Patents

Literature

946 results about "Battery recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Battery recycling is a recycling activity that aims to reduce the number of batteries being disposed as municipal solid waste. Batteries contain a number of heavy metals and toxic chemicals and disposing of them by the same process as regular trash has raised concerns over soil contamination and water pollution.

Battery recycling

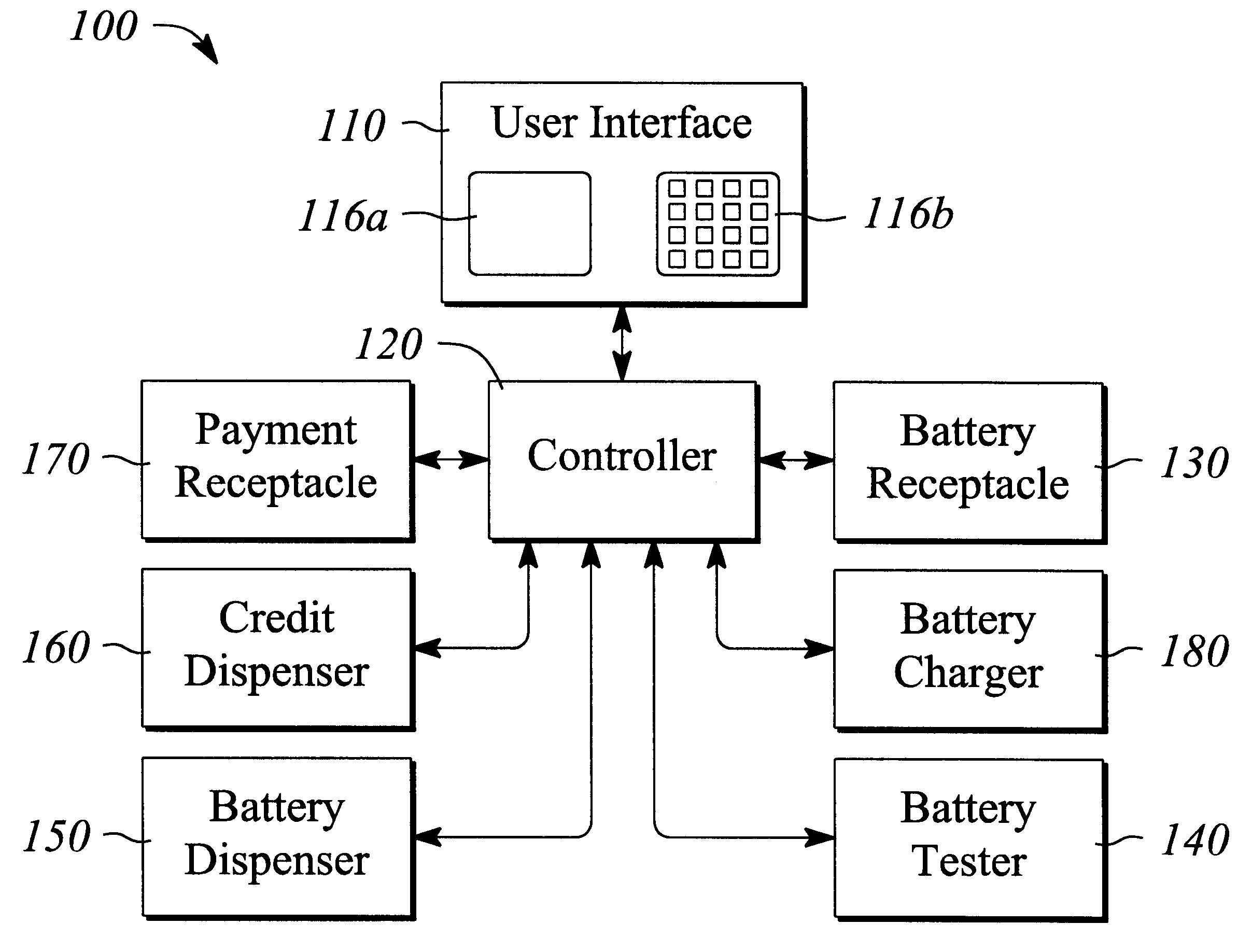

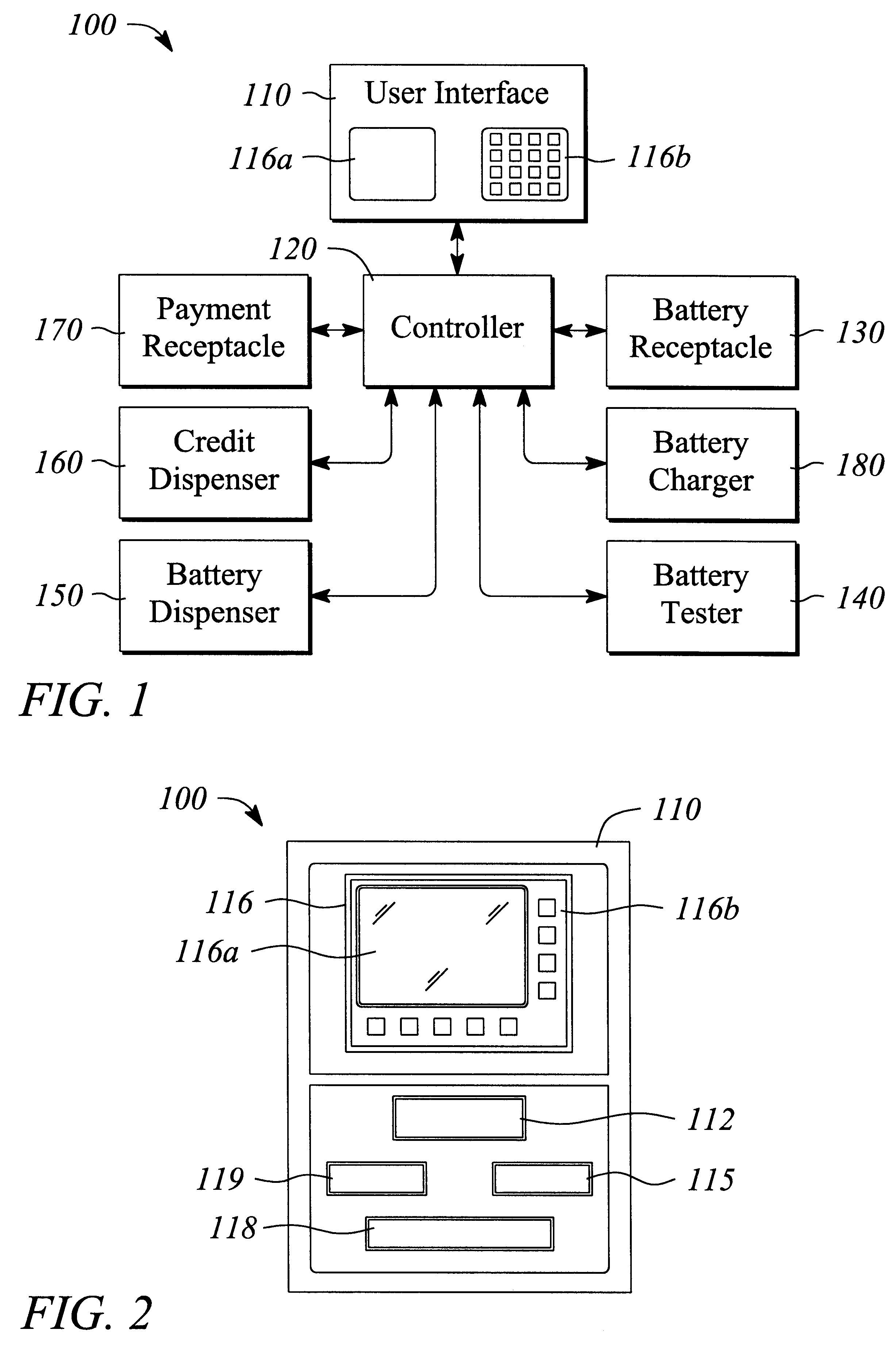

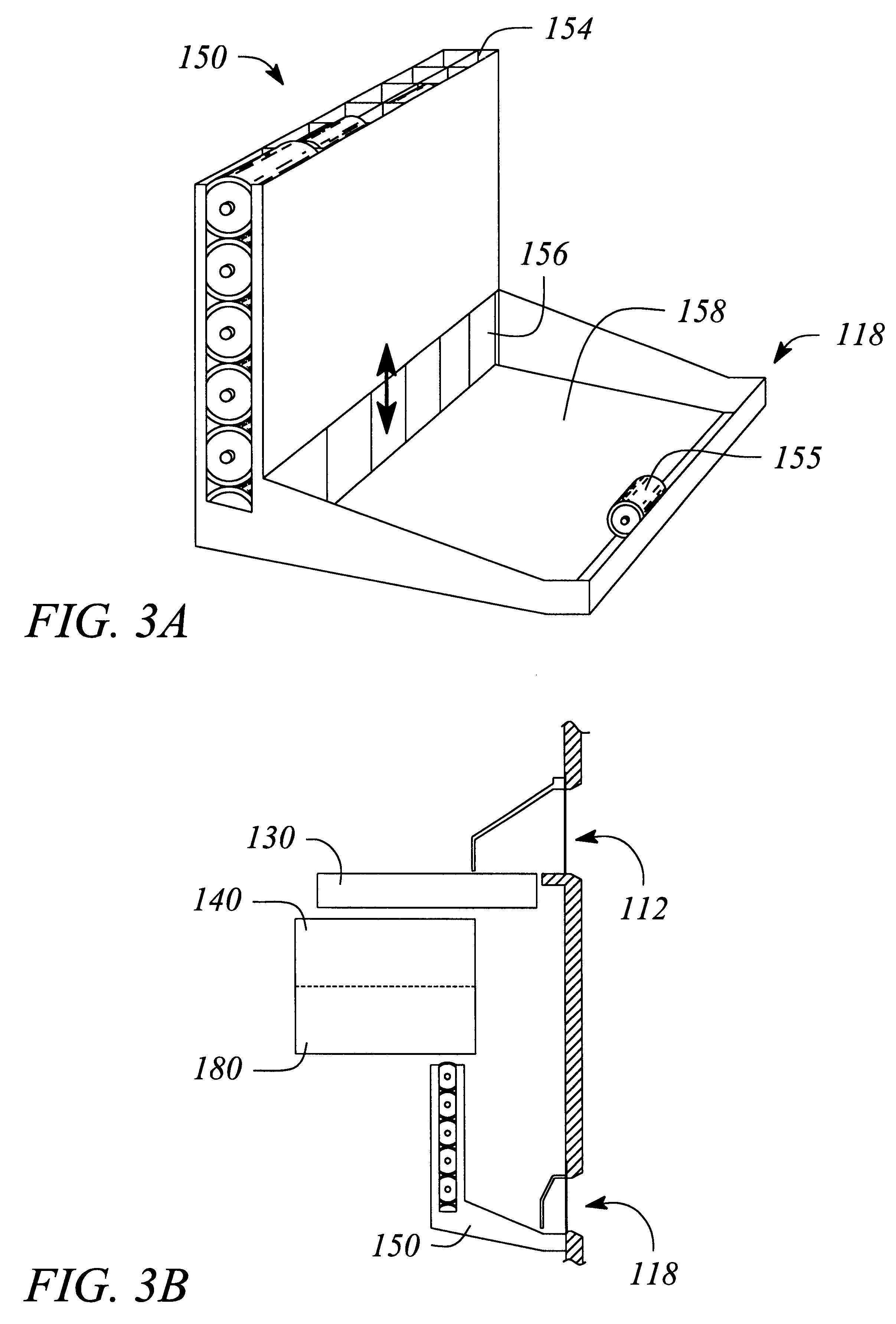

InactiveUS6618644B2Easy accessEncourage useSpecial data processing applicationsReturnable containers actuationElectrical batteryRechargeable cell

An apparatus and a method provide a convenient way for consumers to recycle used batteries. The apparatus is a self-contained station or kiosk that accepts used batteries from a consumer and dispenses one or both of fully charged batteries and credit for the used battery to the consumer. The method determines one or more of chemistry, rechargeability and condition of the used battery, assigns a credit value to the used battery, and dispenses a form of credit based on the assigned credit value. The present invention recycles one or both of used rechargeable and used non-rechargeable batteries and separately dispenses fully charged batteries. Used rechargeable batteries are recharged and reused, and used non-rechargeable batteries are collected for proper disposal according to regulations.

Owner:HEWLETT PACKARD DEV CO LP

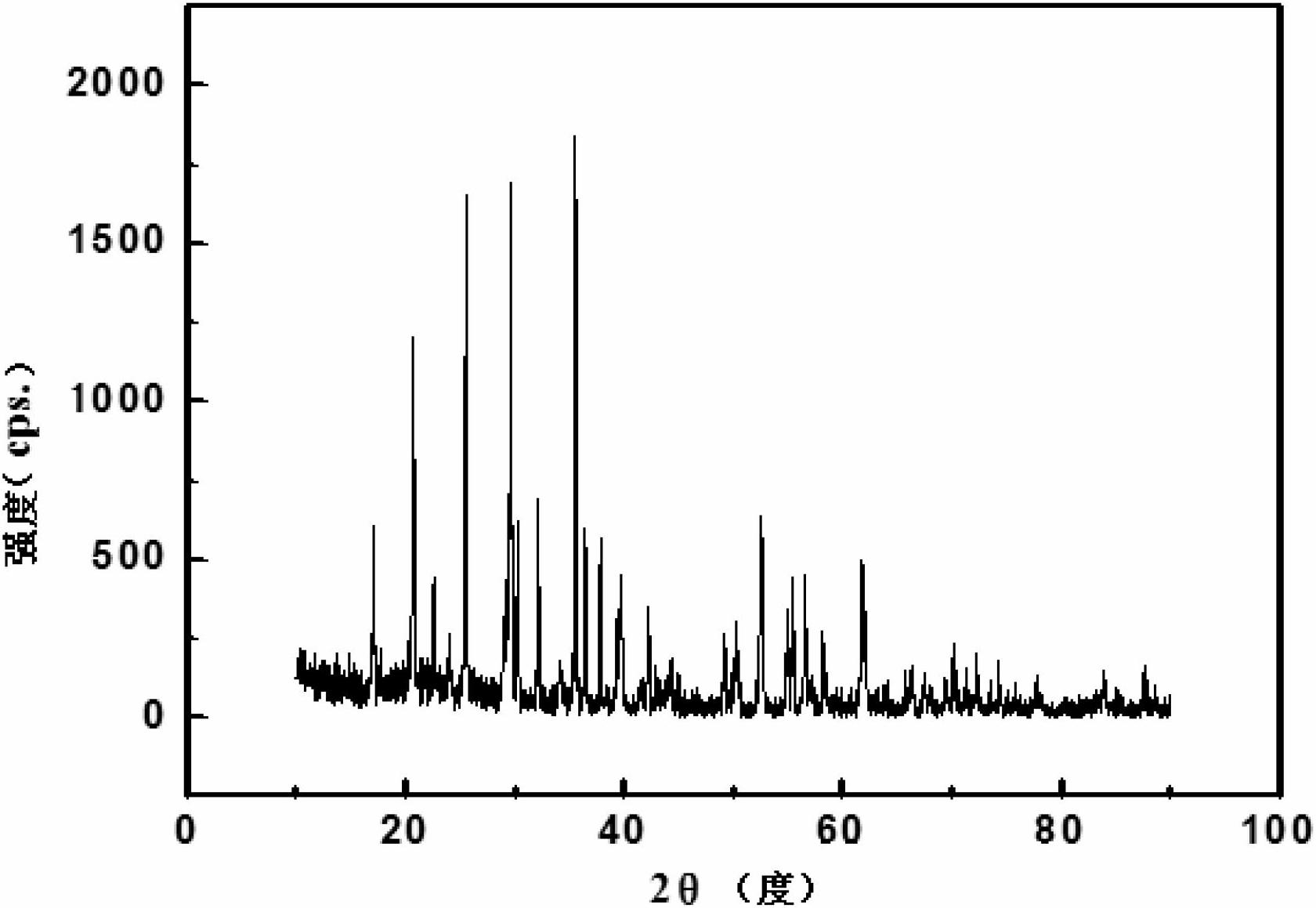

Method for recycling waste lithium iron phosphate batteries

InactiveCN102664294AAchieve recyclingImprove electrochemical performanceWaste accumulators reclaimingBattery recyclingLithium iron phosphateEngineering

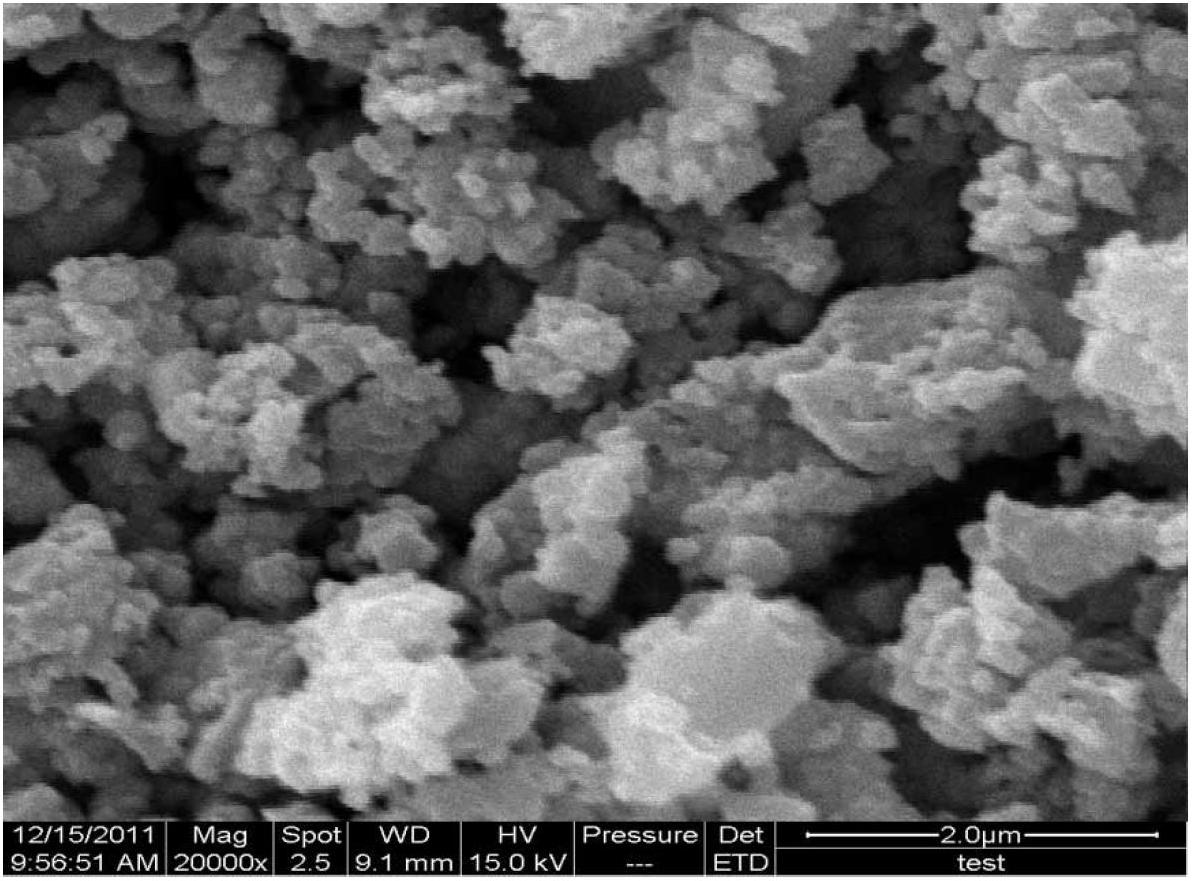

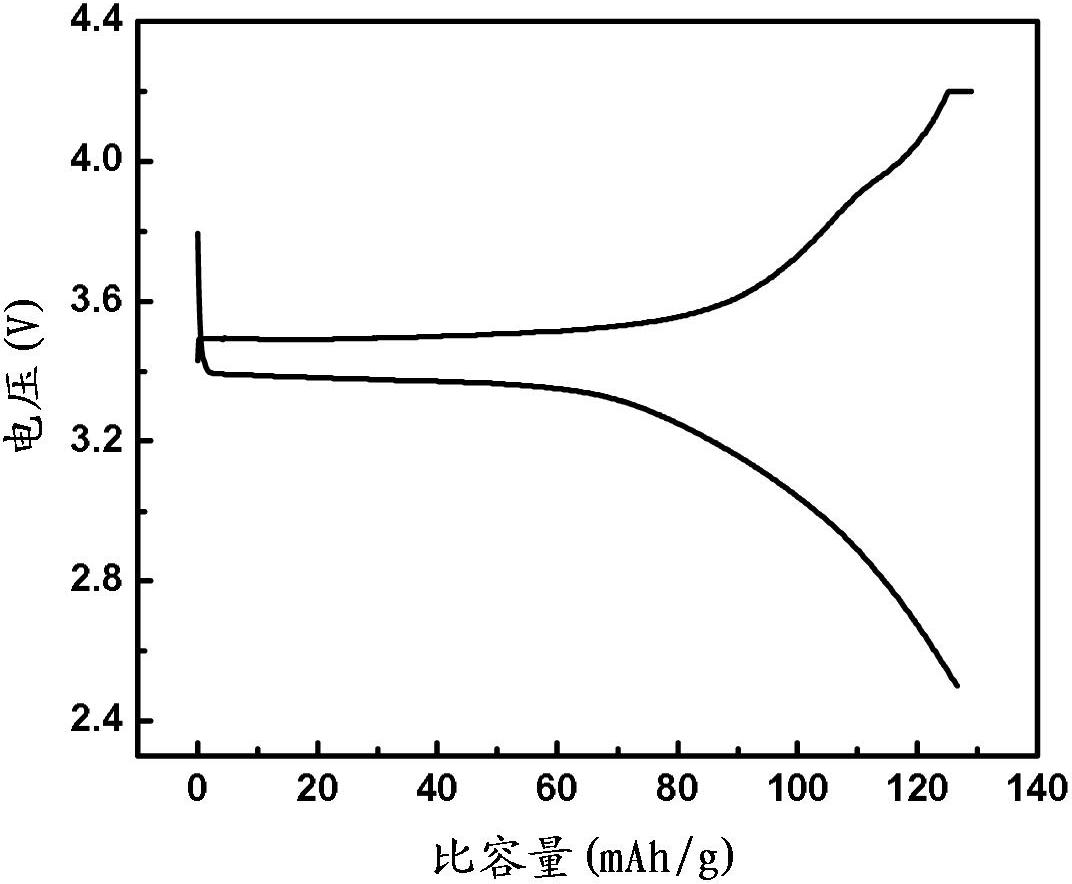

A method for recycling waste lithium iron phosphate batteries relates to a battery recycling method. The method provided by the invention aims to provide a battery recycling method which is simple in process and low in cost. The method comprises the following steps of: removing residual electric quantity of a waste lithium iron phosphate battery, taking out the cell of the battery and crashing the cell into fragments, soaking the cell fragments in sodium hydroxide solution and stirring; and then performing filtering, washing, drying and vibratory screening so as to obtain pure alumium, pure copper and a diaphragm on a screen, recycling alumium and copper through smelting so as to obtain mixed powder under the screen, cleaning the mixed powder by using acidic solution, performing drying and thermal treatment, adjusting the mol ratio of lithium to iron to phosphorus to carbon, and then performing ball milling, drying and roasting, thereby obtaining a lithium iron phosphate anode material. The method for efficiently recycling the waste lithium iron phosphate batteries provided by the invention is simple in process, low in production cost and quick in taking effect.

Owner:HARBIN INST OF TECH

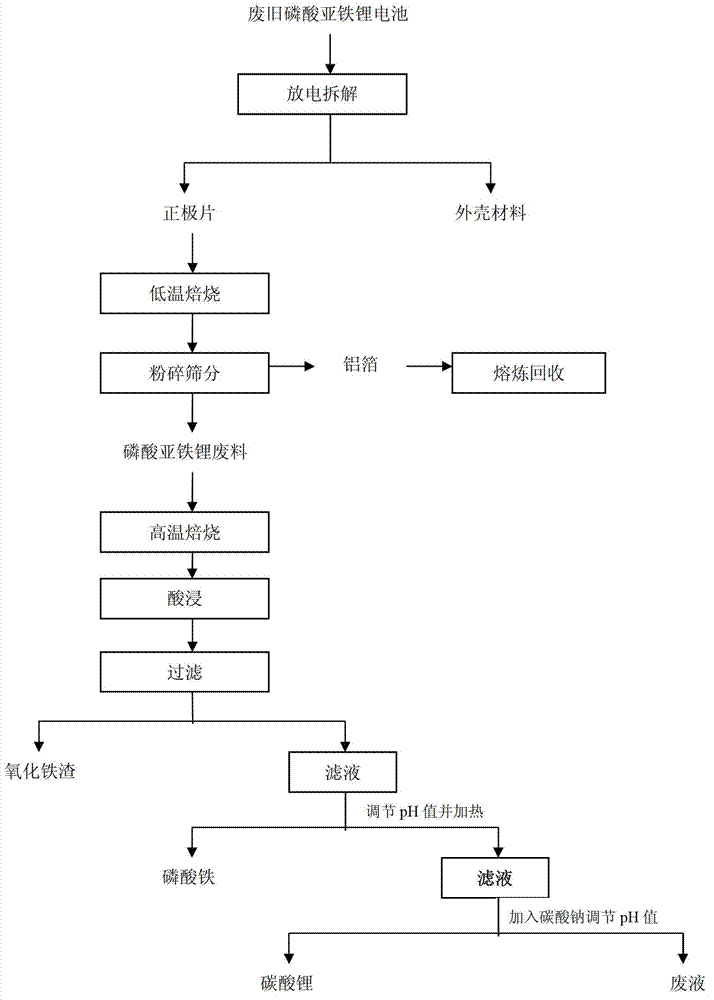

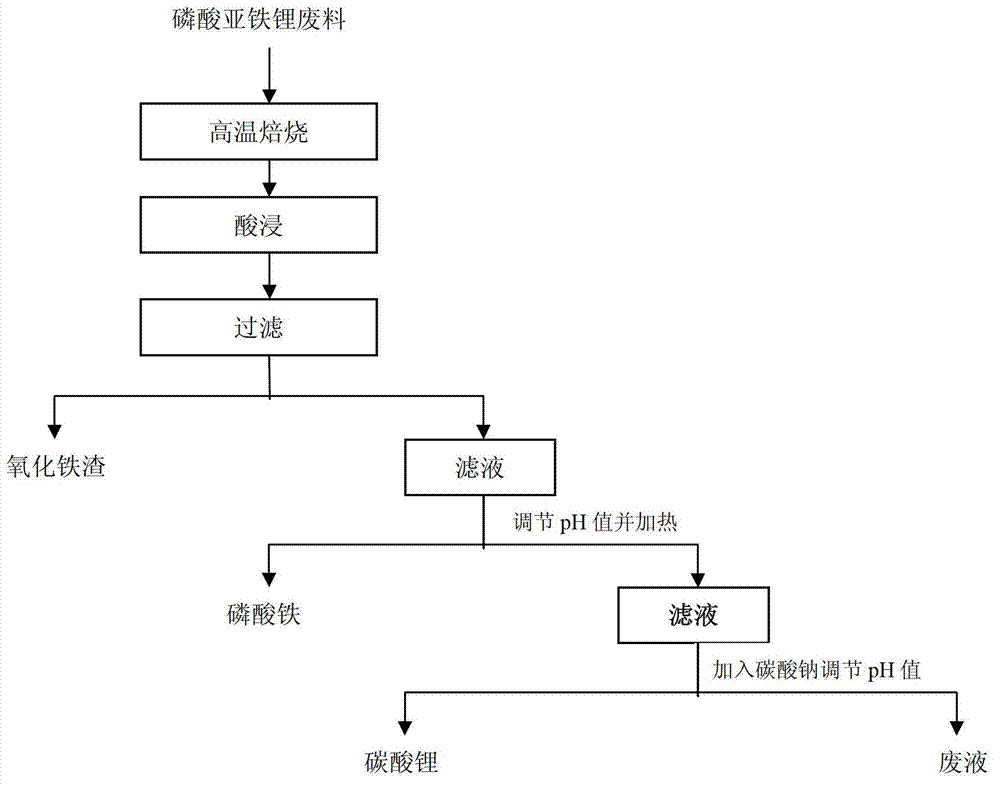

Method for recycling lithium carbonate from lithium iron phosphate waste material

ActiveCN102903985ASolve the problem of resource recyclingSolve your worriesWaste accumulators reclaimingBattery recyclingIron sulfateWaste material

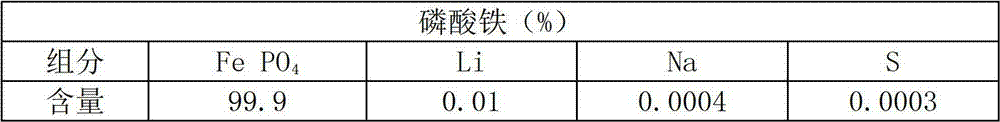

The invention relates to a method for recycling lithium carbonate from a lithium iron phosphate waste material, and belongs to the technical field of waste lithium oil battery recycling. The technical problem to be solved by the invention is that a method for recycling lithium carbonate from the lithium iron phosphate waste material is provided. The method provided by the invention comprises the following steps of: roasting the lithium iron phosphate waste material at 500-800 DEG C for 1-4 hours; adding sulfur into the roasted waste material and leaching, and filtering so as to obtain a mixed solution of lithium phosphate, iron phosphate and ferric sulfate; heating the mixed solution to 80-100 DEG C, and adjusting the pH value to 2-2.5, reacting for 1-4 hours, filtering, washing, and drying to obtain iron phosphate; adjusting the pH value of a filtrate obtained by filtering to be 6-7, adding calcium chloride and dephosphorizing, and filtering; and adjusting the pH value of the filtrate obtained by filtering to be 10-12 by sodium carbonate, reacting for 0.5-2 hours, filtering, washing, and drying so as to obtain battery grade lithium carbonate.

Owner:天齐锂业(江苏)有限公司 +2

Intelligent waste cellphone battery recycling device

InactiveCN103544772AAchieve outputSimple structureReturnable containers actuationLiquid-crystal displayElectrical battery

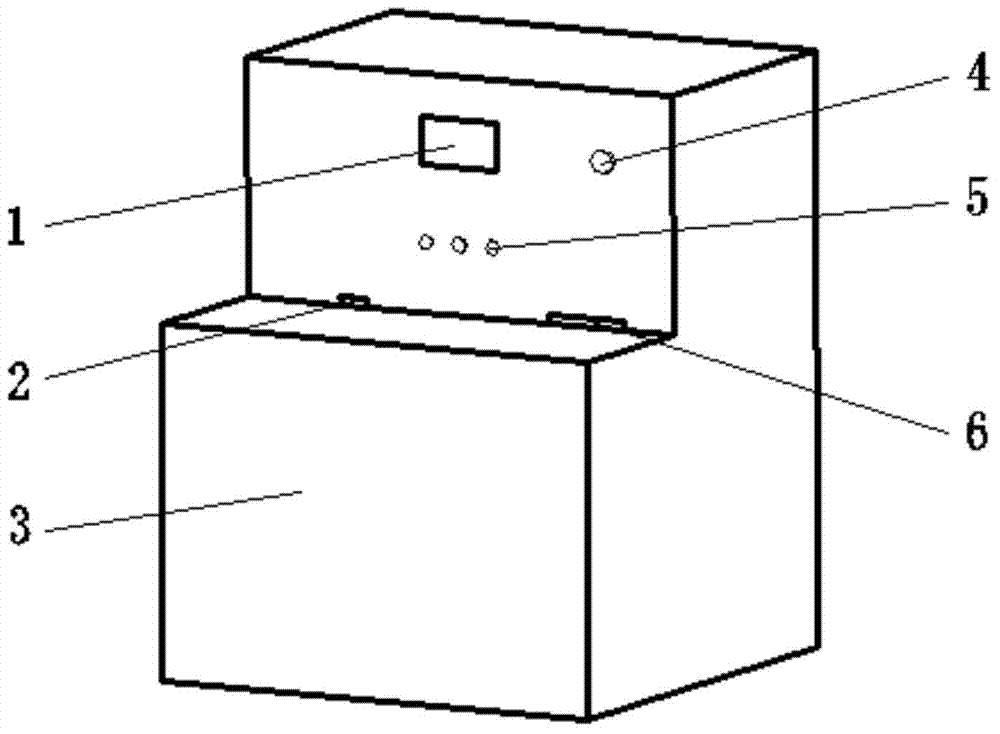

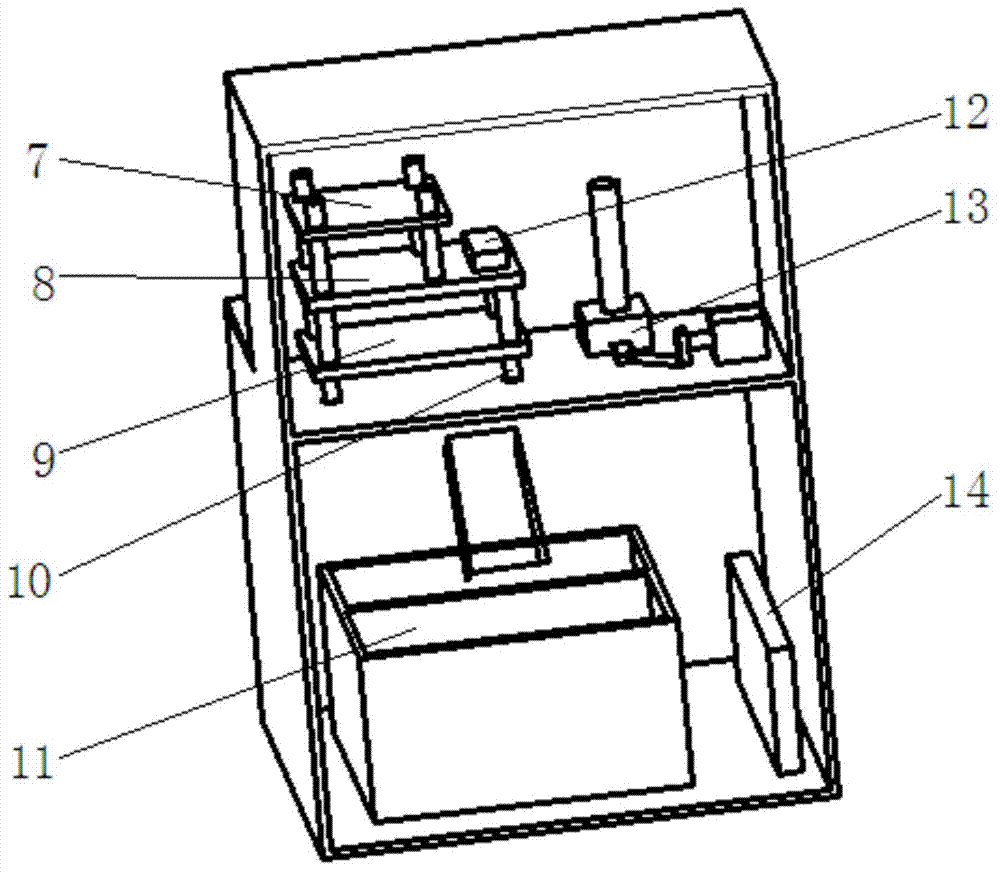

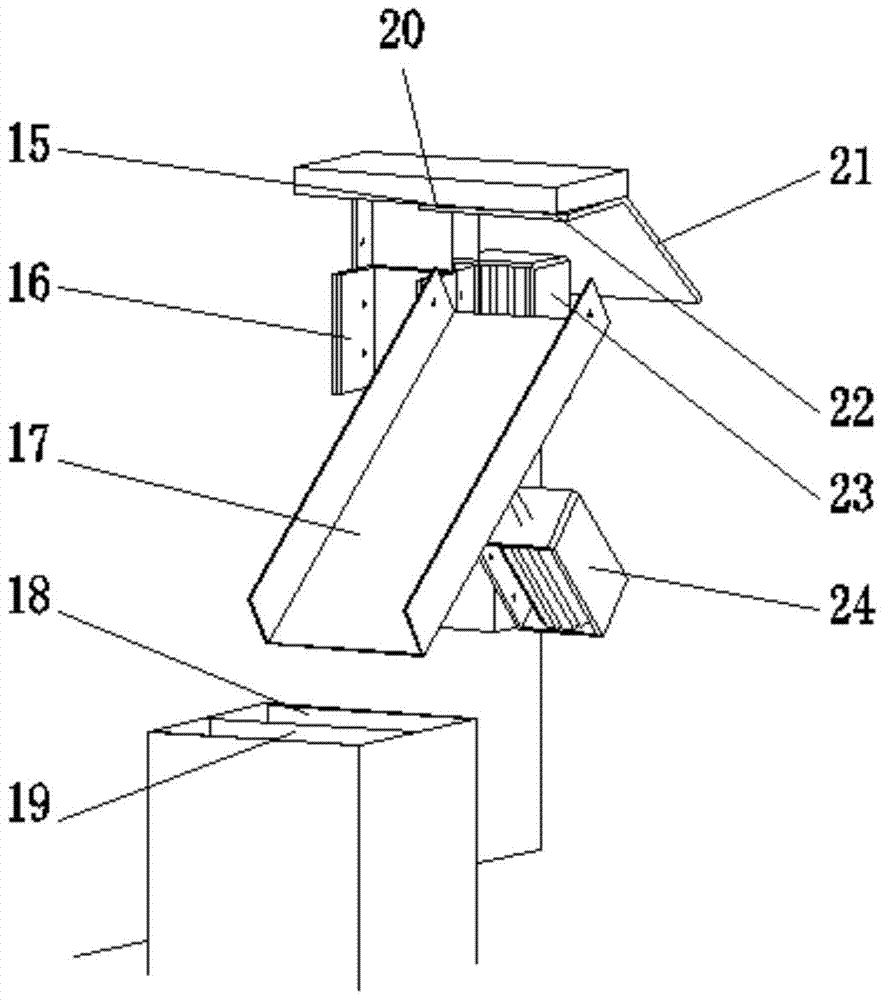

The invention provides an intelligent waste cellphone battery recycling device. The intelligent waste cellphone battery recycling device comprises a battery recycling box and a control system, a battery inlet is arranged on the right side of the middle of the front side of a box body, a coin outlet is arranged on the left side of the middle of the front side of the box body, a liquid crystal display is arranged on the upper side of the front side of the box body, a loudspeaker is arranged on the left side of the liquid crystal display, indicating lamps are arranged below the liquid crystal display, a battery collecting device is arranged on the lower side of the interior of the box body, a battery voltage detecting device is arranged between the battery inlet and the battery collecting device, and a coin output mechanism is arranged on the right side of the upper portion of the box body and connected with the coin outlet. By the battery collecting device, the coin output mechanism and a control system are integrated. Waste cellphone battery recycling is realized by means of incentive measures, the intelligent waste cellphone battery recycling device is simple in structure, high in practicability, intelligent and humanized, and a new idea for large-scale recycling of cellphone batteries is provided.

Owner:SHANDONG UNIV OF SCI & TECH

Carboxylic acid compound as well as preparation method and application thereof

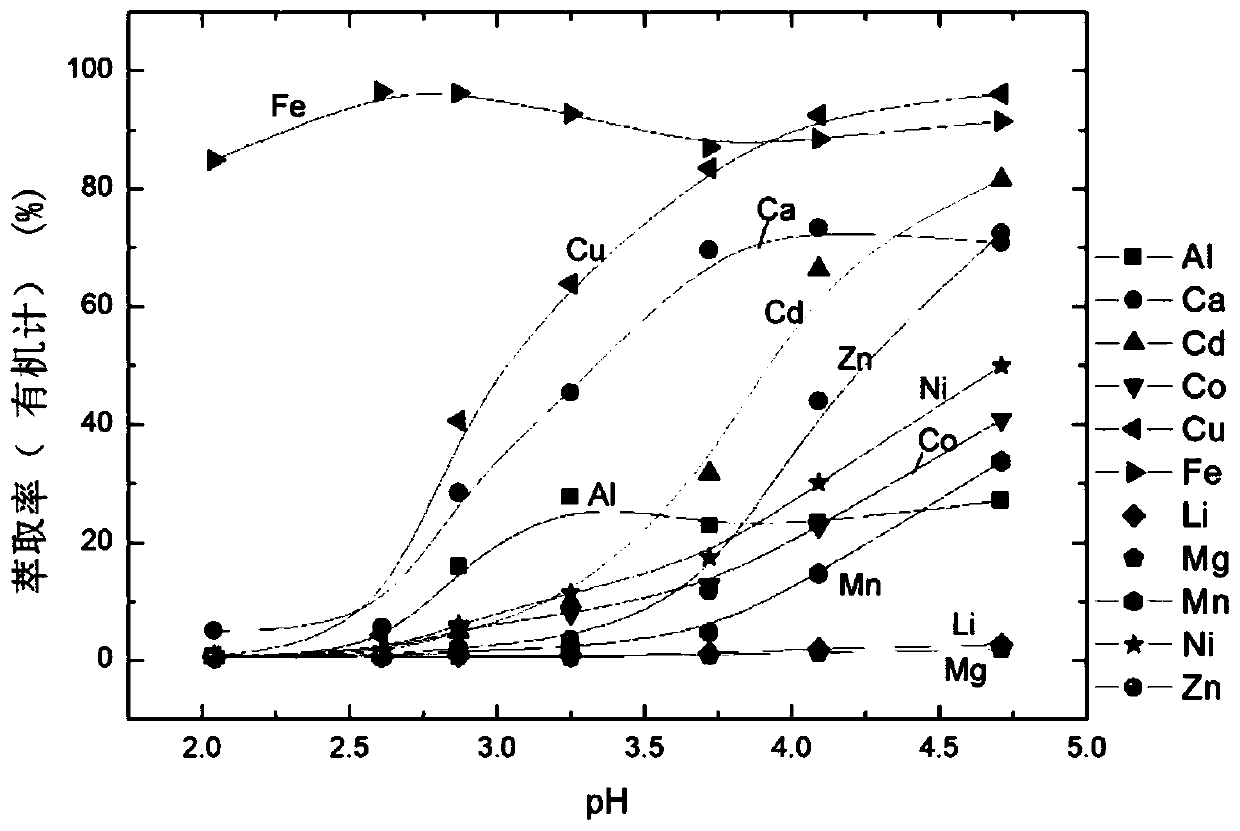

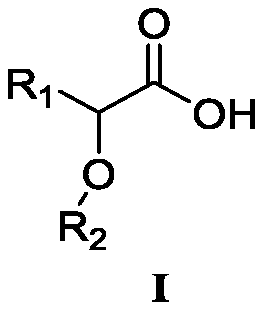

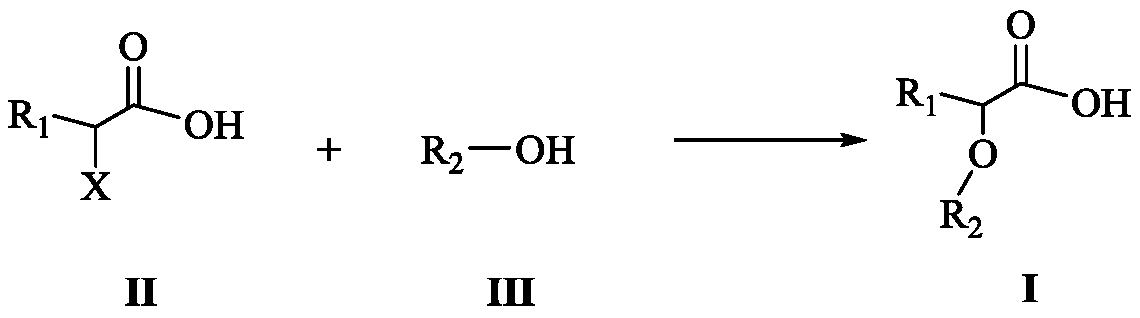

ActiveCN111592459AHigh separation factorHigh load rateOrganic compound preparationCarboxylic compound preparationCarboxylic acidAqueous solubility

The invention discloses a carboxylic acid compound as well as a preparation method and application thereof. When the carboxylic acid compound is applied to extraction separation of metal ions, the separation coefficient is high, the reverse extraction acidity is low, the load rate is high, and the reverse extraction rate is high. The carboxylic acid compound serving as an extraction agent is highin stability and low in water solubility, so that the extraction process is stable, the environmental pollution can be reduced, and the cost is reduced. The carboxylic acid compound disclosed by the invention is low in cost, has a great application prospect and can be used for various systems such as ternary battery recovery and battery-grade nickel sulfate preparation.

Owner:BOTREE CYCLING SCI & TECH CO LTD

Method for recovering valuable metals from waste lithium-ion power batteries

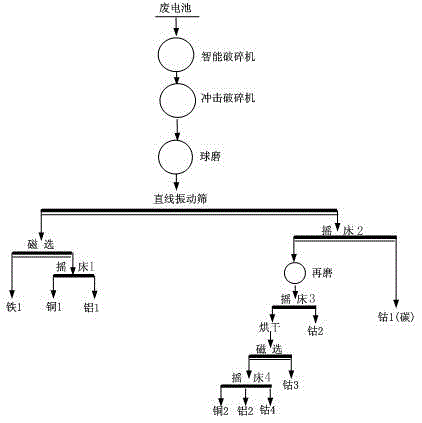

InactiveCN105671316ALow costReliable workmanshipWaste accumulators reclaimingProcess efficiency improvementCrusherBall mill

The invention discloses a method for recovering valuable metals from waste lithium-ion power batteries and belongs to the field of recovery of the valuable metals. According to the method, discharging and calcination are performed in advance, a low-intelligent crusher and an impact crusher are adopted for secondary crushing, then crushed products enter a ball mill for scrubbing, screening and classification are performed by the aid of a vibrating screen, oversize products and undersize products are separated through beneficiation methods of magnetic separation, tables, regrinding and the like, and four products including iron, copper, aluminum and lithium cobalt oxide powder containingcarbon are obtained. The method has the advantages of environmental protection, low cost, reliable technology, easiness in industrial production and the like.

Owner:JIANGXI UNIV OF SCI & TECH

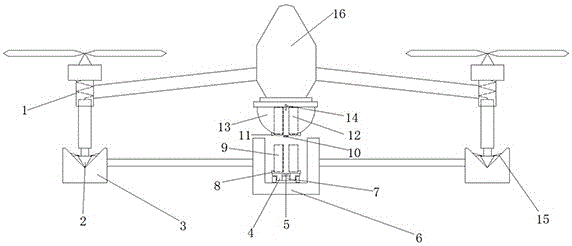

Automatic power source replacement system of unmanned aerial vehicle

InactiveCN106081163AStrong battery lifePrecise positioningFinal product manufactureVehicular energy storageElectrical batteryUncrewed vehicle

The invention discloses an automatic power source replacement system of an unmanned aerial vehicle. The automatic power source replacement system of the unmanned aerial vehicle comprises a machine body and a battery, and further comprises supporting legs installed at the two ends of the machine body, and a battery bin installed at the bottom of the machine body. An infrared sensor is arranged in the battery bin. A battery bin cover is arranged at the bottom of the battery bin and connected with an electromagnetic bin through an electromagnet. The battery is installed in the closed space defined by the battery bin and the battery bin cover. The automatic power source replacement system of the unmanned aerial vehicle further comprises supporting leg rails and a main rail. A battery cart is arranged on the main rail and provided with a battery recycling tank and a lifting device. A bin cover for replacement is placed on the lifting device. Batteries for replacement are arranged on the bin cover for replacement. The supporting leg rails and the main rail are connected with a battery station. The automatic power source replacement system of the unmanned aerial vehicle has the advantages that a power source can be replaced, and the cruising capacity of the unmanned aerial vehicle is high; by means of various assistant positioning devices, positioning is accurate, and the success rate of positioning is high; and the automatic power source replacement system is provided with the independent battery station, thereby being basically free of manual maintenance when arranged in the field.

Owner:成都翼高九天科技有限公司

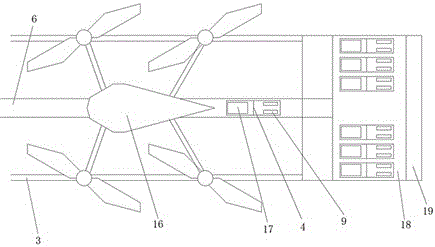

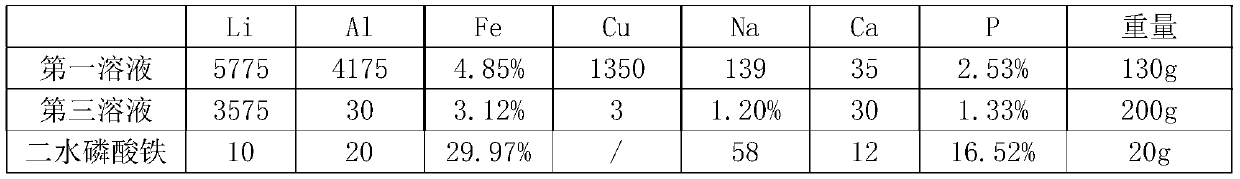

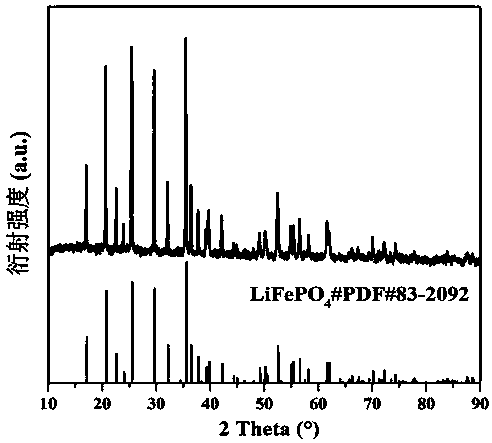

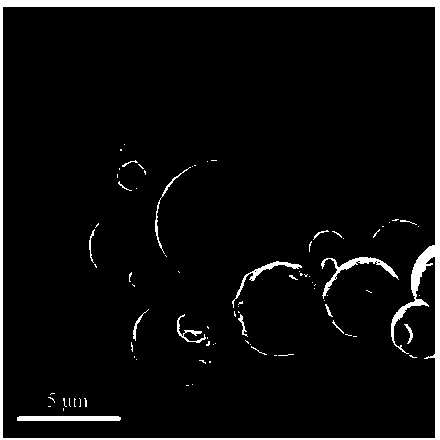

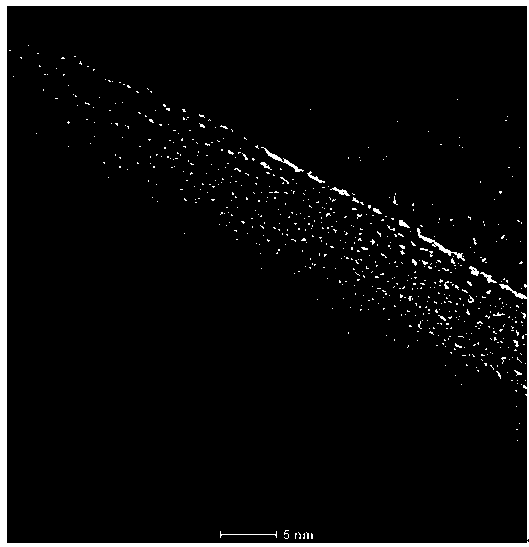

Method for preparing lithium iron phosphate positive electrode material from waste lithium iron phosphate battery

ActiveCN111009660AImprove performanceHigh purityPositive electrodesWaste accumulators reclaimingLithium iron phosphateEnvironmental engineering

The invention belongs to the field of lithium iron phosphate waste battery recovery, and particularly relates to a method for preparing a lithium iron phosphate positive electrode material from a waste lithium iron phosphate battery. The specific production steps are as follows: acid leaching, copper removal, aluminum removal, preparation of iron phosphate dihydrate, lithium precipitation and preparation of lithium iron phosphate. The method is simple in process, easy to operate and free of pollution, useful resources in the waste batteries are utilized to the maximum extent, and the product utilization rate is high; impurities such as aluminum, copper and calcium in the powder can be removed at low cost, various waste lithium iron phosphate batteries can be recycled, the application rangeis wide, and industrial large-scale production can be achieved conveniently; the recovered iron phosphate dihydrate and lithium phosphate are high in purity, the recovery rate of iron and phosphorusin the waste is greater than 95%, and the recovery rate of lithium is greater than 90%; all components of the waste lithium iron phosphate battery material are recycled, the prepared lithium iron phosphate is good in performance, and resource recycling is truly achieved.

Owner:宁夏百川新材料有限公司

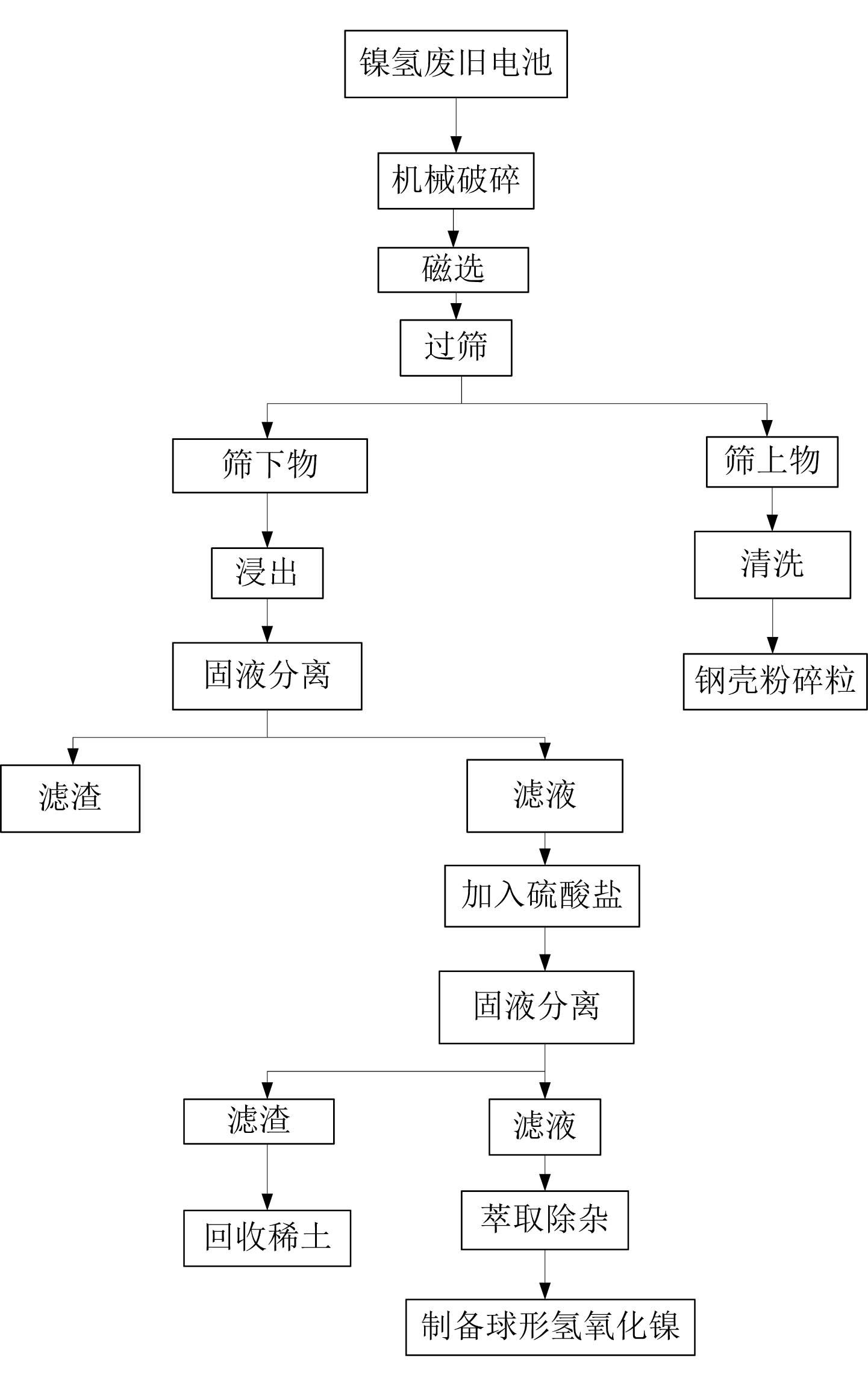

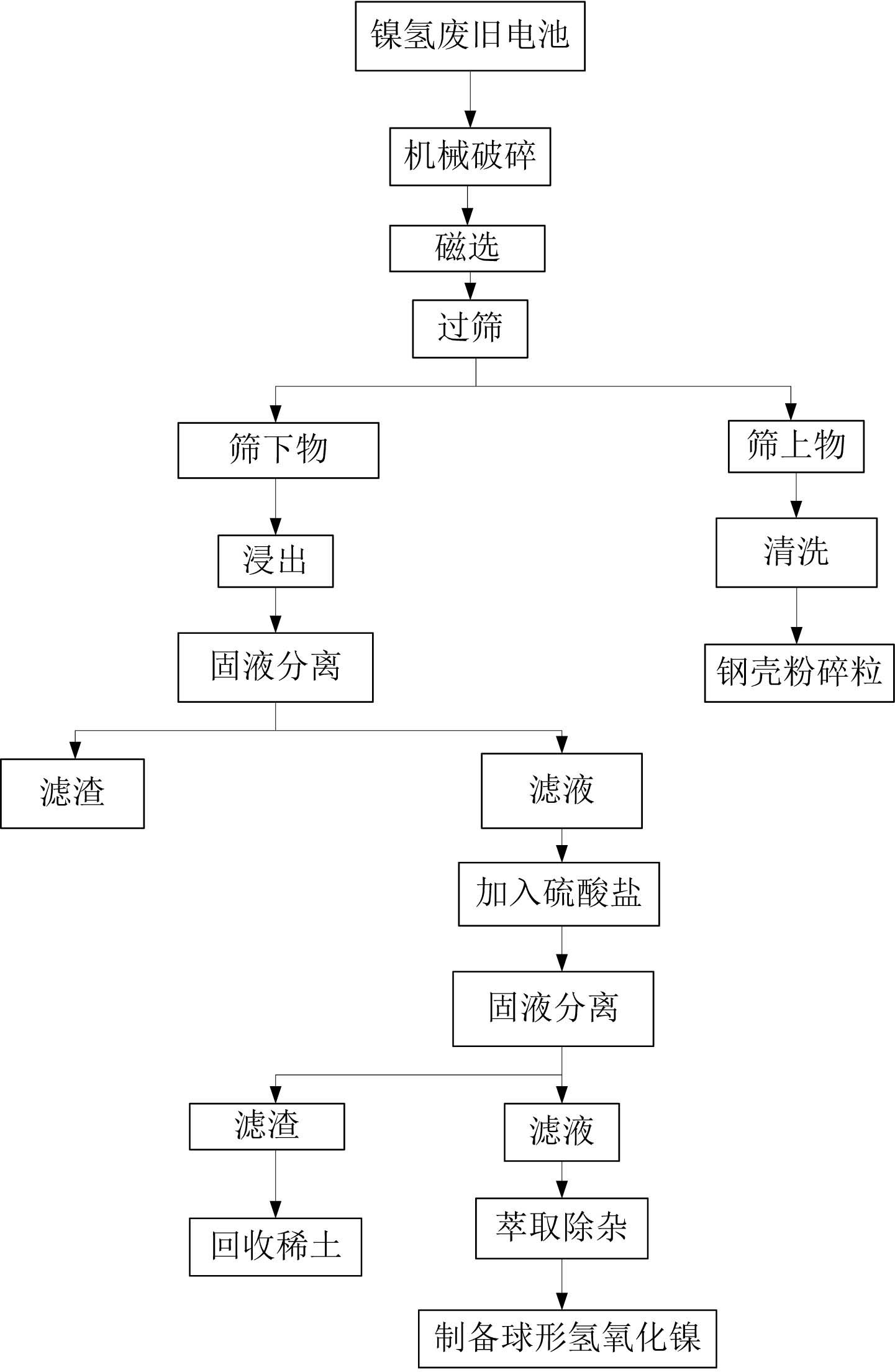

Comprehensive recovery method for nickel-hydrogen waste battery

ActiveCN101886178AEfficient recyclingReduce consumptionProcess efficiency improvementRecovery methodRare-earth element

The invention discloses a comprehensive recovery method for a nickel-hydrogen waste battery. The method comprises the following steps of: crushing the nickel-hydrogen waste battery and sieving the crushed battery by magnetic separation; preparing leaching solution which contains sulfuric acid and oxidant; throwing undersize powder into the leaching solution, increasing the temperature to 50 to 100 DEG C and leaching the mixture for 1 to 3 hours; performing solid-liquid separation, adjusting the pH value of filtrate to be 2 to 5 and adding water soluble sulfate to precipitate rare earth elements therein; and performing the solid-liquid separation and adding an extraction agent into the filtrate to remove impurities to obtain nickel and cobalt-containing sulfate solution. The comprehensive recovery method for the nickel-hydrogen waste battery can effectively recover various valuable metal elements in various nickel-hydrogen batteries. The extracted and purified nickel and cobalt-containing sulfate solution can be directly applied to the production of positive material spherical nickel hydroxide of the nickel-hydrogen battery. The recovery method has the advantages of low energy consumption in the recovery process, short route and good recovery benefit.

Owner:JIANGMEN CHANCSUN UMICORE IND

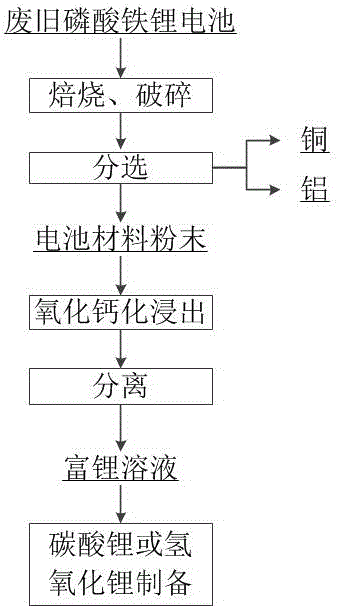

Method for recovering lithium in waste and old lithium iron phosphate batteries

ActiveCN106848472AHigh purityImprove recycling efficiencyWaste accumulators reclaimingBattery recyclingWater insolubleLithium hydroxide

The invention provides a method for efficiently recovering lithium in waste and old lithium iron phosphate batteries. The method comprises that waste and old lithium iron phosphate batteries are roasted and sorted to form lithium-containing positive pole powder, lithium-containing positive pole powder and a calcium-containing alkaline solution undergo a reaction under conditions of oxidation so that iron and phosphate radical are converted into a water-insoluble compound and lithium is converted into water soluble lithium hydroxide, and the reaction products are filtered so that a lithium hydroxide solution is obtained and can be used for further preparation of lithium hydroxide or lithium carbonate products. The method replaces the conventional wet acid leaching method in waste and old lithium iron phosphate battery recovery and is free of a strong acid so that production of a large amount of high-salt waste water is avoided. The method realizes selective leaching of lithium, prevents iron impurities from entering the leaching liquid from the source, can produce a high-purity lithium product, has simple processes, utilizes chemical agents having wide sources, has simple process conditions, can prepare a high-purity lithium product through a one-step method, greatly improves recovery efficiency of waste and old lithium iron phosphate batteries and has a good industrial application prospect.

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

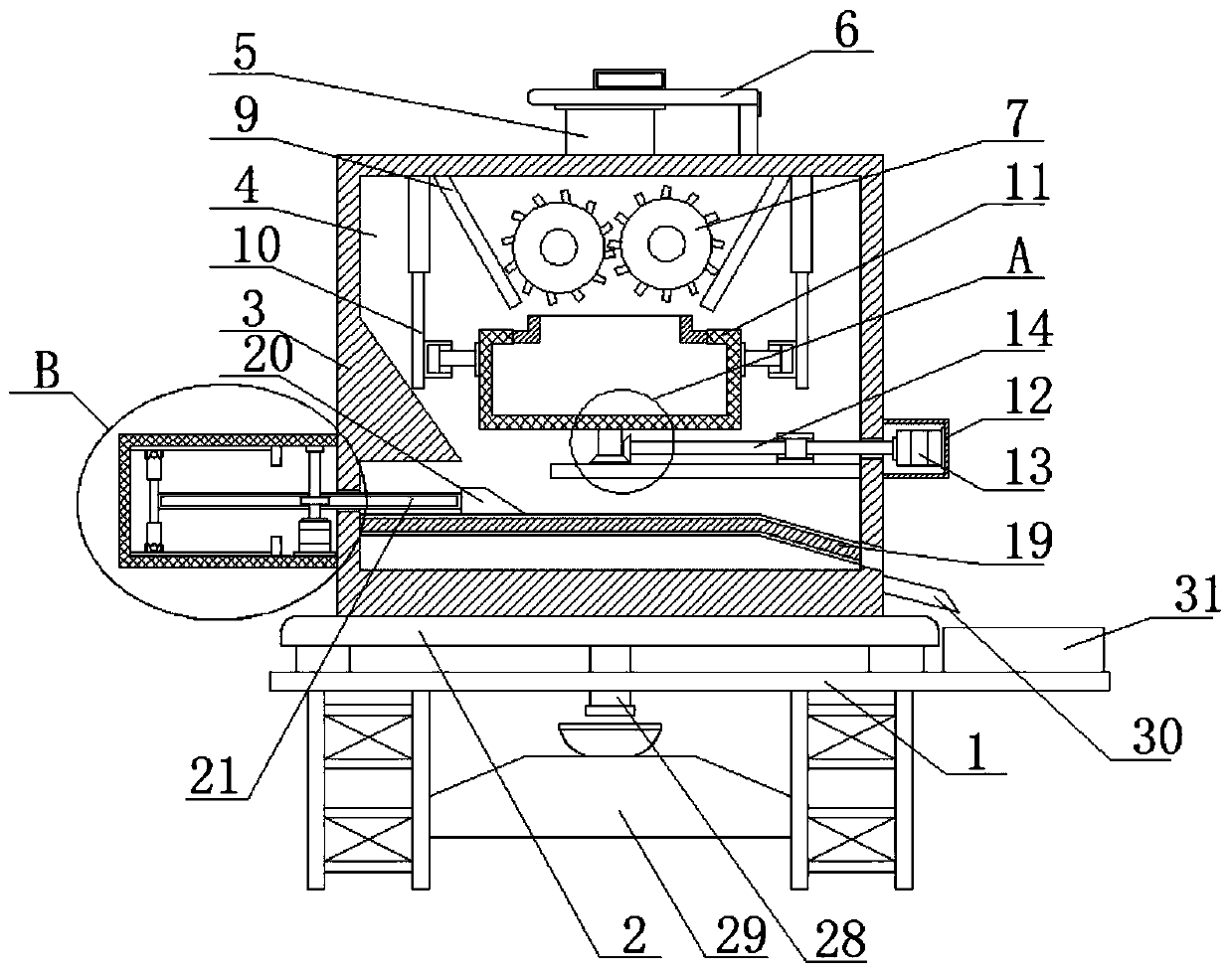

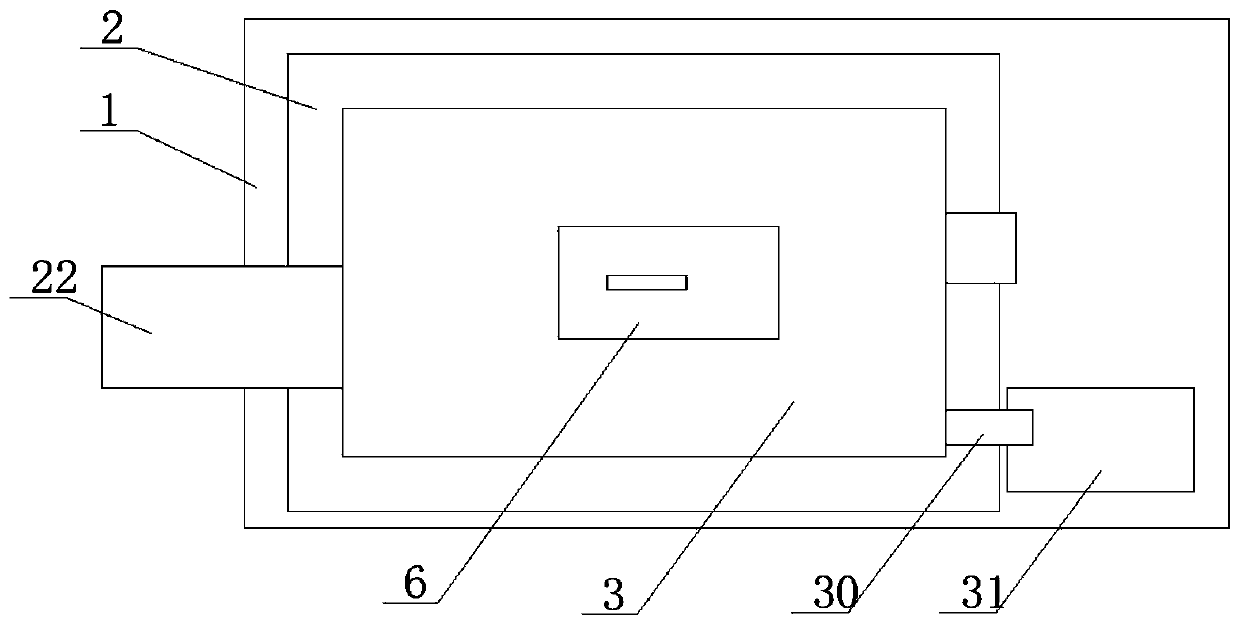

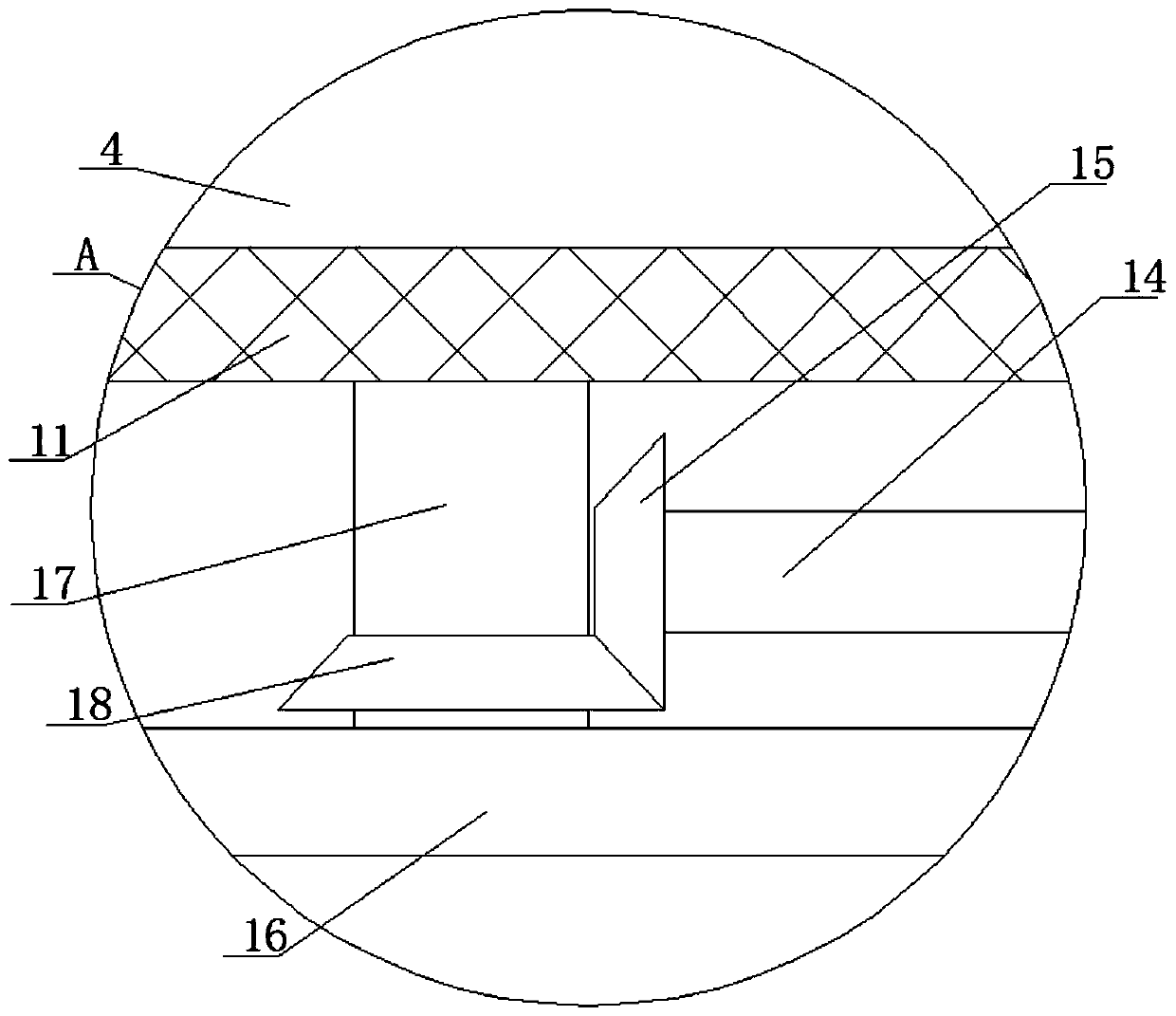

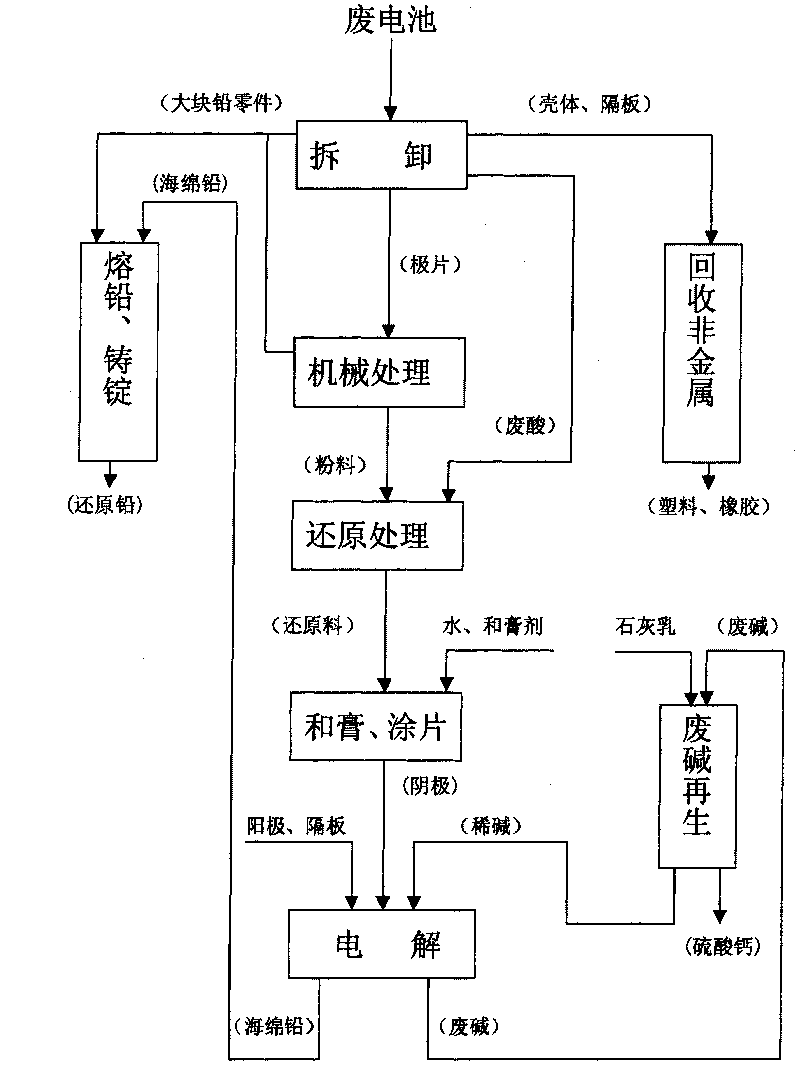

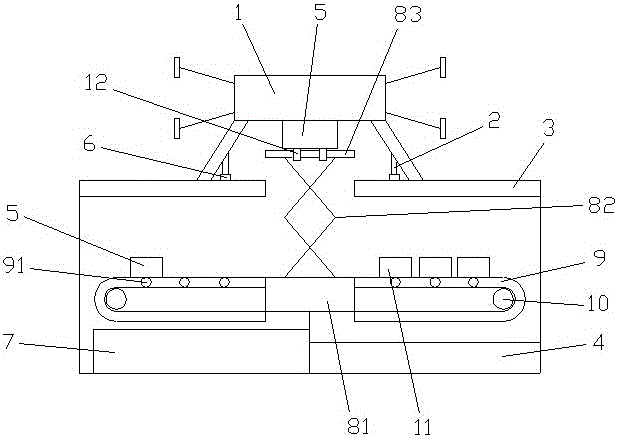

Recycling device of waste lead-acid storage battery and technological process thereof

InactiveCN110180638AReduce processing timeImprove recycling efficiencyWaste accumulators reclaimingGrain treatmentsScreening proceduresDrive motor

The invention belongs to the technical field of waste lead-acid storage battery recycling and discloses a recycling device of a waste lead-acid storage battery and a technological process of the recycling device of the waste lead-acid storage battery. The recycling device of the waste lead-acid storage battery aims to solve the problem that in the prior art, a battery crushing procedure and a screening procedure are separated, so that treatment time is long, and then the recycling efficiency of the waste battery is influenced. The recycling device comprises an installation frame. The top of the installation frame is fixedly provided with a fixing seat, and the top of the fixing base is fixedly provided with a recycling seat. The recycling seat is provided with a recycling cavity, and thetop of the recycling seat is fixedly connected with a feeding pipe. The feeding pipe communicates with the recycling cavity. Two driving motors are symmetrically and fixedly mounted on the inner wallof one side of the recycling cavity, and crushing shafts are fixedly connected to output shafts of the driving motors. The structure of the recycling device is simple, and the recycling device body integrates crushing, screening and collecting of the waste battery, so that the processing time of the waste battery is shortened, and the recycling efficiency of the waste battery is effectively improved.

Owner:安吉绿金金属材料有限公司

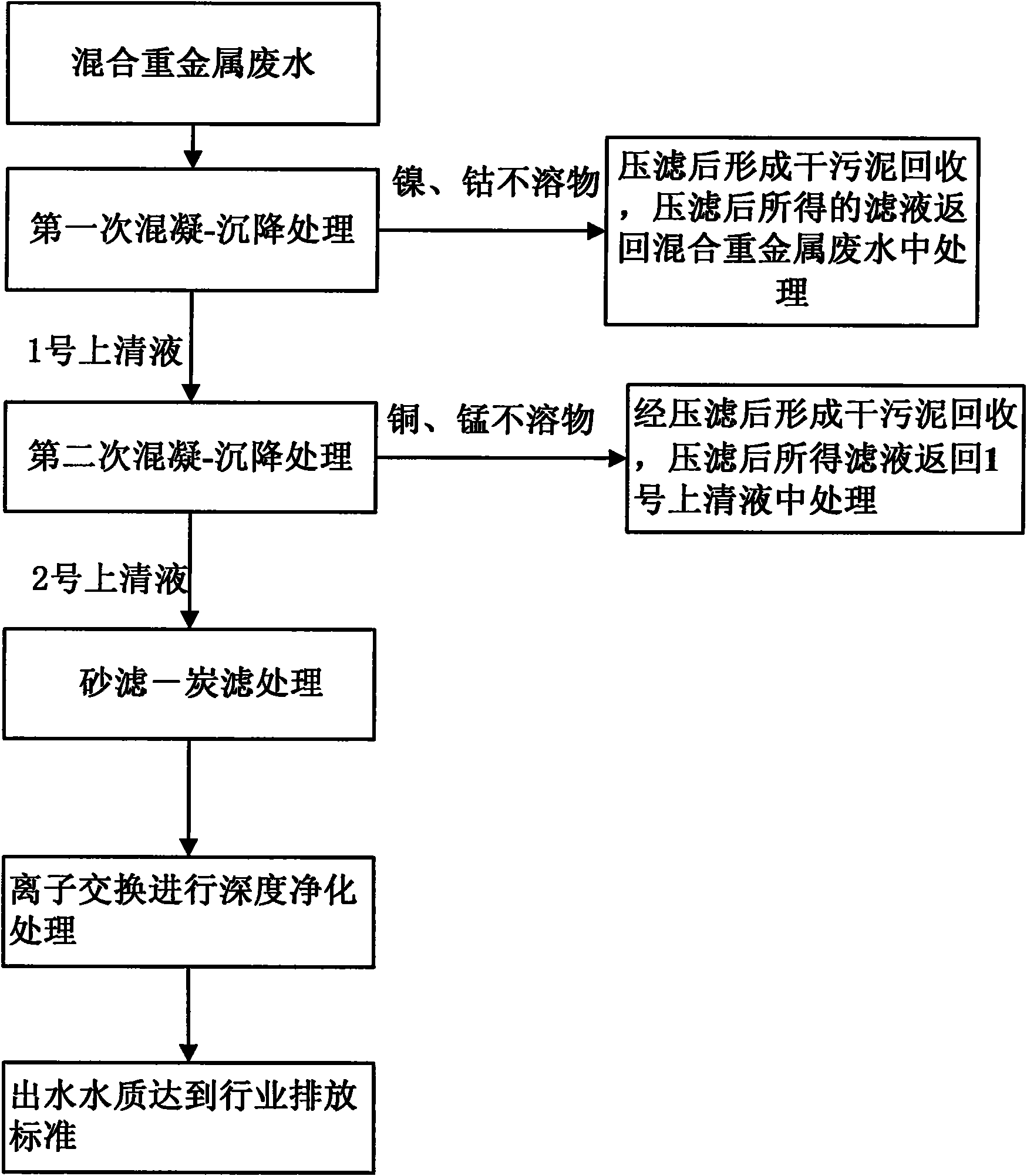

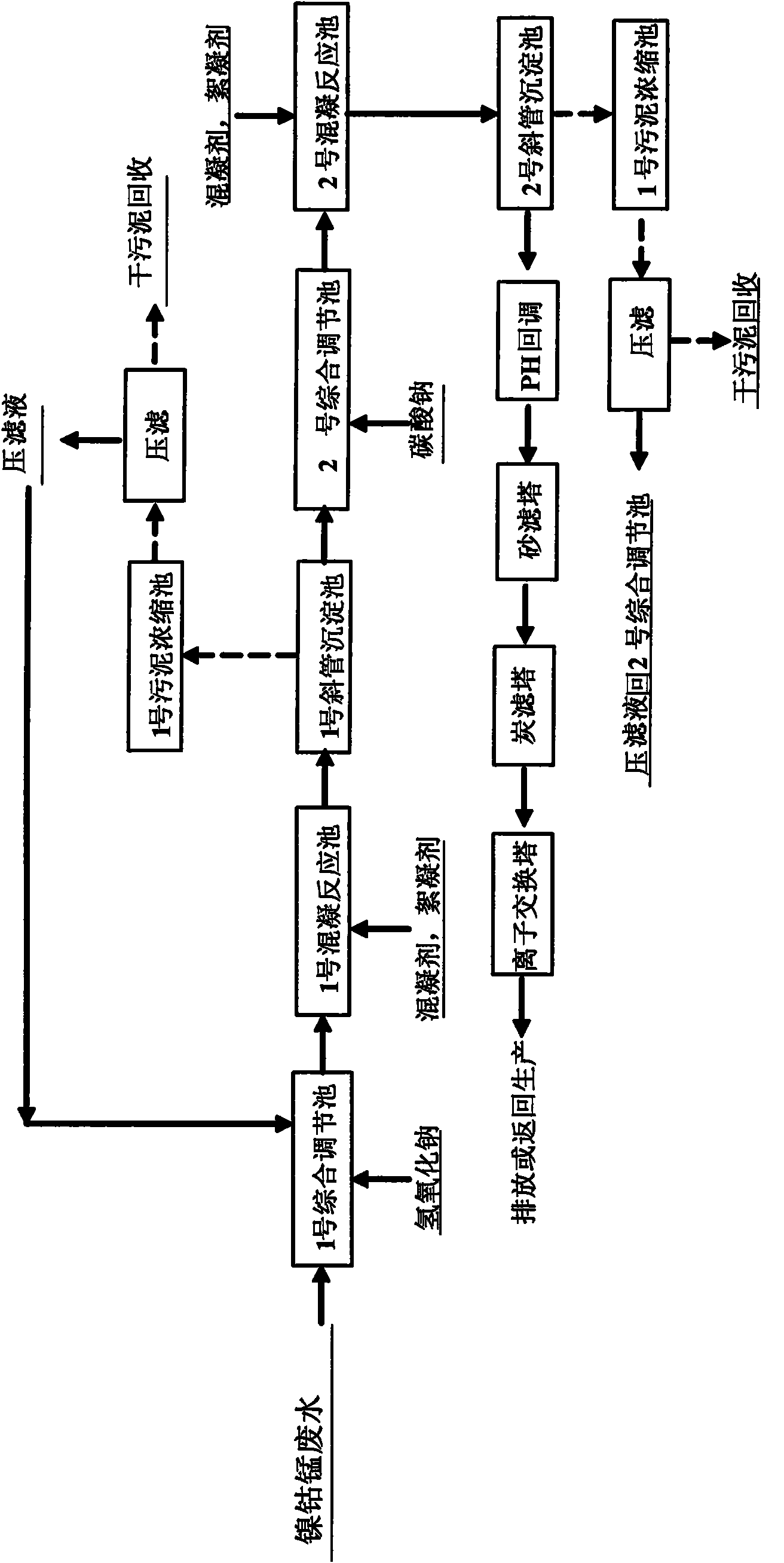

Treatment method of nickel-cobalt-manganese wastewater generated in waste and old battery treatment process

ActiveCN101628761AShort processHigh recovery rateSludge treatment by de-watering/drying/thickeningWater contaminantsFiltrationManganese

The invention discloses a treatment method of nickel-cobalt-manganese wastewater generated in waste and old battery treatment process and the wastewater mainly contains metal ions such as ions of nickel, cobalt, manganese, copper and the like and little organic matter which is insoluble in water. The invention is mainly characterized in that first the wastewater is treated by stepwise coagulation-sedimentation treatment, then sand filtration-carbon filtration-ion-exchange deep purification treatment is performed, the effluent quality reaches the first-class standard of National Discharge Standards and also corresponds to the demand of industrial production water and the effluent can be reused in production for recycling. The invention facilitates the reuse of nickel-cobalt-manganese wastewater, is characterized by low cost, high metal recovery, large treating capacity, reasonable process flow, simple operation, stable operation, easy execution in industry and the like and is an effective way for the treatment of nickel-cobalt-manganese wastewater generated in waste and old battery recovery process.

Owner:HUNAN BRUNP RECYCLING TECH

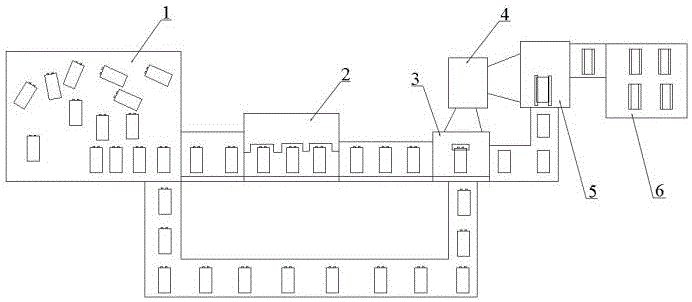

Controllable discharging and safe and automatic disassembling device for waste hard-housing power lithium-ion battery

The invention relates to a Controllable discharging and safe and automatic disassembling device for a waste hard-housing power lithium-ion battery. The device comprises 1, a charging device, 2, a controllable discharging device, 3, an end cover cutting device, 4, a partial atmosphere protecting device, 5, a housing cutting device, and 6, a core removing device. The device is clear in structure, high in disassembling efficiency, safe and controllable in disassembling process; the device is applicable to the field of recovery of the waste hard-housing power lithium-ion batteries.

Owner:天津赛德美新能源科技有限公司

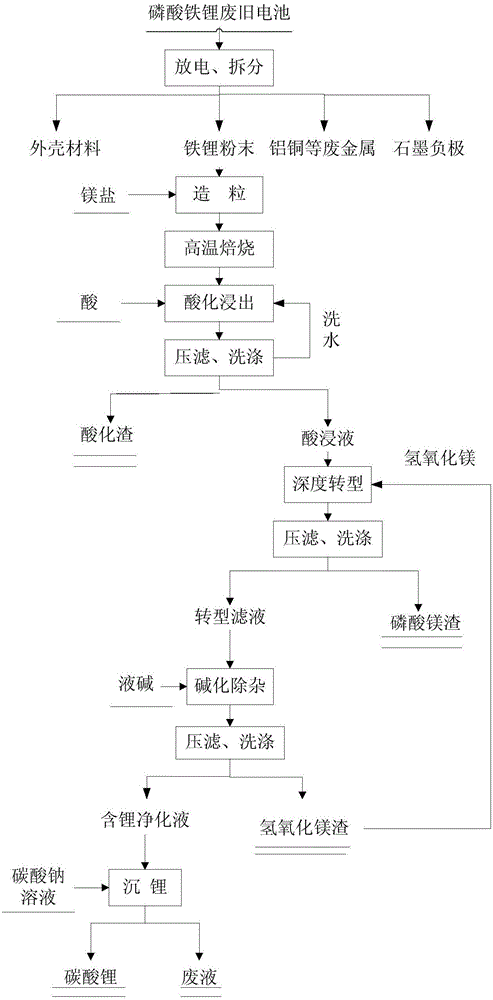

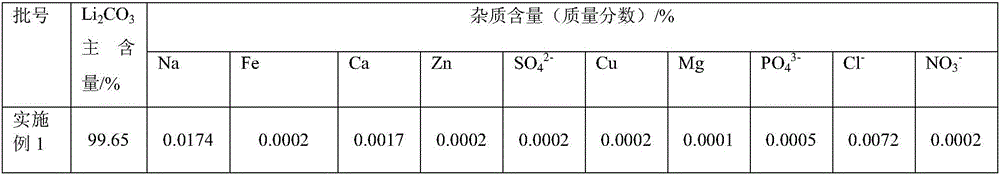

Method for preparing battery grade lithium carbonate by recovering lithium from lithium iron phosphate waste battery

ActiveCN106785166AHigh recovery rateLarge particle sizeWaste accumulators reclaimingLithium carbonates/bicarbonatesLithium iron phosphateLithium carbonate

The invention relates to a method for preparing battery grade lithium carbonate by recovering lithium from a lithium iron phosphate waste battery. The lithium iron phosphate waste battery is taken as a raw material to prepare the battery grade lithium carbonate. The method comprises the following steps: (1) carrying out battery disassembling; (2) carrying out disk granulation; (3) carrying out high-temperature roasting; (4) carrying out acidification leaching; (5) carrying out deep transition; (6) carrying out alkalization edulcoration; (7) carrying out lithium deposition by sodium carbonate. The method has the beneficial effects that the method for preparing the battery grade lithium carbonate by recovering the lithium from the lithium iron phosphate waste battery has the advantages of high recovery rate, environment friendliness, high product purity and the like, the main content of a product exceeds 99.5%, and meets battery grade product requirements, and the method has the characteristics of simple technology and low production cost and is suitable for industrial production.

Owner:GANFENG LITHIUM CO LTD

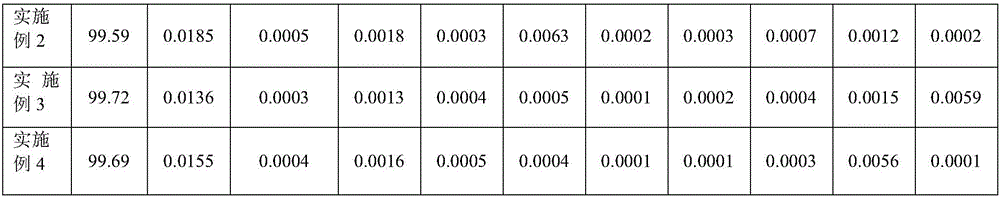

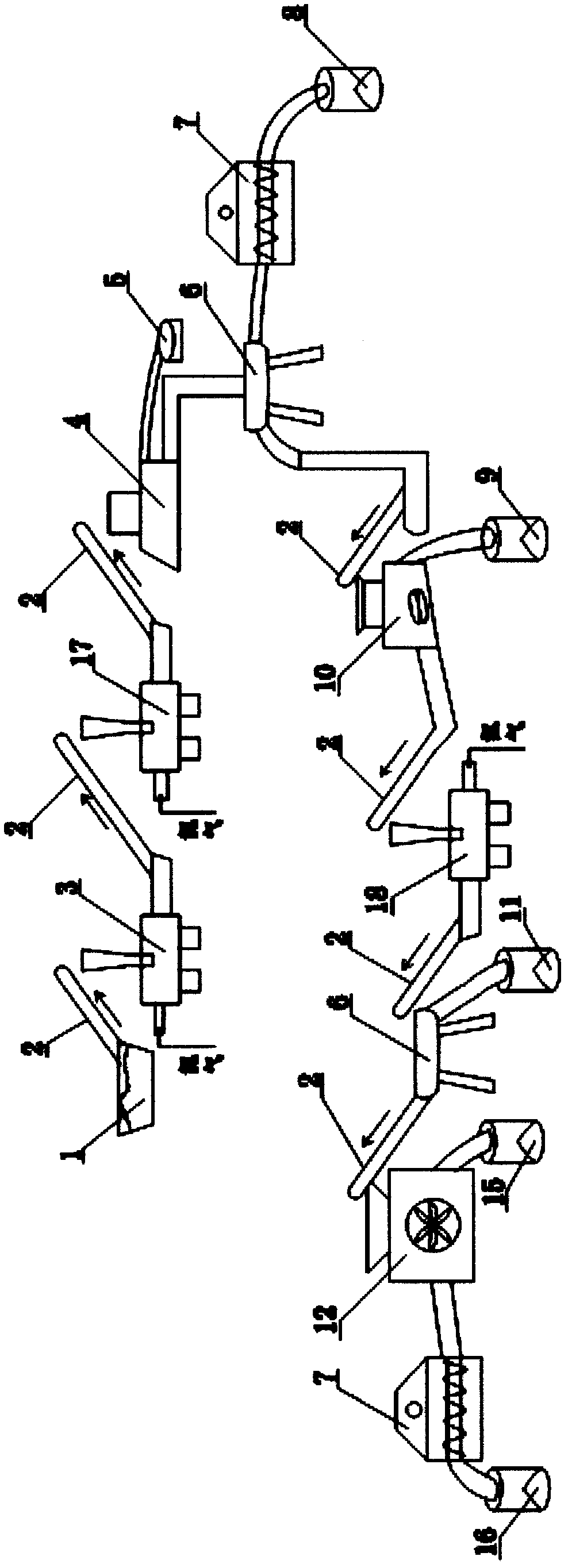

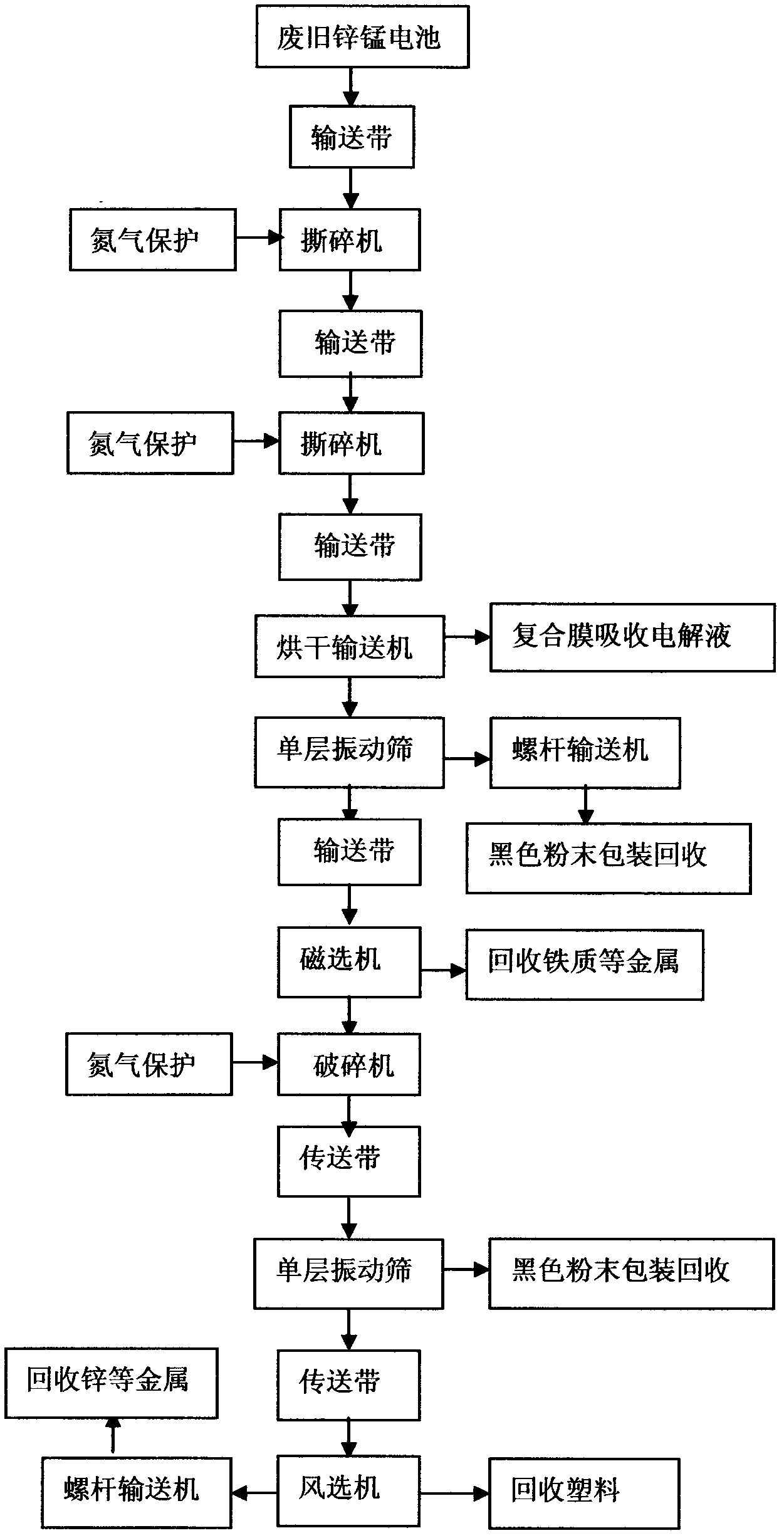

Method for industrializedly recovering zinc and manganese in waste dry cells

ActiveCN102509807AWill not cause secondary pollutionSimple processSolid waste disposalReclaiming serviceable partsThree levelManganese

The invention discloses a method for industrializedly recovering zinc and manganese in waste dry cells. The method comprises the following steps of: primarily shredding cells and secondarily shredding the cells; drying, screening and recovering partial black carbon powder, and recovering irony metal by magnetic separation; carrying out three-level crushing on broken fragments of the cells; and screening and recovering rest black powder, and winnowing to separate metal powder such as plastics and zinc. The method is a mechanical processing method, so that the waste cell recovery process cannot result in three wastes and secondary pollution and is operated in a full-automatic assembly line manner, the method is simple in process and low in production cost, is used for adsorbing and recovering through a self-made film and favorable for solving the problems that mercury easily volatilizes and is difficult to control and the like, and ensures high recovery rate of various valuable constituents.

Owner:深圳市泰力废旧电池回收技术有限公司

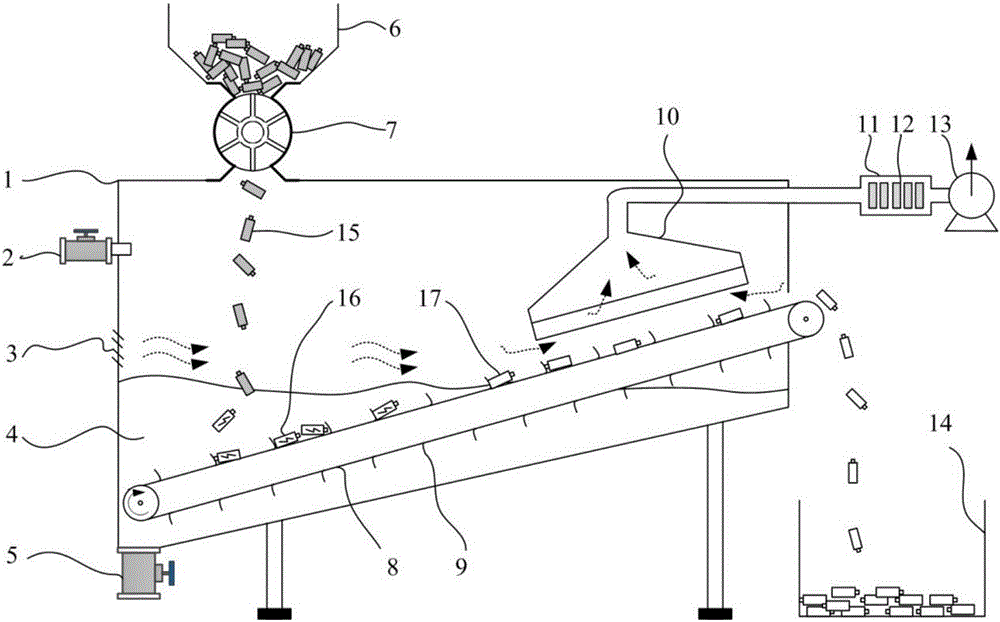

Semi-sealed discharging device for batched recovery of waste and used lithium ion batteries

InactiveCN106229571ALow costNo pollution in the processWaste accumulators reclaimingSecondary cells charging/dischargingSulfateManganese

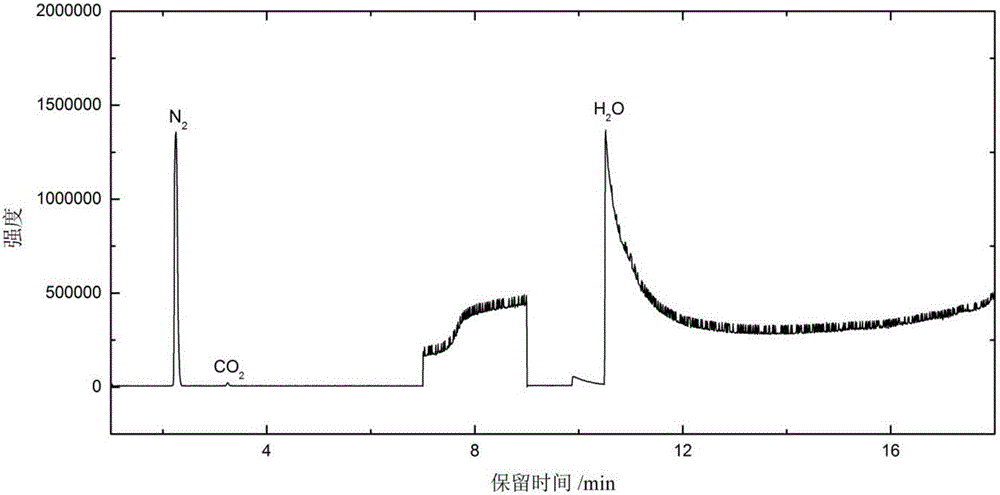

A semi-sealed discharging device for batched recovery of waste and used lithium ion batteries includes: a semi-sealed discharging container filled with a discharging solution, a battery feeding apparatus, a discharge transmission apparatus, a tail gas treatment apparatus, and a battery recovery groove. The lithium ion batteries are fed into a battery storage bin, and then enter the discharging container through a star-shaped material adding device. The batteries then fall into the discharging solution, of which the molar ratio of ferrous sulfate to manganese sulfate is 2:1, to start discharge; after discharging for 14 h, the batteries are floated to the liquid level of the solution along with a conveyor belt and enter a drainage zone; in the draining zone, the solution on the surfaces of the batteries flows away from the holes in the conveyor belt, air generated from an air collecting cover accelerating the draining process; the drained batteries then move to the end of the conveyor belt and fall into the battery recovery groove, wherein the air in the container flows into and is collected in the air collecting cover through an air inlet, so that potential volatile gas are adsorbed through an adsorption chamber and the air is discharged by means of a centrifugal fan. The device is easy to use, is safe and high-effective, is low in cost and is green and environment-friendly.

Owner:SHANGHAI JIAO TONG UNIV

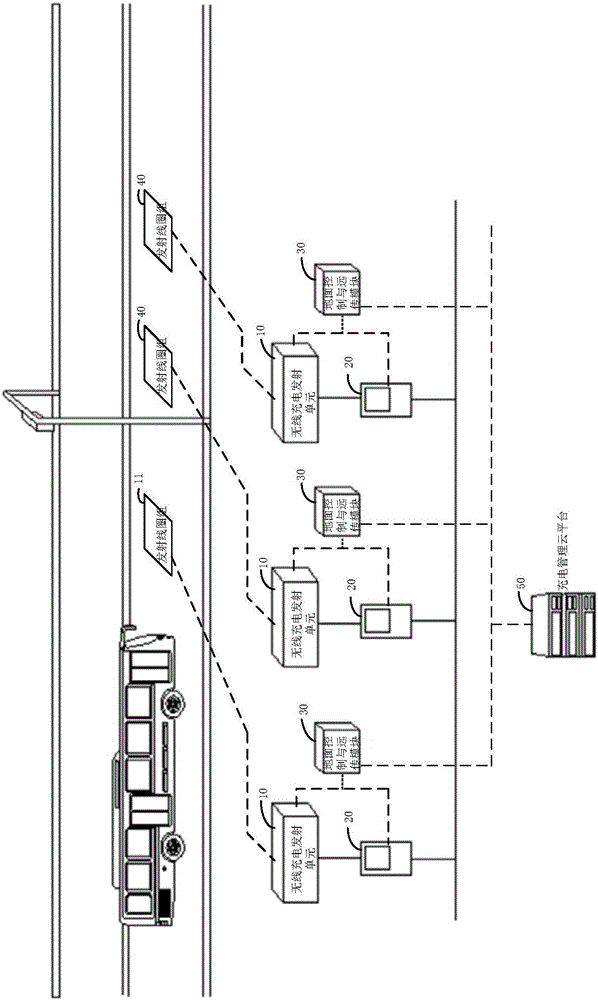

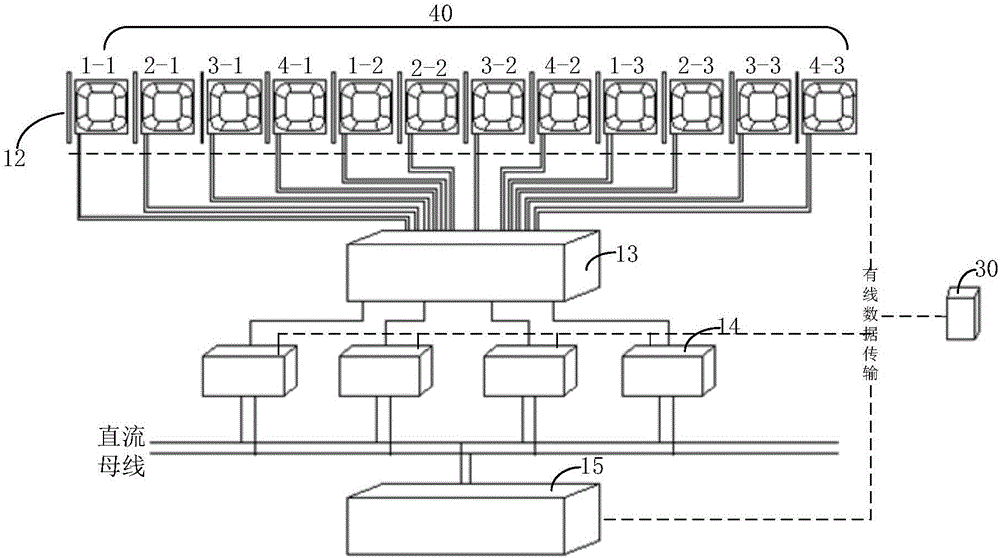

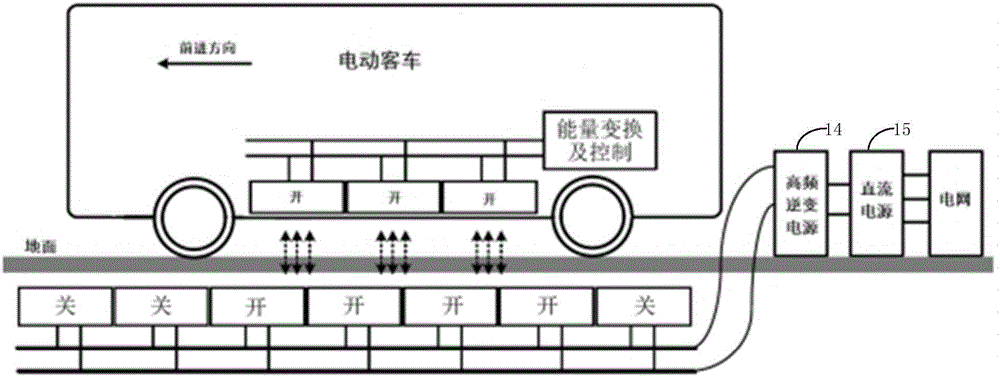

Dynamic induction wireless charging system and charging system for vehicle

ActiveCN107176045AAvoid waitingReduce weightData processing applicationsCharging stationsOn boardControl system

The invention provides a dynamic induction wireless charging system and charging system for a vehicle. Either of the dynamic induction wireless charging system and the charging system for a vehicle comprises a position sensor for detecting the wheel position information of the vehicle, a coil switching control system for controlling the state of corresponding transmitting coils in a transmitting coil group according to the wheel position information, a power supply cabinet for supplying electric power according to the state of the corresponding transmitting coils in the transmitting coil group and charging the vehicle, and AC side electric quantity for calculating the AC side electric quantity generated by the vehicle passing through each wireless charging area and sending the AC side electric quantity generated by each wireless charging area to a charging management cloud platform through ground control and a remote transmission module, wherein the charging management cloud platform is used for obtaining the total AC side electric quantity according to the AC side electric quantity generated by each wireless charging area, so that the problem that a vehicle needs to wait during the charging process can be solved, endurance can be achieved without an on-board battery, the weight of the vehicle is reduced and secondary pollution caused by battery recycling is avoided.

Owner:ZONECHARGE (SHENZHEN) WIRELESS POWER TECH CO LTD

Method for recovering lithium manganate battery anode material

ActiveCN103219561ATo achieve the purpose of leachingSolve the problem of resource recyclingSolid waste disposalWaste accumulators reclaimingSilicon alloyAdhesive

The invention relates to a method for recovering lithium manganate battery anode material, belongs to the field of waste battery recovery technology, and aims at providing the method for recovering the lithium manganate battery anode material. The method for recovering the lithium manganate battery anode material comprises the following steps of: separating an aluminium foil from a positive plate of a lithium manganate battery, and heating the positive plate of the lithium manganate battery at the temperature of 300-600 DEG C for 1-4h; after that, separating the aluminium foil to obtain a mixture of lithium manganate anode material, a conductive agent and an adhesive; calcining the mixture at the temperature of 1000-12000 DEG C for 1-3h, and pelletizing; evenly mixing the pelletized mixture with the carbonaceous reducing agent, silica and lime according to the weight ratio of 100: (18-22): (13-17): (14-18); smelting for 1-3h by an electric furnace to obtain manganese-silicon alloy and slag; and carrying out acid leaching on the slag, and adding sodium carbonate solution into the slag for precipitating and filtering to obtain the lithium carbonate.

Owner:天齐锂业(江苏)有限公司 +2

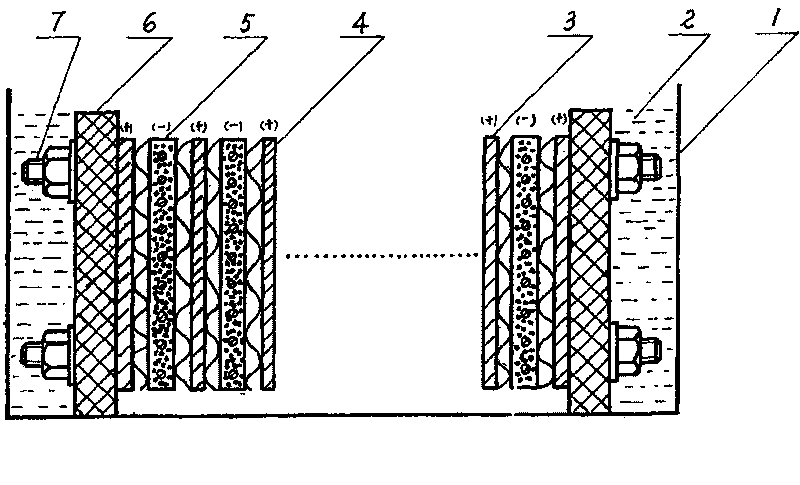

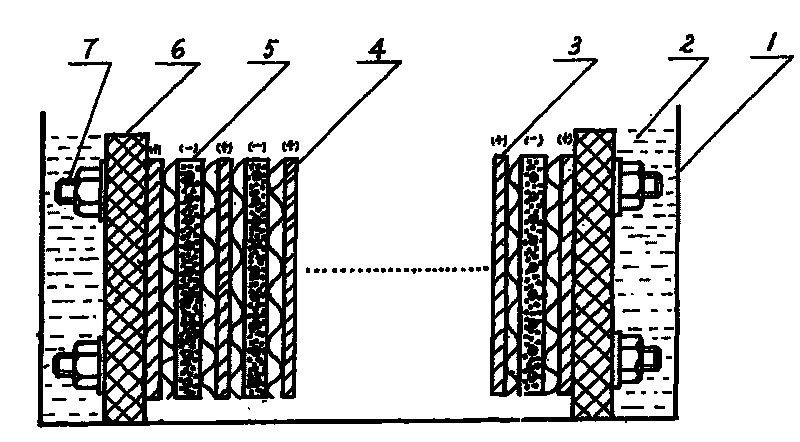

Method for recovering lead from waste lead acid batteries

InactiveCN101748277AResidue reductionIncrease productivityPhotography auxillary processesProcess efficiency improvementElectrolysisMaterials science

The present invention relates to a method for recovering lead from waste lead acid batteries. The electrolytic device adopted comprises an electrolytic bath, dilute alkali electrolyte, an anode, a baffle and a pasted cathode. The anode, the baffle and the pasted cathode are arranged in a tight assembly structure. The pasted cathode is prepared from waste lead powder processed by reduction, water and paste. Lead is reduced from the pasted cathode with a solid phase reduction electrolytic method. Besides the advantage of no pollution, the present invention also has the advantages of short electrolysis time, low energy consumption and low production cost due to the characteristics of low electrolysis voltage, large current density and high current efficiency.

Owner:江苏航虹电源有限公司

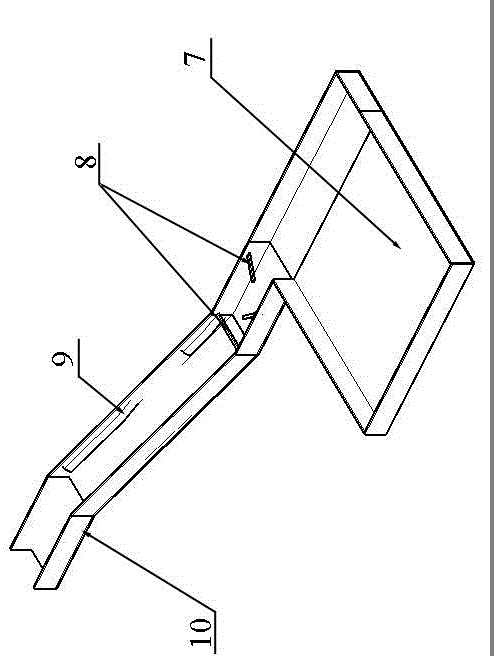

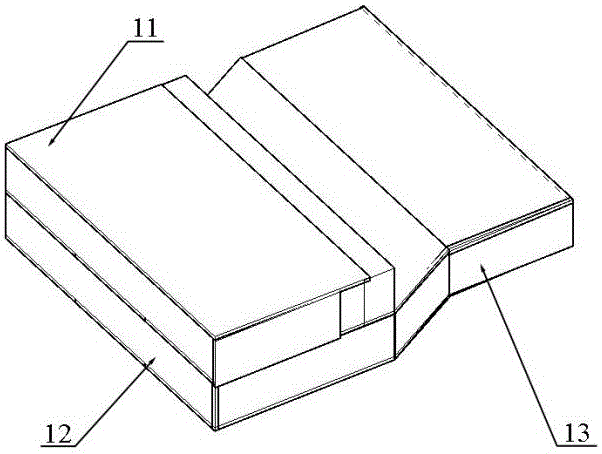

Uninterrupted power unmanned aerial vehicle (UAV) capable of automatically replacing battery

InactiveCN106384797AShorten the timeDoes not affect normal useCell component detailsEngineeringBattery recycling

The invention discloses an uninterrupted power unmanned aerial vehicle (UAV) capable of automatically replacing a battery. The uninterrupted power UAV comprises a UAV body, a metal contact point, an uninterrupted power parking apron, a power supply unit, a UAV battery, an uninterrupted power plug, an old battery recycling area and a battery replacing component, wherein the power supply unit is arranged below the uninterrupted power parking apron; the uninterrupted power plug is arranged on the uninterrupted power parking apron; the metal contact point is arranged at the bottom of an undercarriage of the UAV body; the UAV body is parked on the uninterrupted power parking apron so that the metal contact point is adapted to socket with the uninterrupted power plug and supplies the power for the UAV body; a battery replacing hollow part is arranged on the uninterrupted power parking apron; the UAV battery is installed at the bottom center of the UAV body; the battery replacing component and the old battery recycling area are respectively arranged below the uninterrupted power parking apron; and the UAV battery is dismounted through the battery replacing component and conveyed to the old battery recycling area. The battery is automatically replaced without interrupting the power, the time of replacing the battery of the UAV is greatly saved, and the usage of the UAV is rarely influenced.

Owner:青海航旭电子科技有限公司

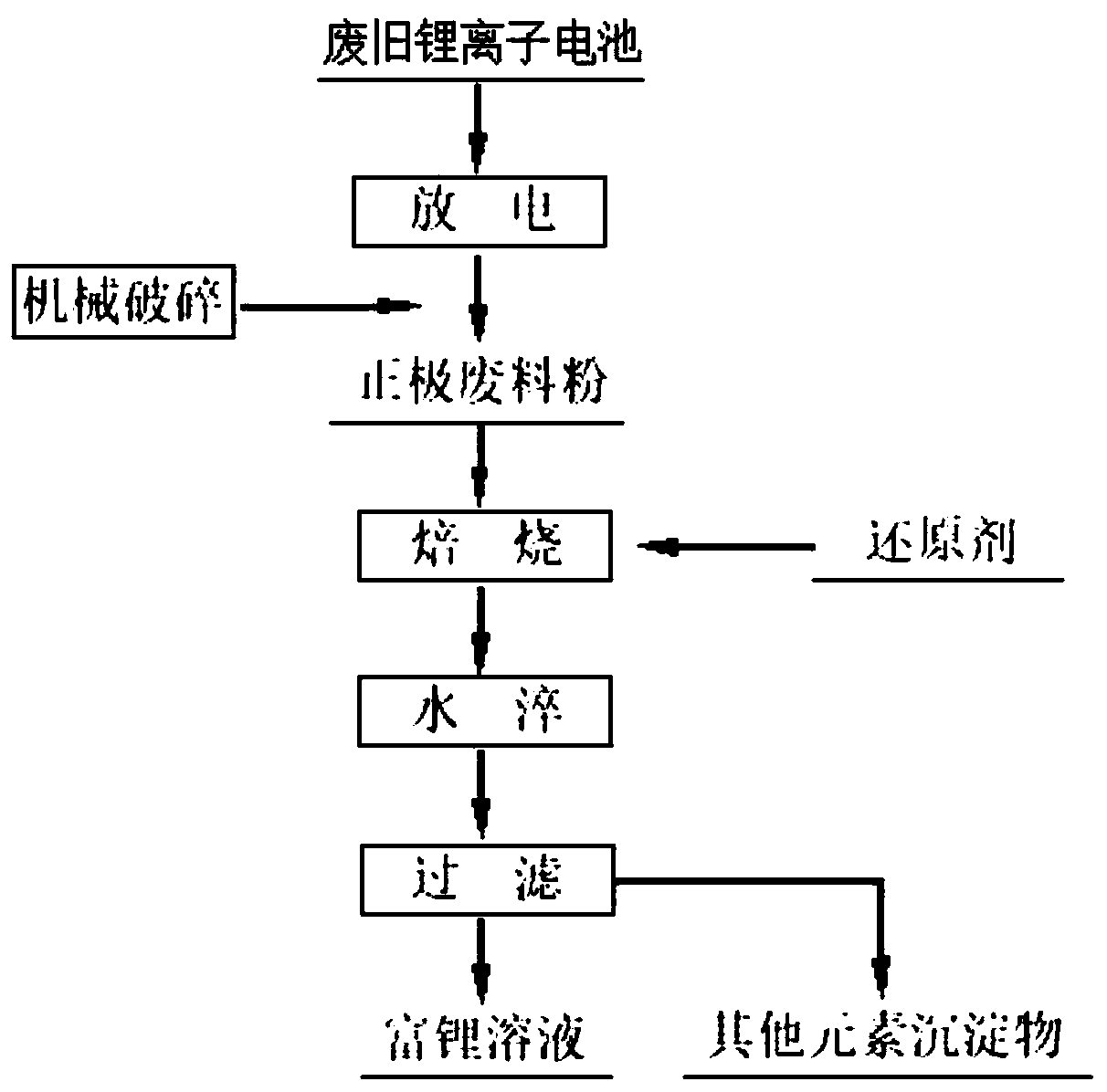

Method for recycling lithium in waste lithium-ion batteries with reduction roasting-water quenching method

InactiveCN109881008AEfficient separationLow costWaste accumulators reclaimingProcess efficiency improvementMechanical crushingElectrical battery

The invention relates to a method for recycling lithium in waste lithium-ion batteries with a reduction roasting-water quenching method, and belongs to the technical field of waste battery recovery. The method includes the following steps that the waste lithium-ion batteries are subjected to mechanical crushing and screening after being discharged so that positive electrode waste powder can be obtained; the positive electrode waste powder and a reducing agent are evenly mixed to obtain a mixture; the mixture is subjected to reduction roasting; and the mixture subjected to reduction roasting isthrown into water quickly for water quenching, lithium in the mixture enters the water to obtain a lithium-rich solution, and the recovery rate of the lithium in the waste lithium-ion batteries is 92%-98%. By adoption of the method, the lithium in the waste lithium-ion batteries can be efficiently and selectively separated, the technological process is simple, operation is convenient, and the problems that prior technological processes are complex, and investment cost and recovery cost are high are solved.

Owner:广西银亿新材料有限公司 +1

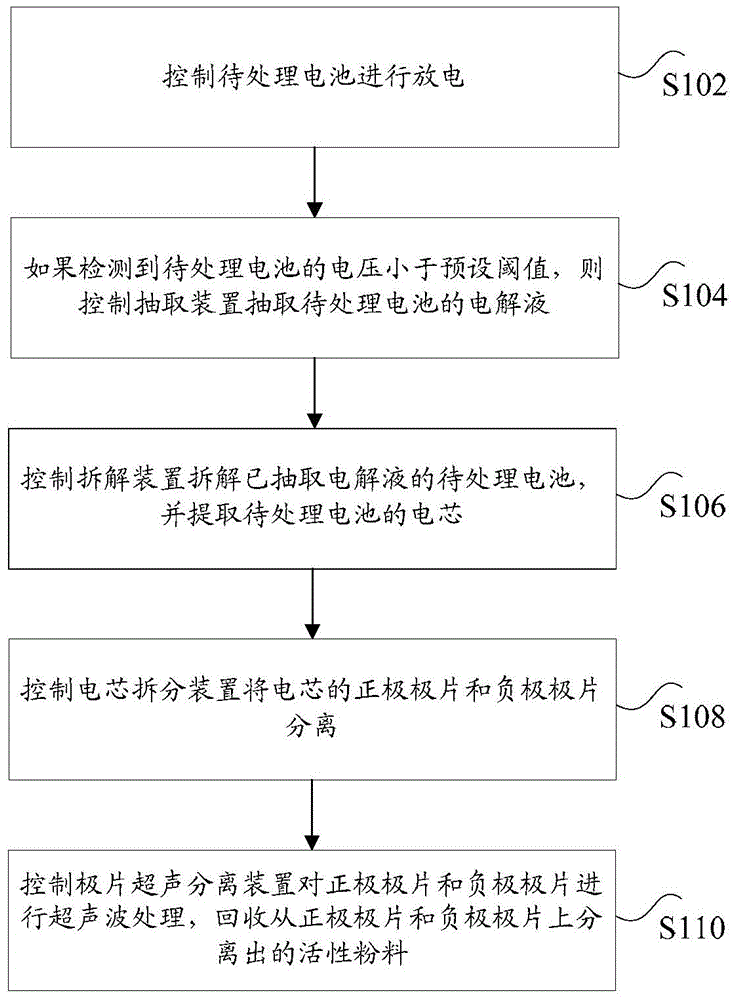

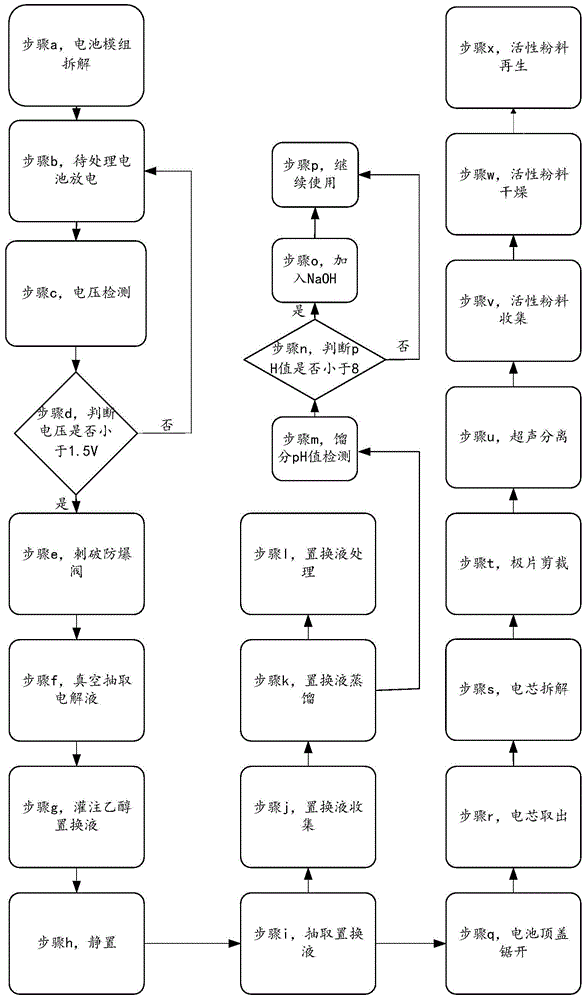

Battery recycling and disposal method and device

InactiveCN105098284AReach the purpose of recyclingImprove protectionWaste accumulators reclaimingBattery recyclingEngineeringPole piece

The invention discloses a battery recycling and disposal method and device. The method comprises: controlling a to-be-disposed battery to discharge; if detecting that the voltage of the to-be-disposed battery is less than a preset threshold value, controlling an extraction apparatus to extract the electrolyte of the to-be-disposed battery; controlling a disassembling apparatus to disassemble the to-be-disposed battery after extracting the electrolyte, and extracting the core of the to-be-disposed battery; controlling a core separating apparatus to separate the positive electrode pole piece from the negative electrode pole piece of the core; and controlling a pole piece ultrasonic separating device to perform ultrasonic treatment on the positive electrode pole piece and the negative electrode pole piece, and recycling active powder material separated from the positive electrode pole piece and the negative electrode pole piece. The technical problem of over-high resource consumption caused by impossibility in recycling waste lithium ion batteries is solved by the battery recycling and disposal method.

Owner:STATE GRID BEIJING ELECTRIC POWER +1

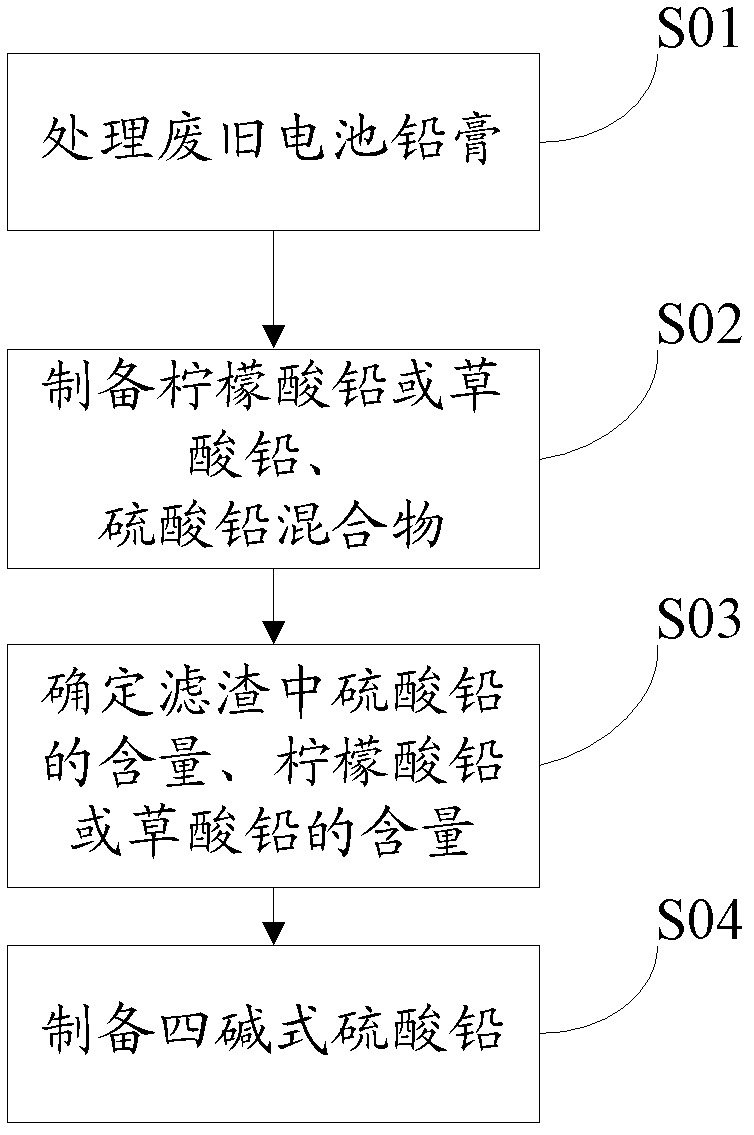

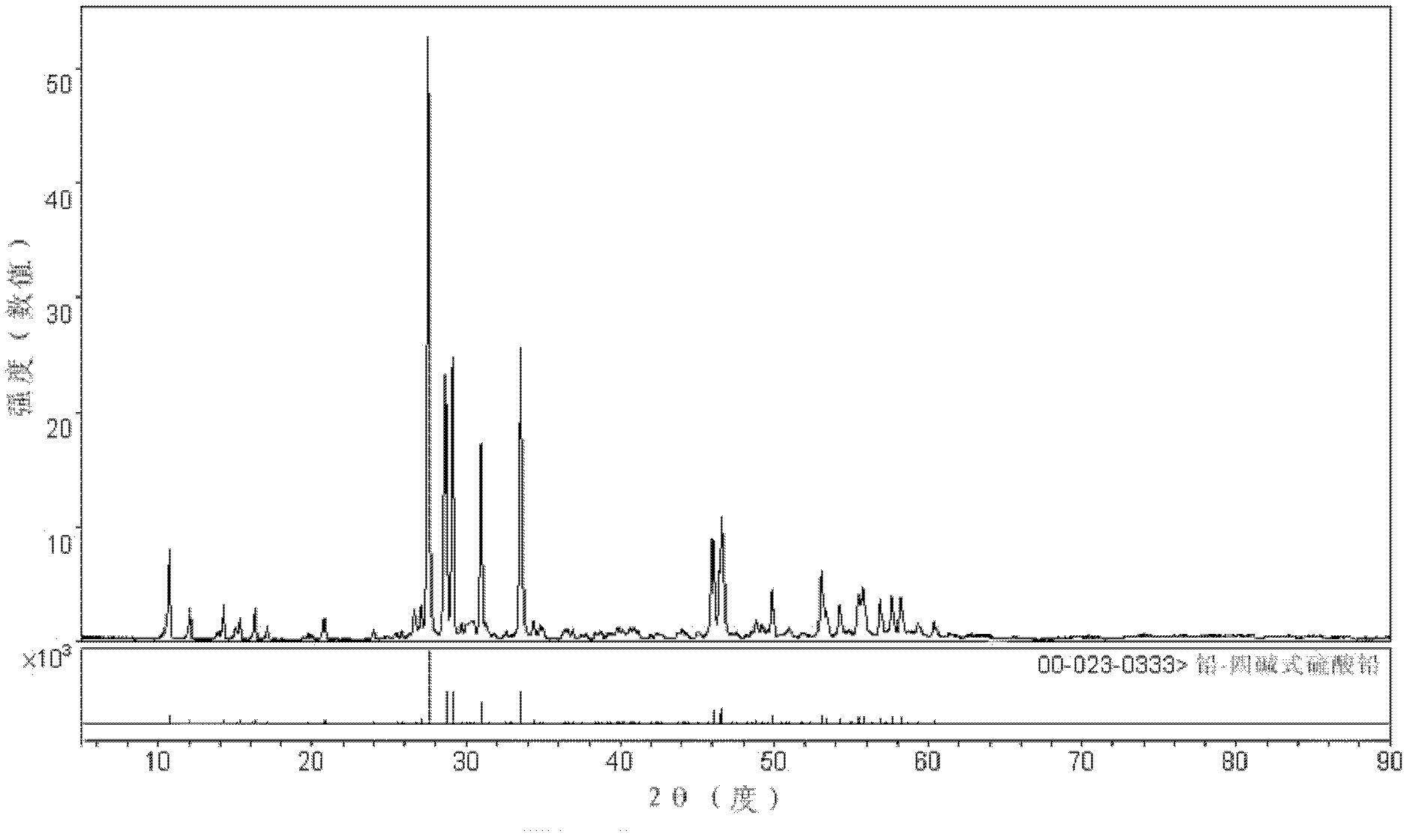

Method for preparing tetrabasic lead sulfate from waste batteries and application of tetrabasic lead sulfate

ActiveCN103022594AEasy to operateLow costWaste accumulators reclaimingLead sulfatesEconomic benefitsEnvironmental engineering

The invention is applicable to the field of waste treatment technologies and provides a method for preparing tetrabasic lead sulfate from waste batteries and the application of the prepared tetrabasic lead sulfate in batteries. The method comprises the steps of processing lead plaster of the waste batteries, preparing a lead citrate or lead oxalate and lead sulfate mixture, determining the content of lead oxalate and the content of the lead citrate or lead oxalate in filter residue, preparing the tetrabasic lead sulfate, and the like. According to the method for preparing the tetrabasic lead sulfate from the waste batteries and the application of the tetrabasic lead sulfate, the lead plaster is recovered from the waste batteries and used for preparing the tetrabasic lead sulfate, so that the battery recovery processing has a great economic benefit, and substances polluting the environment are not generated, thereby being environment-friendly; and the method is simple in operation and low in cost, thereby being very applicable to industrialized production.

Owner:SHENZHEN CENT POWER TECH

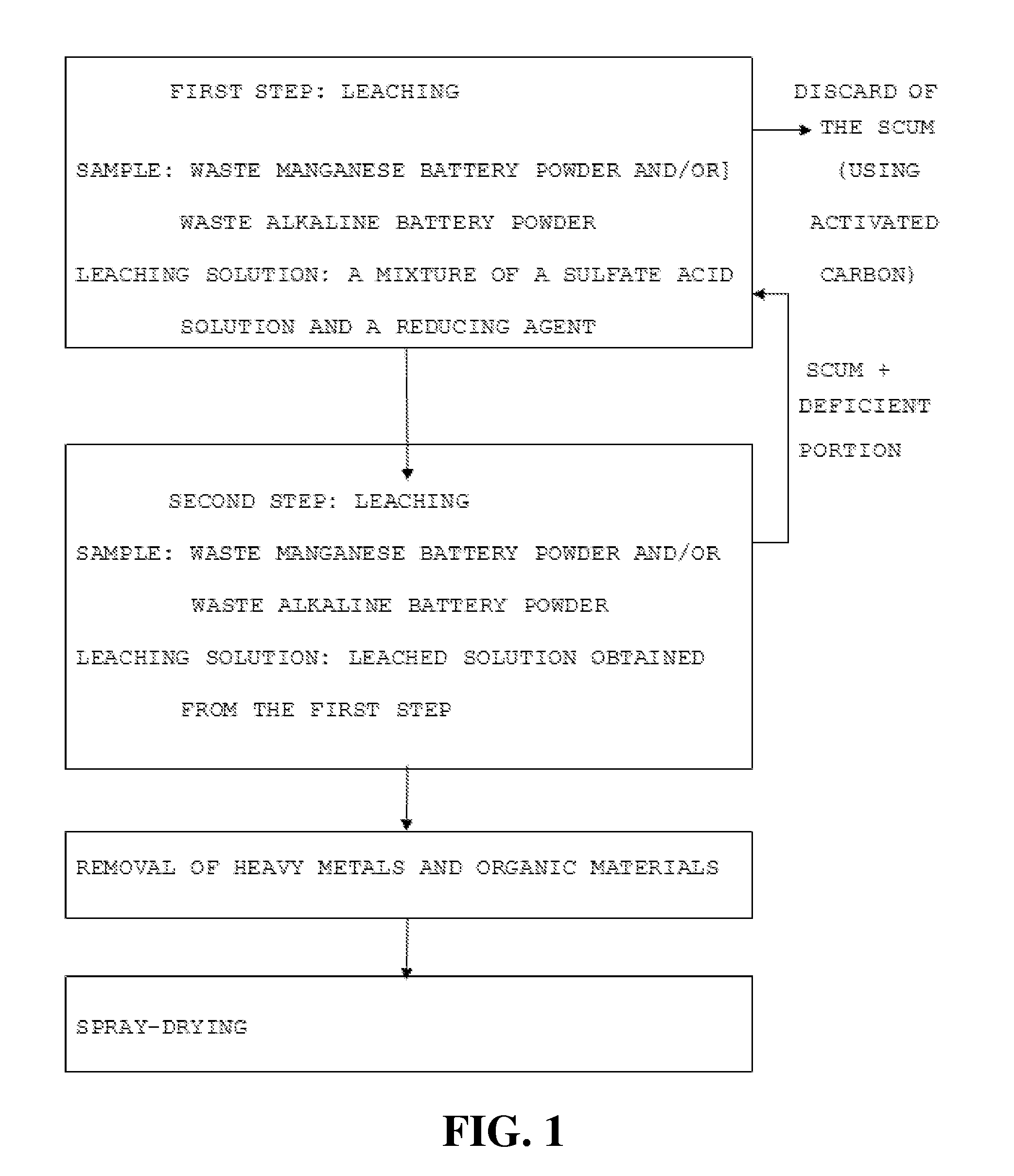

Method for preparing manganese sulfate and zinc sulfate from waste batteries containing manganese and zinc

ActiveUS20110123419A1Simple processEconomical efficiencyZinc sulatesCell electrodesCyclic processManganese

A method for preparing manganese sulfate and zinc sulfate from waste batteries containing manganese and zinc, and more particularly to a method for preparing manganese sulfate and zinc sulfate from waste batteries containing manganese and zinc. Zinc powder and activated carbon are added to a leached solution obtained from a continuous leaching process so as to remove heavy metals and organic materials from the leached solution, and then the leached solution is spray-dried to simultaneously obtain manganese sulfate and zinc sulfate at high-purity by a simple process without generating wastewater. An environmentally friendly waste battery recycling process is thereby provided, because it is not required to use additional chemical substances for neutralization titration or impurity removal in recovering manganese sulfate and zinc sulfate by leaching a waste battery powder.

Owner:ECONIX

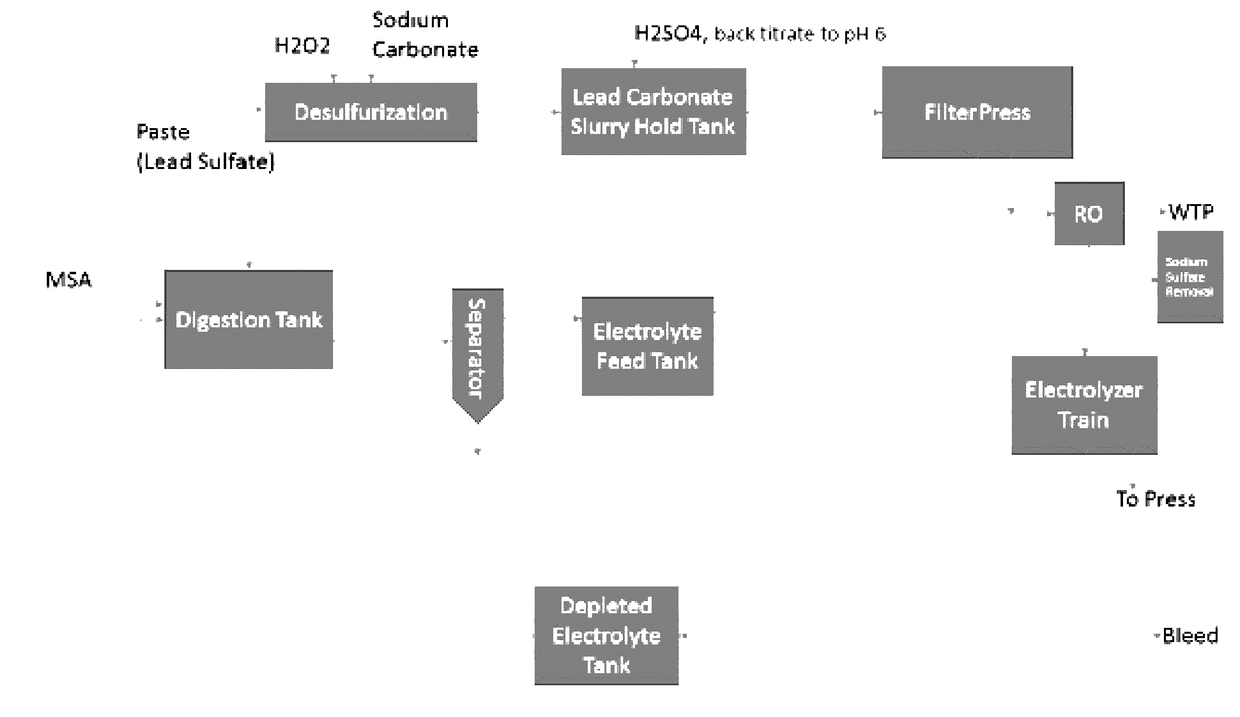

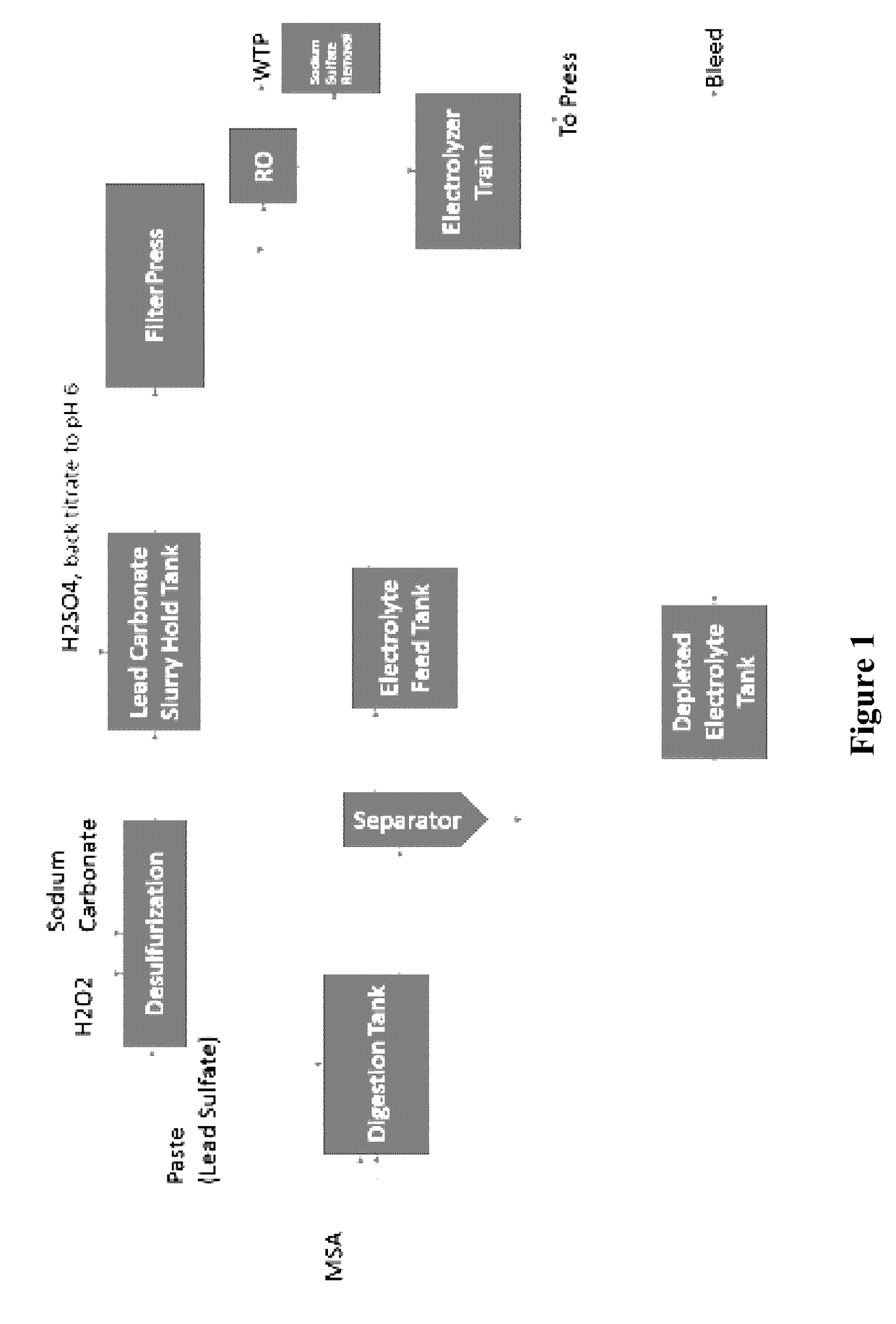

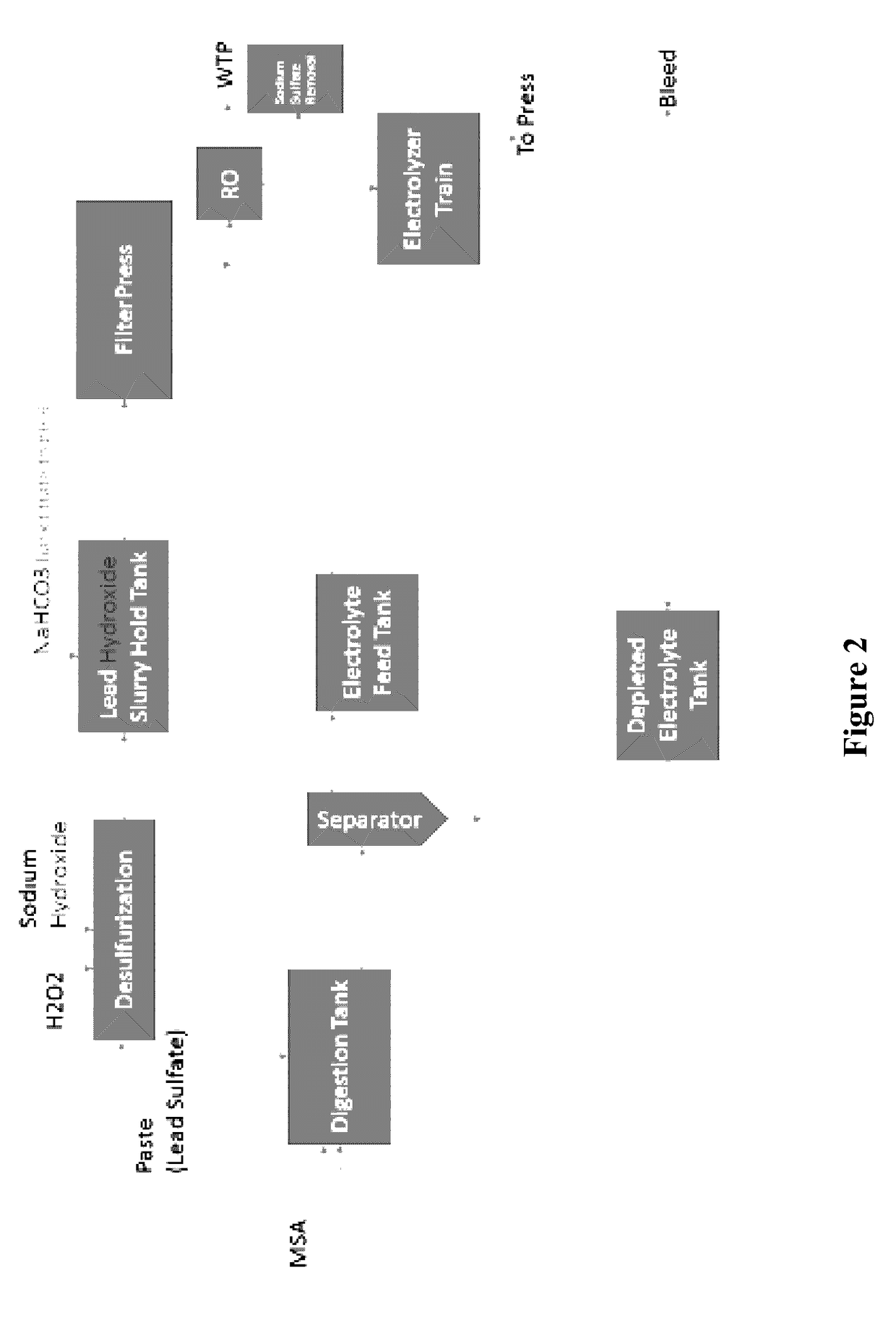

Systems And Methods For Continuous Alkaline Lead Acid Battery Recycling

Lead is recycled from lead paste of lead acid batteries in a process that employs alkaline desulfurization followed by formation of plumbite that is then electrolytically converted to pure lead. Remaining insoluble lead dioxide is removed from the lead plumbite solution and reduced to produce lead oxide that can be fed back to the recovery system. Sulfate is recovered as sodium sulfate, while the so produced lead oxide can be added to lead paste for recovery.

Owner:AQUA METALS INC

Method for recycling multiple components of waste lithium iron phosphate battery

PendingCN113285135ASolve flammable and explosiveImprove friendlinessPositive electrodesWaste accumulators reclaimingLithium iron phosphateElectrical battery

The invention discloses a method for recycling multiple components of a waste lithium iron phosphate battery. The method comprises the following steps of breaking a shell of the discharged waste lithium iron phosphate battery, disassembling and separating, treating the battery core to obtain a solvent recovery solution, crushing and sorting the battery core to obtain lithium iron phosphate coarse powder, copper powder and aluminum powder, adding the lithium iron phosphate coarse powder into an acid solution to react, filtering to obtain an acid leaching solution and carbon residues, washing the carbon residues with water, and drying to obtain high-carbon graphite, adjusting the PH value of the acid leaching solution, adding a reducing agent to remove copper, and filtering to obtain a copper-removed solution and copper slag, adding an oxidizing agent and a proper amount of phosphorus source into the copper-removed solution to obtain ferric orthophosphate, adding alkali liquor into the iron precipitation liquid to obtain aluminum-removed liquid and aluminum slag, adding alkali liquor into the aluminum precipitation liquid to obtain alkalized liquid and alkaline slag, and evaporating and concentrating the alkalized solution to obtain a lithium-rich solution, and adding the lithium-rich solution into a sodium carbonate solution to obtain lithium carbonate. The invention relates to the technical field of battery recycling, and particularly provides a method for recycling multiple components of a waste lithium iron phosphate battery.

Owner:宁夏百川新材料有限公司 +1

Method for recycling valuable metals from spent batteries

InactiveUS20170170532A1Cheap and simpleEliminate needElectrolysis componentsPhotography auxillary processesElectrolysisFiltration

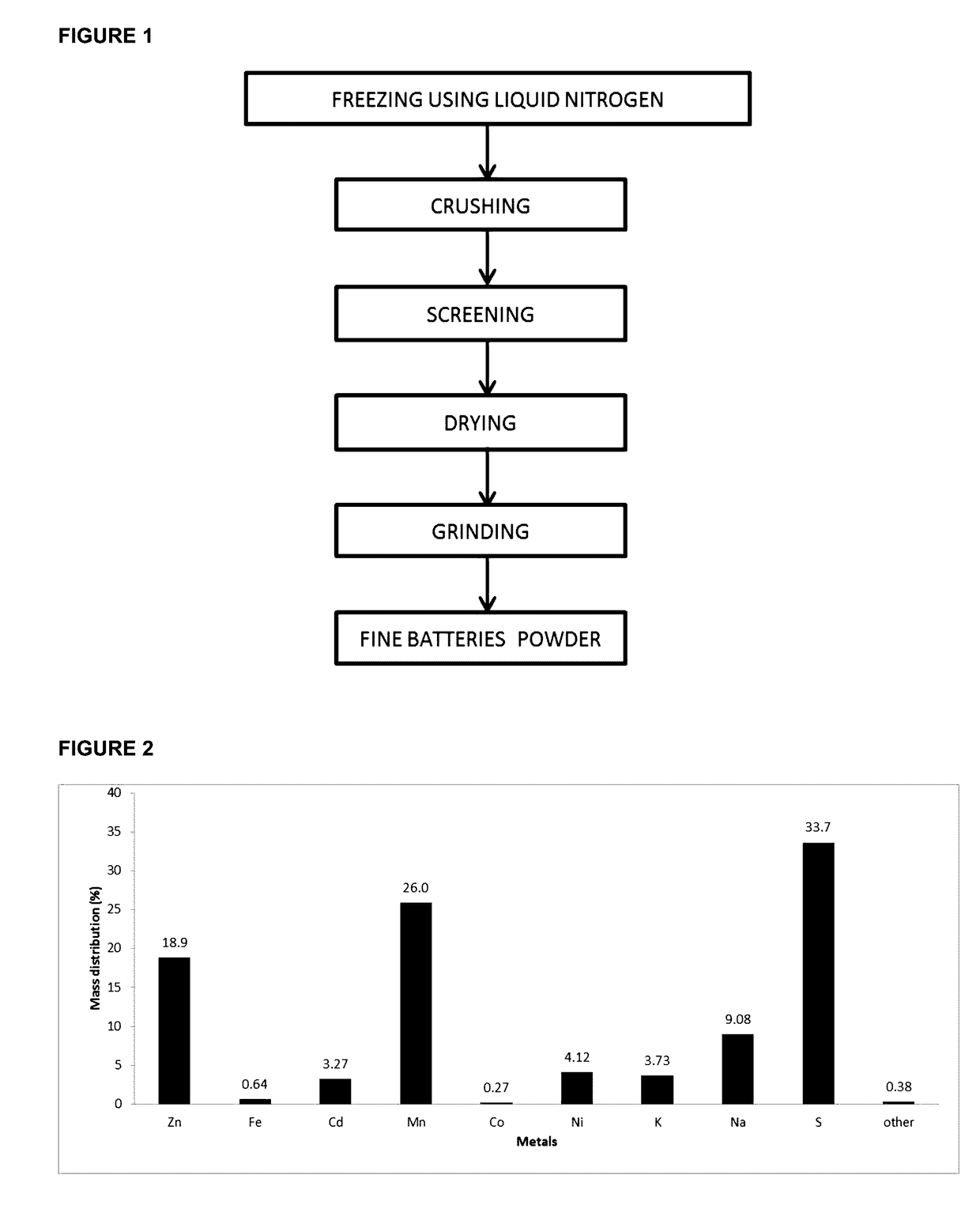

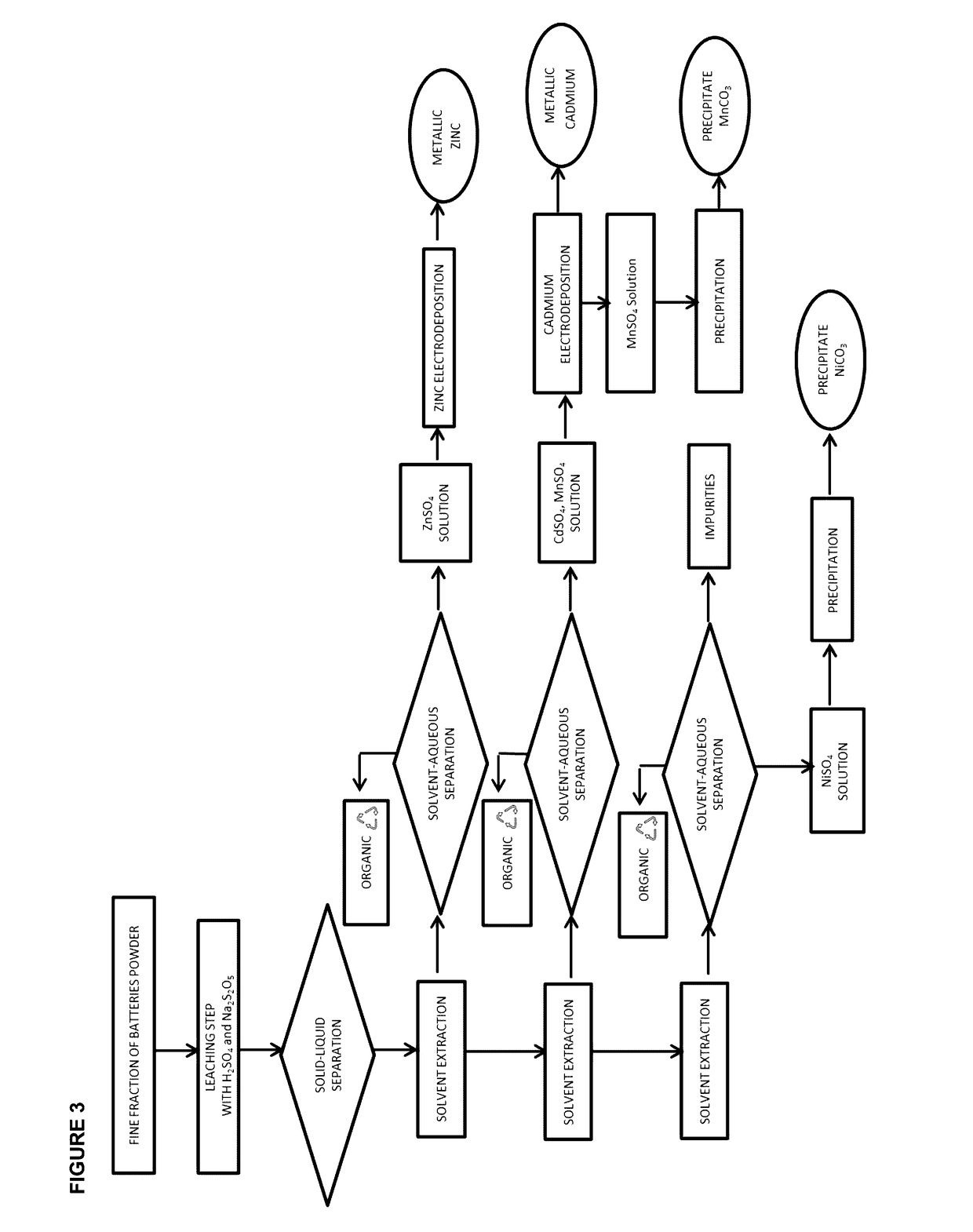

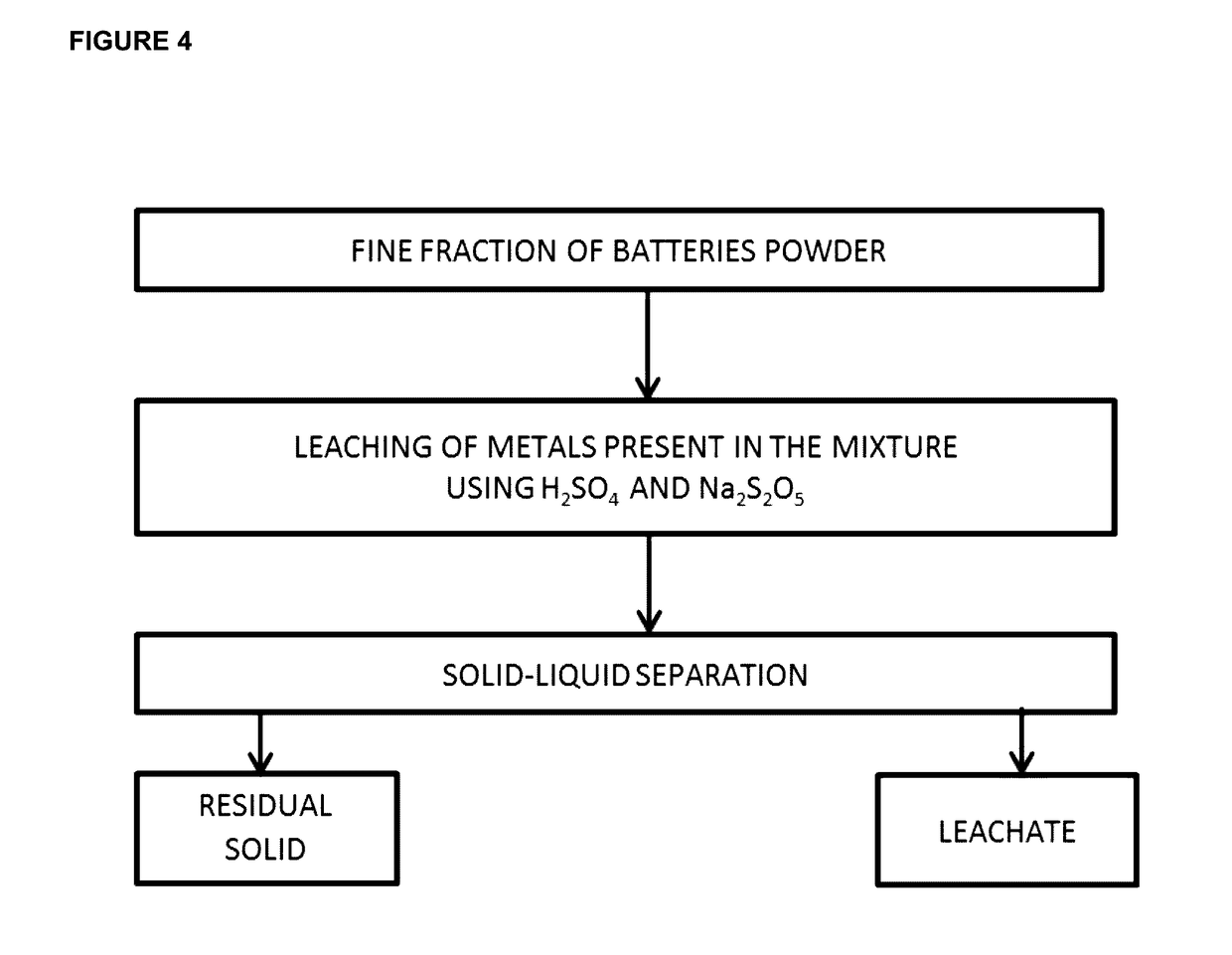

A process has been developed in order to recover and recycle the metals present in spent batteries, including alkaline spent batteries alone or mixed with other types of spent batteries. This method shows a good potential in terms of metals recoveries efficiencies and economic feasibility. Firstly, the spent batteries are crushed (optionally after having been frozen in the case of spent batteries of mixed types). Then, the undesirable parts (plastics, steel cases, papers, etc.) are removed by screening. The collected powder, containing the metals, is mixed with a solution of sulfuric acid in the presence of a reducing agent. The solid / liquid separation is carried out by filtration and the leachate is purified in order to selectively recover the metals. The purification steps consist of: a) recovering Zn by solvent extraction followed by an electrowinning process; b) simultaneously recovering Mn and Cd by solvent extraction process; c) selectively recovering Cd from the mixture solution of Cd and Mn by electrowinning process; d) precipitating Mn from a pure solution of MnSO4 in a carbonate form; e) removing the impurities present in the effluent by solvent extraction in order to obtain a pure NiSO4 solution; f) precipitating Ni from a NiSO4 solution in a carbonate form.

Owner:INSTITUT NATIONAL DE LA RECHERCHE SCIENTIFIQUE

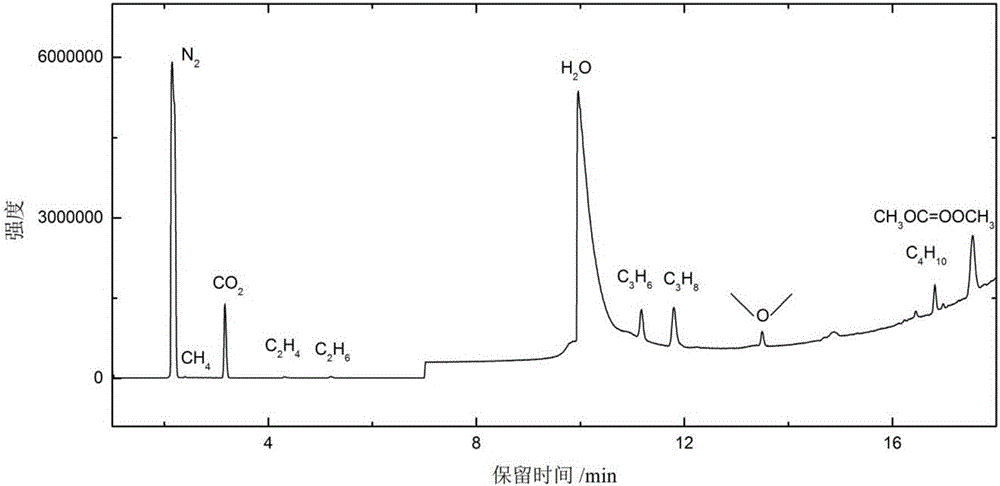

Recycling method of waste lithium battery

ActiveCN108011146AHigh recovery rateEasy to separateWaste accumulators reclaimingProcess efficiency improvementElectrical batteryResource recovery

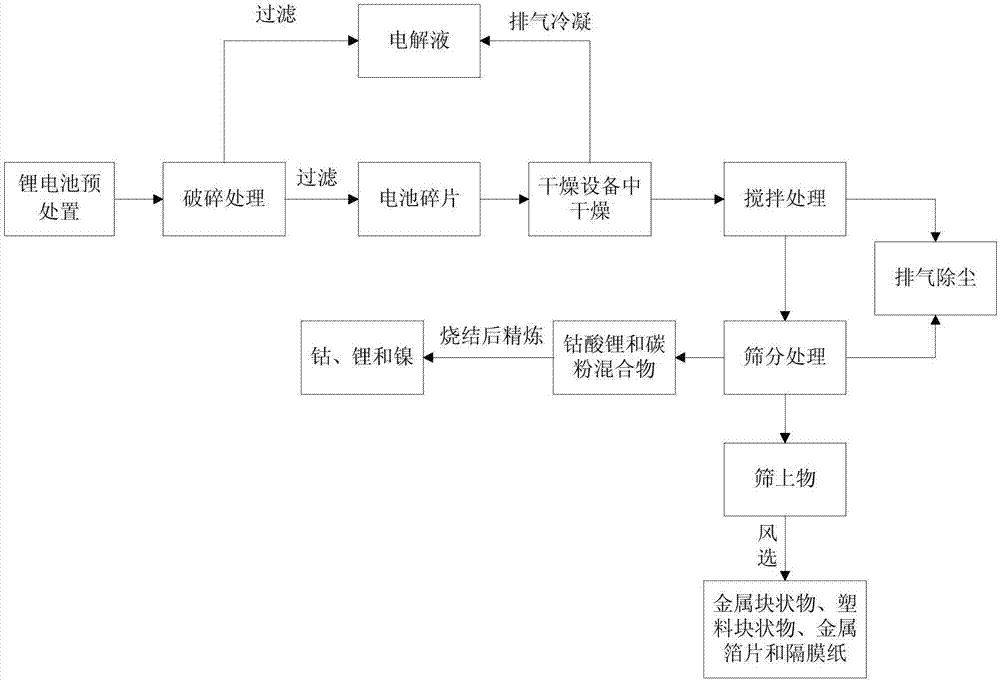

The invention belongs to the recycling field of a battery, and specifically discloses a recycling method of a waste lithium battery with high resource recycling rate and green and environment protection properties. The recycling method of the waste lithium battery comprises the steps of performing pretreatment, smashing and drying on the lithium battery, performing separation on battery fragmentsand performing processing on the separated objects. By performing electrolyte filtering and recycling on the smashed lithium battery, and by performing condensing and electrolyte collecting on the exhausted air of drying equipment, the electrolyte recycling rate is improved, and sewage and waste gas processing quantity are decreased; meanwhile, by virtue of the drying equipment for drying, complete separation of the electrolyte on the battery fragments can be facilitated; the dried battery fragments are subjected to stirring and screening treatment in sequence, so that recycling of battery pole piece current collectors, noble and rare metals and other resources from the lithium battery can be facilitated separately; and in addition, the recycling rate is relatively high, and pollution in the whole recycling process is relatively low.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

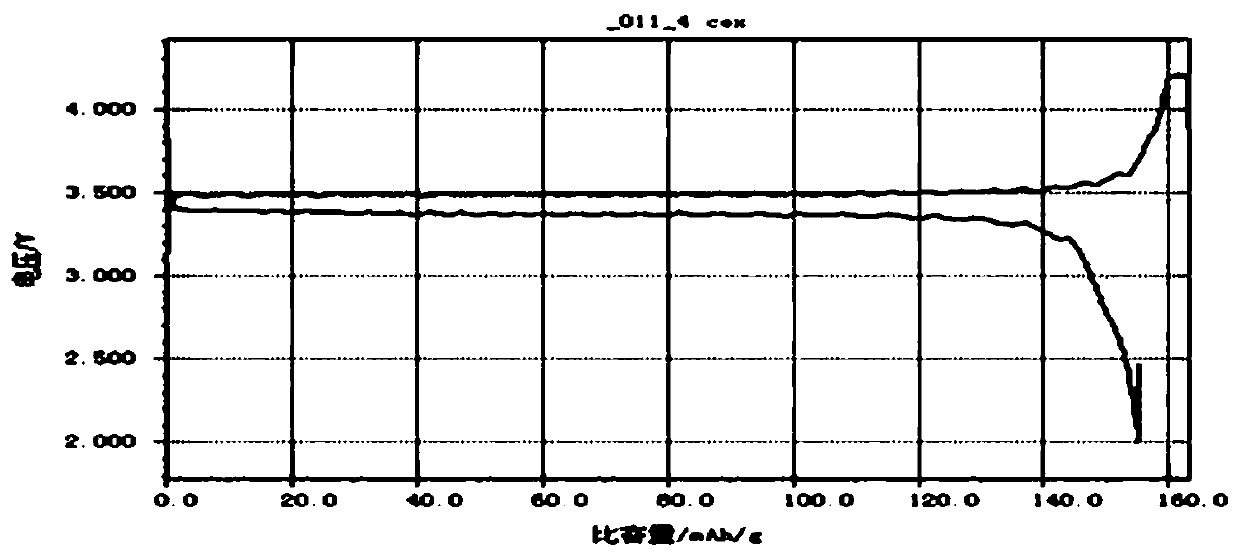

Method for regenerating lithium iron phosphate by leaching, spray drying and solid phase method

InactiveCN110098442AImprove leaching rateUniform particle size distributionCell electrodesWaste accumulators reclaimingSolid phasesPregnant leach solution

The invention discloses a method for regenerating lithium iron phosphate by a leaching, spray drying and solid phase method, and belongs to the field of waste battery recycling. The method comprises the steps of discharging a waste lithium iron phosphate battery in a salt solution, then disassembling to separate a positive pole piece; separating the positive pole piece obtained in the previous step to obtain an aluminum foil and a waste lithium iron phosphate positive electrode, adding the waste lithium iron phosphate positive electrode powder into an acid solution to leach so as to obtain a leachate; additionally adding a lithium source, an iron source and a phosphorus source to the leachate, and adding a carbon source and a metal cation doped compound to prepare a precursor solution; carrying out spray drying on the precursor solution to obtain precursor powder; and carrying out two-stage calcining on the precursor powder in the atmosphere of argon or argon-hydrogen mixture to obtainmetal cation doped regenerated lithium iron phosphate. The regenerated lithium iron phosphate prepared according to the method of the invention has the advantages of stable structure, high specific capacity and excellent cycle performance and rate performance.

Owner:KUNMING UNIV OF SCI & TECH

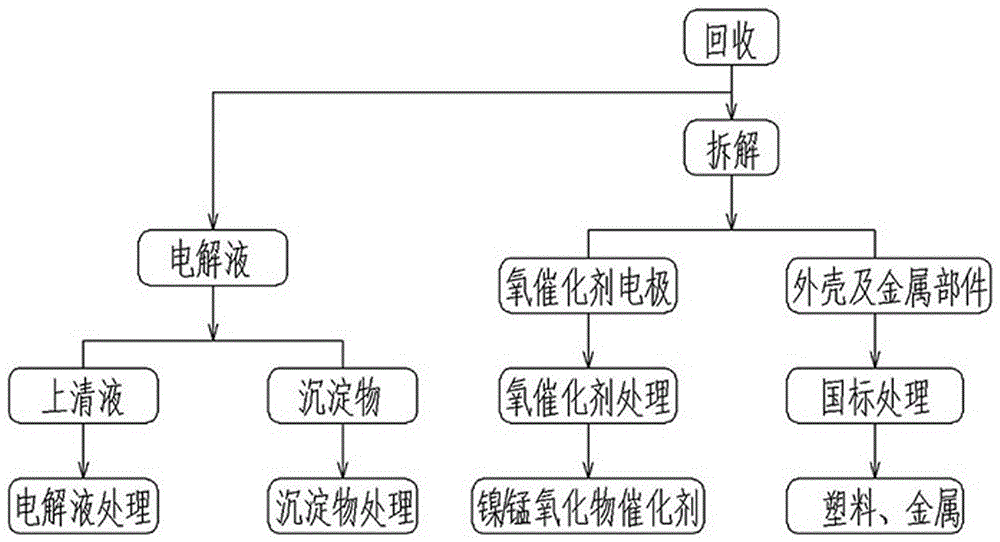

Aluminum-air battery recycling method

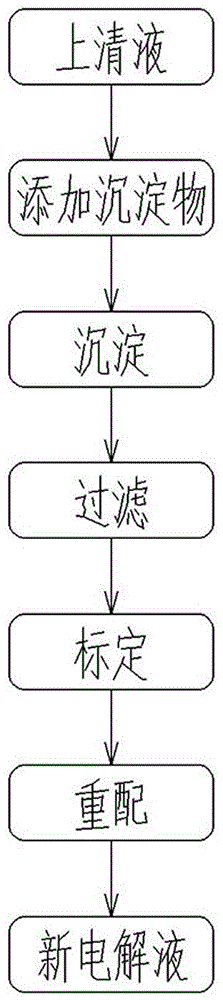

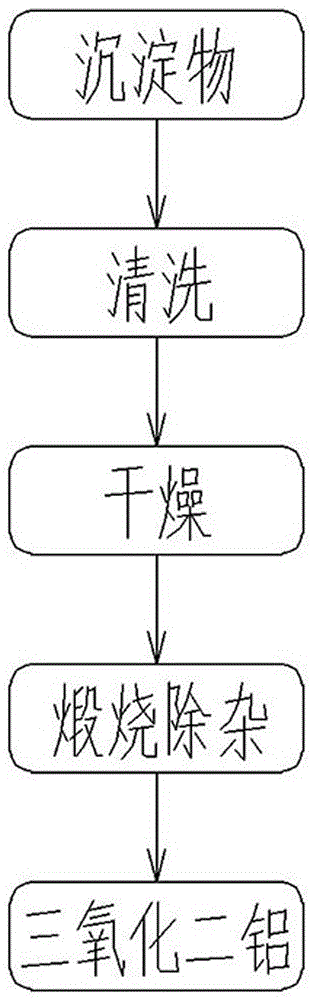

InactiveCN106410330ANo pollution involvedZero pollutionFuel and primary cellsAluminum IonNational standard

The invention discloses an aluminum-air battery recycling method. The method includes the following steps that used waste aluminum-air batteries are recycled; electrolyte in the recycled aluminum-air batteries is pumped into a settling pond, precipitator is added, the mixture is still standing and precipitated, and precipitate and supernate are collected; the pretreated electrolyte precipitate is purified and converted to obtain pure aluminum oxide for recycling; free aluminum ions of the supernate generated after pretreatment of the electrolyte are removed, and after the aluminum ions are subjected to sedimentation treatment, aluminum-air battery electrolyte capable of being recycled is obtained; battery bodies without the electrolyte are detached, plastic shells and metal parts are obtained, plastic is recycled according to the national standard GB / T 30102-2013, and metal is recycled according to corresponding metal national standards to be reused; obtained oxygen catalyst electrodes are processed to obtain a catalyst containing nickel oxide and manganese oxide, and then the obtained catalyst containing nickel oxide and manganese oxide is prepared into new oxygen catalyst electrodes of aluminum-air batteries.

Owner:深圳市锐劲宝能源电子有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com