Patents

Literature

112results about "Alkali metal bromides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

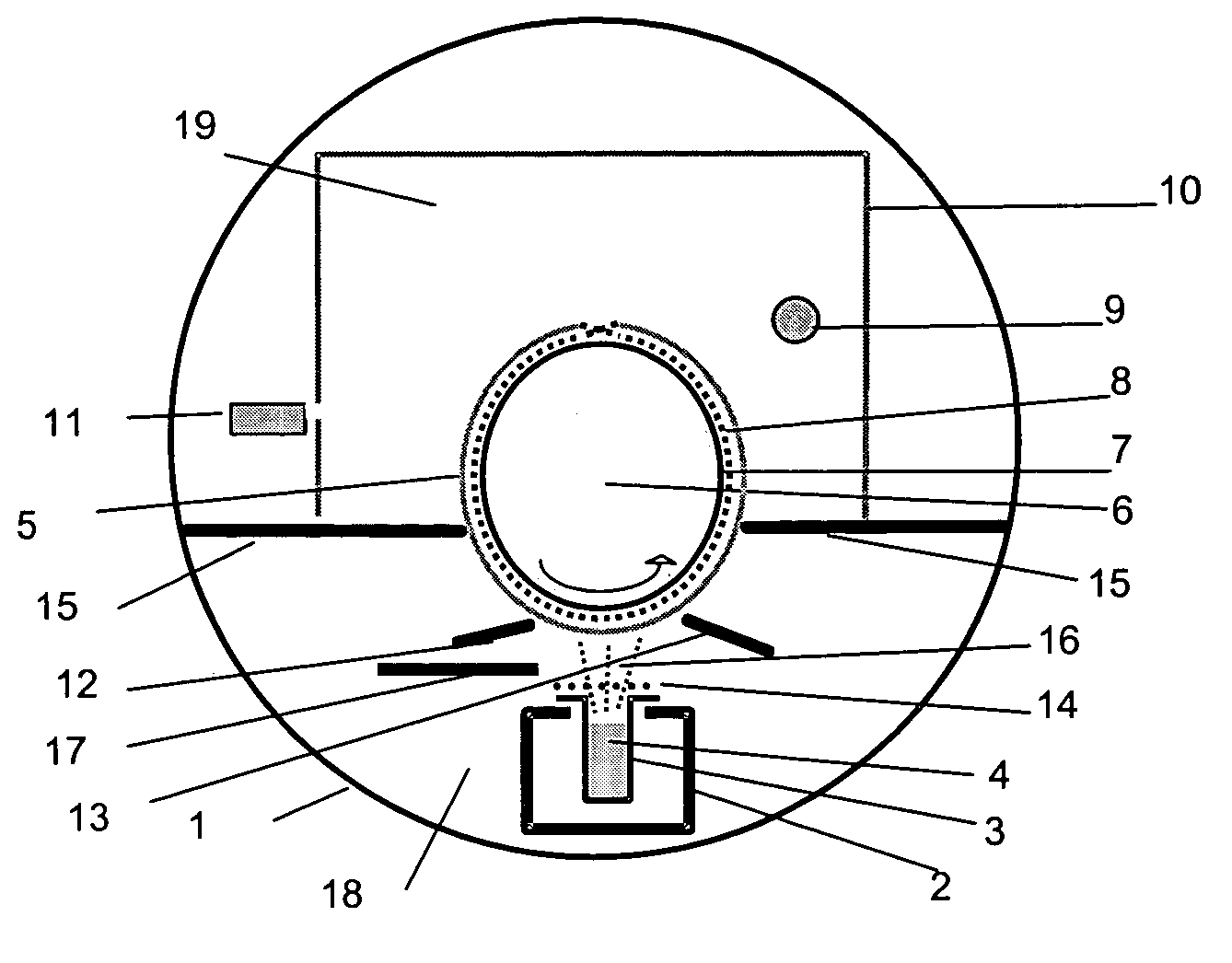

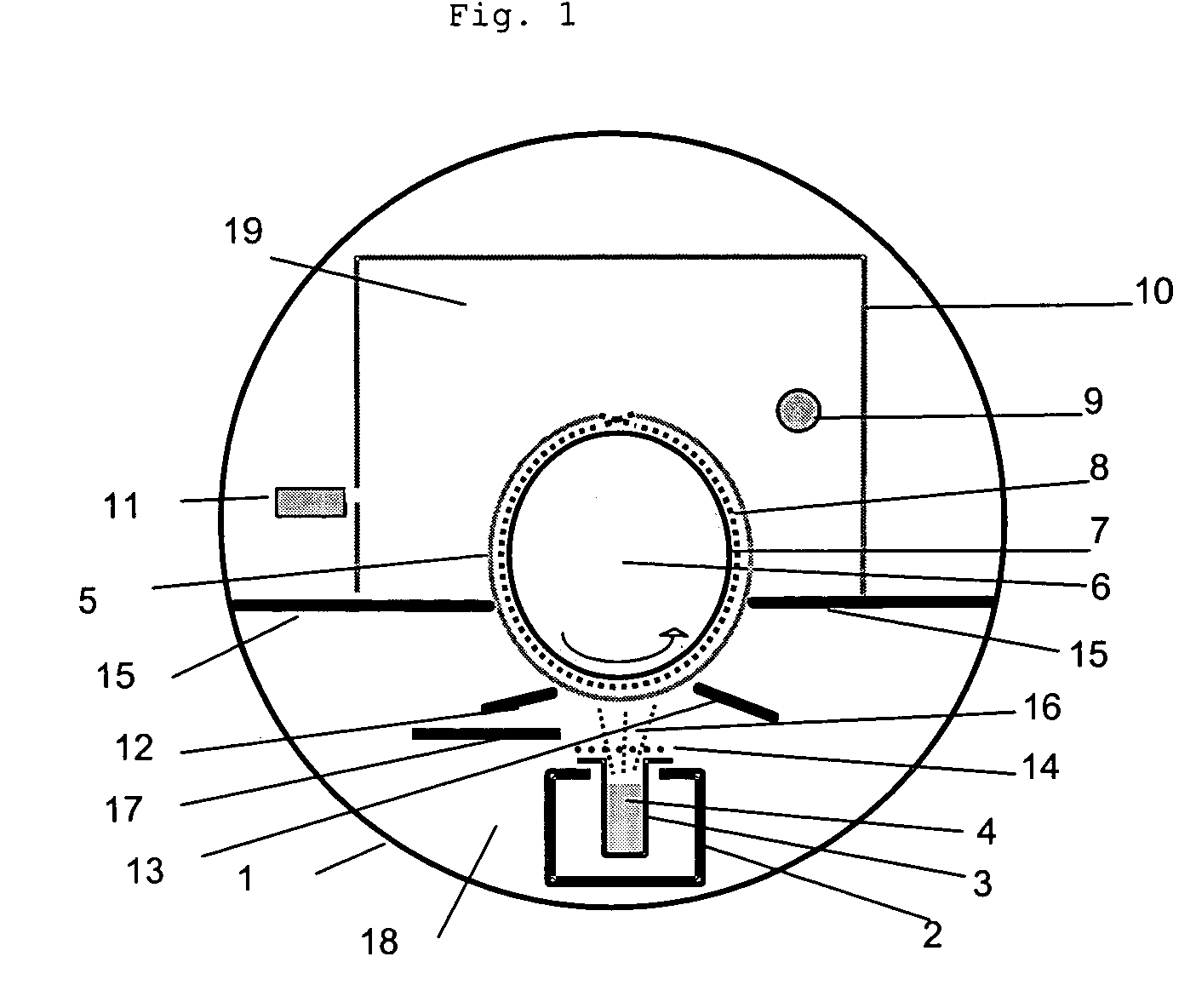

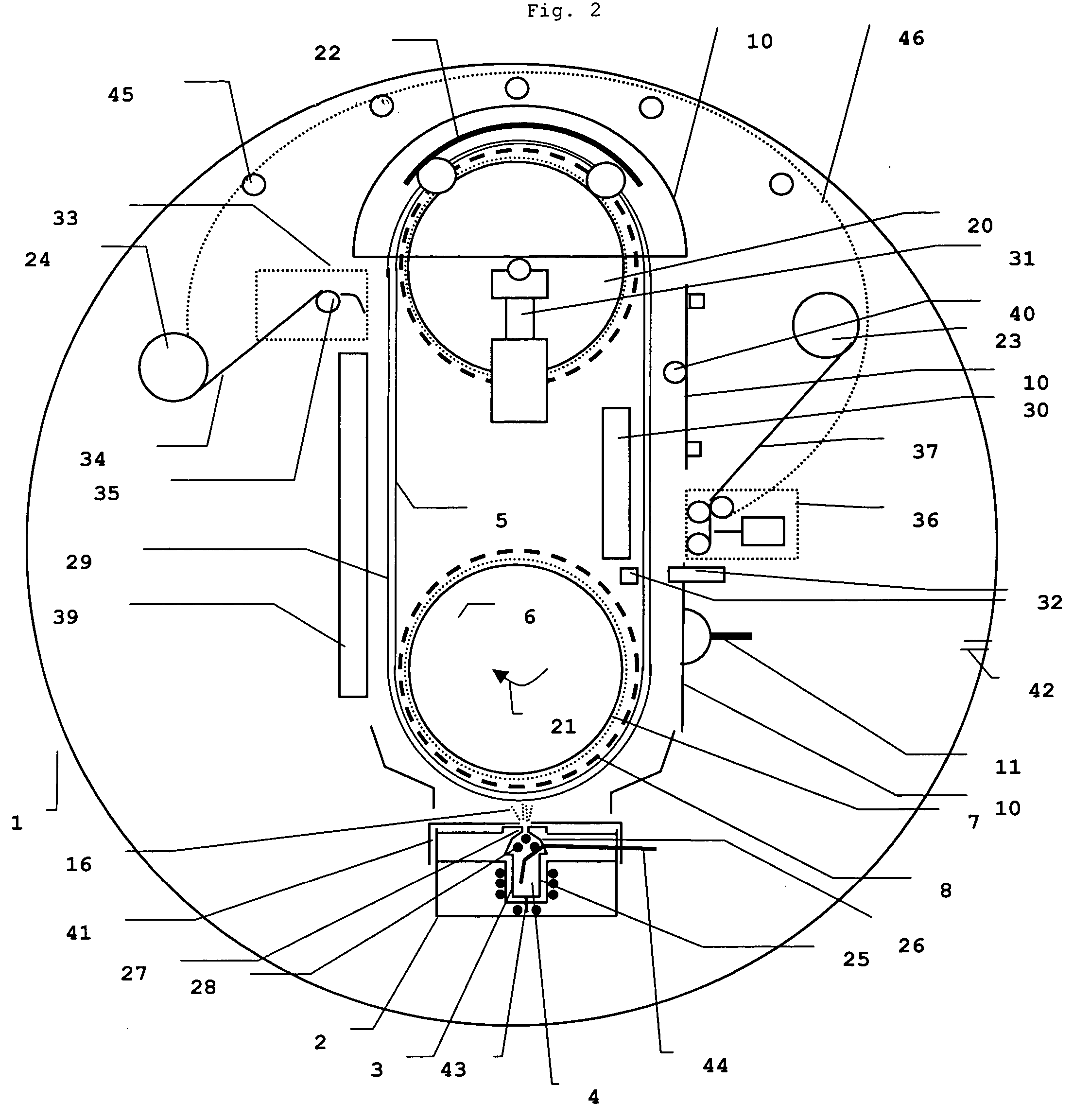

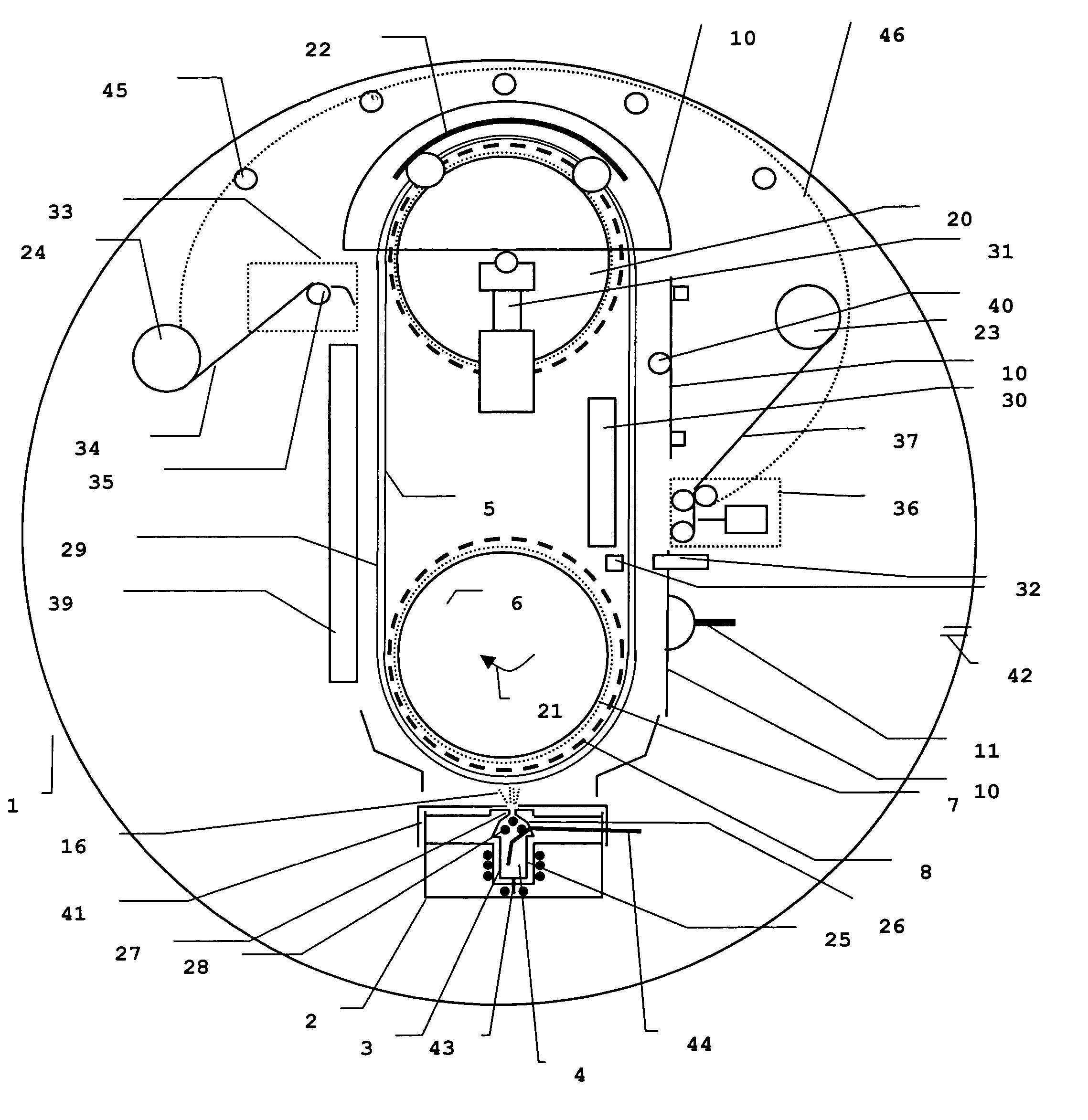

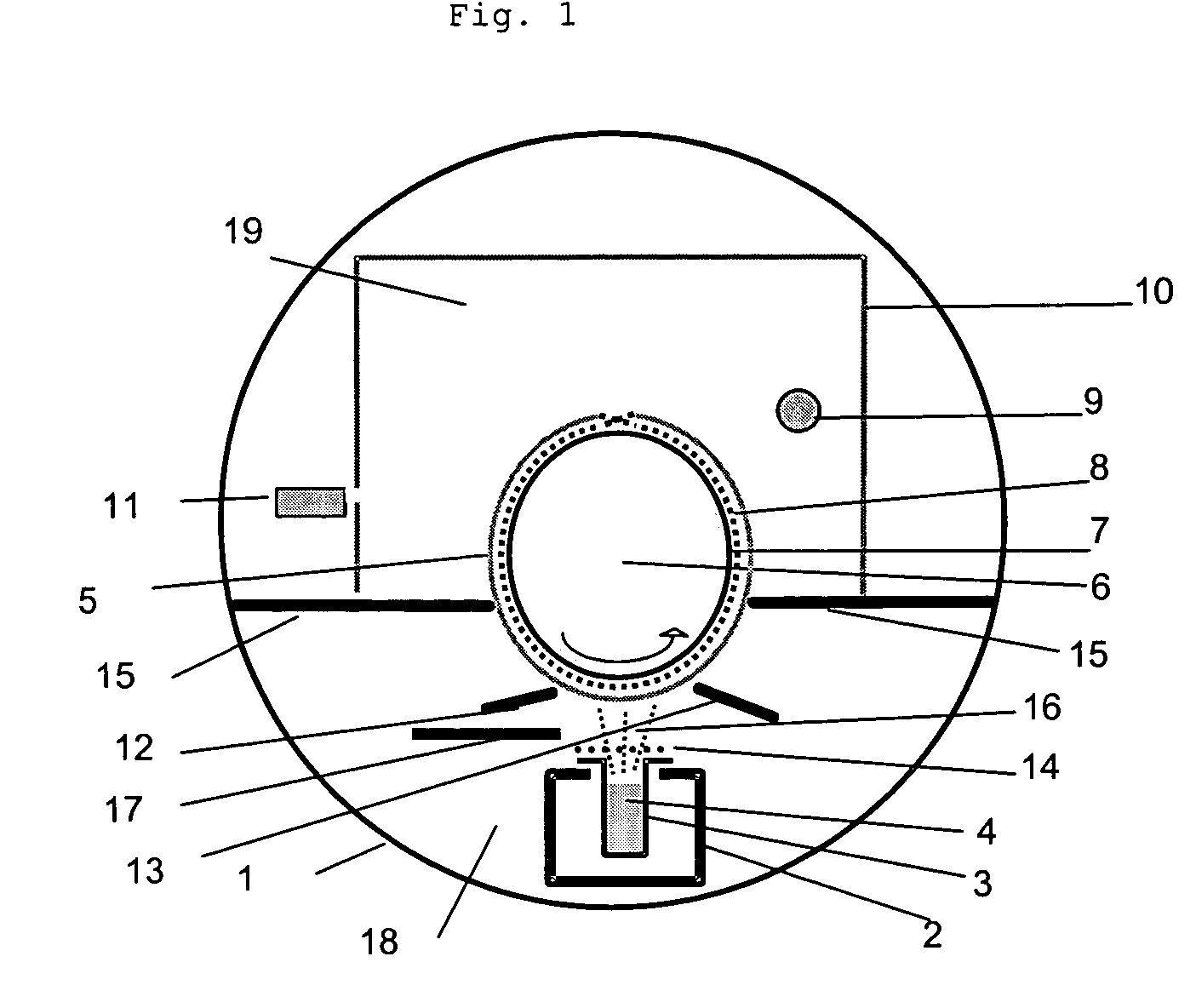

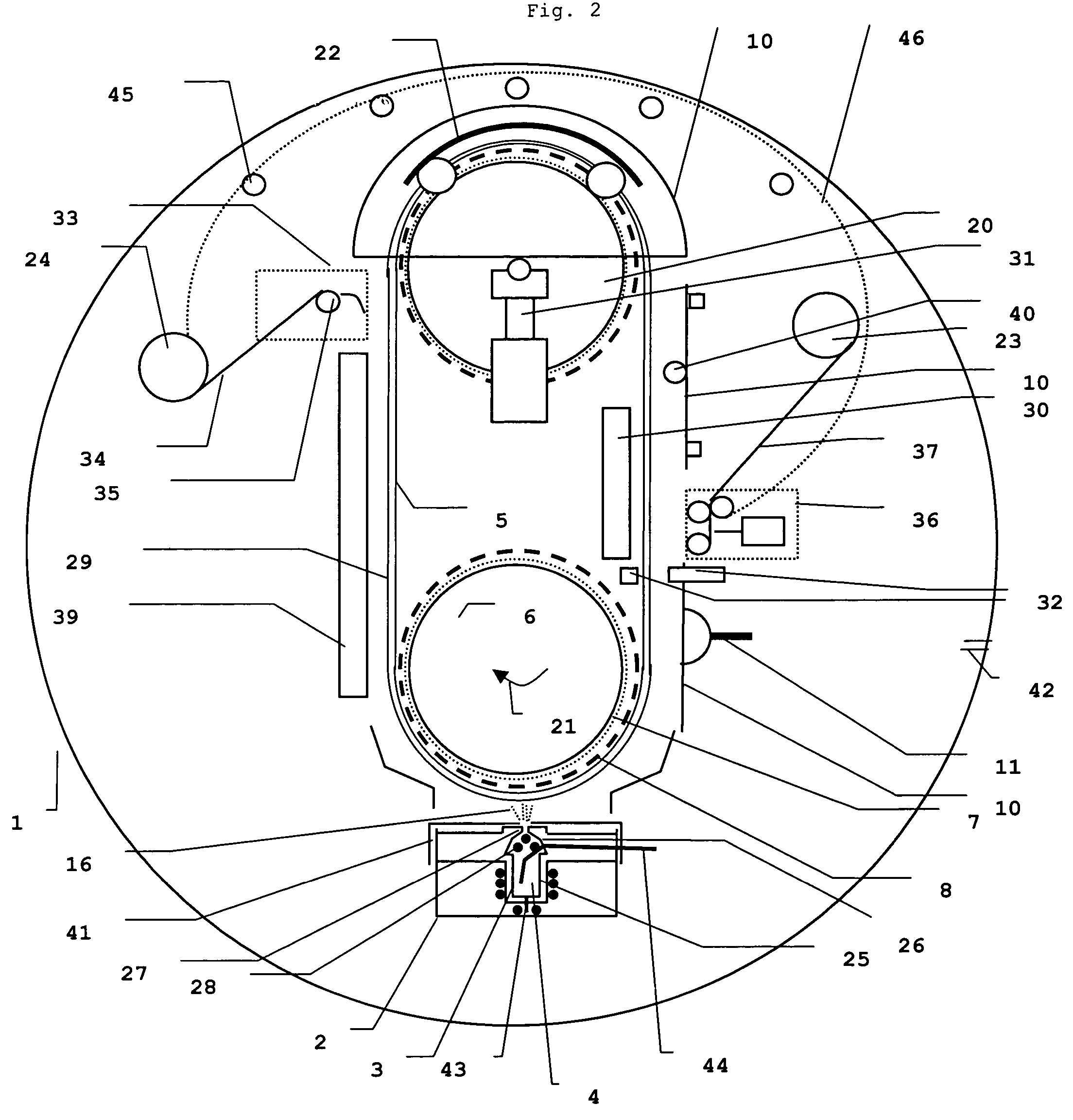

Manufacturing method of phosphor or scintillator sheets and panels suitable for use in a scanning apparatus

InactiveUS20040224084A1Easy to implementInhibition formationVacuum evaporation coatingSputtering coatingCrucibleGas phase

In a method for homogeneously and dust-free coating of a phosphor or a scintillator layer onto a flexible substrate, in order to obtain a plurality of phosphor or scintillator sheets or panels having flexible supports or substrates, a coating procedure within a sealed zone is performed, wherein said zone comprises at least two cylindrical carrier rollers for carrying a flexible substrate exceeding dimensional formats of desired phosphor or scintillator sheets or panels with a factor of at least 5, wherein said cylindrical carrier rollers each have an axis in a parallel arrangement with one another; wherein said zone comprises at least one crucible containing a mixture of raw materials providing desired phosphor or scintillator compositions for said layer; and wherein said zone comprises a laminating unit; wherein said method comprises the steps of mounting said flexible substrate onto said carrier rollers, vapor depositing said phosphor or scintillator layer having a desired phosphor or scintillator composition onto said flexible substrate, and laminating said phosphor or scintillator layer, thereby covering said layer with a protective foil; further comprising the step of cutting said layer into sheets or panels having desired formats, and wherein at least during said vapor depositing step said zone is maintained under vacuum conditions as a vacuum chamber.

Owner:T2PHARMA GMBH

Preparation of non-hazardous brominating reagents

InactiveUS6740253B2Easy to handleStable storageDispersed particle filtrationOrganic compound preparationAqueous sodium hydroxideBromate

The present invention relates to a non-hazardous brominating reagent from an aqueous alkaline bromine byproduct solution obtained from bromine recovery plant and containing 25 to 35% bromine dissolved in aqueous lime or sodium hydroxide containing alkali bromide and alkali bromate mixture having bromide to bromate stoichiometric ratio in the range of 5:1 to 5.1:1 or 2:1 to 2.1:1 and a pH ranging between 8-12 and also relates to a method for borminating aromatic compounds by using the above brominating agent.

Owner:COUNCIL OF SCI & IND RES

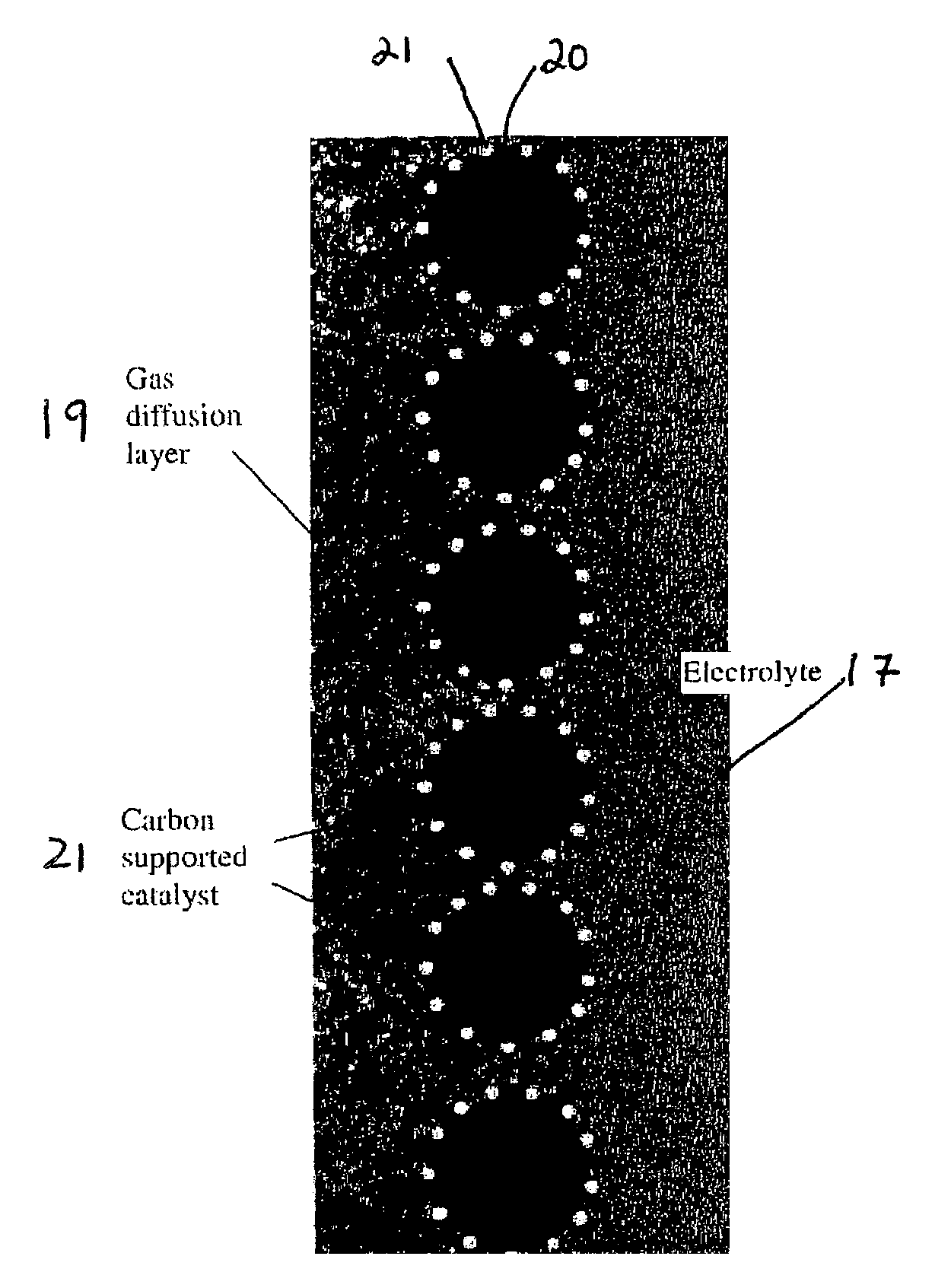

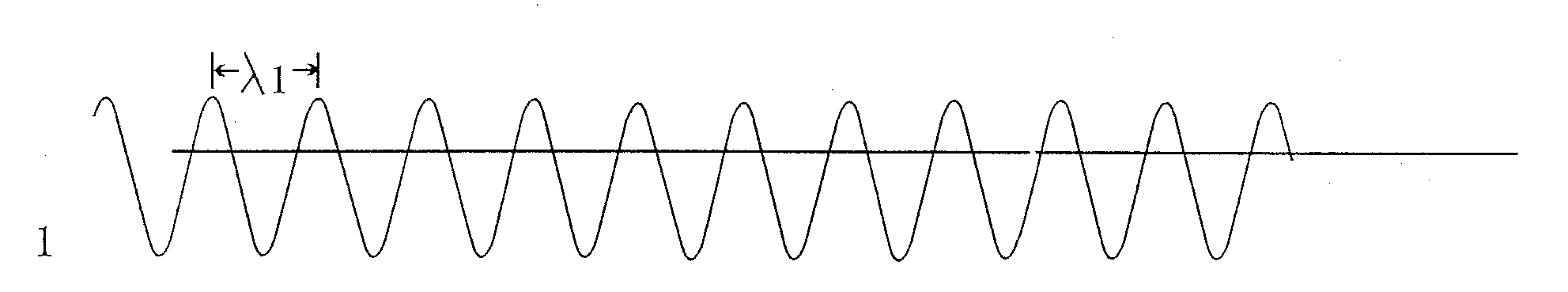

Optimizing reactions in fuel cells and electrochemical reactions

InactiveUS7482072B2Increase ratingsReduce the amount requiredCell electrodesRegenerative fuel cellsElectrochemical responseFuel cells

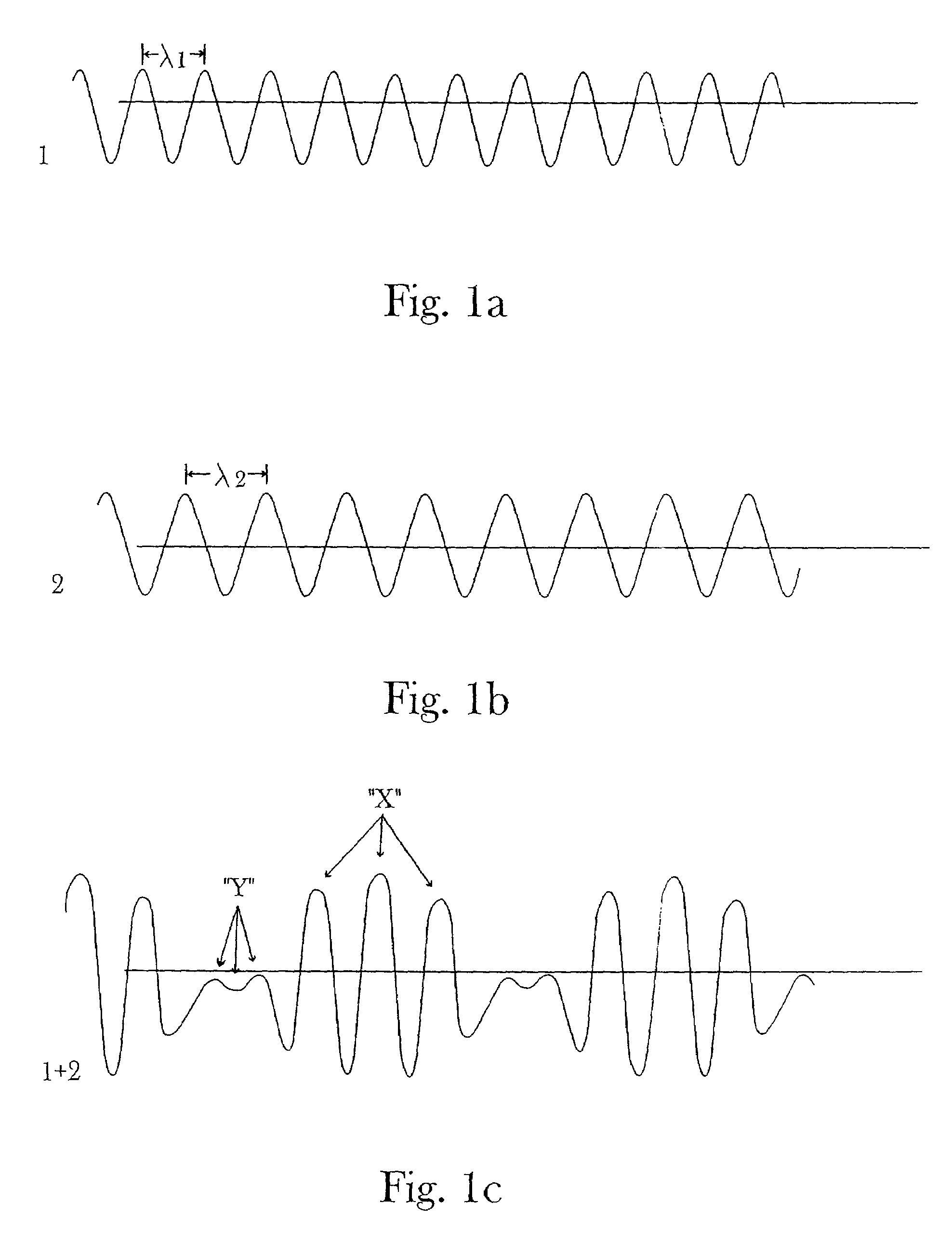

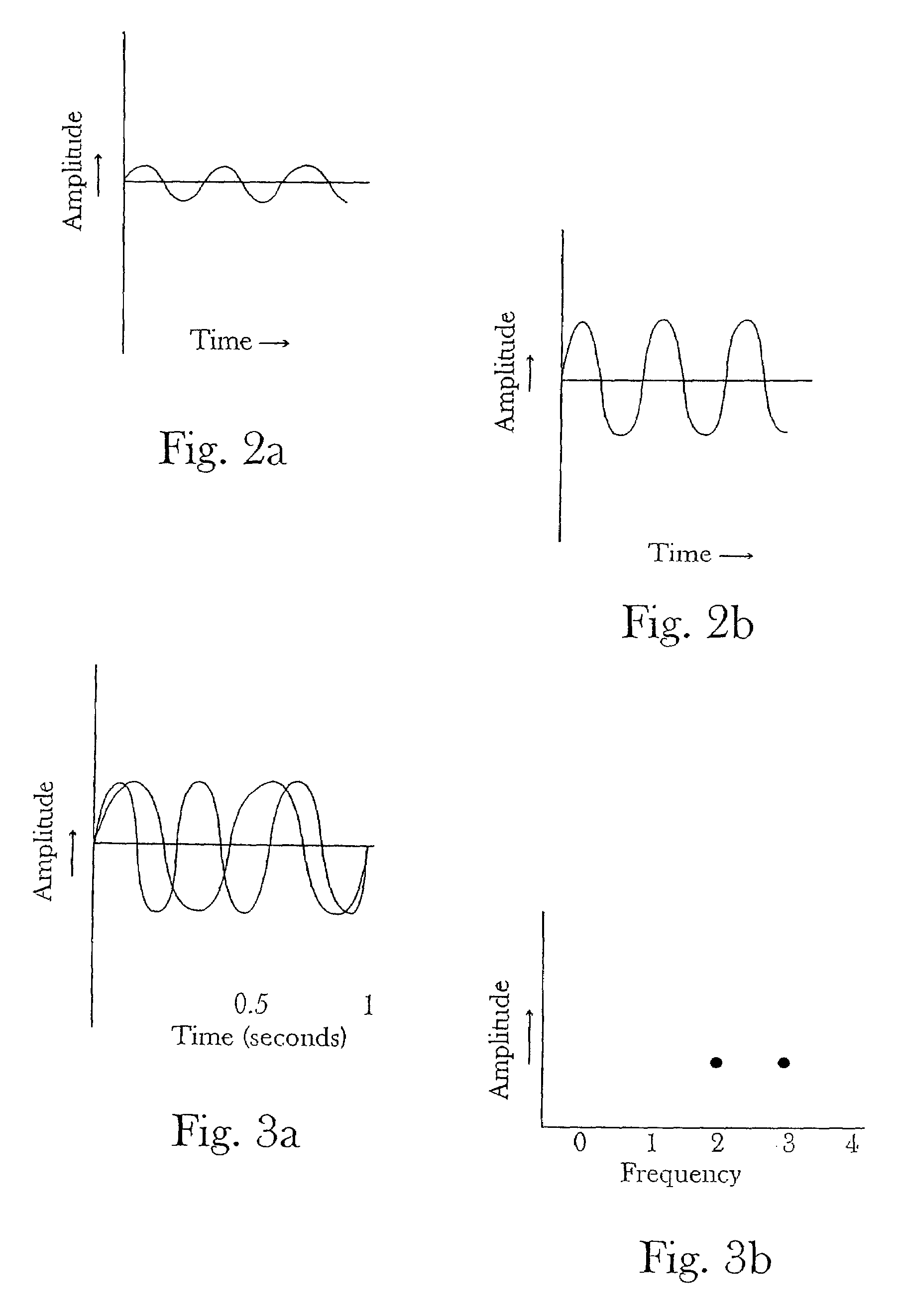

This invention relates to novel methods for affecting, controlling and / or directing various reactions and / or reaction pathways or systems by exposing one or more components in a fuel cell reaction system to at least one spectral energy pattern. In a first aspect of the invention, at least one spectral energy pattern can be applied to a fuel cell reaction system. In a second aspect of the invention, at least one spectral energy conditioning pattern can be applied to a conditioning reaction system. The spectral energy conditioning pattern can, for example, be applied at a separate location from the reaction vessel (e.g., in a conditioning reaction vessel) or can be applied in (or to) the reaction vessel, but prior to other reaction system participants being introduced into the reaction vessel.

Owner:GR INTELLECTUAL RESERVE LLC

Methods of making cesium salts and other alkali metal salts

A method of making a cesium salt is described and involves reacting a cesium sulfate containing solution with lime to form 1) a solution containing at least cesium hydroxide and 2) a residue comprising calcium sulfate. The method further involves removing the residue from the solution and converting the cesium hydroxide that is present in the solution to at least one type of cesium salt. The present invention further relates to uses of the cesium salt as well as methods of making cesium hydroxide using lime. Also, methods of making alkali metal salts and alkali metal hydroxides are also described.

Owner:CABOT SPECIALTY FLUIDS

Methods of making cesium salts and other alkali metal salts

A method of making a cesium salt is described and involves reacting a cesium sulfate containing solution with lime to form 1) a solution containing at least cesium hydroxide and 2) a residue comprising calcium sulfate. The method further involves removing the residue from the solution and converting the cesium hydroxide that is present in the solution to at least one type of cesium salt. The present invention further relates to uses of the cesium salt as well as methods of making cesium hydroxide using lime. Also, methods of making alkali metal salts and alkali metal hydroxides are also described.

Owner:CABOT SPECIALTY FLUIDS

Method for recovering and refining sodium bromide from dipropyl cyanoacetate mixture

The invention provides a method for recovering refining sodium bromide from dipropyl cyanoacetate mixture. The method comprises the following steps: filtering a dipropyl cyanoacetate mixture containing sodium bromide, filtering and colleting sodium bromide, dissolving sodium bromide, adjusting the pH value to 6-6.5 by hydrobromic acid, adding an extraction agent of an ether and alkane mixture, stirring for mixing, standing and layering; separating water liquid, boiling, cooling to 80 DEG C, adding an active carbon and diatomite mixed decolorizing agent, decolorizing at 50-80 DEG C, filtering, and conducting spray drying on the filtrate to obtain a white powdered anhydrous sodium bromide with high purity and high recycling rate.

Owner:湖南省湘中制药有限公司

Recovery comprehensive utilization method of disperse red 60 byproduct

ActiveCN101225239AReduce dosageHigh recovery rateOrganic chemistryAmino-hydroxy-anthraquinone dyesRecovery methodLiquid water

The invention discloses a recovery method and comprehensive utilization of disperse red 60 by-products, belonging to the comprehensive treatment technical field of the chemical dyes and auxiliaries by-products, which comprises the following process steps: (1) acidification: the condensation mother liquid water obtained by condensation reaction of the 1-amino-2- bromine-4- hydroxyl anthraquinone and the phenol is acidi-regulated to the acid pH value, and sulfate or hydrochloride is added for acidulating; (2) standing stratification: the acidulated mother liquid water is kept still for more than a half hour, upper solution of disperse red sixty with phenol and dissolved in the phenol, and lower solution with potassium bromide and phenol are obtained; (3) separation: the lower solution is put in the potassium bromide catch trough, and then is derived into the potassium bromide extraction boiler; (4) extraction: organic solvent is put into the potassium bromide extraction boiler, after extracting, standing and stratification, the upper layer is phenol which can dissolve in the organic solvent, the lower layer is potassium bromide solution. The recovery method and comprehensive utilization of disperse red 60 by-products has the advantages of reducing production cost and environmental pollution effectively.

Owner:浙江长征化工有限公司

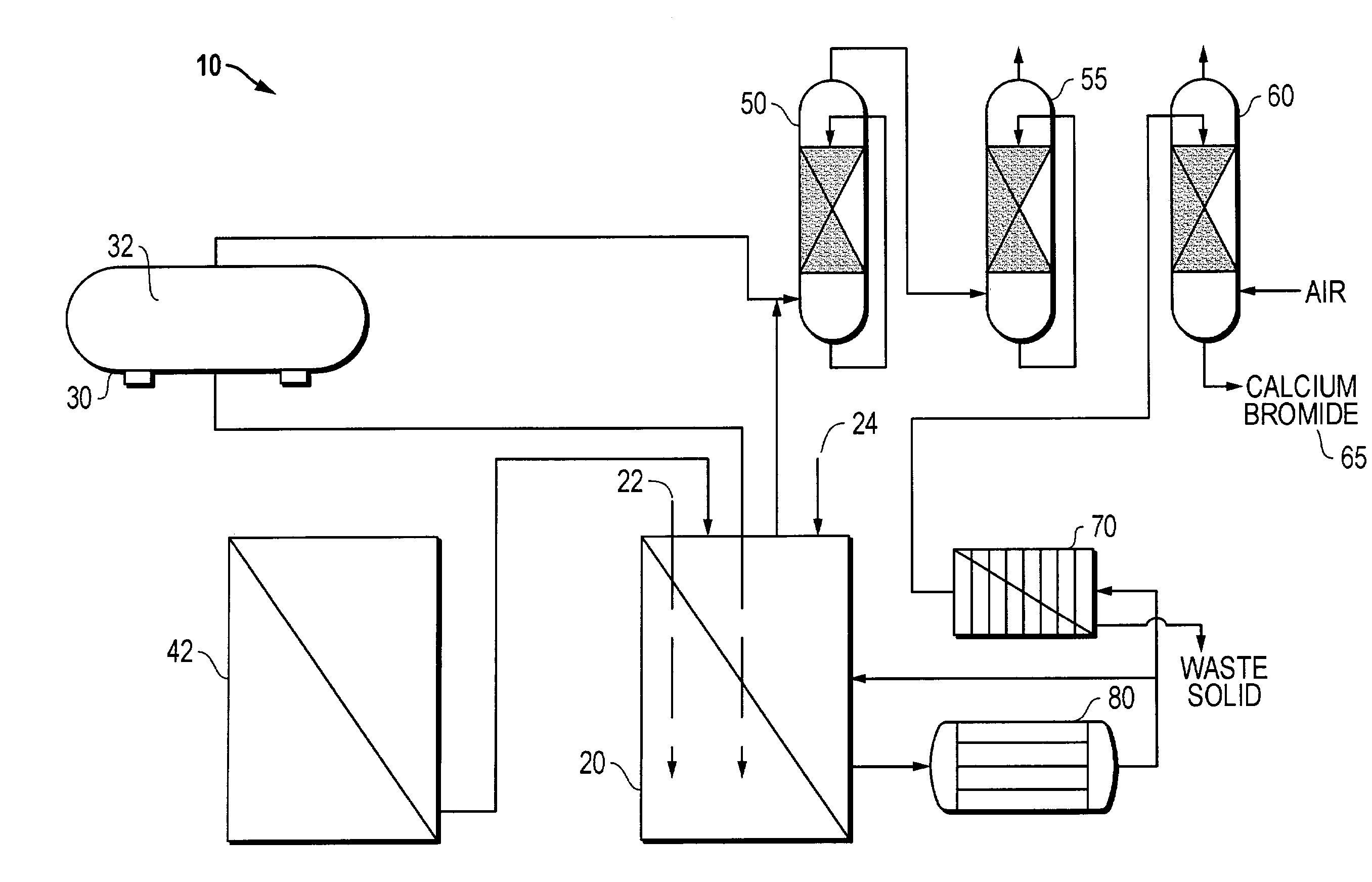

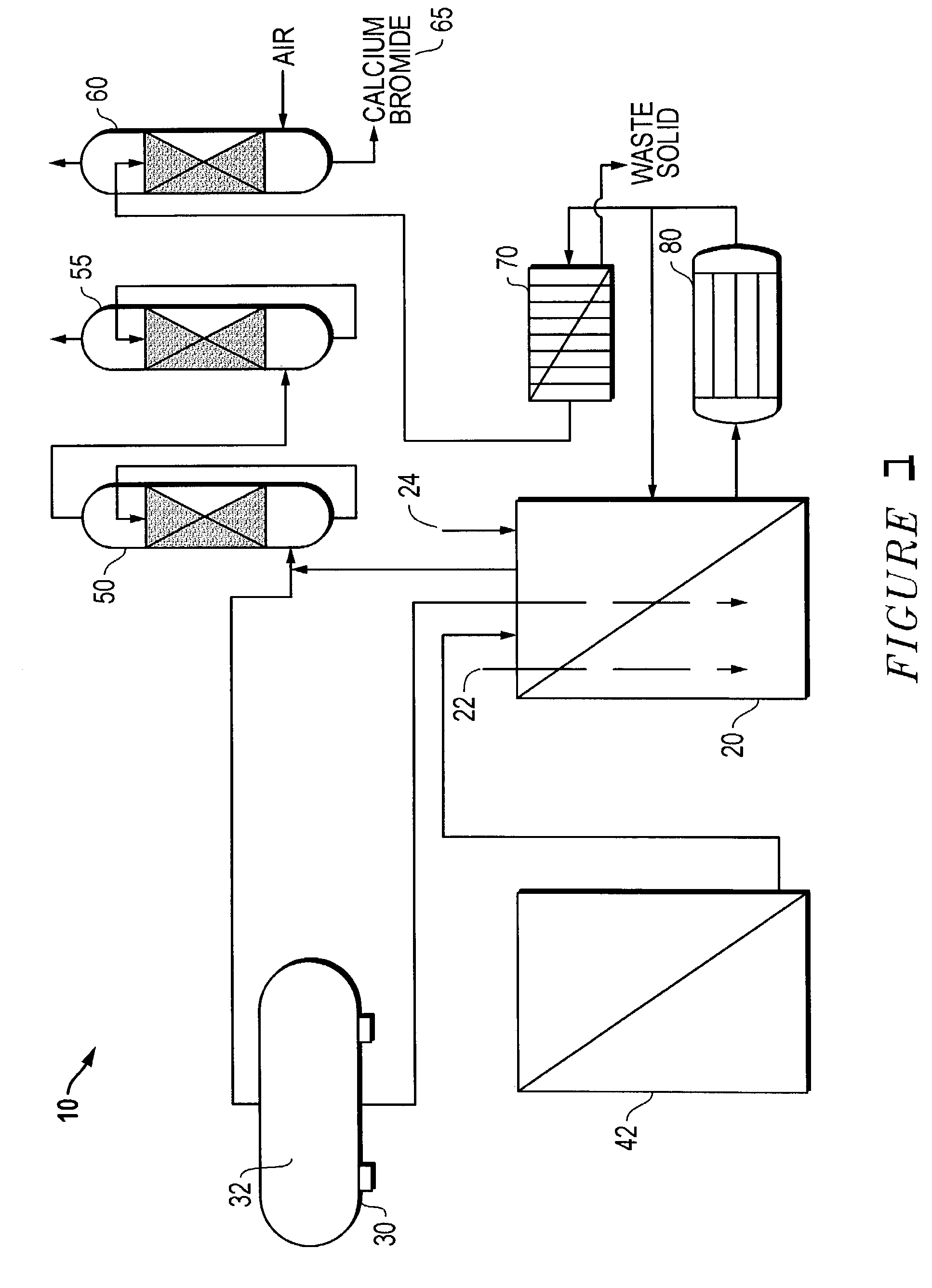

Method for producing a halide brine

ActiveUS7087209B2Simple and inexpensive methodLow costMagnesium halidesGallium/indium/thallium compoundsHalogenSalt water

A method for producing halide brine wherein an alkali and a reducing agent are added to an aqueous fluid having a density greater than 8.30 lb / gal., (0.996 kg / L) water, waste water or sea water for example. The resulting fluid is then contacted with a halogen to form a halide brine. The reaction occurs in a conventional reactor such as a mixing tank.

Owner:TETRA TECH INC

Extended lathering pillow article for personal care

InactiveUS7179772B2Inorganic/elemental detergent compounding agentsCosmetic preparationsPersonal careWater insoluble

A personal care cleansing article is provided which includes a cleansing composition having a lathering surfactant and a water absorbing material capable of accepting at least ten times the weight of the material of water, the composition being held within a water-insoluble sachet.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

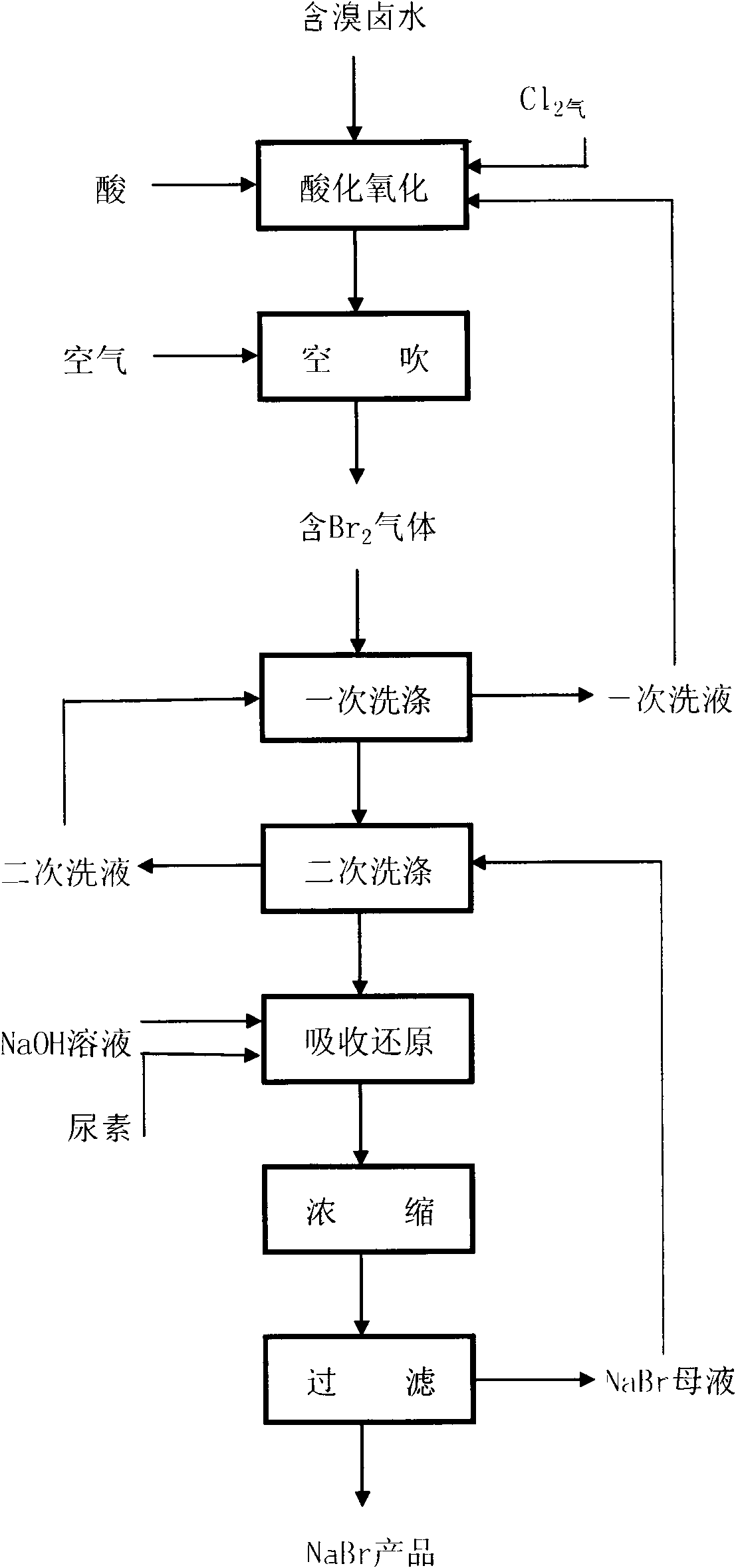

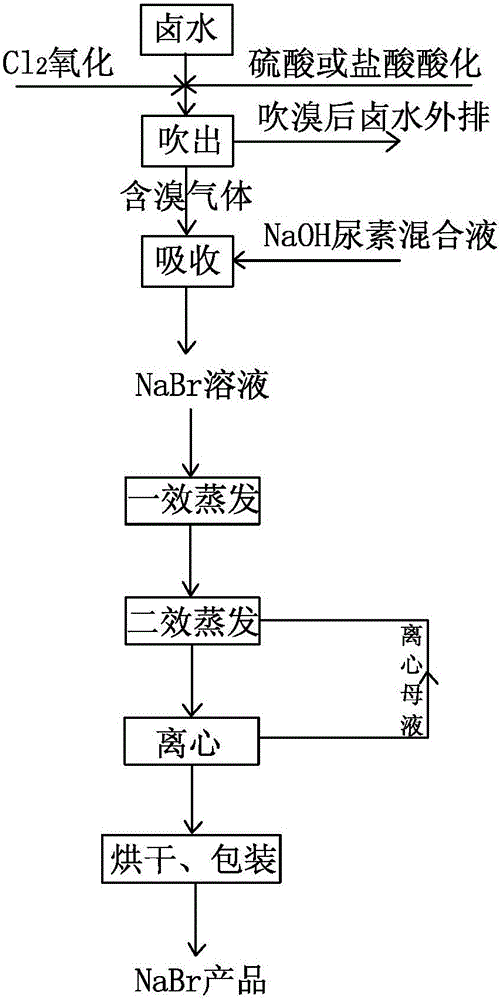

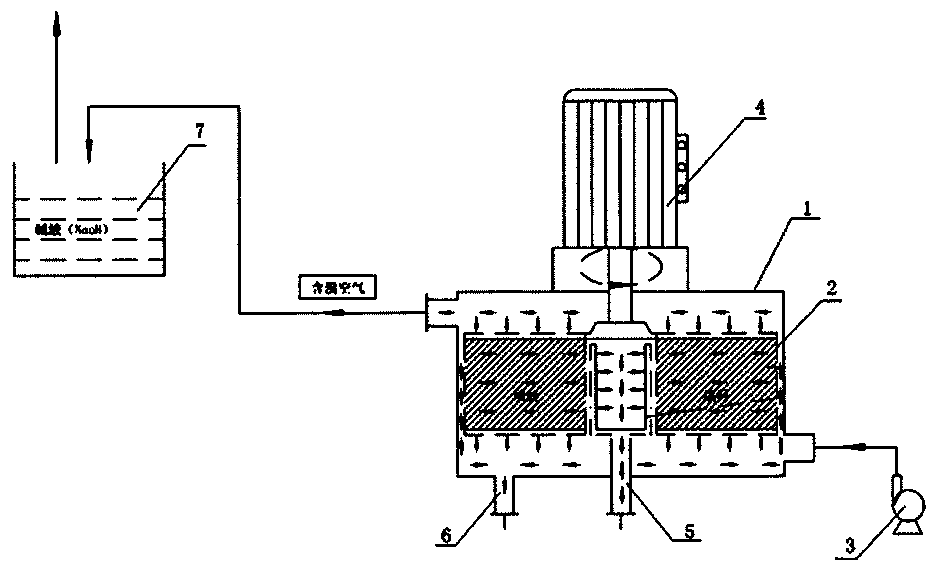

Method for preparing sodium bromide by continuous multi-stage air blow

InactiveCN101659426ASimple process equipmentReduce manufacturing costAlkali metal bromidesSocial benefitsProcess equipment

The invention relates to a method for preparing sodium bromide by continuous multi-stage air blow in deep marine facies potassium-rich brine. Bromine-containing brine is processed by the working procedure of acidification and oxidation, heating air blow, washing, absorbtion and concentration, so that the sodium bromide can be prepared. The method has the advantages of simple technological equipment, low production cost and energy consumption, high product purity and yield, strong practicability and better economic and social benefits.

Owner:DAZHOU HENGCHENG ENERGY GROUP

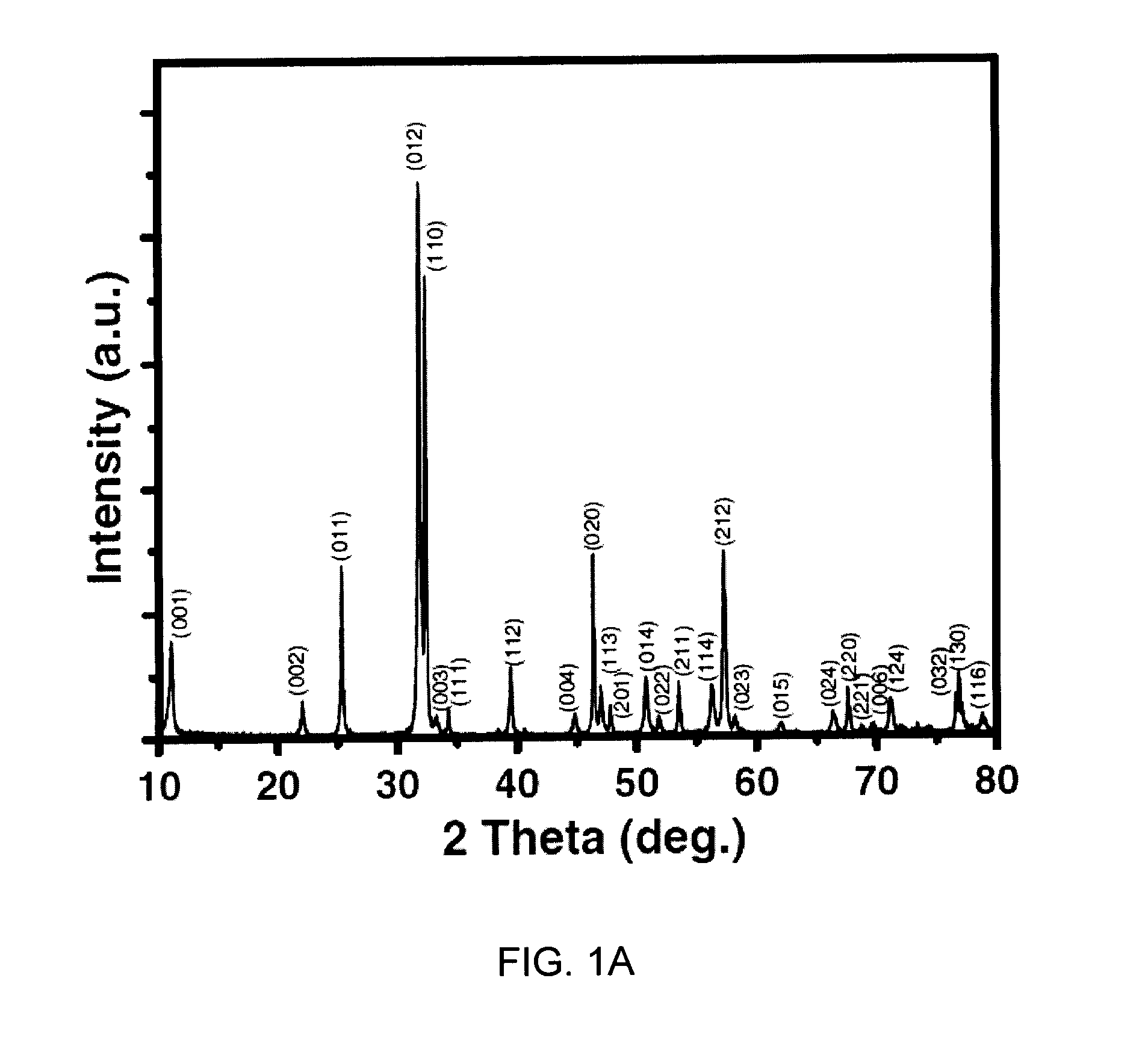

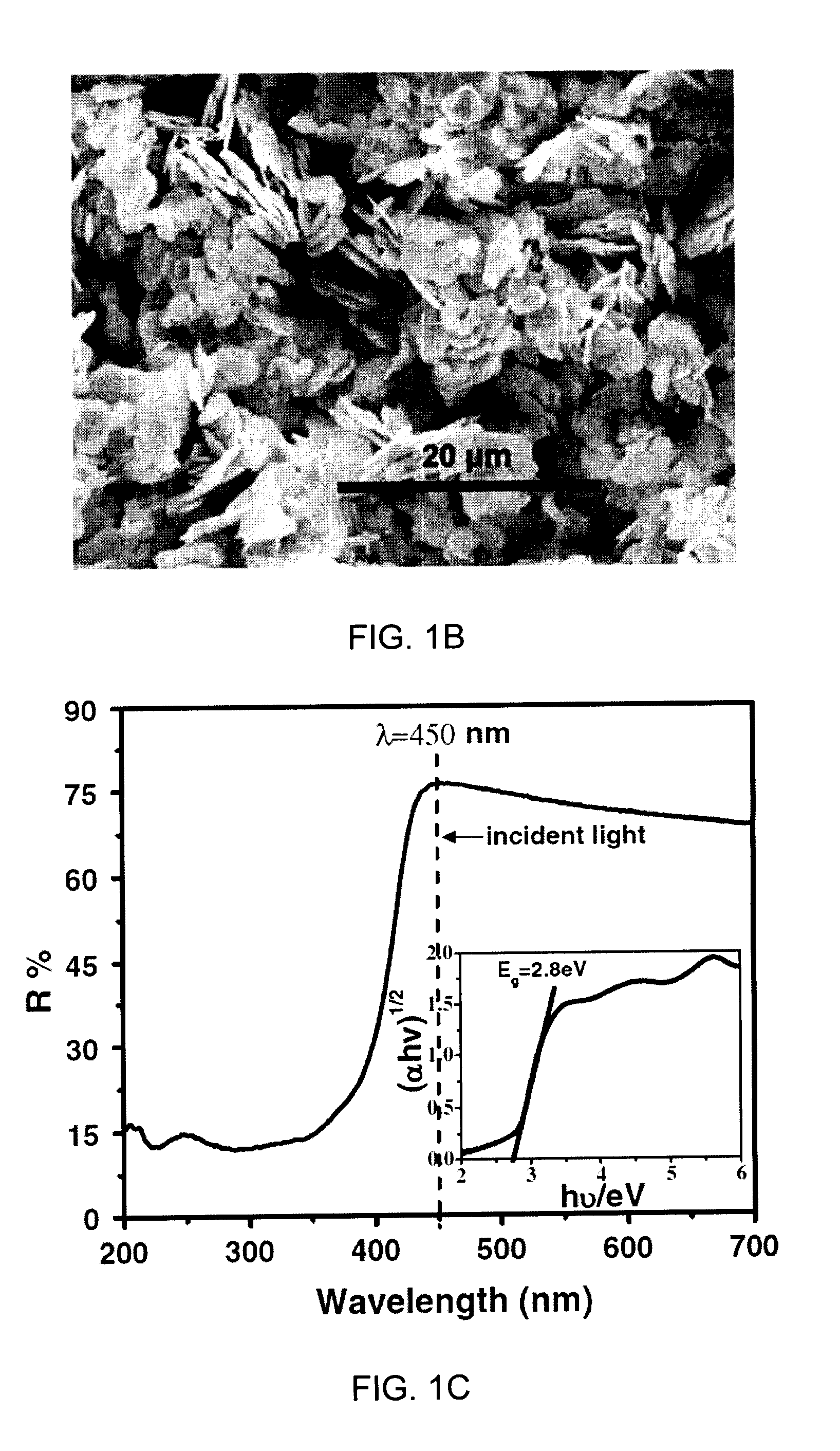

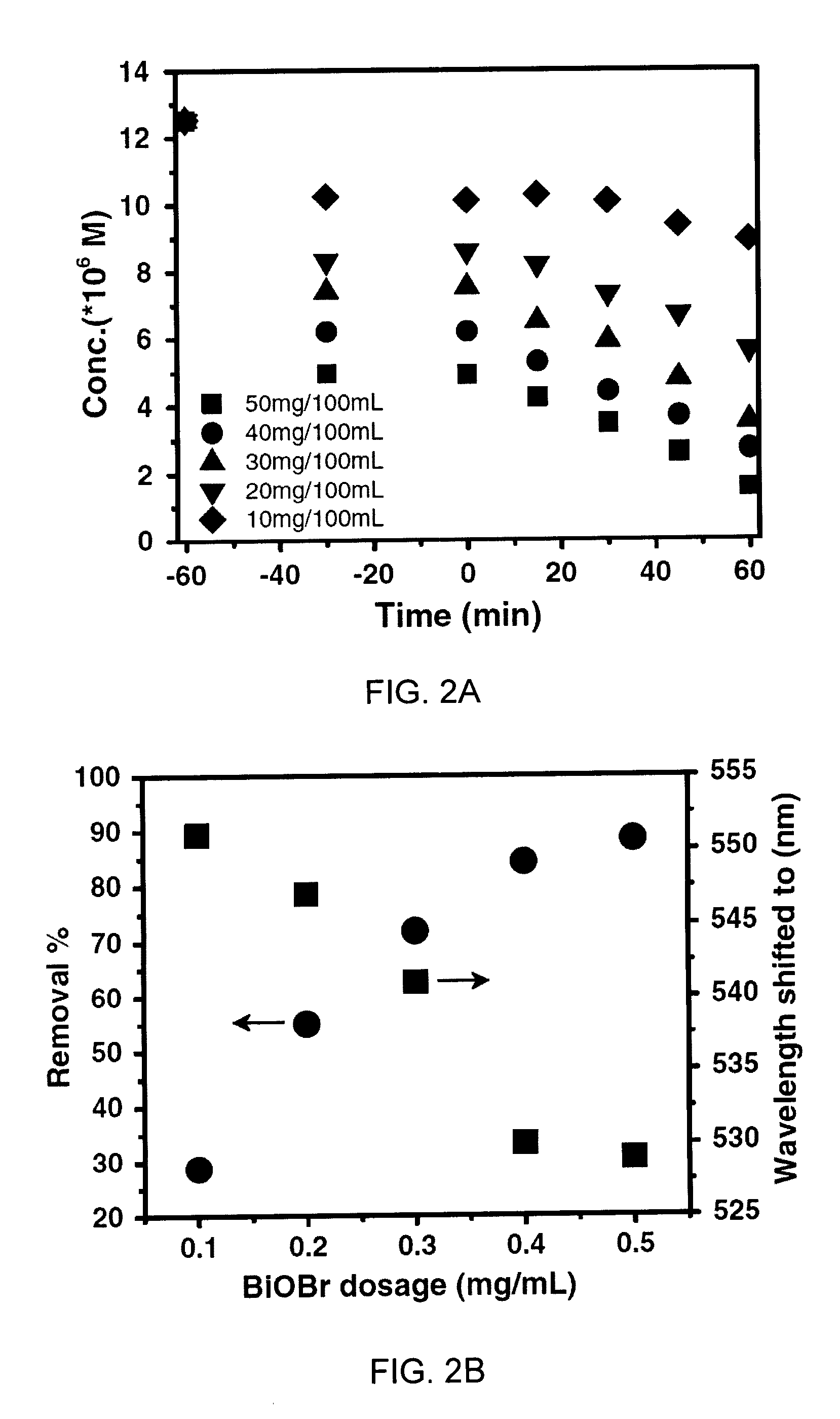

450 nm visible light-induced photosensitized degradation of rhodamine b molecules over biobr in aqueous solution

A method for degrading Rhodamine B including: mixing BiOBr and Rhodamine B; and irradiating the mixture with a radiation having a wavelength of from 440 nm to 554 nm. The Rhodamine B may be in an aqueous solution. The BiOBr may be added to the aqueous solution of Rhodamine B in an amount of from 0.2 to 0.5 mg / ml. The BiOBr may have a sheet-like structure with particles having a diameter of from 3 μm to 5 μm. The BiOBr may be in a pure crystal tetragonal phase.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

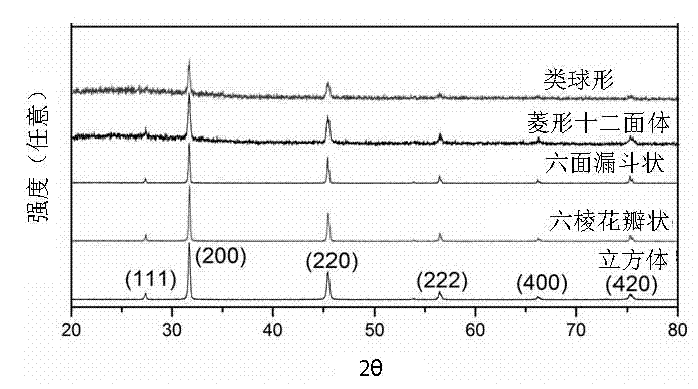

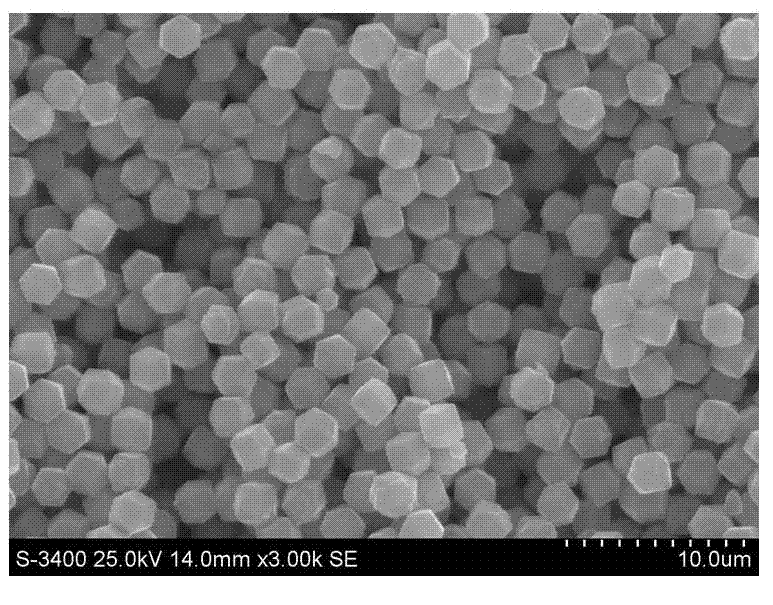

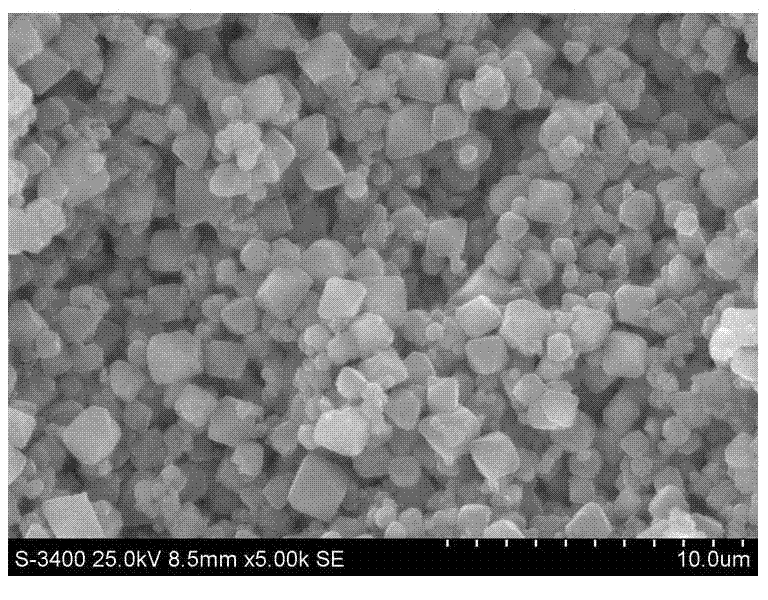

Water-soluble sodium halide micro-particles, and preparation method and application thereof

The invention relates to water-soluble sodium halide micro-particles, and a preparation method an application thereof. The water-soluble sodium halide micro-particles has a sodium-chloride-type crystal structure and at least one morphology and dimension of the following: the particles are cube, rhombic dodecahedron, regular octahedron, sphere or sphere-like shape, hexagonal-shaped petals or hexagonal star-shape, six-sided funnel-shape, octagonal-shaped petals, or nano-wires with three-dimensional size of 50 nanometers to 20 micrometers.

Owner:江苏先进无机材料研究院

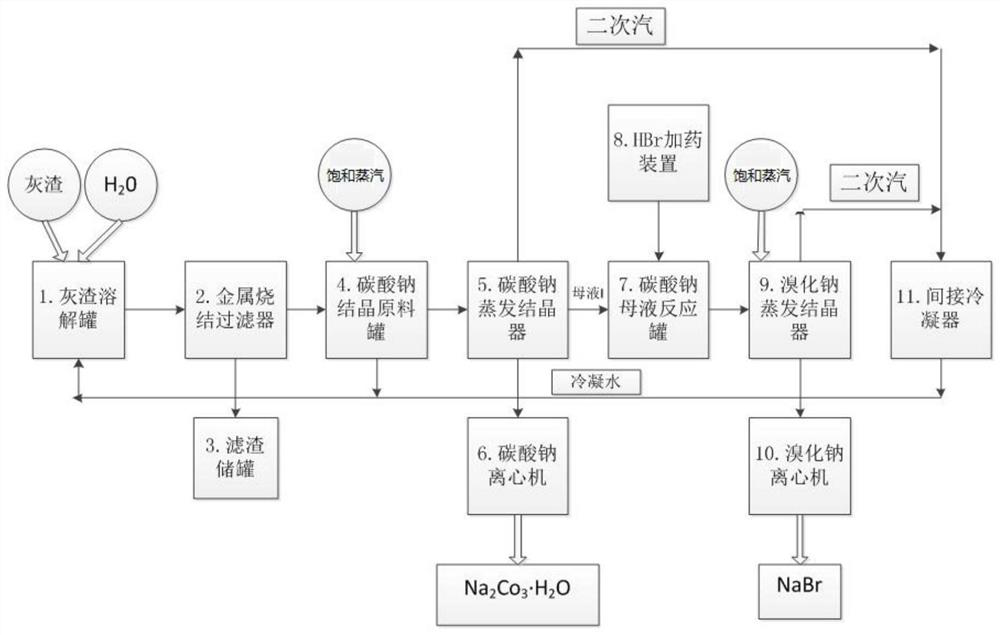

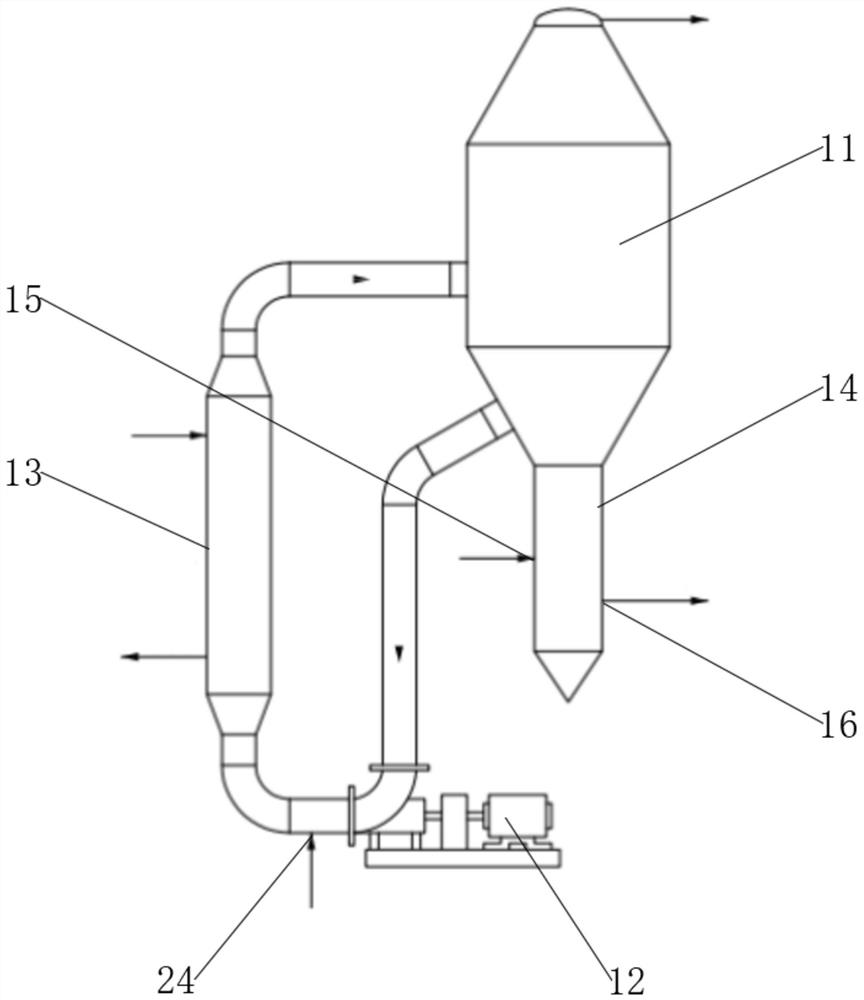

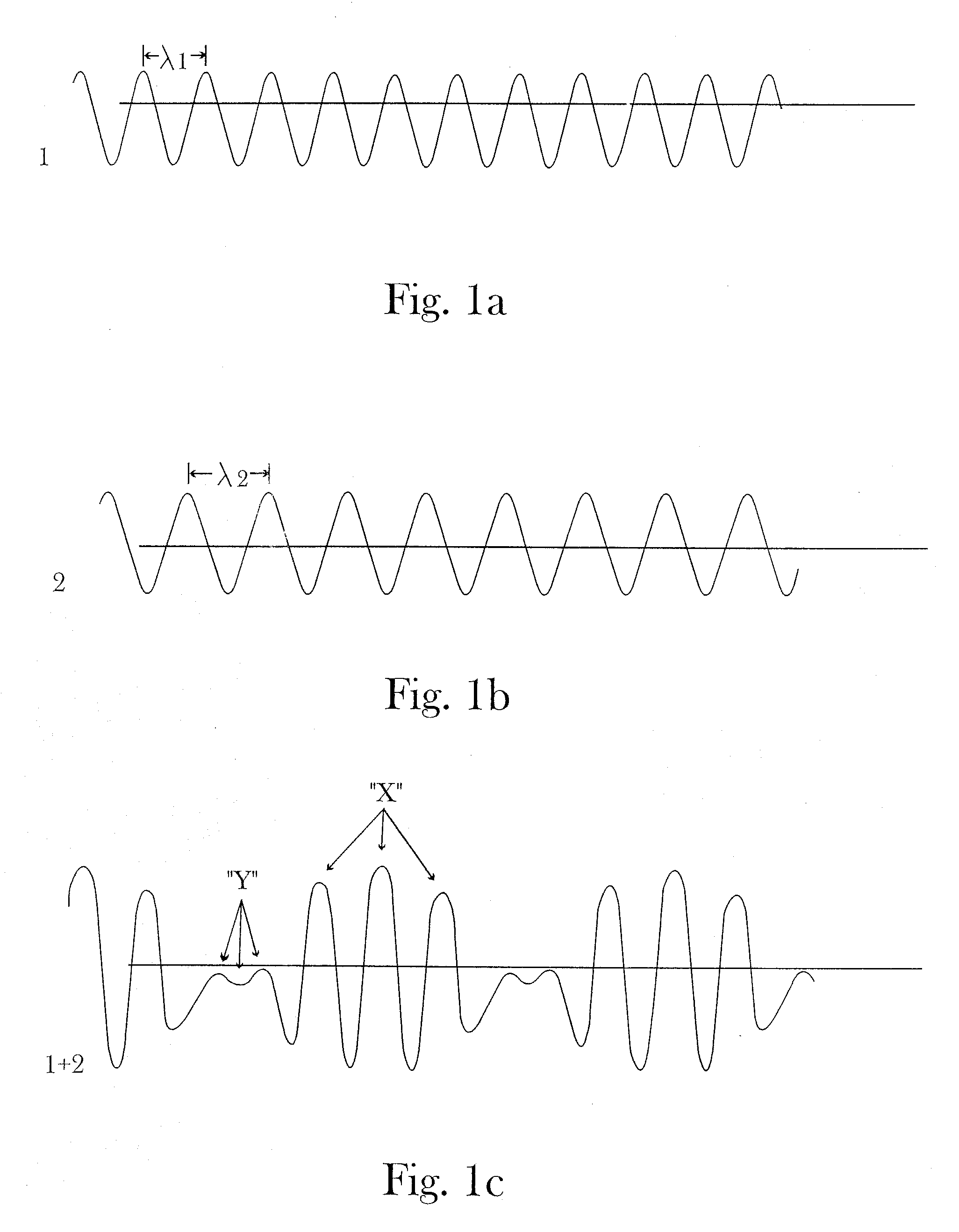

PTA incineration boiler ash residue solution salt separation crystallization process

ActiveCN112811444AFulfill quality requirementsRealize resourcesAlkali metal carbonates shape formationEnergy inputPhysical chemistryWastewater

The invention relates to a PTA incineration boiler ash residue solution salt separation crystallization process, and belongs to the technical field of evaporative crystallization. The process comprises the following steps of: dissolving ash of the PTA incineration boiler with waste heat into a nearly saturated solution of sodium carbonate and sodium bromide, and removing metals and other insoluble substances from the solution by adopting a metal sintering filter, separating the obtained filtrate by adopting an evaporative crystallization method to obtain sodium carbonate monohydrate crystals, removing sodium carbonate from the mother liquor by adopting a replacement method, and then separating by adopting an evaporative crystallization method to obtain sodium bromide crystals. Sodium carbonate and sodium bromide in the PTA boiler ash are separated and recovered by adopting an evaporative crystallization method, the process flow is simple, the operation conditions are simple, convenient and stable, and industrialization is facilitated; the high-purity sodium carbonate and sodium bromide recovered by the method can meet the quality requirements of industrial-grade products and can be directly recovered and reused or sold as by-products, so that the purpose of treating waste residues and wastewater is achieved, the requirements of the current environmental protection situation are met, waste can be turned into wealth, recycling of salt is realized, and the benefits of factories are improved.

Owner:河北工大晟珂工程科技有限公司

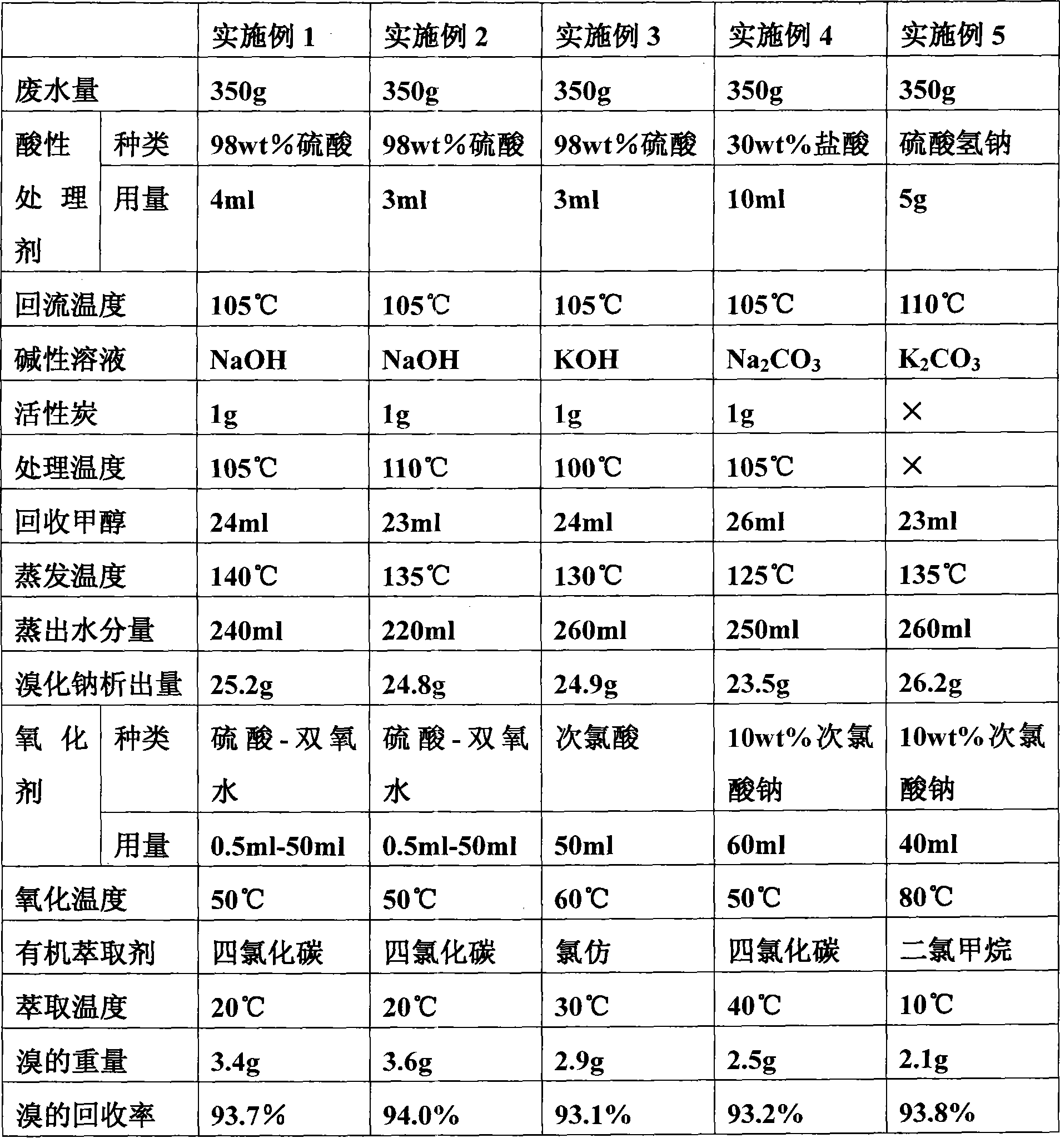

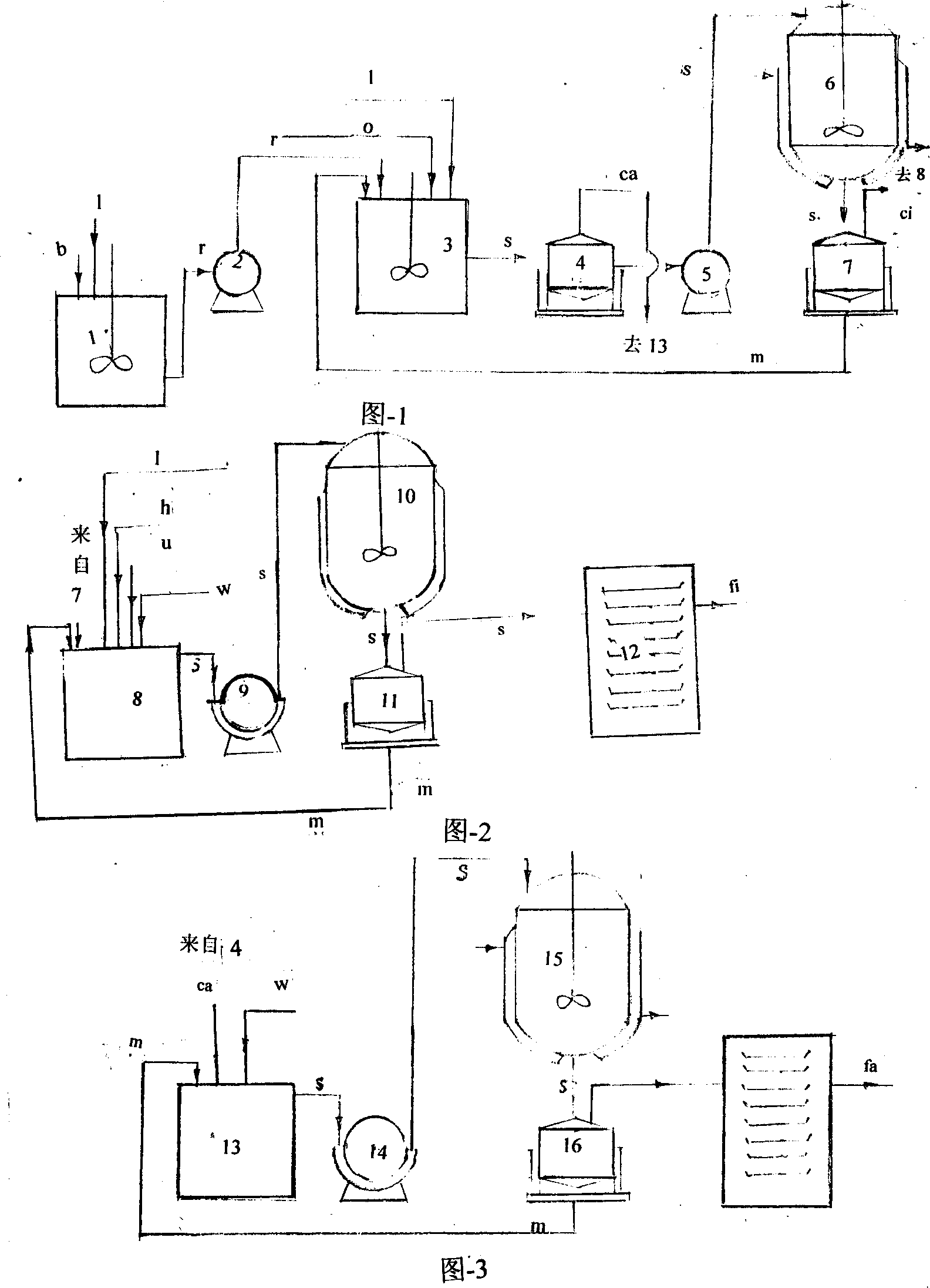

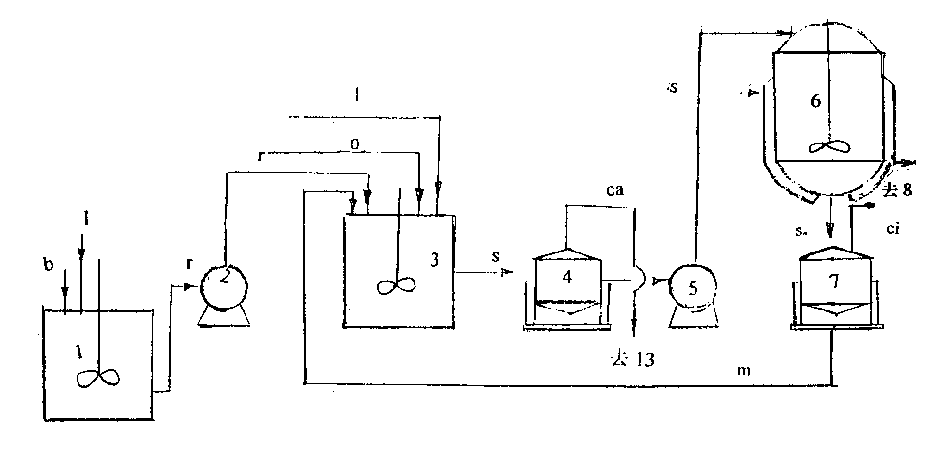

Method for treating wastewater produced by methylation reaction in metribuzin synthesis

InactiveCN101445304AReduce processingReduce pollutionMultistage water/sewage treatmentNature of treatment waterRefluxBromine

The invention discloses a method for treating wastewater produced by methylation reaction in metribuzin synthesis. In the method, the wastewater produced by the methylation reaction in the metribuzin synthesis is added with an acidic treating agent, and the obtained mixture is heated to 90 DEG C-120 DEG C and refluxed for deodorization and decolorization; and volatile gas in the wastewater and gas produced in the reflux are absorbed by alkaline solution for deodorization. Methanol in the wastewater is recovered by a batch distillation method. Residual liquid is heated to 100 DEG C-150 DEG C for evaporation, and then the residual liquid is naturally cooled by stirring until sodium bromide crystal is separated out. Filtrate is oxidized by an oxidant at the oxidation temperature of 50 DEG C-80 DEG C. A system is cooled to 10 DEG C-40 DEG C, and bromine in the system is extracted by an organic extractant, thus obtaining organic phase extracting solution with the bromine. The method helps solve the problem of treating methylated wastewater in metribuzin production, and reduce environmental pollution and production cost, the recovery rate of the bromine reaches more than 93%, and the method has good use value, and is simple and feasible.

Owner:JIANGSU HUAYI GARMENT CO LTD +1

Production method of sodium bromide, sodium bromate, potassium bromide and potassium bromate by using bromide and alkali

InactiveCN1354125AImprove protectionEfficient separationBromine oxygen compoundsAlkali metal bromidesPotassiumDisproportionation

The present invention uses bromide and sodium (potassium) hydroxide as raw material, makes them produce disproportionation reaction, regulates specific weight and pH value, uses hydrogen peroxide to remove free bromine, and adopts the processes of cooling and dewatering to separate sodium (potassium) bromate crude product, and makes the mother liquor undergo the processes of dewatering and concentration to obtain sodium (potassium) bromide crude product. The sodium (potassium) bromide crude product is disclosed, and undergone dthe processes of removing small quantity of sodium (potassium) bromate by using urea, filtering, dewatering, concentrating, drying and packaging to obtain sodium (potassium) bromide finished product. The sodium (potassium) bromate crude product is undergone the processes of dissolving, filtering, dewatering, concentrating, drying and packaging so as to obtain sodium (potassium) bromate finished product.

Owner:周群领

Preparation of non-hazardous brominating reagents

InactiveUS20030136941A1Easy to handleStable storageOther chemical processesOrganic compound preparationBromineBromate

The present invention relates to a non-hazardous brominating reagent from an aqueous alkaline bromine byproduct solution obtained from bromine recovery plant and containing 25 to 35% bromine dissolved in aqueous lime or sodium hydroxide containing alkali bromide and alkali bromate mixture having bromide to bromate stoichiometric ratio in the range of 5:1 to 5.1:1 or 2:1 to 2.1:1 and a pH ranging between 8-12 and also relates to a method for borminating aromatic compounds by using the above brominating agent

Owner:COUNCIL OF SCI & IND RES

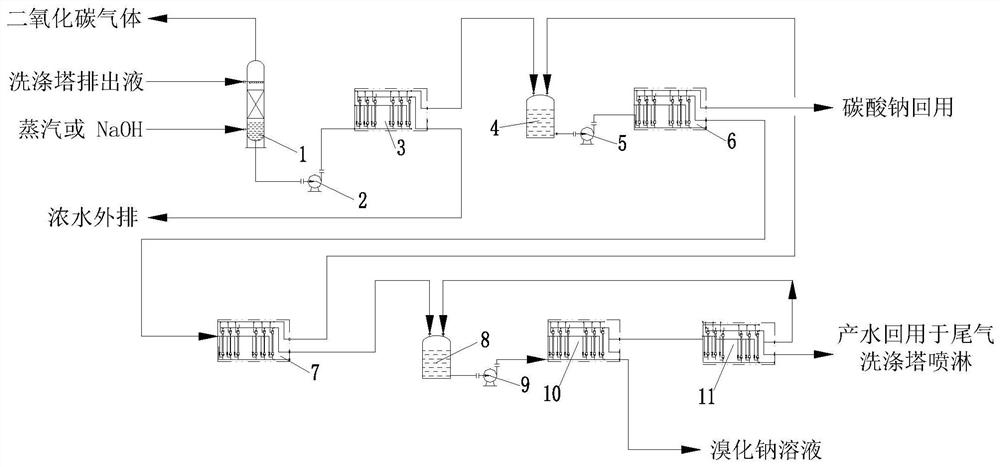

Method and system for separating sodium carbonate and sodium bromide in PTA oxidation tail gas washing tower discharge liquid

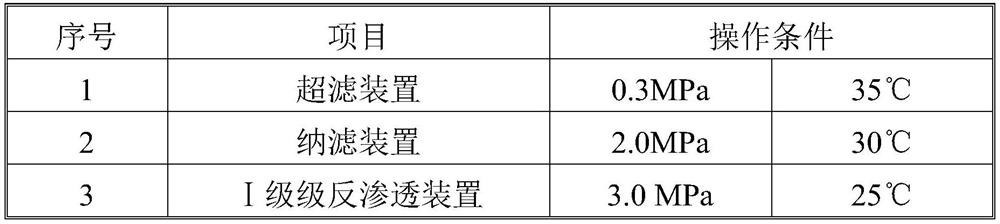

PendingCN113461199AWater contaminantsWaste water treatment from gaseous effluentsUltrafiltrationPhysical chemistry

The invention relates to a method for separating sodium carbonate and sodium bromide in a PTA oxidation tail gas washing tower discharge liquid. The method comprises the following steps: in a sodium bicarbonate removal tower, adjusting the pH value of the washing tower discharge liquid to be 11.0-12.0 in a steam heating or sodium hydroxide adding manner to obtain a decarbonized washing tower discharge liquid; conveying the decarbonized washing tower discharge liquid to an ultrafiltration device to remove suspended particulate matters so as to obtain ultrafiltration produced water and ultrafiltration concentrated water, and discharging the ultrafiltration concentrated water; and conveying the ultrafiltration produced water to a two-stage nanofiltration device and a two-stage RO device, wherein the first-stage nanofiltration concentrated water is a sodium carbonate-containing solution, and the first-stage RO concentrated water is a sodium bromide-rich solution. The invention relates to a system for separating sodium carbonate and sodium bromide in the PTA oxidation tail gas washing tower discharge liquid. According to the method and the system, sodium bicarbonate in the discharged liquid of the PTA oxidation tail gas washing tower can be converted into sodium carbonate, and the sodium carbonate is separated from sodium bromide.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

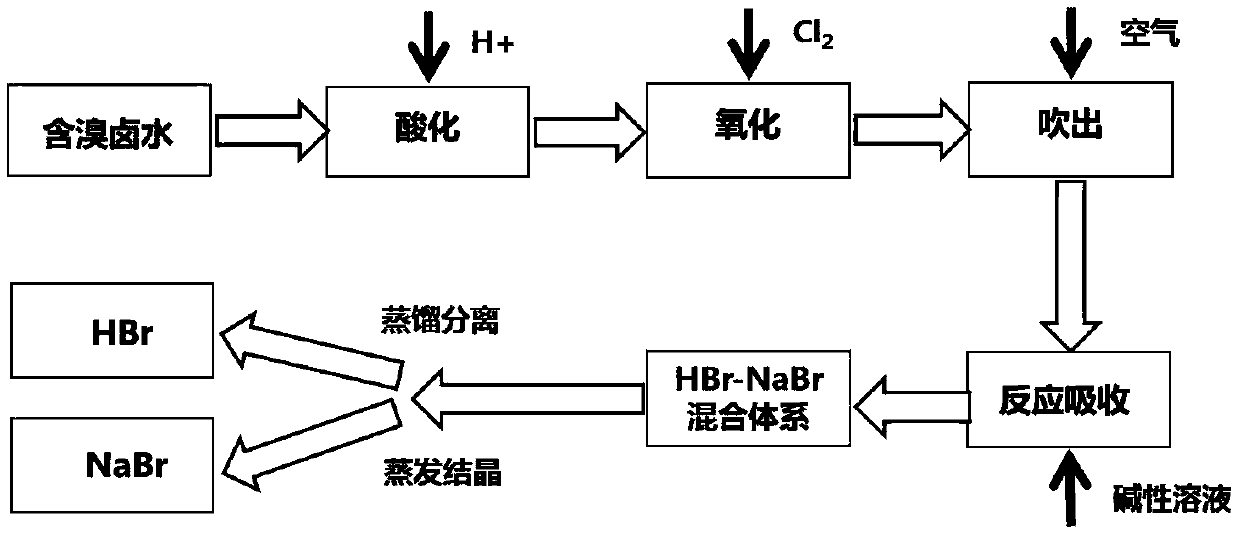

Preparation method for sodium bromide

The invention discloses a preparation method for sodium bromide. The method comprises the following steps: acidizing and oxidizing; blowing out air; absorbing for three times; concentrating, separating and drying end products. When the method is adopted, the bittern is at room temperature and needs not be heated, so that the energy can be saved; the blown molecular bromine needs not be washed; the process is simplified; air is sealed and recycled; no environmental pollution is caused; the one-blowing three-absorbing process is adopted, the absorbing is sufficient, the absorbing efficiency is high, the extracting ratio can reach 97% or above and 99% excellent sodium bromide end product is acquired; according to the method, the waste water after potassium extraction can be utilized to extract bromine; the sodium bromide product can be further produced; the resource reutilization can be realized.

Owner:SHANDONG HAIWANG CHEM

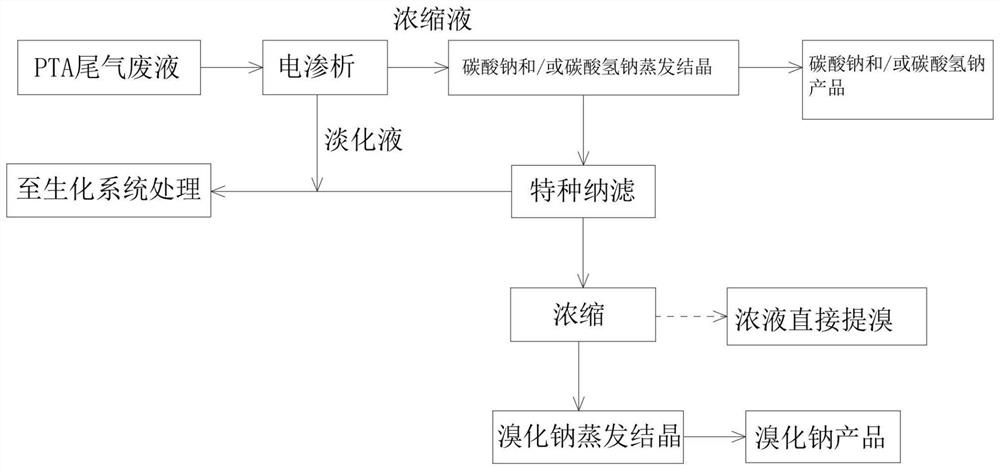

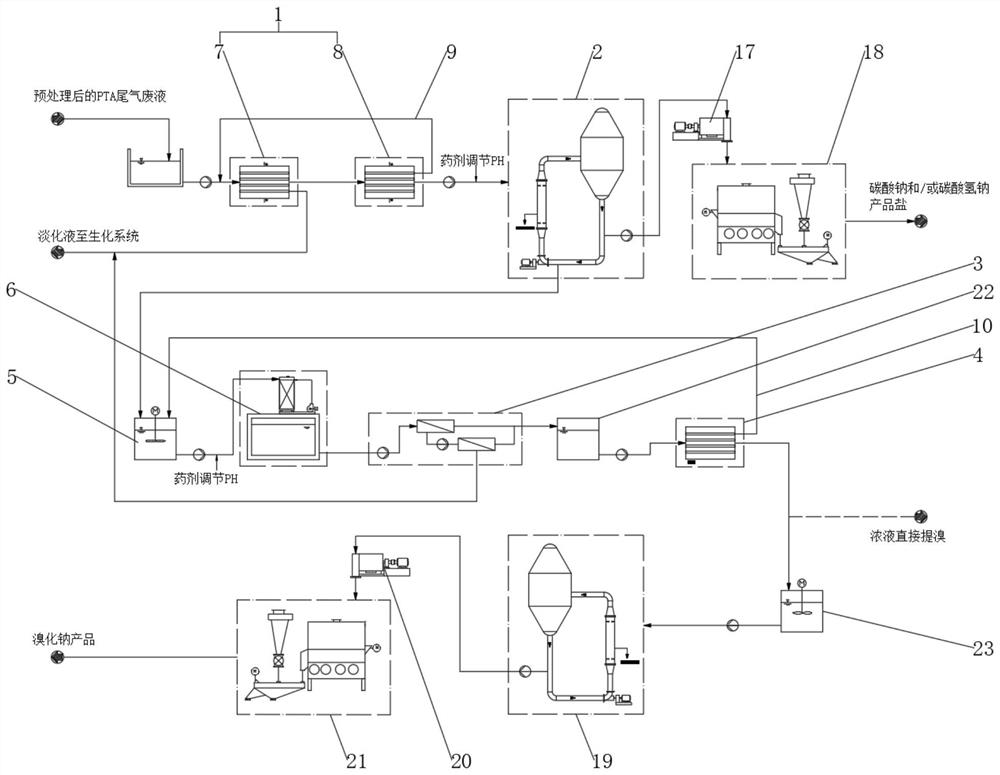

Method and device for recovering bromine element and sodium element from PTA tail gas treatment waste liquid

PendingCN114380441AIncrease valueHigh purityWaste water treatment from gaseous effluentsMultistage water/sewage treatmentTerephthalic acidSodium acid carbonate

The invention provides a method and a device for recovering bromine elements and sodium elements from PTA tail gas treatment waste liquid, relates to the technical field of treatment of oxidation waste liquid of terephthalic acid, and solves the problems that in the prior art, the PTA waste liquid is discharged only through sulfuric acid neutralization and biochemical treatment; the loss of high-value materials such as sodium bicarbonate, sodium carbonate and sodium bromide is easily caused. The recovery method comprises the following steps: carrying out concentration treatment on pretreated waste liquid to form a concentrated solution; adjusting the pH value of the concentrated solution to be alkaline, and performing evaporative crystallization on the concentrated solution to obtain sodium carbonate crystals and / or sodium bicarbonate crystals; carrying out special nanofiltration treatment on the evaporated and crystallized mother liquor to obtain a sodium bromide fresh water solution; the sodium bromide fresh water solution is concentrated, a high-concentration sodium bromide solution is obtained, follow-up evaporative crystallization or bromine extraction treatment is facilitated, solute in the waste liquid can be recycled and converted into product salt with high economic value, and the remaining waste liquid is more beneficial to follow-up treatment and discharge.

Owner:南京南环水务科技有限公司

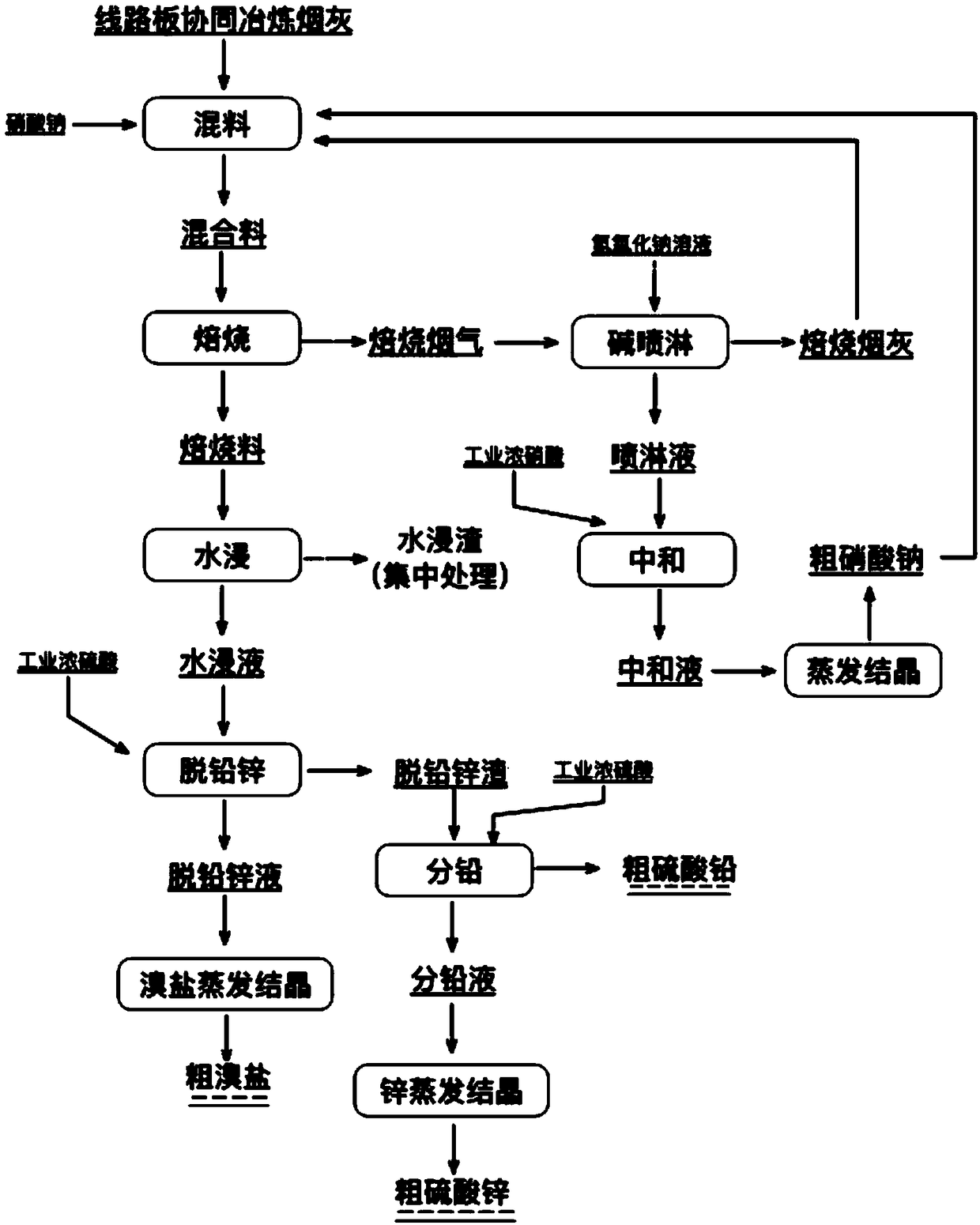

Method for separating bromine from synergistic smelting ash of circuit boards through roasting with sodium nitrate

PendingCN109055722AEasy to recycleCompared with the recovery process, the inventive technology utilizes sodium nitrate decomposition to facilitateZinc sulatesAlkali metal bromidesSodium nitratePollution

The invention provides a method for separating bromine from synergistic smelting ash of circuit boards through roasting with sodium nitrate, belongs to the field of comprehensive recovery of valuableelements from ash through a whole wet method, and particularly relates to a method for efficiently separating and extracting bromine, lead and zinc from synergistic smelting ash of circuit boards through roasting with sodium nitrate. The method mainly comprises the steps of mixing, roasting, step-by-step regulation of pH with industrial sulfuric acid to separate and extract lead and zinc, evaporative crystallization of bromine to recover coarse bromine, smoke treatment and the like. Compared with a traditional ash comprehensive recovery process, oxidization of cuprous bromide and solidification of bromine are achieved through roasting with sodium nitrate, so that conversion and separation of soluble bromine, lead and tin are achieved; a sodium hydroxide and nitric acid system is used for smoke treatment, ash and nitrate generated in the roasting process are recovered to be used repeatedly, and thus, pollution caused by smoke and tail liquid is avoided in the recovery process.

Owner:BEIJING UNIV OF TECH

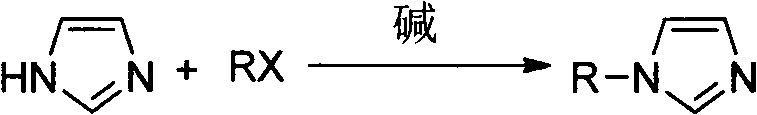

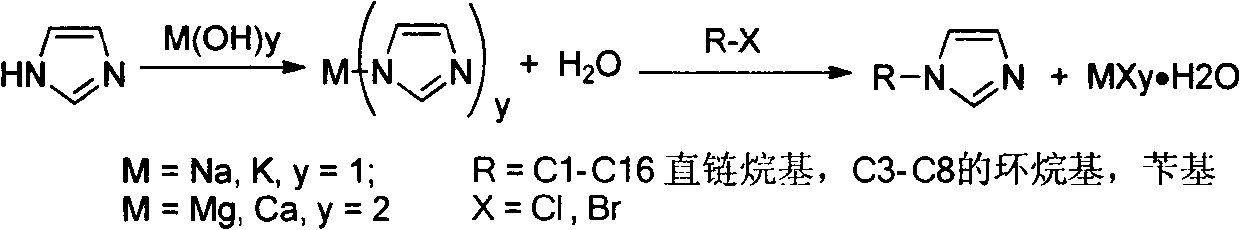

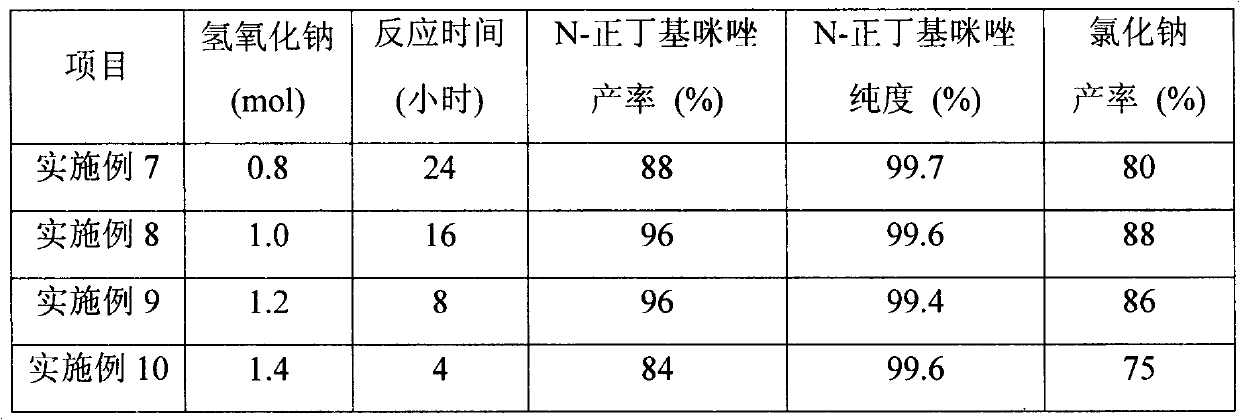

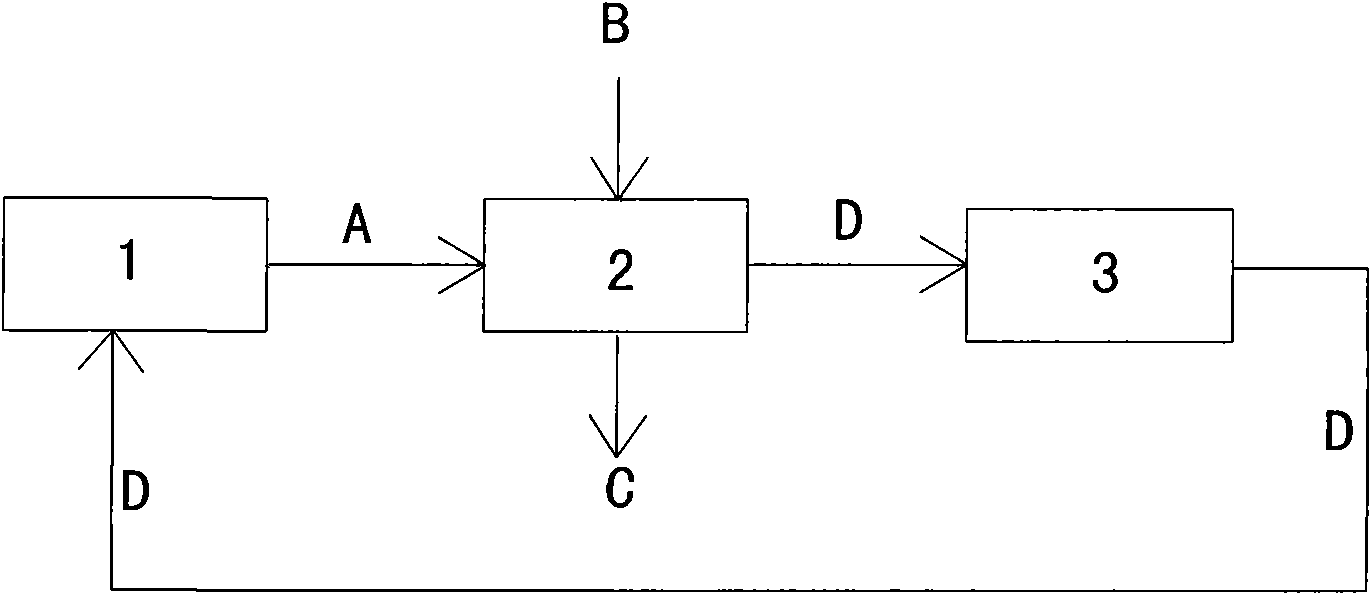

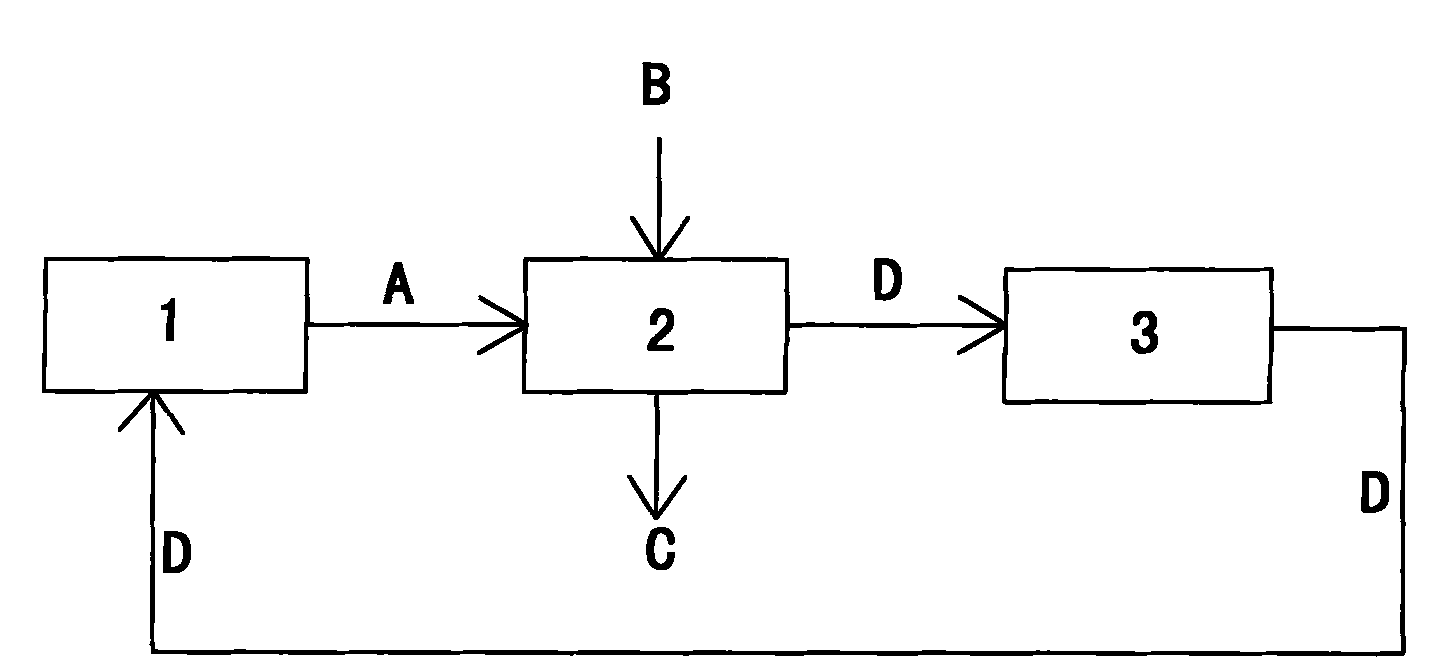

Method for producing high-purity N-alkyl imidazole

InactiveCN103012275AReduce corrosionReduce pollutionOrganic chemistryCalcium/strontium/barium chloridesCarbon numberAlkaline earth metal

The invention discloses a method for producing high-purity N-alkyl imidazole, comprising the following steps of: a, putting imidazole and alkali metal hydroxide or alkaline-earth metal hydroxide into a reaction bottle in a mol ratio ranging from (1: 0.5) to (1: 1.5); violently agitating at 90-150 DEG C for 0.2-24 hours; b, reducing the temperature to 0-60 DEG C and adding tetrahydrofuran (THF), wherein the ratio of the volume THF to the mass of the imidazole is (1-100): 1; c, adding alkyl halide according to the mol ratio ranging from (1: 0.8) to (1: 1.5) (imidazole to RX); reacting at 20-80 DEG C for 4-48 hours, wherein R is any one of straight-chain alkyl with a carbon number of 1-16, naphthenic base with a carbon number of 3-8, allyl, propargyl and benzyl, and X is any one of chlorine and bromine; d, after the reaction, filtering; utilizing the THF which is 10% of the previous volume to wash a solid for three times; dissolving the solid into a suitable amount of hot water to carry out crystallization and purification, and obtaining a by-product to be stored for other use; and e, distilling the THF from an organic phase, and recycling; and finally, rectifying residual liquid to obtain a high-purity product. The method disclosed by the invention has the advantages that 1, the process is simple to operate; water-removing operation is not needed after a first-step reaction, and a second-step reaction is directly carried out; 2, the product is high-purity colorless transparent liquid or white solid; and 3, the synthesizing time is short, suitable conditions are wide and pollution to the environment is small, so that the method is suitable for industrial production.

Owner:JIANGNAN UNIV

Method for recovering and recycling sodium bromide from diethylbutylmalonate waste water

InactiveCN101798121AReduce recycling costsHigh recovery rateWater/sewage treatment by heatingAlkali metal bromidesProduction lineWastewater

The invention relates to a method for recovering and recycling sodium bromide from diethylbutylmalonate waste water. The method comprises the following steps of: sending waste water which is generated in a production process of diethylbutylmalonate and contains sodium bromide into an evaporator, and introducing steam into the evaporator to ensure that water in the waste water is evaporated out by using the steam; when the waste water is evaporated and concentrated to the condition that residual water accounts for 8-12 percent of the weight of the sodium bromide, sending an obtained concentrated solution into a cooling pot for cooling to obtain a solid sodium bromide crystalline hydrate; and sending the solid sodium bromide crystalline hydrate to an industrial production line of the diethylbutylmalonate for recycling by using the solid sodium bromide crystalline hydrate as a raw material. The invention provides the method for recovering the solid sodium bromide crystalline hydrate from the waste water generated in the production process of the diethylbutylmalonate and for recycling and producing the diethylbutylmalonate by using the solid sodium bromide crystalline hydrate as a raw material. When the method is used for recovering the sodium bromide, the method has low recovery cost and high recovery rate; meanwhile, the production cost of the diethylbutylmalonate is also greatly reduced.

Owner:LIYANG YONGAN FINE CHEM

Method for separating sodium chloride and sodium bromide by organic solvent

InactiveCN109437245ANothing producedSeparation equipment is simpleAlkali metal bromidesAlkali metal chloridesOrganic solventHalogen

The invention belongs to the technical field of halogen element salt separation, and particularly relates to a method for separating sodium chloride and sodium bromide by an organic solvent. The organic solvent is added into dry sodium chloride and sodium bromide mixed salt; stirring dissolution is performed at normal temperature; filtering is performed; undissolved salt is filtered out; filteringliquid is heated to be evaporated; methanol is evaporated out; the temperature is lowered for crystallization; filtering is performed; crystallized salt is filtered out; the content of sodium bromidein the salt reaches 90 weight percent or higher; the filtering liquid is continuously heated and evaporated; the rest methanol is evaporated out; the temperature is lowered for filtering; a finishedproduct sodium bromide salt is obtained; all evaporation recovered methanol is used again for next batch of dissolving salt. The method for separating sodium chloride and sodium bromide by the organicsolvent has the advantages that the separation equipment is simple; the operation cost is low; the process is reasonable; the realization is easy; the recovery rate is high; no waste water is generated; no environment pollution exists; the industrialization can be easily realized.

Owner:山东金城晖瑞环保科技有限公司

Manufacturing method of phosphor or scintillator sheets and panels suitable for use in a scanning apparatus

In a method for homogeneously and dust-free coating of a phosphor or a scintillator layer onto a flexible substrate, in order to obtain a plurality of phosphor or scintillator sheets or panels having flexible supports or substrates, a coating procedure within a sealed zone is performed, wherein said zone comprises at least two cylindrical carrier rollers for carrying a flexible substrate exceeding dimensional formats of desired phosphor or scintillator sheets or panels with a factor of at least 5, wherein said cylindrical carrier rollers each have an axis in a parallel arrangement with one another; wherein said zone comprises at least one crucible containing a mixture of raw materials providing desired phosphor or scintillator compositions for said layer; and wherein said zone comprises a laminating unit; wherein said method comprises the steps of mounting said flexible substrate onto said carrier rollers, vapor depositing said phosphor or scintillator layer having a desired phosphor or scintillator composition onto said flexible substrate, and laminating said phosphor or scintillator layer, thereby covering said layer with a protective foil; further comprising the step of cutting said layer into sheets or panels having desired formats, and wherein at least during said vapor depositing step said zone is maintained under vacuum conditions as a vacuum chamber.

Owner:T2PHARMA GMBH

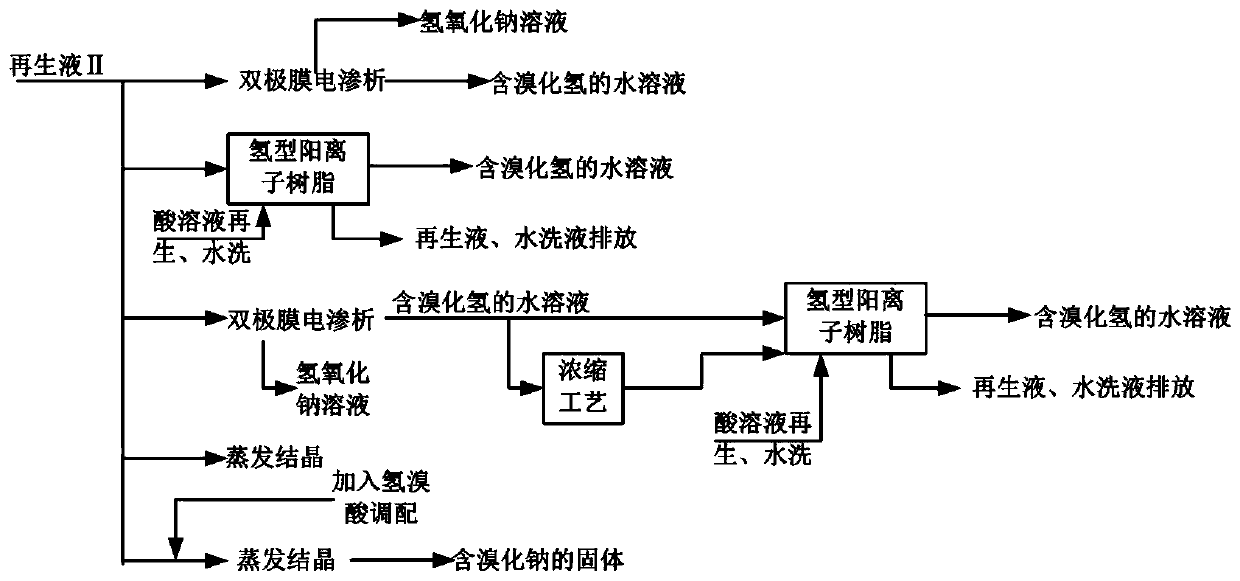

Method for preparing hydrobromic acid and sodium bromide from bromine-containing brine in short process

PendingCN111285331AReduce usageReduce generationHydrogen bromideAlkali metal bromidesIndustrial waste waterDistillation

The invention belongs to the field of resource utilization of bromine-containing brine such as salt lakes, seawater, underground brine, industrial wastewater and the like, and particularly provides amethod for preparing hydrobromic acid and sodium bromide from bromine-containing brine in a short process. The technological process mainly comprises the steps of bromine-containing brine oxidation, alkaline solution absorption, hydrobromic acid preparation through distillation, sodium bromide preparation through crystallization, and the like. The technology provides a brand-new process scheme forpreparing hydrobromic acid and sodium bromide by extracting bromine from brine, and compared with a traditional process, the process flow is greatly shortened, the process is simple, industrialization is easy, and the application prospect is wide.

Owner:EAST CHINA UNIV OF SCI & TECH +1

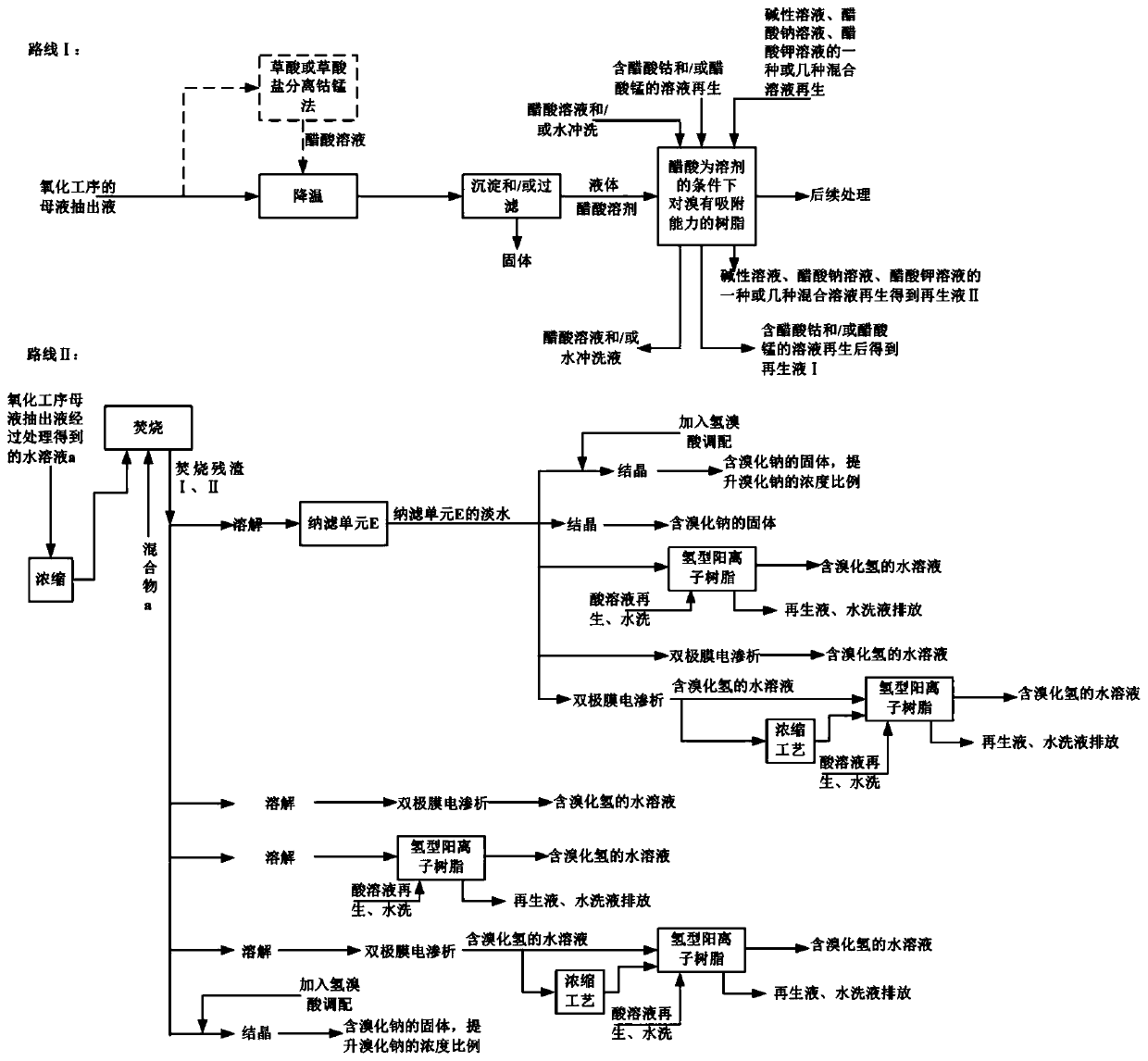

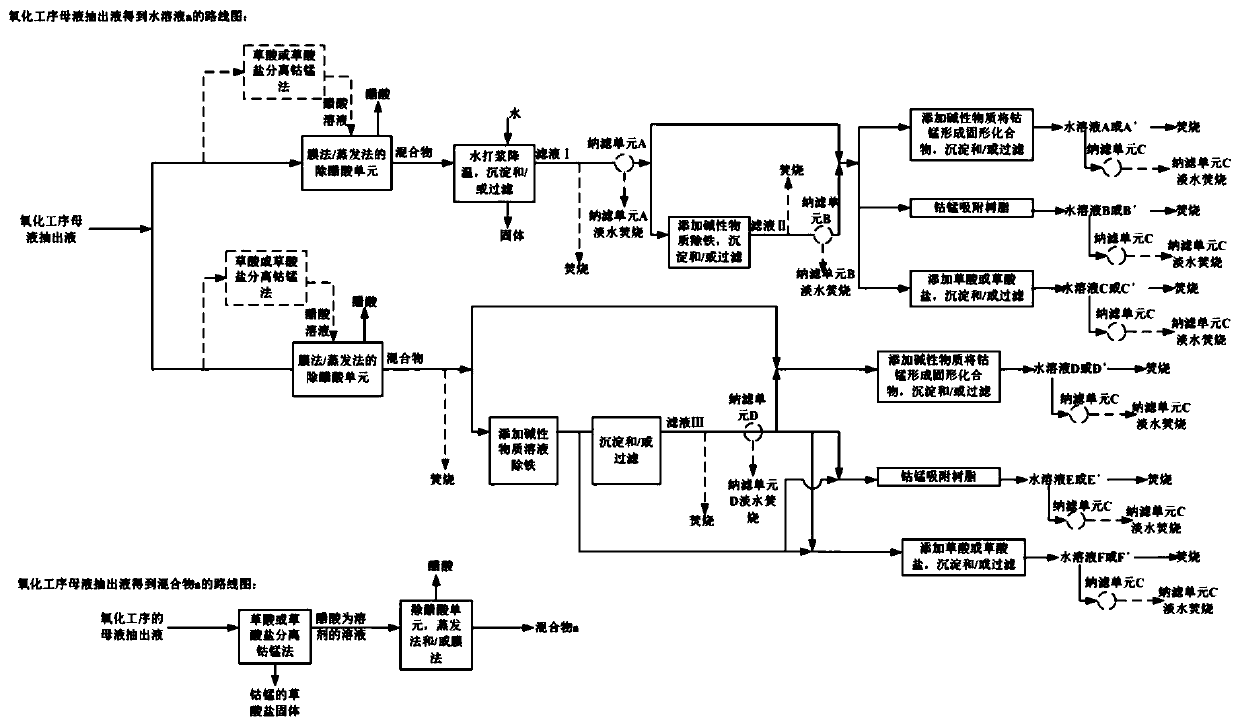

Technology for recovering bromine element from mother liquor extract of oxidation process of terephthalic acid production device

ActiveCN111217333AAffect activityIncrease running consumptionHydrogen bromideOrganic compound preparationEthylic acidIonized sodium

The invention provides a technology for recovering bromine element from mother liquor extract of an oxidation process of a terephthalic acid production device, and belongs to the field of process recovery. The mother liquor extract of the oxidation process of the terephthalic acid production device mainly contains acetic acid according to the material content, and acetic acid is used as a solventto dissolve cobalt ions, manganese ions, bromide ions, BA, sodium ions, iron ions, 4-CBA, PT acid and the like with relatively low concentrations. The bromine element is extracted by using the technology to achieve recovery in a form of hydrobromic acid or sodium bromide, and the economic value of the bromine element is recovered; and the situation that in the prior art, bromine is discharged intosewage, the bromine element can cause adverse effects on biological florae of a sewage treatment unit, and the activity of the biological florae is affected is also avoided.

Owner:佰仕邦水处理环保科技(大连)有限公司

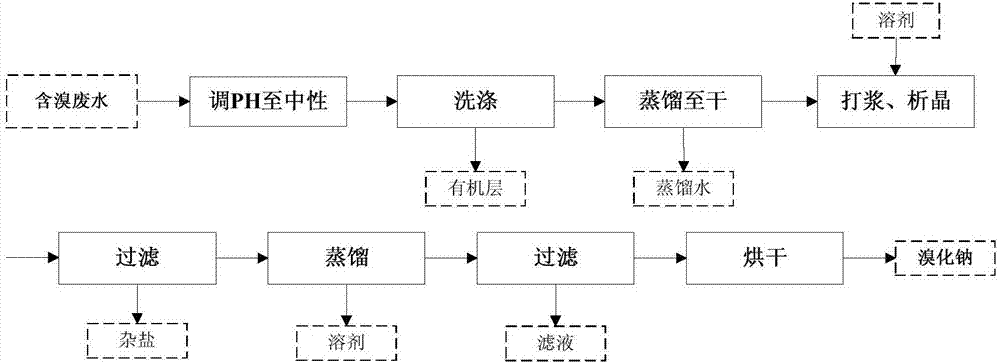

Method for recovering sodium bromide from bromine-containing wastewater

ActiveCN107337218AEasy to operateLow costWater contaminantsMultistage water/sewage treatmentBromineWastewater

The invention relates to a method for recovering sodium bromide from bromine-containing wastewater. The method comprises the following steps: adjusting the pH value of the bromine-containing wastewater with acid, adding a solvent for washing and distilling a water layer to dryness; and adding a solvent into a material obtained after distilling, carrying out smashing, then carrying out filtering to remove impurity salts, and subjecting a filtrate to concentration so as to obtain sodium bromide. The method provided by the invention is easy to operate and friendly to environment and can prepare a crude sodium bromide product with a purity of 90%. The method is low in cost, low in requirements on equipment, simple to operate, friendly to environment and suitable for industrial production.

Owner:ZHEJIANG HUAHAI TIANCHENG PHARMA CO LTD +1

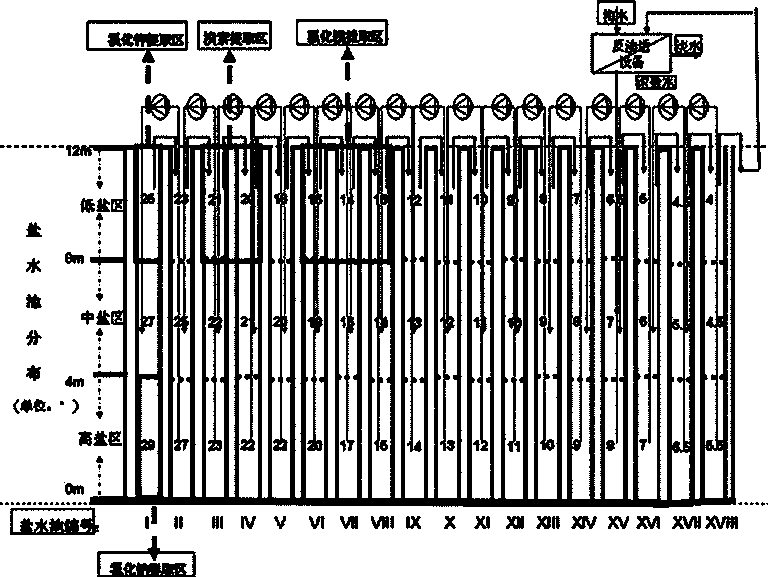

Process for producing salt through concentrating strong brine after sea water desalination adopting two-way cycle method and bromine extraction

ActiveCN104030320ASolve pollutionLow costMembranesSemi-permeable membranesSaline waterWater desalination

The invention discloses a process for producing salt through concentrating strong brine after sea water desalination adopting two-way cycle method and bromine extraction. The process comprises the following steps of A, preparing fresh water and strong brine from sea water through a reverse osmosis process in a high-pressure reverse osmosis unit, wherein the concentration of the prepared strong brine is 70000-80000PPM; and B, performing fresh and concentrated separation on the strong brine with the concentration of 70000-80000PPM by utilizing a concentration difference method by adopting two-way cycle until the strong brine is crystallized. The salt is produced by carrying out sea water desalination on the strong brine, the problem that pollution is caused due to discharge of the strong brine after sea water desalination is solved, the yield in unit area is 30-50 times of the yield of a salt pan producing method, and the cost is far lower than that of salt pan production.

Owner:QINGDAO EASTERN SEA OASIS SEAWATER TREATMENT TECH CO LTD

Optimizing Reactions in Fuel Cells and Electrochemical Reactions

InactiveUS20090253002A1Increase ratingsReduce the amount requiredCell electrodesRegenerative fuel cellsElectrochemical responseFuel cells

This invention relates to novel methods for affecting, controlling and / or directing various reactions and / or reaction pathways or systems by exposing one or more components in a fuel cell reaction system to at least one spectral energy pattern. In a first aspect of the invention, at least one spectral energy pattern can be applied to a fuel cell reaction system. In a second aspect of the invention, at least one spectral energy conditioning pattern can be applied to a conditioning reaction system. The spectral energy conditioning pattern can, for example, be applied at a separate location from the reaction vessel (e.g., in a conditioning reaction vessel) or can be applied in (or to) the reaction vessel, but prior to other reaction system participants being introduced into the reaction vessel.

Owner:GR INTELLECTUAL RESERVE LLC

Method for recycling halogenated short chain quaternary ammonium salt waste

InactiveCN107673979AReduce manufacturing costIncrease profitAmino compound purification/separationAlkali metal bromidesQuaternary ammonium cationDistillation

The invention discloses a method for recycling halogenated short chain quaternary ammonium salt waste. The method comprises the following process steps: the halogenated short chain quaternary ammoniumsalt waste is dissolved in water and decomposed under the action of inorganic base, a tertiary amine organic layer is produced and separated from a water layer, and raw material tertiary amine is recovered from the tertiary amine organic layer through distillation and applied to production of halogenated short chain quaternary ammonium salt; the water layer is subjected to extraction through trichloromethane, an extracted organic layer and an extracted water layer are produced, trichloromethane is recovered from the extracted organic layer through distillation for recycling, halogenated shortchain quaternary ammonium salt after recovery of trichloromethane is recrystallized, and qualified halogenated short chain quaternary ammonium salt is obtained; distilling concentration, crystallization and centrifugation are performed on the extracted water layer, and an inorganic bromide byproduct is obtained for recycling. The efficient, economical and environment-friendly method for recyclinghalogenated short chain quaternary ammonium salt waste is provided, so that the environment-friendliness of production of halogenated short chain quaternary ammonium salt is improved, waste dischargeis reduced, and production cost is reduced.

Owner:KENTE CATALYSTS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com