Patents

Literature

131results about "Lead sulfates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

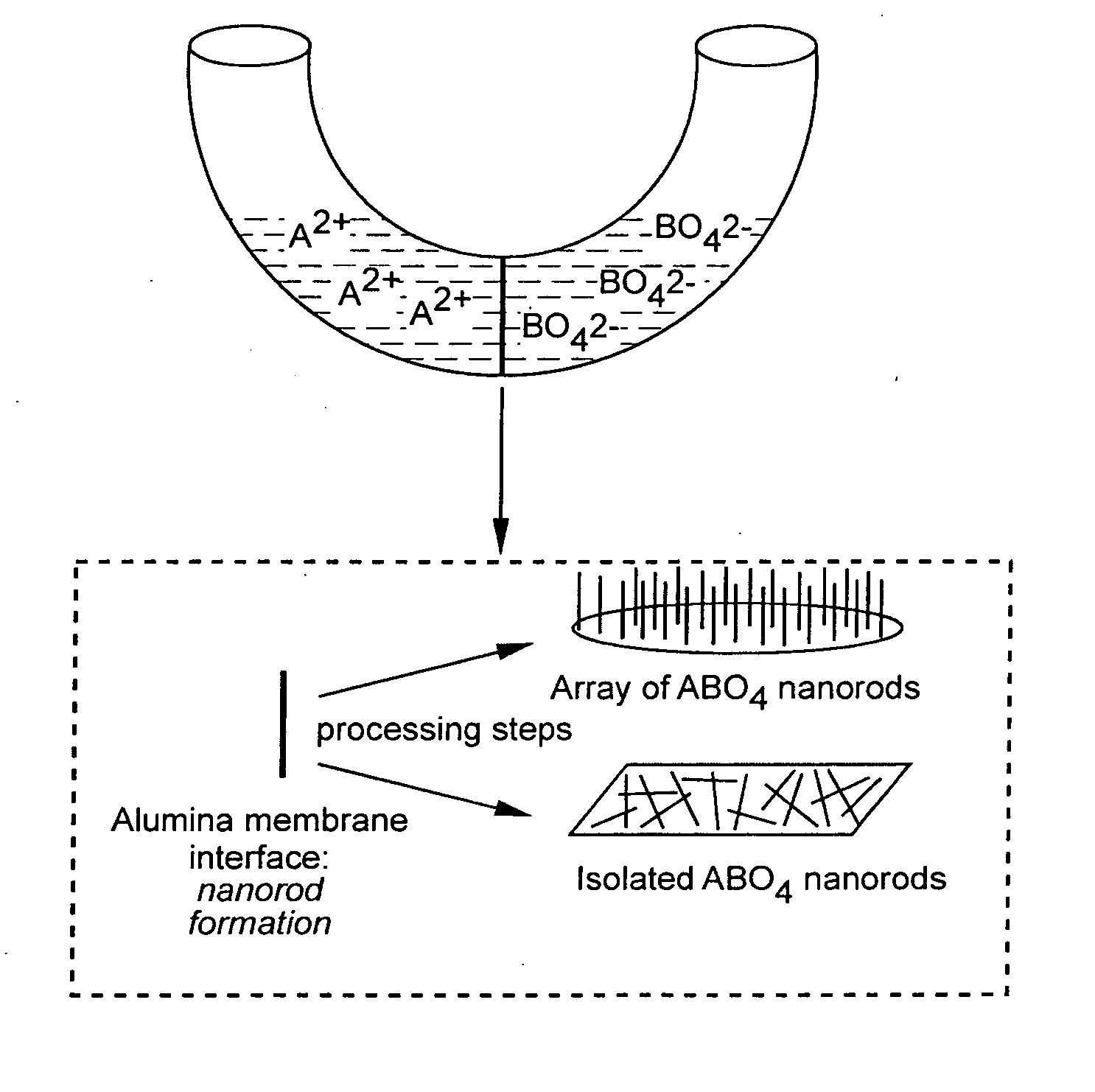

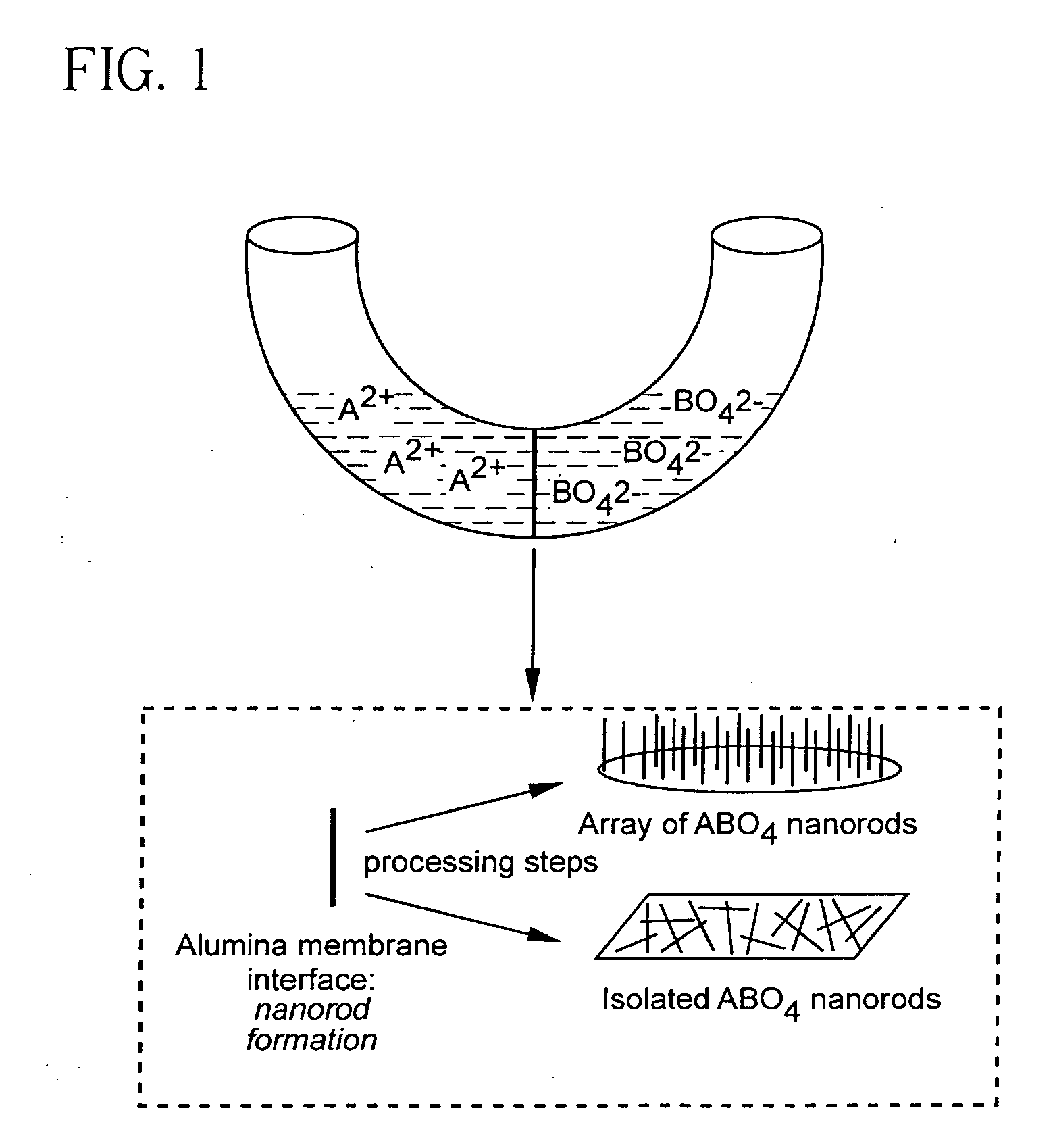

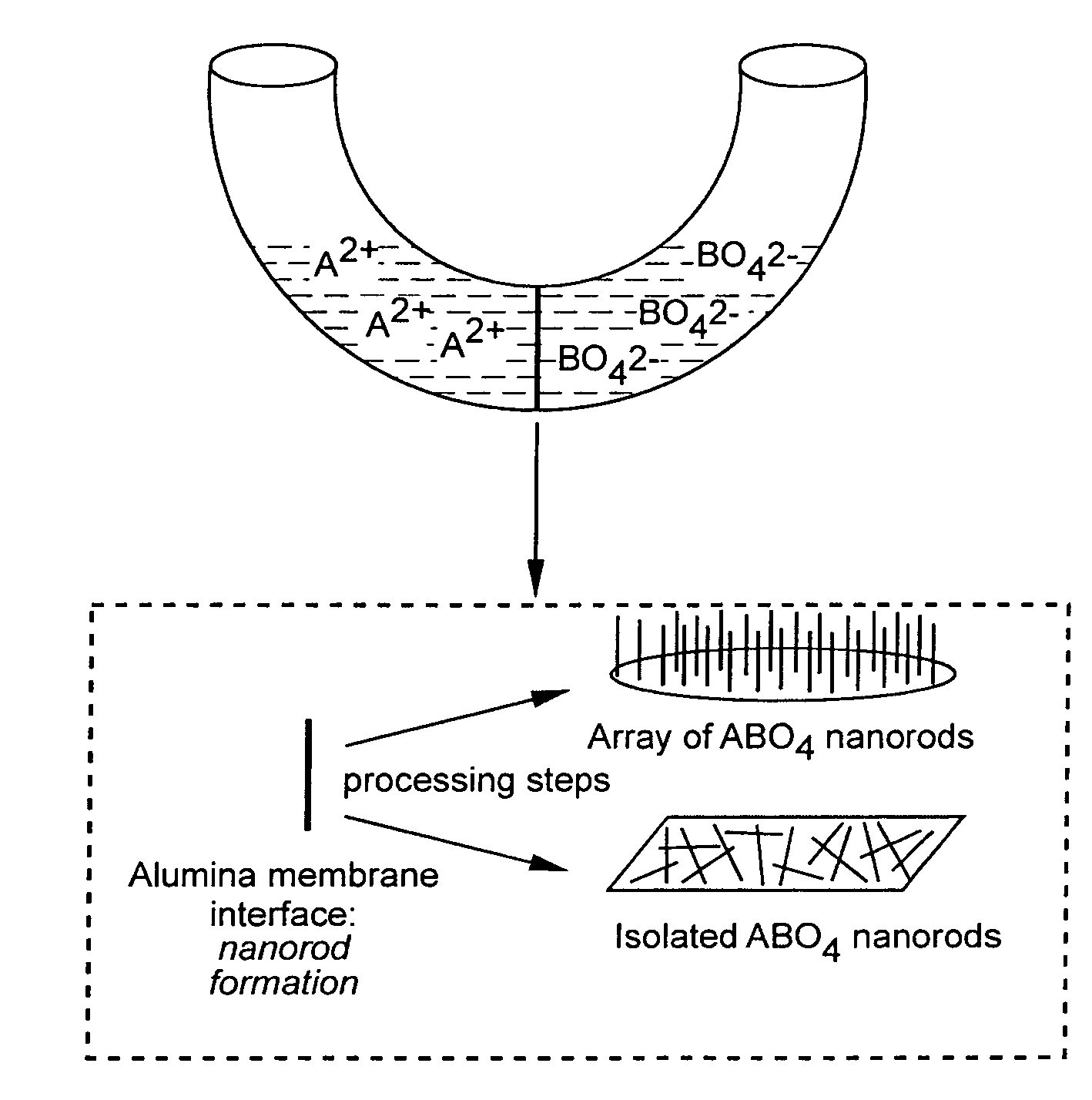

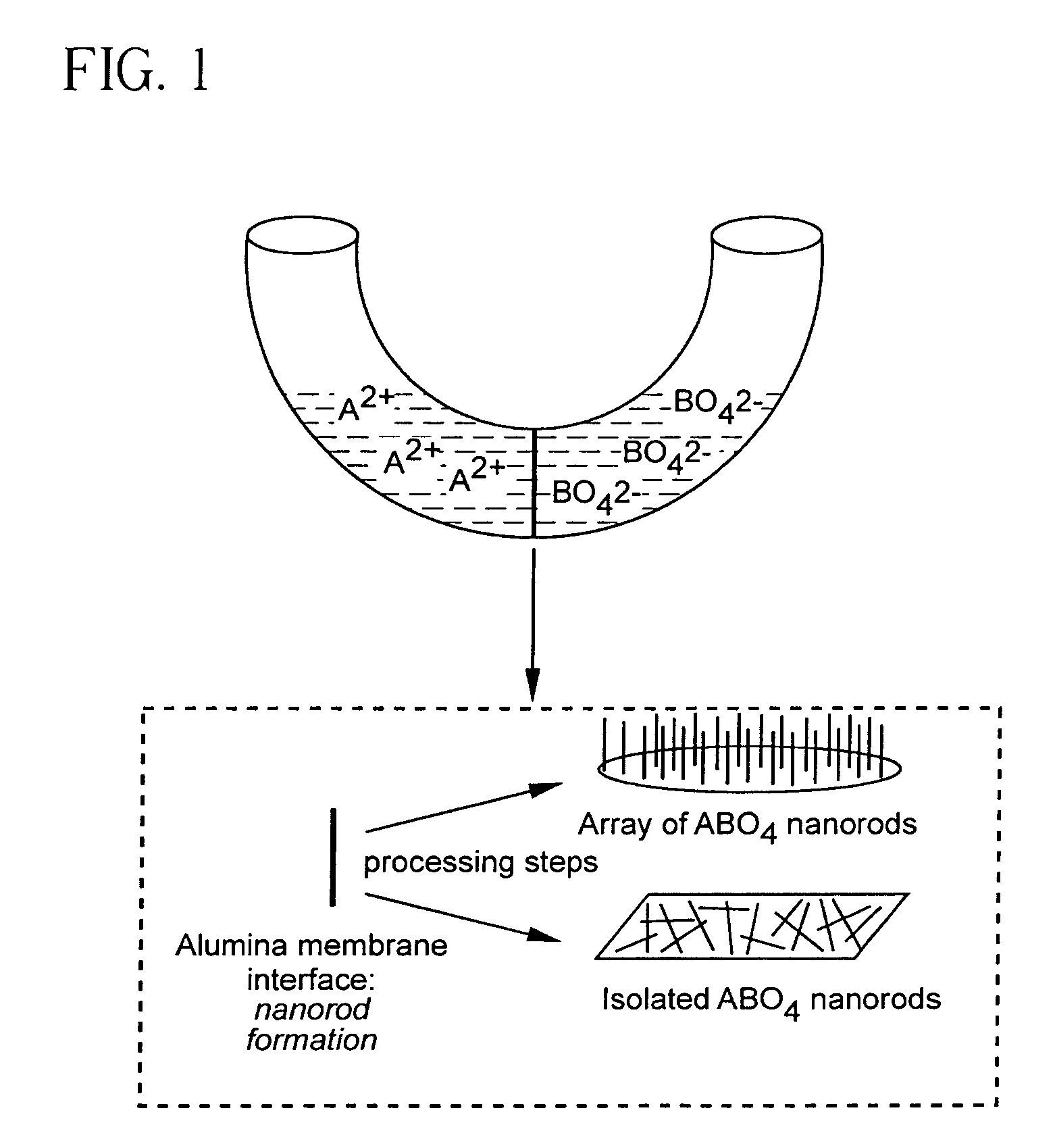

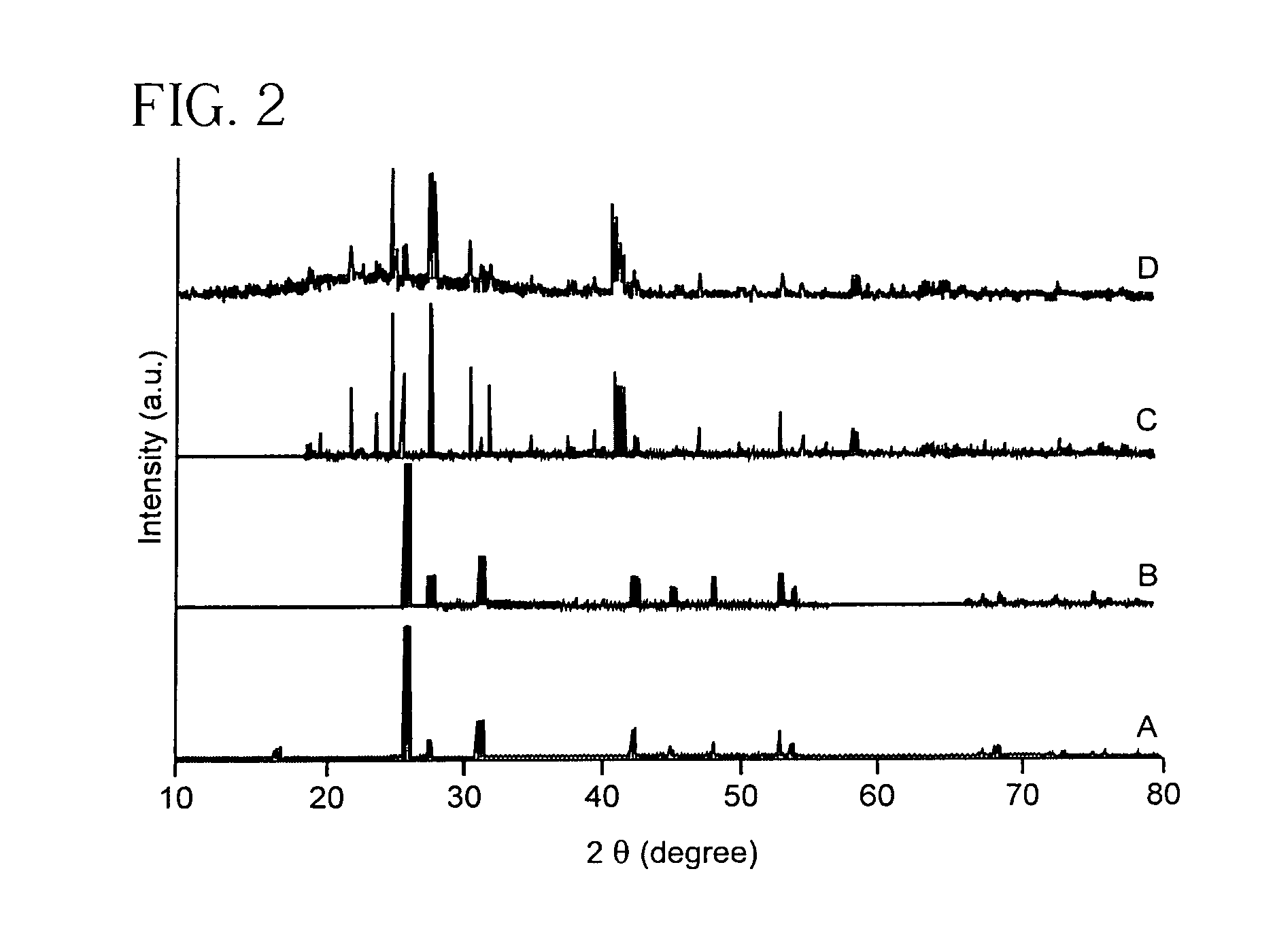

Metal oxide and metal fluoride nanostructures and methods of making same

InactiveUS20070113779A1Easy to controlOvercomes shortcomingMercury oxidesAlkali metal oxides/hydroxidesSingle crystalNanostructure

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

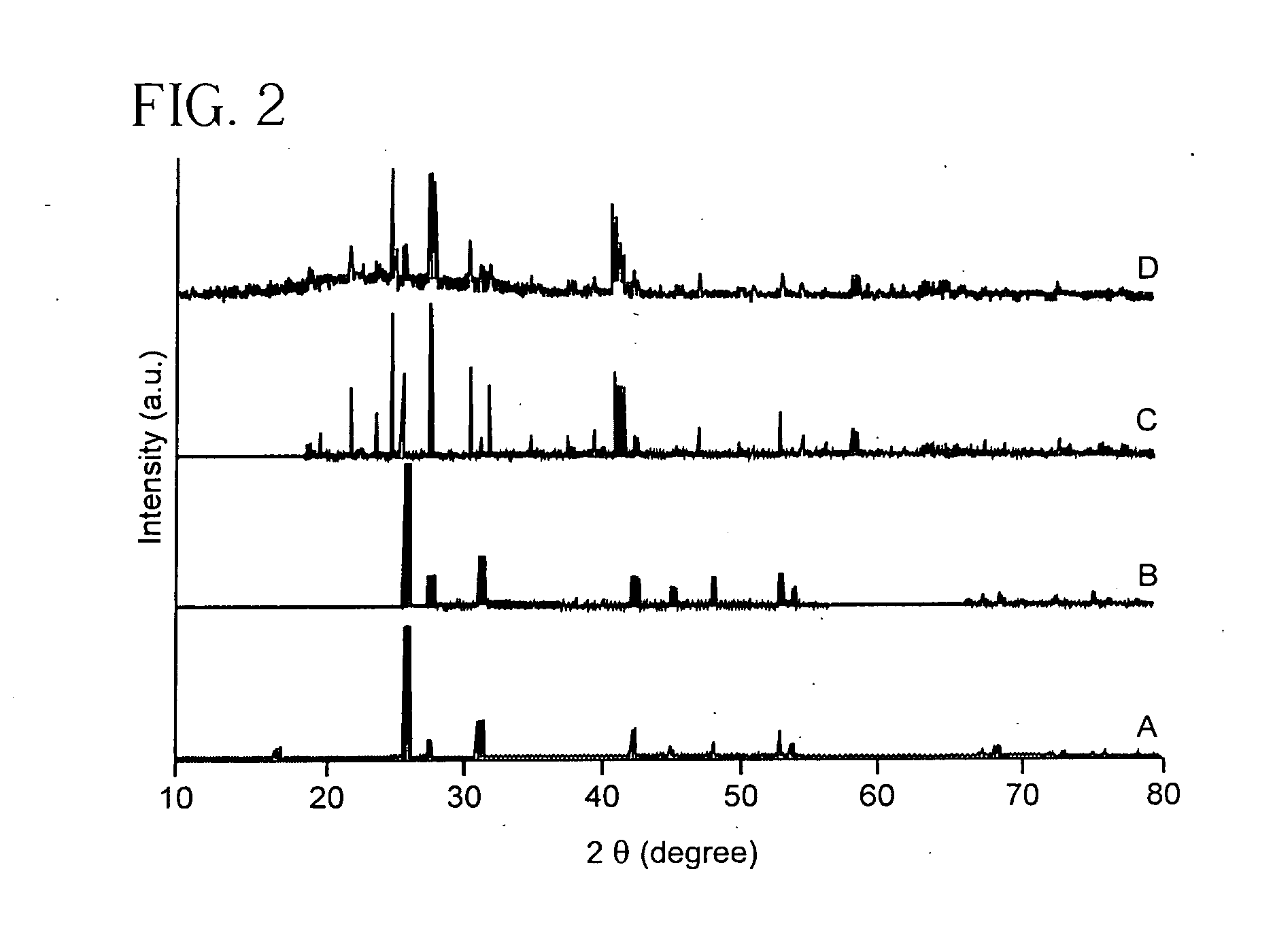

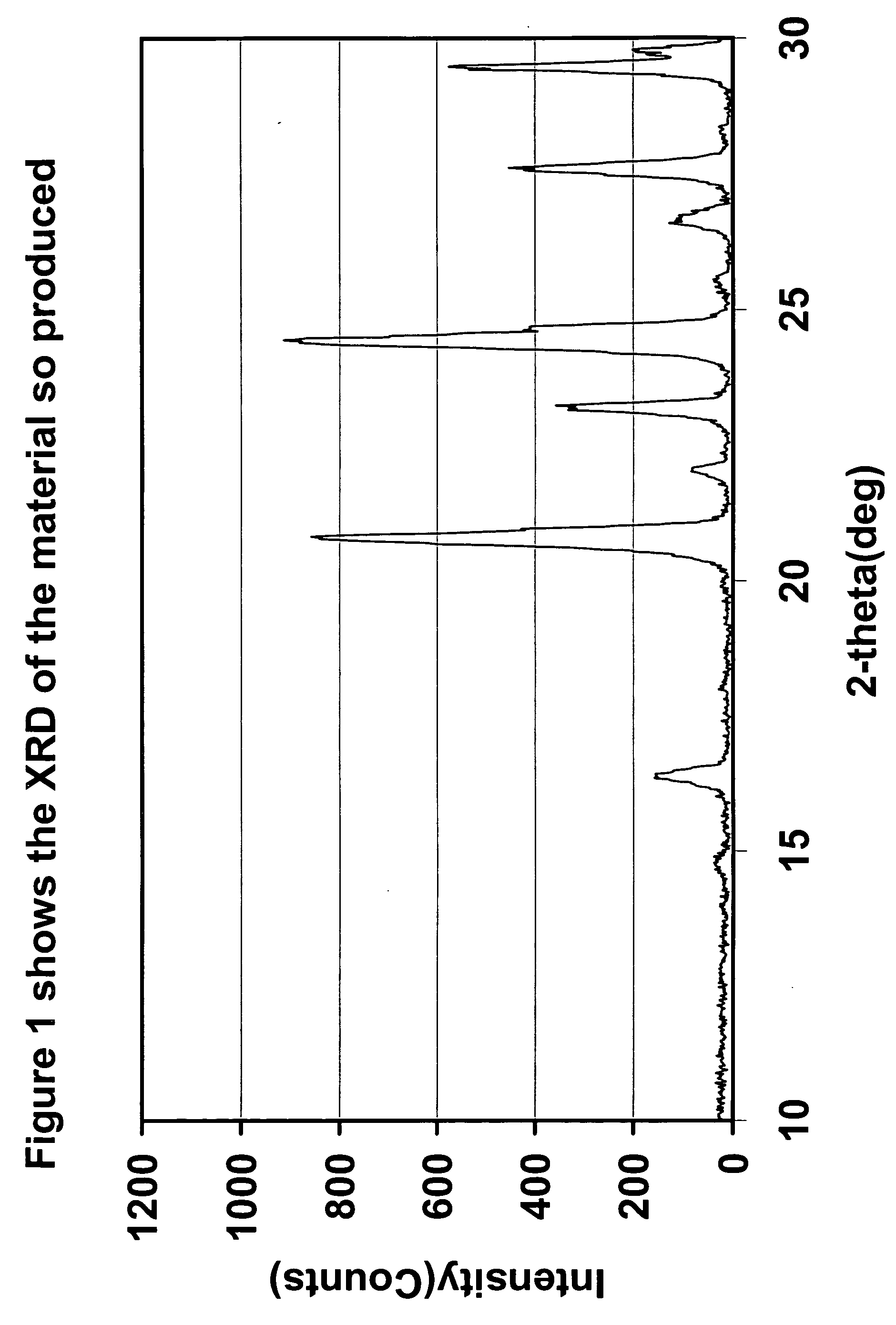

Synthesis of cathode active materials

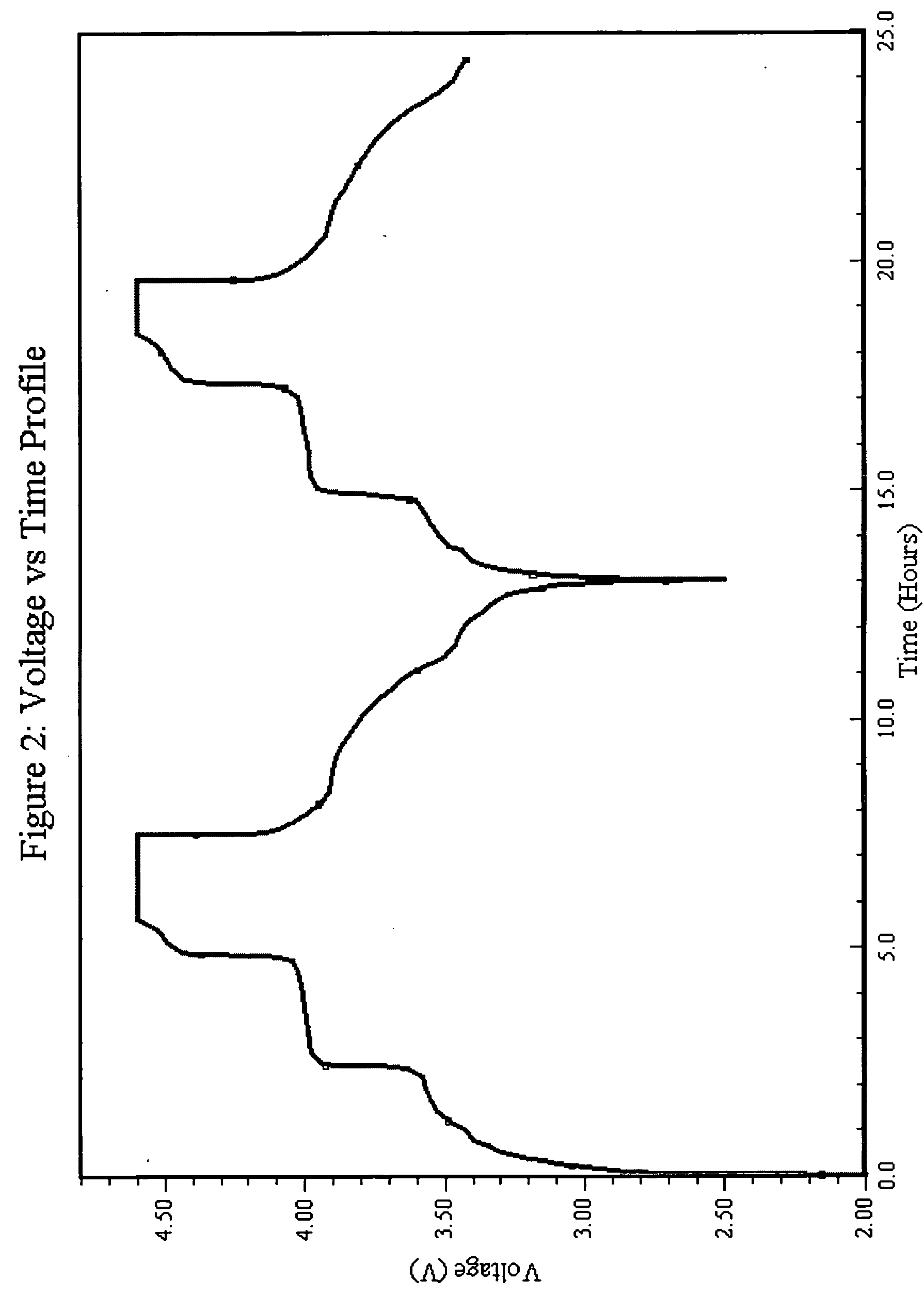

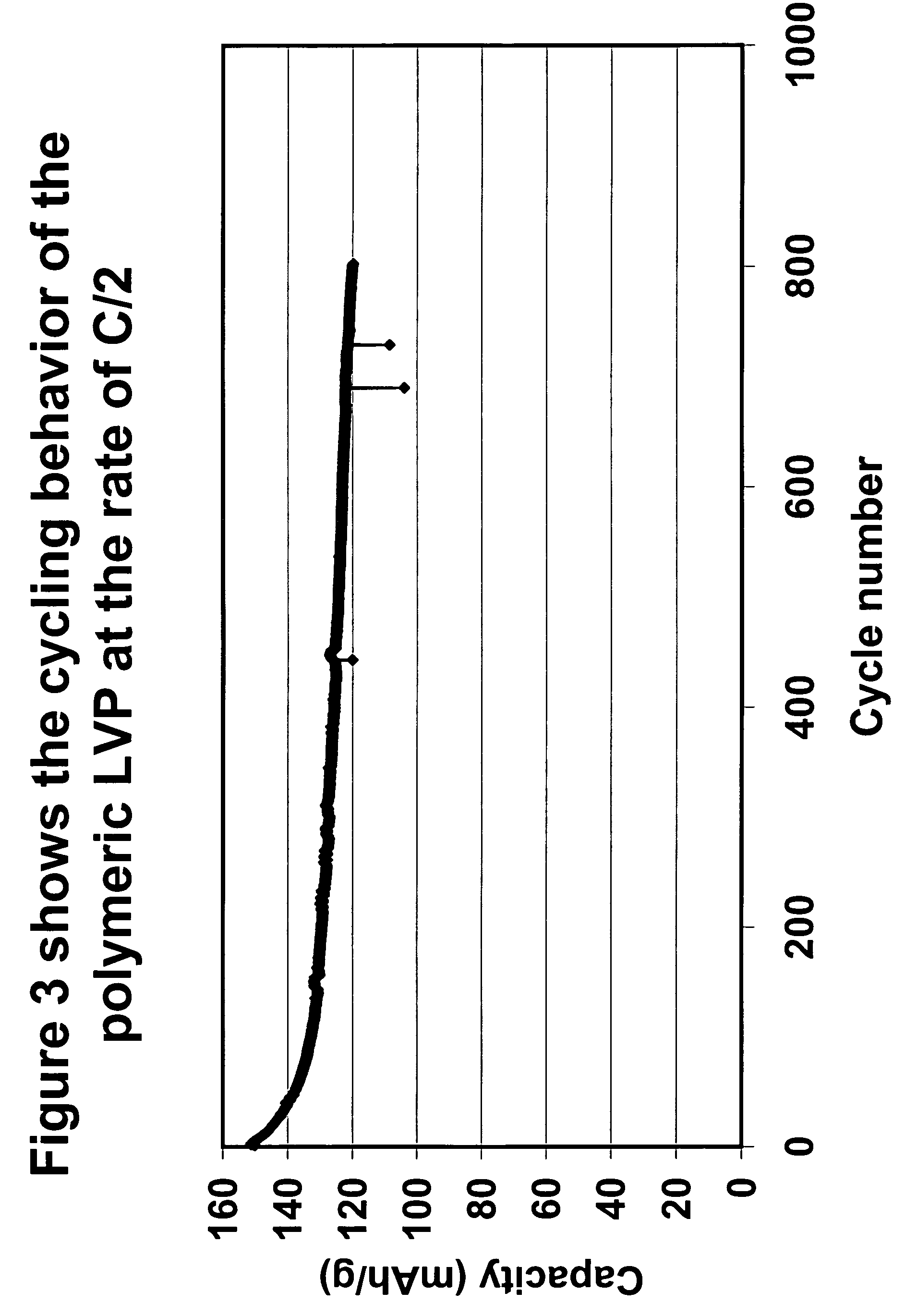

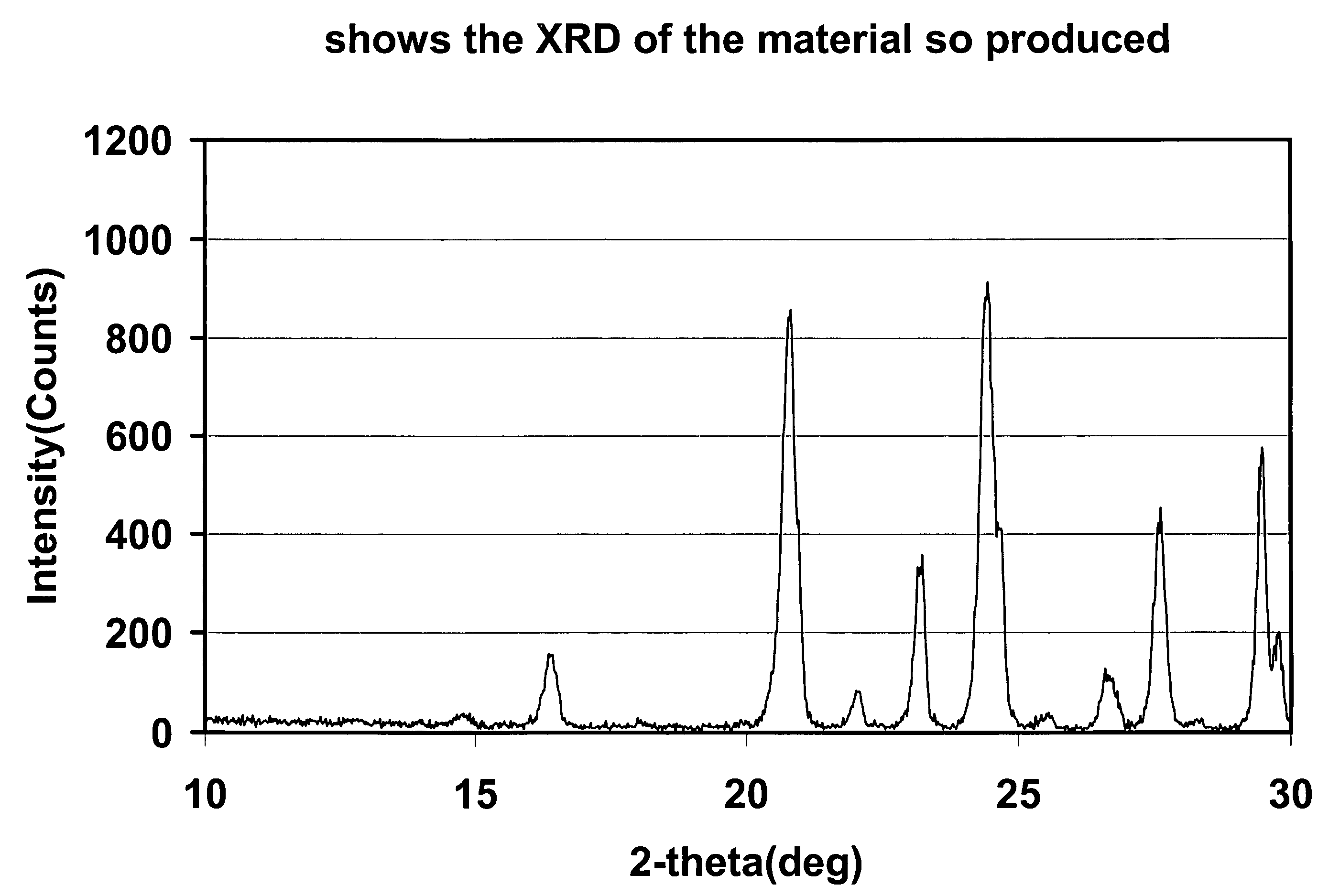

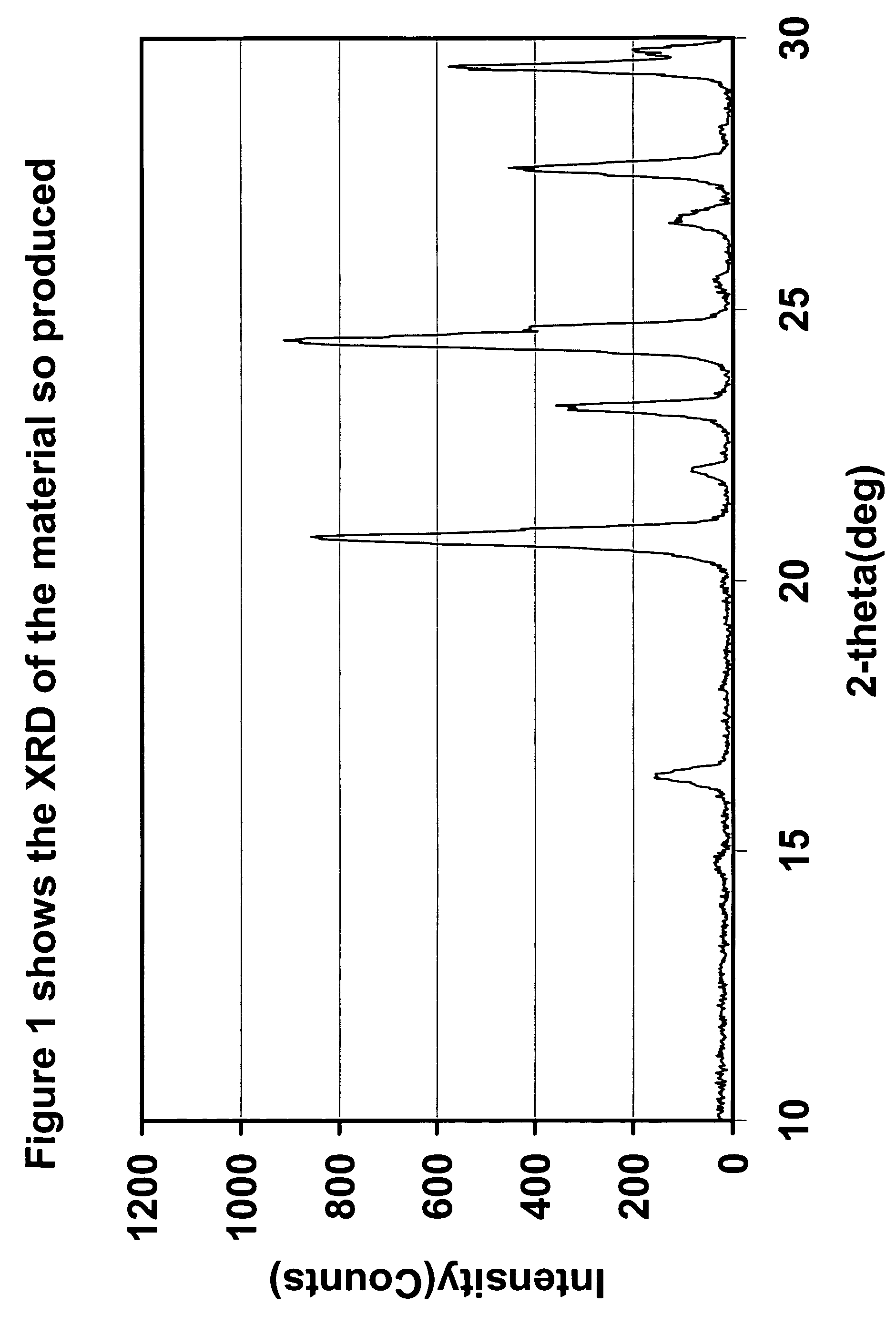

The present invention relates to a method for preparing an electroactive metal polyanion or a mixed metal polyanion comprising forming a slurry comprising a polymeric material, a solvent, a polyanion source or alkali metal polyanion source and at least one metal ion source; heating said slurry at a temperature and for a time sufficient to remove the solvent and form an essentially dried mixture; and heating said mixture at a temperature and for a time sufficient to produce an electroactive metal polyanion or electroactive mixed metal polyanion. In an alternative embodiment the present invention relates to a method for preparing a metal polyanion or a mixed metal polyanion which comprises mixing a polymeric material with a polyanion source or alternatively an alkali metal polyanion source and a source of at least one metal ion to produce a fine mixture and heating the mixture to a temperature higher than the melting point of the polymeric material, milling the resulting material and then heating the milled material. It is another object of the invention to provide electrochemically active materials produced by said methods. The electrochemically active materials so produced are useful in making electrodes and batteries.

Owner:LITHIUM WERKS TECH BV +1

Synthesis of cathode active materials

Owner:LITHIUM WERKS TECH BV +1

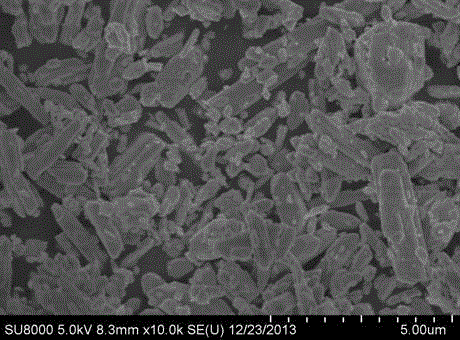

Preparing method for nano micron lead sulfate with electrochemical activity and method adopting lead sulfate to prepare lead-acid cell

ActiveCN103723761AShorten the production cycleShorten board making timeMaterial nanotechnologyLead-acid accumulator electrodesFiberSulfate

The invention discloses a preparing method for nano micron lead sulfate with electrochemical activity and a method adopting the lead sulfate to prepare a lead-acid cell. The preparing method for nano micron lead sulfate includes the following steps: using a morphological control agent for controlling the crystal growth of lead sulfate; enabling a water solution of soluble lead salt to react with a water solution of soluble sulfate / sulfuric acid, or enabling an aqueous dispersion of lead elementary substance / insoluble lead compound to react with a water solution of sulfuric acid in a clash flow reactor; finally obtaining the nano micron lead sulfate. The preparing method for the lead-acid cell includes the following steps: adopting the lead sulfate as active substances for an anode and a cathode; preparing a positive plate and a negative plate through adding fibers, a conductive agent, an expanding agent and the like; adding membranes between the two poles; then placing the two plates in a cell box for battery charging and formation. The invention has the advantages that the nano micron lead sulfate is high in electrochemical activity; the performance of the lead-acid cell is high and the service life of the lead-acid cell is long after the nano micron lead sulfate is adopted as the active substances of the lead-acid cell; besides, the preparing methods for the lead sulfate and the lead-acid cell are simple and feasible and have the characteristics of energy conservation and environmental protection.

Owner:SOUTHEAST UNIV

Paste curing additive

InactiveUS20060093912A1Increase productionShorten the curing timeLead-acid accumulator electrodesNon-aqueous electrolyte accumulator electrodesPolymer scienceLead oxide

The disclosed invention relates to additives for use in, such as, battery pastes and in polymers. The additive is the reaction product of sulphuric acid, water and leady oxide. The additive may be used in a mixture of sulphuric acid, water and leady oxide to produce a modified battery paste that, when pasted onto battery plates, yields plates of improved performance. The additive also may be used as a stabilizer for chlorine containing polymers such as polyvinyl chloride.

Owner:MAYER GEORGE E

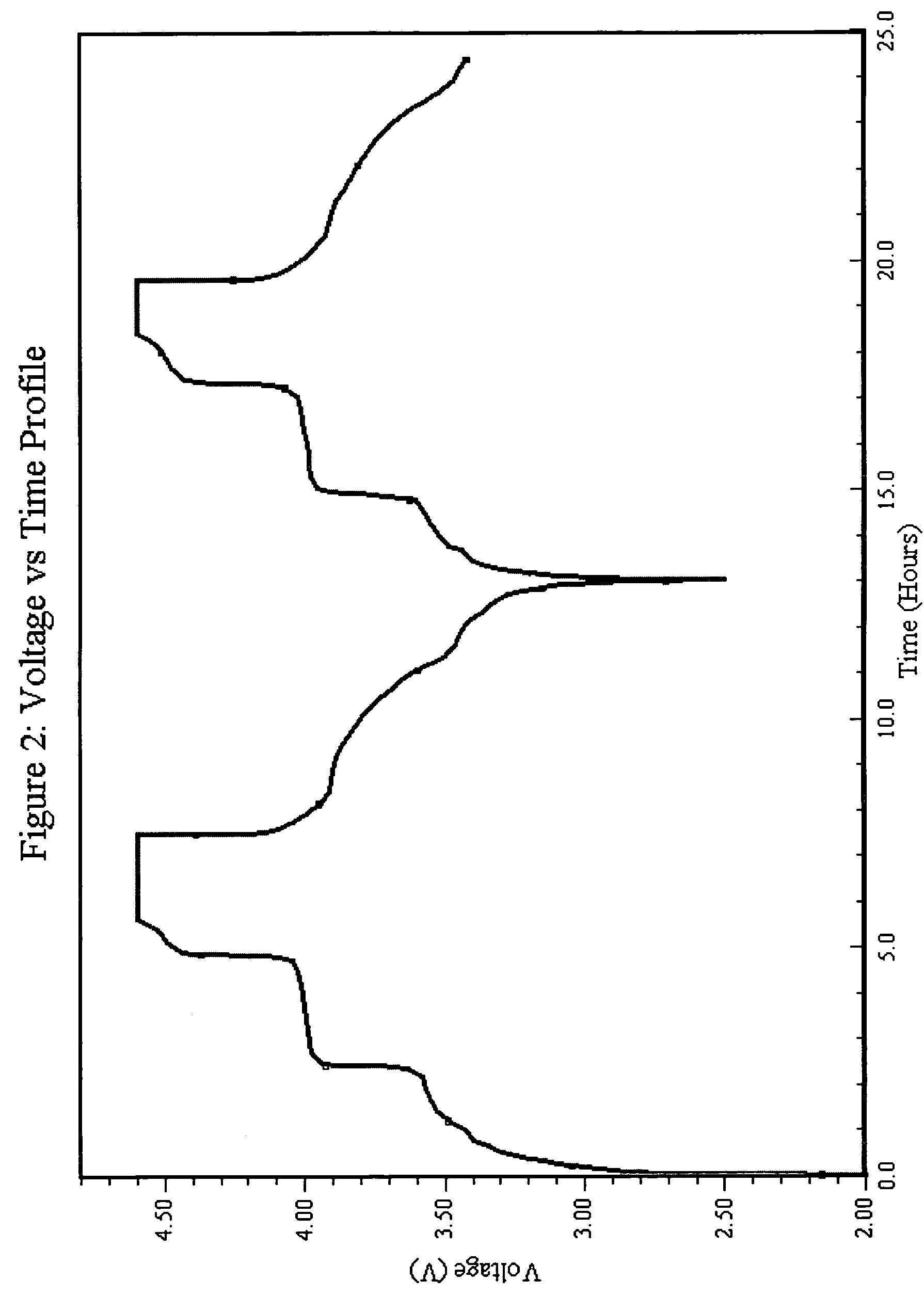

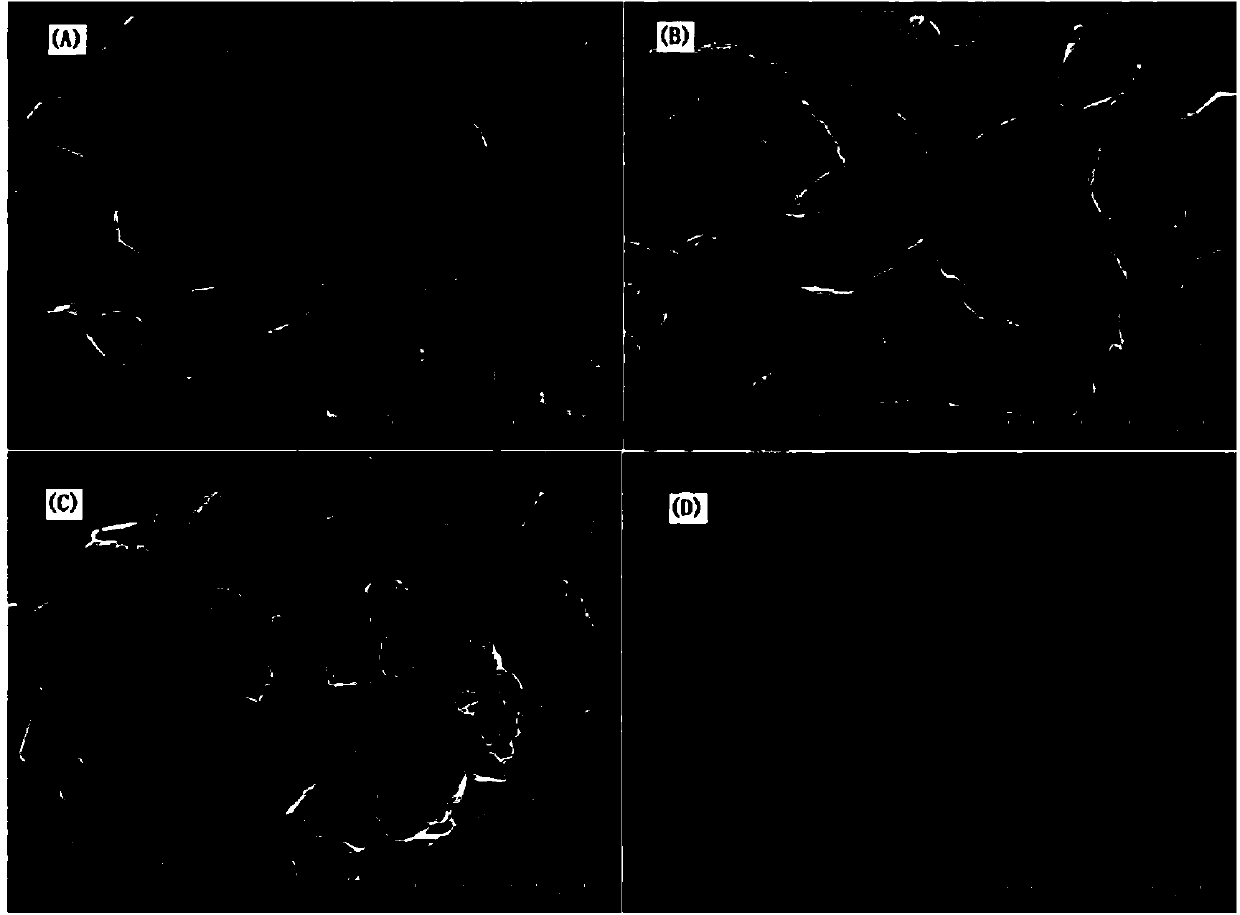

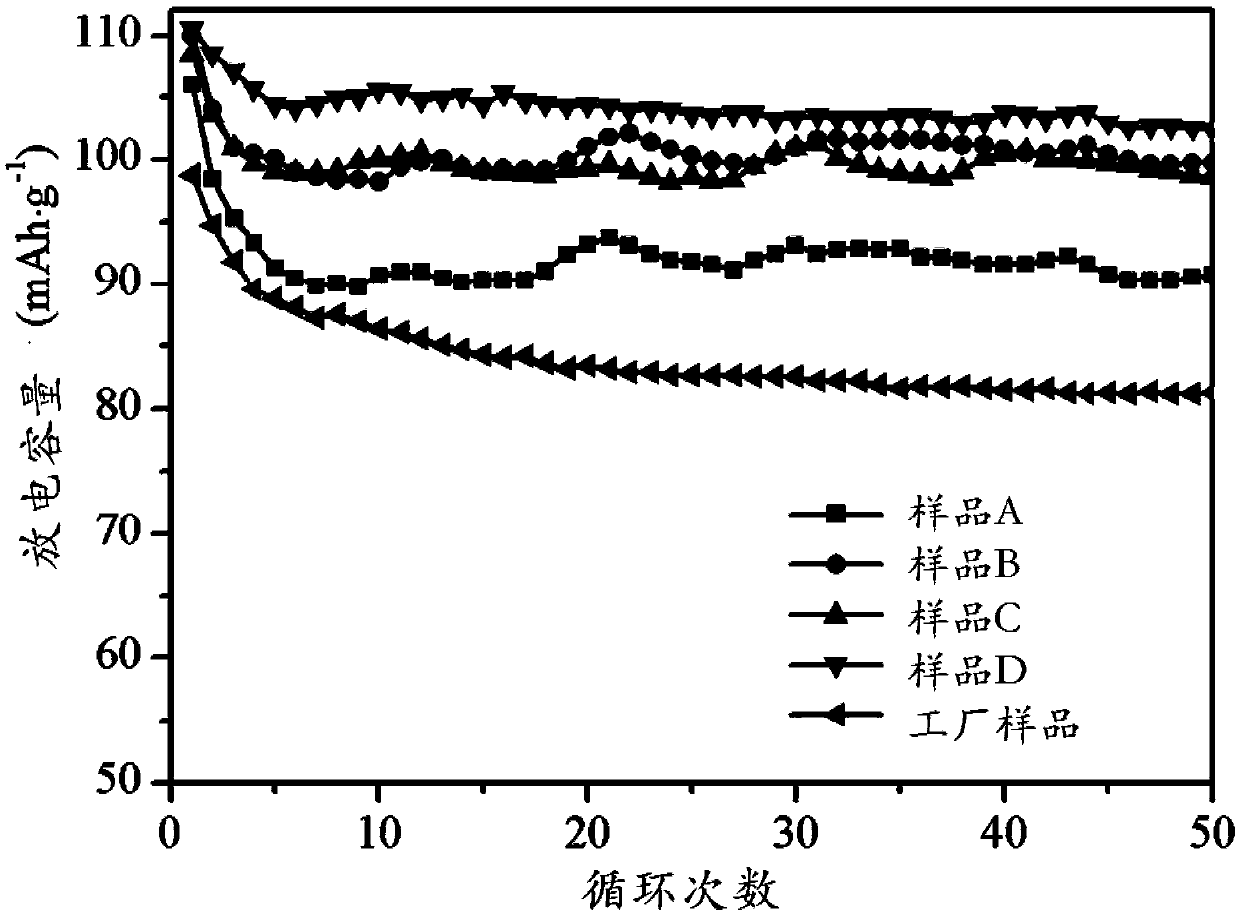

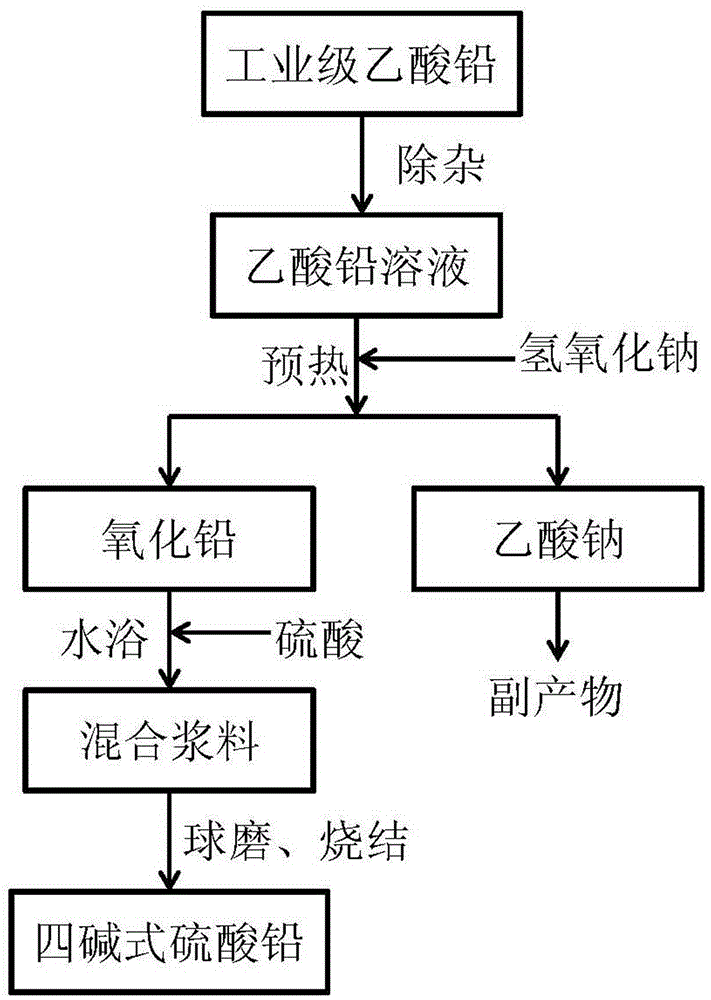

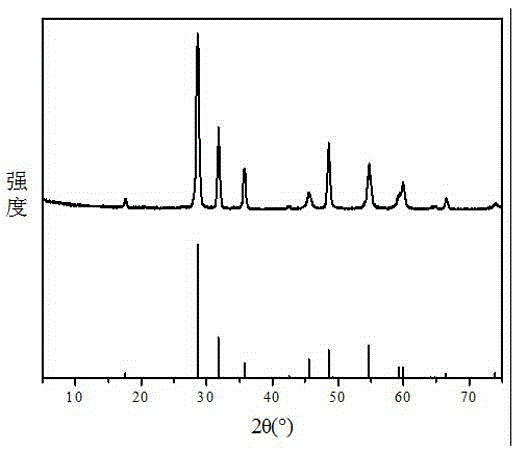

Method for preparing tetrabasic lead sulfate

ActiveCN105271375AHigh purityThe process is simple and easy to controlLead sulfatesAcetic acidLead acetate

The invention provides a method for preparing tetrabasic lead sulfate. The method comprises the following steps: S10. impurities are removed from a lead acetate stock solution, so as to obtain a lead acetate solution; S20. the lead acetate solution is mixed with an alkaline solution under a heated condition, and lead oxide is obtained after filtering; S30. the lead oxide is mixed with sulfuric acid, filtering is carried out after reaction, and ball milling is carried out after sintering to obtain the tetrabasic lead sulfate. The method provided by the invention has the advantages of simple and controllable processes, high product purity (above 99 percent), and uniform and controllable particle sizes; moreover, according to the method, the lead acetate serves as the initiator to prepare the high-purity tetrabasic lead sulfate, and multiple batches of measurements of the tetrabasic lead sulfate show that the contents of iron element and barium element, which are the impurities significantly affecting the battery performance, are below 20 ppm and below 2 ppm respectively.

Owner:SHENZHEN CENT POWER TECH +1

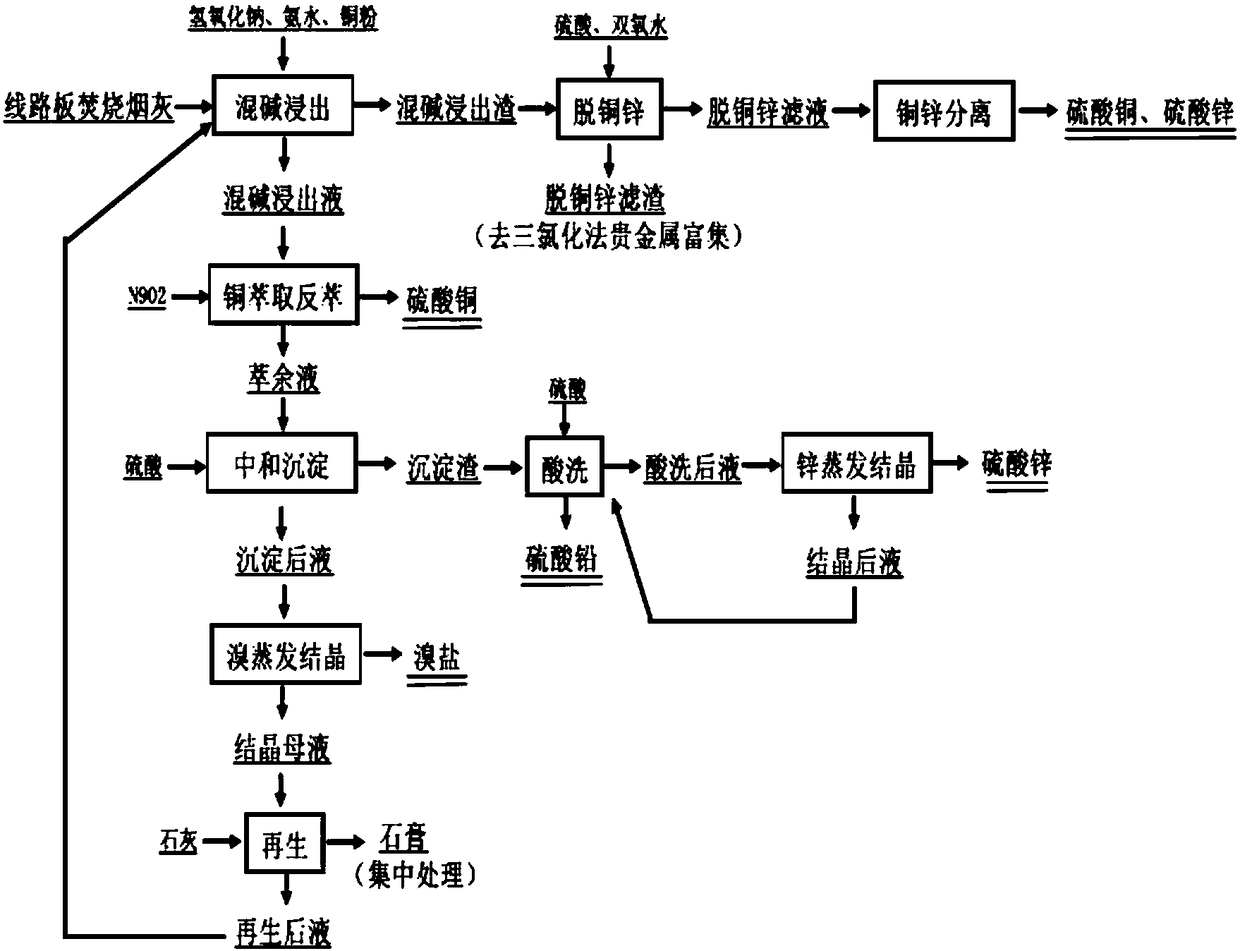

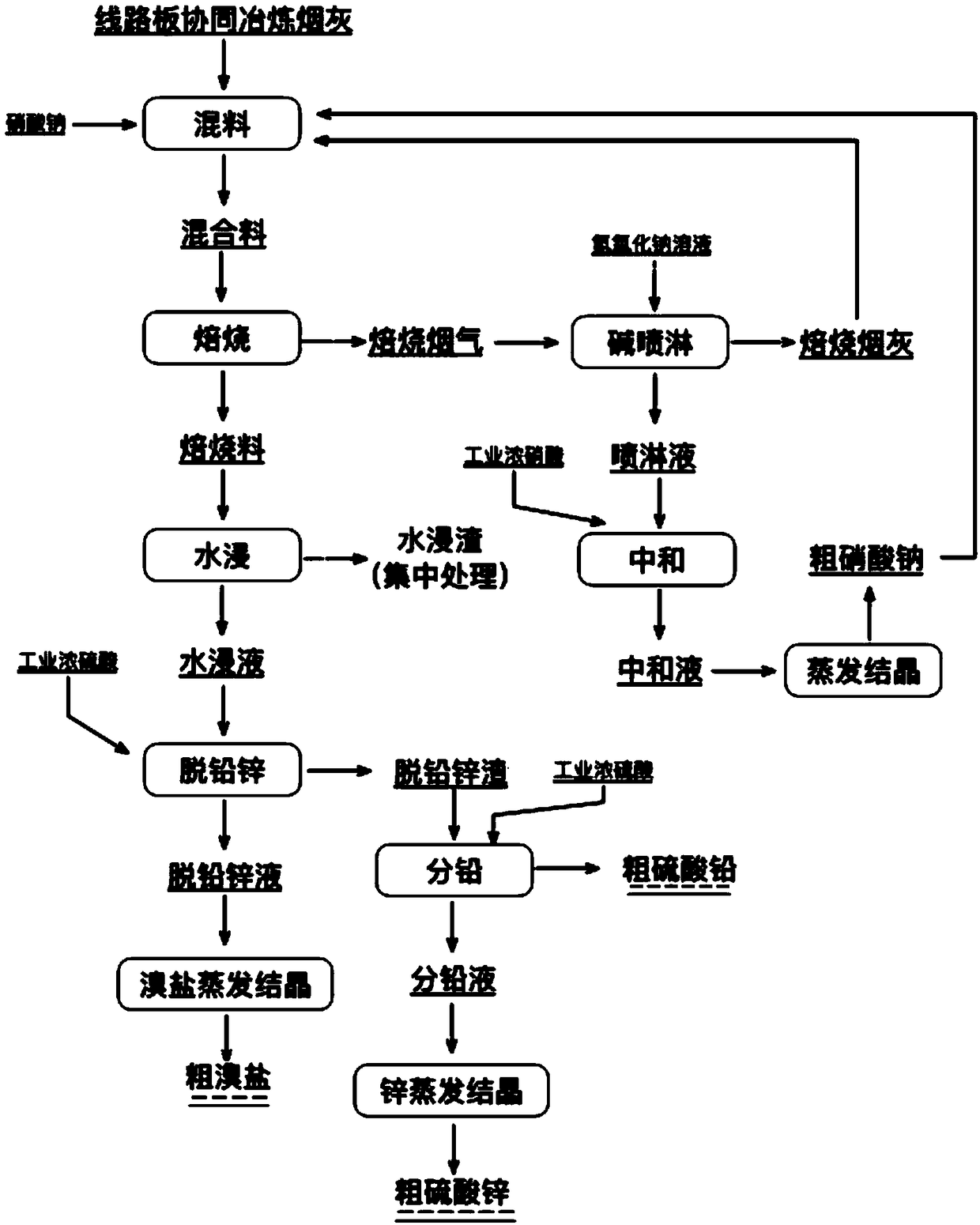

Method for pretreating incineration ash of circuit board and recovering bromine

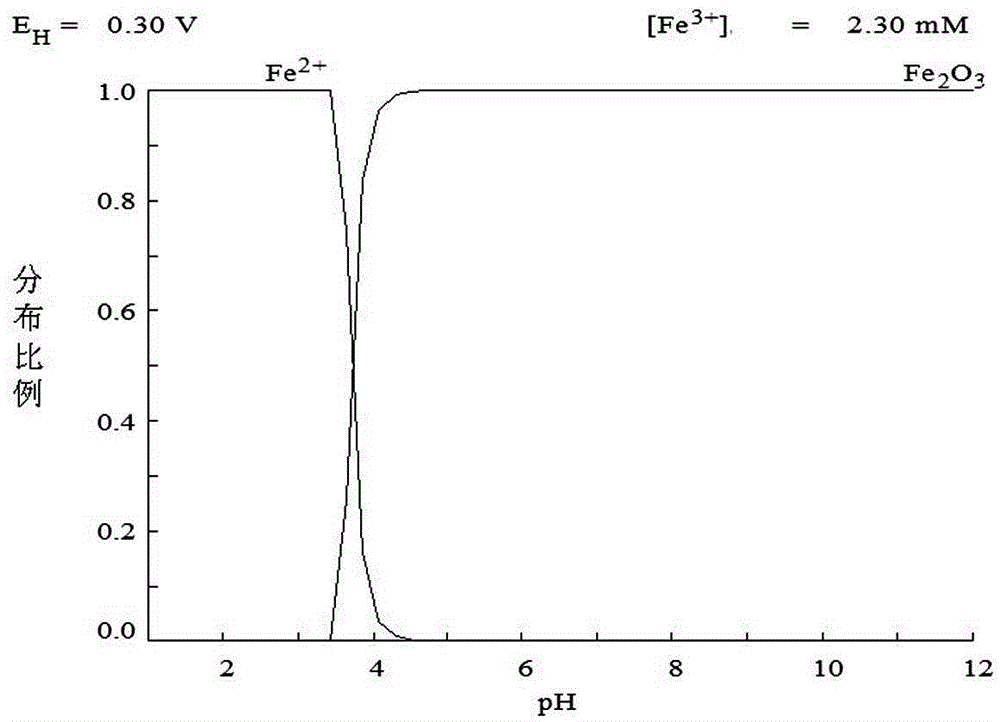

ActiveCN108118157AEasy to recycleNo emissionsZinc sulatesCalcium/strontium/barium sulfatesRecovery methodBromine

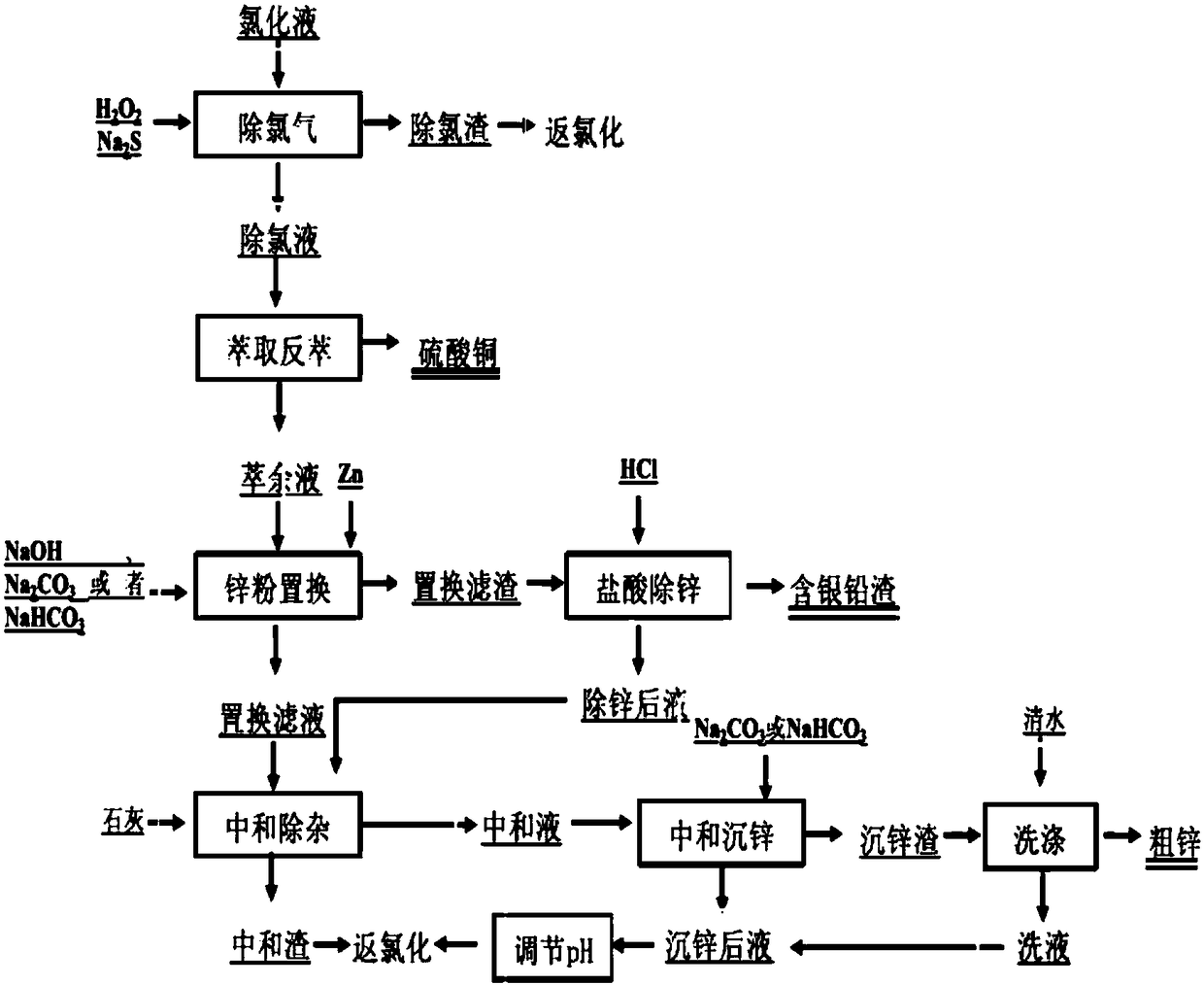

The invention discloses a method for pretreating incineration ash of a circuit board and recovering bromine, belongs to the field of comprehensive recovery of ash whole-wet valuable metal and particularly relates to a method for recovering valuable metal, enriching precious metal and recovering bromine salt in the pretreatment process of incineration ash of the circuit board. The method mainly comprises the steps: extracting mixed alkali; recovering copper by copper extraction and back extraction; carrying out neutralization and precipitation to separate lead and zinc; evaporating and crystallizing bromine; regenerating mixed alkali extracting liquor; removing zinc by acid pickling; evaporating and crystallizing zinc; carrying out zinc and copper removal on mixed alkali extracting residuesand the like. Compared with a traditional ash comprehensive process, the technology disclosed by the invention has the advantages that recovery of valuable metals such as copper, zinc and lead and enrichment of precious metal such as silver in the pretreatment process of the ash is realized to the maximum extent; meanwhile, the bromine salt is separated and recovered; the method has the characteristics of high recovery added value, no tail liquid drainage and the like.

Owner:BEIJING UNIV OF TECH

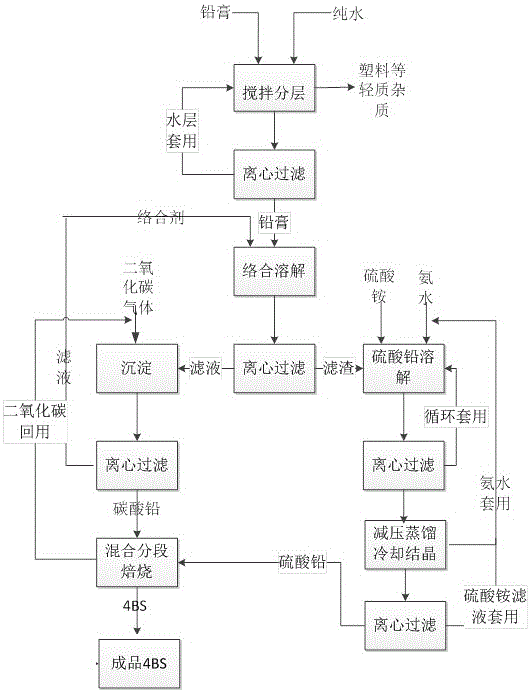

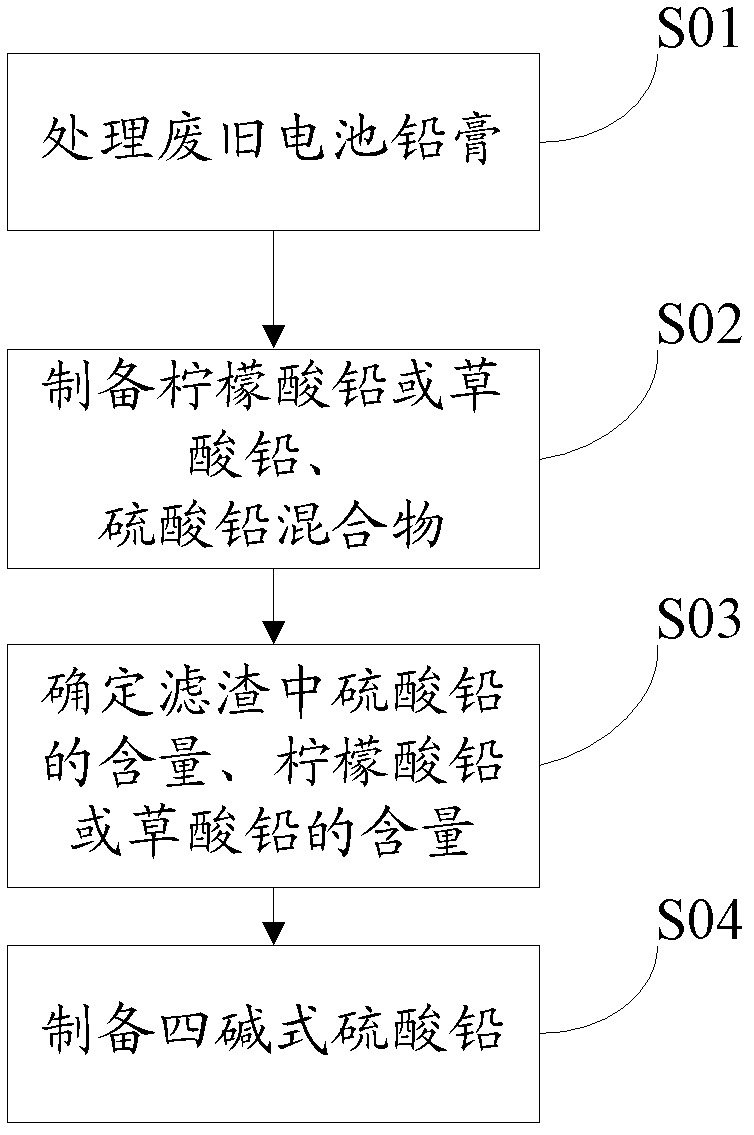

Method for preparing 4BS through waste lead-acid battery

ActiveCN106587142AIncrease profitHigh purityCell electrodesWaste accumulators reclaimingLead dioxideEnvironmental engineering

The invention relates to the field of recycling and reusing, and provides a method for preparing 4BS through a waste lead-acid battery. By adoption of the method, recycling and reusing of lead paste in waste lead-acid batteries can be achieved currently. The method for preparing the 4BS through the waste lead-acid battery comprises the steps of removal of impurities, complexing dissolution of lead and lead dioxide, the purification reaction of lead sulfate, purification of the lead and the lead sulfate in the lead paste, dissolution of lead sulfate and the like. The purity of the 4BS prepared through the method is high, and the yield is high; and the method is environmentally friendly, and industrial production can be achieved easily.

Owner:CHAOWEI POWER CO LTD

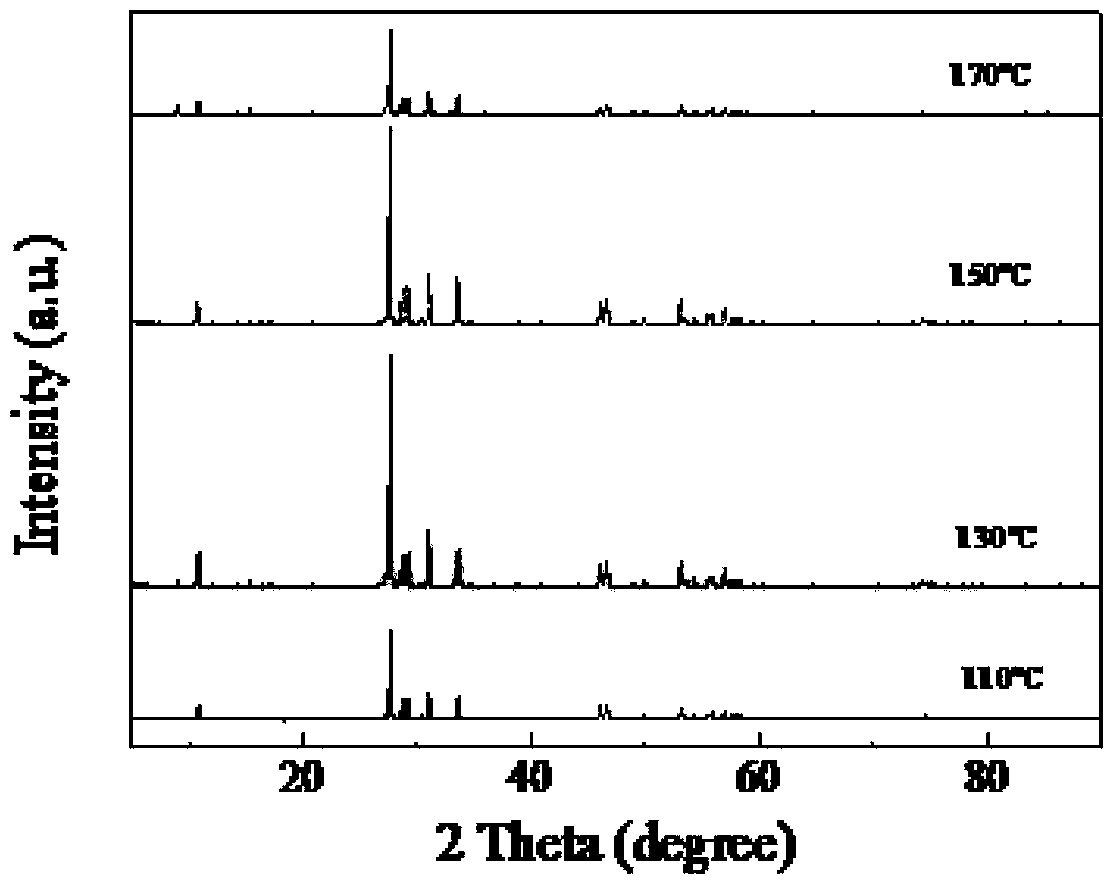

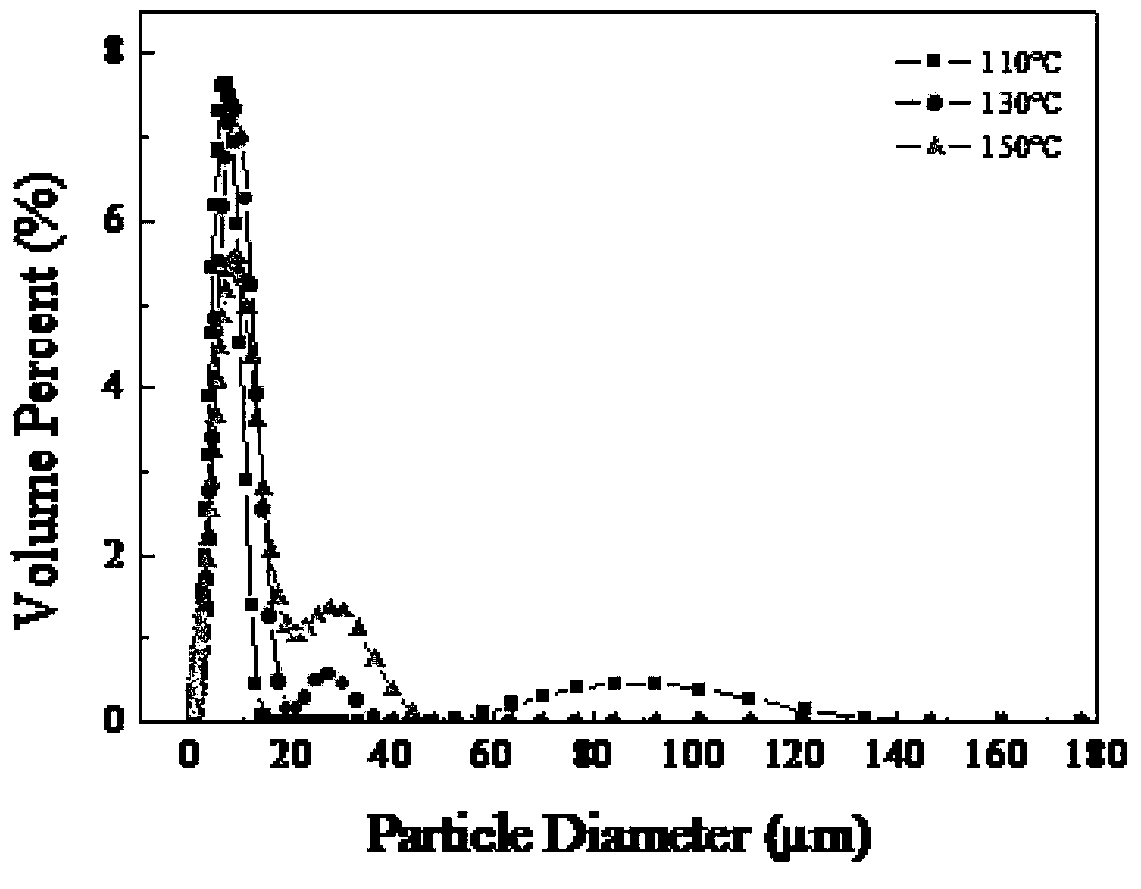

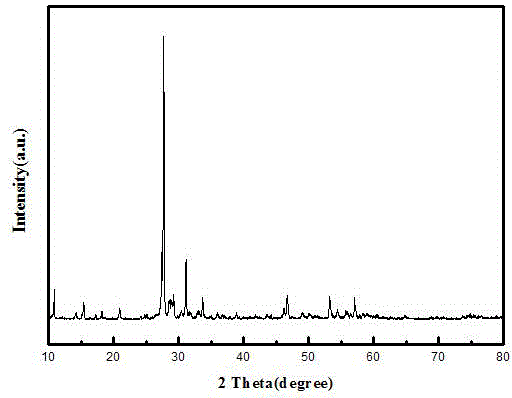

Preparation method of tetrabasic lead sulfate

ActiveCN103384010ASuppress generationPromote conversionLead-acid accumulatorsCell electrodesLead sulfateVacuum drying

The invention discloses a preparation method of tetrabasic lead sulfate. The preparation method comprises following steps: A, samples are weighed; B, hydro-thermal reaction; C, ball milling processing; and D, vacuum drying. The preparation method may also comprise steps such as E, post-processing. Hydro-thermal reaction and ball milling processing are combined to prepare 4BS according to the invention. The 4BS prepared by the preparation method possesses characteristics that: the 4BS content can reach 95% or more; and average particle size can reach 10um or less. The preparation method is capable of solving problems that: pole plate formation is difficult, consistency is poor and initial capacity is less; shortening curing time; improving combination properties such as storage battery cycle life; and realizing true energy-saving, low carbon and environmental protection.

Owner:ANHUI YONGHENG STORAGE BATTERY

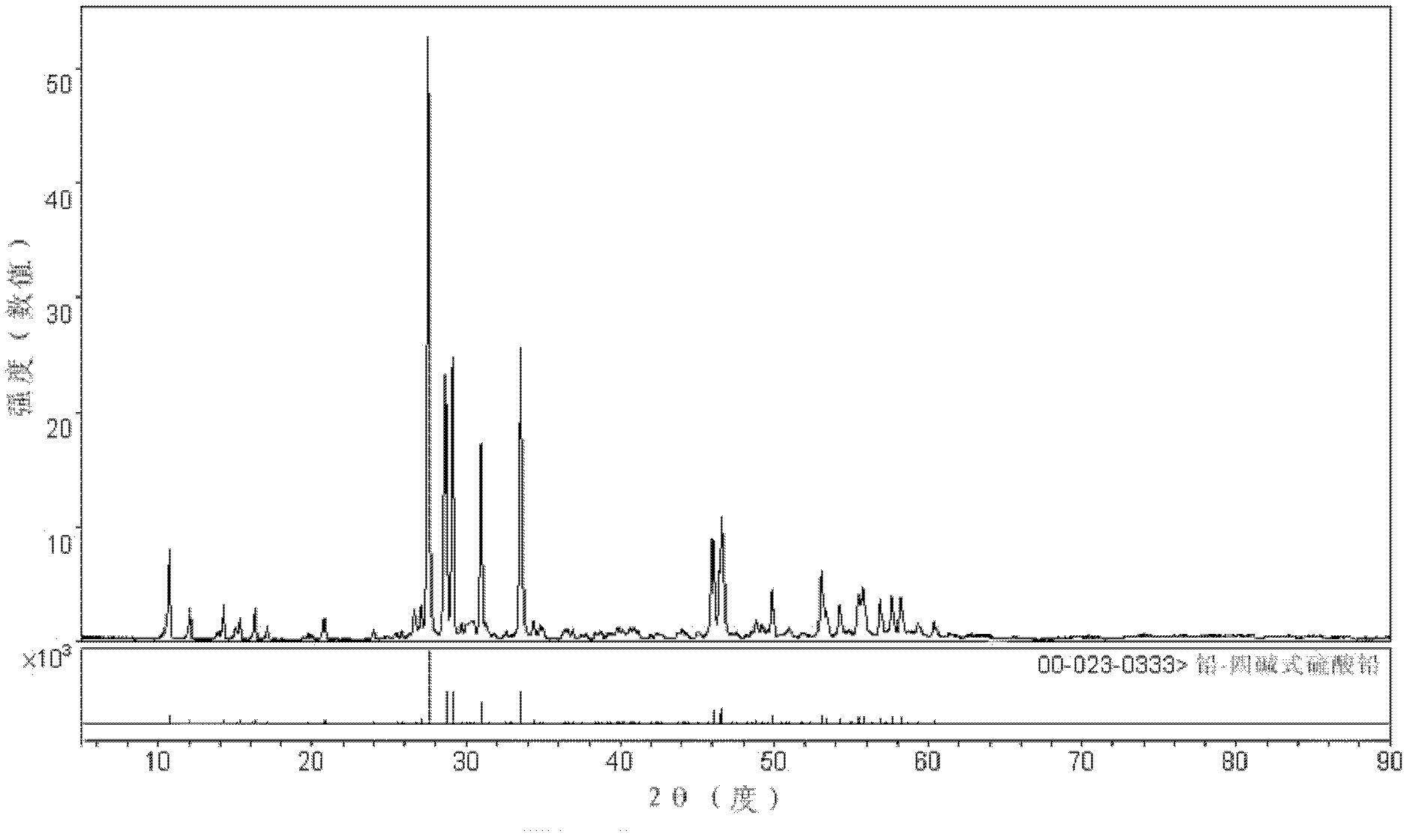

Method for preparing tetrabasic lead sulfate from waste batteries and application of tetrabasic lead sulfate

ActiveCN103022594AEasy to operateLow costWaste accumulators reclaimingLead sulfatesEconomic benefitsEnvironmental engineering

The invention is applicable to the field of waste treatment technologies and provides a method for preparing tetrabasic lead sulfate from waste batteries and the application of the prepared tetrabasic lead sulfate in batteries. The method comprises the steps of processing lead plaster of the waste batteries, preparing a lead citrate or lead oxalate and lead sulfate mixture, determining the content of lead oxalate and the content of the lead citrate or lead oxalate in filter residue, preparing the tetrabasic lead sulfate, and the like. According to the method for preparing the tetrabasic lead sulfate from the waste batteries and the application of the tetrabasic lead sulfate, the lead plaster is recovered from the waste batteries and used for preparing the tetrabasic lead sulfate, so that the battery recovery processing has a great economic benefit, and substances polluting the environment are not generated, thereby being environment-friendly; and the method is simple in operation and low in cost, thereby being very applicable to industrialized production.

Owner:SHENZHEN CENT POWER TECH

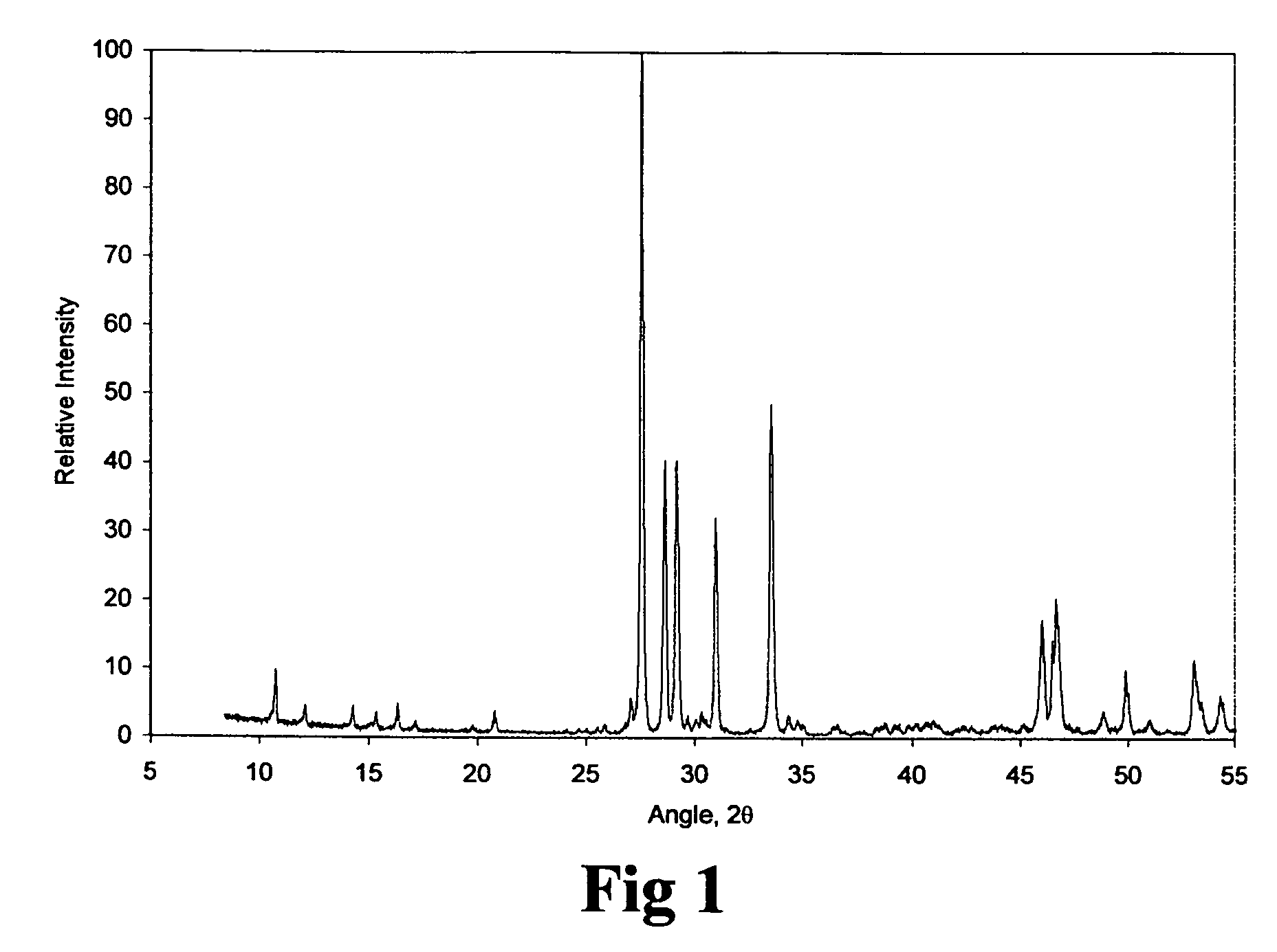

Production of tetrabasic lead sulfate from solid state reactions for the preparation of active plates to be used in lead-acid batteries

The production of tetrabasic lead sulfate by means of solid state reactions at high temperatures allow the formation of powders having a particle size of less than 10 μm. In the methods the chemical reaction that takes place between lead oxide and different sulfated compounds occurs in a single high temperature treatment. The sulfated compounds used in the present invention to produce the tetrabasic lead sulfate are: PbSO4, 3PbO.PbSO4.H2O, H2SO4 and (NH4)2SO4. There are lead-acid battery pastes produced using the tetrabasic lead sulfate made, the lead-acid battery plates made with the pastes, and the lead-acid batteries subsequently made with the plates.

Owner:CPS TECH HLDG LLC

Method for preparing tetrabasic lead sulfate by using acid leaching byproduct in production of lead acid storage battery positive electrode plate

InactiveCN104218270ASlow down early capacity fading phenomenonImprove cycle lifeWaste accumulators reclaimingLead sulfatesElectrical batteryLead oxide

The invention relates to a method for preparing tetrabasic lead sulfate by using an acid leaching byproduct in the production of a lead acid storage battery positive electrode plate. The method comprises the following steps: 1, draining water on the surface of the acid leaching byproduct, respectively determining the content of lead sulfate, lead oxide, simple substance lead and water in the acid leaching byproduct through a chemical analysis technology and a gravimetric analysis technology, and determining the percentage content of lead sulfate and lead oxide; 2, adding the surface water drained acid leaching byproduct into a reaction kettle, supplementing lead oxide or lead powder used for producing the lead acid storage battery according to the determination results obtained in step 1 to make a molar ratio of lead oxide to lead sulfate in the reaction kettle reach 3-6.5:1, and using deionized water as a reaction medium in a reaction system; and 3, preparing the tetrabasic lead sulfate. The above raw material is the lead acid battery byproduct and is applied to the production of the lead acid battery, so waste recycling is realized, the production cost of the lead acid storage battery is reduced, the method is environmentally friendly, and the quality of the battery is improved.

Owner:CHAOWEI POWER CO LTD

Method for recycling waste lead-acid storage battery and producing tribasic lead sulfate

ActiveCN102642866AAchieve recyclingSolid waste disposalAmmonium sulfatesLead sulfateWaste management

The invention provides a method for recycling a waste lead-acid storage battery and producing tribasic lead sulfate, which comprises the steps of waste battery dismantling, anode recycling, cathode recycling and product generation. The method has the advantages that a most valuable by-product is produced with a cheapest raw material, the waste lead-acid storage battery is recycled at a utilizing rate of approximately 100%, and the waste lead-acid storage battery is recycled at a maximum ratio.

Owner:DALIAN JIAOTONG UNIVERSITY

Method for preparing tetrabasic lead sulfate

ActiveCN106564941AShorten mixing timeShorten heating timeFinal product manufactureLead-acid accumulators constructionGranularityReaction temperature

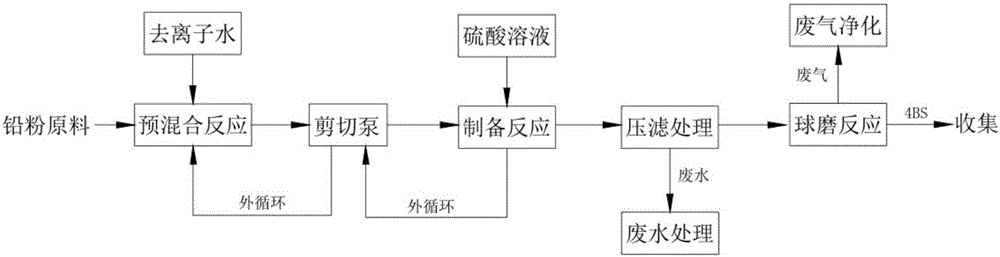

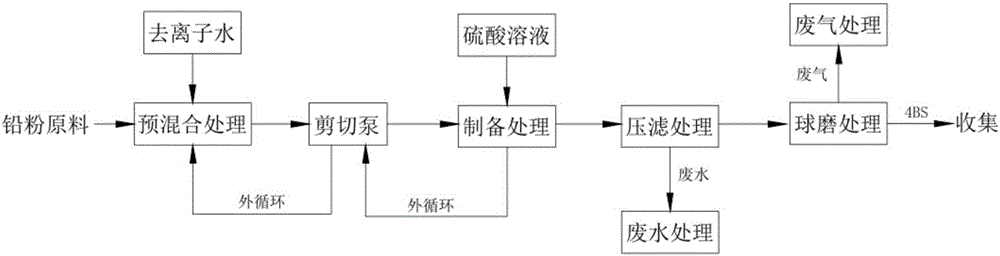

The invention relates to a method for preparing tetrabasic lead sulfate. The method comprises the following steps: 1, carrying out a preparation reaction: sending a premixed lead material to a reaction kettle, adding a sulfuric acid solution to the reaction kettle while carrying out uniform cyclic stirring, and introducing compressed air to the reaction kettle to cool in order to obtain lead mud; and 2, carrying out a ball milling reaction: conveying the lead mud obtained in step 1 to a dry ball mill, and synchronously carrying out drying and ball milling treatment to obtain the tetrabasic lead sulfate product. The premixed lead material directly reacts with sulfuric acid, and heat generated in the exothermic reaction of concentrated sulfuric acid is fully used to rapidly heat the reaction kettle, so the preparation reaction time is shortened; and a reaction product is rapidly cooled by the compressed air to further effectively inhibit growth of 4BS crystal particles, so the granularity of the formed 48S is small, uniform and controllable, and the technical problems of large and non-uniform crystal particles of the reaction product, caused by high preparation reaction temperature and long reaction time of the 4BS in the prior art are effectively solved.

Owner:ZHEJIANG DOULAN INTELLIGENT EQUIP CO LTD

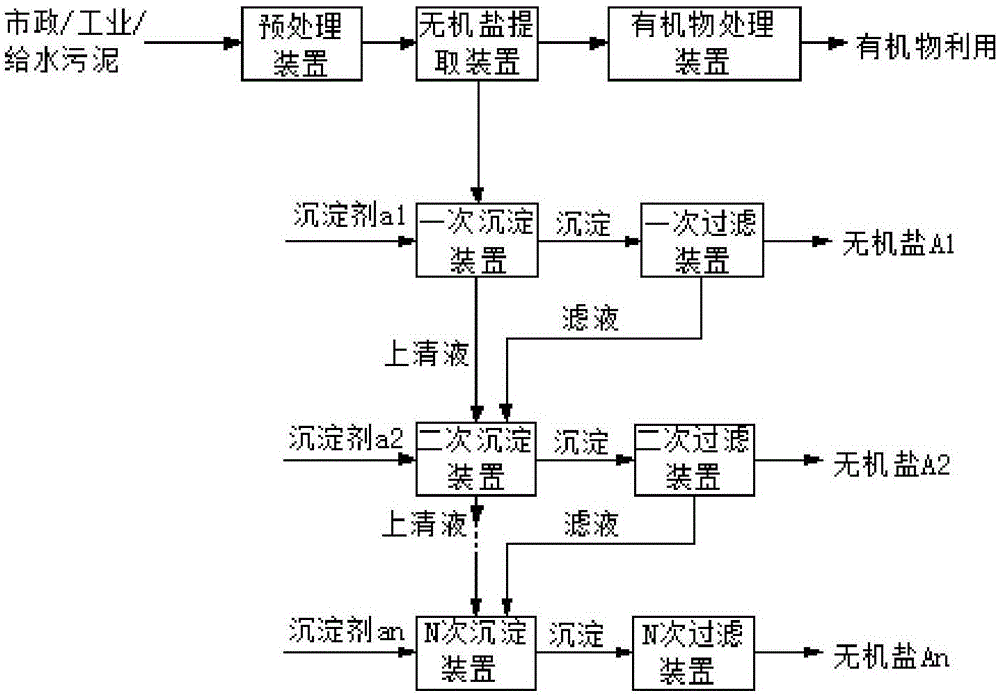

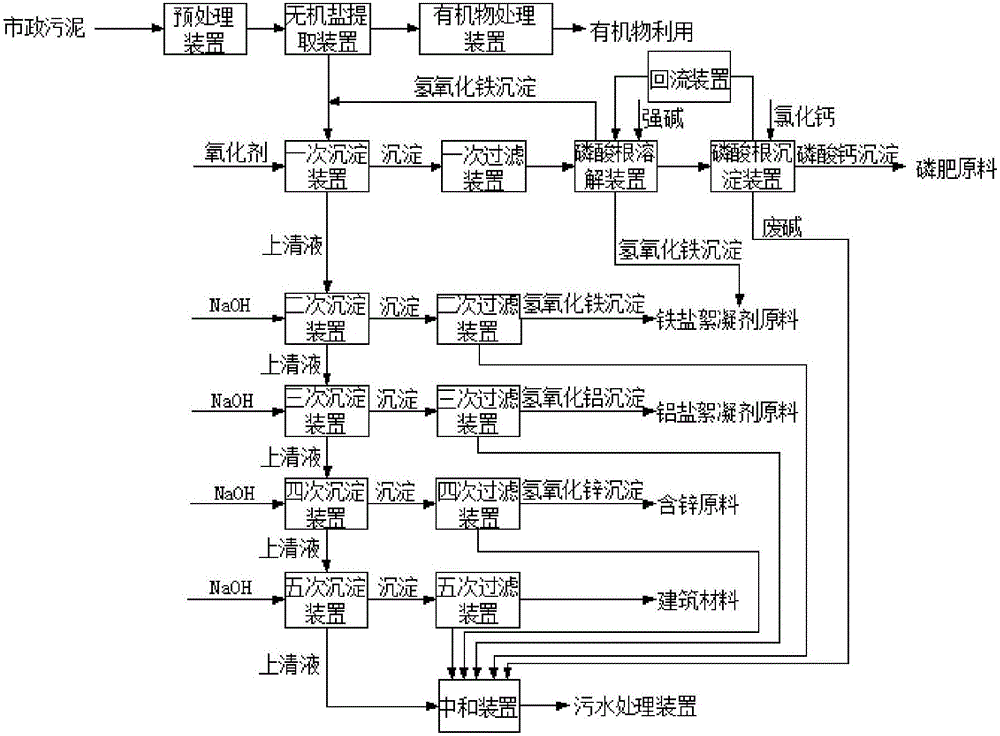

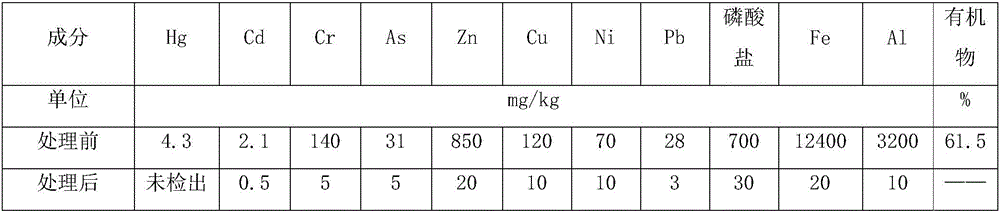

Method and device for respectively extracting and using inorganic matters in sludge

InactiveCN106007292ALow impurity contentHigh puritySludge treatmentLead hydroxidesInorganic saltsResource utilization

The invention provides a method for respectively extracting and using inorganic matters in sludge, and belongs to the technical field of sludge treatment. The method comprises the following steps: (1) pretreating the sludge; (2) extracting inorganic salt from a sludge solution subjected to pretreatment; (3) adding a precipitant a1 into the inorganic salt extracting solution obtained in the step (2) till precipitates are separated, and forming inorganic salt A1 for recycling; (4) adding a precipitant a2 into precipitate-removed supernate in the step (3) till precipitates are separated, and forming inorganic salt A2 for recycling; (5) by parity of reasoning, adding a precipitant an into the precipitate-removed supernate in the former step till precipitates are separated, forming inorganic salt An for recycling. According to the method, the inorganic matters in the sludge are respectively recycled, so that weight reduction for the sludge is realized, and resource utilization of the sludge is also realized; the method is simple in process, high in applicability, simple and convenient to operate, easy to control, low in operating cost, good in treatment effect, wide in application range and easy to popularize and use.

Owner:TIANJIN ENEW ENVIRONMENTAL PROTECTION ENGCO LTD

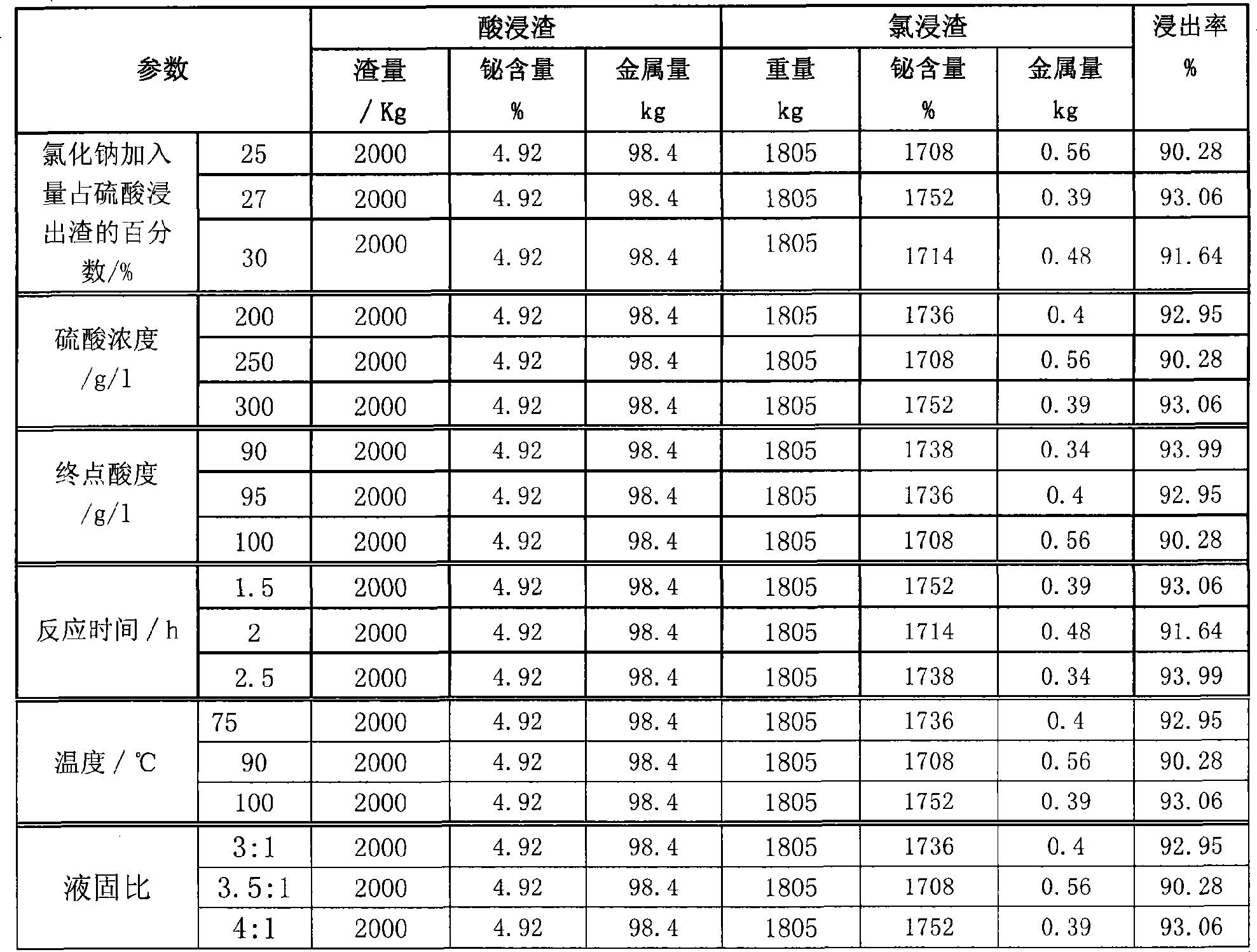

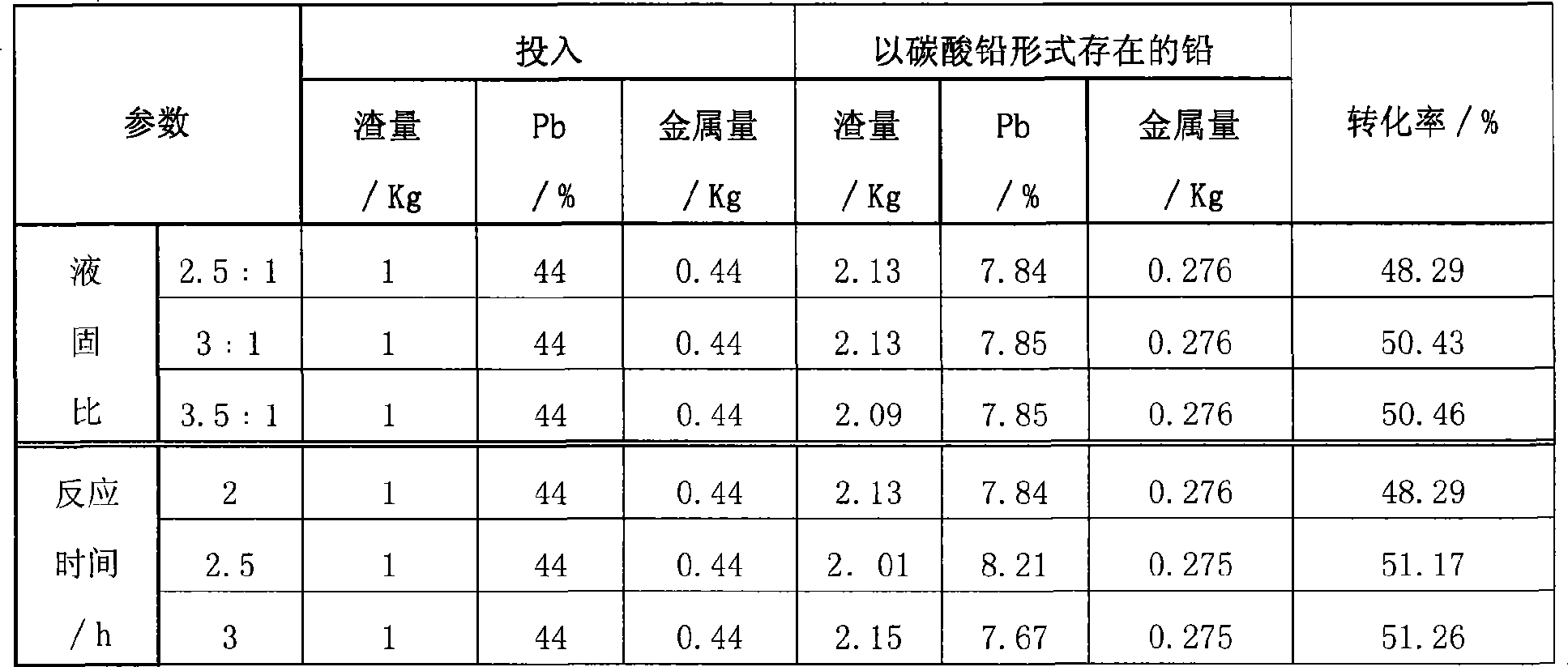

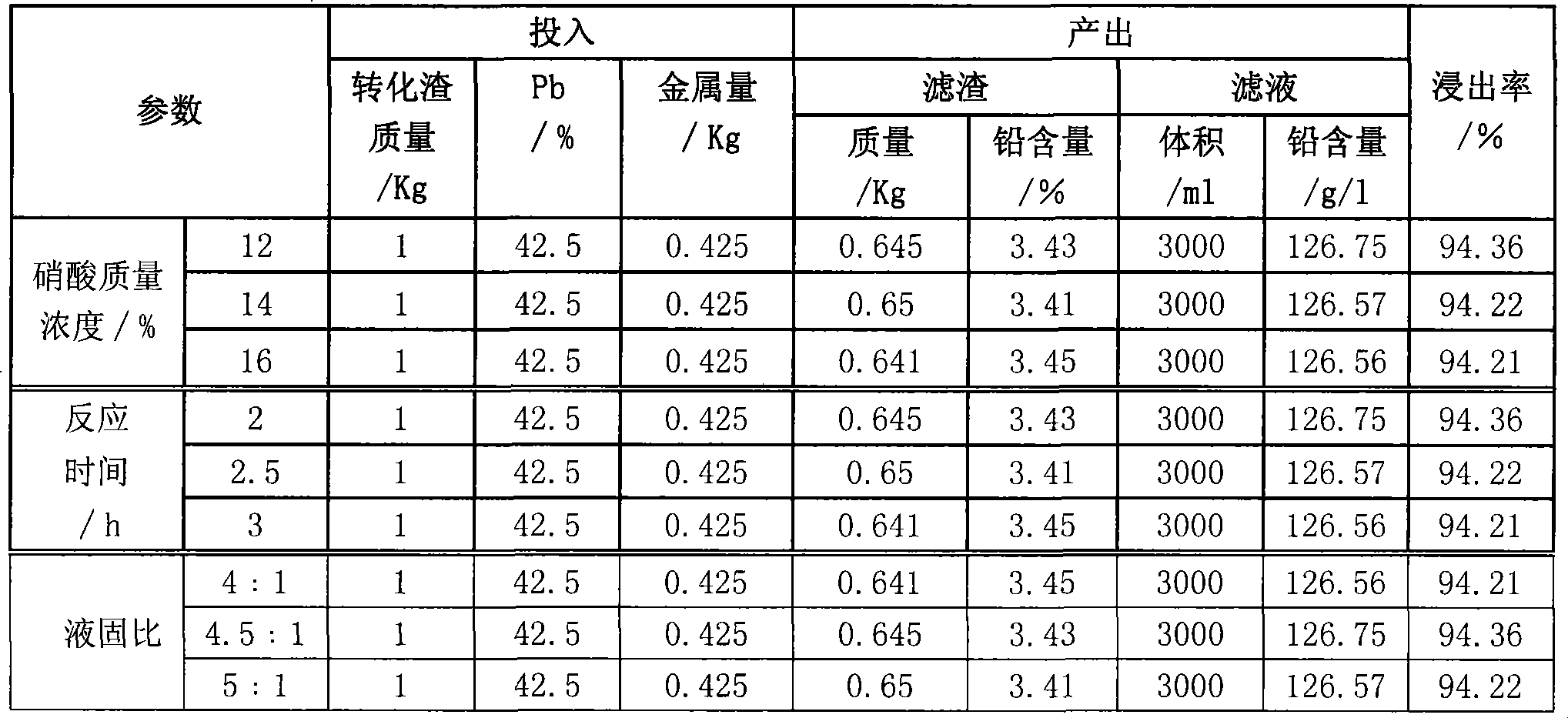

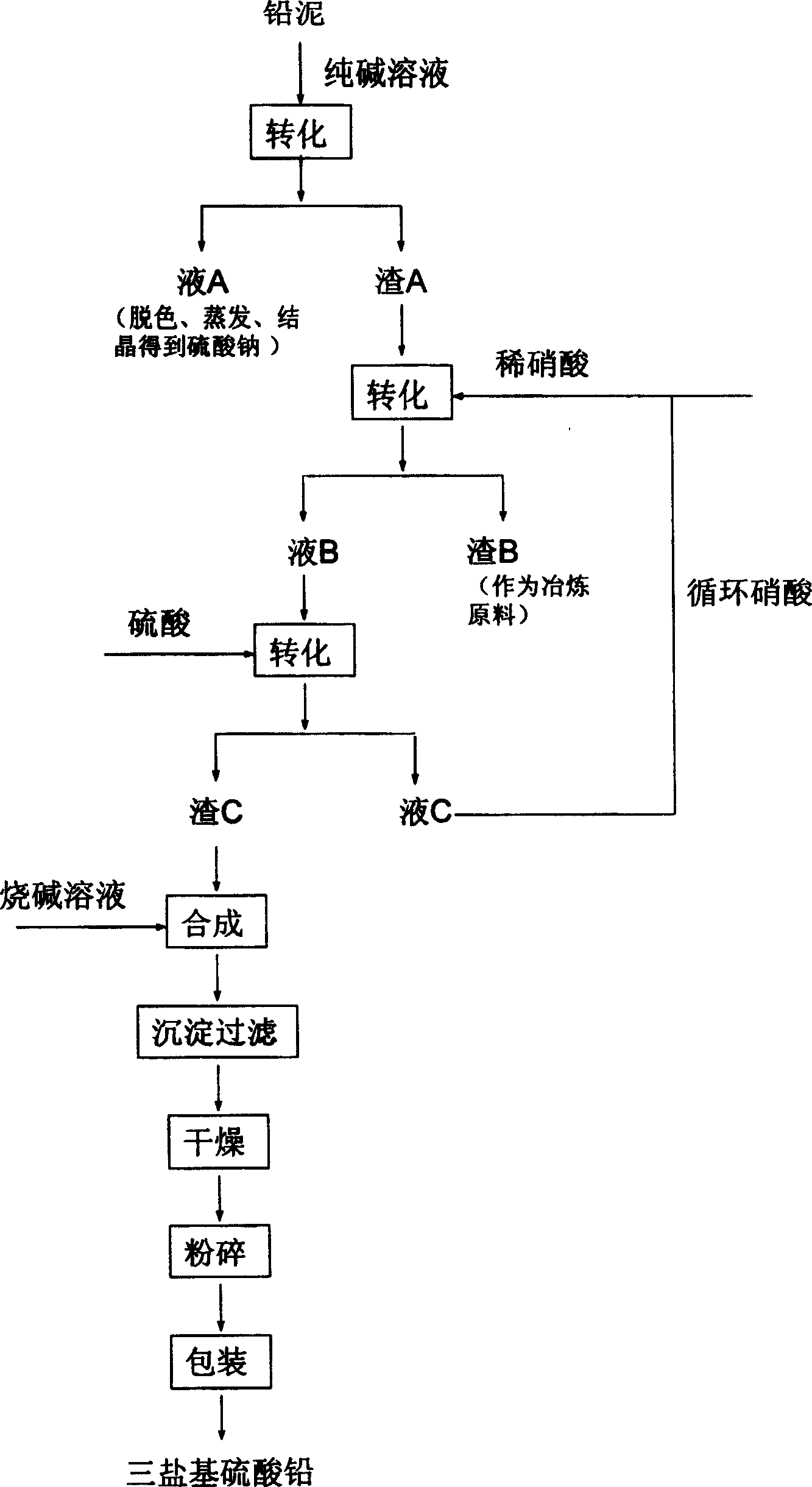

Method for preparing tribasic lead sulfate by using ash of copper converter

InactiveCN101519729ASimple processImprove the operating environmentProcess efficiency improvementLead sulfatesPregnant leach solutionLead carbonate

The invention relates to a method for preparing tribasic lead sulfate by using ash of a copper converter, which comprises the step: (1) the ash of the copper converter is leached by dilute sulphuric acid to obtain leach liquor containing copper and zinc and lixiviated residues containing lead and bismuth. The method is characterized by also comprising the steps: (2) sodium chloride is added into the leached residues containing lead and bismuth, and the leached residues containing lead and bismuth are leached by concentrated sulfuric acid to obtain leach liquor containing bismuth and chloride leached residues; (3) the chloride leached residues are converted by ammonium carbonate to obtain ammonium carbonate converting residues; (4) the ammonium carbonate converting residues are dissolved by nitric acid; (5) the ammonium carbonate converting residue solution dissolved by the nitric acid is deposited by sulphuric acid; (6) the formed lead sulfate deposition and sodium hydroxide reacts to synthesize tribasic lead sulfate. The method adopts a wet process, lead in the ash is transformed into lead carbonate through sectioning leaching, and then, the lead carbonate is dissolved by nitric acid, deposited by sulphuric acid and added with sodium hydroxide to synthesize the tribasic lead sulfate. The technical process is simpler, and has good operating environment due to the adoption of the wet process.

Owner:JINCHUAN GROUP LIMITED

Method of preparing tribasic lead sulphate using lead mud in waste lead battery

A process for preparing lead trihydroxy sulfate from the lead mud of used lead accumulator includes such steps as reaction between said lead mud and sodium carbonate, desulfurizing to obtain lead carbonate, filtering, decoloring the filtrate, evaporating, crystallizing to obtain sodium sulfate as by-product, dissolving the filtered dregs in nitric acid, reacting on sulfuric acid to obtain the deposit of pure lead sulfate, reacting on sodium hydroxide to obtain lead trihydroxy sulfate, filtering, drying and pulverizing.

Owner:HUNAN UNIV

Method for synthesizing tetrabasic lead sulfate by utilizing positive electrode waste lead plaster and application thereof

InactiveCN103482690ALead sulfate accurateLead oxide accurateWaste accumulators reclaimingLead sulfatesCapacity lossElectrical battery

The invention discloses a method for synthesizing tetrabasic lead sulfate by utilizing positive electrode waste lead plaster and application thereof. The method comprises the following steps of washing, filtering, separating, dehydrating, drying, sieving and purifying the positive electrode waste lead plaster, and then, carrying out chemical analysis on a treated mixture, thereby obtaining contents of various components of lead sulfate, lead oxide and free lead in the treated mixture according to chemical analysis, adding lead powder to carry out mixing, grinding and sieving, so that the molar ratio of the lead oxide to lead sulfate after hybrid reaction is (4-5):1; and preserving the heat and presintering the sieved mixture in a resistance furnace, and then heating up to sinter, cooling and drying to obtain the tetrabasic lead sulfate. The method can be used for a storage battery manufacturer to prepare according to convenient conditions of the manufacturer, is simple and easy to implement; the prepared tetrabasic lead sulfate can completely satisfy performance requirements while being applied to battery production, so that early capacity loss of a lead storage battery is restrained, various electrical performances of the battery and a cycle life of the storage battery are greatly improved and prolonged, respectively, thereby not only solving a treatment problem of lead-containing waste materials of the storage battery enterprises, but also lowering production cost of enterprises and changing waste into things of value.

Owner:TIANNENG GRP JIANGSU SPECIAL POWER SUPPLY

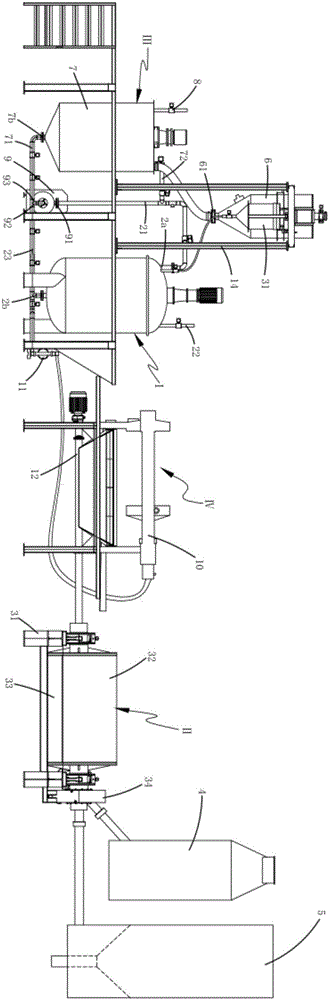

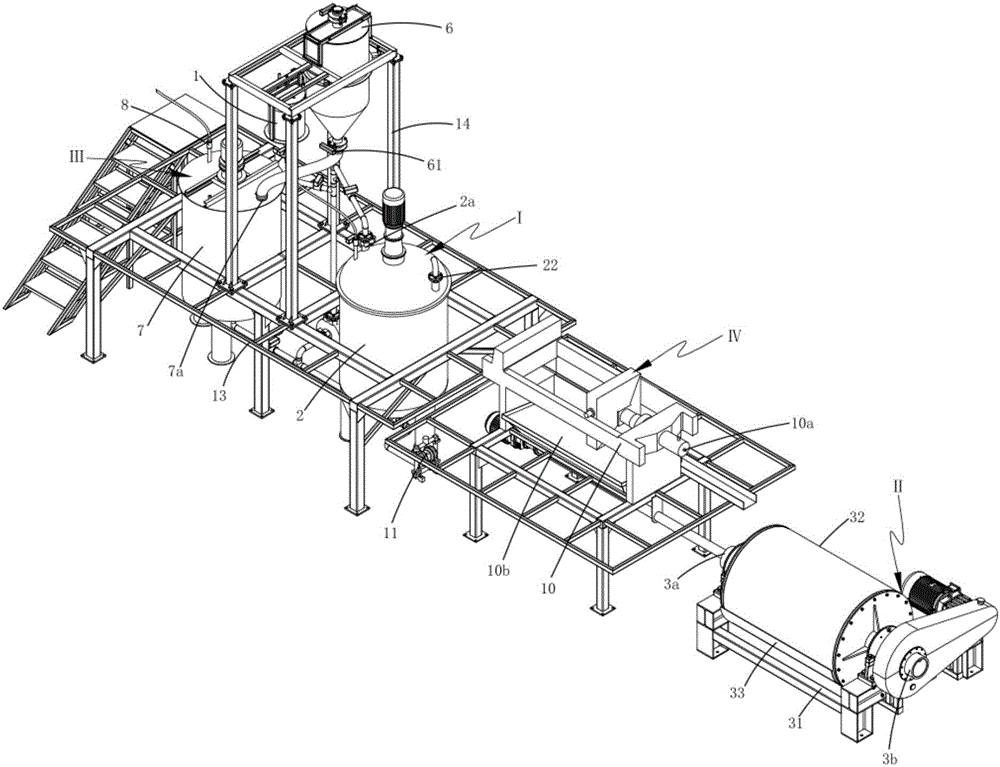

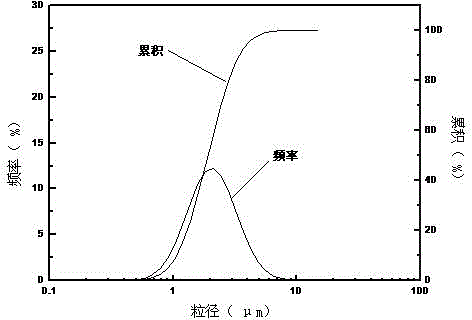

Production process and device for tetrabasic lead sulfate (4BS)

The invention relates to a production process for tetrabasic lead sulfate (4BS). The process includes the following steps that (1) preparation treatment is conducted, specifically, lead which is subjected to a pre-mixing reaction is delivered into a reaction kettle through a shear pump, a sulfuric acid solution is added into the reaction kettle while internal circulation type stirring is conducted, meanwhile, part of compressed air is led into the reaction kettle, after the sulfuric acid solution is added, the shear pump is started, the reaction kettle is heated, after internal and external circulation type uniform stirring, heating is stopped, the shear pump is shut down, internal circulation type stirring in the reaction kettle is maintained, and meanwhile, compressed air is led into the reaction kettle to cool lead slime; and (2) ball milling is conducted, specifically, the lead slime obtained in the step (1) is conveyed into a dry ball mill, heating drying and a ball milling reaction are conducted synchronously, and the 4BS is obtained. The invention further provides a production device for the 4BS. According to the production process and device, the preparation reaction time is short, the formed 4BS is small in grain size, uniform and controllable, and the average grain size of the obtained 4BS is 2 [mu]m or less.

Owner:ZHEJIANG DOULAN INTELLIGENT EQUIP CO LTD

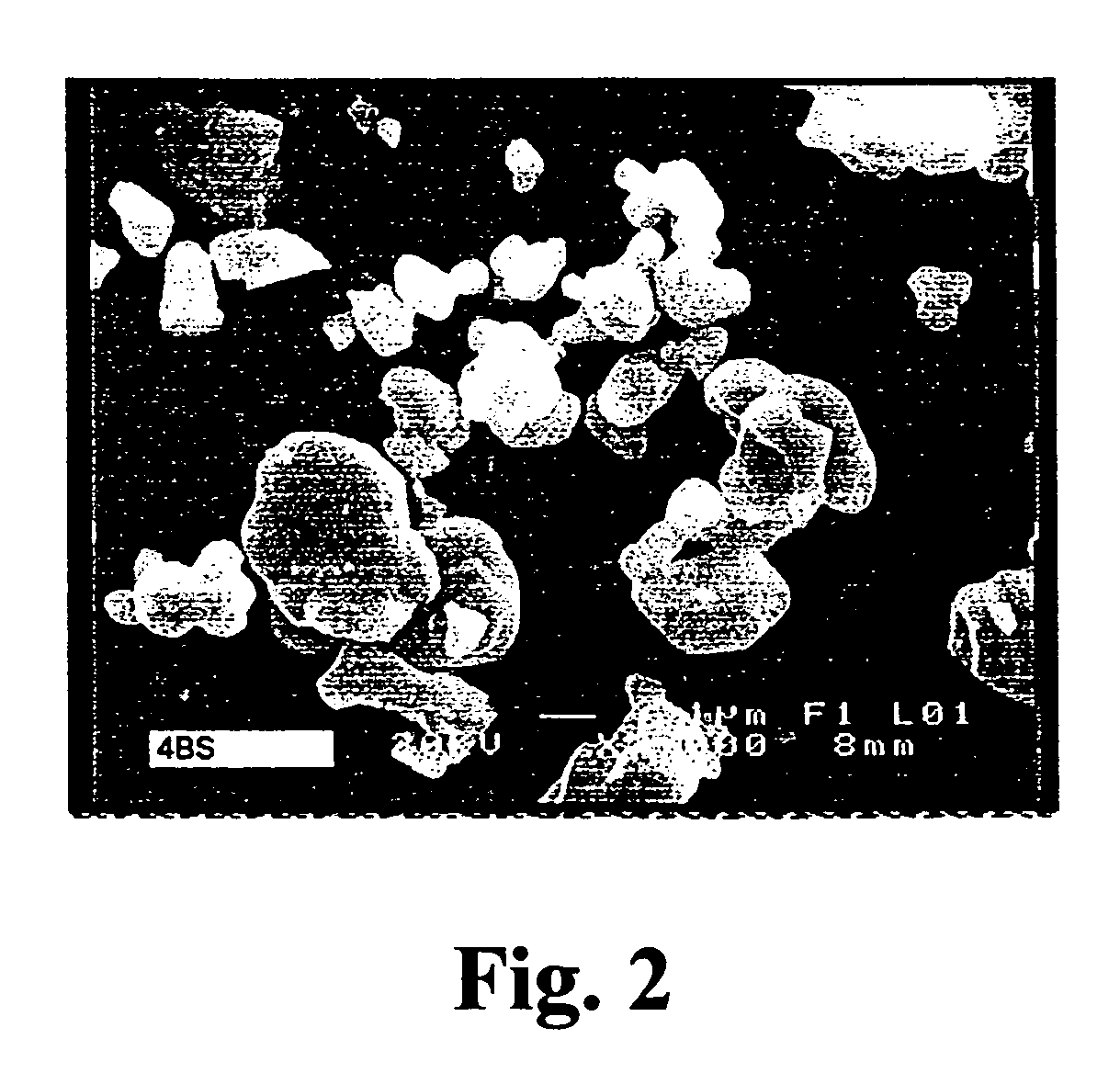

Additive for producing a positive active material for lead-acid storage batteries, a method for its production and a method for its use

ActiveUS7091250B2Avoid particle agglomerationMixing methodsLead-acid accumulator electrodesSilicic acidLead oxide

The present invention is an additive for producing a positive active material for lead-acid storage batteries on the basis of finely divided tetrabasic lead sulfate. The additive contains a tetrabasic lead sulfate of an average particle size less than about 3 μm as well as finely divided hydrophobic silicic acid for preventing agglomeration of the particles of the tetrabasic lead sulfate. During maturation, this additive ensures the formation of the structure of a tetrabasic lead sulfate crystal with a very narrow bandwidth of crystal sizes and a very homogeneous distribution. In the subsequent electrochemical formation to lead oxide, this leads to particularly efficient lead-acid storage batteries. Furthermore, the invention relates to a method of making the additive according to the invention as well as its advantageous use in the positive material for the maturation and drying of plates in the production of lead-acid storage batteries.

Owner:PENOX

Method for preparing high purity tetrabasic lead sulfate by using lead powder used for production of lead acid battery

ActiveCN103936060AHigh purityNo adverse effect on performanceLead sulfatesCell cycle lifeCapacity loss

The invention discloses a method for preparing high purity tetrabasic lead sulfate by using lead powder used for production of a lead acid battery, which is characterized in that a simple two-step reaction method is used for preparing the tetrabasic lead sulfate, the product purity is high, the particle size is small, the distribution of the particles is uniform, the product raw material lead powder is same with the lead powder used for producing the lead acid battery, impurity is not introduced, no impurity pollution problem is existed, and no adverse influence is generated to cell performance, the lead powder can be taken as an additive for obviously increasing the cell pole plate strength, the capacity loss of the cell at an initial stage is reduced, the cell cycle life is prolonged, in addition, no waste water and waste lead can be generated during a production process, and the method is green and has performance of environmental protection.

Owner:CHAOWEI POWER CO LTD

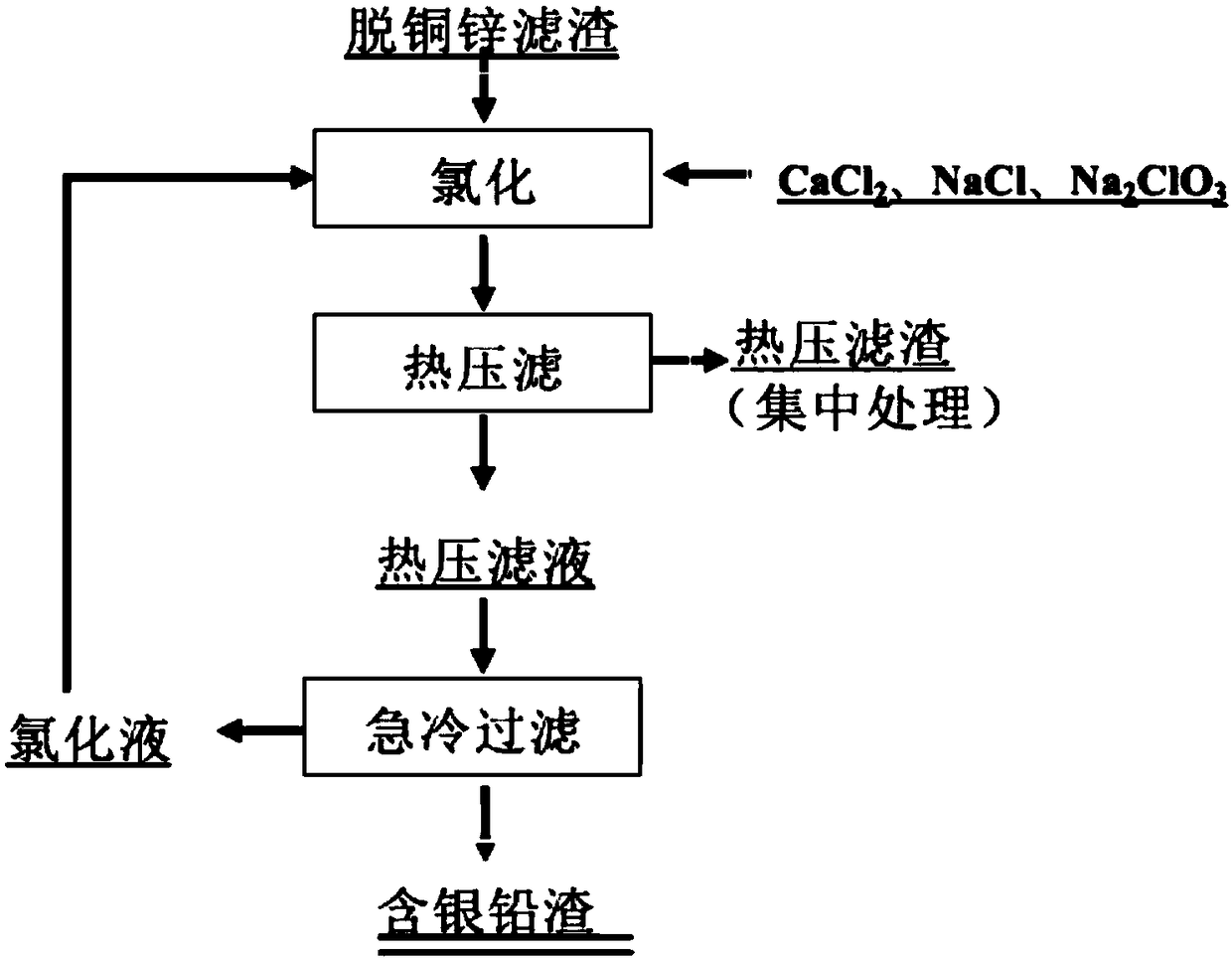

Method for separating bromine from synergistic smelting ash of circuit boards through roasting with sodium nitrate

PendingCN109055722AEasy to recycleCompared with the recovery process, the inventive technology utilizes sodium nitrate decomposition to facilitateZinc sulatesAlkali metal bromidesSodium nitratePollution

The invention provides a method for separating bromine from synergistic smelting ash of circuit boards through roasting with sodium nitrate, belongs to the field of comprehensive recovery of valuableelements from ash through a whole wet method, and particularly relates to a method for efficiently separating and extracting bromine, lead and zinc from synergistic smelting ash of circuit boards through roasting with sodium nitrate. The method mainly comprises the steps of mixing, roasting, step-by-step regulation of pH with industrial sulfuric acid to separate and extract lead and zinc, evaporative crystallization of bromine to recover coarse bromine, smoke treatment and the like. Compared with a traditional ash comprehensive recovery process, oxidization of cuprous bromide and solidification of bromine are achieved through roasting with sodium nitrate, so that conversion and separation of soluble bromine, lead and tin are achieved; a sodium hydroxide and nitric acid system is used for smoke treatment, ash and nitrate generated in the roasting process are recovered to be used repeatedly, and thus, pollution caused by smoke and tail liquid is avoided in the recovery process.

Owner:BEIJING UNIV OF TECH

Method for preparing tetrabasic lead sulfate from waste lead plaster

ActiveCN105390763AImprove consistencyLow costWaste accumulators reclaimingLead sulfatesSteam pressureEngineering

The invention discloses a method for preparing tetrabasic lead sulfate from waste lead plaster. The method comprises the following steps of: 1) collecting waste lead plaster generated in lead-acid battery production, feeding the waste lead plaster into a settling pond, adding clear water to perform stirring and cleaning, and then performing static settlement naturally; 2) adding a proper amount of lead powder into sediments, and stirring uniformly to ensure that the sediments become pasty lead plaster; 3) putting the pasty lead plaster in the step 2) into a container, keeping the temperature for 3-3.5 hours by using 2.5-3 kg of steam pressure, then releasing the pressure to ensure that the pasty lead plaster returns to a normal state, and keeping the state for 2-5 hours to obtain pressurized lead plaster; 4) drying the pressurized lead plaster obtained in the step 3) in a drying device with the temperature of 100-105 DEG C; 5) putting dried lead plaster in the step 4) into a nylon ball-milling tank to perform ball-milling continuously for 3-4 hours; and 6) pouring ball-milled powder and an agate milling ball into a powder plate, drying the powder at 80 DEG C, sieving the dried powder, then grinding the powder until no relatively large agglomerates exist to obtain tetrabasic lead sulfate.

Owner:TIANNENG BATTERY GRP ANHUI

Metal oxide and metal fluoride nanostructures and methods of making same

InactiveUS7575735B2Easy to controlOvercomes shortcomingMercury oxidesAlkali metal oxides/hydroxidesSingle crystalFluoride

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

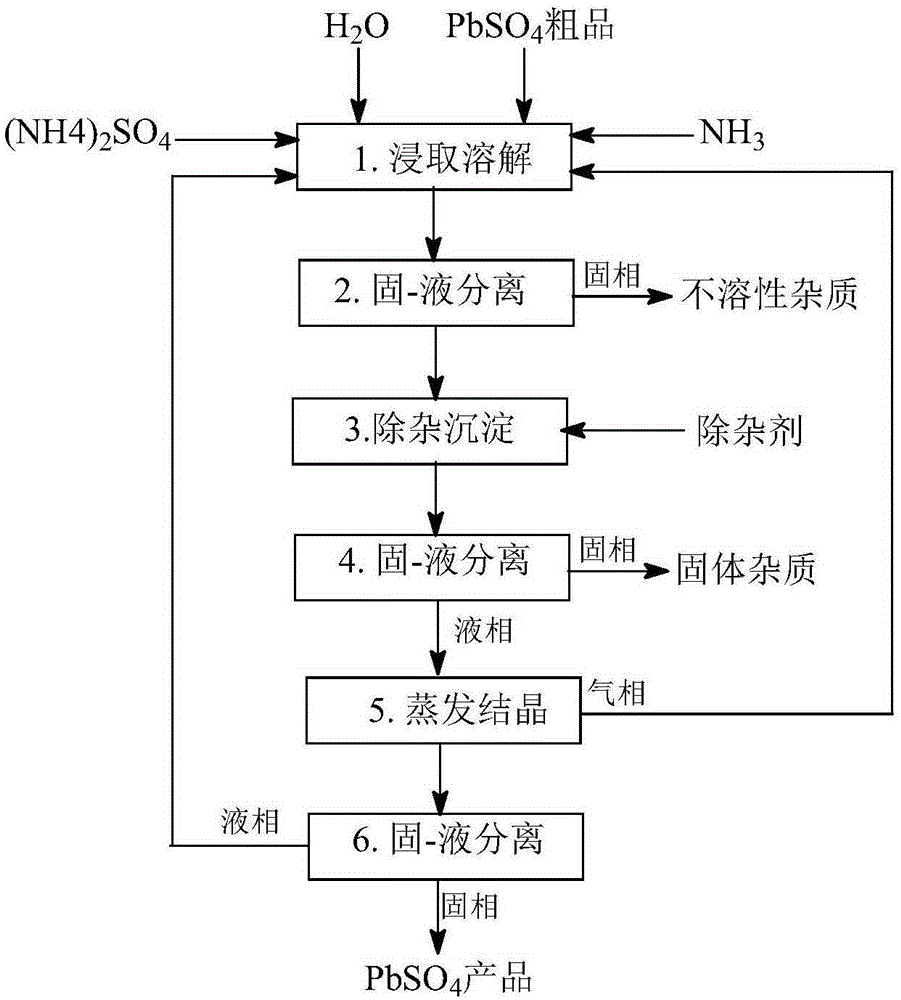

Ammonia process separation and refinement method of lead sulfate

InactiveCN105197988AEasy to separateEasy to achieve separation and refinementLead sulfatesInorganic ChemicalDissolution

The invention relates to an ammonia process separation and refinement method of lead sulfate (PbSO4) and belongs to the technical field of preparation of inorganic chemical products and three-waste comprehensive utilization of lead storage battery electrode materials. Particularly, a PbSO4 crude product is taken as a raw material, an NH3*H2O-(NH4)2SO4 aqueous solution is taken as a solvent, separation and refinement of PbSO4 are realized through leaching dissolution, purification, refinement, evaporative crystallization and solid-liquid separation and coupling techniques, and meanwhile, ammonia is recycled by means of characteristics of easy dissolution of PbSO4 in a NH3 aqueous solution at the low temperature and under high pressure and easy volatilization and removal at the high temperature and under low pressure. The method adopts a reasonable procedure and is simple, the product purity is high, the quality is stable, the yield is high, and the process is safe and reliable.

Owner:YANGZHOU UNIV

Mixture of basic lead sulfates

InactiveUS20110076562A1Improved high rate battery performanceSmall sizeLead-acid accumulator electrodesNon-aqueous electrolyte accumulator electrodesLead sulfateBorax

A microporous lead-containing solid material is produced, which can serve as a carrier for desired materials into a reaction for various desired purposes. For example, if the microporous solid is impregnated with borax it tends to inhibit the growth of unduly large crystals of tetrabasic lead, which is useful in producing batteries having improved functional qualities.

Owner:MAYER GEORGE E

A mixed solvent for dissolving lead sulfate

A mixed solvent for dissolving lead sulfate, involving a chemical solvent, the solvent is composed of ethylenediaminetetraacetic acid (EDTA), ammonium citrate, distilled water, 4-5% of ethylenediaminetetraacetic acid (EDTA); ammonium citrate 2~3%; add distilled water to 100%; the sum of each component is 100%. First, weigh ethylenediaminetetraacetic acid (EDTA) and ammonium citrate according to the selected weight percentage, and then mix the weighed materials, then add distilled water, the amount of distilled water is added to 100% of the total weight, after It is the product after stirring and dissolving. The invention has strong economic benefit and environmental benefit. The recovery of lead sulfate has the characteristics of no pollution to the environment, simple equipment and process, convenient operation, high metal recovery rate, low production cost, and suitable scales.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

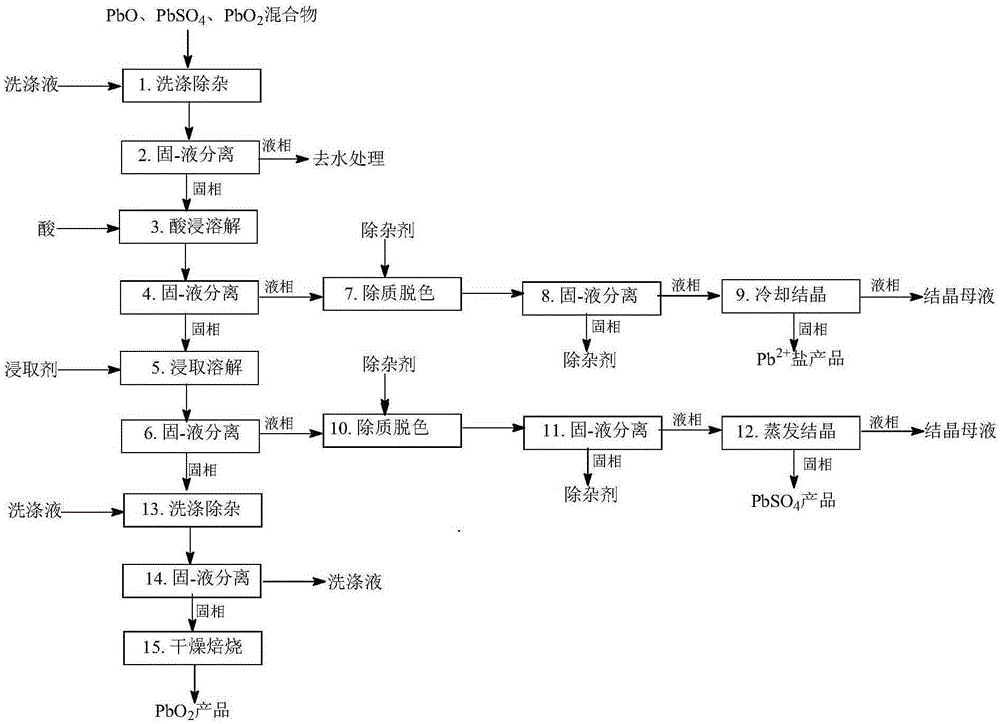

Separation method of PbO, PbSO4 and PbO2 mixture

ActiveCN105197987ADirect useSimple processLead compounds preparationLead dioxideCouplingInorganic compound

The invention relates to a separation method of a PbO, PbSO4 and PbO2 mixture, in particular to a process and a technology of resource comprehensive utilization of a lead containing material of a waste lead storage battery, and belongs to the technical field of comprehensive utilization of three wastes of the waste lead storage battery or separation and refining of inorganic compounds. The separation method comprises steps as follows: PbO, PbSO4 and PbO2 mixture containing lead plaster obtained from the lead containing material, treated with a physical separation method, of the waste lead storage battery is taken as a raw material, the raw material is treated with technologies including acid pickling dissolving, leaching dissolving, separation, refining and solid-liquid separation coupling, and separation of the PbO, PbSO4 and PbO2 mixture is realized. The process is reasonable, the preparation method is simple, the purity and the yield of products are high, by-products in the process are greatly reduced, the comprehensive utilization cost of the lead plaster resource is reduced, the process is safe and reliable, and large-scale industrialization is facilitated.

Owner:YANGZHOU UNIV

Treatment method for contaminated acid from nonferrous metals smelting

ActiveCN110451680AHigh purityAvoid it happening againWater/sewage treatment by centrifugal separationWater contaminantsSlagLead sulfate

The invention discloses a treatment method for contaminated acid from nonferrous metals smelting. At first, that nonferrous metals smelting waste acid is filtered by a membrane filter to obtain lead sulfate filter residue, and lead sulfate is recovered; a vulcanizing agent is added into the obtained filtrate to sulfurize the copper in the filtrate to form a copper sulfide precipitate, and copper resources are recovered after filtering; the vulcanizing agent is then added to that obtain filtrate to sulfurize heavy metals such as arsenic to form a precipitate for removal; carbide slag is added into that obtained filtrate to adjust the pH value to prepare gypsum, and then the gypsum is dewatered with a centrifuge to obtain dewatered gypsum; finally, the obtained sewage is subjected to advanced treatment, up-to-standard discharge or recycling. The treatment method of the present invention can effectively solve the technical problem of producing large amount of dangerous waste residue in the existing non-ferrous metals smelting contaminated acid treatment technology.

Owner:济源豫光有色冶金设计研究院有限公司

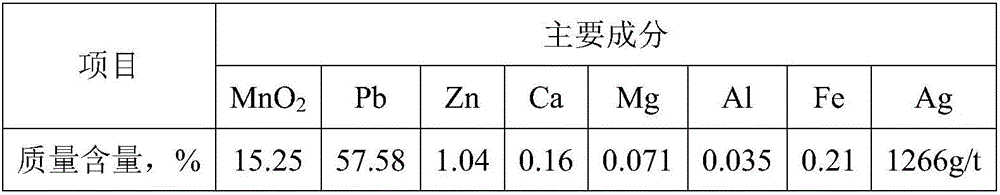

Method for combined resourceful treatment of lead concentrate and zinc anode mud

InactiveCN105907960AIncrease added valueAvoid pollutionProcess efficiency improvementLead sulfatesSocial benefitsIron chloride

The invention discloses a method for combined resourceful treatment of lead concentrate and zinc anode mud. The method comprises the following steps: 1, carrying out oxidation leaching on the lead concentrate by using an acidic solution of iron chloride and sodium chloride to obtain a filtrate A; 2, adding sodium sulfate to the filtrate A, and carrying out a lead precipitation reaction to obtain a filtrate B; 3, adding the zinc anode mud and hydrochloric acid to the filtrate B, and carrying out a manganese leaching reaction to obtain a filter cake C; 4, adding a sodium carbonate solution to the filter cake C, and carrying out a conversion rate to obtain a filter cake D; 5, adding nitric acid to the filter cake D, carrying out an acidolysis reaction, and filtering the obtained reaction solution to obtain a filtrate E; and 6, adding the filtrate D and / or sodium sulfate to the filtrate E, carrying out a lead precipitation reaction, and filtering the obtained reaction solution to obtain a filter cake F which is crude lead sulfate. The above treatment method realizes combined resourceful treatment and comprehensive recycling of the lead concentrate and the zinc anode mud, and has very good economic, environmental and social benefits.

Owner:王树立

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com