Method for separating bromine from synergistic smelting ash of circuit boards through roasting with sodium nitrate

A technology of sodium nitrate and circuit board, which is applied in the field of high-efficiency separation and recovery of bromine, can solve the problems of hindering the separation of bromine, failure to use recovery, complex soot metal, etc., achieve high-efficiency separation, and avoid smoke and tail liquid pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

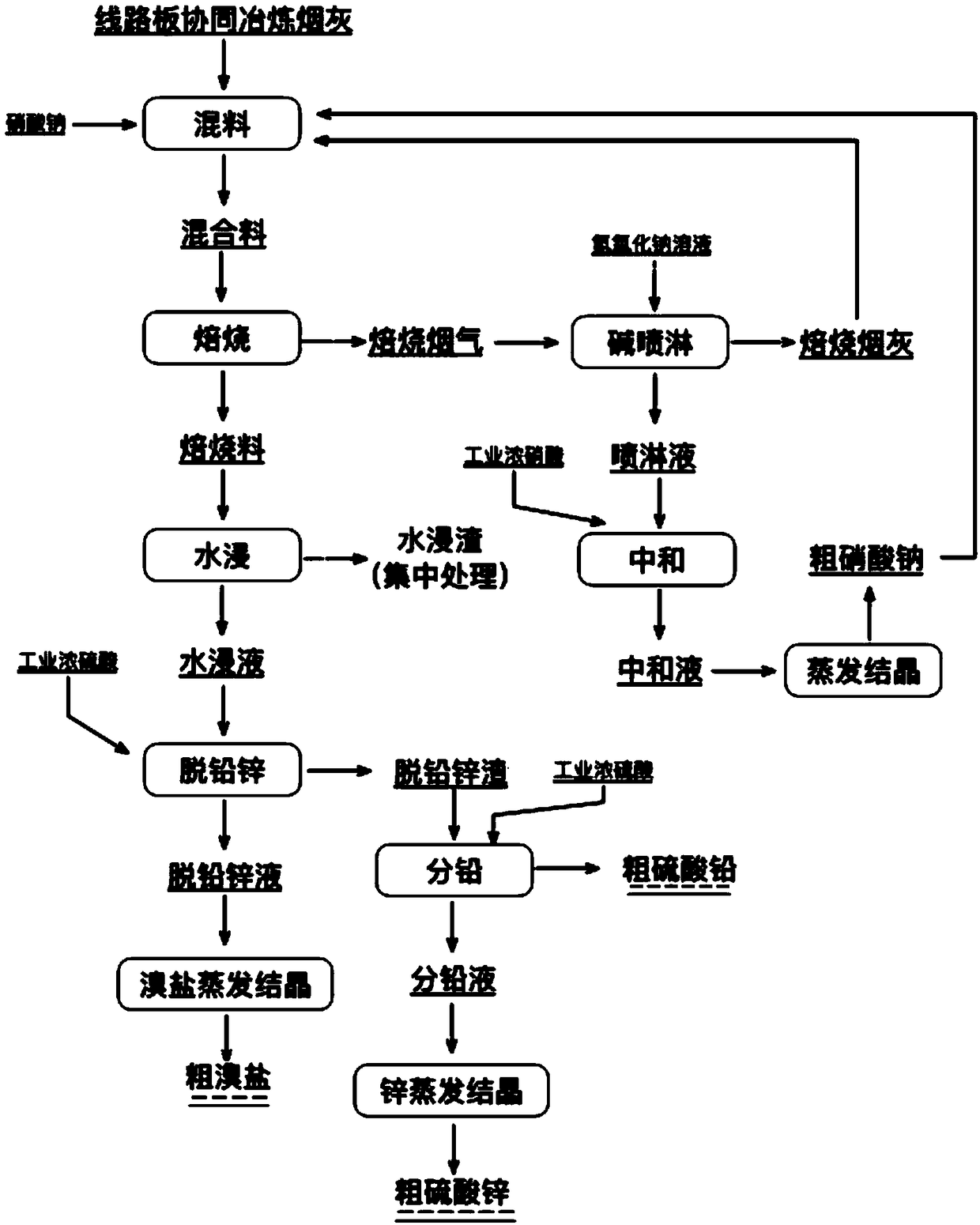

[0021] Proceed as follows:

[0022] (1) Mixing material: mix and ball mill the circuit board co-smelting soot and sodium nitrate, and obtain the mixture after ball milling for 1 hour, wherein the mass ratio of sodium nitrate and circuit board co-smelting soot is 1:2;

[0023] (2) Roasting: Roasting the mixture obtained in step (1), at first the mixture is heated up to 350°C at a heating rate of 5°C / min, then to 450°C at a heating rate of 20°C / min, and kept for 1 hour. Obtain roasting flue gas and roasting material;

[0024] (3) The roasted material obtained in step (2) is immersed in water, the solid-to-liquid ratio of the roasted material to water is 1:5 kg / liter, the leaching temperature is 45° C., and the leaching time is 0.5 hour to obtain the leaching residue and leaching solution, leaching residue centralized treatment;

[0025] (4) Deleading and zinc removal: add 98% industrial concentrated sulfuric acid to the water immersion solution obtained in step (3), until the ...

Embodiment 2

[0034] Proceed as follows:

[0035] (1) Mixing material: mix and ball mill the circuit board co-smelting soot and sodium nitrate, and obtain the mixture after ball milling for 2 hours, wherein the mass ratio of sodium nitrate and circuit board co-smelting soot is 1:10;

[0036] (2) Roasting: Roasting the mixture obtained in step (1), at first the mixture is heated up to 350°C at a heating rate of 10°C / min, then to 650°C at a heating rate of 25°C / min, and kept for 3 hours, Obtain roasting flue gas and roasting material;

[0037] (3) The roasted material obtained in step (2) is immersed in water, the solid-to-liquid ratio of the roasted material and water is 1:10 kg / liter in the water immersion process, the leaching temperature is 55 ° C, and the leaching time is 1.5 hours to obtain the leaching residue and leaching solution, leaching residue centralized treatment;

[0038] (4) Deleading and zinc removal: add 98% industrial concentrated sulfuric acid to the water immersion sol...

Embodiment 3

[0047] Proceed as follows:

[0048](1) Mixing material: mix and ball mill the circuit board co-smelting soot and sodium nitrate, and obtain the mixture after ball milling for 1.5 hours, wherein the mass ratio of sodium nitrate and circuit board co-smelting soot is 1:5;

[0049] (2) Roasting: Roasting the mixture obtained in step (1), first the mixture is heated up to 350°C at a heating rate of 8°C / min, and then heated to 550°C at a heating rate of 22°C / min, and kept for 2 hours, Obtain roasting flue gas and roasting material;

[0050] (3) The roasted material obtained in step (2) is immersed in water, the solid-to-liquid ratio of the roasted material and water is 1:8 kg / liter in the water immersion process, the leaching temperature is 50 ° C, and the leaching time is 1 hour to obtain the leaching residue and leaching solution, leaching residue centralized treatment;

[0051] (4) Deleading and zinc removal: add 98% industrial concentrated sulfuric acid to the water immersion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com