Method for recovering sodium bromide from bromine-containing wastewater

A recovery method, sodium bromide technology, applied in the field of sodium bromide recovery, can solve environmental impact and other problems, and achieve the effect of low equipment requirements, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

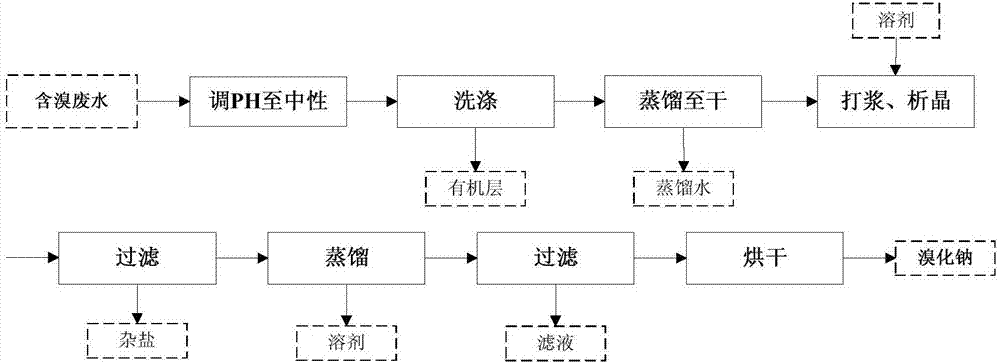

Method used

Image

Examples

Embodiment 1

[0018] Add 300ml of bromine-containing waste water to a 1000ml three-necked reaction flask, add 2.1g of refined hydrochloric acid to adjust the pH to 8, then add 100ml of toluene to wash twice, separate the organic layer and control the temperature of the water layer at 40-50°C for vacuum distillation To dry 46.1g. Add 300g of methanol, control the temperature at 25-35°C and stir for 1 hour, and filter to obtain 18.6g of miscellaneous salt wet product. The filtrate was distilled under reduced pressure at a temperature of 40-50°C to dryness of 32.5g. Then add 40g of methanol, control the temperature at 25-35°C and stir for 1 hour, then filter to obtain 30.3g of wet product, and dry to obtain 25.2g of crude sodium bromide. The purity of sodium bromide is 90.2%, and the yield is 94.3%.

Embodiment 2

[0020] Add 300ml of bromine-containing waste water to a 1000ml three-necked reaction flask, add 2.2g of refined hydrochloric acid to adjust the pH to 7, then add 100ml of toluene to wash once, remove the organic layer and control the temperature of the water layer at 40-50°C for vacuum distillation To dry 45.5g. Add 300g of methanol, control the temperature at 25-35°C and stir for 1 hour, and filter to obtain 19.1g of miscellaneous salt wet product. The filtrate was distilled under reduced pressure at a temperature of 40-50°C to dryness of 33.1 g. Then add 40g of methanol, control the temperature at 25-35°C and stir for 1 hour, then filter to obtain 31.3g of wet product, and dry to obtain 25.5g of crude sodium bromide. The purity of sodium bromide is 90.5%, and the yield is 95.4%.

Embodiment 3

[0022] Add 300ml of bromine-containing waste water to a 1000ml three-necked reaction flask, add 2.3g of refined hydrochloric acid to adjust the pH to 6, then add 100ml of toluene to wash once, separate the organic layer and control the temperature of the water layer at 40-50°C for vacuum distillation To dry 46.1g. Add 300g of methanol, control the temperature at 25-35°C and stir for 1 hour, and filter to obtain 18.9g of miscellaneous salt wet product. The filtrate was distilled under reduced pressure at a controlled temperature of 40-50°C to dryness of 33.5g. Then add 50g of methanol, control the temperature at 25-35°C and stir for 1 hour, then filter to obtain 29.3g of wet product, and dry to obtain 23.7g of crude sodium bromide. The purity of sodium bromide is 87.8%, and the yield is 88.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com