Process for producing salt through concentrating strong brine after sea water desalination adopting two-way cycle method and bromine extraction

A two-way cycle, concentrated brine technology, applied in seawater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as low production efficiency, pollution, and poor quality, and achieve high quality and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

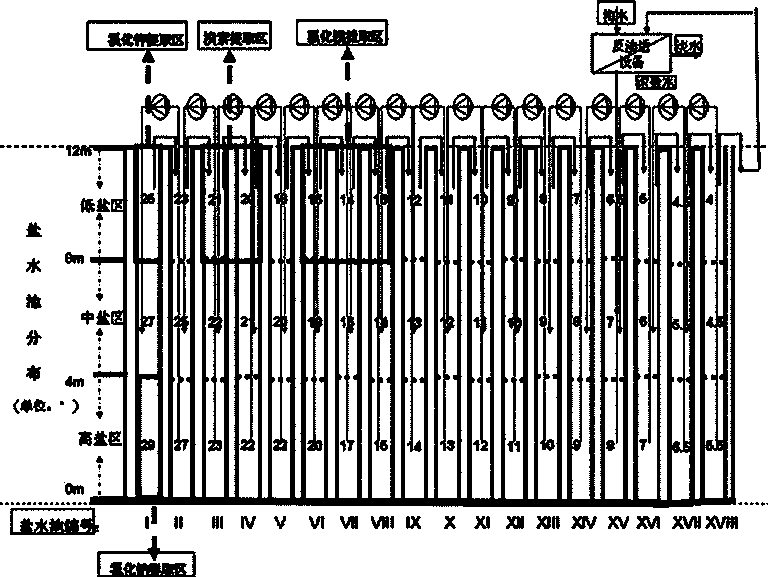

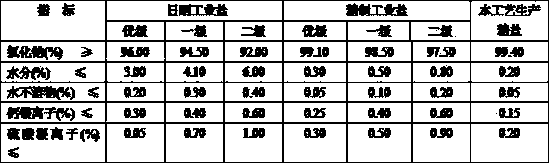

[0045] Embodiment 1, a two-way circulation method seawater desalination and extracting bromine concentrated brine concentration salt production process, comprising the following steps:

[0046] A. Firstly, the seawater is passed through the high-pressure reverse osmosis unit to produce fresh water and concentrated brine through the reverse osmosis method, and the concentration of the prepared concentrated brine is 70000~80000PPM (7~8°);

[0047] B. The concentrated brine with a concentration of 70000~80000PPM is used for two-way circulation by the concentration difference method to separate the concentration until the concentrated brine crystallizes.

[0048] C. In the process of separating the thick and thin brine, the magnesium chloride, potassium chloride and bromine contained in the brine are sequentially extracted.

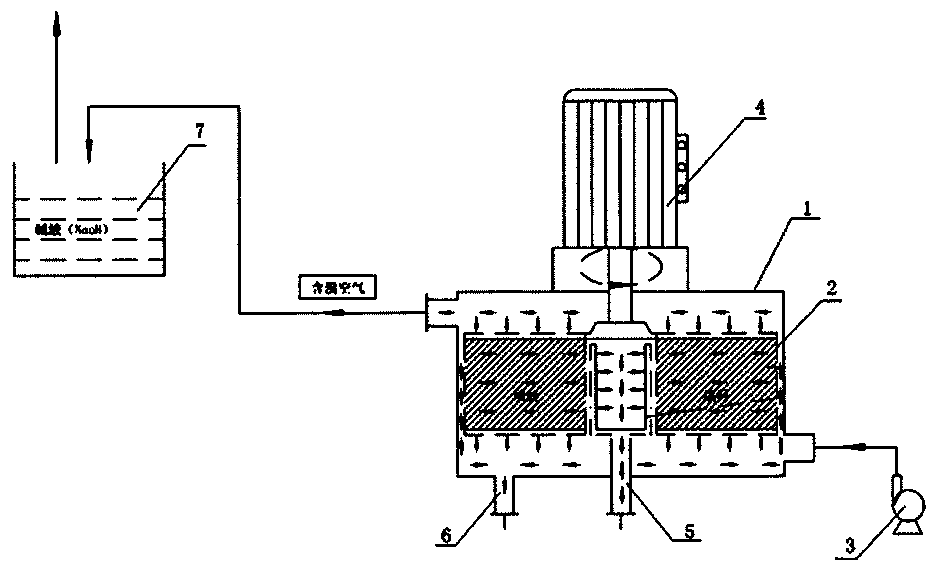

[0049] In the above step B, the concentration difference method is carried out in a two-way cycle for concentration separation process, including the followi...

Embodiment 2

[0055] Embodiment 2, in above-mentioned embodiment 1, magnesium chloride extraction adopts physical method, the extraction that carries out in 14~16 degree concentrated brine area, after magnesium chloride crystallizes when about 15 °, proposes magnesium chloride crystal.

Embodiment 3

[0056] Embodiment 3, in above-mentioned embodiment 1, potassium chloride extraction adopts physical method, the extraction that carries out in 25~26 degree concentrated brines, after potassium chloride crystallizes when about 25 °, proposes potassium chloride crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com