Disassembly and recovery device for waste power lithium batteries

A recycling device and lithium battery technology, applied in the field of environmental protection, can solve the problems of reducing work intensity and increasing the workload of refining, and achieve the effects of reducing work intensity, facilitating work processing, and increasing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

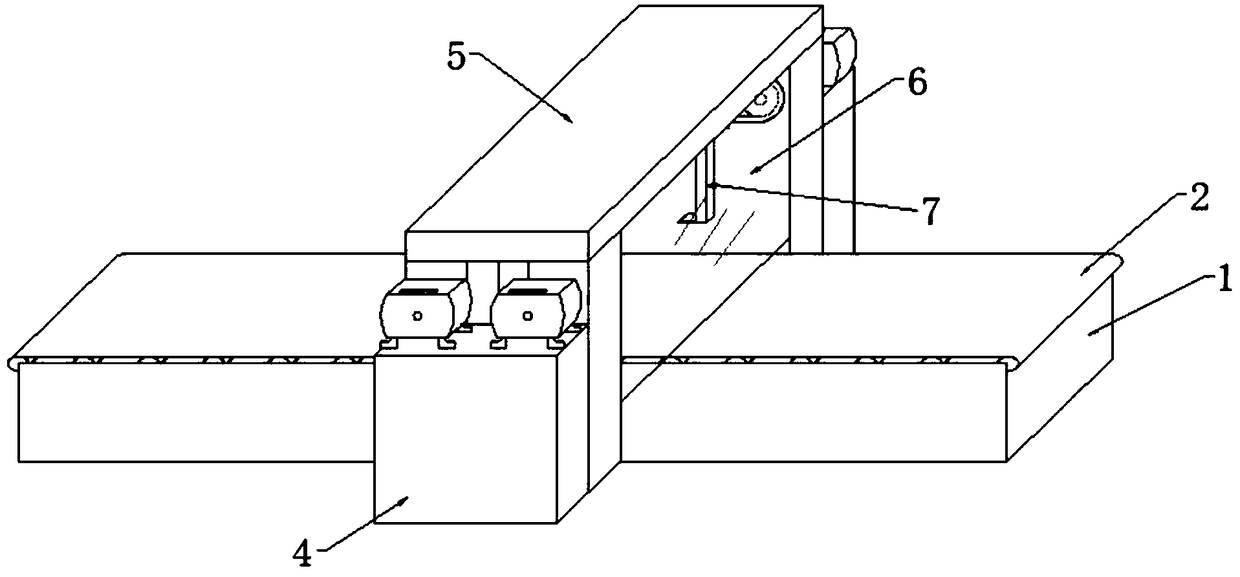

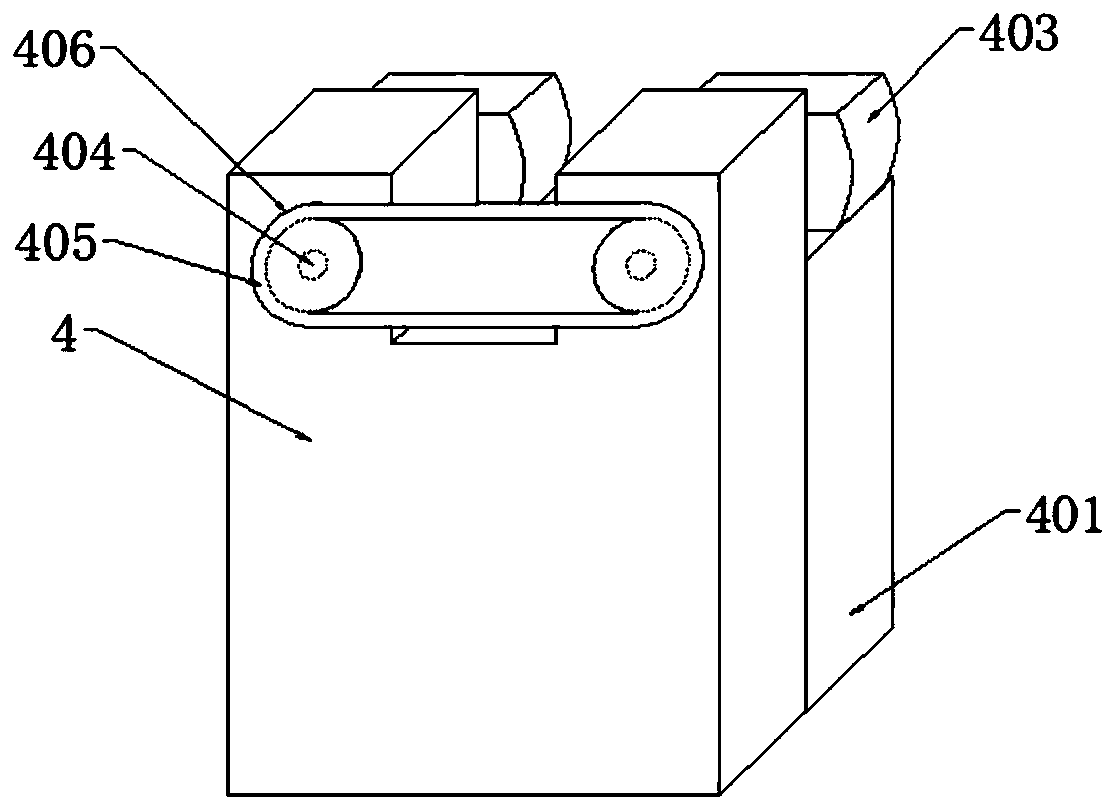

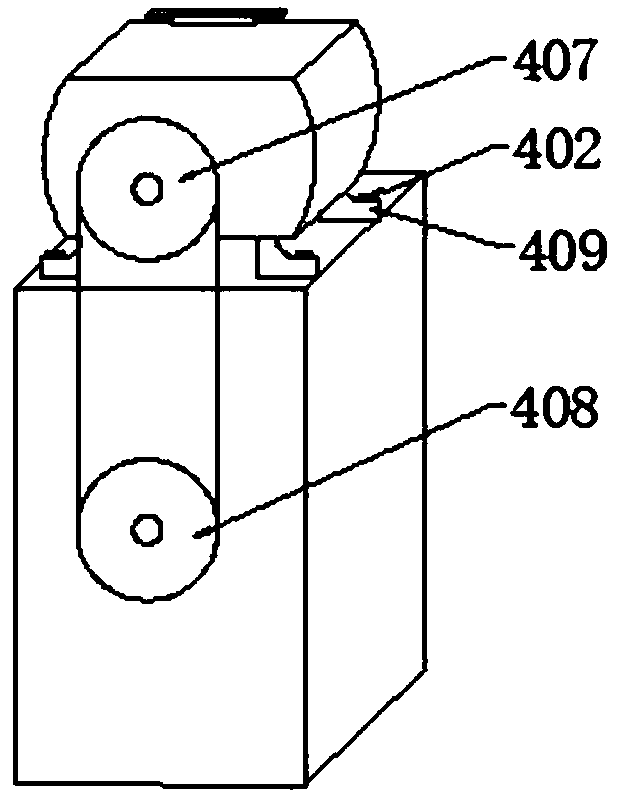

[0028] Such as Figure 1-5 As shown, a dismantling and recycling device for waste power lithium batteries includes a transmission base 1, a cutting table 4 and a stabilizing clip 7. A conveyor belt 2 is arranged on the upper side of the transmission base 1, and the interior of the conveyor belt 2 is evenly arranged with Support rod 3, the left and right sides of the transmission base 1 are respectively provided with a cutting table 4, the rear side of the cutting table 4 is provided with a motor stabilization table 401, and the top of the motor stabilization table 401 is provided with a motor 403, and the motor 403 There are at least two, the motor 403 is provided with a shaft 404 inside, the shaft 404 runs through the cutting table 4 and extends out of the front side of the cutting table 4, the shaft 404 is covered with a gear 405, and the gear 405 is covered with a The cutting belt 406, the top of the cutting table 4 is provided with a top plate 5, the lower side of the top ...

Embodiment 2

[0030] A dismantling and recycling device for waste power lithium batteries, including a transmission base 1, a cutting table 4 and a stabilizing clip 7, a conveyor belt 2 is arranged on the upper side of the transmission base 1, and support rods 3 are evenly arranged inside the conveyor belt 2 , the left and right sides of the transmission base 1 are respectively provided with a cutting table 4, the rear side of the cutting table 4 is provided with a motor stabilizing table 401, and the top of the motor stabilizing table 401 is provided with a motor 403, and the motor 403 is at least provided with Two, the motor 403 is provided with a rotating shaft 404 inside, the rotating shaft 404 runs through the cutting table 4 and extends out of the front side of the cutting table 4, the rotating shaft 404 is equipped with a gear 405, and the gear 405 is equipped with a cutting belt 406 , the top of the cutting table 4 is provided with a top plate 5 , and the lower side of the top plate ...

Embodiment 3

[0033] A dismantling and recycling device for waste power lithium batteries, including a transmission base 1, a cutting table 4 and a stabilizing clip 7, a conveyor belt 2 is arranged on the upper side of the transmission base 1, and support rods 3 are evenly arranged inside the conveyor belt 2 , the left and right sides of the transmission base 1 are respectively provided with a cutting table 4, the rear side of the cutting table 4 is provided with a motor stabilizing table 401, and the top of the motor stabilizing table 401 is provided with a motor 403, and the motor 403 is at least provided with Two, the motor 403 is provided with a rotating shaft 404 inside, the rotating shaft 404 runs through the cutting table 4 and extends out of the front side of the cutting table 4, the rotating shaft 404 is equipped with a gear 405, and the gear 405 is equipped with a cutting belt 406 , the top of the cutting table 4 is provided with a top plate 5 , and the lower side of the top plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com