Patents

Literature

97results about How to "Cut thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

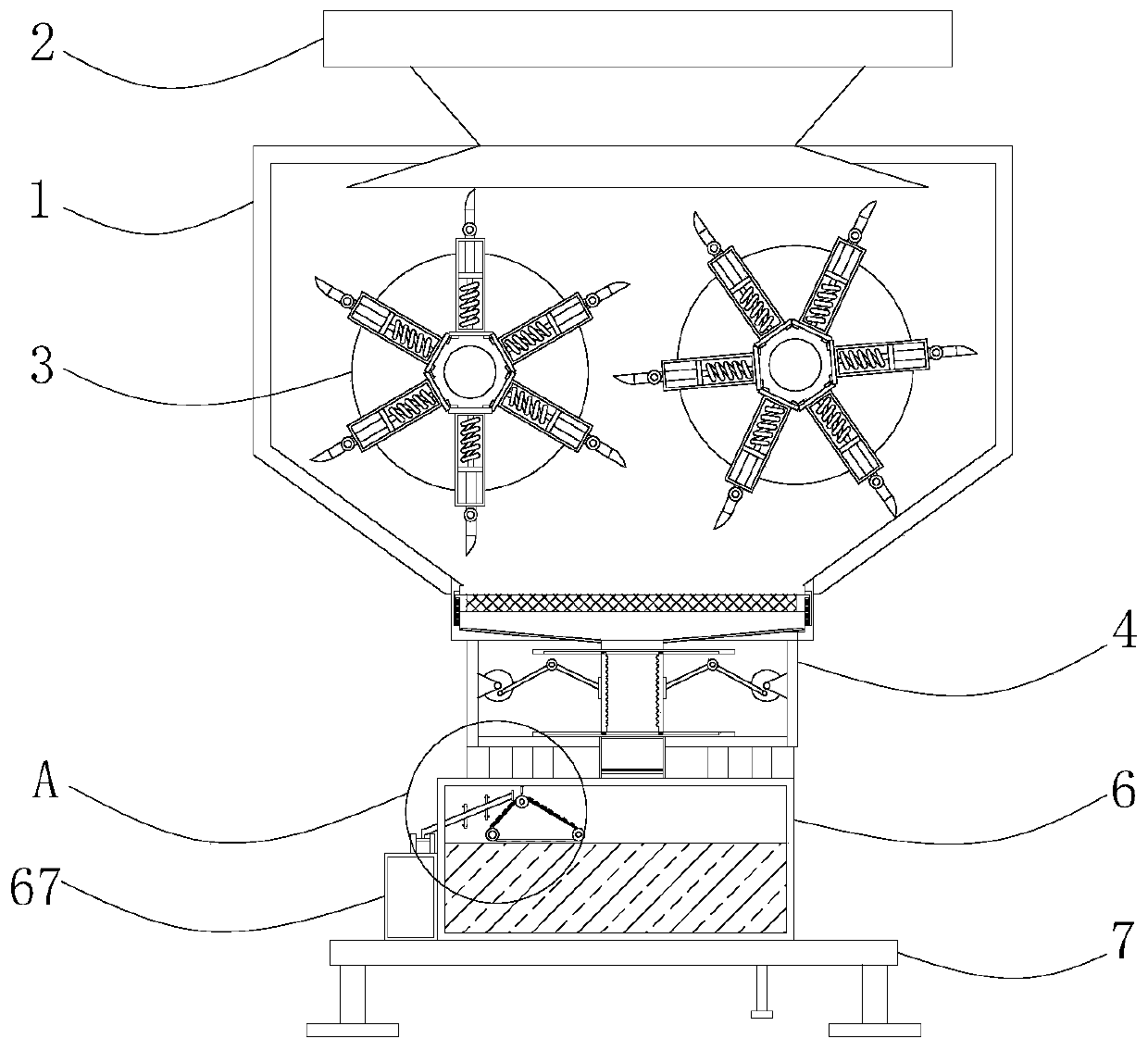

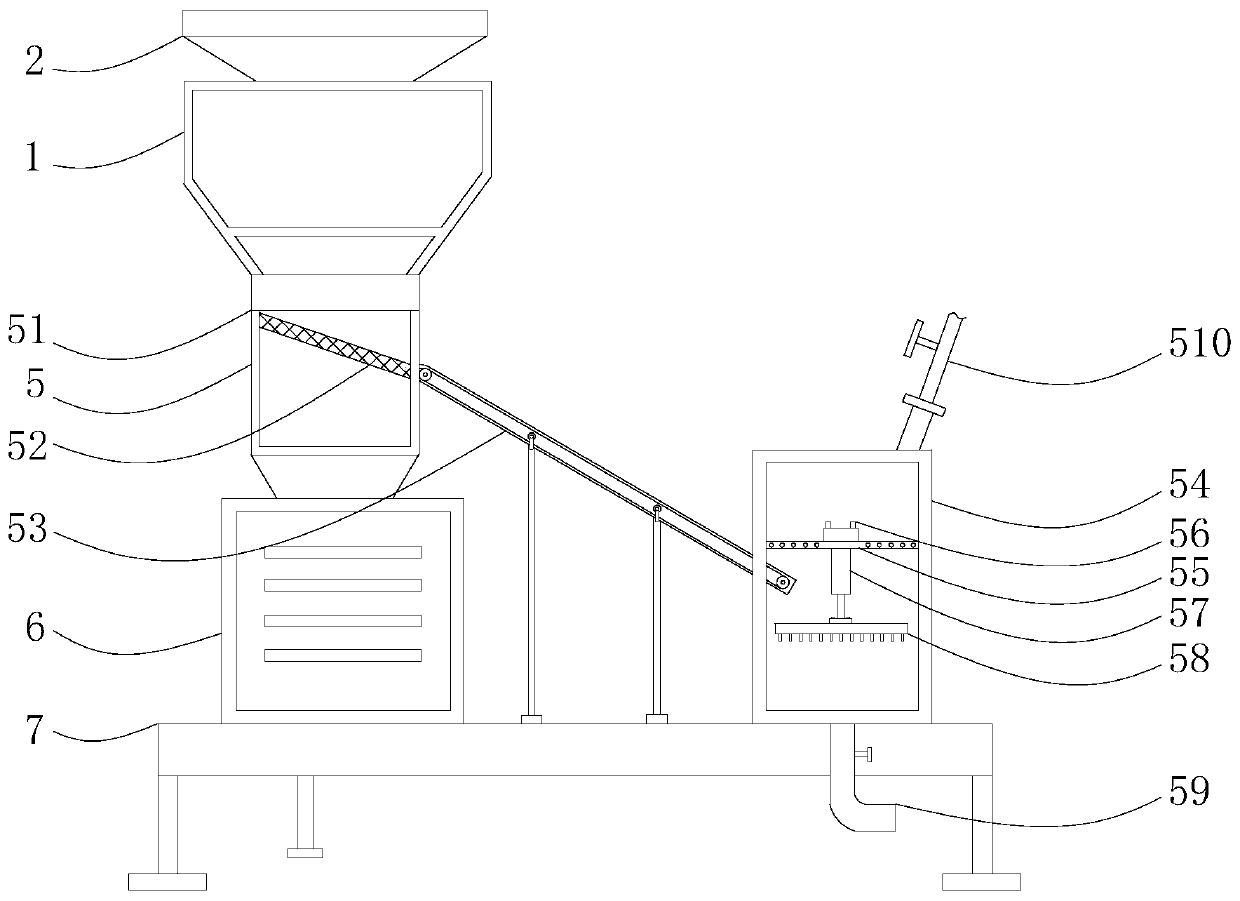

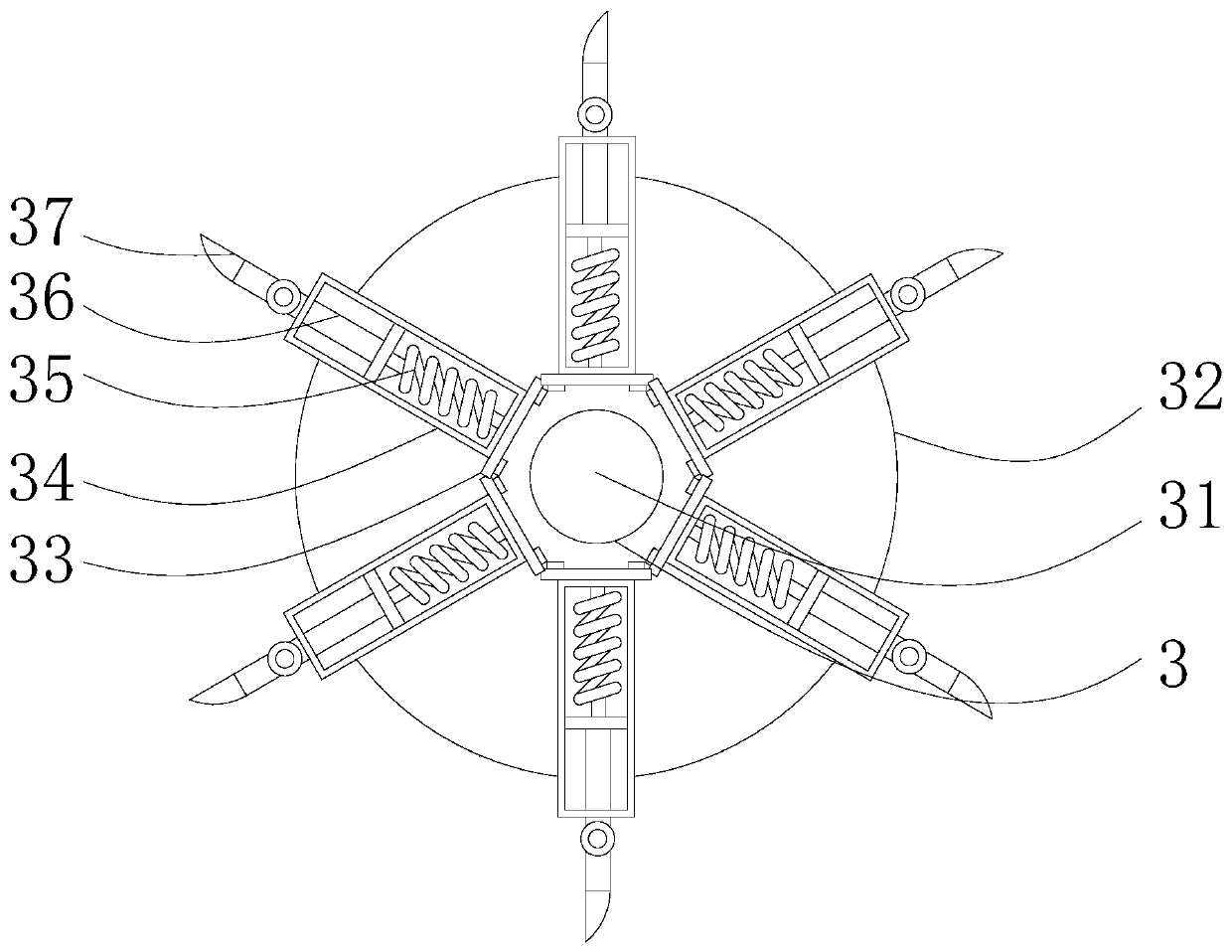

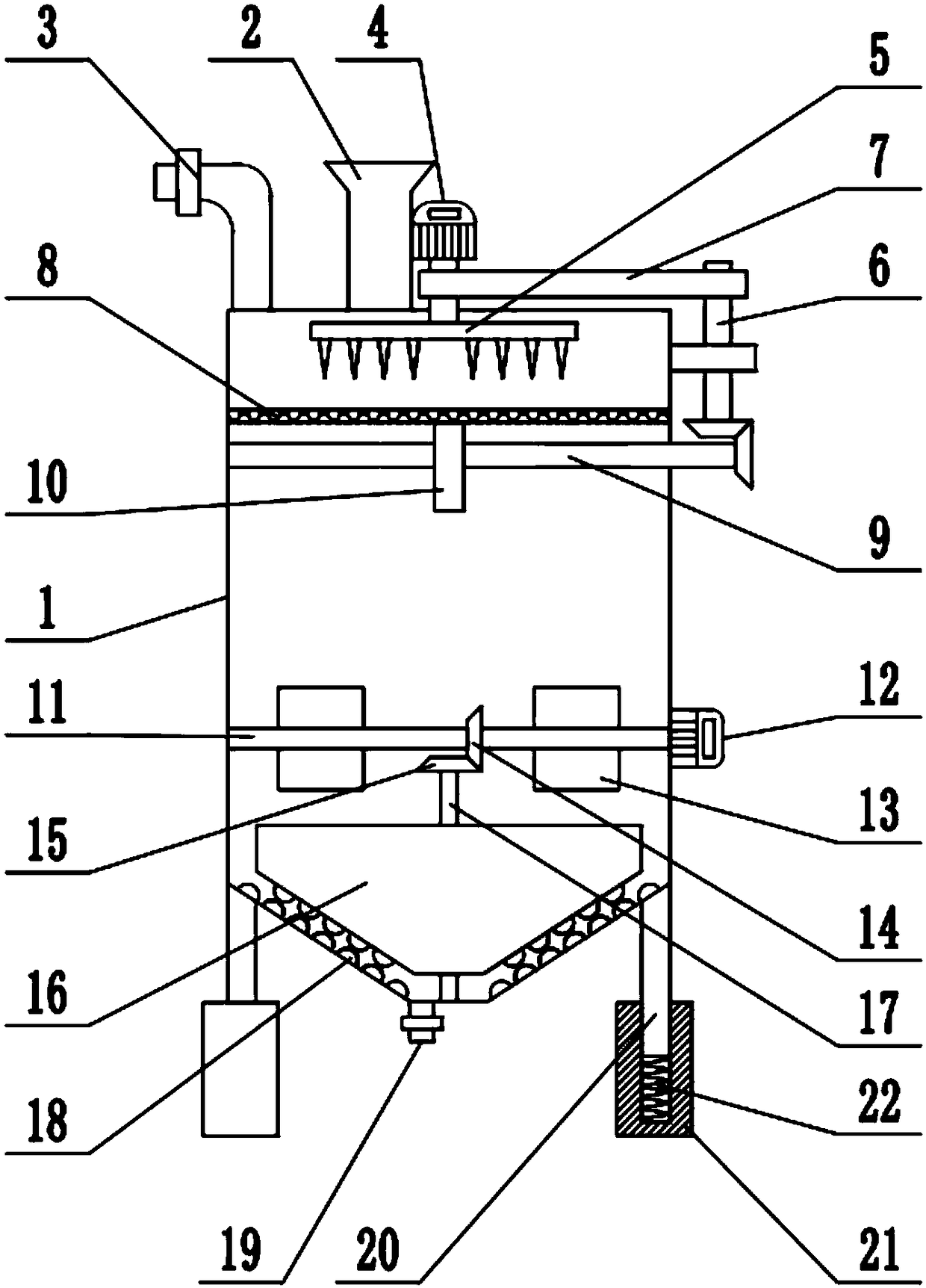

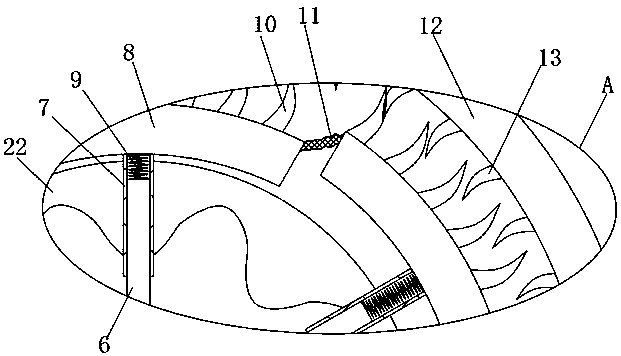

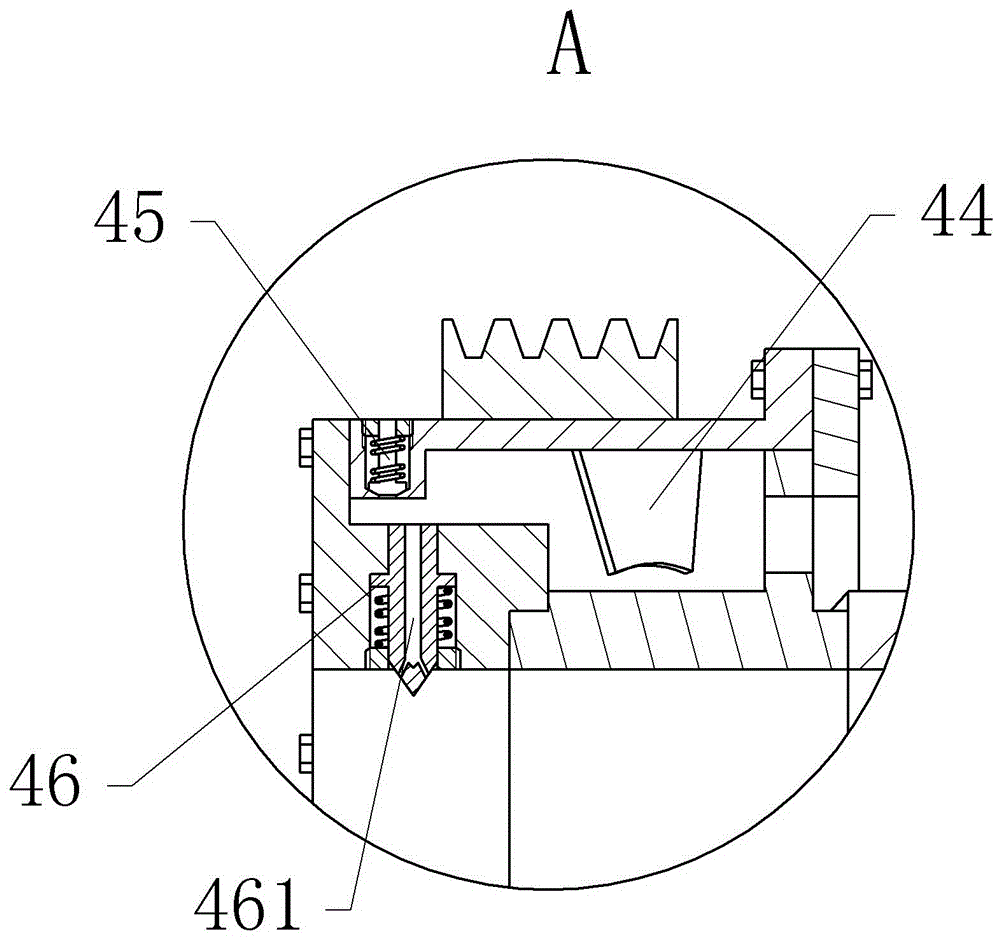

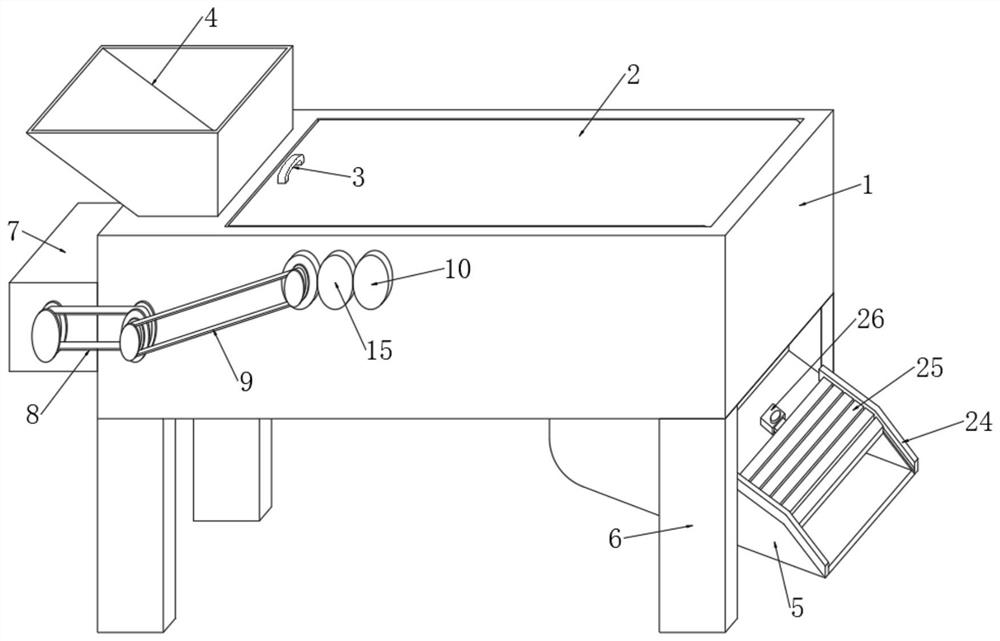

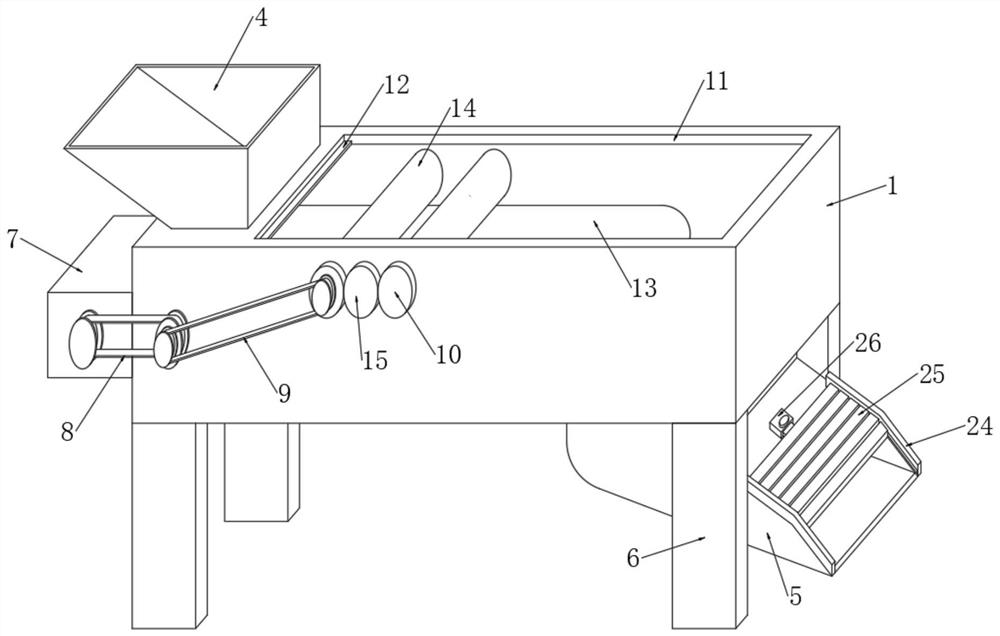

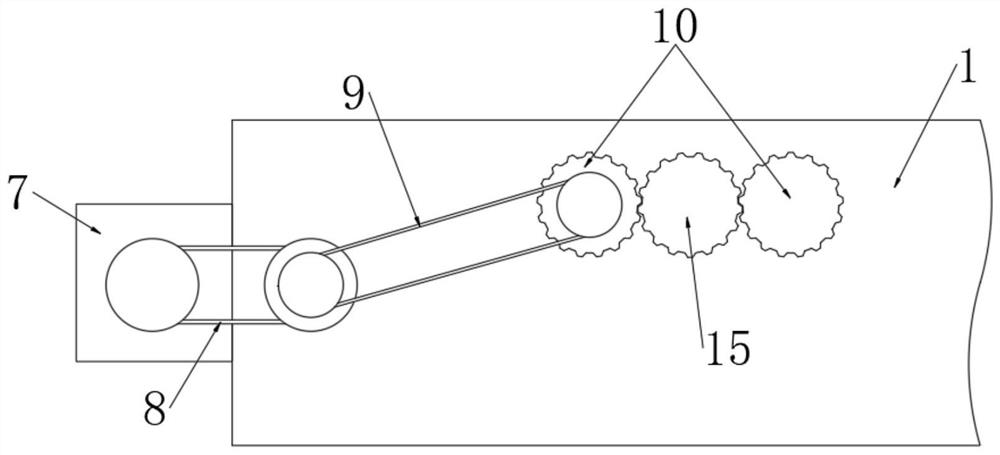

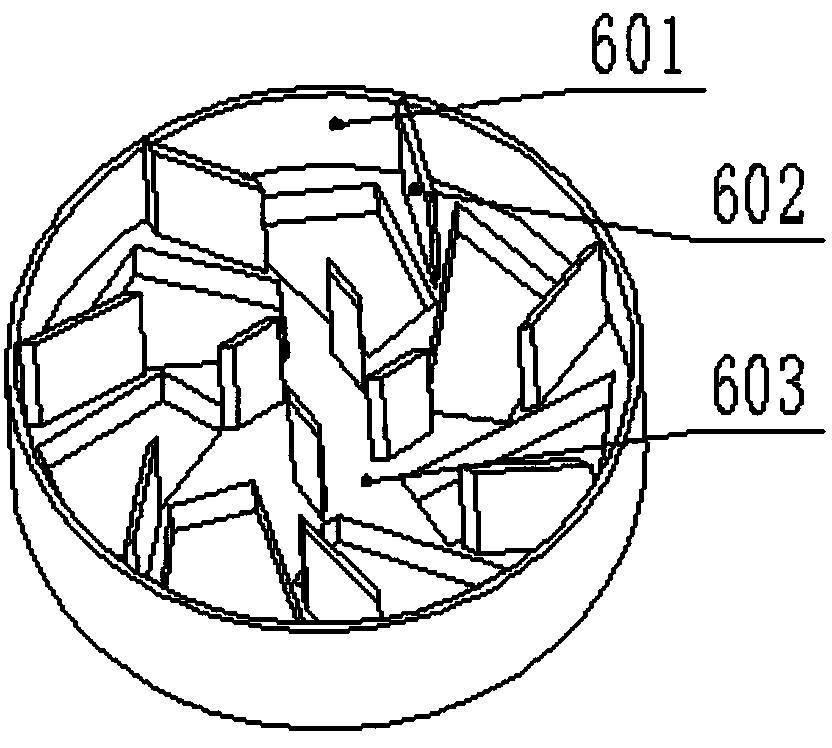

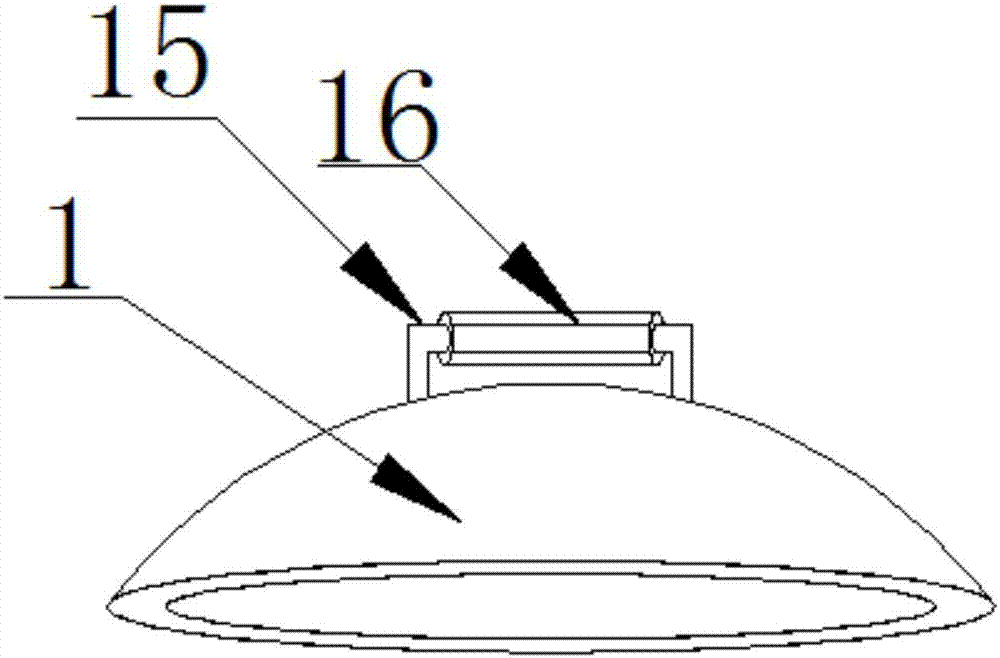

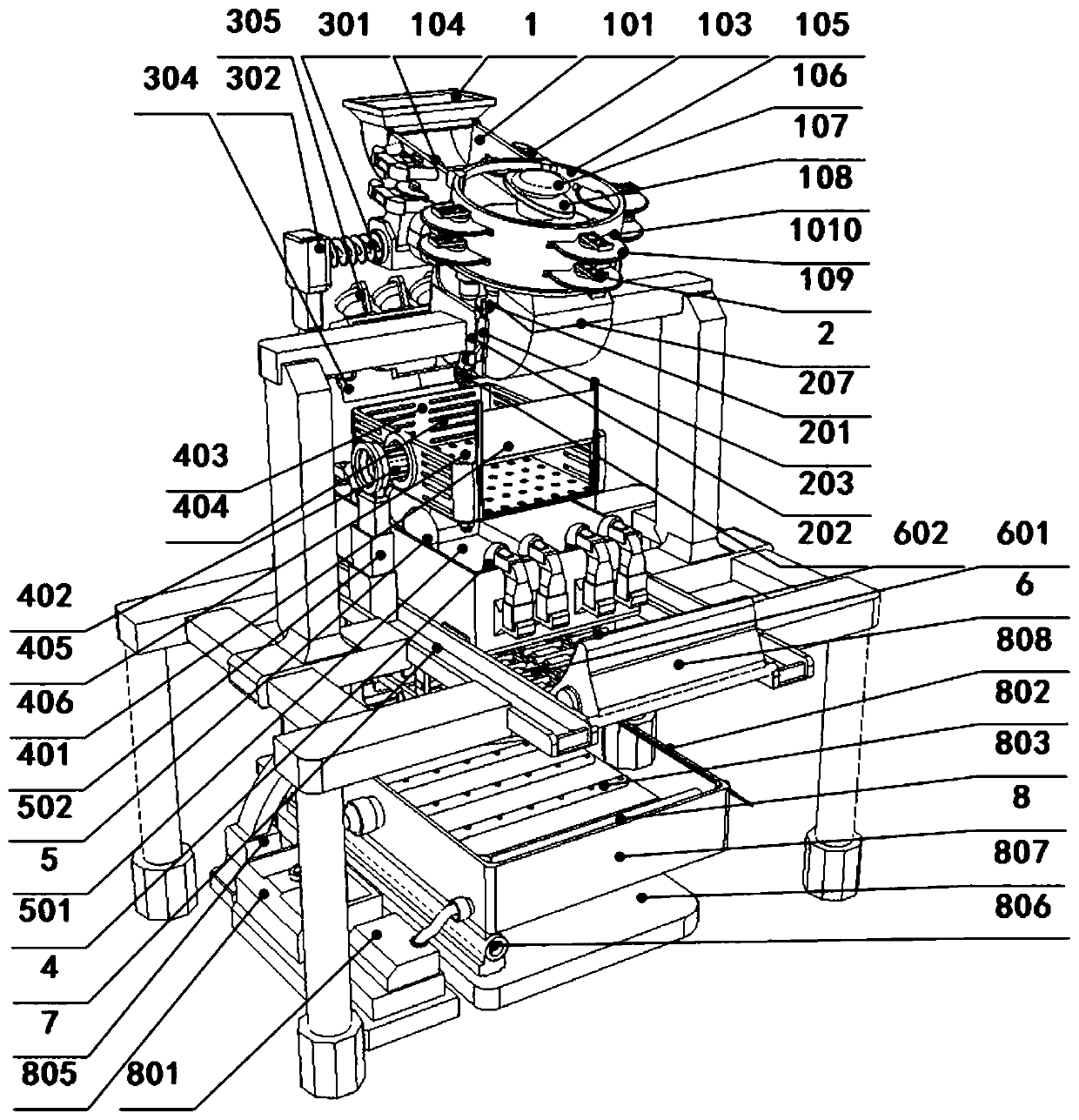

Anaerobic fermentation equipment for organic garbage

InactiveCN110004034ACut finely and thoroughlyCut thoroughlyBiological substance pretreatmentsGas production bioreactorsPhysical healthLitter

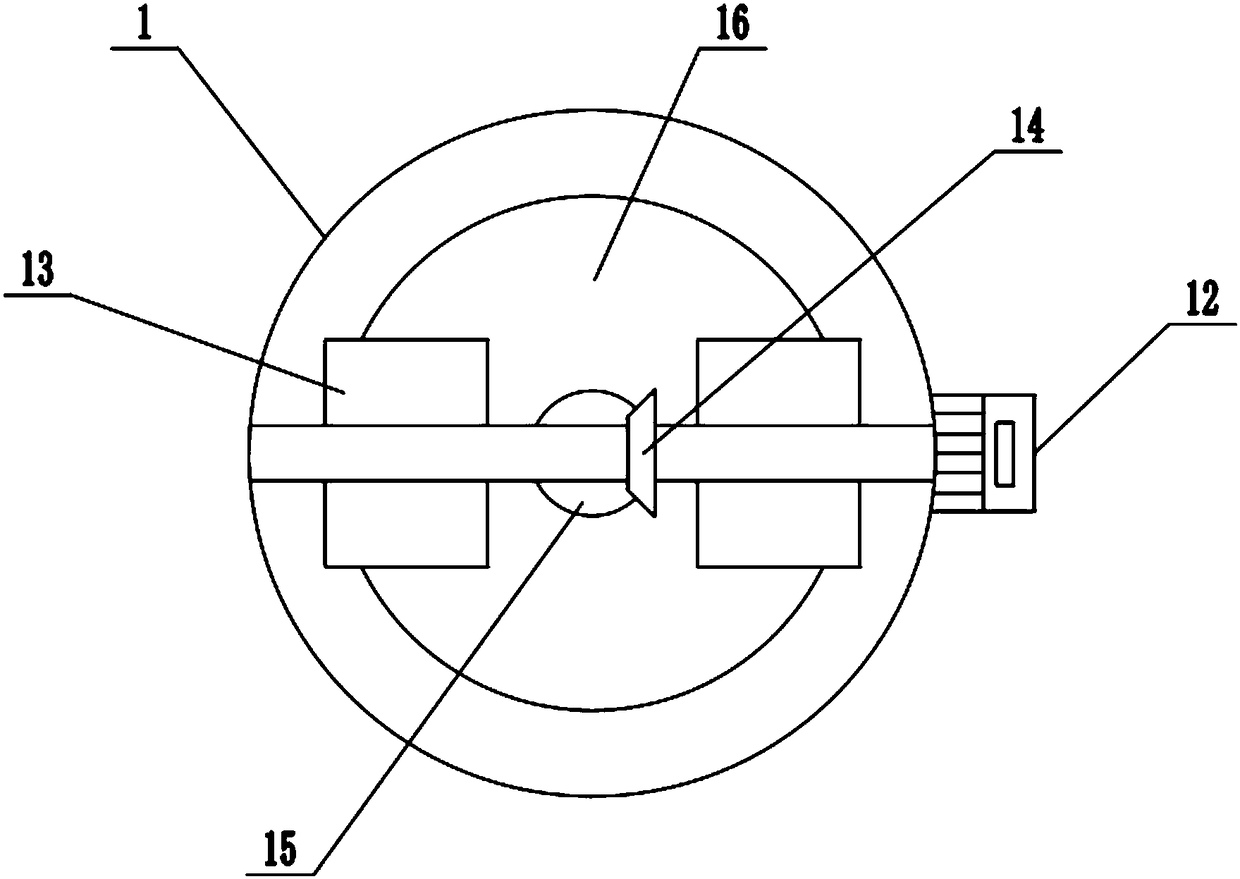

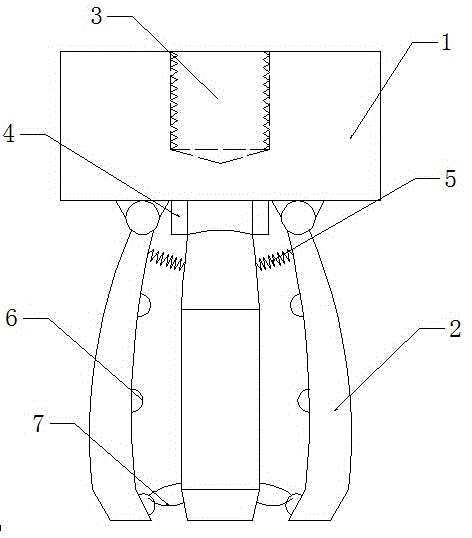

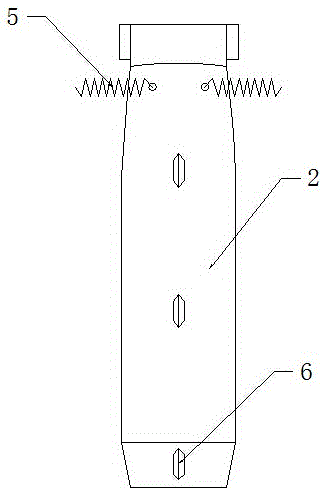

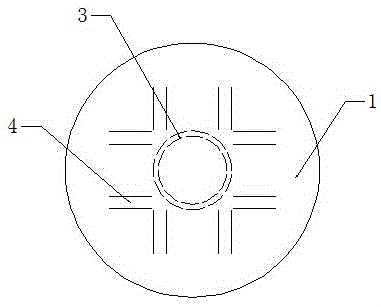

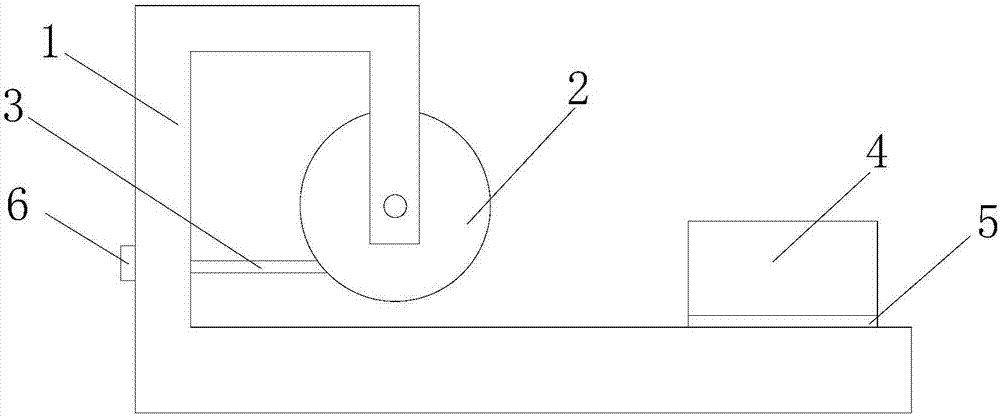

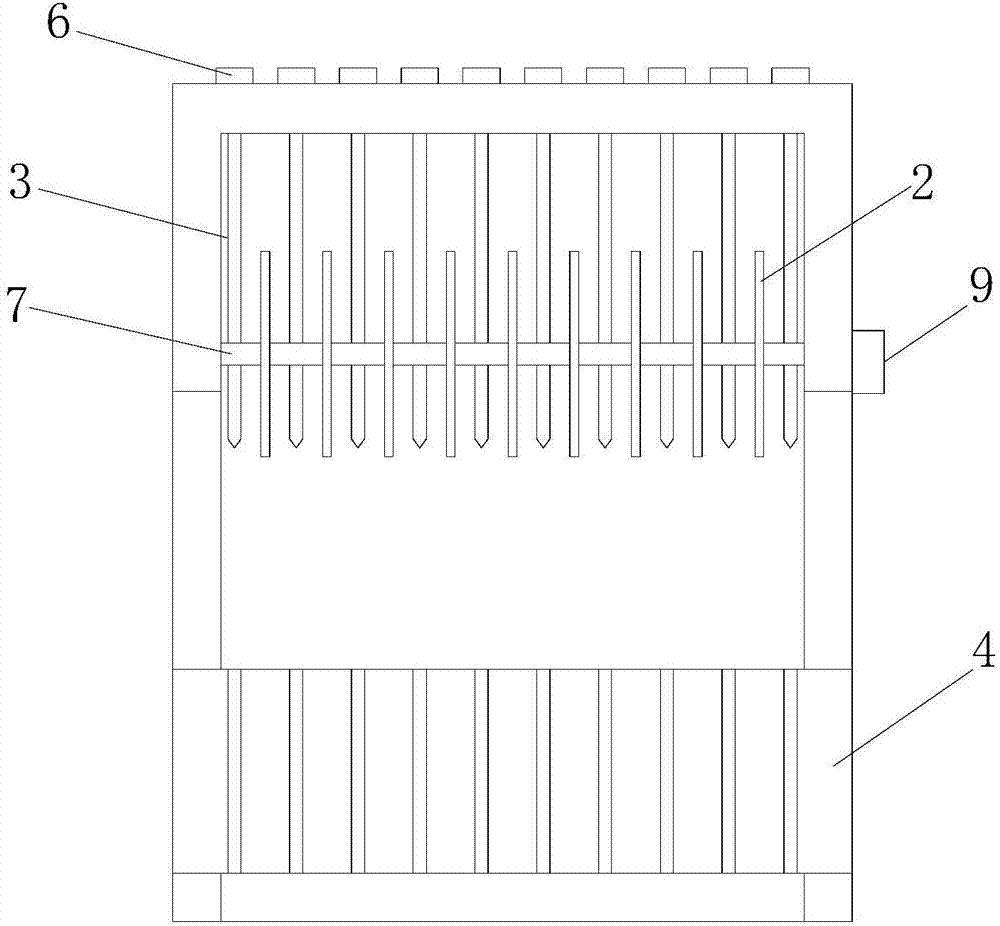

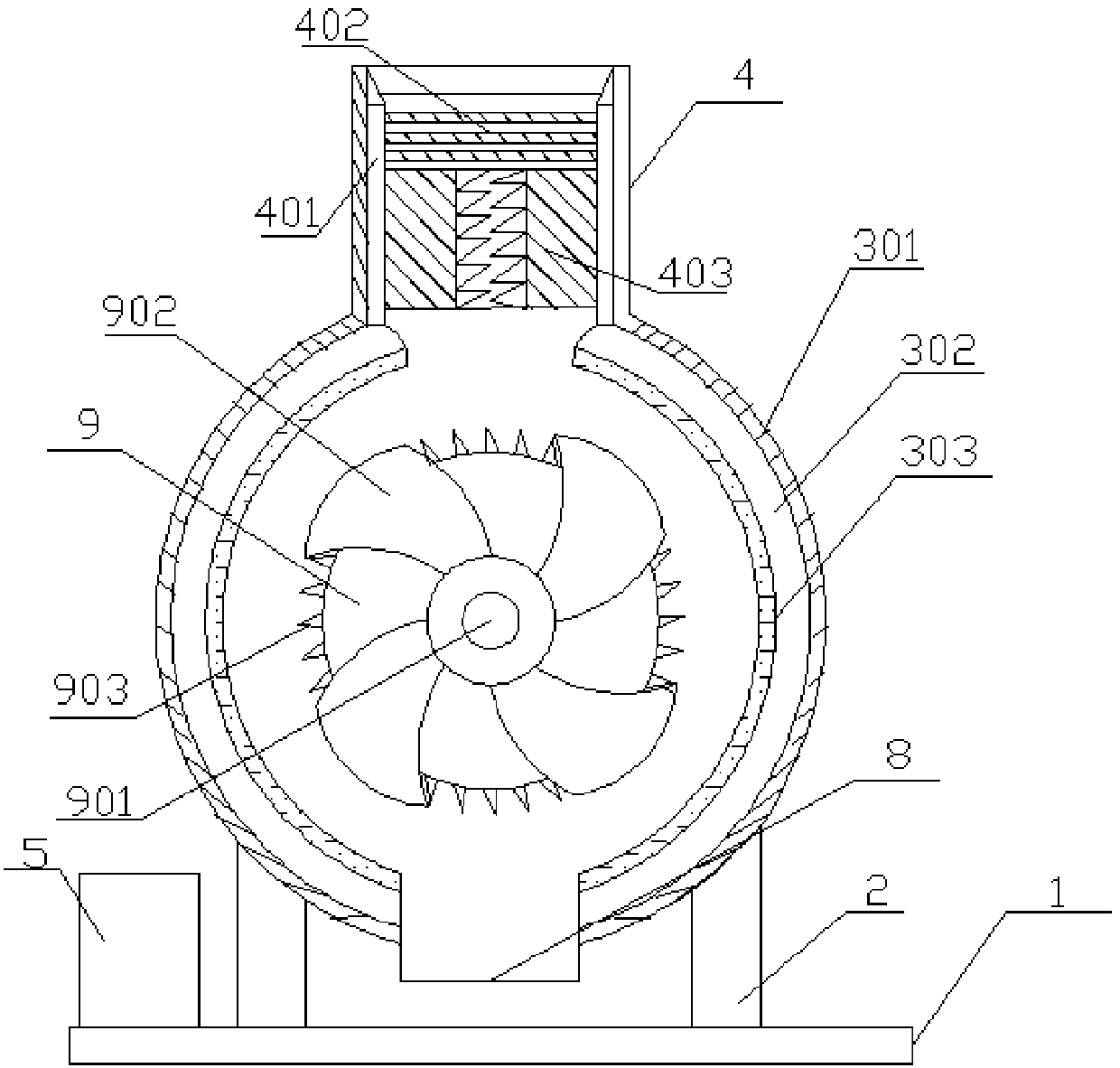

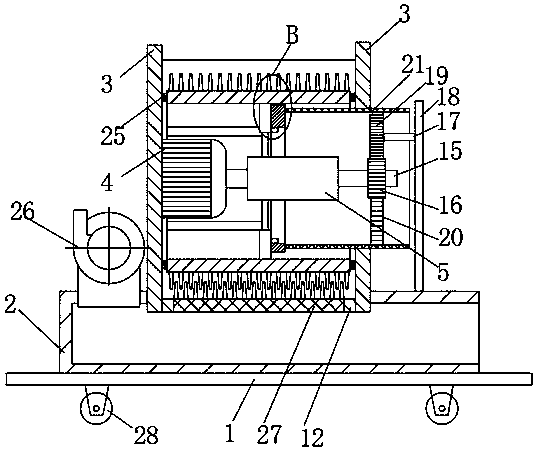

The invention discloses anaerobic fermentation equipment for organic garbage. The equipment comprises a shell, a cutting device, an extrusion device, a solid waste treatment device and a waste liquidtreatment device, the cutting device is installed in the shell, and the extrusion device is installed at the lower end of the shell; the solid waste treatment device is installed at the lower end of the extrusion device, the waste liquid treatment device is installed at the lower end of the solid waste treatment device, the cutting device comprises a motor, and a turntable is fixedly installed atthe front end of the motor. By arranging the cutting device, the phenomenon that the garbage adheres to blades, so that the smashing and cutting effects are influenced is avoided, it is guaranteed that the surfaces of the blades are kept clean, the organic garbage is cut more completely, and smashing is more complete; by arranging the extrusion device, the solid waste treatment device and the waste liquid treatment device, the organic garbage is treated more completely, the environment is protected, and the physical health of people is also ensured.

Owner:南通富海环保设备有限公司

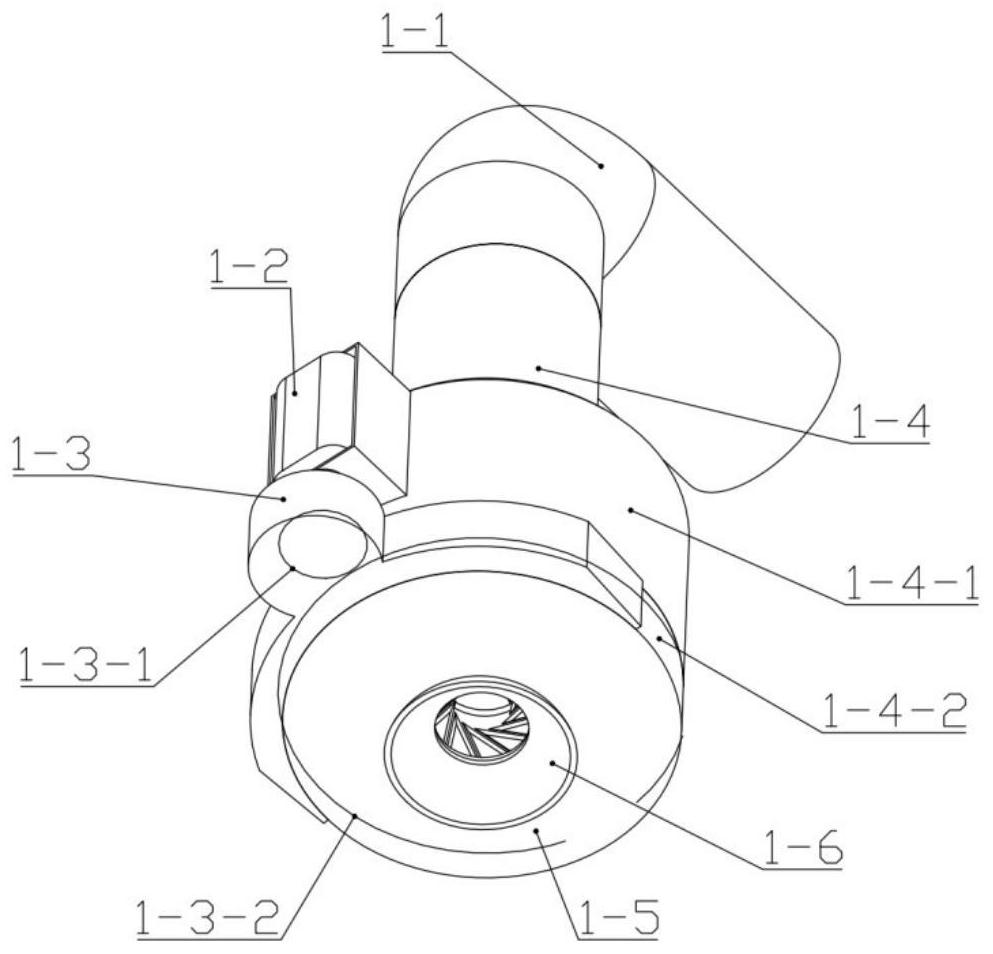

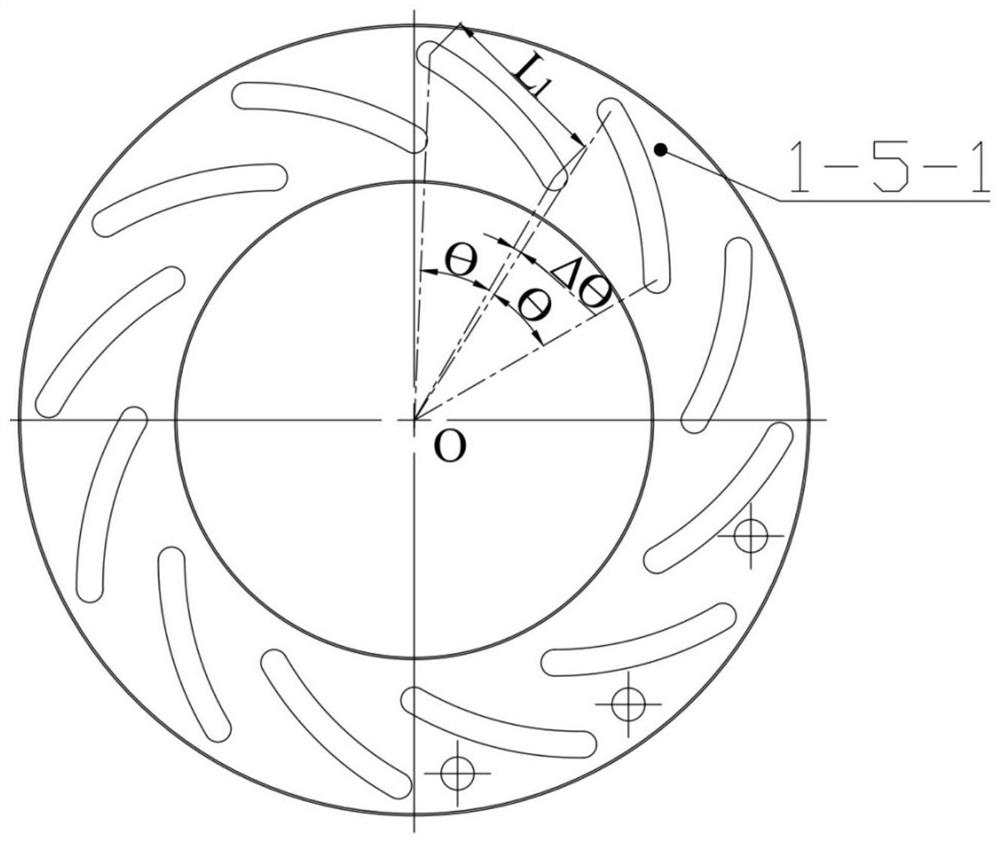

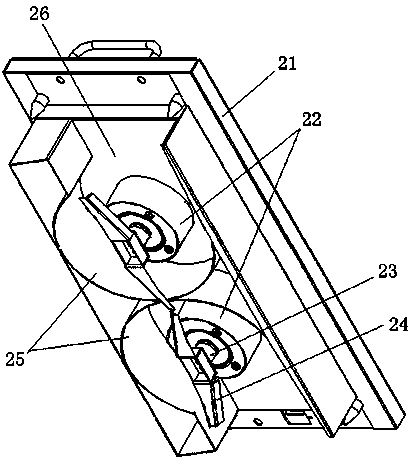

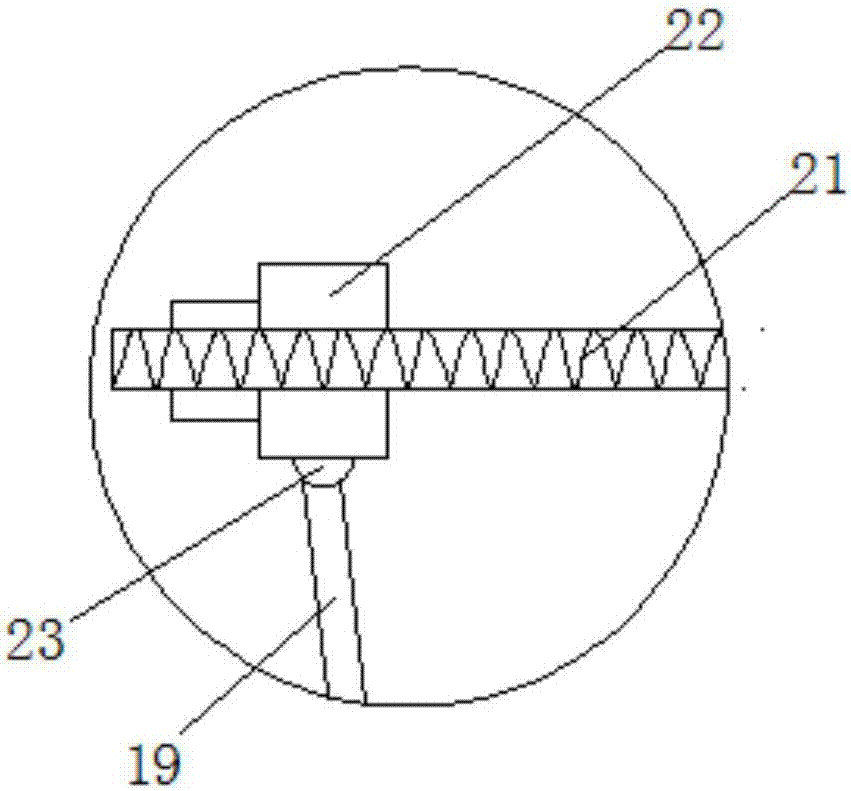

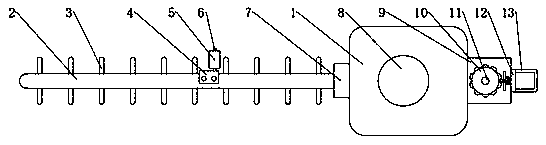

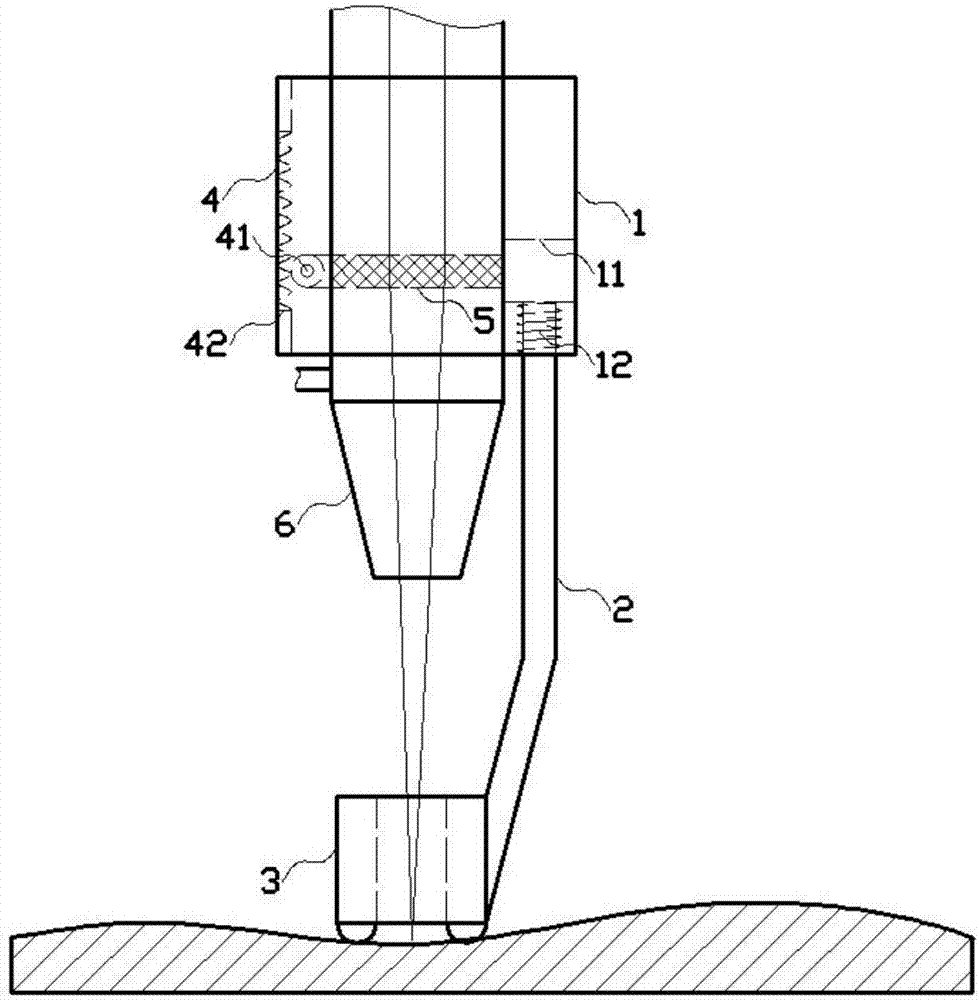

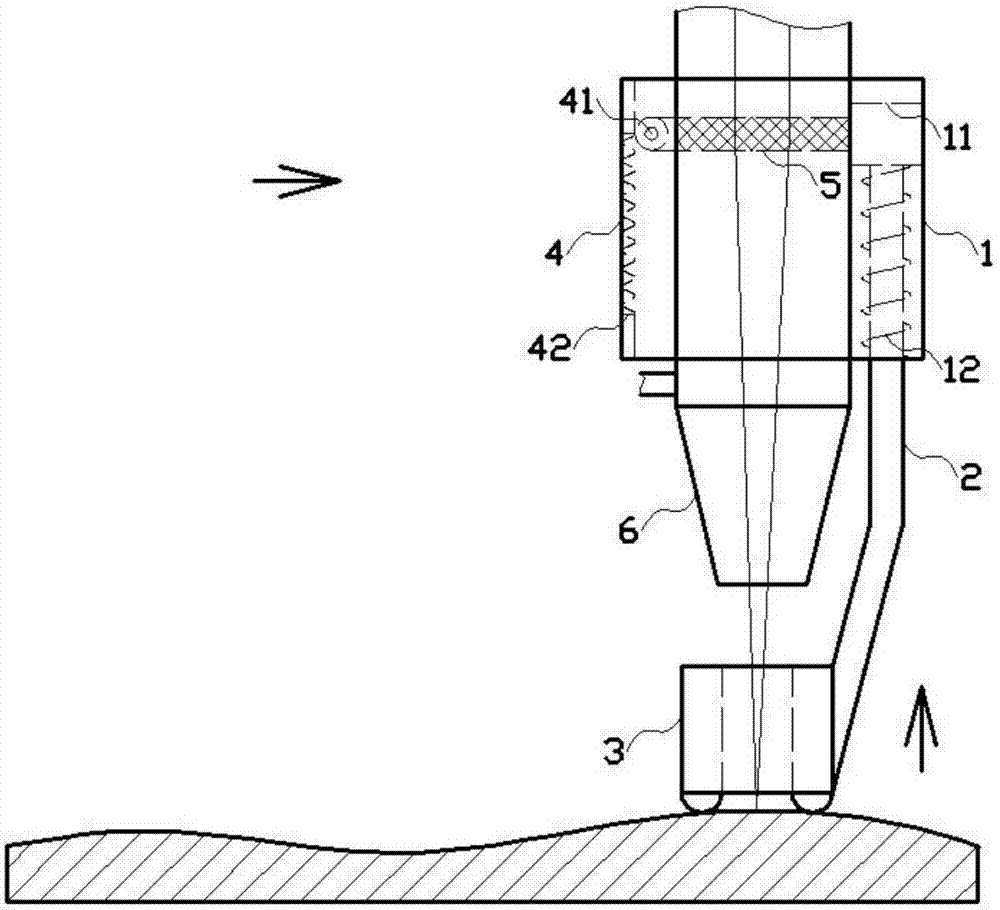

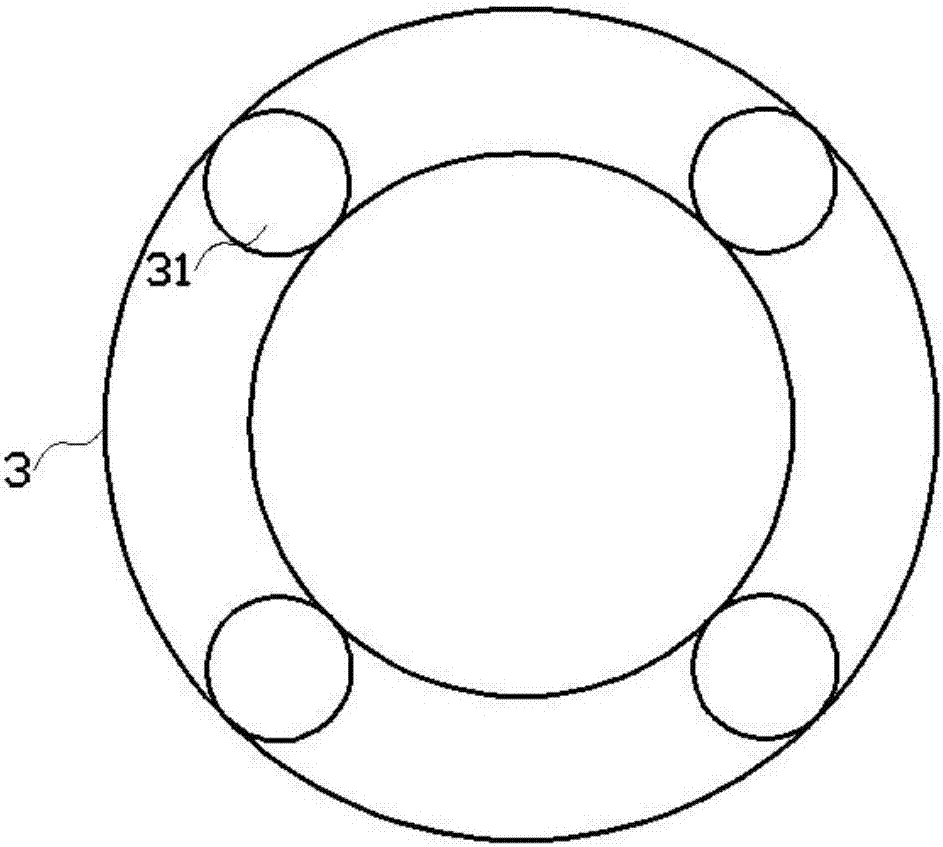

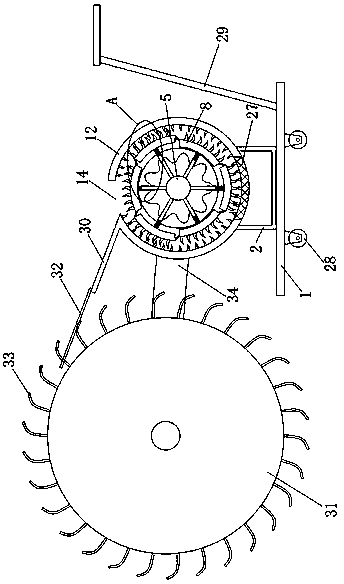

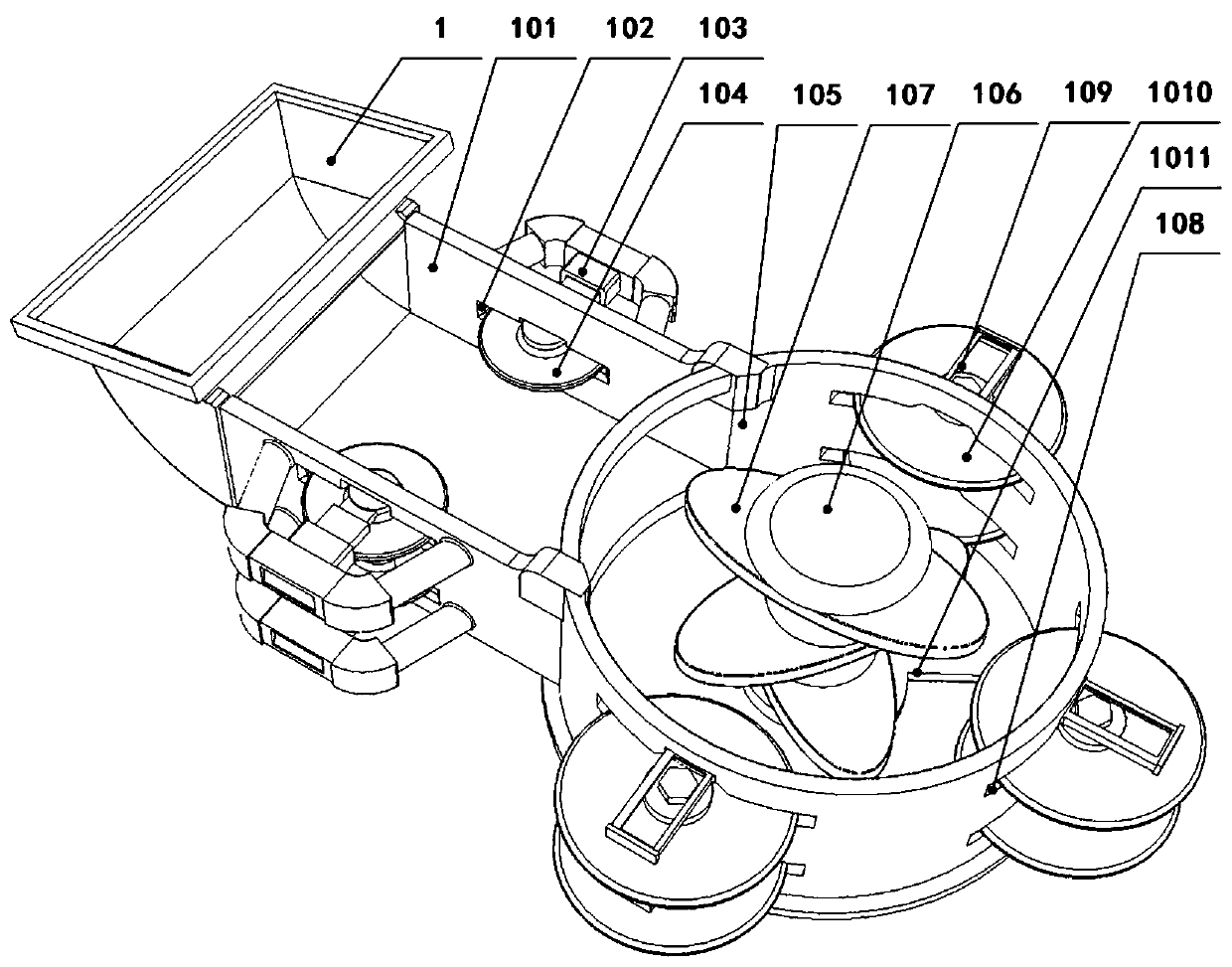

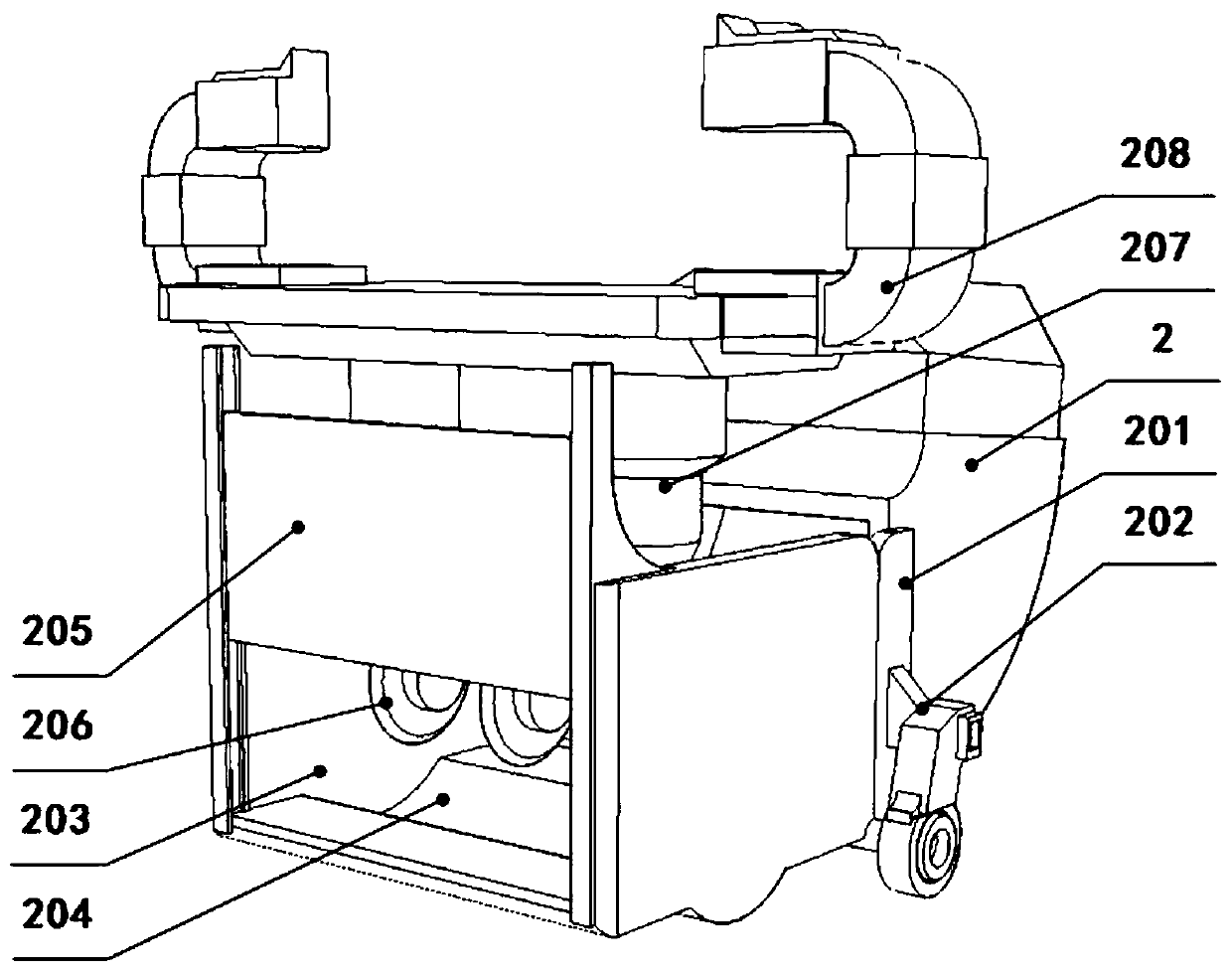

Multi-cutting-edge internal rotation shearing safflower filament harvesting machine and method

InactiveCN111955158AEasy to cutGuaranteed cutting integrityPicking devicesAgricultural engineeringElectric machinery

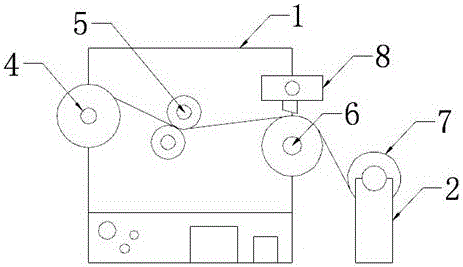

The invention belongs to the field of agricultural machinery, and relates to a multi-cutting-edge internal rotation shearing safflower filament harvesting machine and method. The harvesting machine comprises a picking manipulator, a filament collecting box and an electric control system; the picking manipulator comprises a conveying bent pipe, a driving motor, a transmission device, a manipulatorshell, a cutting device and a laser opposite-emission device; the manipulator shell comprises a manipulator box body and a cutting device shell used for accommodating the transmission device and the cutting device; the cutting device comprises an upper cutter head, a lower cutter head and a cutting blade; the laser opposite-emission device comprises a light source emitter and a light source receiver which are fixedly connected to two sides of a flower inlet of an upper cover plate. According to the harvesting machine and method, discontinuous automatic cutting of filaments is achieved, it is guaranteed that after the filaments completely enter the harvesting machine, the filaments are cut from the roots of the filaments, and the filament breakage rate is reduced.

Owner:XINJIANG AGRI UNIV

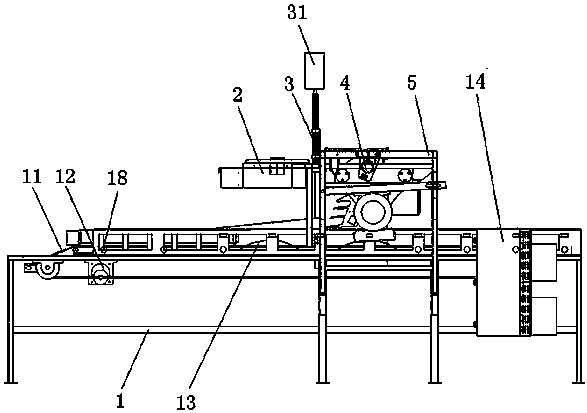

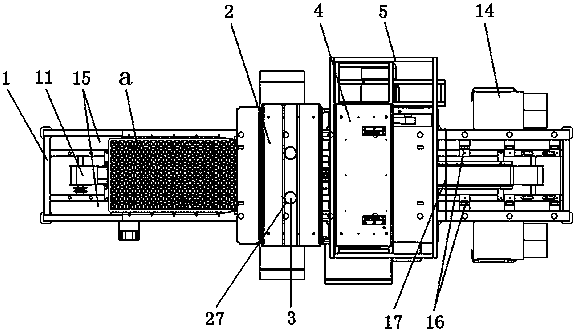

Multifunctional solid leaf trimming machine

The invention provides a multifunctional solid leaf trimming machine. The multifunctional solid leaf trimming machine comprises a frame, a conveying belt and a residual leaf collection tank, wherein the conveying belt is arranged on the frame, and the residual leaf collection tank is arranged at the tail end of the conveying belt. The multifunctional solid leaf trimming machine is characterized in that a cutter rest with a top leaf cutter set and a leaf pinching cutter set thereon is arranged on the frame. By matching of the top leaf cutter set and the leaf pinching cutter set, top leaves and side leaves of tobacco seedlings in seedling growing trays conveyed on the conveying belt can be conveniently cut in sequence. In particular, by multiple leaf combing and pinching mechanisms, tobacco seedlings subjected to top leaf trimming are combed by combing teeth and straightened and subjected to trimming of transversely and diagonally growing side leaves by trimming blades on a moving chain, and root hair of the tobacco seedlings can be trimmed according to needs. Accordingly, the multifunctional solid leaf trimming machine is thorough in trimming, good in trimming quality and high in operation efficiency, full automation of trimming of the tobacco seedlings is realized, labor and material resources are greatly saved, superfluous investment and expenditure of entrepreneurs are saved, and economic benefits are maximized.

Owner:YUNNAN RADIO

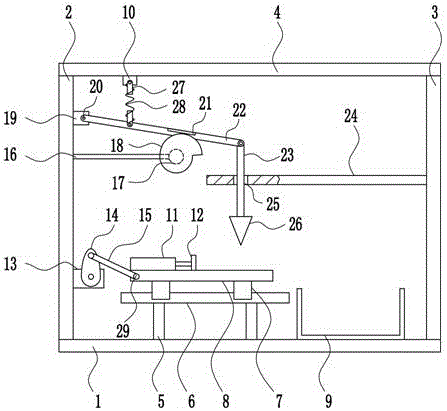

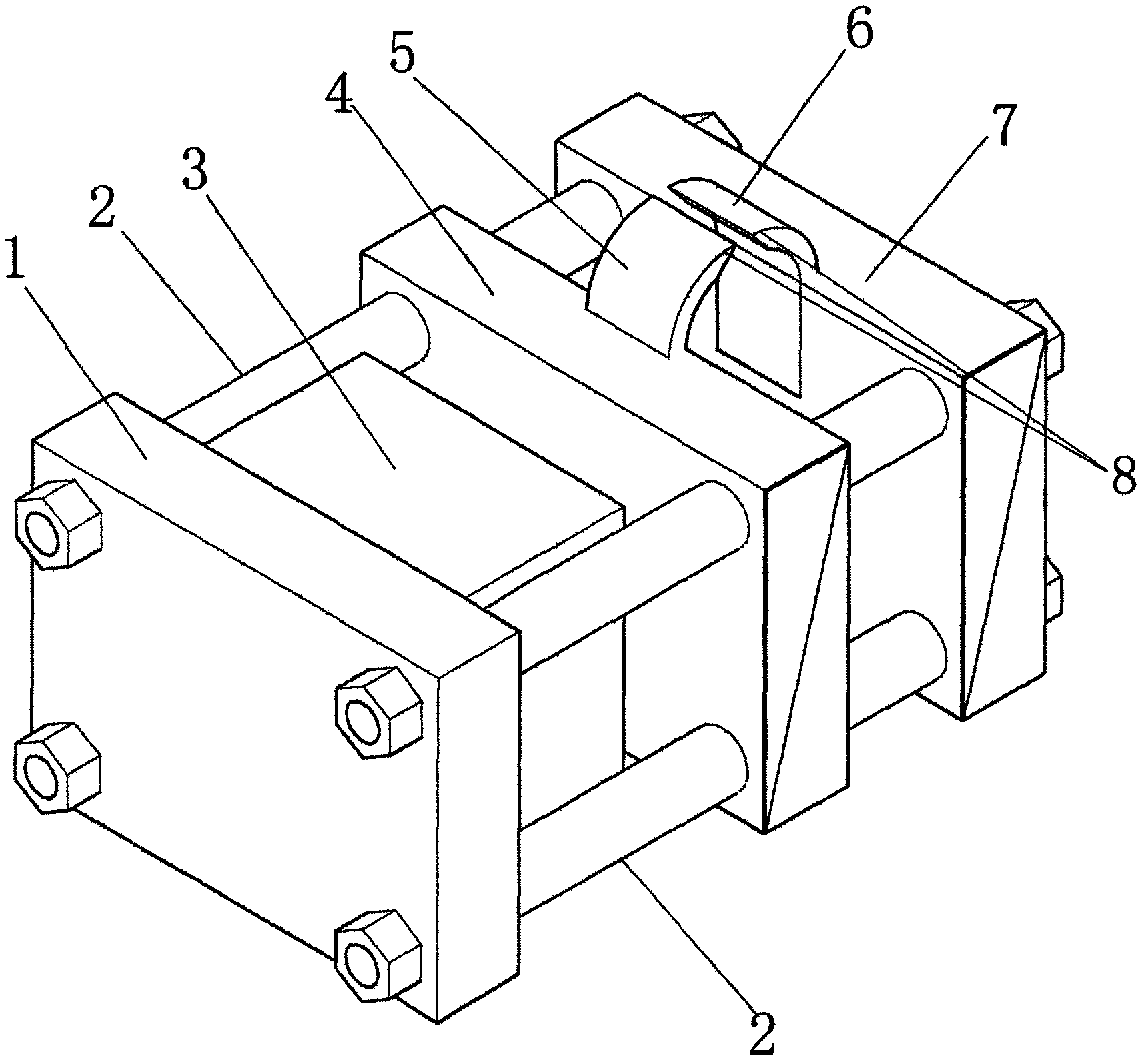

Silicon wafer cutting machine used for silicon solar energy production

InactiveCN106363827AFlexible swingExtended service lifeWorking accessoriesFine working devicesEngineeringSilicon

The invention relates to a silicon wafer cutting machine, in particular to a silicon wafer cutting machine used for silicon solar energy production. The silicon wafer cutting machine used for silicon solar energy production is high in cutting speed and even and thorough in cutting. The silicon wafer cutting machine used for silicon solar energy production comprises a bottom plate, a left frame, a right frame, a top plate, a first support rod, a sliding rail, sliding blocks, a cutting plate, a collecting frame, a first fixing block, an electric pushing rod, a pushing plate, a first motor and others; the left frame is welded to the left end of the top of the bottom plate, a second fixing block is connected to the upper portion of the right side of the left frame through a bolt, and a swinging rod is connected to the front side of the second fixing block through a first hinged component. According to the embodiment, only the preferable implementation mode is expressed, the embodiment has detailed description, but it shall not be understood that the silicon wafer cutting machine is limited to the range which the embodiment is implemented in.

Owner:WUXI YANAO ELECTRONICS TECH

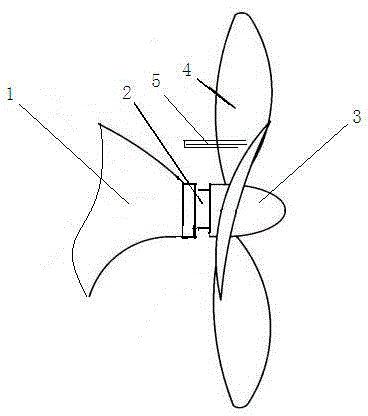

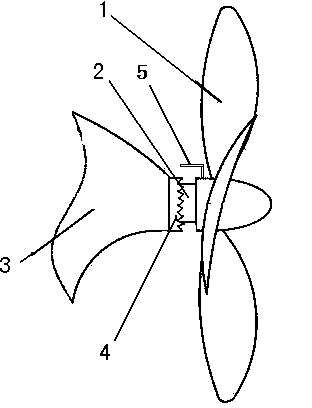

Anti-wind propeller device

The invention relates to the technical field of the power drive device of a ship, in particular to an anti-wind propeller device, which comprises a streamline support, a stern shaft, a paddle drum and propeller blades, wherein the stern shaft is fixed into the streamline support through a bearing; one end of the stern shaft is connected with an internal combustion engine output shaft, and the other end of the stern shaft is connected with the paddle drum. The anti-wind propeller device is characterized in that the back face of at least one propeller blade is provided with a strip anti-wind cutter, and cutting edges of the cutters face to the tangent directions of the propeller blades; the anti-wind cutters are parallel to the axis of the paddle drum, so that the resistance of the anti-wind cutters is the minimum in rotation. The winding articles are cut automatically by means of the rotation of the propeller, the anti-wind propeller device has the advantages of simple structure, convenience in installation, complete cutting and the like, and all kinds of accidents or faults caused by the fact that a propeller shaft is wound are effectively prevented.

Owner:WEIHAI ZHONGFU XIGANG SHIP

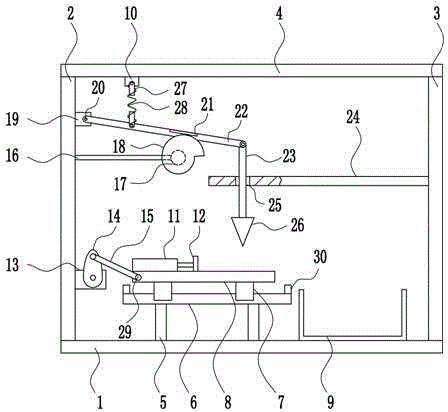

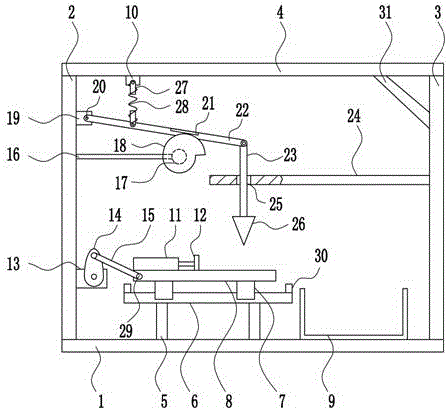

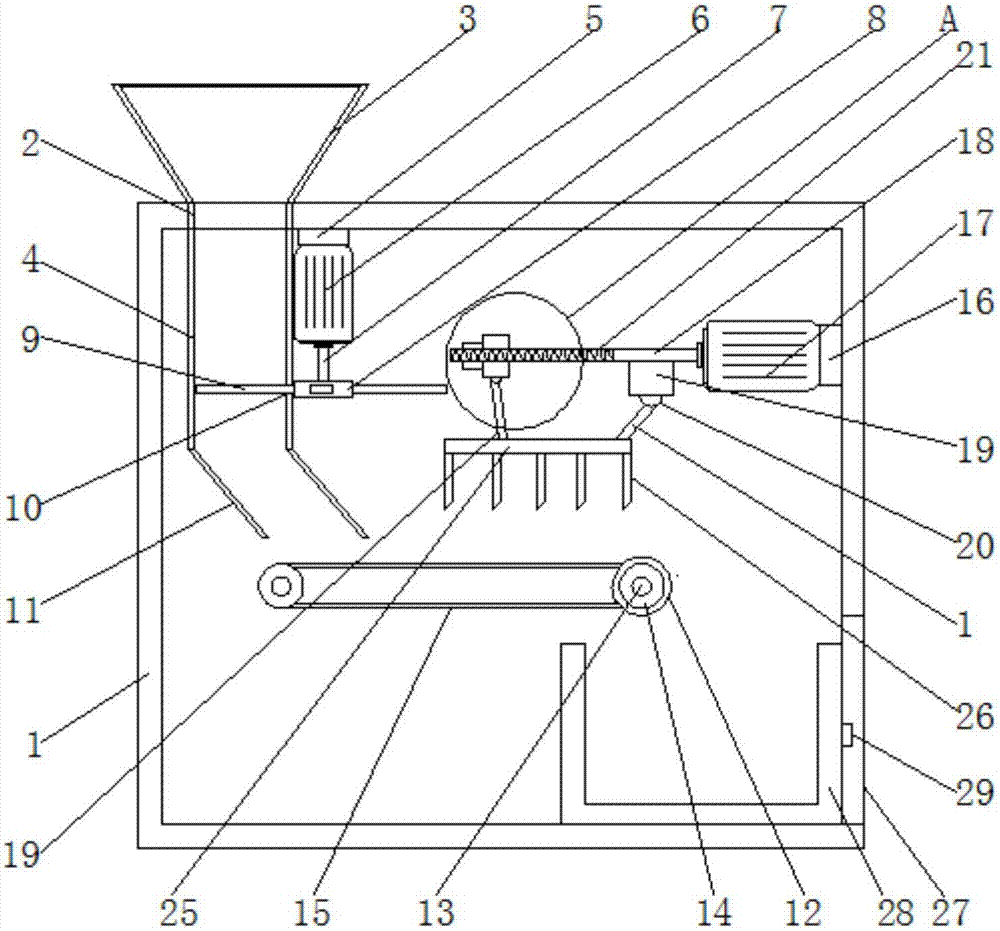

Medicinal material cutting machine capable of performing repeated cutting

ActiveCN107042542AStable and convenient feedingConvenient Cutting CaseMetal working apparatusEngineering

The invention provides a medicinal material cutting machine capable of performing repeated cutting, and relates to the field of cutting machines. The medicinal material cutting machine comprises a housing, wherein a feed opening is formed in the left side of the top of the housing; a feed hopper is fixedly connected to the top, corresponding to the feed opening, of the casing; a feed pipeline is fixedly connected to the top, corresponding to the feed opening, of the inner wall of the casing; a fixed block is fixedly connected to the top, located on the right side of the feed pipeline, of the inner wall of the casing; a first motor is fixedly mounted at one end, away from the top of the inner wall of the casing, of the fixed block; a first rotating shaft is fixedly connected to an output shaft of the first motor; and a connecting block is fixedly connected to one end, away from the first motor, of the first rotating shaft. According to the medicinal material cutting machine capable of performing repeated cutting, a third motor, a second rotating shaft, a ball screw, two hinged seats, connecting rods and cutting knives are matched, so that medicinal materials can be repeatedly cut, and the medicinal materials can be cut to the largest extent, so that medicinal materials can be thoroughly cut, and the medicinal materials can be used to the largest extent.

Owner:高广明

Angle adjusting device for hedge trimmer

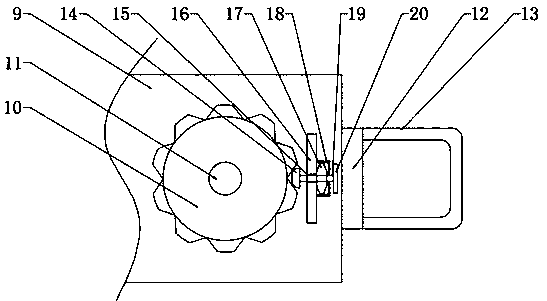

PendingCN109964676ASimple structureEasy to operateCuttersCutting implementsGear wheelIntegrated design

The invention discloses an angle adjusting device for a hedge trimmer. The angle adjusting device comprises a hedge trimmer body, a chain, blades, a fixing block, a handle wheel, a fixing rod, a connecting sleeve, a rotating motor, a connecting block, a rotating gear, a screw rod, a stiffening plate, a handle sleeve, a clamping block, a side hole, a baffle, a nut sleeve, an L-shaped clamping plate, a circular slide way and a T-shaped sliding block, wherein one end of the hedge trimmer body is provided with the connecting sleeve, the connecting sleeve sleeves the chain, one end of the chain isconnected with the hedge trimmer body, the two sides of the chain are provided with the blades respectively, the top of the center of the chain is provided with the fixing block, and one end of the fixing block is fixedly provided with the fixing rod through screws. The angle adjusting device for the hedge trimmer has the advantages that the structure is simple, the operation is convenient, traditional integrated design is abandoned, the angle can be freely adjusted, the angle adjusting device can be suitable for different occasions and can trim grass and trees of different angles, the trimming face is wide, trimming is thorough, manual re-trimming is not needed, and the operation and use of users are convenient.

Owner:REED XINXIANG ROAD INC

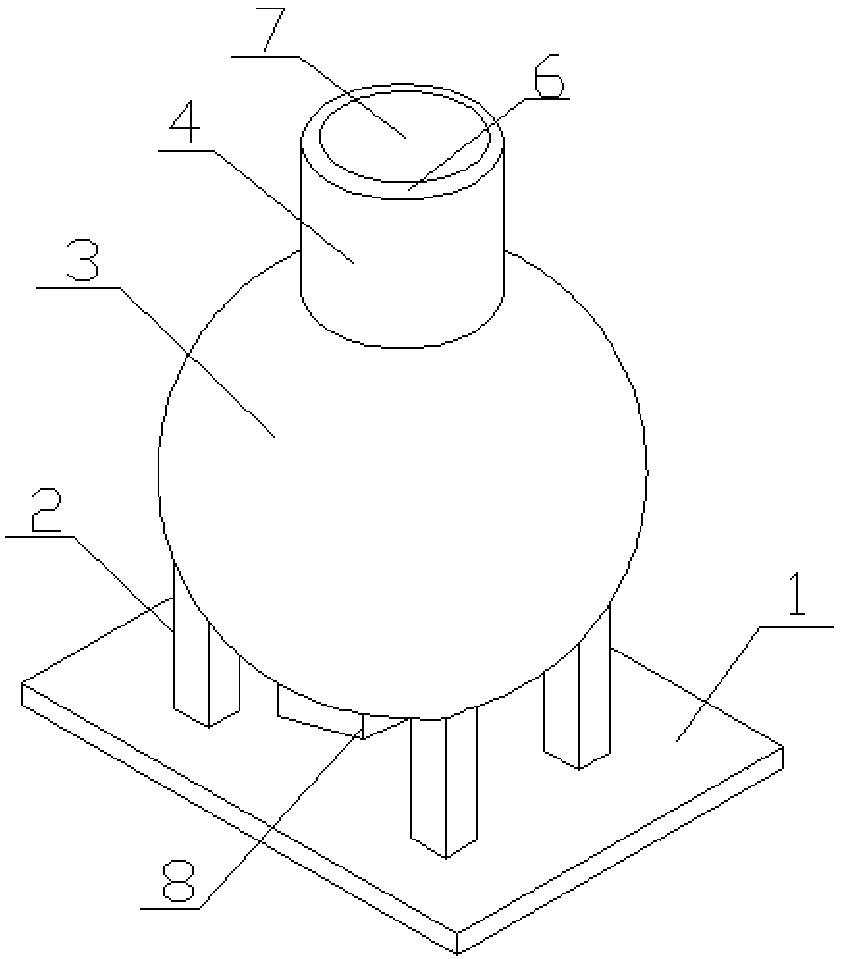

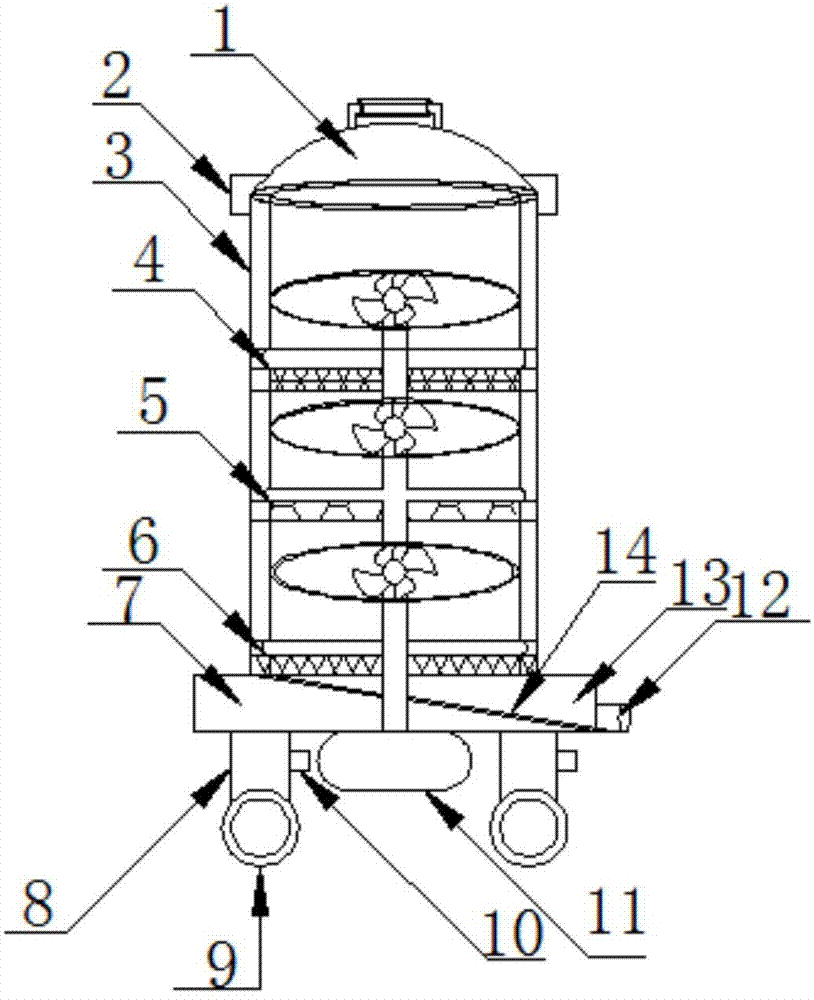

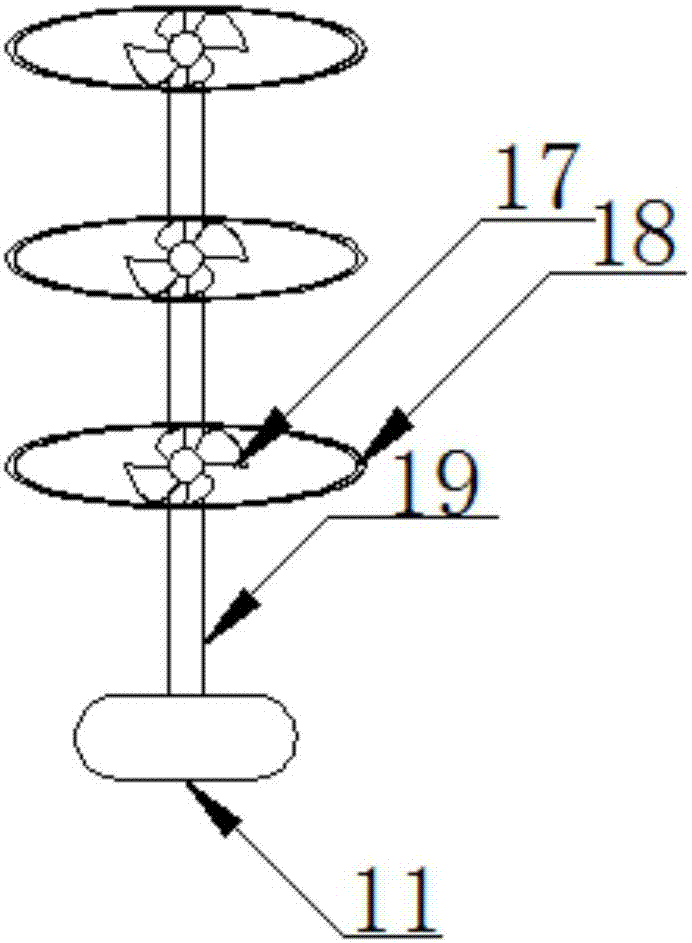

Solid-liquid reaction kettle for chemical engineering production

InactiveCN108393052ACut thoroughlyIncrease contact areaCocoaChemical/physical/physico-chemical stationary reactorsDrive shaftFixed frame

The invention discloses a solid-liquid reaction kettle for chemical engineering production. The reaction kettle comprises a kettle body, a feeding opening, a liquid inlet pipe, a cutter frame, a discharging pipe and support feet, wherein a first motor is fixedly connected onto the right side wall of the feeding opening; the shaft extending end of the first motor is fixedly connected with the cutter frame; the right side of the kettle body is rotationally connected with a transmission shaft through a fixed frame; a sieve plate is arranged under the cutter frame; a vibration shaft is arranged under the sieve plate; a cam is sleeved in the middle of the vibration shaft; the right side wall of the kettle body is fixedly connected with a second motor; a stirring plate is distributed on the stirring shaft; a driving bevel gear is sleeved in the middle part of the stirring shaft; a grinding shaft is arranged under the stirring shaft; a grinding disc is sleeved in the middle part of the grinding shaft; the cutting edge is used for cutting solid reactants; the contact area between solid reactants and liquid reactants is increased; the reaction efficiency is improved; the sieve plate vertically vibrates, so that the cut solid reactants can favorably pass through the sieve plate; the stirring plate is driven to drive the mixed liquid to upwards turn, so that the mixing of the solid reactants and the liquid reactants is more sufficient.

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

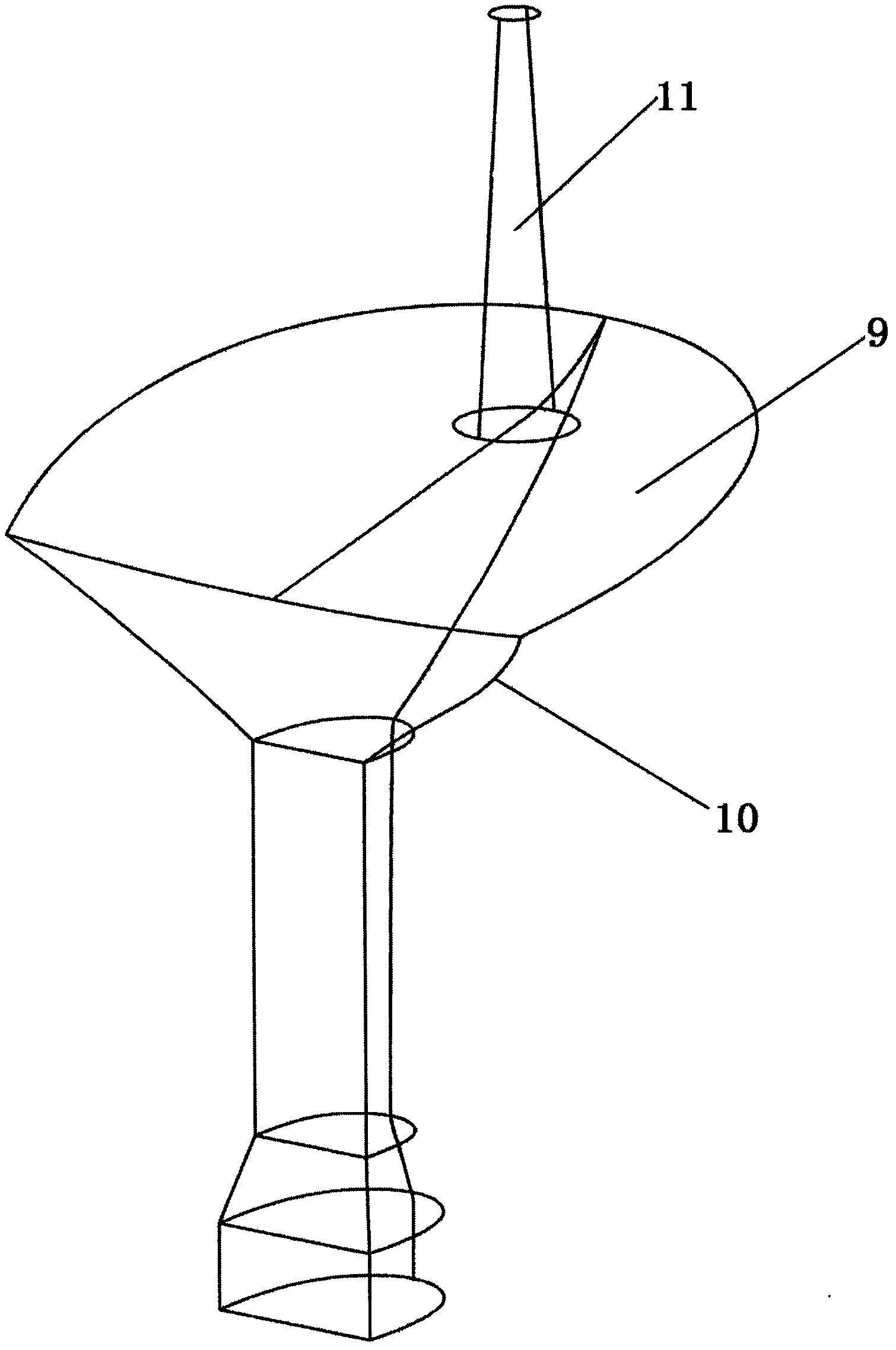

Tangerine peeling device

The invention discloses a tangerine peeling device in the tangerine processing field. The tangerine peeling device comprises a supporting base and multiple peeling knives. The supporting base is in a round table shape, and multiple mounting bases evenly distributed in the circumferential direction are arranged at the lower end of the supporting base. Each peeling knife is in an arc shape, wherein the top end of the peeling knife is hinged to the corresponding mounting base, and the inner arc surface of the peeling knife faces the circle center of the supporting base. Multiple circular arc blades are longitudinally distributed on the inner arc surface of each peeling knife in an embedded mode. A tension spring is connected between the upper ends of every two adjacent peeling knives. A peeling line is connected between the blades on every two adjacent peeling knives. According to the scheme, tangerines are peeled through the peeling knives, manual peeling is not needed, peeling efficiency is higher, labor intensity is lower, and the tangerines are peeled more conveniently.

Owner:CHONGQING PINGWEI CHAOYANG AGRI DEV CO LTD

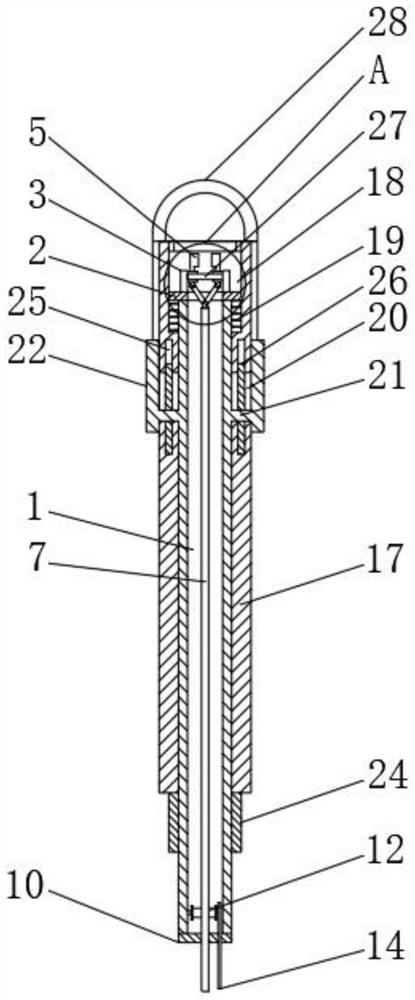

Automatic focusing high-efficiency laser cutting device

ActiveCN107335927AAchieve the role of laser cuttingAchieve the function of automatic adjustment of laser cuttingLaser beam welding apparatusEngineeringLaser cutting

The invention provides an automatic focusing high-efficiency laser cutting device. The automatic focusing high-efficiency laser cutting device comprises a sliding module, a connecting rod, a detection module and an adjusting module. The sliding module comprises a sliding block and a tension spring. The sliding module is provided with a sliding shell. The sliding shell is internally provided with a cavity. A sliding groove is formed in the portion, making contact with a laser cutting head, of the sliding shell. The lower end of the sliding shell is provided with a through hole. The detection module is designed into a circular ring shape. The adjusting module comprises an adjustment lever. An adjustment groove corresponding to the sliding groove is formed in the portion, making contact with the laser cutting head, of the adjusting module. The automatic focusing high-efficiency laser cutting device can automatically change the position of a laser cutting focus according to the thickness of a workpiece and meanwhile adjust the laser cutting strength for more flexible cutting.

Owner:温州市镭诺科技有限公司

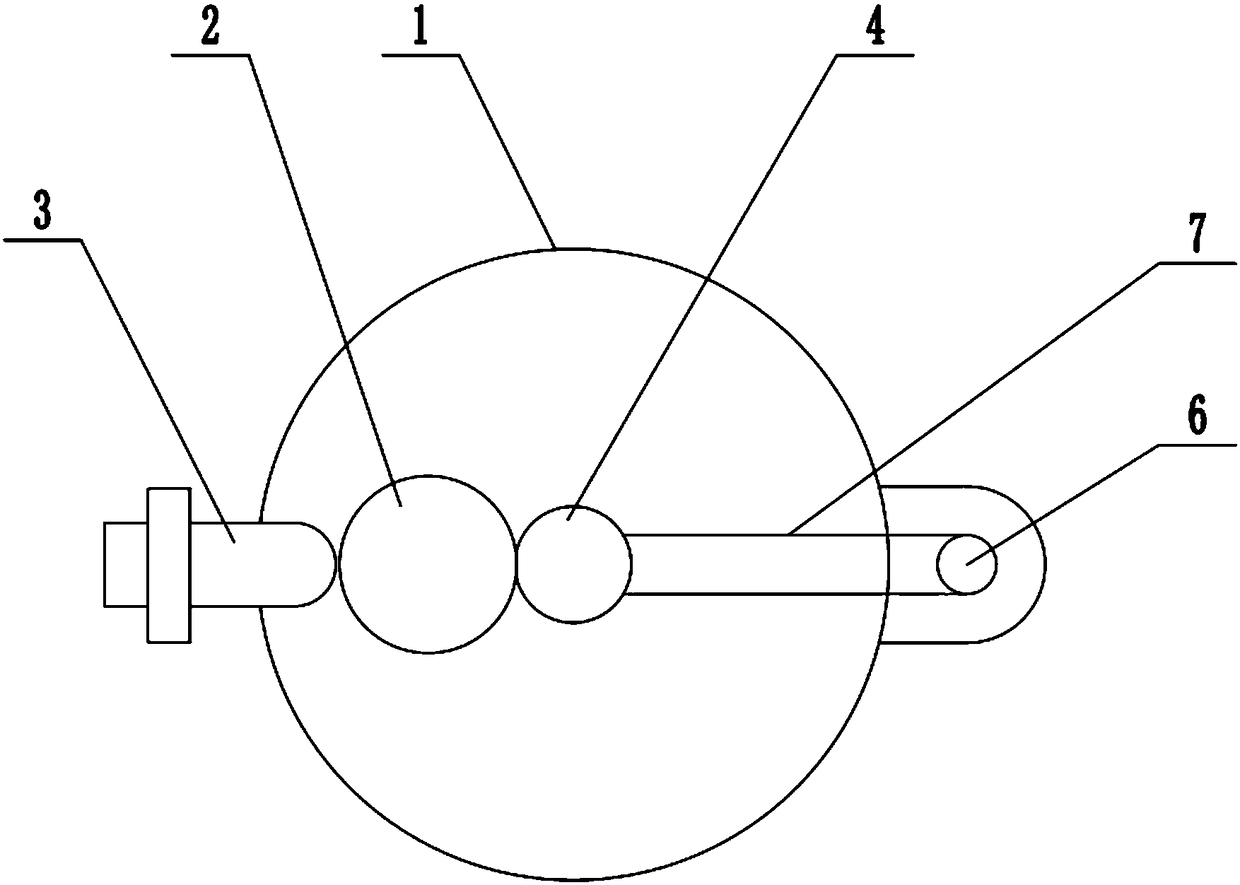

Automatic meat perforation device

InactiveCN107019022AImprove processing efficiencyTransmission friction loss is smallMeat shaping/cuttingDrive shaftElectric machinery

The invention discloses an automatic meat piercing device, which belongs to the field of food processing. It includes a frame, a cutting device, a drilling device and a material transport device. The support includes a bottom plate, a vertical plate and a cutting knife frame, the bottom of the vertical plate is connected with the bottom plate, and the cutting tool frame is connected to the vertical plate. The top of the straight plate is connected; the cutting device includes a cutting motor, a rotating shaft and some circular cutters, and the several circular cutting knives are connected in a row by the rotating shaft to form a cutting blade group, and the cutting blade group is connected with the cutting blade The frame is rotatably connected, and the output shaft of the cutting motor is connected to the rotating shaft; the drilling device includes several drills and drilling motors, the drills are rotatably connected to the vertical plate, and the output of the drilling motor is The shaft is in transmission connection with the drill, the drill is arranged in parallel with the circular cutter at intervals, and the drill is located below the rotating shaft. The invention aims to provide a high-efficiency automatic meat piercing device integrating meat cutting and drilling.

Owner:JINGXI XIUMEI BIANCHENG AGRI SCI & TECH CO LTD

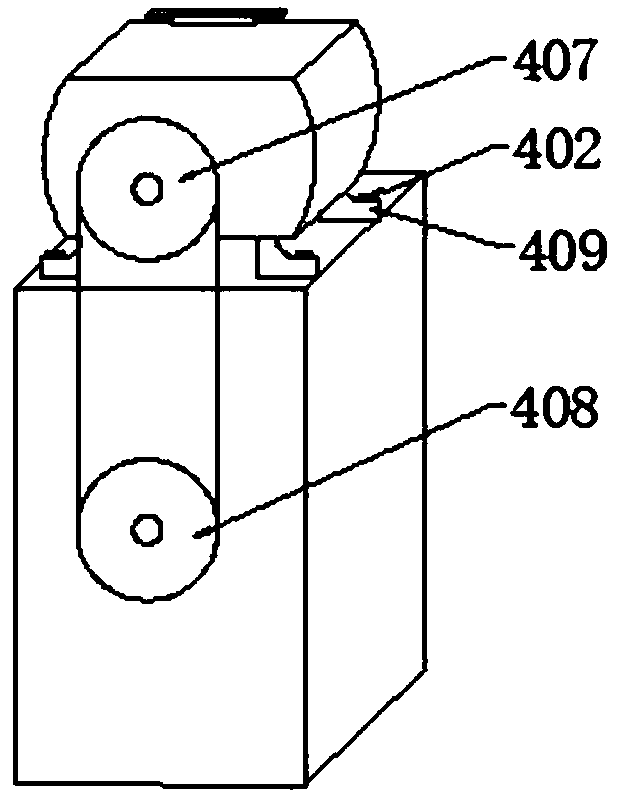

Disassembly and recovery device for waste power lithium batteries

InactiveCN109261701AReduce work intensityEasy to handle workSolid waste disposalWaste accumulators reclaimingElectrical batteryEngineering

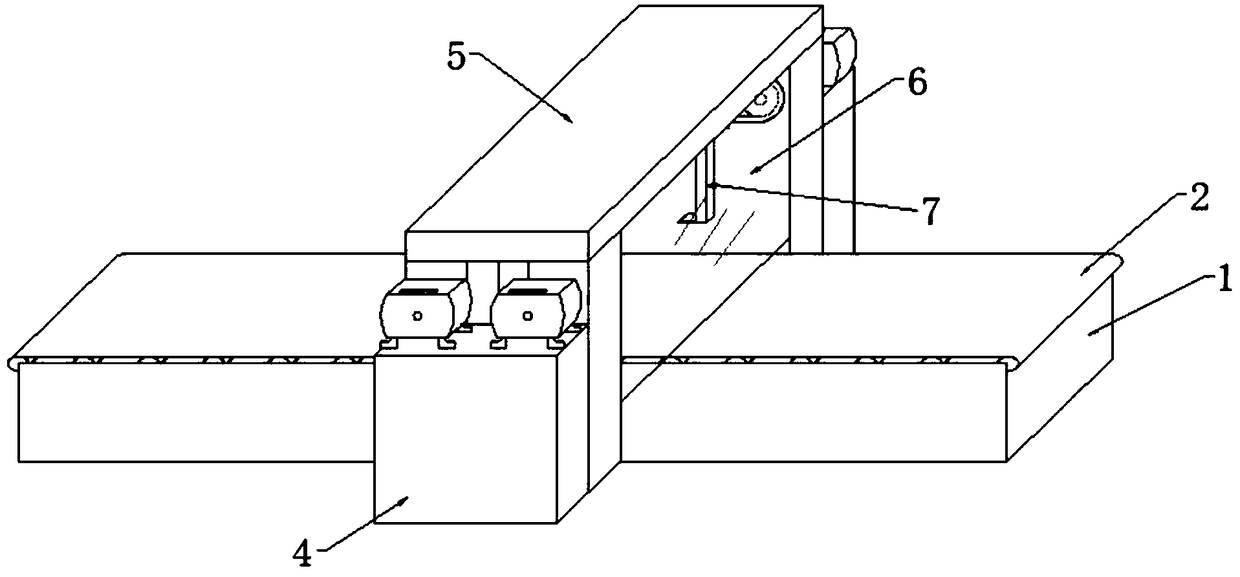

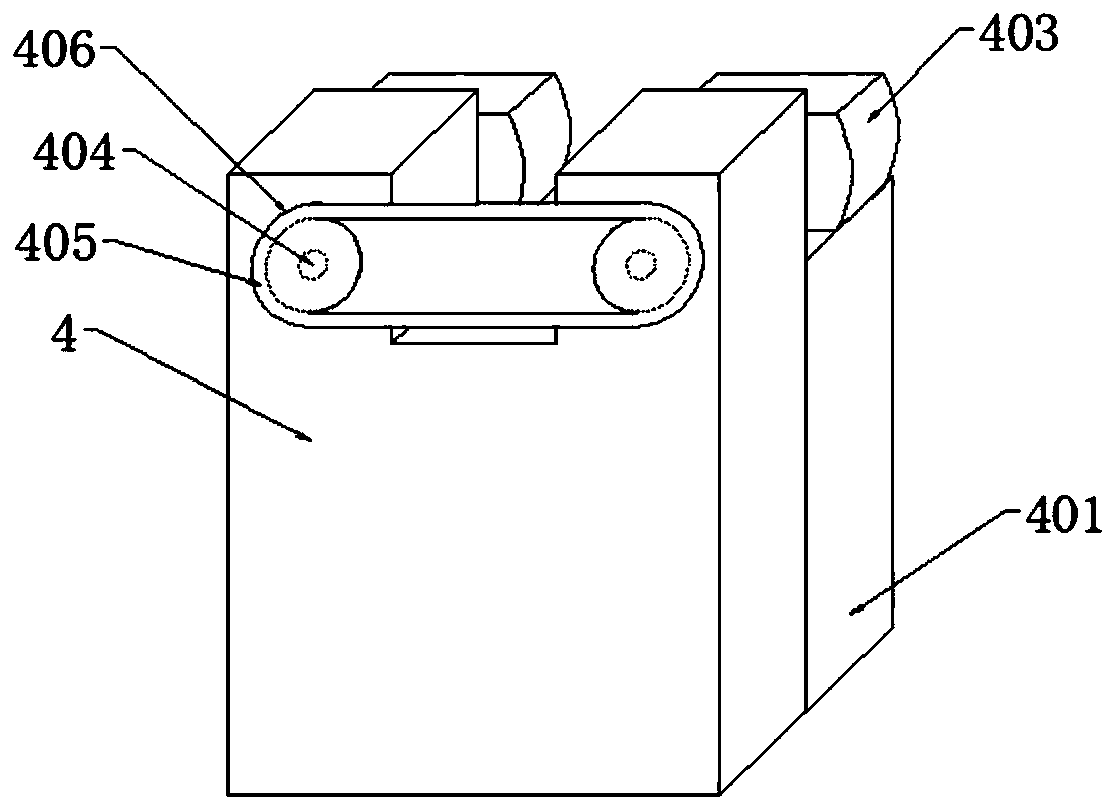

The invention discloses a disassembly and recovery device for waste power lithium batteries. The device includes a conveying base, cutting platforms and stably fixing clamps. The upper side of the conveying base is provided with a conveyor belt, the conveyor belt is internally and uniformly provided with support rods, the left and right sides of the conveying base are provided with the cutting platforms, the rear sides of the cutting platforms are provided with motor stably fixing platforms, the tops of the motor stably fixing platforms are each provided with at least two motors, rotating shafts are arranged in the motors, the rotating shafts run through the cutting platforms and extend out from the front side faces of the cutting platforms, the outer parts of the rotating shafts are sleeved with gears, the outer parts of the gears are sleeved with cutting belts, the tops of the cutting platforms are provided with jacking plates, the lower side faces of the jacking plates are providedwith sliding rails, and the stably fixing clamps are embedded in the sliding rails. The disassembly and recovery device for the waste power lithium batteries can effectively cut the heads and tails ofthe waste batteries, the working intensity of a subsequent refining process is reduced, the working efficiency is improved, and the device facilitate waste battery treatment work for people.

Owner:ZHEJIANG XINSHIDAI ZHONGNENG RECYCLING TECH CO LTD

A multi-cut medicinal material cutting machine

ActiveCN107042542BStable and convenient feedingConvenient Cutting CaseMetal working apparatusEngineering

The invention provides a medicinal material cutting machine capable of performing repeated cutting, and relates to the field of cutting machines. The medicinal material cutting machine comprises a housing, wherein a feed opening is formed in the left side of the top of the housing; a feed hopper is fixedly connected to the top, corresponding to the feed opening, of the casing; a feed pipeline is fixedly connected to the top, corresponding to the feed opening, of the inner wall of the casing; a fixed block is fixedly connected to the top, located on the right side of the feed pipeline, of the inner wall of the casing; a first motor is fixedly mounted at one end, away from the top of the inner wall of the casing, of the fixed block; a first rotating shaft is fixedly connected to an output shaft of the first motor; and a connecting block is fixedly connected to one end, away from the first motor, of the first rotating shaft. According to the medicinal material cutting machine capable of performing repeated cutting, a third motor, a second rotating shaft, a ball screw, two hinged seats, connecting rods and cutting knives are matched, so that medicinal materials can be repeatedly cut, and the medicinal materials can be cut to the largest extent, so that medicinal materials can be thoroughly cut, and the medicinal materials can be used to the largest extent.

Owner:高广明

Novel plastic processing crusher

PendingCN107813443AExtended service lifeCut evenlyPlastic recyclingMechanical material recoveryEngineeringCrusher

The invention provides a novel plastic processing crusher. The novel plastic processing crusher comprises a pedestal; the pedestal is provided with a motor control box and a frame; the frame is connected with a first shell; the bottom of the first shell is connected with a second shell; the first shell and the second shell communicates with each other and are positioned at the same axis; a crushing device is arranged inside the first shell; the crushing device comprises a rotating shaft, a third blade unit and a fourth blade unit; the third blade unit and the fourth blade unit are separately rotationally connected with the rotating shaft; the inner wall of the second shell is symmetrically provided with a group of fixing seats; the fixing seats are correspondingly connected with a first blade unit and a second blade unit through vibrators; the top of the second shell is provided with a feeding hole and a feeding pipe fixing groove; and the bottom of the second shell is provided with adischarging hole. By adopting four blade units for cutting and crushing plastics, the novel plastic processing crusher provided by the invention realizes a better crushing effect, also prolongs the service life of each blade, effectively prevents vibration and noises by adopting a hollow shell structure, and plays an environmental protection effect.

Owner:TIANJIN JINYI NON FERROUS WIRE

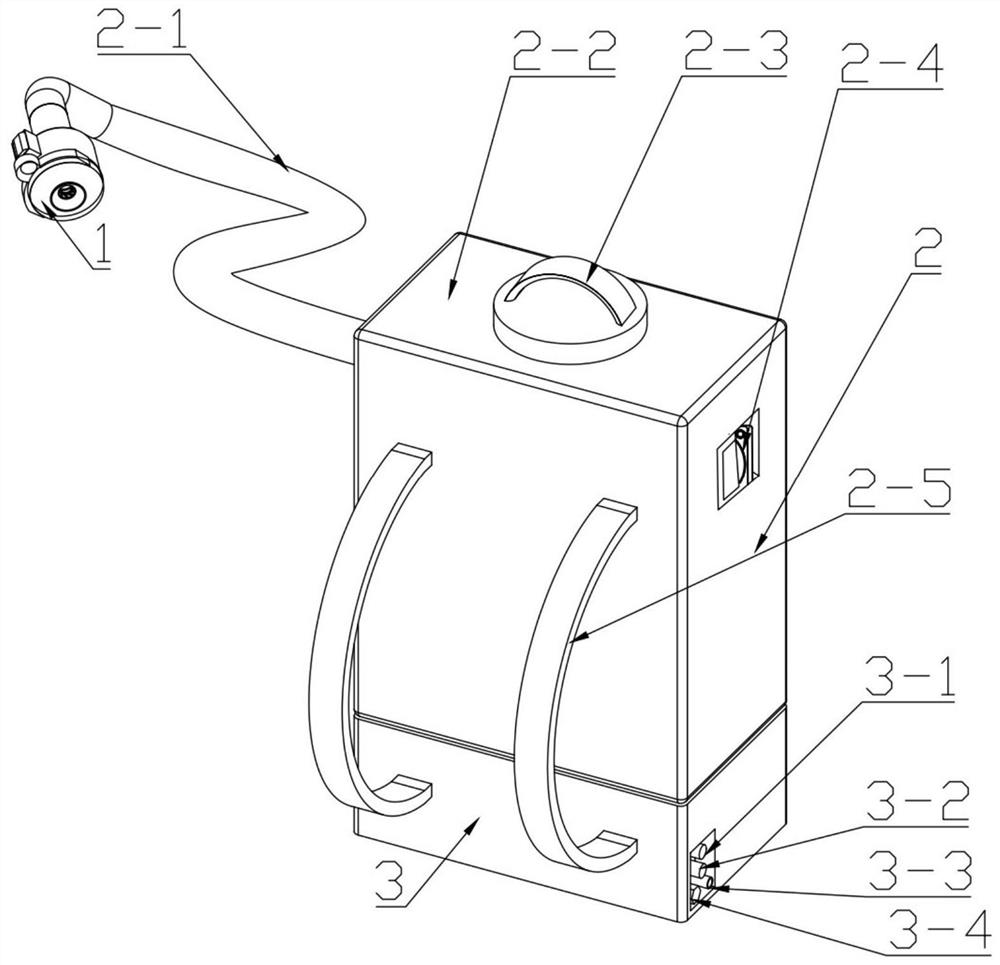

Dust and hair cleaning device

ActiveCN112674693AClean up in timeAvoid bringing inFootwear cleanersBrush deviceMechanical engineering

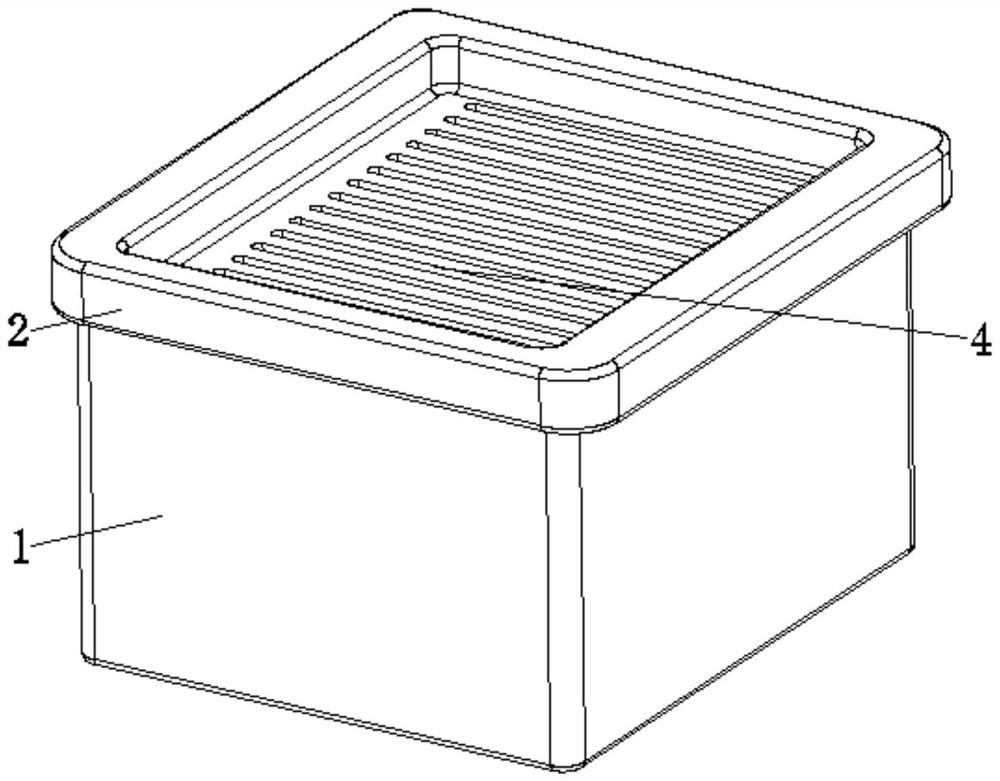

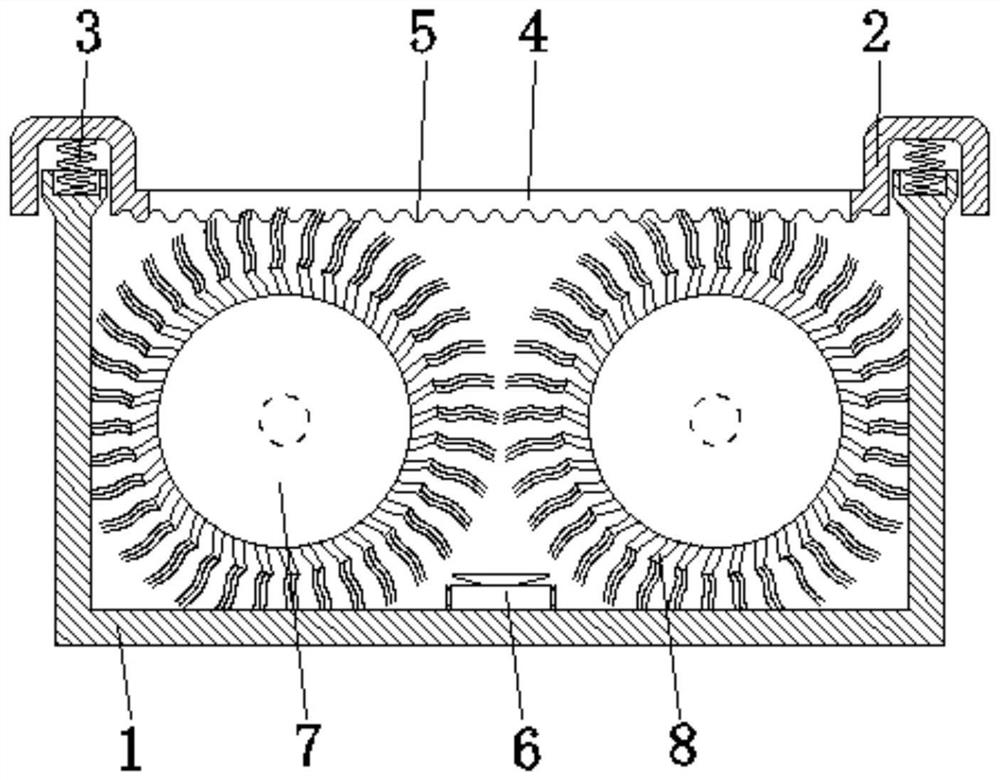

The invention discloses a dust and hair cleaning device. The device comprises a box body, a top cover, a supporting spring, a linear hole and raised grains, the top cover is connected with the top of the box body in a matched mode, the supporting spring is fixed between the two corresponding sides of the top of the box body and the top of the inner wall of the top cover, the linear hole is formed in the center of the surface of the top cover, the raised grains are formed in the bottom of the top cover and located at the position of the linear hole, a dust collector is fixed to the center of the bottom of the inner wall of the box body, a roller device is rotationally connected between the two corresponding sides of the inner wall of the box body and located on the two sides of the dust collector, and a dust brushing device is fixed to the surface of the roller device and corresponds to the linear hole in position. According to the dust and hair cleaning device, the purpose of cleaning dust and hair is achieved, dust, hair, cotton threads and other flexible threads can be treated in time, dust treatment is rapid and thorough, meanwhile, hair winding is reduced, and the use performance is improved.

Owner:衡阳瑞源源实业发展有限公司

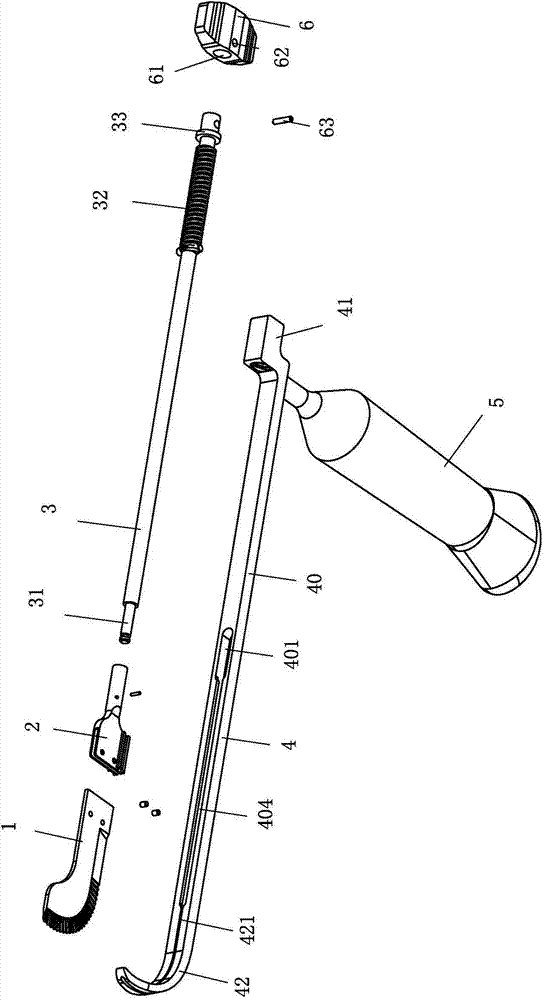

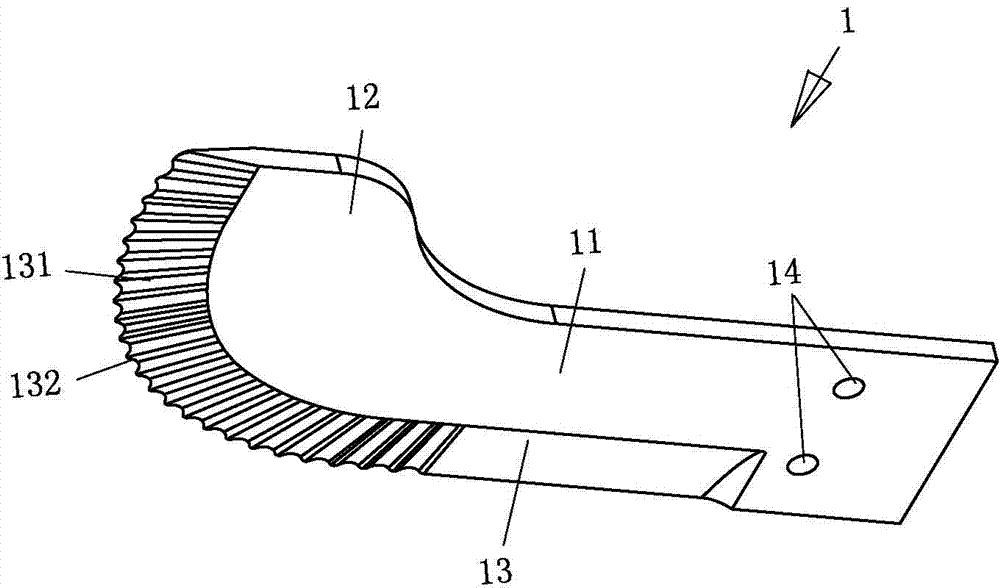

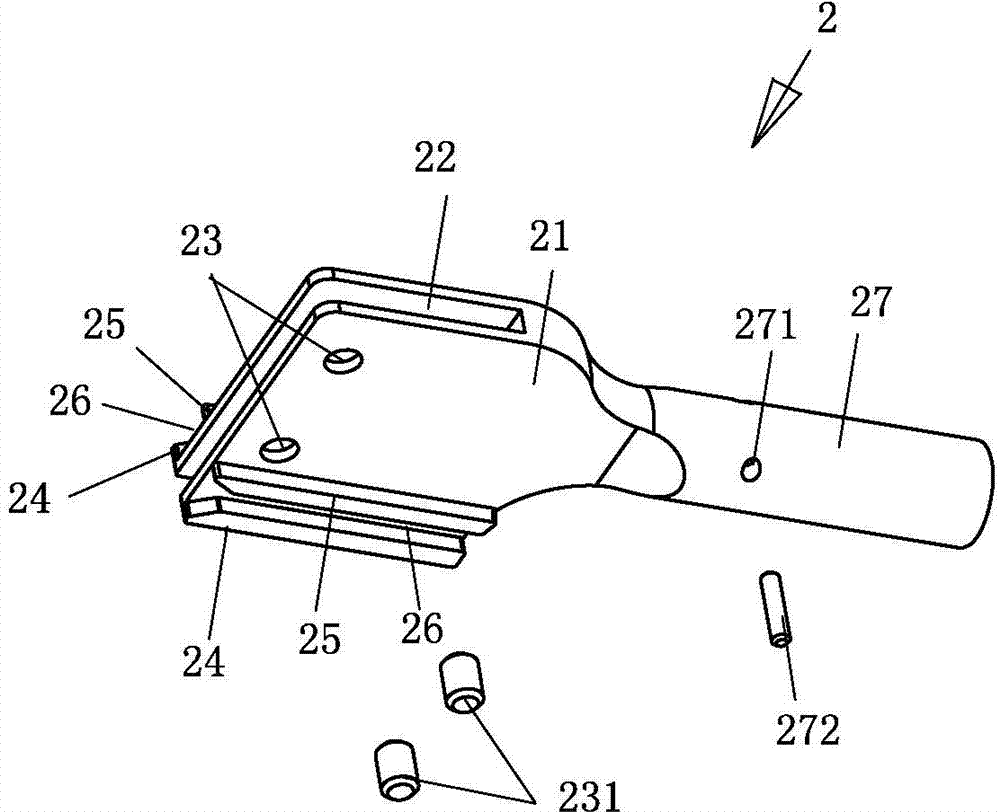

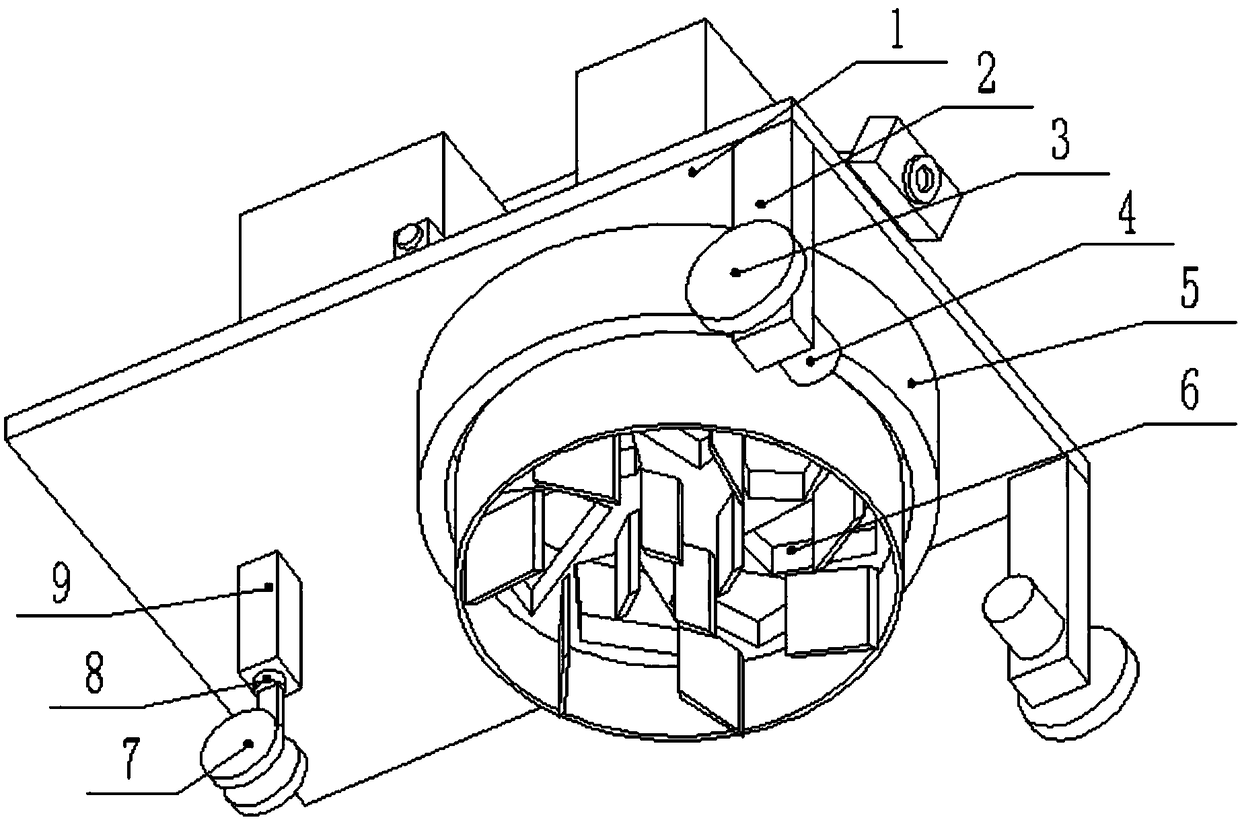

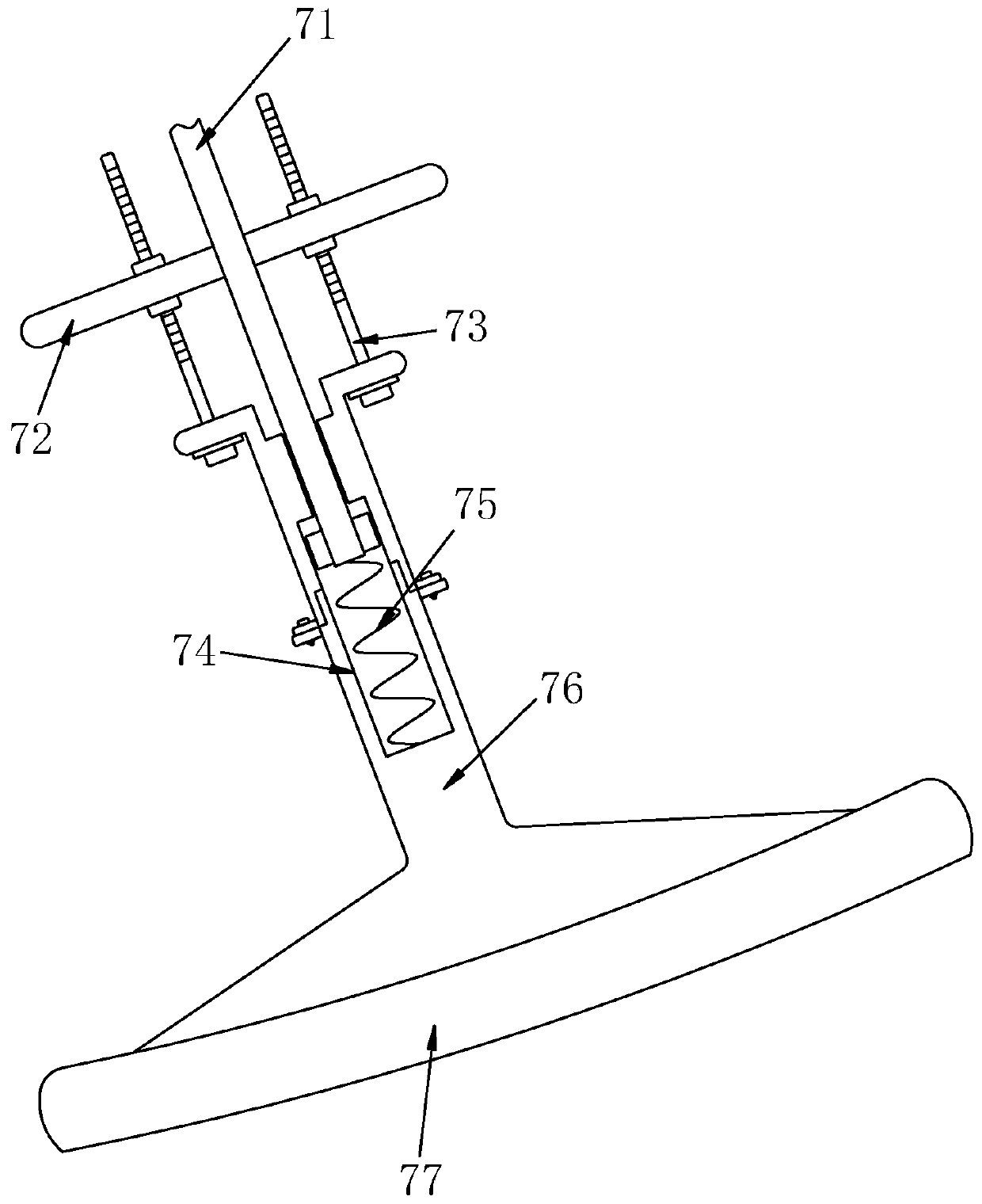

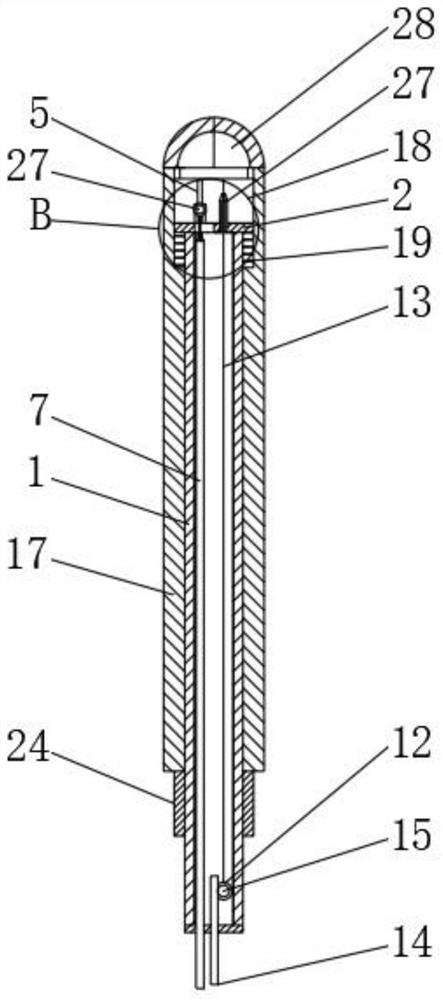

Total spondylectomy intercalated disc cutter

InactiveCN104323831AAvoid surgical risksShorten operation timeIncision instrumentsSurgical riskIntervertebral disc

The invention discloses a total spondylectomy intercalated disc cutter, and relates to a surgical instrument for use in posterior spinal total spondylectomy. The total spondylectomy intercalated disc cutter is characterized in that a holding handle is arranged on the lower part behind a strip-shaped bracket; a blocking hook which is bent upwards is arranged at the front end of the bracket; a knife is arranged on the bracket; a tool bit at the front end of the knife can move forward and backward on the bracket, and the cutting edge of the tool bit corresponds to the blocking hook; when the blocking hook is pressed against one side of an intervertebral disc from the front side, the tool bit of the knife can be used for finishing cutting of the same side of the intervertebral disc forwards; when the blocking hook is pressed against the other opposite side of the intervertebral disc from the front side, the tool bit of the knife can be used for finishing cutting of the other opposite side on the same cutting plane of the intervertebral disc forwards, thereby finishing cutting of the whole intervertebral disc. By adopting the total spondylectomy intercalated disc cutter, possible surgical risk caused by the conventional instrument can be avoided, and the surgery time is shortened.

Owner:175TH HOSPITAL OF PEOPLES LIBERATION ARMY

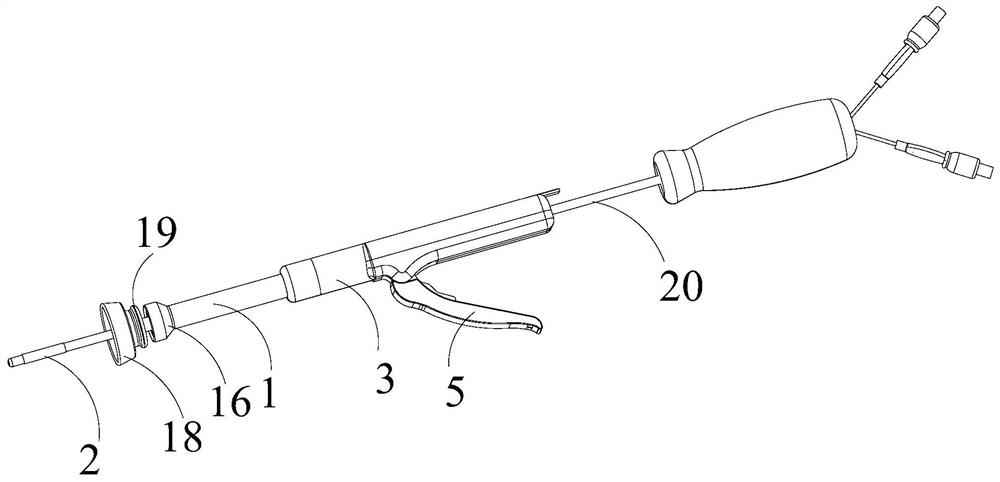

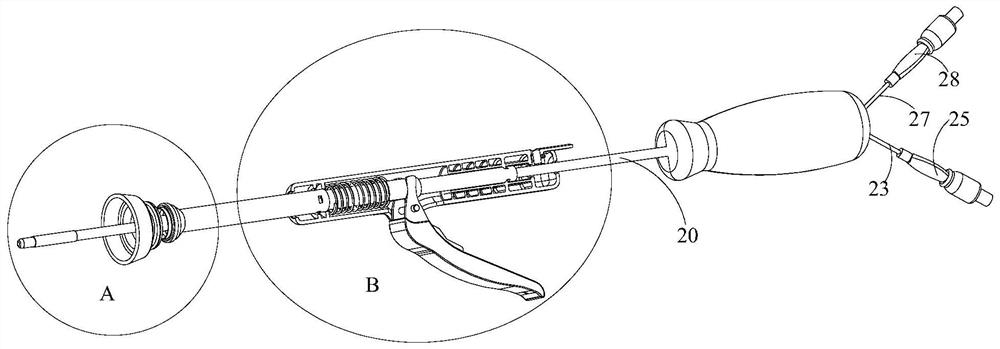

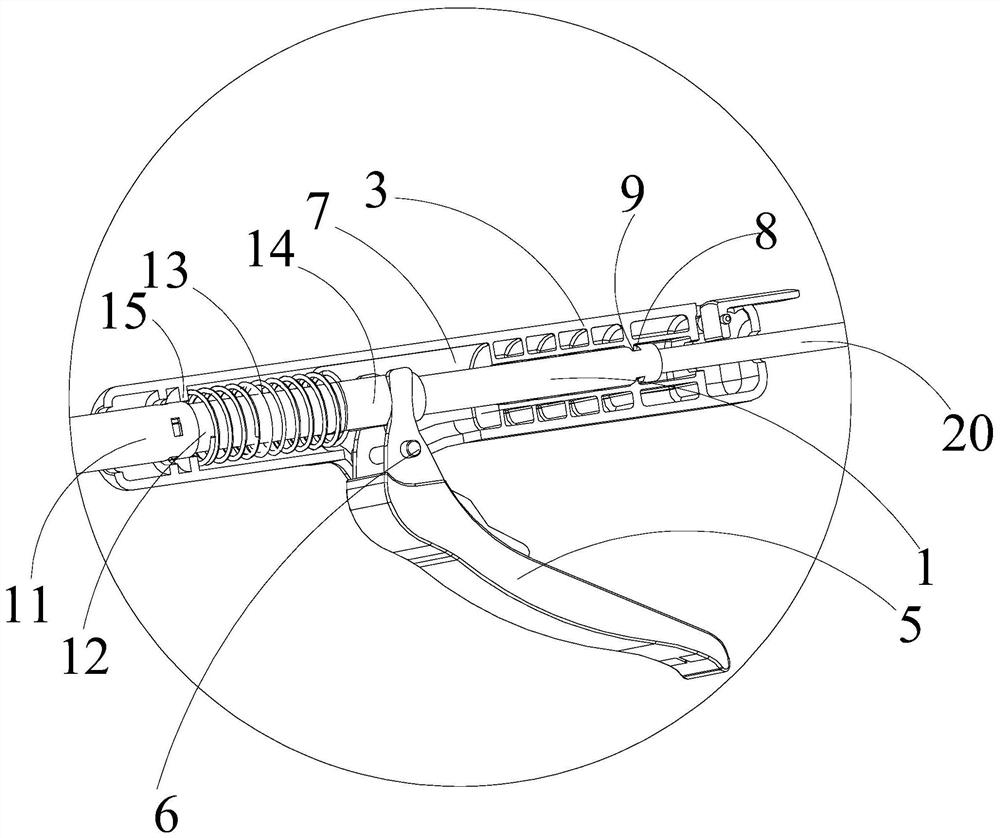

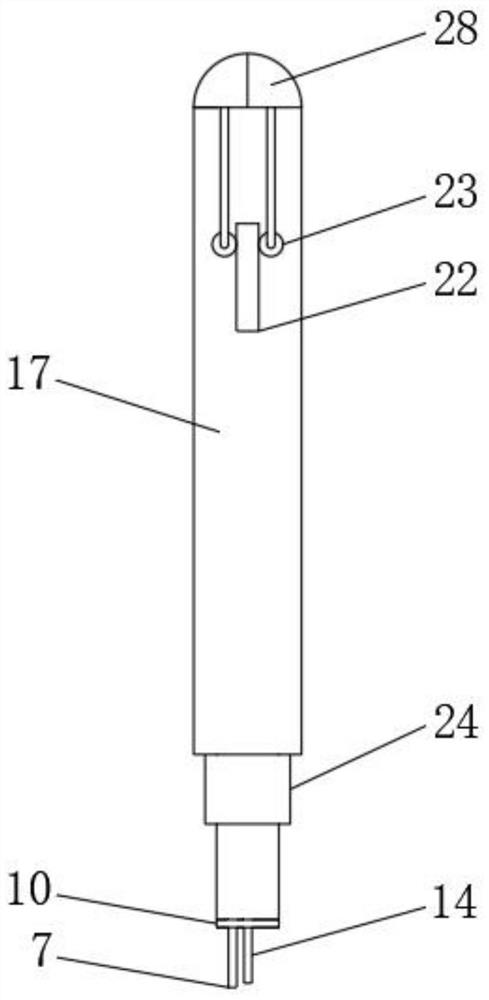

Uterus lifting instrument

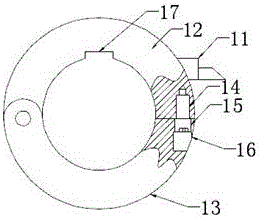

PendingCN112274228AMaintain stabilityCut thoroughlyObstetrical instrumentsEngineeringMechanical engineering

The invention discloses a uterus lifting instrument which comprises a uterus lifting rod, a balloon arranged at the end, close to the far hand, of the uterus lifting rod, and an operating handle arranged at the end, close to the hand, of the uterus lifting rod. A uterus lifting cup and a cutting assembly are further arranged on the uterus lifting rod and located between the balloon and the operating handle; The cutting assembly is connected with the operating handle so that the operating handle can excite the cutting assembly; the uterus lifting cup is located on the side, away from the operation handle, of the cutting assembly. According to the uterus lifting instrument, the use stability of the uterus lifting instrument can be improved.

Owner:欣瑞德(江苏)医疗科技有限公司

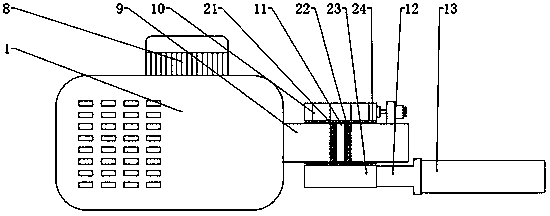

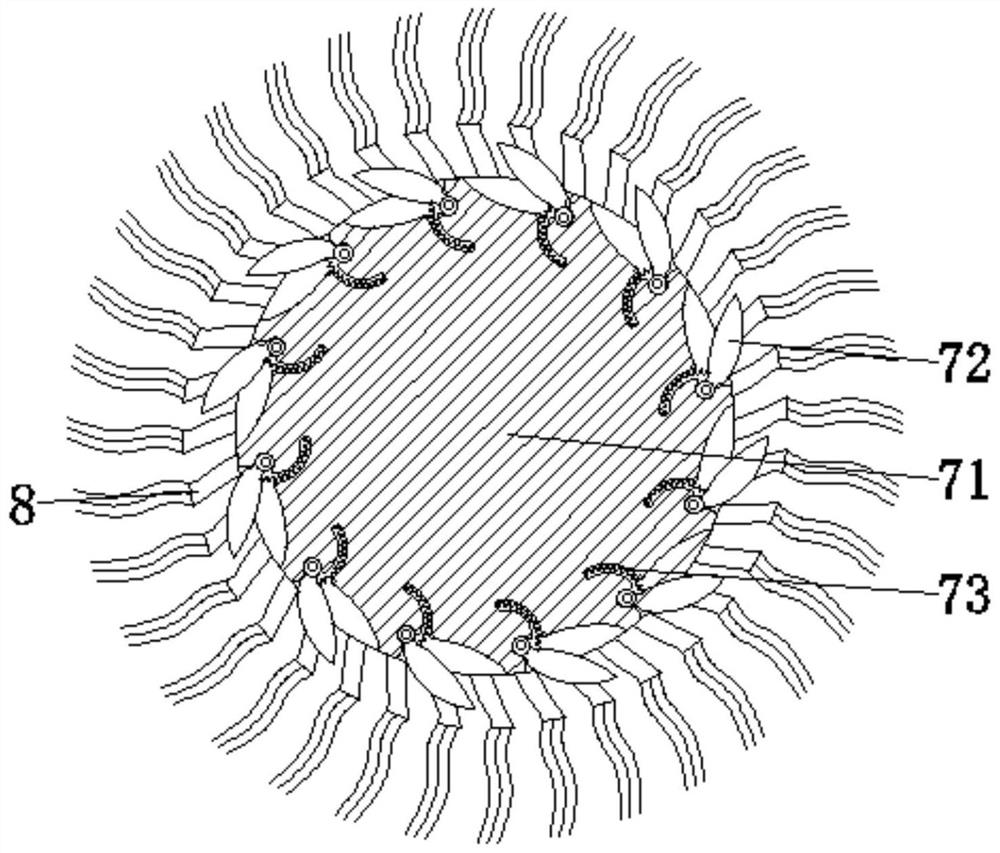

Crop straw crusher

The invention discloses a crop straw crusher. The crusher comprises a bottom plate, a powder bin is welded to the bottom plate, and two side plates are welded to the upper end of the powder bin; a motor is installed on the left side plate through bolts, and a center wheel is welded to an output shaft of the motor. The crusher has the advantages that the motor drives arc-shaped plates to rotate soas to drive a first blade to rotate, so that two blades complete cutting of straw together; a sliding sleeve slides along the inner wall track of a flower-shaped guide rail, and then each arc-shaped plate slides back and forth in the direction of a sliding column so that the first blade can slide and cut in the direction of the sliding column while rotating and cutting; the flower-shaped guide rail is driven by a gear ring part structure to rotate, so that the movement track of the first blade is more complex; it is guaranteed that in the running process of the device, when the two blades areused for cutting the straw, the straw can be thoroughly cut and crushed without generating cutting dead corners.

Owner:沈军

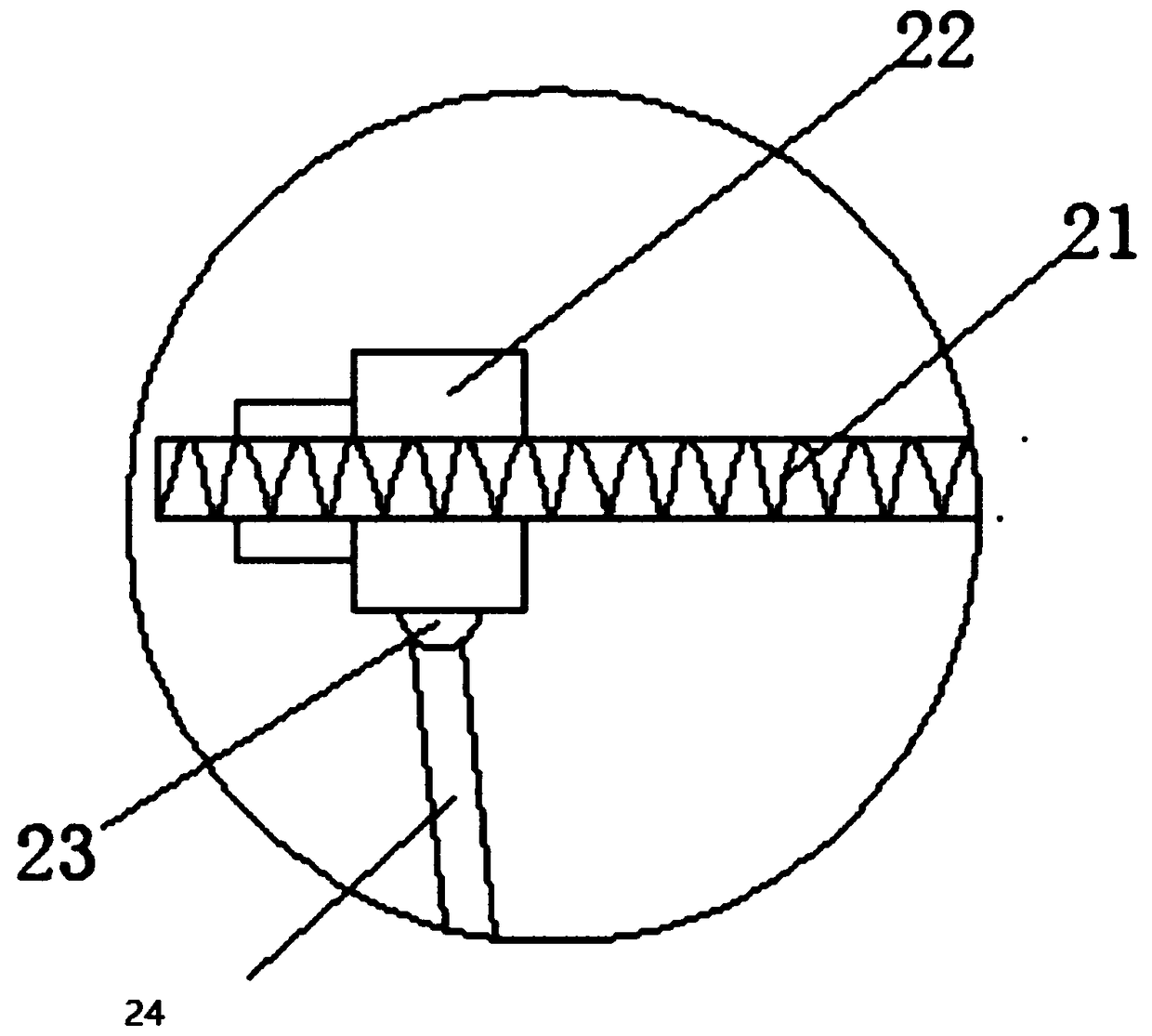

Vapor deposition and thin film collecting mechanism

The invention provides a vapor deposition and thin film collecting mechanism which comprises a slitting support and a take-up support. A transmission device and a cutting device are arranged on the slitting support, a take-up roller is arranged on the take-up support, the transmission device comprises a receiving rotary shaft, a straight rolling rotary shaft and a cutting rotary shaft, the cutting device comprises a cutter shaft fixing support, a cutter shaft, a cutter rest and a cutter, a gap is formed in the middle of the outer end of the cutter rest, and the cutter is fixed in the gap through a fixing pin and can swing around the fixing pin. The vapor deposition and thin film collecting mechanism further comprises an elastic sheet arranged between the back of the cutter and the edge bottom of the gap and capable of making the cutter swinging and rebounding, wherein the elastic sheet is fixed to the edge bottom of the gap. The vapor deposition and thin film collecting mechanism has the following advantages that the elastic sheet is mainly used for playing a shock absorption and buffering effect between the cutter and the edge bottom of the gap of the cutter rest, a slitting tension is always kept at appropriate strength during thin metal film slitting, and thin metal films are thoroughly slit.

Owner:TONGLING CHAOYUE ELECTRON CO LTD

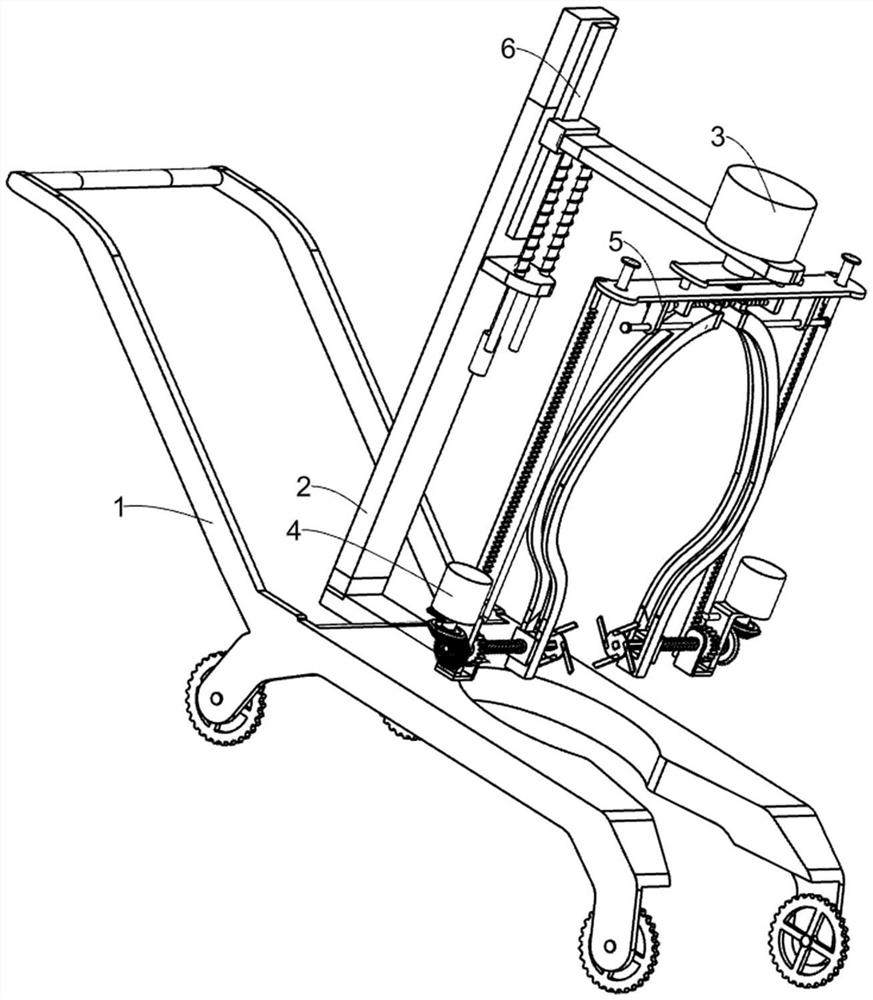

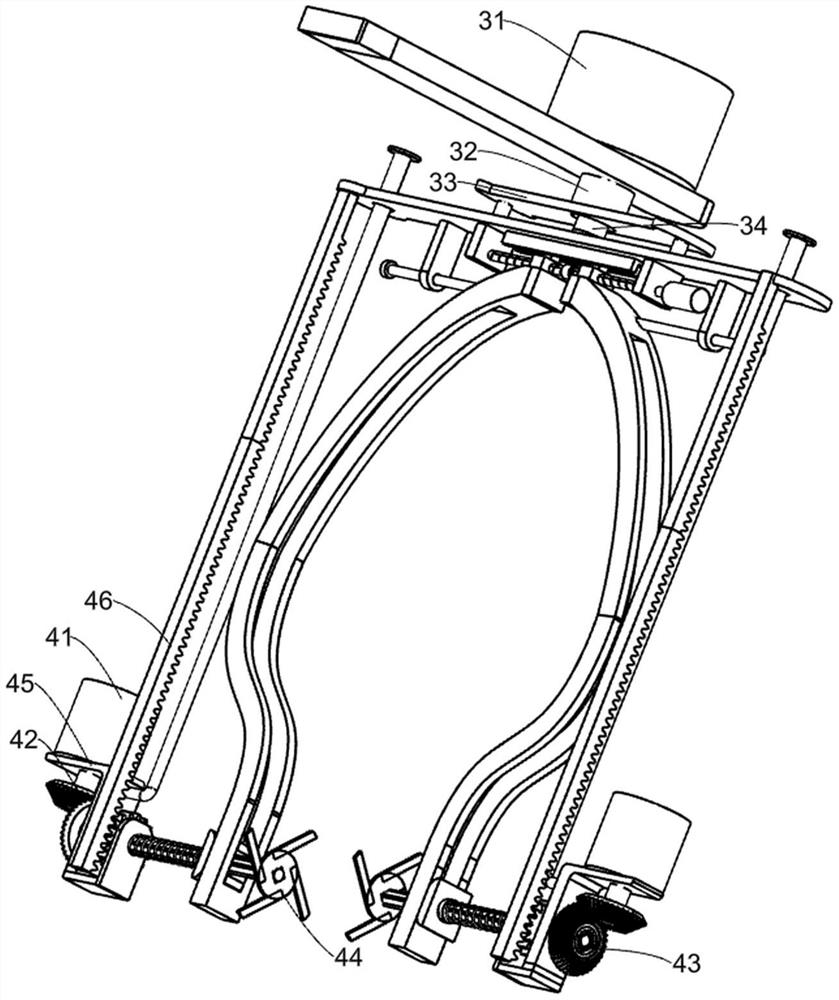

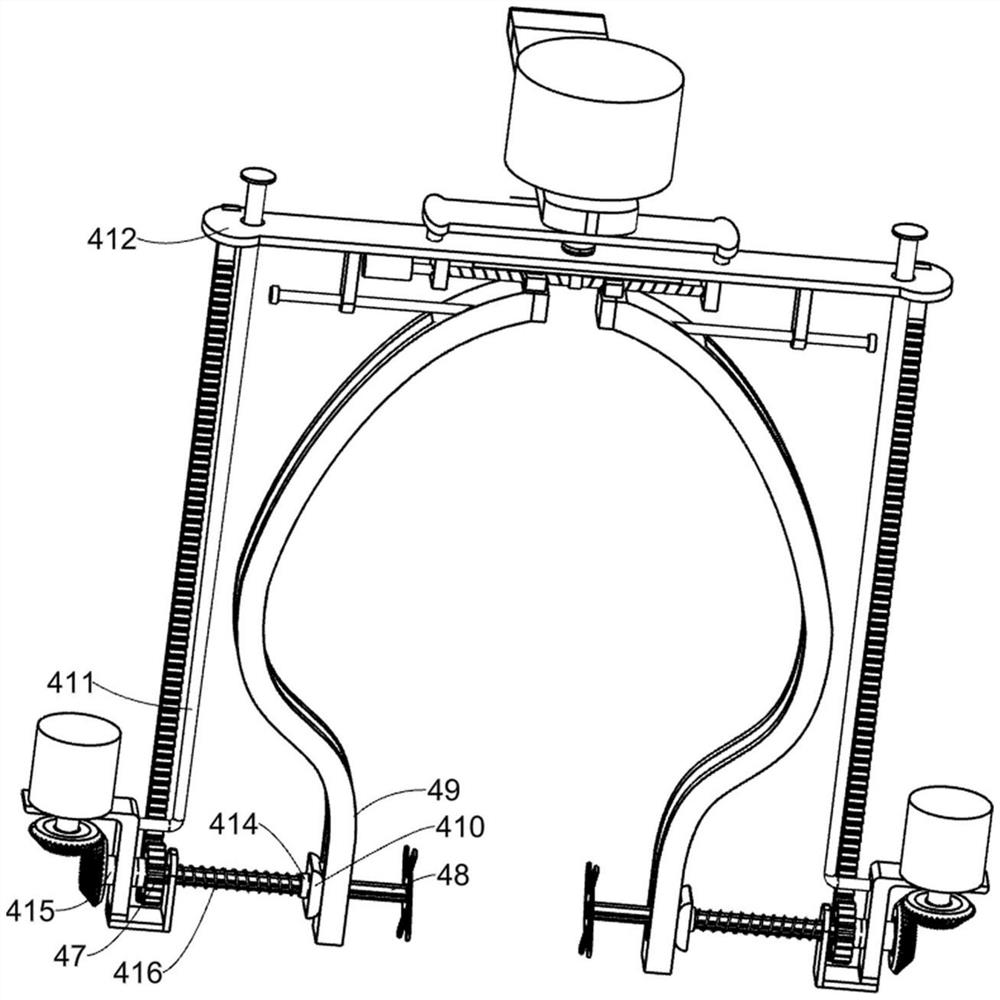

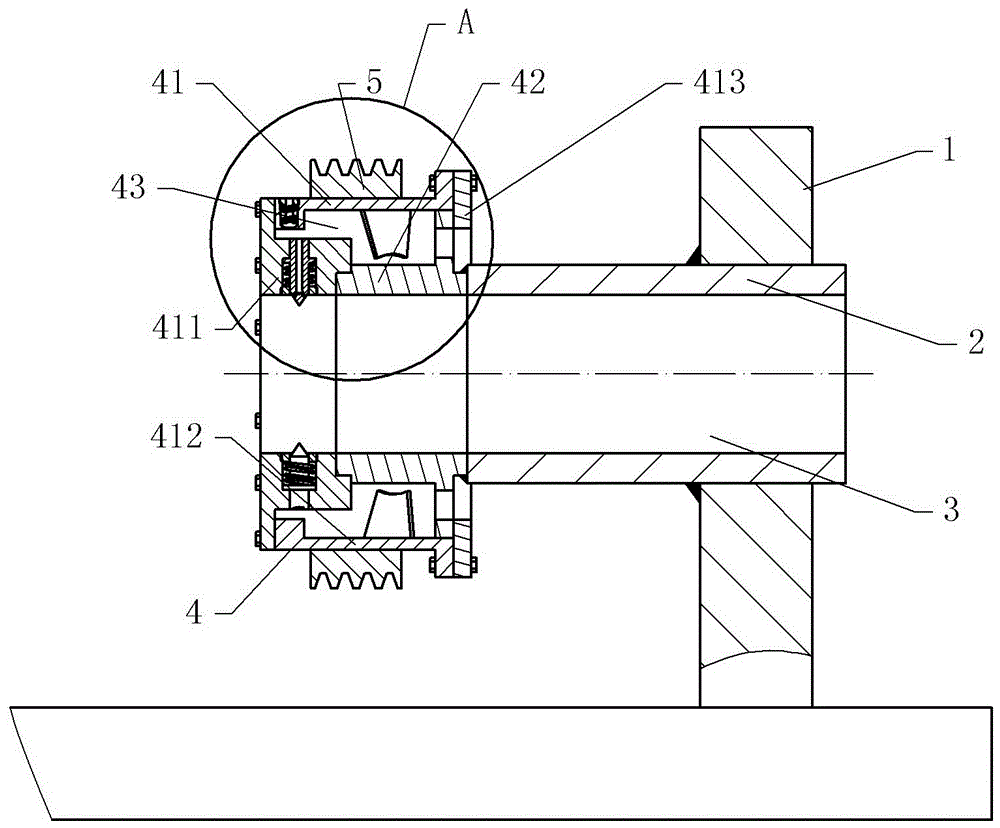

Rotary nursery stock pruning device

ActiveCN111869454AImprove aesthetics and appreciationIncrease the scope of applicationCuttersCutting implementsPruningAgricultural engineering

The invention discloses a rotary nursery stock pruning device, relates to the technical field of nursery stock planting, and solves the problems that the efficiency of manually pruning nursery stocksby workers is low, and existing nursery stock pruning equipment is inconvenient to operate and cannot prune the nursery stocks of different sizes. The rotary nursery stock pruning device comprises a cart frame, a supporting frame, a rotary assembly and the like. The supporting frame is fixedly arranged at one side face of the cart frame, the rotary assembly is arranged on the supporting frame andcomprises a rotating motor, a hollow movable shaft, a supporting plate, a connecting shaft and a connecting plate, and the connecting plate is arranged at one side face of the upper portion of the supporting frame. According to the rotary nursery stock pruning device, a whole pruning assembly can be driven to rotate by 360 degrees through the rotary assembly, so that two pruning blades can prune branches and leaves around the nursery stocks, and the two pruning blades can slide up and down to prune the whole nursery stocks.

Owner:北京冠森园林工程有限公司

Plastic smelting device

The invention discloses a plastic smelting device and relates to the field of plastic machining. The plastic smelting device comprises a rack and a driving motor. A cantilever is fixed on the rack. One end of the cantilever is fixed on the rack and the other end of the cantilever is provided with a cutting mechanism. The cutting mechanism comprises a stator which is fixed on the cantilever and a rotor which is rotationally connected with the stator. A center through hole interpenetrates the centers of the rotor, the stator and the cantilever. An air suction cavity is arranged between the stator and the rotor. A rotary vane rotating with the rotor is arranged in the air suction cavity and the air suction cavity is divided into a pressure chamber and an air inlet passage by the rotary vane. The air inlet passage communicates with the outside. A plurality of cutters which are uniformly distributed along the center of the rotor are arranged on the rotor and the cutters can slide radially along the rotor. Tensioning springs sleeves outside the cutters. The rotor can be driven to rotate by the driving motor. According to the plastic smelting device, a plastic pipe can be uniformly forced when cut and located in the center through hole after cut, so that damage of the plastic pipe can be prevented.

Owner:重庆敏驰塑胶有限公司

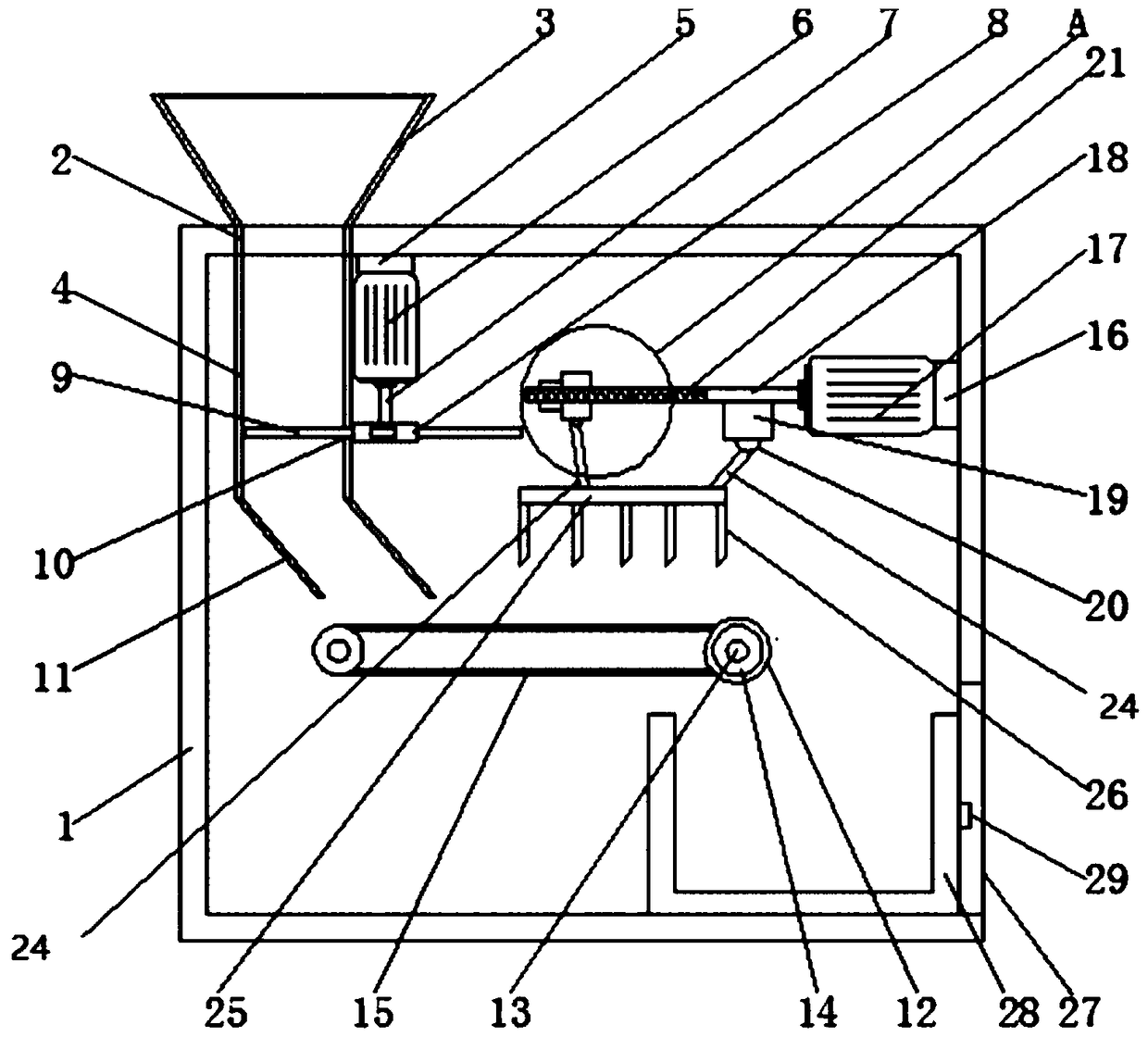

Chili chopping device for chopped chili production

InactiveCN114082496ACut thoroughlyPrevent fallingGrain treatmentsAgricultural engineeringConveyor belt

The invention relates to the technical field of agricultural product processing, discloses a chili chopping device for chopped chili production, and solves the problems that a chili chopping device in the current market cannot longitudinally cut chili when chopping the chili and cannot remove the chili adhered to the surface of a conveyor belt, and the chili falling out of a discharging port cannot be blocked at will. The device comprises a processing box body, a cavity is formed in the processing box body, a feeding port communicated with an inner cavity of the processing box body is fixedly mounted in the top of the processing box body, and a discharging port communicated with the inner cavity of the processing box body is fixedly formed in the bottom of the processing box body; an opening is formed in the top of the processing box body, a fixing shaft is fixedly connected to the end, away from the feeding port, of the opening, and a sealing cover is arranged at the opening. According to the chili chopping device, chili in the device can be chopped more thoroughly, the chopped chili adhering to the surface of the conveying belt can be cleaned down, and finally the chili falling from the discharging port can be stopped at will.

Owner:怀化市酱香和农业科技股份有限公司

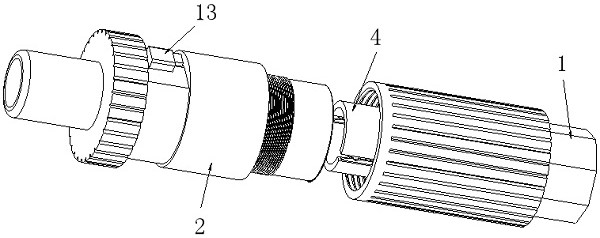

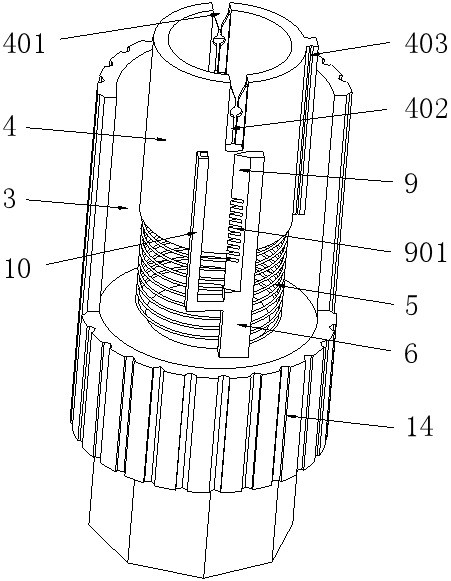

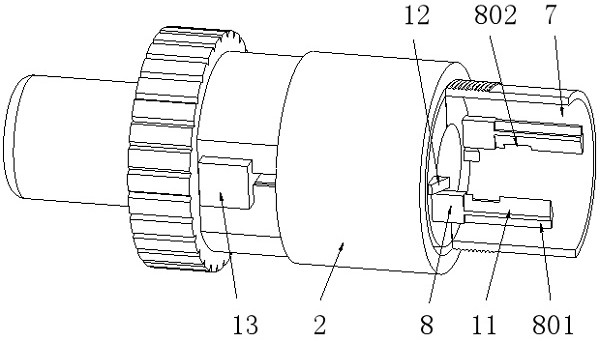

High-voltage wiring harness system for new energy automobile

ActiveCN112918405AFree of manual strippingEasy to installElectrically conductive connectionsElectric/fluid circuitElectrical conductorNew energy

The invention relates to the technical field of automobile wire harnesses, and discloses a high-voltage wire harness system for a new energy automobile, the high-voltage wire harness system comprises a first connector and a second connector, the first connector and the second connector are both of hollow structures, one end of the first connector is provided with a first fixing groove, and a wire harness fixing seat is arranged in the first fixing groove; the wire harness fixing seat is elastically connected with the first fixing groove through an elastic connecting piece, a first cutter bar is arranged on the outer side of the wire harness fixing seat, a second fixing groove is formed in one end of the second connector, and a second cutter bar is arranged in the second fixing groove. According to the technical scheme, the first cutter bar with the first cutter is arranged in the first connector, and the second cutter bar with the second cutter is arranged in the second connector, so that when the first connector is inserted into the second connector, an insulating layer of a conductor fixed on the guide fixing seat can be cut off through the first cutter and the second cutter; therefore, the purpose of avoiding manual wire stripping is achieved.

Owner:HEMEI (ZHEJIANG) AUTOMOBILE CO LTD

Floor cleaning device for decoration

ActiveCN108113566AAvoid pollutionGreat suctionCarpet cleanersFloor cleanersUltrasonic sensorGuide tube

A floor cleaning device for decoration belongs to the field of cleaning equipment. Two wheels are mounted on the outer sides of two first supports respectively; two first motors are mounted on the inner sides of the two first supports respectively. A seal ring that is in band ring shape is annularly arranged on a cutting device; a cutting device is fixed to a spindle of a second motor; universal wheels are fixed to the bottom of a turnplate; two cameras are mounted at the front center and rear center of the workbench respectively; a first ultrasonic sensor is fixed to a guide tube; two secondultrasonic sensors are mounted on two sides of a workbench; a controller is mounted beside a suction pump; a base of the second motor is mounted on a third support through a screw; a box is mounted atthe front of the workbench. The floor cleaning device for decoration can crush waste on a floor; the suction pump sucks the crushed waste into the box for mixing, so that dust pollution is relieved,manpower expenditure is saved, and working efficiency is improved.

Owner:瑞安市新瑞建筑设备租赁有限公司

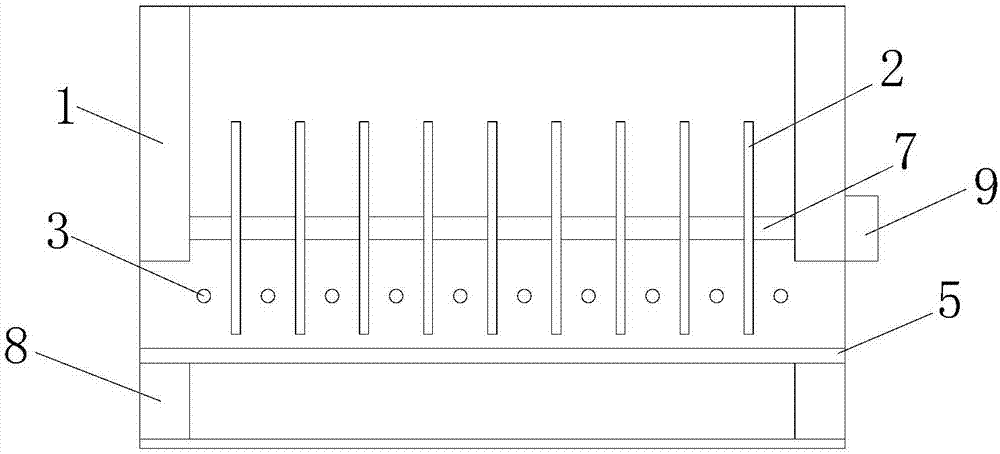

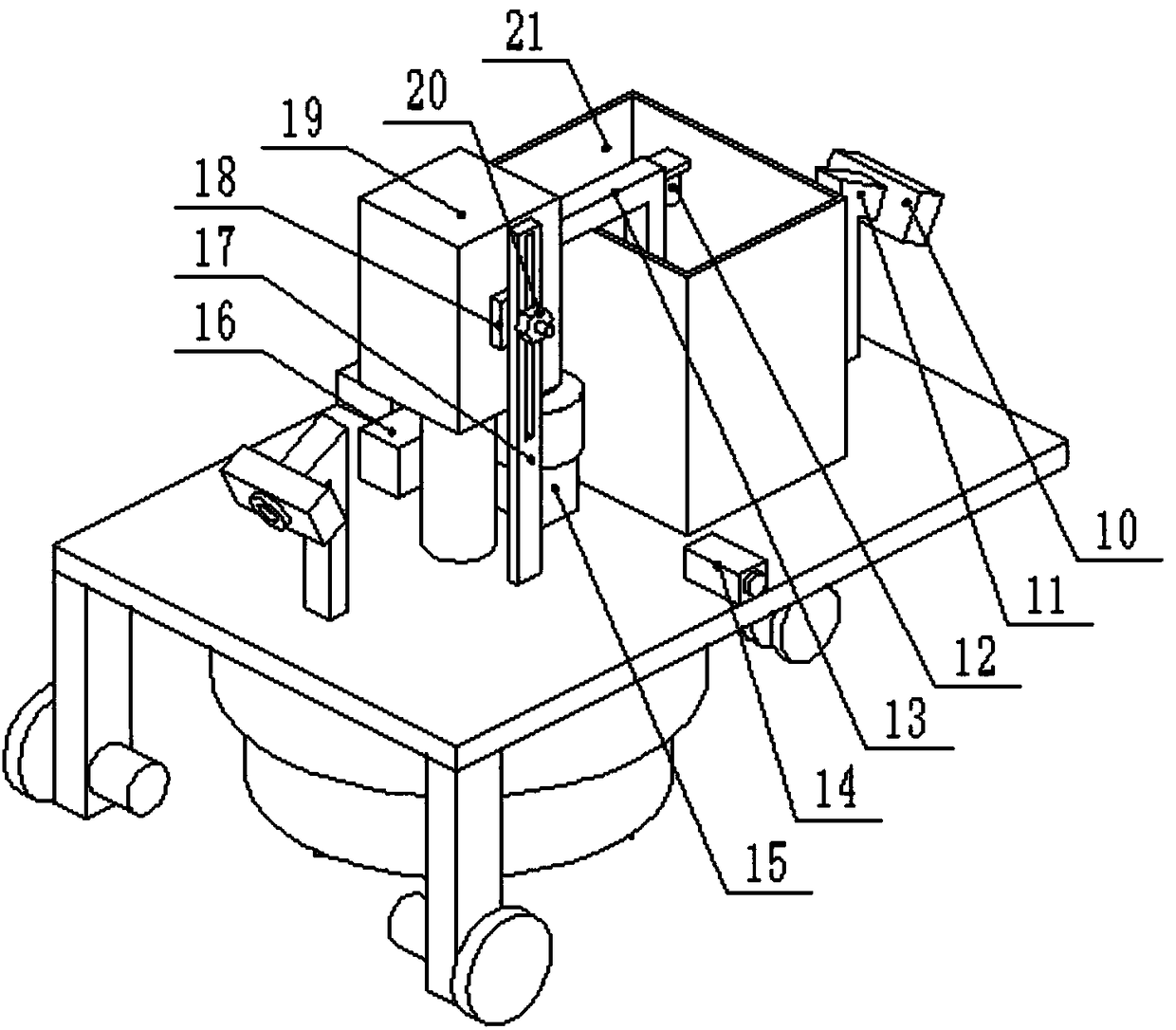

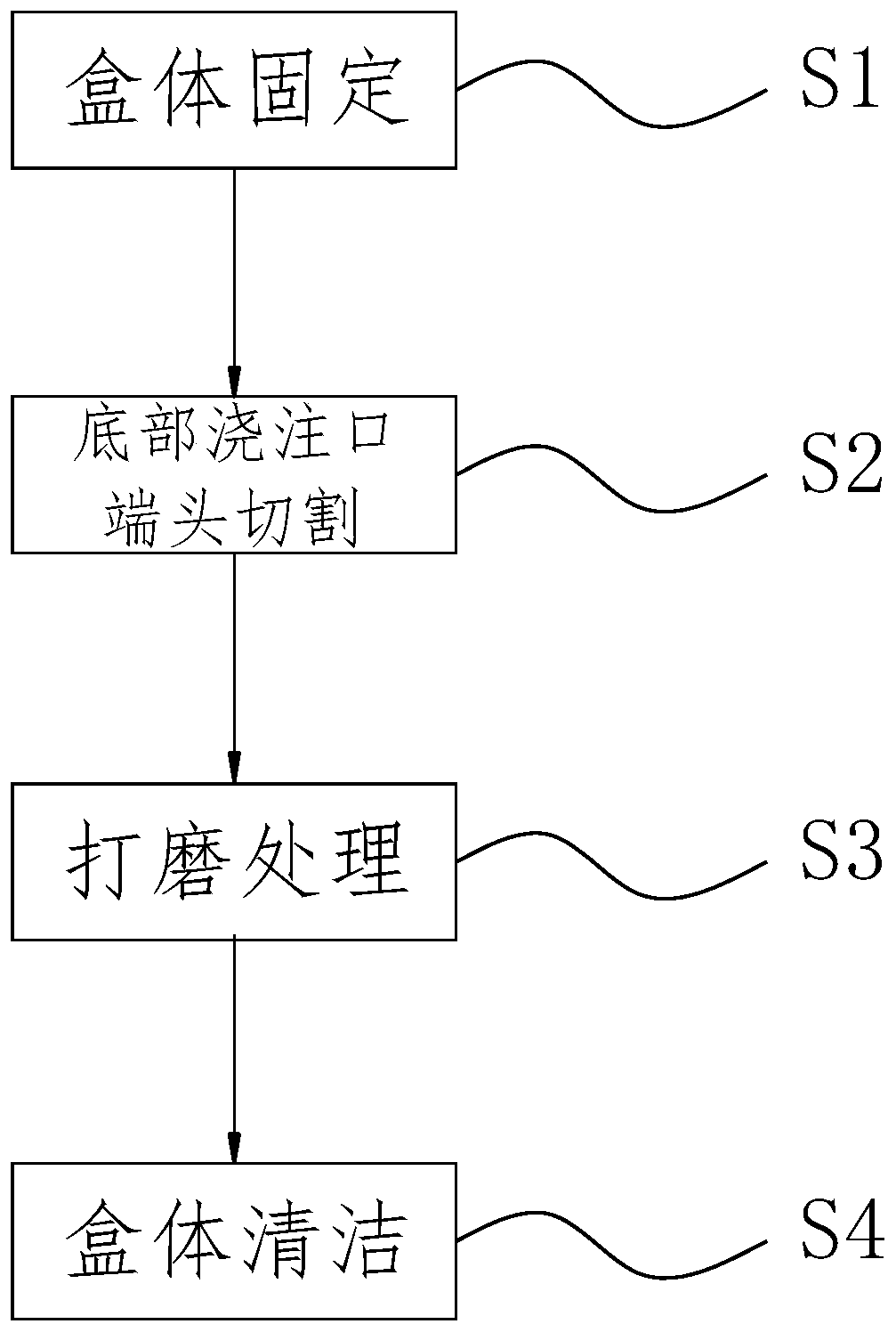

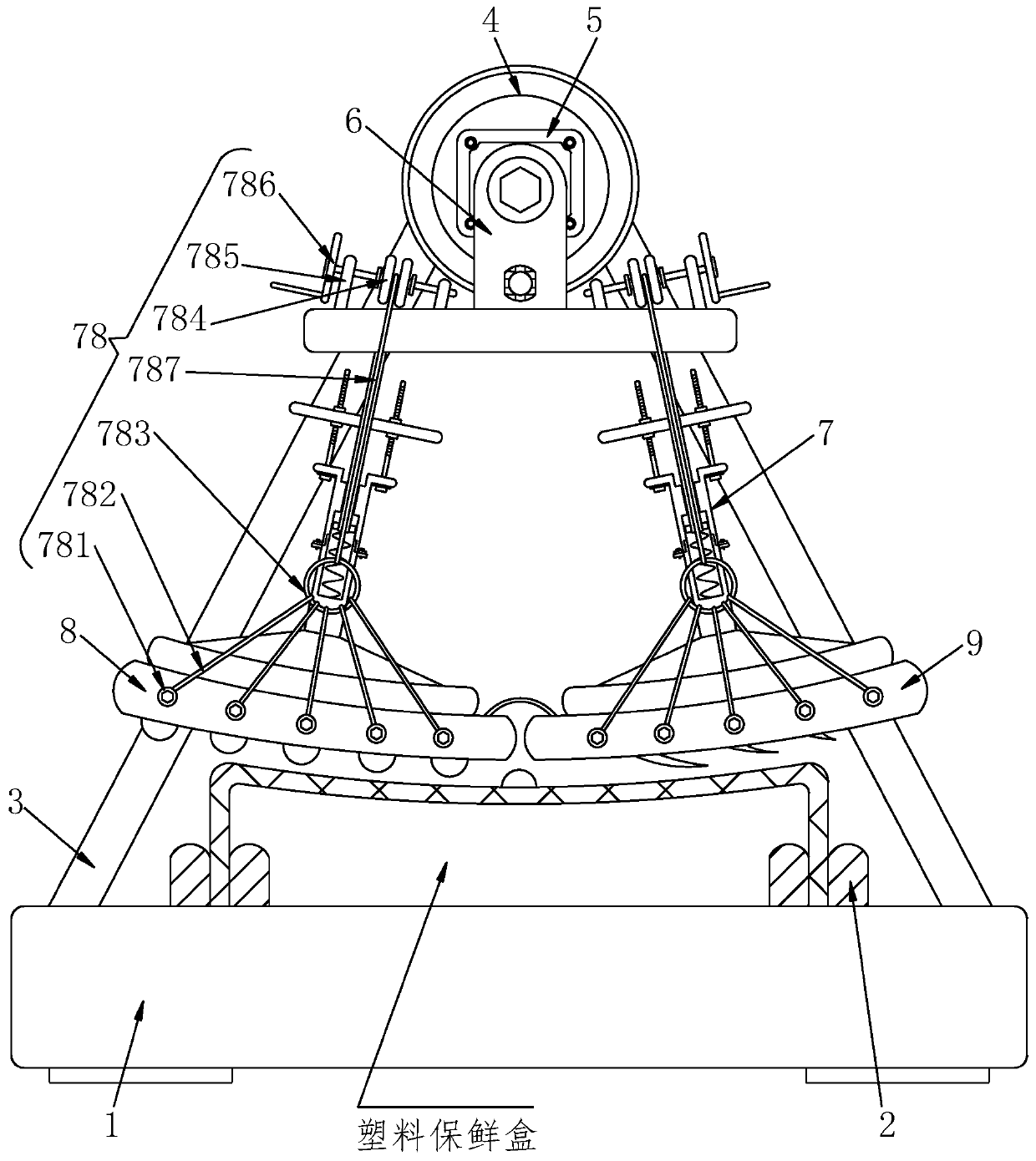

Plastic fresh-keeping box injection molding surface finishing processing method

ActiveCN110789075AImprove processing efficiencyImprove processing qualityEdge grinding machinesGrinding carriagesElectric machinerySpot welding

The invention relates to a plastic fresh-keeping box injection molding surface finishing processing method. The processing method comprises a workbench, a placing frame, supporting frames, a fixed cylinder, a motor, a T-shaped frame, adjusting mechanisms, a grinding assembly and a cutting assembly, wherein the placing frame is arranged at the top of the workbench, the positions of the two sides ofthe placing frame are symmetrically provided with the supporting frames, the supporting frames and the upper end face of the workbench are fixed through spot welding, the fixed circular column is welded to the tops of the two supporting frames, a motor placing groove is formed in the fixed cylinder, the motor is installed in the motor placing groove, the output shaft end of the motor is connectedwith the T-shaped frame, the lower end face of the T-shaped frame is connected with the grinding assembly and the cutting assembly through the adjusting mechanisms, fixed rods is fixedly welded to the lower end face of the T-shaped frame, the outer sides of the two fixed rods are sleeved with T-shaped rods, and a movable groove is formed in each T-shaped rod. The processing method has the characteristics of wide application range, high processing quality and high processing efficiency.

Owner:安徽华赛包装有限公司

Sprue material shearing machine

The invention relates to a shearing machine and particularly relates to a sprue material shearing machine which comprises a movable cutter, a fixed cutter, a gas cylinder, a movable plate of the movable cutter, a fixed cutter fixing plate, a gas cylinder fixing plate and movable plate supporting shafts, wherein the two ends of each supporting shaft of the movable plate are respectively fixed on the gas cylinder fixing plate and the fixed cutter fixing plate; the movable plate of the movable cutter and the movable plate supporting shaft are in sliding connection; the gas cylinder is fixed on the gas cylinder fixing plate; the output end of the gas cylinder is connected with the movable plate of the movable cutter; the movable cutter is fixed on the movable plate of the movable cutter; the fixed cutter is fixed on the fixed cutter fixing plate. The sprue material shearing machine is capable of shearing a sprue material. Compared with the prior art, the sprue material shearing machine disclosed by the invention has the advantages of high shearing efficiency, small labor intensity, convenience in shearing, complete shearing of the sprue material, and the like.

Owner:浙江心为心科技股份有限公司

Minimally invasive resection device for pediatric surgery tumor

The invention discloses a minimally invasive resection device for pediatric surgery tumor. The resection device includes a first main body; the first main body is a cylindrical rod, and the two ends of the first main body are opened; one end of the first main body is fixedly connected to an installation plate; the surface on the side, away from the first main body, of the installation plate is provided with connecting plates; a guiding rod is fixedly connected between the two connecting plates; the surfaces of connecting rods are respectively and slidingly provided with sleeves; and the surfaces on the sides, away from the installation plate, of the two sleeves are respectively and fixedly connected to fixing clamps. Through the arrangement of a roller, medical silk suture can be arrangedon the roller and passes out through a catheter, so that the medical silk suture can be sleeved on tumor; the medical silk suture can be tightened by rotating the roller, so that the tumor can be cut,and more complete cutting can be achieved; and the front end of the device is small, so that the device can be conveniently inserted into a patient.

Owner:王仲秋

Crop shredding device

The invention provides a crop shredding device. The crop shredding device comprises a barrel cap, a fixing pressing buckle, a barrel body, a first stage filter screen, a second stage filter screen, athird stage filter screen, a wedge block, supporting pillars, universal wheels, fixing switches, an electromotor, a material discharging port, a material discharging chamber, a material discharging sliding plate, a handle, an anti-slip rubber sleeve, cutting blades, cutting groups and a rotary shaft. The barrel cap is arranged at the upper end of the barrel body; the fixing pressing buckle is arranged at the left end of the barrel cap; the handle is arranged at the upper end of the barrel cap and the anti-slip rubber sleeve is arranged on the surface of the handle; the first stage filter screen is arranged at the upper side of the interior of the barrel body; the second stage filter screen is arranged below the first stage filter screen and the third stage filter screen is arranged below the second stage filter screen; the wedge block is arranged at the lower end of the barrel body; the material discharging sliding plate is arranged at the right end of the wedge block and the materialdischarging chamber is arranged at the right end of the material discharging sliding plate. By means of the device, the crop can be thoroughly shredded and the human and material resource can be saved.

Owner:广西梧州金广丰生物肥料有限公司

Anti-twining driving device for ships

The invention relates to the technical field of power driving devices for ships and particularly to an anti-twining driving device for the ships. The anti-twining driving device for the ships comprises a propeller, a transmission shaft and a ship stern pipe or a Y-shaped tail stand. The anti-twining driving device for the ships is characterized by comprising a saw-tooth-shaped cylindrical cutting tool; the cutting tool is installed on the outer wall of the ship stern pipe or the outer wall of the Y-shaped tail stand; the cutting edge of the saw-tooth-shaped cutting tool faces to the propeller; the rear end surface of the propeller is provided with a cutting strip knife; the lateral side of the cutting strip knife is provided with a cutting edge; the cutting strip knife is parallel to the transmission shaft of the propeller. According to the anti-twining driving device for the ships, two-stage cutting can be achieved due to rotation of the propeller, the cutting strip knife rotates along with the propeller to cut a linear object close to the propeller, and once the linear object is close to the transmission shaft, the saw-tooth-shaped tubular cutting tool automatically cuts the linear object. The anti-twining driving device for the ships has the advantages of being simple in structure and thorough in cutting, enabling the working efficiency of the propeller to be high and being applied to various ships to prevent failures due to the fact that the propeller is twined.

Owner:WEIHAI ZHONGFU XIGANG SHIP

Magnetite pretreatment device

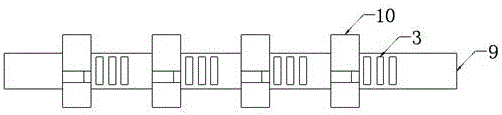

ActiveCN110523626AUniform size and qualityUniform processing surfaceSievingGas current separationMagnetiteEngineering

A magnetite pretreatment device comprises a cutting system, a screening system, a washing system, a magnetic separation system and a flotation system which are sequentially arranged from top to bottom. According to the cutting system, the ore raw materials are cut three times in sequence, the cutting effect is good, the efficiency is high, and the situation that during the follow-up machining process, the ore size is too large, so that a machine gets stuck, can be effectively prevented. Meanwhile, the cutting system can adjust the number of the parts, extending into the corresponding working grooves, of the rotary cutters according to the size of ore raw materials and the cutting requirements, so that the cutting efficiency is changed, and the work scheduling is flexible. According to thescreening system, the mineral aggregate is screened through the vibration and the wind power, so that the screening efficiency is effectively improved. According to the magnetic separation system, through the design of the two layers of conveying crawler belts and the shifting plates, more magnetic separation heads can be used for magnetic separation at the same time, the magnetic separation efficiency is improved, and themetallic magnetite can be rapidly and effectively separated out.

Owner:肖春槐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com