Method for recovering lead from waste lead acid batteries

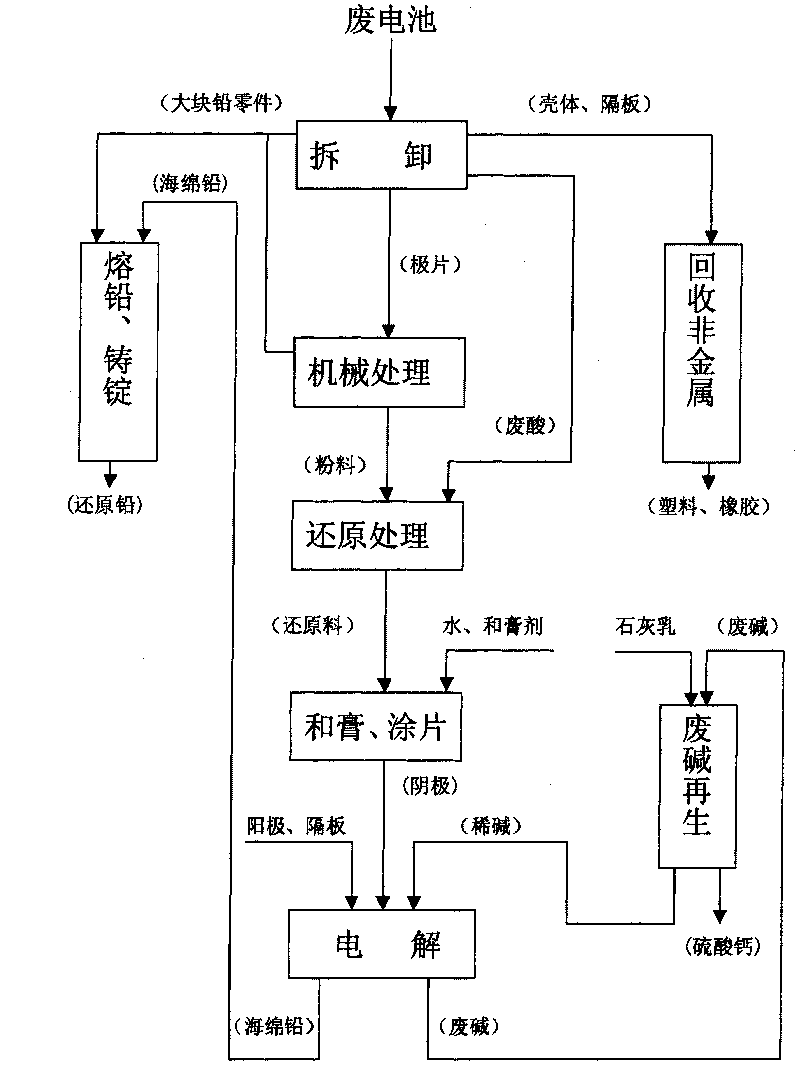

A technology for recycling waste storage batteries and lead, which is applied in photography technology, instruments, photography auxiliary technology, etc., can solve the problems of long electrolysis time, high production cost, and many side reactions, and achieves short electrolysis time, low production cost, and lead compounds. less residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

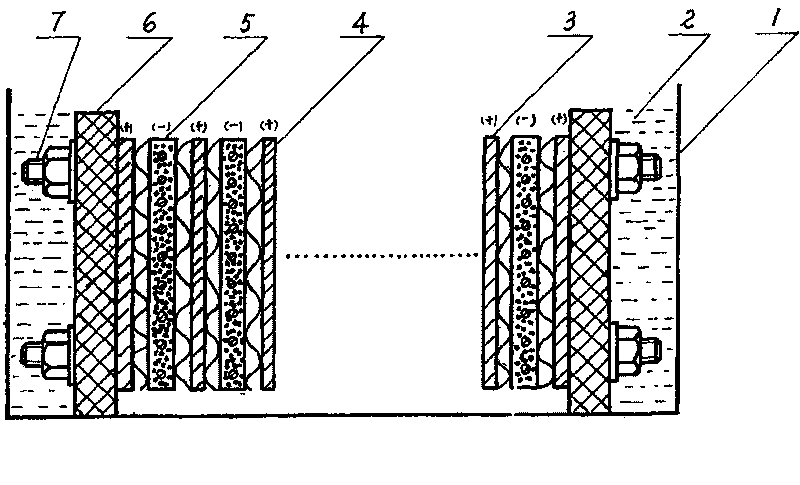

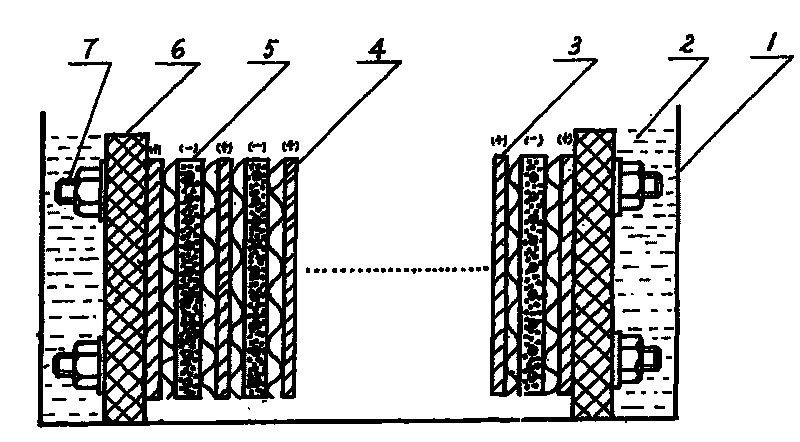

[0017] Embodiment 1: lead-containing waste powder is obtained after waste lead storage battery is processed mechanically, and its composition is lead oxide 7.80%, lead sulfate 51.74%, metallic lead 6.59%, lead dioxide 33.79%. Put the waste lead powder into the waste sulfuric acid obtained from the waste lead battery, heat it at 140°C to reduce the lead dioxide to low-priced lead compounds, and then prepare the low-priced lead compounds with 0.1% polyvinyl alcohol and 10% water Make a paste and apply it on a metal mesh to make a paste-type cathode 5 with a thickness of about 3mm, and then assemble the paste-type cathode 5, separator 4, and anode 3 into a Figure 1 The electrolysis pile shown, and make it carry out electrolysis in 2N sodium hydroxide solution at room temperature, and current density is 50-30 A times / kg waste material, and electrolysis voltage is 1.5-2 volts, completes through 4-5 hours electrolysis, and cathode becomes Sponge lead plate, which contains about 2% ...

Embodiment 2

[0018] Embodiment 2: The waste material to be recovered is the waste lead ash of the lead storage battery factory, and the composition is mainly lead oxide and about 15% lead sulfate, and the remainder is a small amount of metallic lead. This kind of waste does not require mechanical treatment and reduction treatment. Directly make a paste-type cathode with a thickness of about 3 mm as in Example 1 and assemble it into an electrolytic stack. Electrolysis was performed in 2N sodium hydroxide at room temperature. The electrolysis voltage is 1.4-2 volts, the cathode current density is 50-40 ampere / kg waste, and the electrolysis is completed in about 4 hours. The cathode gets a sponge lead electrode. It contains 2-1.5% lead sulfate, 97-98% lead, and 94% cathode current efficiency.

[0019] The post-processing of the sponge lead plate and the lead-containing parts obtained by mechanically processing waste batteries in the above embodiments is to put them into a lead-melting furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com