Method for preparing battery grade lithium carbonate by recovering lithium from lithium iron phosphate waste battery

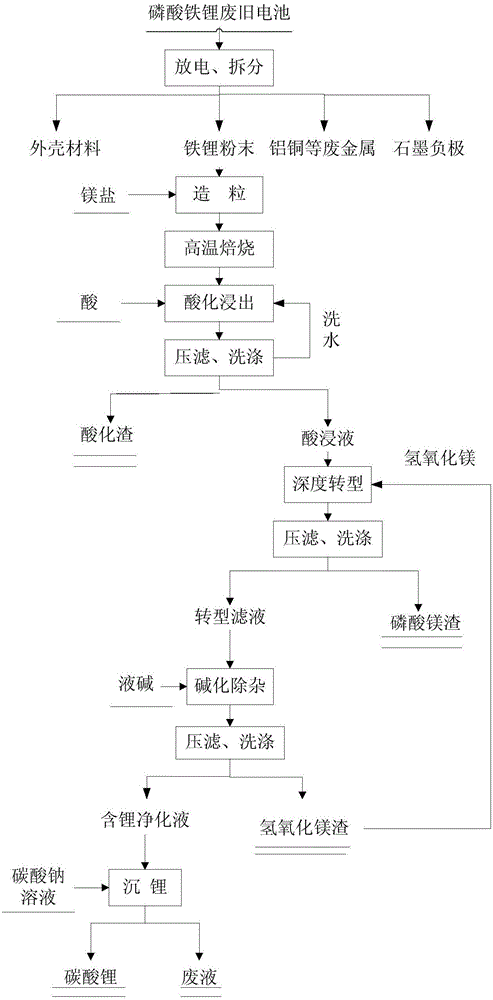

A technology for lithium ferrous phosphate and waste batteries, applied in battery recycling, waste collector recycling, lithium carbonate;/acid carbonate, etc., can solve the problems of low lithium yield, low product purity, and product impurity content Advanced problems, to achieve the effect of improving lithium recovery rate, high product purity, and high lithium recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

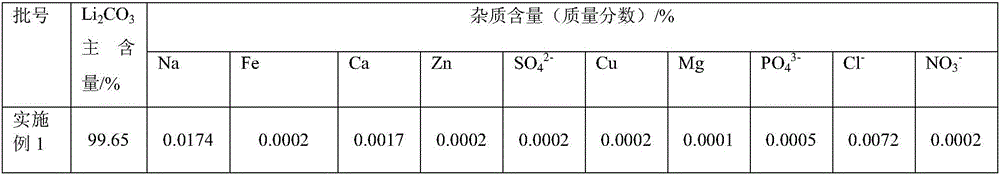

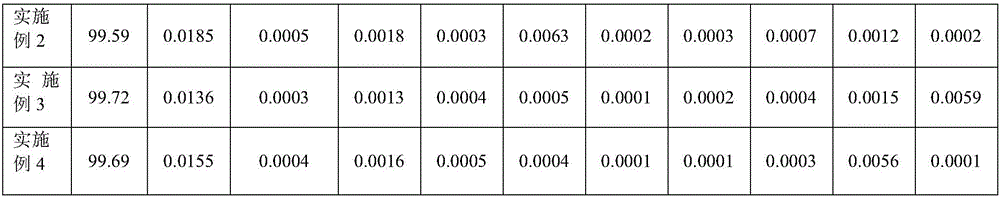

Embodiment 1

[0053] A. Battery dismantling: Lithium ferrous phosphate powder is separated from lithium iron phosphate waste batteries through discharging, dismantling, sorting, crushing and other processes;

[0054] B. disc granulation: take by weighing the lithium iron phosphate powder 100.0kg that step A separates, analyze wherein lithium content is 3.8%, add the magnesium chloride solution of 20.0kg 10.0% (wt%) in the lithium iron phosphate powder, stir 30min, then carry out disc granulation, the average particle size is 10.0mm;

[0055] C. High-temperature roasting: roast the granulated material in step B at 600°C for 3 hours, and continuously blow in air during the roasting process;

[0056] D. Acidification leaching: the material after roasting is first added with water to adjust slurry, and adding 64.0Kg of hydrochloric acid with a weight ratio of 31.0%, leaching at normal temperature for 30min, keeping the pH value of the material at 1.0, obtaining iron phosphate, lithium phosphate...

Embodiment 2

[0061] A. Battery dismantling: Lithium ferrous phosphate powder is separated from lithium iron phosphate waste batteries through discharging, dismantling, sorting, crushing and other processes;

[0062] B. disc granulation: take by weighing the lithium iron phosphate powder 100.0kg that step A separates, analyze wherein lithium content is 3.6%, add the magnesium sulfate solution of 12.5kg 15.0% (wt%) in the lithium iron phosphate powder, Stir for 60min, then carry out disk granulation, the average particle size is 5.0mm;

[0063] C. High-temperature roasting: roast the granulated material in step B at 500°C for 4 hours, and continuously blow in oxygen during the roasting process;

[0064] D. Acidification leaching: the material after roasting is first added with water to adjust slurry, and adding 38.0Kg of sulfuric acid with a weight ratio of 98%, leaching at normal temperature for 60min, keeping the pH value of the material at 0.5, obtaining ferric phosphate, lithium phosphat...

Embodiment 3

[0069] A. Battery dismantling: Lithium ferrous phosphate powder is separated from lithium iron phosphate waste batteries through discharging, dismantling, sorting, crushing and other processes;

[0070] B. disc granulation: take by weighing the lithium iron phosphate powder 100.0kg that step A separates, analyze wherein lithium content is 3.4%, add the magnesium nitrate solution of 25kg 5.0% (wt%) in the lithium iron phosphate powder, stir 45min, then disc granulation, the average particle size is 20.0mm;

[0071] C. High-temperature roasting: roast the granulated material in step B at 800°C for 1 hour, and continuously blow air into it during the roasting process;

[0072] D. Acidification leaching: add water to the material after roasting, and add 28.3Kg of nitric acid with a weight ratio of 65%, leaching for 45min at normal temperature, keeping the pH value of the material at 1.5, obtaining ferric phosphate, lithium phosphate, Lithium-containing solution mixed with ferric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com