Method for preparing lithium iron phosphate positive electrode material from waste lithium iron phosphate battery

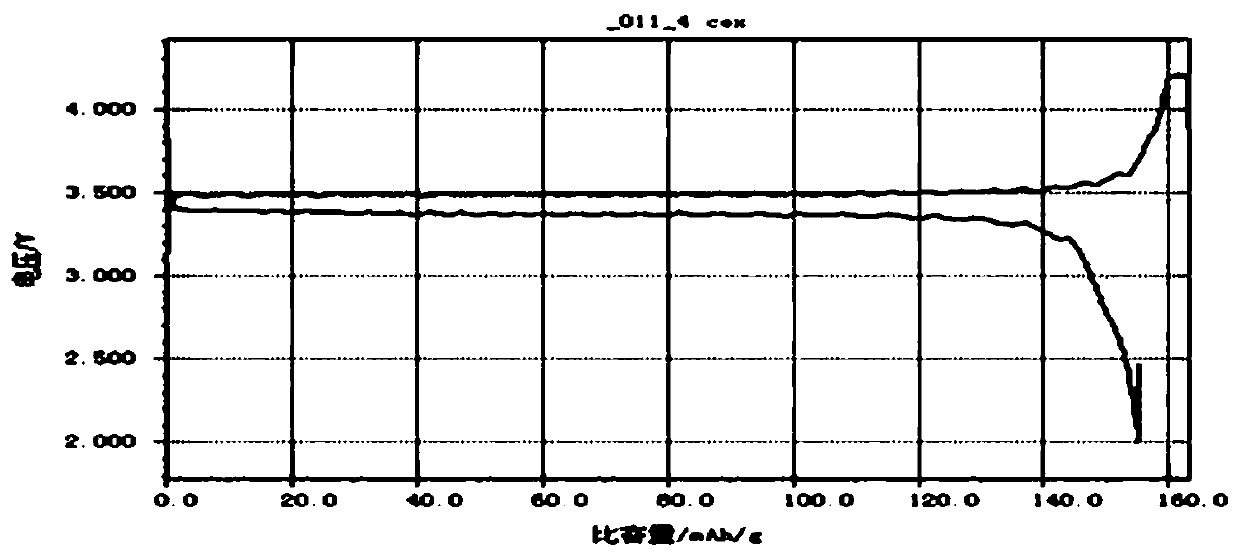

A lithium iron phosphate battery, lithium iron phosphate technology, applied in battery electrodes, lithium storage batteries, positive electrodes and other directions, can solve the problems of low lithium leaching rate, non-compliance with environmental protection requirements, excessive slag amount, etc., to achieve high purity, The effect of high product utilization and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

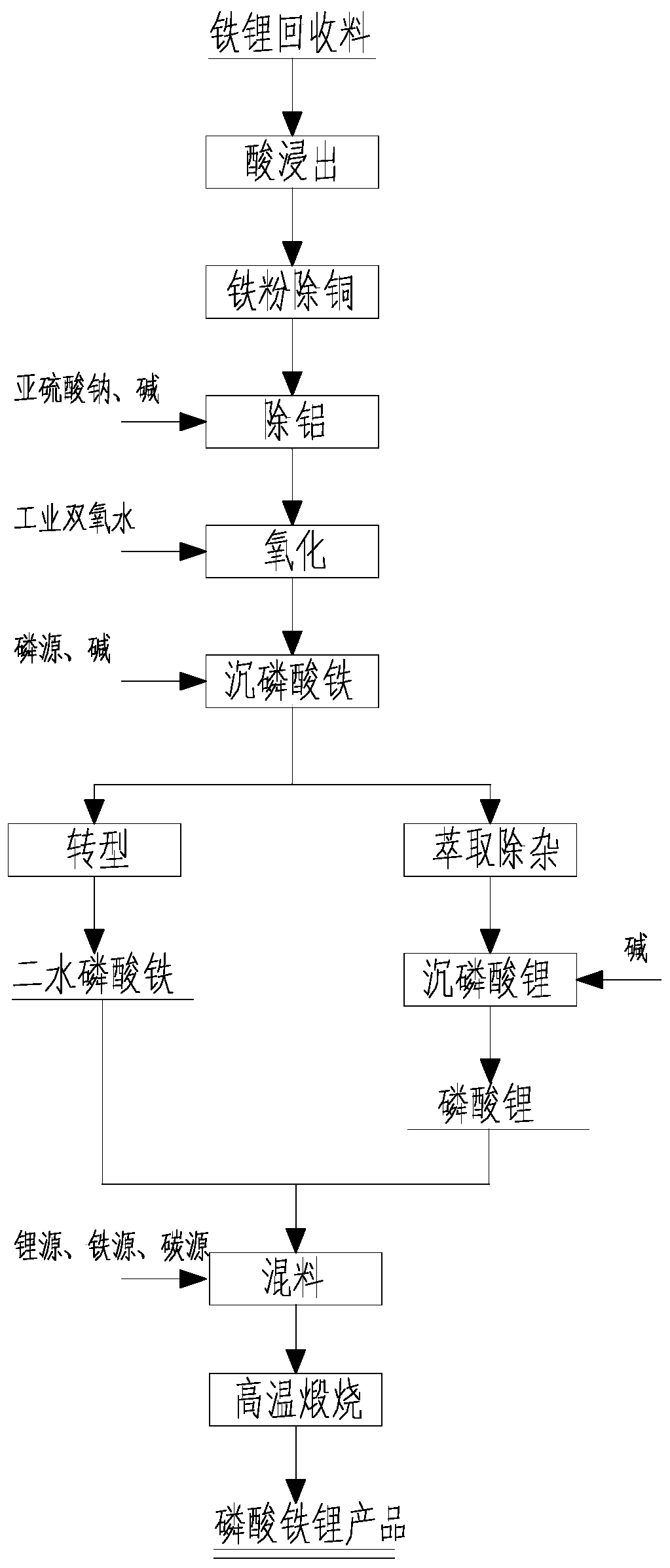

[0023] A method for preparing a lithium iron phosphate cathode material from a waste lithium iron phosphate battery, the specific production steps are as follows:

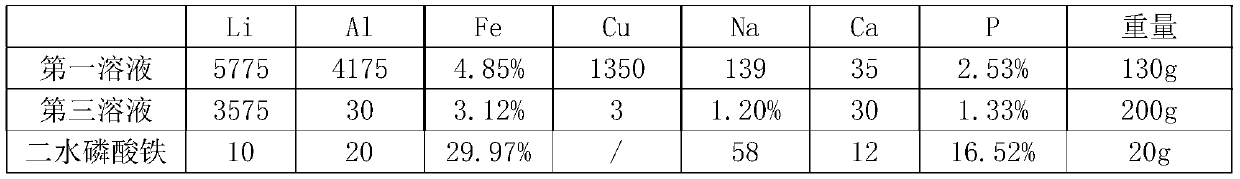

[0024] The first step: acid leaching, take 20g of lithium iron phosphate, copper and aluminum impurities, and negative electrode powder obtained from the waste lithium iron phosphate battery after discharge crushing and screening, add 100ml of 0.1mol / L dilute sulfuric acid solution, and put it in a water bath The temperature was 40°C, leaching for 2 hours, wherein the volume ratio of liquid to solid was 2:1, and the liquid was filtered to obtain the first solution after immersion, and the metal components in the leaching solution were shown in Table 1;

[0025]

[0026] Analysis results of each component in Table 1 implementation case 1

[0027] The second step: remove copper, add iron powder with a copper content of 0.8 times to the first solution, wherein the reaction temperature is 30°C, the stirring time is ...

Embodiment 2

[0033]A method for preparing a lithium iron phosphate cathode material from a waste lithium iron phosphate battery, the specific production steps are as follows:

[0034] The first step: acid leaching, take 1000g of lithium iron phosphate, copper and aluminum impurities, and negative electrode powder obtained from waste lithium iron phosphate batteries after discharge, crushing and screening, add 6000ml of 0.5mol / L dilute sulfuric acid solution, water bath The temperature is 60°C, leaching for 3 hours, wherein the volume ratio of liquid to solid is 5:1, and the liquid is filtered to obtain the first solution after soaking;

[0035] The second step: remove copper, add iron powder with a copper content of 0.9 times to the first solution, the reaction temperature is 55 ° C, the stirring time is 45 minutes, and the solution after copper removal is filtered to obtain the second solution;

[0036] Step 3: In addition to aluminum, gradually add 100ml of 1.5mol / L sodium sulfite dropwi...

Embodiment 3

[0041] A method for preparing a lithium iron phosphate cathode material from a waste lithium iron phosphate battery, the specific production steps are as follows:

[0042] The first step: acid leaching, take 1500g of lithium iron phosphate, copper and aluminum impurities, and negative electrode powder obtained from the waste lithium iron phosphate battery after discharge crushing and screening, add 6000ml1mol / L dilute sulfuric acid solution, water bath temperature 80 ℃, soak for 5 hours, wherein the volume ratio of liquid to solid is 8:1, after soaking, the liquid is filtered to obtain the first solution;

[0043] The second step: remove copper, add iron powder with 1 times the copper content to the first solution, the reaction temperature is 80°C, the stirring time is 60min, and the solution after copper removal is filtered to obtain the second solution;

[0044] Step 3: In addition to aluminum, gradually add 100ml of 2mol / L sodium sulfite dropwise to the second solution, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com