficiency laser cutting device

An automatic focusing and laser cutting technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of not being able to cut freely and unfavorable laser cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

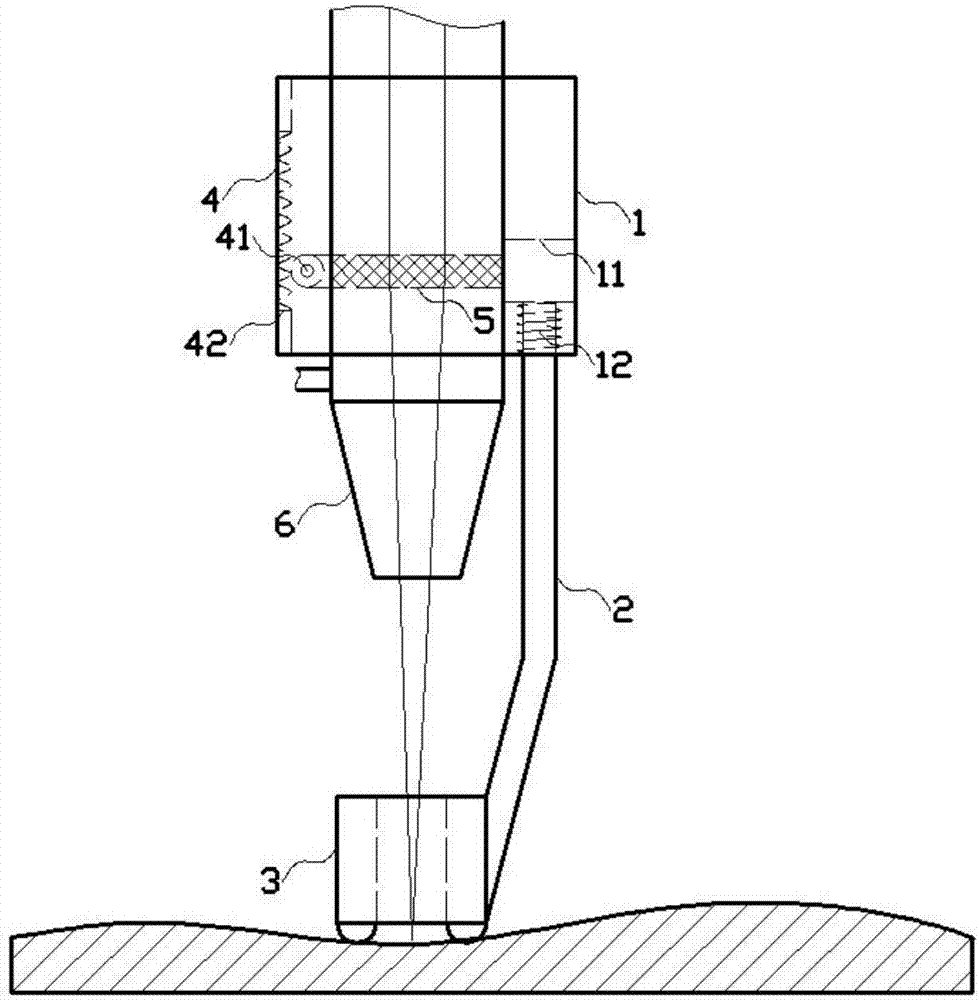

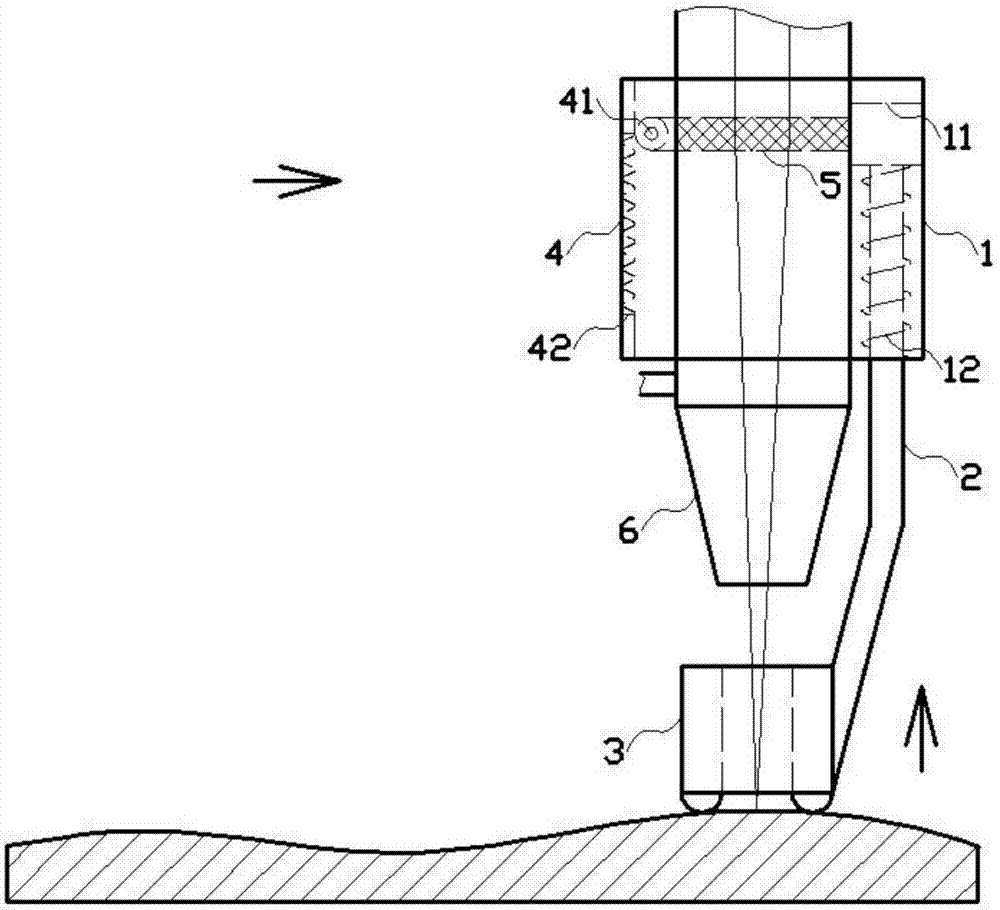

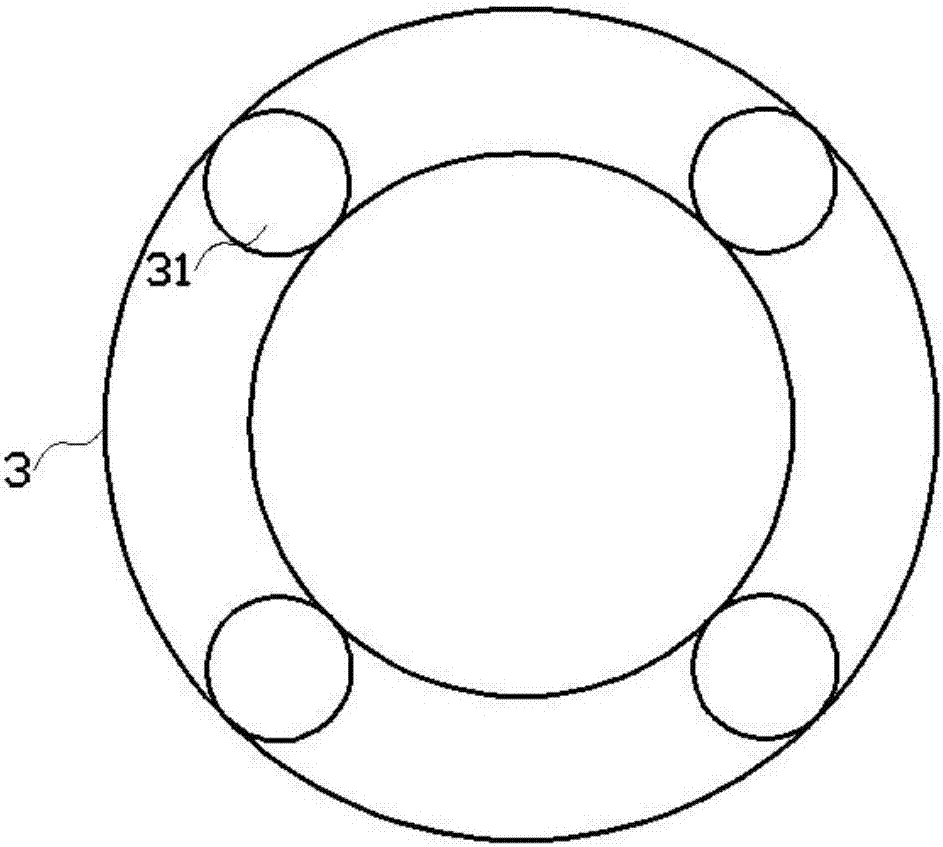

[0014] Such as figure 1 , figure 2 , image 3 As shown in the embodiment, the automatic focusing high-efficiency laser cutting device is a device that automatically changes the focal length position of laser cutting according to the thickness of the workpiece, and at the same time adjusts the intensity of laser cutting to make cutting more flexible. It includes a sliding module 1, Connecting rod 2, detection module 3 and adjustment module 4; described sliding module 1 comprises sliding block 11 and extension spring 12, and described sliding module 1 is designed with sliding shell, and the inside of described sliding shell is designed with cavity, and described sliding shell The left end face of the laser cutting head is fixedly installed on the outer surface of the laser cutting head, the sliding housing is designed with a sliding groove at the part in contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com