Patents

Literature

87 results about "Pure crystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

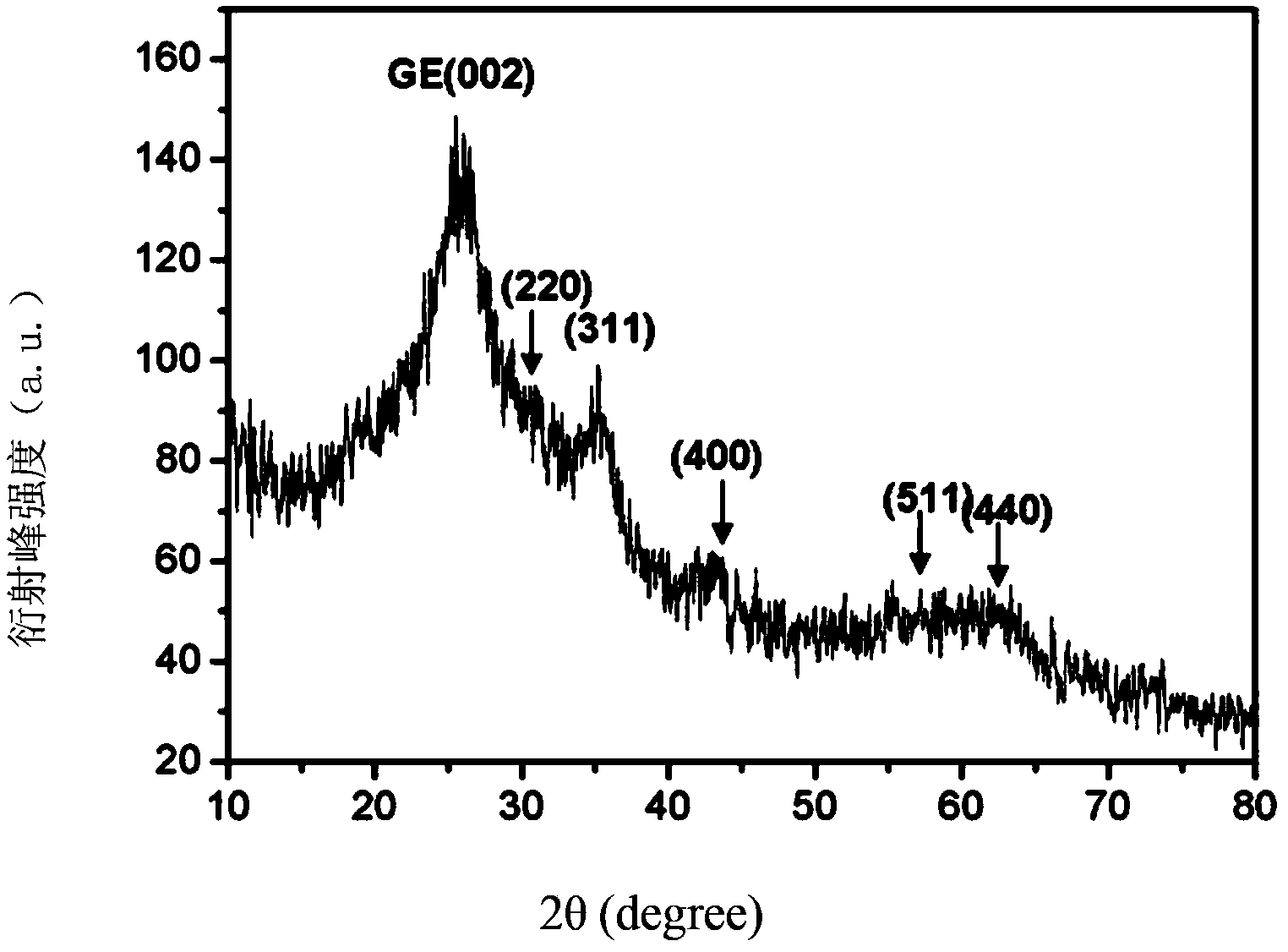

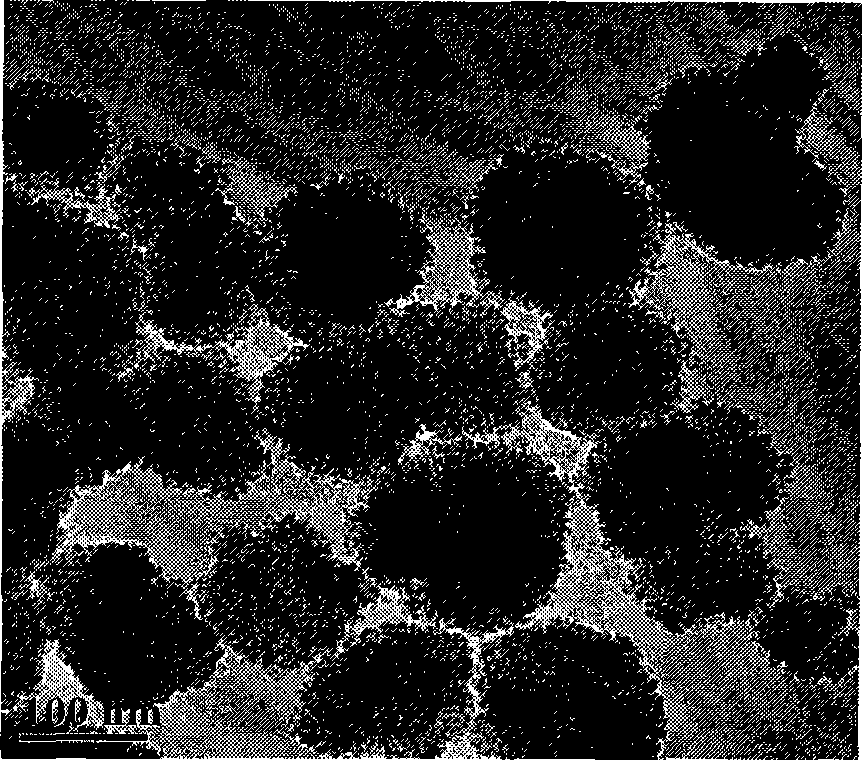

Method for preparing graphene loaded ferroferric oxide magnetic nanometer particle composite material

InactiveCN101941842AGood dispersionPromote crystallizationMaterial electrochemical variablesElectrodesHydrazine compoundNitrogen gas

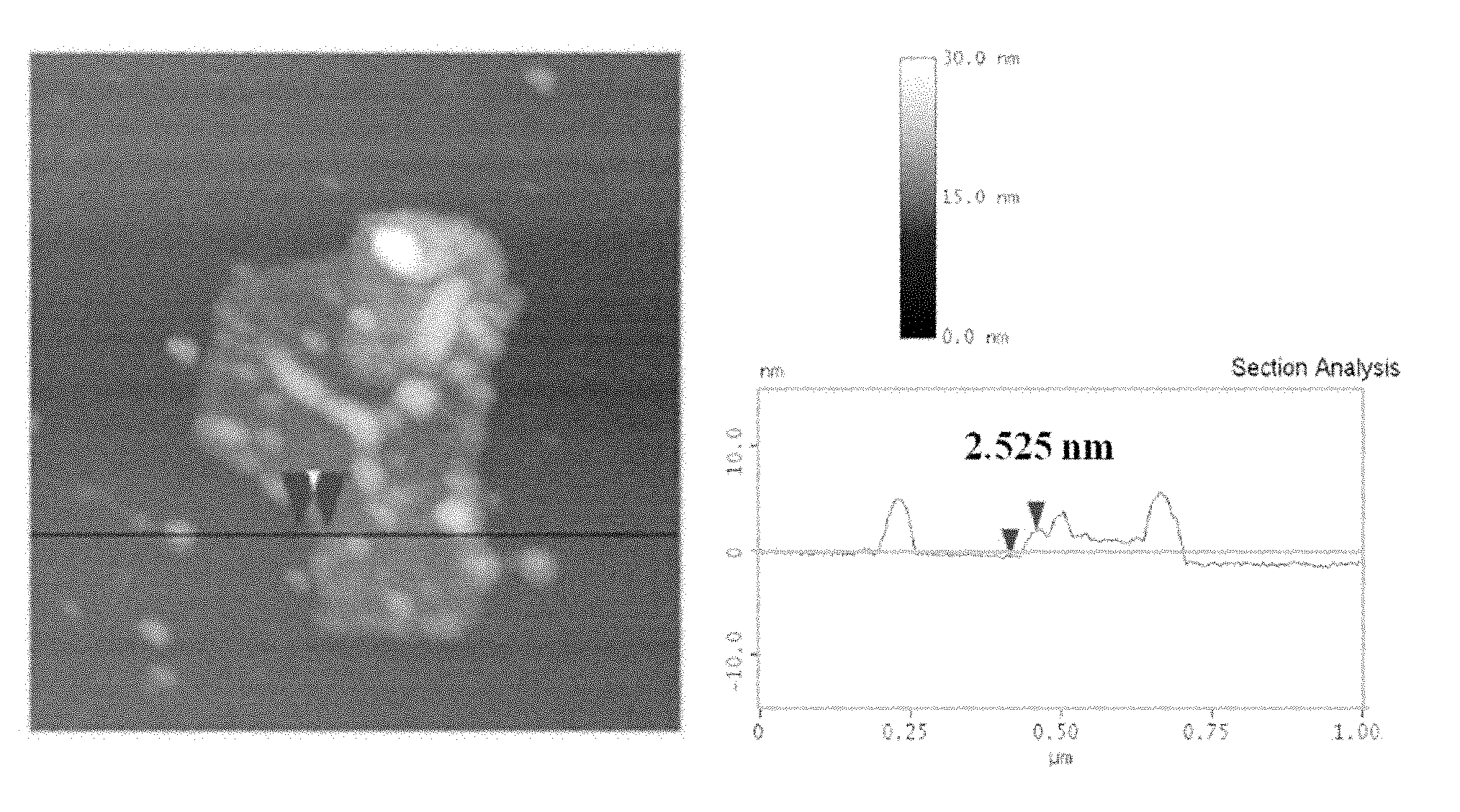

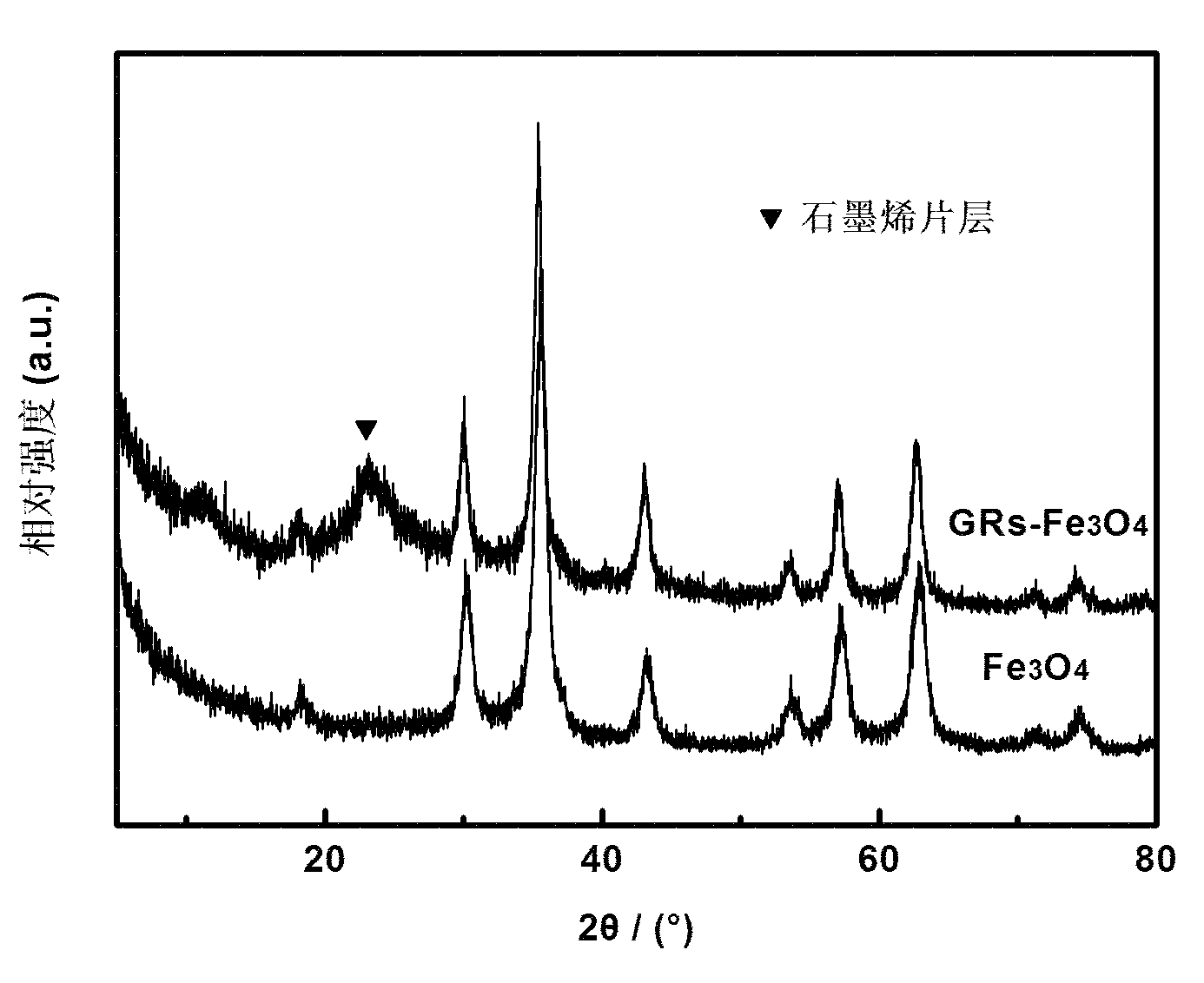

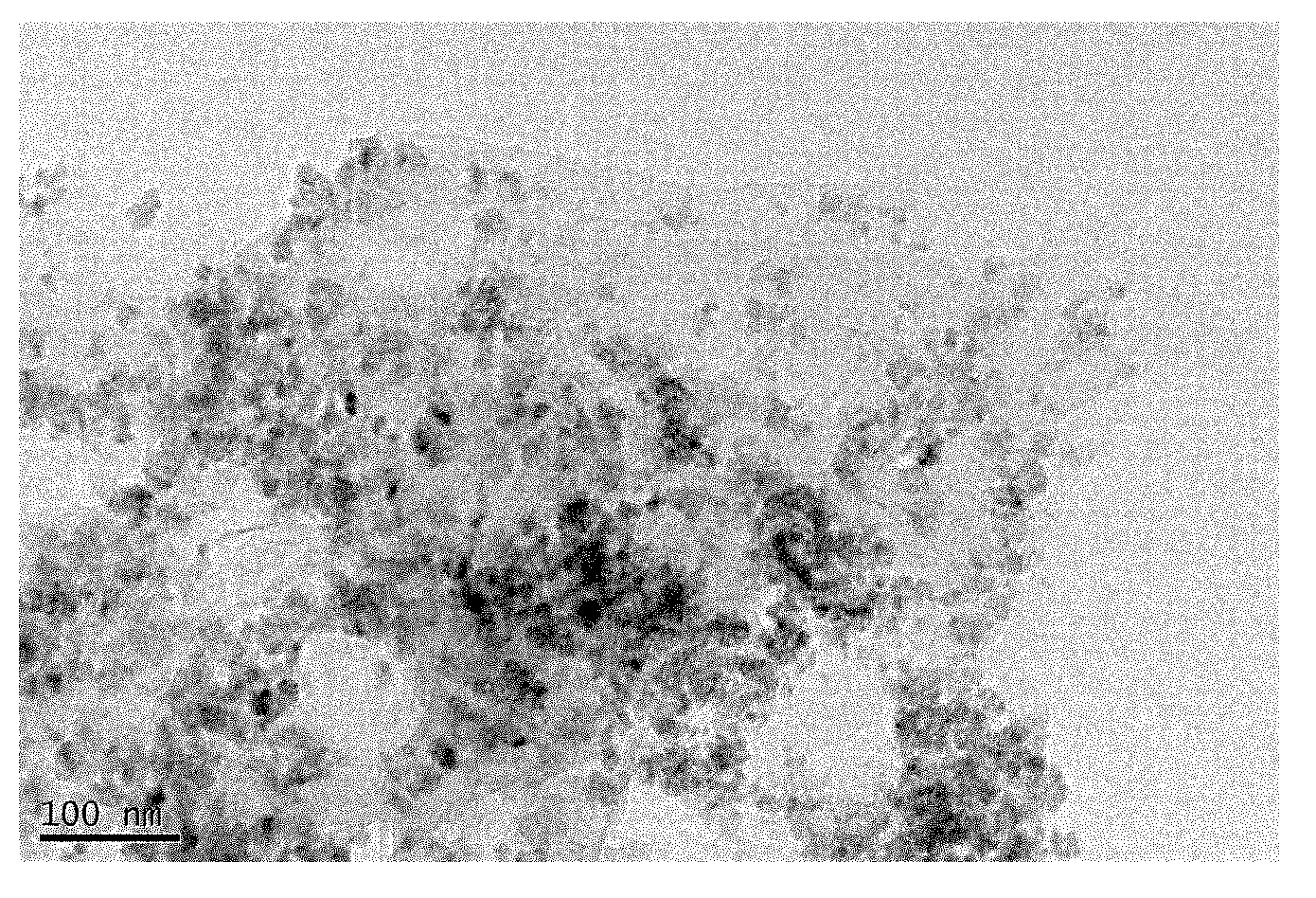

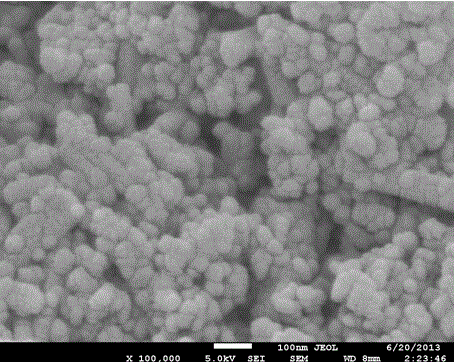

The invention relates to a method for preparing a graphene loaded ferroferric oxide magnetic nanometer particle composite material. The method comprises the following steps of: (1) dispersing graphite oxide into deionized water, pouring into a vessel after ultrasonic and centrifuging, putting the vessel into an oil-bath pan, adding hydrazine hydrate and an anionic surfactant for heating, condensing and refluxing, and cooling and drying to obtain modified graphene; and (2) dispersing the graphene into aqueous solution, and ultrasonically stirring and centrifuging to obtain modified graphene dispersion liquid; and weighing a soluble trivalent ferric salt and divalent ferric salt, dissolving the salt into the deionized water, introducing nitrogen, pouring into the modified graphene dispersion liquid, dripping ammonia after uniform ultrasonic stirring, heating for reaction, washing and collecting a product, and drying the product. The method is simple and easy for industrial production; and the prepared composite material has the advantages of pure crystal phase, uniform distribution and excellent electrocatalytic activity.

Owner:DONGHUA UNIV

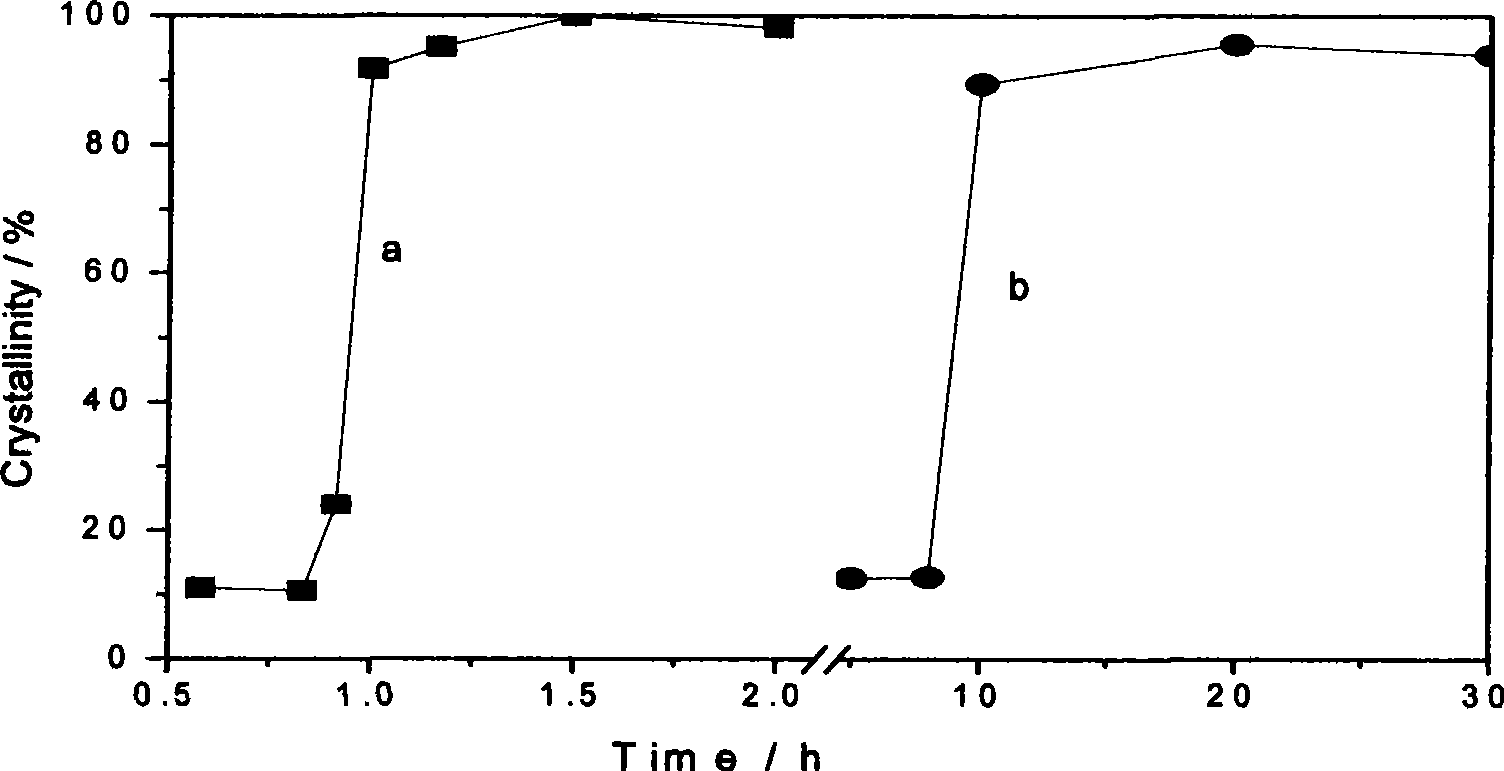

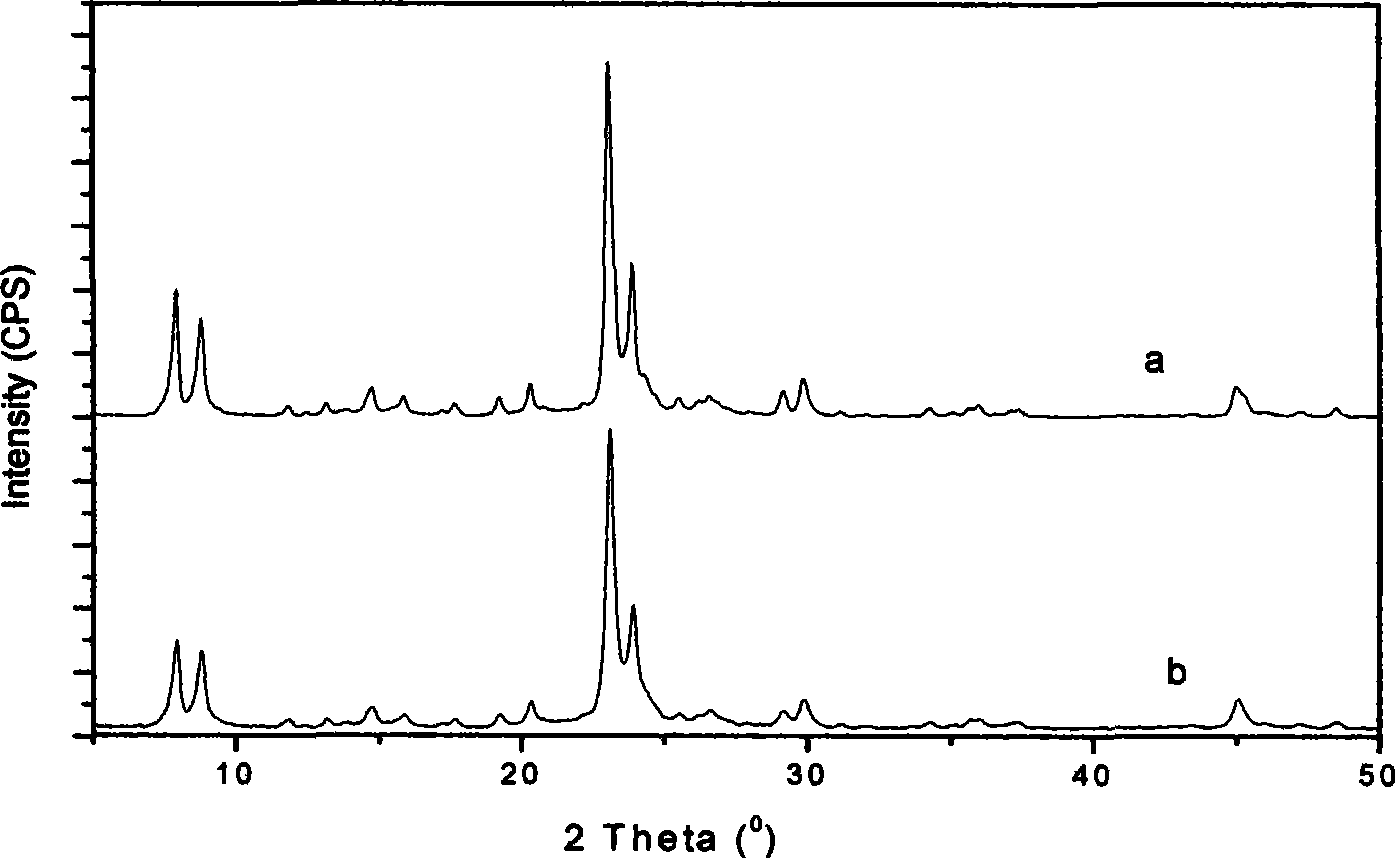

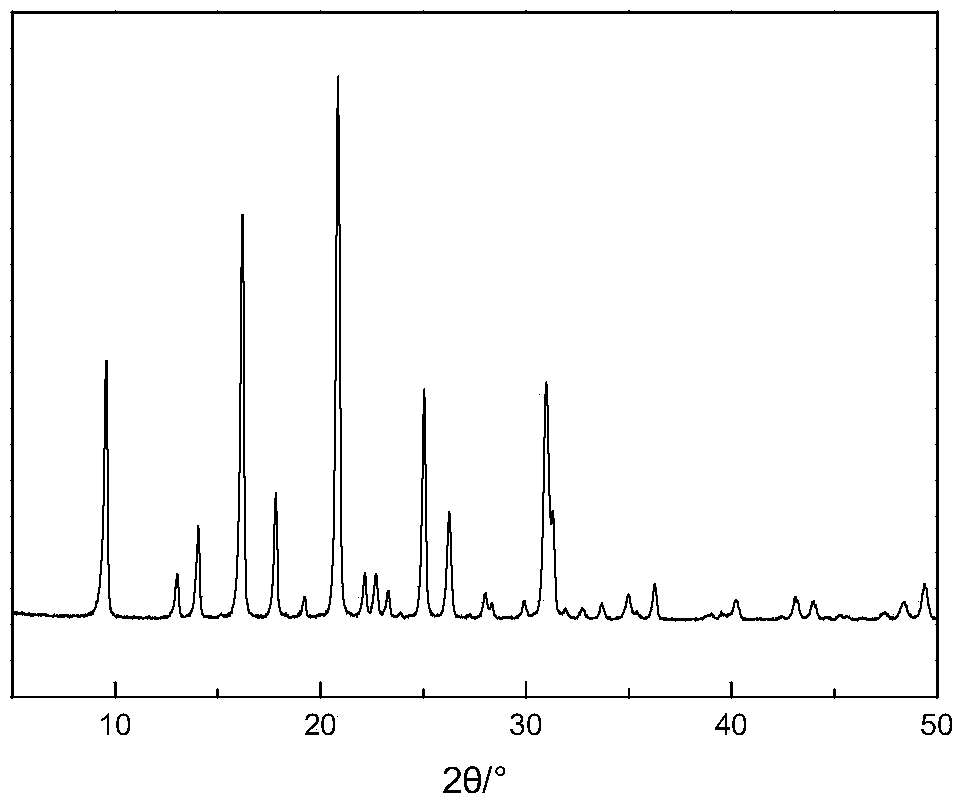

Microwave synthesis process for ZSM-11 molecular sieve

InactiveCN101531376AIncrease growth rateHigh crystallinityPentasil aluminosilicate zeoliteCrystallinityCrystal growth rate

The invention relates to a microwave synthesis process for a ZSM-11 molecular sieve. The process uses aluminum source, alkali source, silicon source, tetrabutylammonium bromide and de-ionized water as the raw materials and adopts the heating mode of microwave radiation. The reaction mixture is crystallized for 1 to 8 hours under microwave radiation and self-generated pressure at 130 to 180 DEG C, solid is separated from the mother liquid, and then the product is washed by the de-ionized water until the pH value is 8 to 9, thus obtaining the raw powder of the ZSM-11 molecular sieve. The microwave synthesis process for the ZSM-11 molecular sieve has the advantages of replacing traditional water heating by microwave radiation heating and obtaining the ZSM-11 molecular sieve with the advantages of high crystallinity, pure crystal phase and controllable and wide range of grain size, and the process accelerates the nucleation rate and crystal growth speed obviously and shortens the crystallization time greatly by pre-placing crystal seeds.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method of producing erythromycin derivative

A method of producing an N-demethyl-N-isopropyl-8,9-anhydroerythromycin A-6,9-hemiacetal or a salt thereof, characterized in that an N-demethylerythromycin A or a salt thereof is reacted with an isopropylating agent and subsequently treated under acidic conditions, and a method of producing a substantially pure crystal of an 8,9-anhydroerythromycin A-6,9-hemiacetal derivative represented formula (VI): wherein R1 and R2, whether identical or not, represent an alkyl having 1 to 6 carbon atoms, an alkenyl having 2 to 6 carbon atoms or an alkynyl having 2 to 6 carbon atoms; R3 represents hydrogen or a hydroxyl group; one of R4 and R5 represents hydrogen and the other represents a hydroxyl group, or R4 and R5 bind together to represent O=; R6 represents hydrogen or a hydroxyl group that may be substituted for; R7 represents hydrogen or a hydroxyl group; or a salt thereof, characterized in that a crude crystal of said 8,9-anhydroerythromycin A-6,9-hemiacetal derivative or a salt thereof is recrystallized as a solvation product from hydrated isopropanol.

Owner:TAKEDA PHARMA CO LTD +1

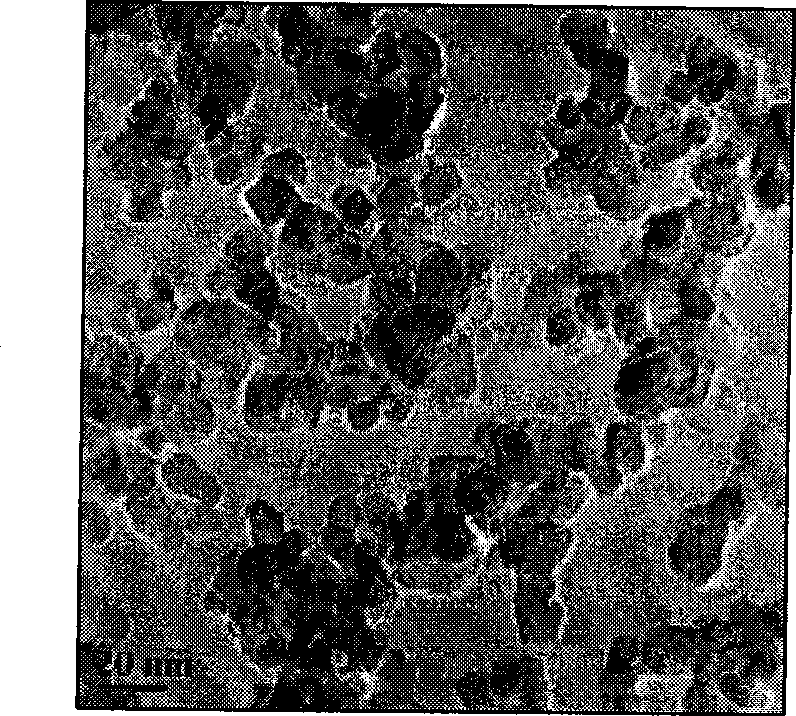

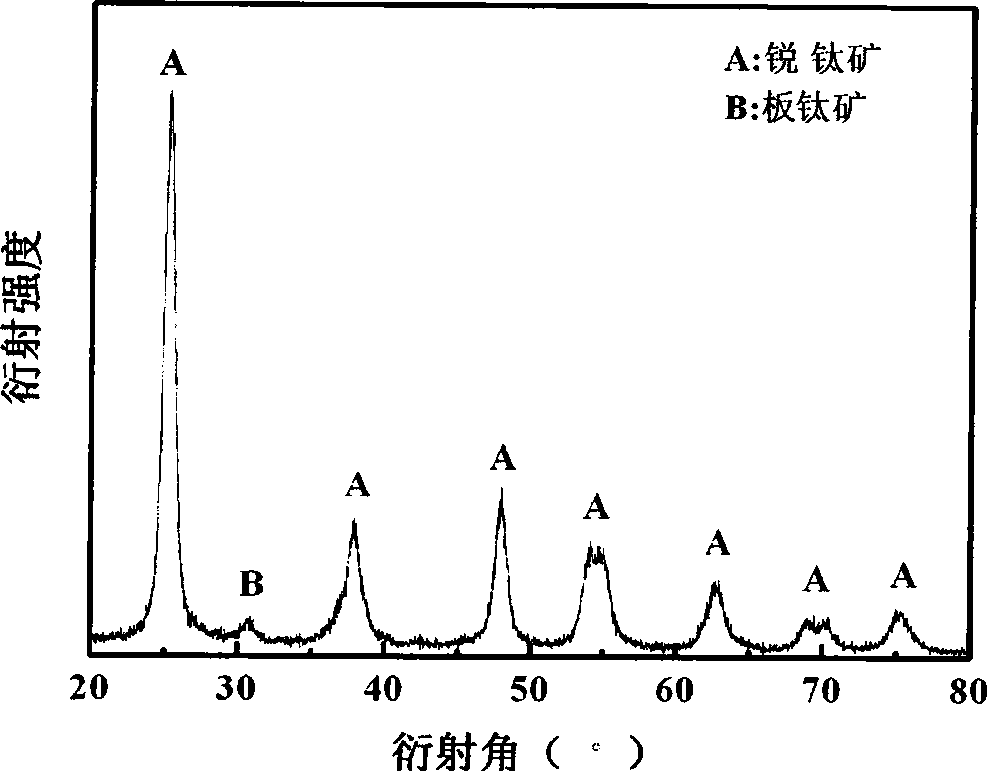

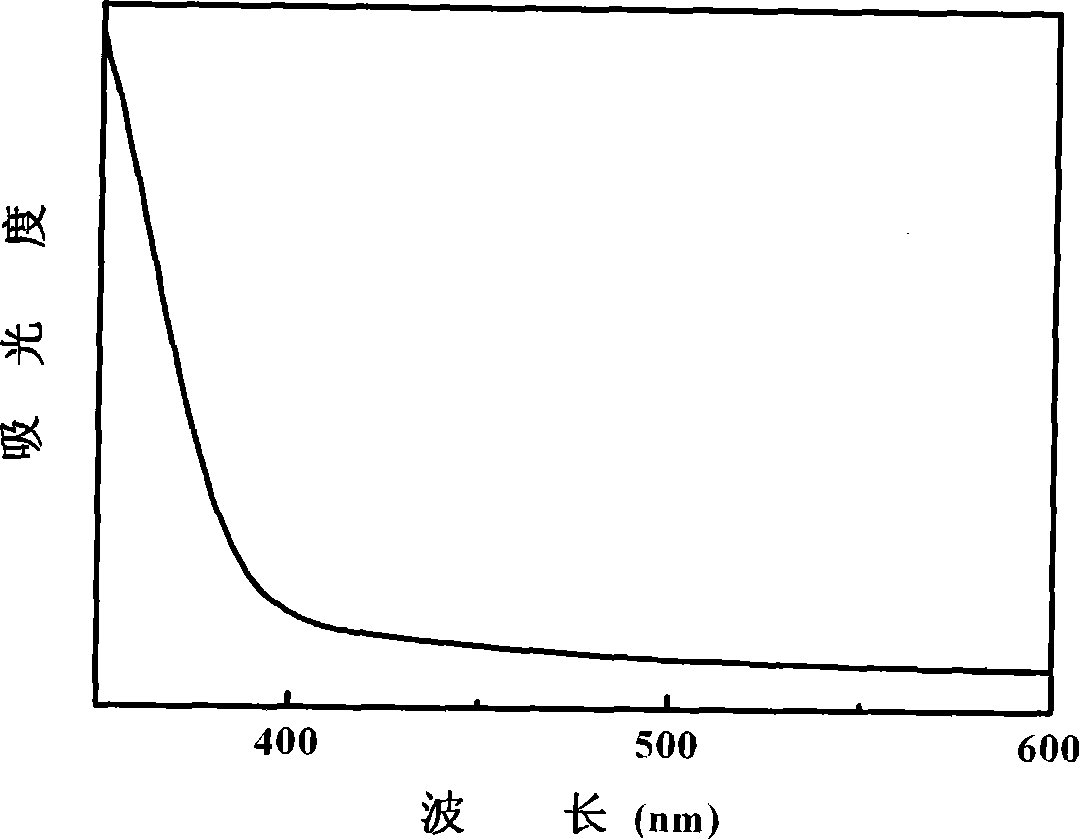

Preparation method of fluorine and lanthanum co-doped nano titanic oxide visible light photocatalyst

InactiveCN101474556AConvenient sourceMild reaction conditionsMetal/metal-oxides/metal-hydroxide catalystsPure crystalLight response

The invention relates to a preparation method for fluorine and lanthanum codoped nanometer TiO2 visible-light photocatalyst, in which titanium alkoxide, lanthanum nitrate and fluoride are used as the raw materials. First, the fluoride is dissolved in the water, and then the titanium alkoxide and the lanthanum nitrate absolute ethyl alcohol solutions are dipped into the fluoride water solution while stirring, and finally the monodisperse TiO2 sol is obtained after stirring at room temperature for a certain period of time for hydrolyzation. Then the TiO2 sol is dried to obtain light-yellow gel which can produce the nanometer TiO2 photocatalyst while calcined at different temperatures. The method has mild and easily-controlled reaction conditions, simple equipment, easily purchased raw materials, simple synthesized process and easy industrial production. And the prepared fluorine and lanthanum codoped nanometer TiO2 photocatalyst has the properties of high specific surface, pure crystal phase, multiple surface acidity points and visible light response.

Owner:DONGHUA UNIV

Preparation of magnetic reduced graphene oxide composite material and method for removing quinolone antibiotics from water by the same

InactiveCN104096536AHigh magnetizationSimple processOther chemical processesMultistage water/sewage treatmentIron saltsFreeze-drying

Belonging to the technical field of water treatment, the invention relates to preparation of a magnetic reduced graphene oxide composite material. The method includes: (1) placing graphene oxide into ethylene glycol to undergo ultrasonic treatment; (2) dissolving sodium citrate in ethylene glycol to undergo heating reaction; (3) mixing FeCl3.6H2O with urea, then dissolving the mixture into a sodium citrate / ethylene glycol solution under magnetic stirring to obtain an ethylene glycol mixed solution of the iron salt and urea; (4) stirring and mixing the graphene oxide / ethylene glycol mixed solution and the ethylene glycol mixed solution of the iron salt and urea obtained in the preceding step to undergo reaction, then transferring the reaction product into a reaction kettle to undergo heating reaction and cooling; and (5) subjecting the obtained material to centrifugation, washing and filtering, and freeze drying, thus obtaining the product involved in the invention. The magnetic reduced graphene oxide prepared by the method provided by the invention has the advantages of pure crystal phase, difficult agglomeration, and high magnetization degree. Also, the process is simple and has low requirements for production equipment. The invention also relates to a method for removing quinolone antibiotics from water by the composite material.

Owner:TONGJI UNIV

Method for preparing molecular sieve ZSM-5

InactiveCN102001679ASimple processUniform temperaturePentasil aluminosilicate zeoliteProduction rateGranularity

The invention relates to a method for preparing a molecular sieve ZSM-5 by preparing a precursor glue solution, crystallizing, filtering, drying and roasting. The invention adopts two crystallization methods, one method comprises the following steps of: directly illuminating the precursor glue solution in a sealed container by adopting a microwave field, and crystallizing by utilizing the coaction of the microwave effect and the autogenous hydrothermal pressure of the glue solution; and the other method comprises the following steps of: heating the precursor glue solution in the sealed container by adopting saturated steam for crystallization treatment, wherein the heating and the crystallization treatment can be simultaneously carried out in the microwave field. The saturated steam for the crystallization treatment is crystallized at 170-180 DEG C for 1-6h, 1-10 percent by weight of inoculating seeds are added after aging the precursor glue solution and before crystallizing the precursor glue solution which is prepared by adopting a template-free preparation method. The method of the invention has the following advantages of simple and practical process and uniform temperature in the crystallization process, obtains the molecular sieve with high crystallinity, pure crystal phase, controllable grain size, wider range and short crystallization time, can improve the production efficiency, decrease the cost and save energy.

Owner:YUEYANG YITIAN CHEM

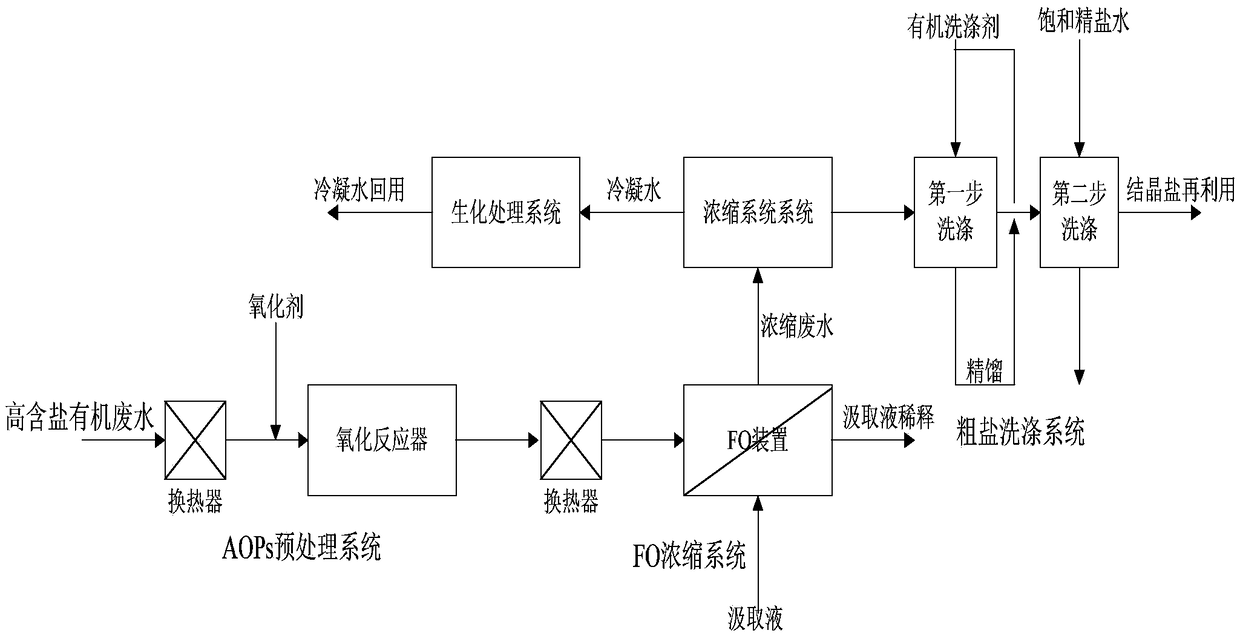

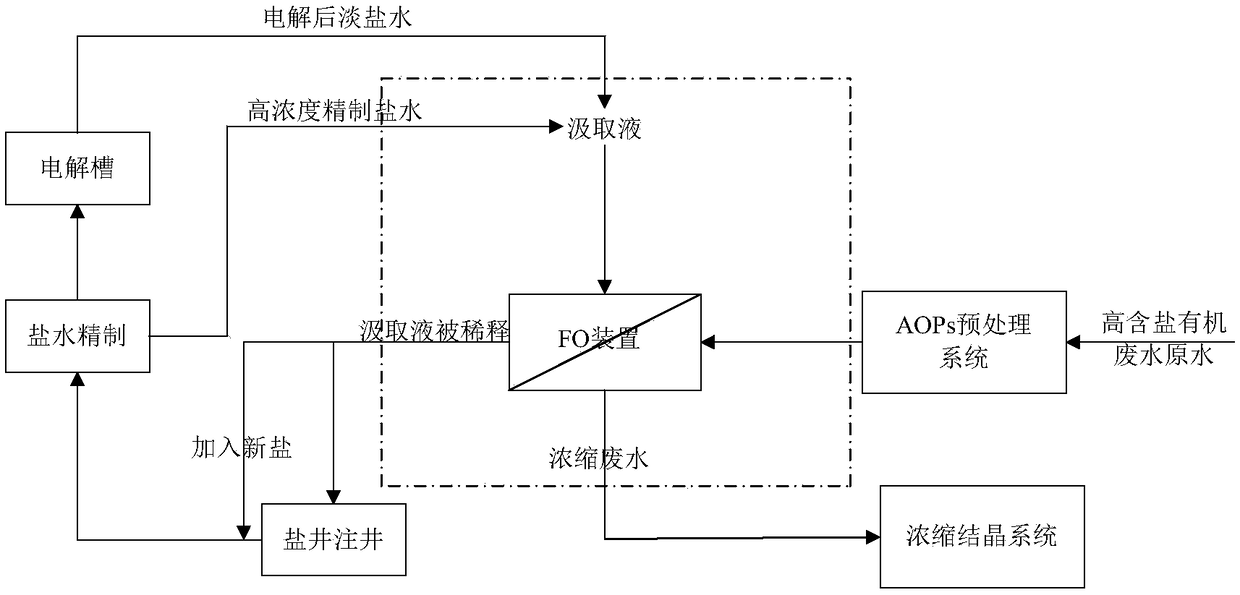

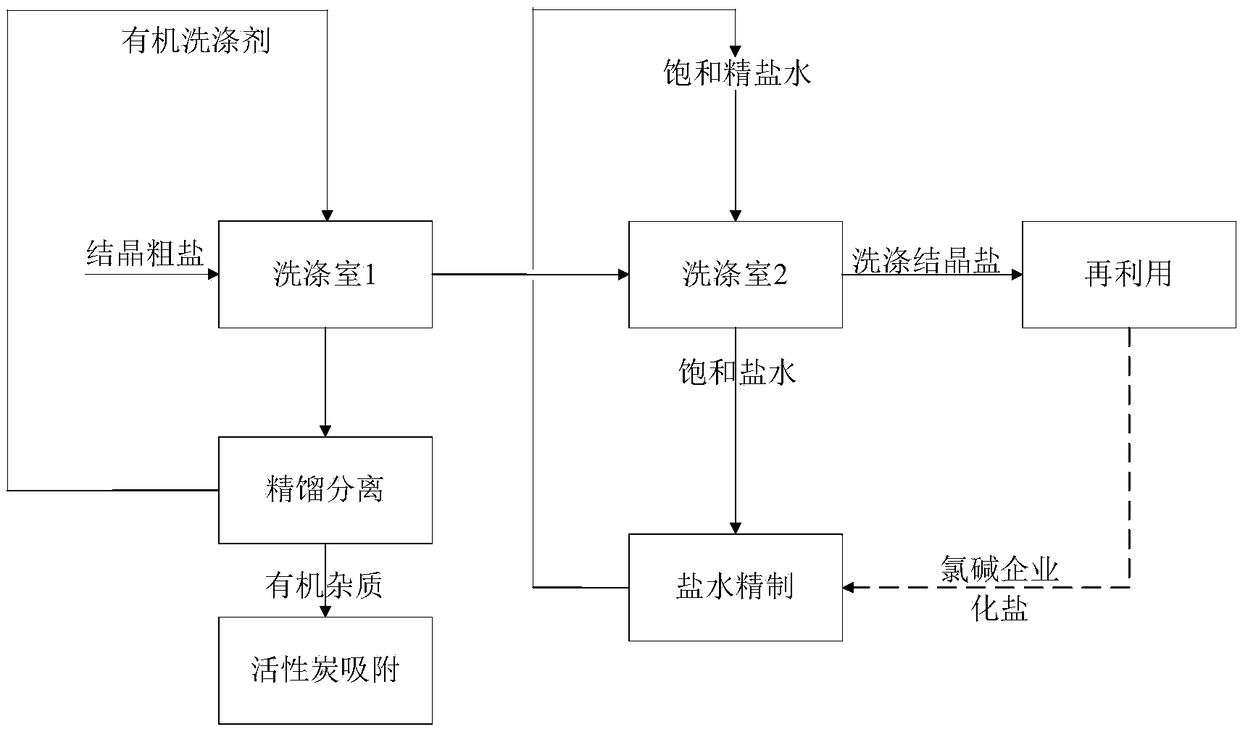

High-salt-content organic waste water treatment system and method

ActiveCN109205960AEfficient use ofImprove water qualityWater/sewage treatment by irradiationWater contaminantsElectrolysisPure crystal

The invention discloses a high-salt-content organic waste water treatment system and method. The system comprises an AOPS pretreatment system, an FO concentration system, a concentration crystallization system and a coarse salt washing system, wherein high-salt-content organic waste water is subjected to heat exchange through the AOPs pretreatment system and then enters the FO concentration system; refined brine passing or electrolyzed light salt brine enters the concentration crystallization system after being subjected to concentration through communicating FO device; the waste water passingthrough the concentration crystallization system is used for obtaining crystal salt and condensed water; a condensed water biochemical treatment system microbial treatment pool treats organic matters; outlet water is reused; the crystal salt entering the coarse salt washing system sequentially enters the two stages of communicated washing chambers to be dissolved and purified; refined saturated table salt water is used for flushing the crystal salts; the obtained pure crystal salts are reused. The zero discharge of the high-salt-content organic waste water can be realized, so that the water resource and salt resources are efficiently utilized.

Owner:SHAANXI BEIYUAN CHEM GROUP

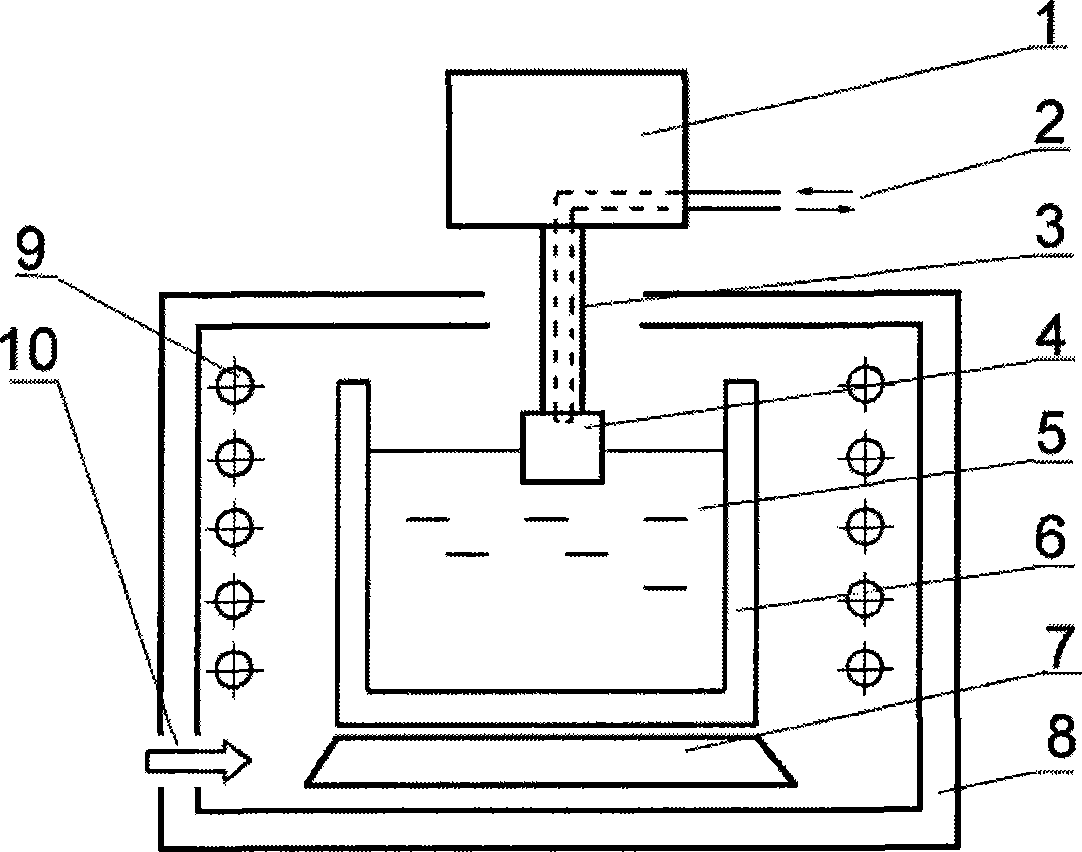

High purity aluminum ultrasonic purification method

The invention relates to a method for ultrasonically purifying high-purity aluminum in the technical field of casting and metallurgy. The method in particular comprises the following steps: melting aluminum in a crucible after a noble protective gas is led into a heating furnace chamber; after the temperature of aluminum liquid is raised to 660-750 DEG C, inoculating crystal is extended below the liquid surface of aluminum fused mass, an ultrasound generating device is started, the other end of the inoculating crystal undergoes forcible cooling of the water-cooling type, and 100-300 K / cm of temperature gradient is ensured to be generated at the front edge of an interface; the temperature of the fused mass is controlled to be around a melting point, after the start of crystallization, the inoculating crystal is slowly lifted upwards or the crucible containing the aluminum fused mass is slowly and downwardly drawn, crystallization speed is controlled to be at 5-25 cm / h, and the lifting, and drawing speed keeps consistent with the crystallization speed; and ultrasonic power is controlled to be between 0.2 kW and 10 kW, a finally formed aluminum ingot is cylindrical, solidoid purity is over 5 N, impurity elements are uniformly distributed in pure crystal, crystal grains are uniform and small, and average crystal grain size is less than 100 microns.

Owner:SHANGHAI JIAO TONG UNIV

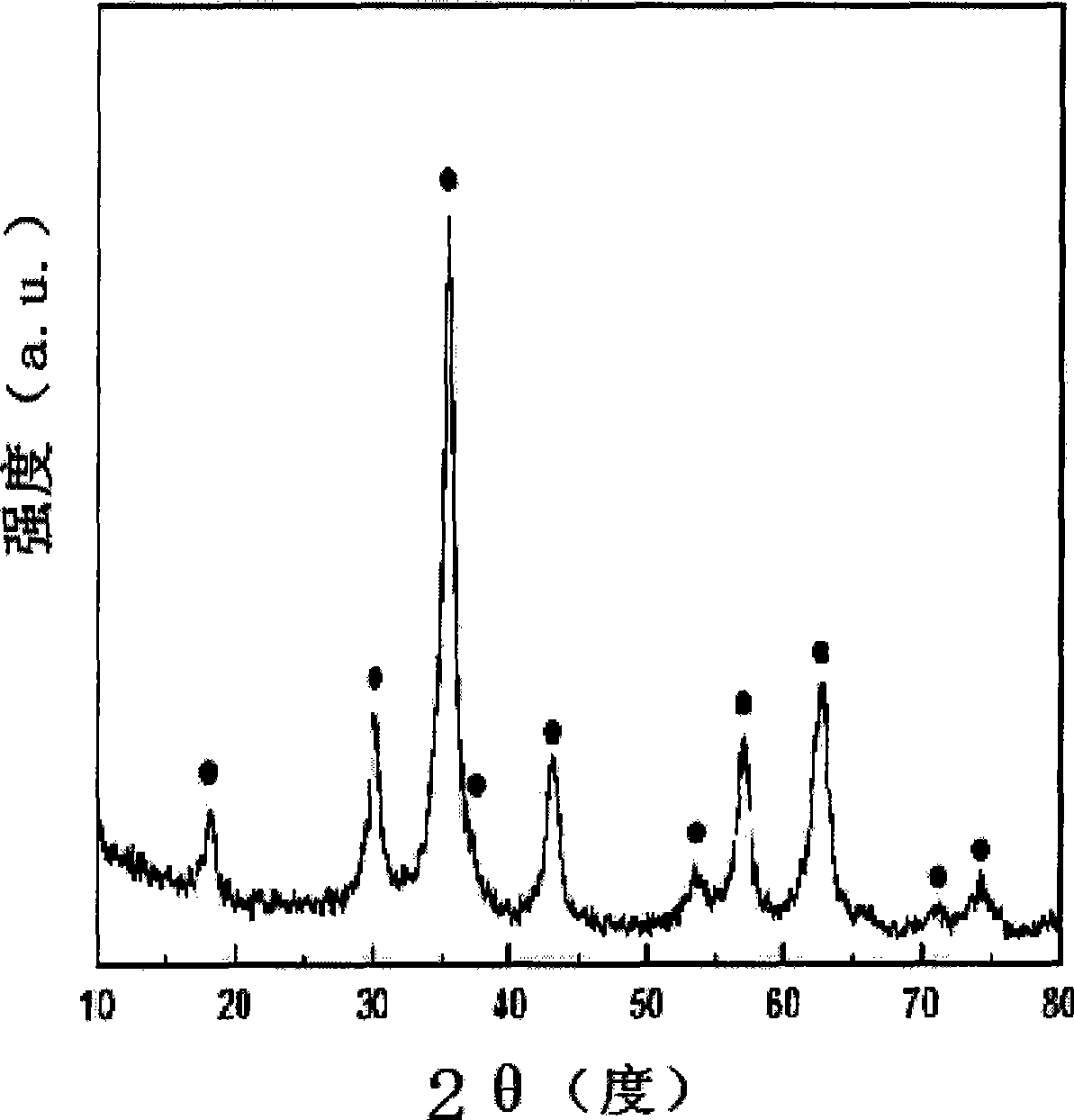

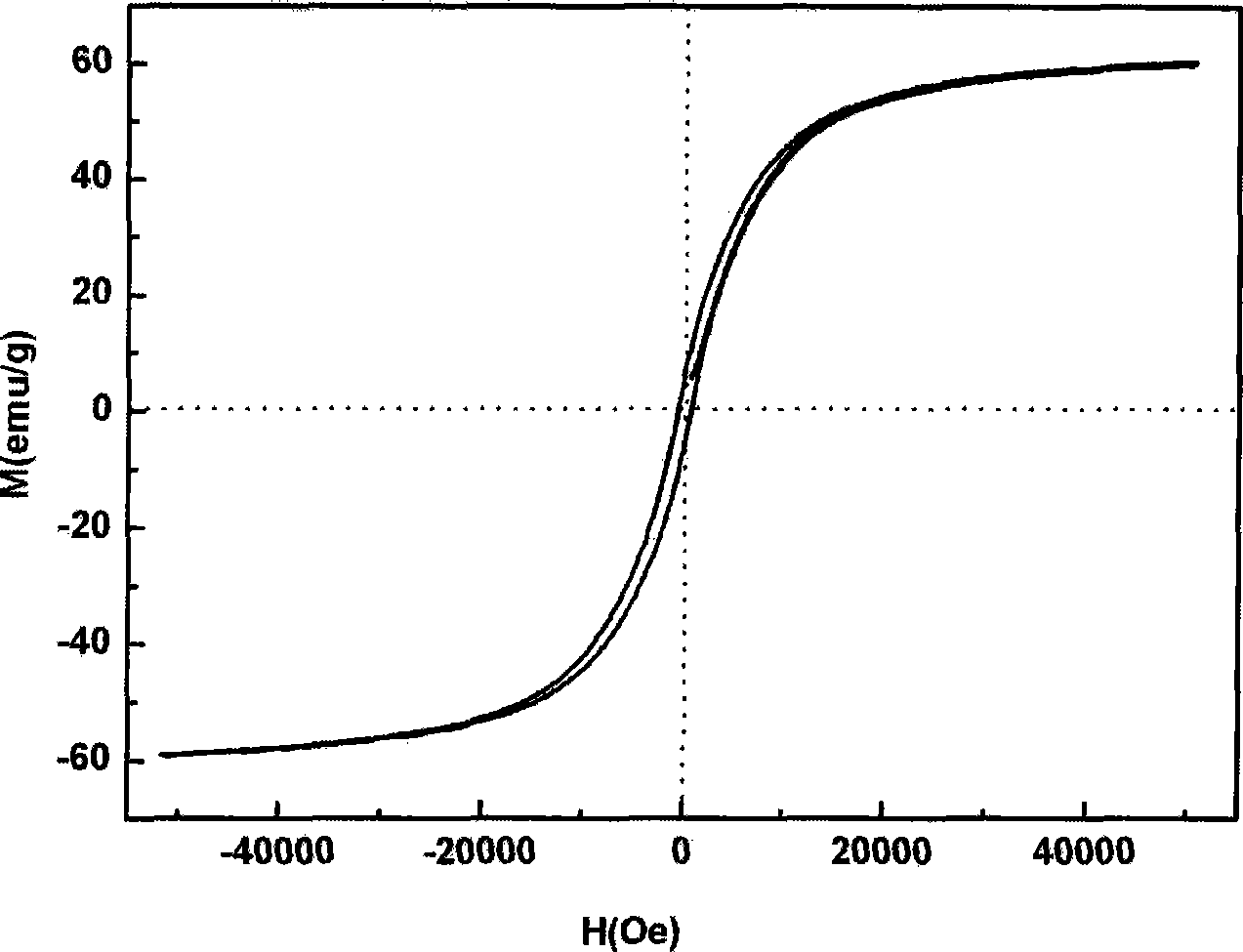

Process for preparing nickel-zine ferrite (NixZn1-xFe2O4) magnetic nano powder by alcohol-heating method

InactiveCN101475368ASimple preparation processLow requirements for production equipmentNickel saltIron salts

The invention relates to a method for preparing nickel zinc ferrite NixZn1-xFe2O4 magnetic nanometer powder through an alcohol heating method. The method comprises the following steps: weighing iron salt, zinc salt and nickel salt and dissolving the iron salt, zinc salt and nickel salt in ethylene glycol at a room temperature, carrying out the ultrasonic dispersion, then adding anhydrous sodium acetate and a polyethylene glycol dispersant, carrying out the mechanical mixing, adding the mixture into a reaction kettle after complete dissolution, cooling down the mixture to the room temperature after the complete reaction, collecting the product through a magnet, washing the product through deionized water and drying the product to obtain the NixZn1-xFe2O4 magnetic nanometer powder. The preparation method has a simple process and is easy for the industrialized production. The NixZn1-xFe2O4 magnetic nanometer powder prepared through the method has a pure crystal phase, good dispersilbility, uneasy agglomeration and higher magnetization; and the magnetic material has the wide application prospect in the industrial and high-tech field due to the unique magnetic performance of the material.

Owner:DONGHUA UNIV

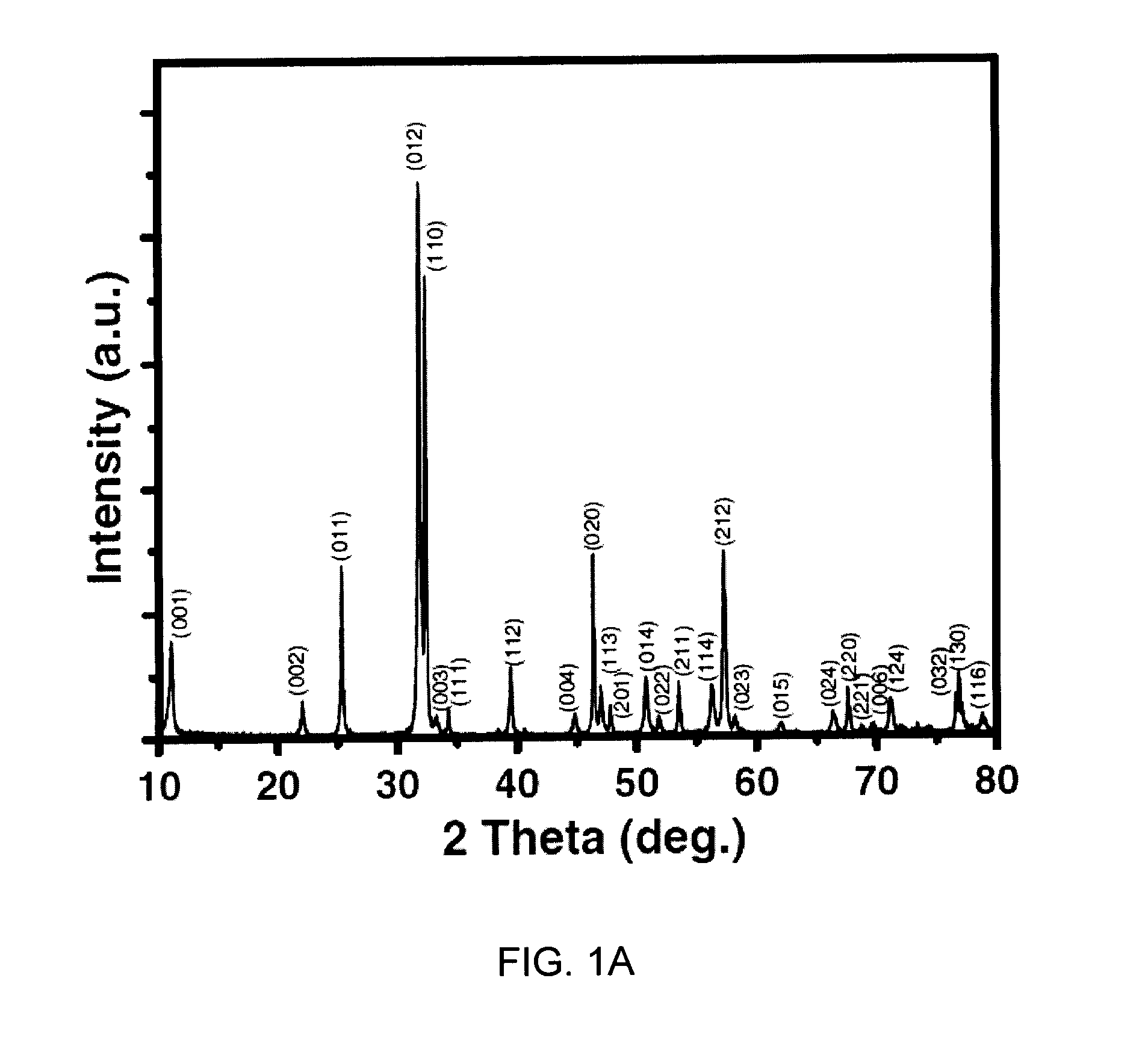

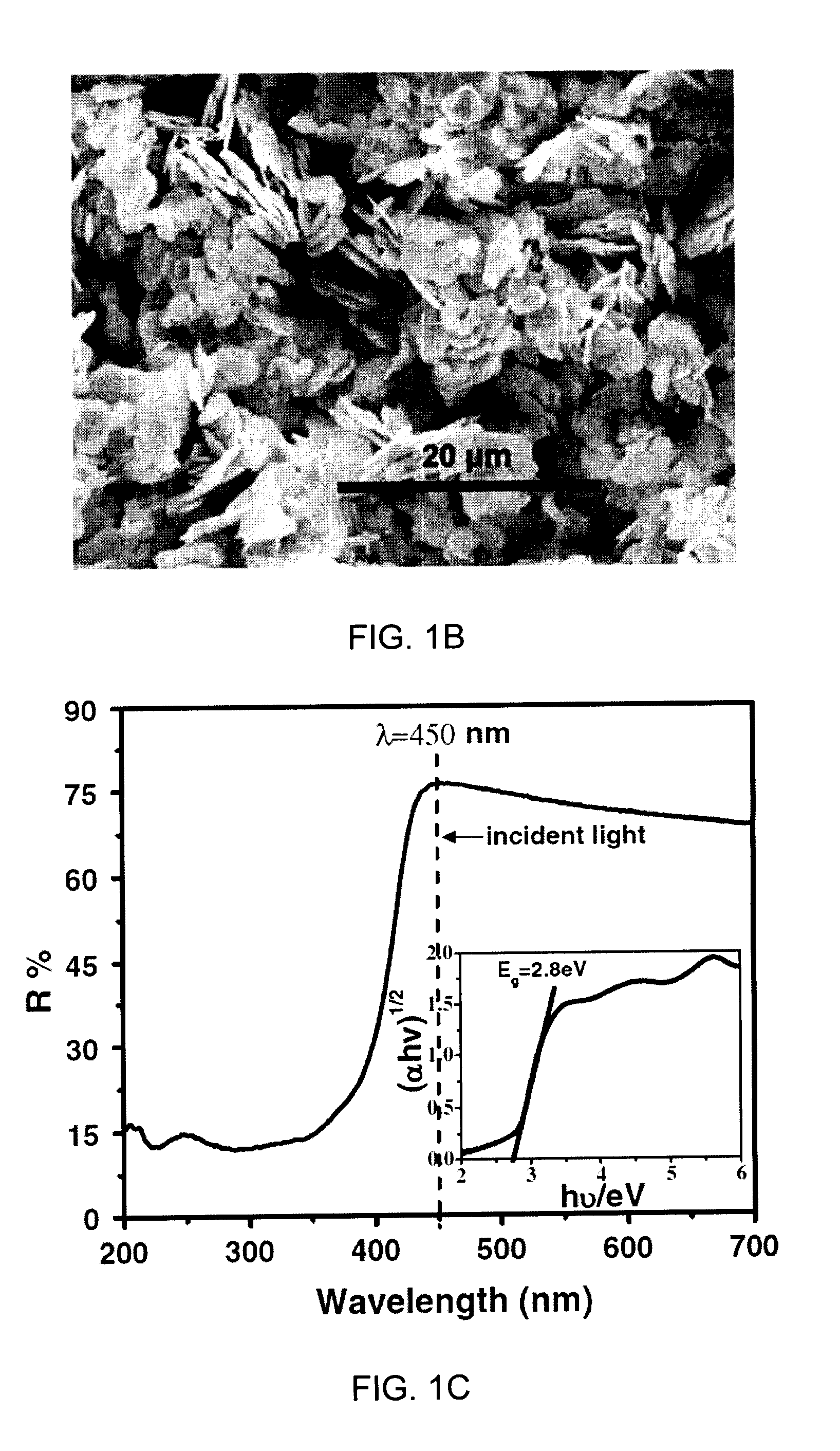

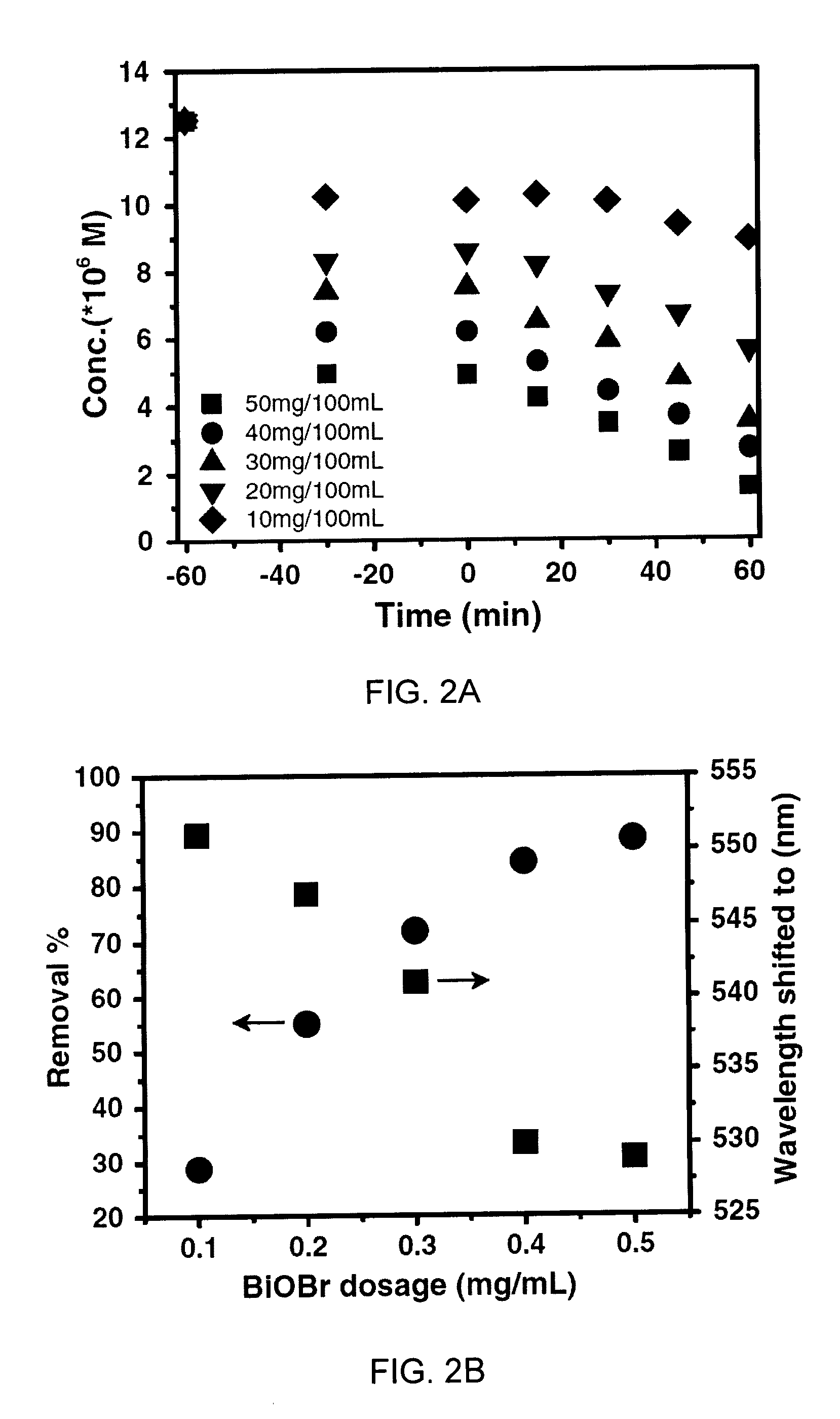

450 nm visible light-induced photosensitized degradation of rhodamine b molecules over biobr in aqueous solution

A method for degrading Rhodamine B including: mixing BiOBr and Rhodamine B; and irradiating the mixture with a radiation having a wavelength of from 440 nm to 554 nm. The Rhodamine B may be in an aqueous solution. The BiOBr may be added to the aqueous solution of Rhodamine B in an amount of from 0.2 to 0.5 mg / ml. The BiOBr may have a sheet-like structure with particles having a diameter of from 3 μm to 5 μm. The BiOBr may be in a pure crystal tetragonal phase.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

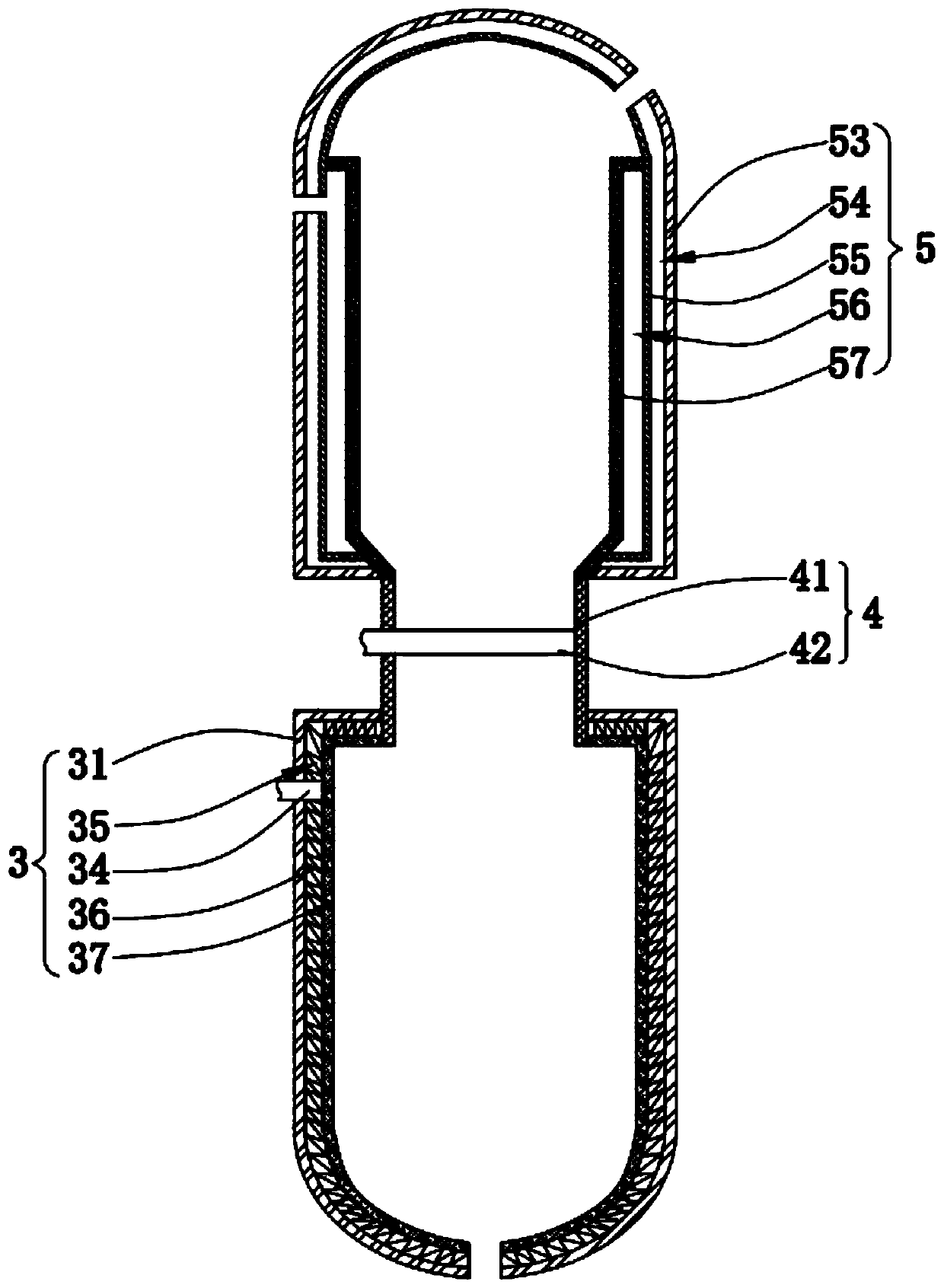

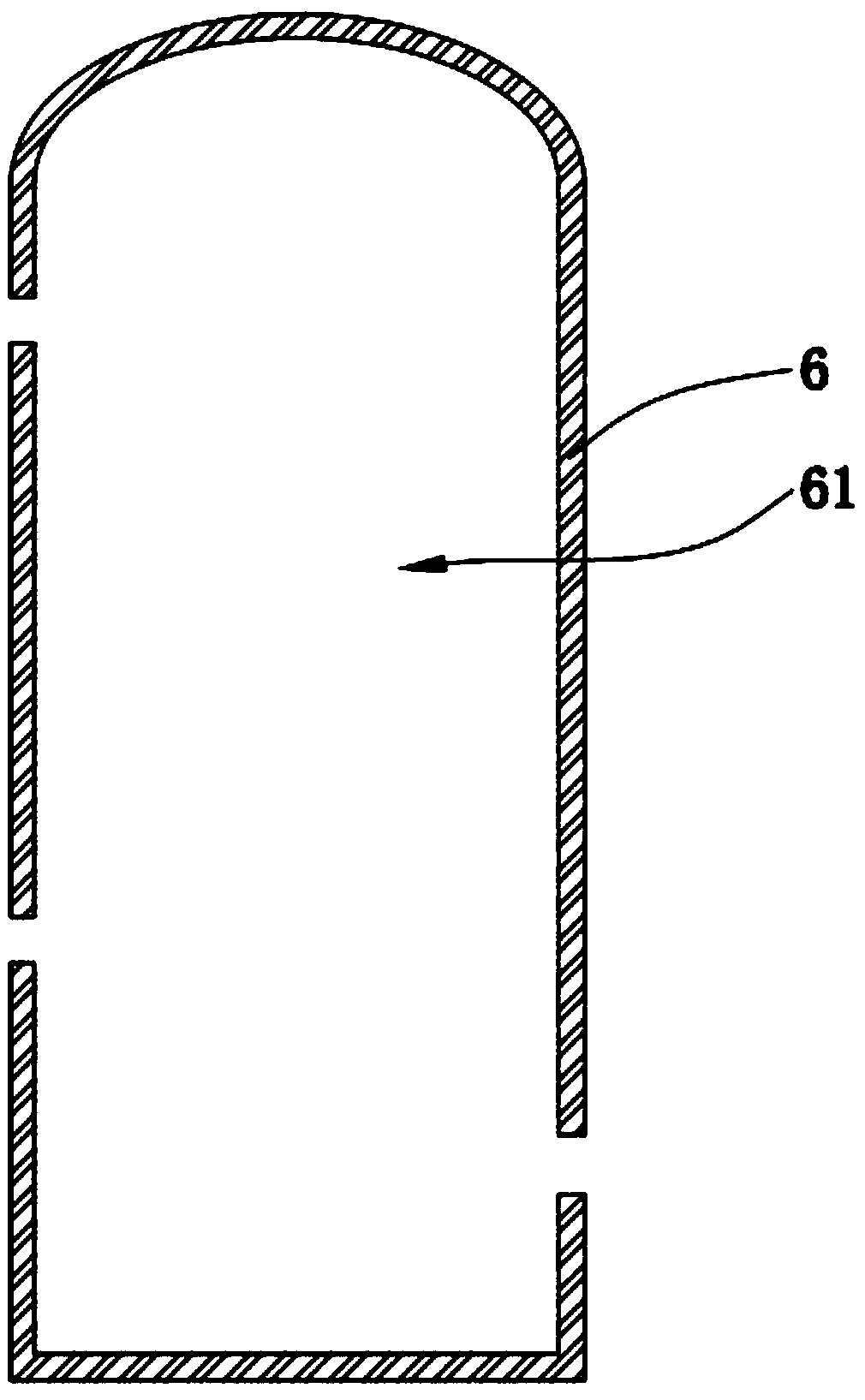

Method and equipment for washing and separating crystals

The invention relates to a method for washing and separating crystals (such as ice crystals), which has low energy consumption and small investment, and ensures high purity of the crystals. The method for washing and separating the crystals comprises the following step of: carrying out mild crystallization on a washing front edge by using a melt of the crystals in a state close to the freezing point (the ice point) as washing liquid (washing water) so as to inhibit viscous fingering and tunnel effect of the washing liquid, generate a horizontal and defined washing front edge, namely piston flow, and make mother liquor in a crystal bed replaced with the washing liquid. The invention also relates to equipment for washing and separating the crystals, which is a crystallization washing columnconsisting of a vertical column body and a feeding mechanism and a cutting mechanism which are respectively arranged at both ends of the vertical column body. A mixture (crystal mush or ice slurry) of the crystals and the mother liquor is pressed into the column from one end of the column to form an isotropic crystal tight stacking bed, the mother liquor in the crystal bed is replaced with the washing liquid, and the washed pure crystals and the washing liquid are planed by the cutting mechanism at the other end of the column body so as to realize high-efficiency low energy consumption separation of the crystals and the mother liquor.

Owner:秦贯丰 +1

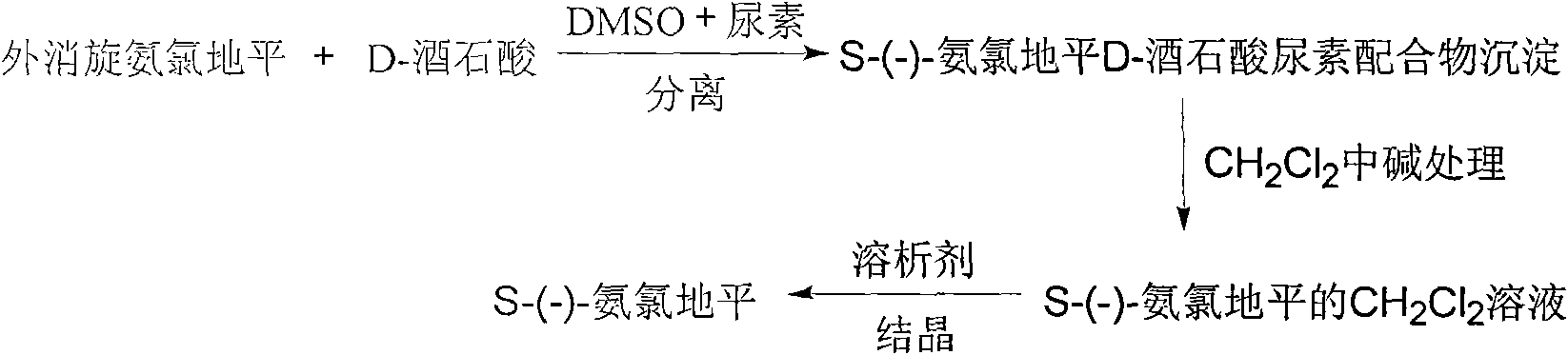

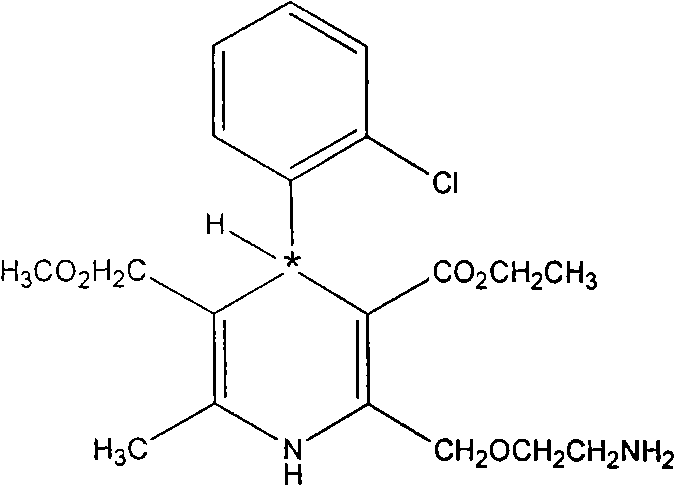

Method for obtaining S-(-)-amlodipine in splitting manner

ActiveCN101654429AMoisture content no special requirementsShort reaction timeOptically-active compound separationOrganic racemisationEnantiomerLevamlodipine

The invention relates to a method for obtaining S-(-)-amlodipine in a splitting manner. The method comprises the following steps: dissolving racemic amlodipine and D-tartaric acid into a mixed cosolvent containg dimethylsulfoxide and urea to carry out a complex reaction, carrying out alkaline treatment, solvent-out crystallization and the like on the S-(-)-amlodipine, the D-tartaric acid and the urea complexes solid sedimentation obtained after the complex reaction is finished, and then obtaining S-(-)-amlodipine pure crystal. The method introduces the other chiral auxiliary reagent-urea in the prior dimethylsulfoxide solution, thus the racemic amlodipine can better react with a splitting agent D-tartaric acid in the cosolvent containing the dimethylsulfoxide and urea, the reaction time islargely shortened, and the reaction does not have special requirements on the water content of the used solvent; the enantiomeric purity of the obtained levamlodipine is over than 99% and the rate ofrecovery is over than 80%. The method can be applied to preparing the intermediate of other chiral medicaments basically meeting the standard of the medical industry, is simple and provides a betterprospect for the preparation of various agents by the amlodipine single enantiomer.

Owner:JIANGXI SHIMEI PHARM CO LTD

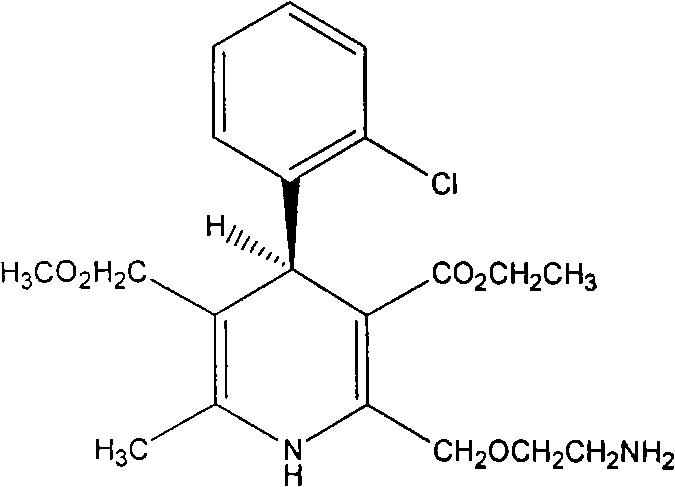

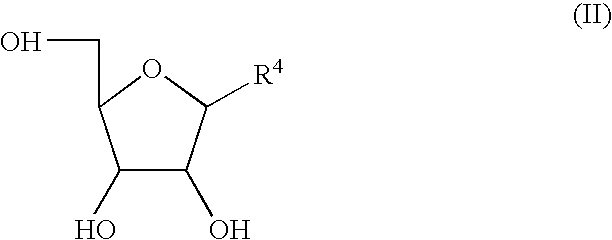

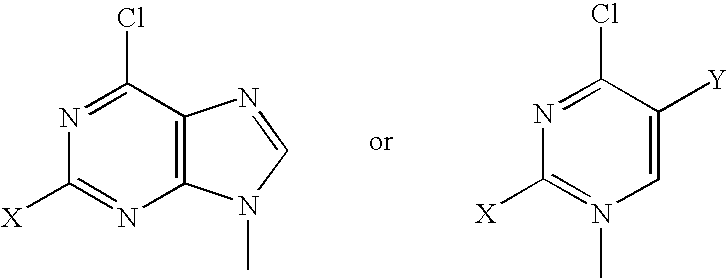

Processes for production of nucleosides

InactiveUS20060014944A1Reaction control is easyImprove securitySugar derivativesAminosugarsHypochloriteOrganic solvent

Nucleoside compounds represented by formula (II) may be prepared by subjecting a 2′,3′,5′-triacyloxynucleoside compound represented by formula (I) to deacylation using alkali metal hydroxide in a 0.01- to 0.5-fold amount in a molar ratio relative to the moles of the 2′,3′,5′-triacyloxynucleoside compound. The production method of the nucleoside compound of formula (II) suppresses the formation of by-products, and the products amy be used for the production of nucleoside derivatives. In addition, oxidation of a nucleoside compound represented by formula (1) in the presence of a 2,2,6,6-tetramethylpiperidine-1-oxy catalyst, and hypochlorite or hypobromite, while adjusting pH to fall within 5 to 9, and further, extracting a nucleoside-carboxylic acid compound represented by the formula (2) into an organic solvent under acidic conditions, back-extracting the compound from the organic solvent into an aqueous alkali solution, and neutralizing the aqueous alkali solution by adding an acid thereto affords highly pure crystals of the compound of formula (2) or a salt thereof. wherein each symbol is as defined in the Description.

Owner:AJINOMOTO CO INC

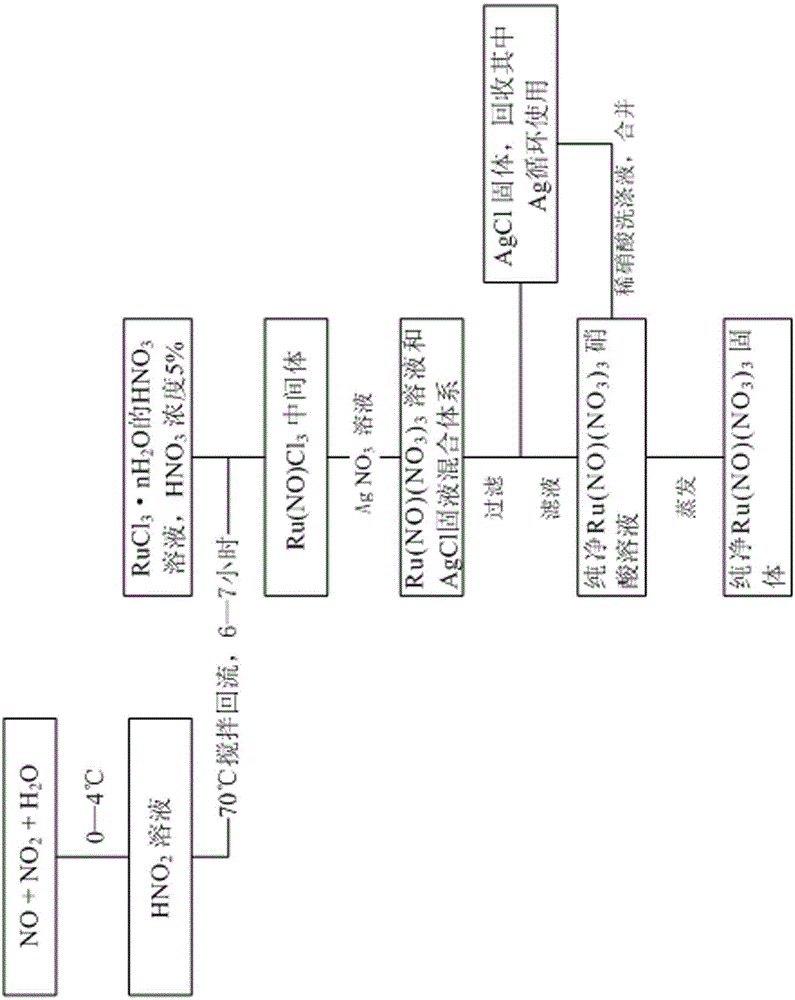

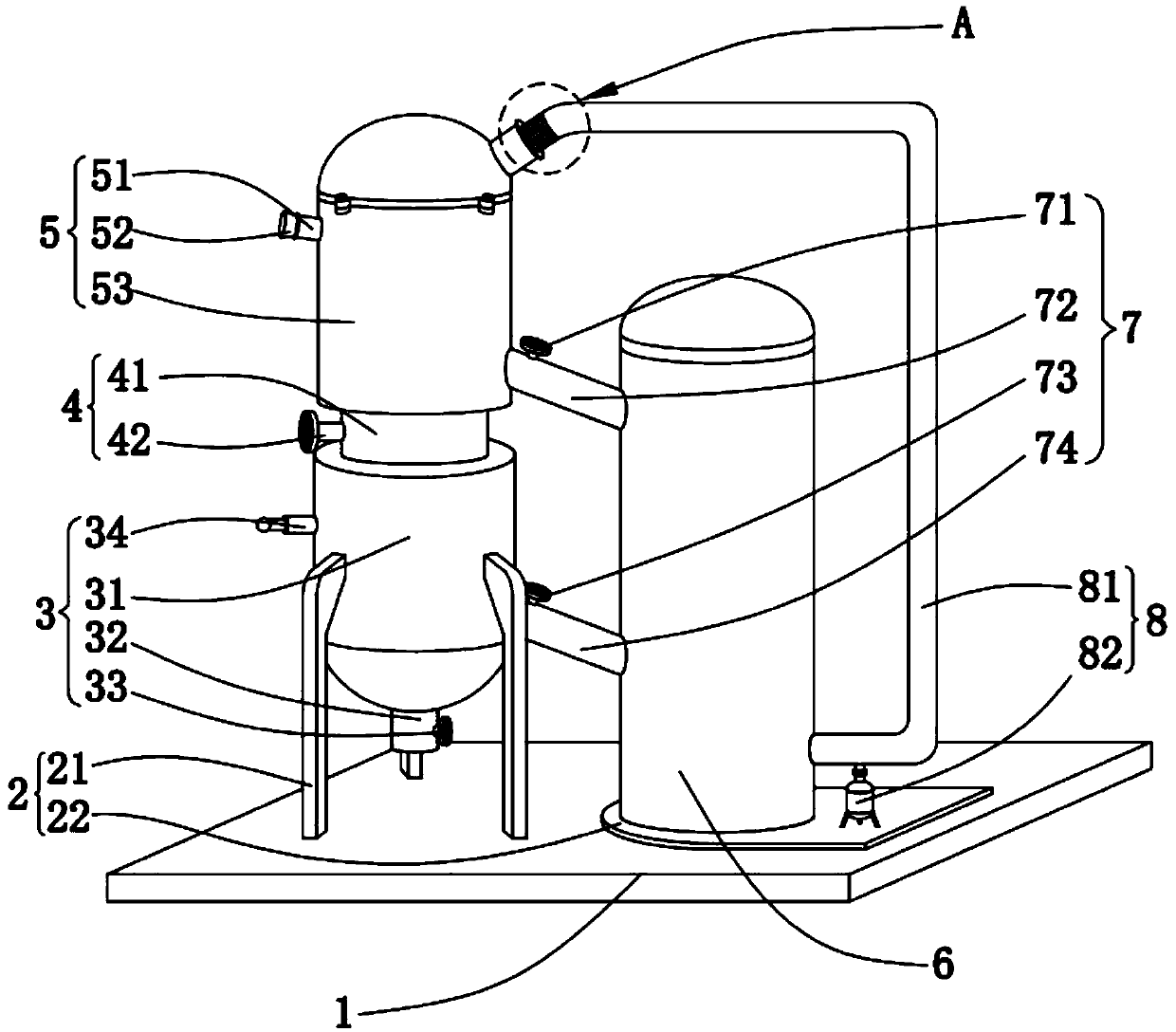

New method for preparing ruthenium nitrosyl nitrate solution or pure crystal

ActiveCN104556250AHigh purityFully removeRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsNitrateDistillation

The invention discloses a new method for preparing a ruthenium nitrosyl nitrate solution or pure crystal, which comprises the following steps: 1. preparing a pure HNO2 solution; 2. dissolving commercially available RuCl3.nH2O in dilute nitric acid, gradually adding the HNO2 solution prepared in the step 1 under reflux conditions, and stirring until the solution completely becomes rose red, thereby obtaining an intermediate ruthenium nitrosyl chloride; 3. removing excess Cl<-> with an AgNO3 solution, and filtering to obtain a ruthenium nitrosyl nitrate nitric acid solution which conforms to the application requirements; and 4. drying the ruthenium nitrosyl nitrate nitric acid solution obtained in the step 3 by distillation to obtain the pure ruthenium nitrosyl nitrate solid. The method has the advantages of cheap and accessible raw materials, fewer steps and environment friendliness, does not need to design or use any special device, has wide application range (from laboratory small testing to industrial-scale generation), and has very high popularization value.

Owner:昆明铂生金属材料加工有限公司

Static state fusing crystallizer used for material purifying and separating

ActiveCN109621478AAvoid wastingEasy to operateFractional crystallizationPulp and paper industryPure crystal

Owner:山西鑫海翔新材料有限公司

Synthesis and preparation method of high dispersibility resorcinol-80

The invention relates to a synthesis and preparation method of high dispersibility resorcinol-80, which comprises the following steps of: 1, preparing for raw materials comprising resorcinol, butadiene-styrene rubber (SBR1502), ethylene-propylene diene monomer (EPDM4640), flux oil, zinc stearate and tissuemat E and preparing the carrier rubber and the dispersant; 2, mixing by using an internal mixer (Lina Machine); 3, extrusion molding for pelleting; 4, carrying out surface treatment on particles of the product; 5, initially cooling and screening the particles; 6, finally cooling the particles; and 7, detecting and packaging the particles of the product. The high dispersibility resorcinol-80 synthesized and prepared in the invention is prepared by adding special rubber and dispersant after subjected to special treatment of high purity resorcinol. The high dispersibility resorcinol-80 is added at lower temperature during mixing and can be dispersed in the rubber material uniformly; and the special rubber and the dispersant selected are beneficial to improving the bonding intensity of the mixed rubber, and solves the problems that the pure crystal of resorcinol during mixing generates toxic smoke due to sublimation, is not easy to disperse and easy to absorb moisture and the like.

Owner:DONGGUAN PUERDUN RUBBER & PLASTIC IND

Preparation method of aluminum-containing layered kenyaite

ActiveCN103204505AHigh aluminum contentCrystal phase pureSilicon compoundsLithium hydroxidePotassium hydroxide

The invention relates to a preparation method of an aluminum-containing layered kenyaite. The method includes: (1) mixing silicon sol with hydrated alumina or a slurry of hydrated alumina and water, stirring the mixture at room temperature for 20-180min; (2) under stirring at room temperature, introducing a solution of alkali selected from one or more of lithium hydroxide, sodium hydroxide and potassium hydroxide into the mixture obtain in step (1); (3) crystallizing the mixture obtained in step (2) in a closed reactor for 24-170h at 130DEG C-170DEG C; and (4) washing the solid product obtained in step (3) until the filtrate becomes a transparent liquid, thus obtaining the aluminum-containing layered kenyaite. Compared with the existing aluminum-containing kenyaite, the aluminum-containing kenyaite prepared by the method provided in the invention has a high aluminum content and a pure crystal phase. In addition, the method provided by the invention has mild reaction conditions, a short cycle, and needs no introduction of organic matters.

Owner:CHINA PETROLEUM & CHEM CORP +1

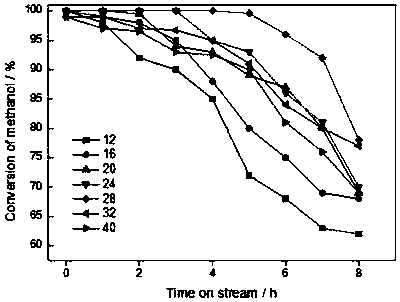

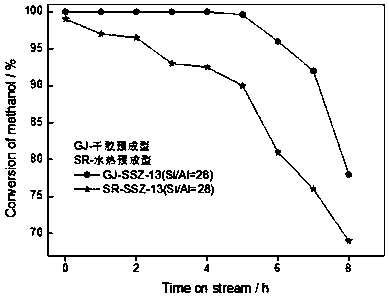

Method for synthesizing integrated SSZ-13 molecular sieve from mixed template agent and dry glue

InactiveCN109319806AHigh crystallinityImprove thermal stabilityMolecular sieve catalystsMolecular sieve catalystWater useAdhesive

The invention discloses a method for synthesizing an integrated SSZ-13 molecular sieve from a mixed template agent and dry glue. According to the method disclosed by the invention, the mixed templateagent mainly adopts choline chloride and N,N,N-trimethyl adamantine ammonium, the mixed template agents and raw materials are kneaded, extruded and preformed according to the proportion, and then dryglue stripes are crystallized under the certain temperature in a high pressure kettle; the prepared SSZ-13 molecular sieve has the advantages of high purity, pure crystal phase, even grain size, moreconcentrated accumulation bore diameter, larger specific surface area and appropriate acid sites. The SSZ-13 molecular sieve synthesized by the method disclosed by the invention has high heat stability, has more concentrated accumulation holes near 4 nm and has a very excellent catalyzing effect in catalytic reaction of MTO methanol to olefin. Compared with hydrothermal synthesis and a traditionaldry glue and solid phase grinding method, an integrated type dry glue synthesizing process has the characteristics that dust pollution and raw material waste in cost powder processing are reduced, the cost is low, the water use amount is small, a preparation process is simple and easy to operate, no adhesive is added, active sites are exposed, a catalytic effect is strong and the like.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

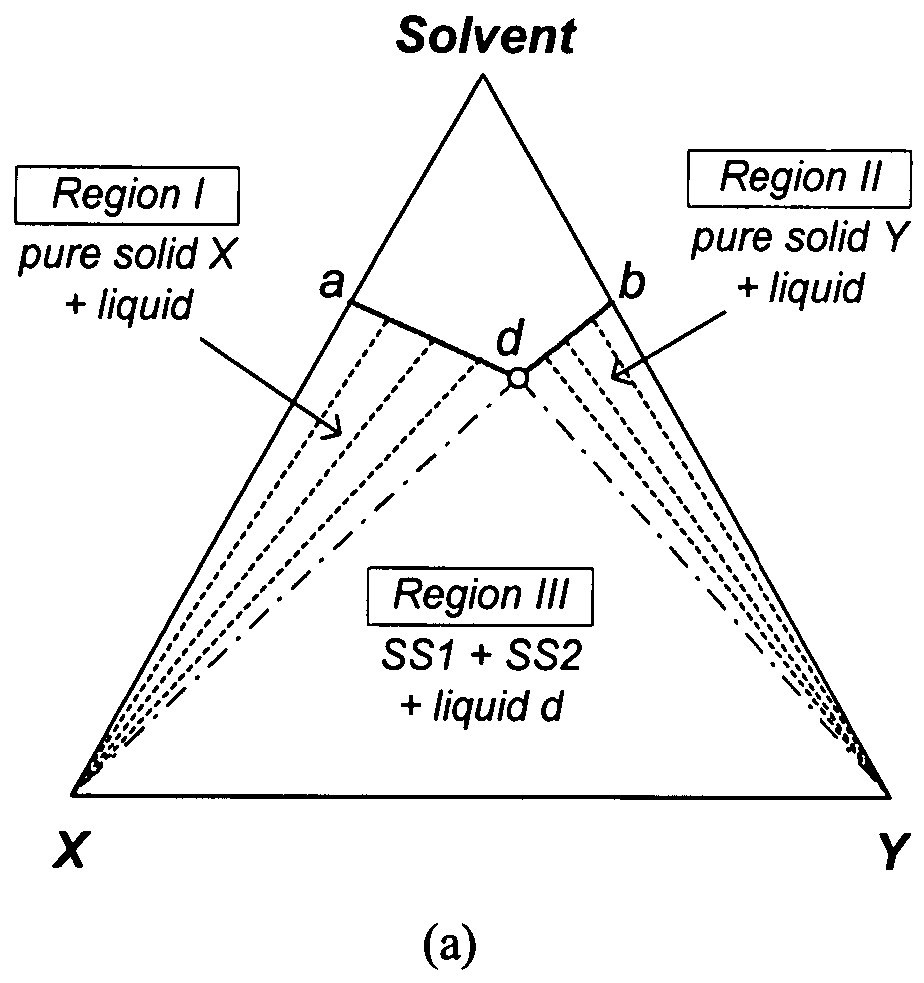

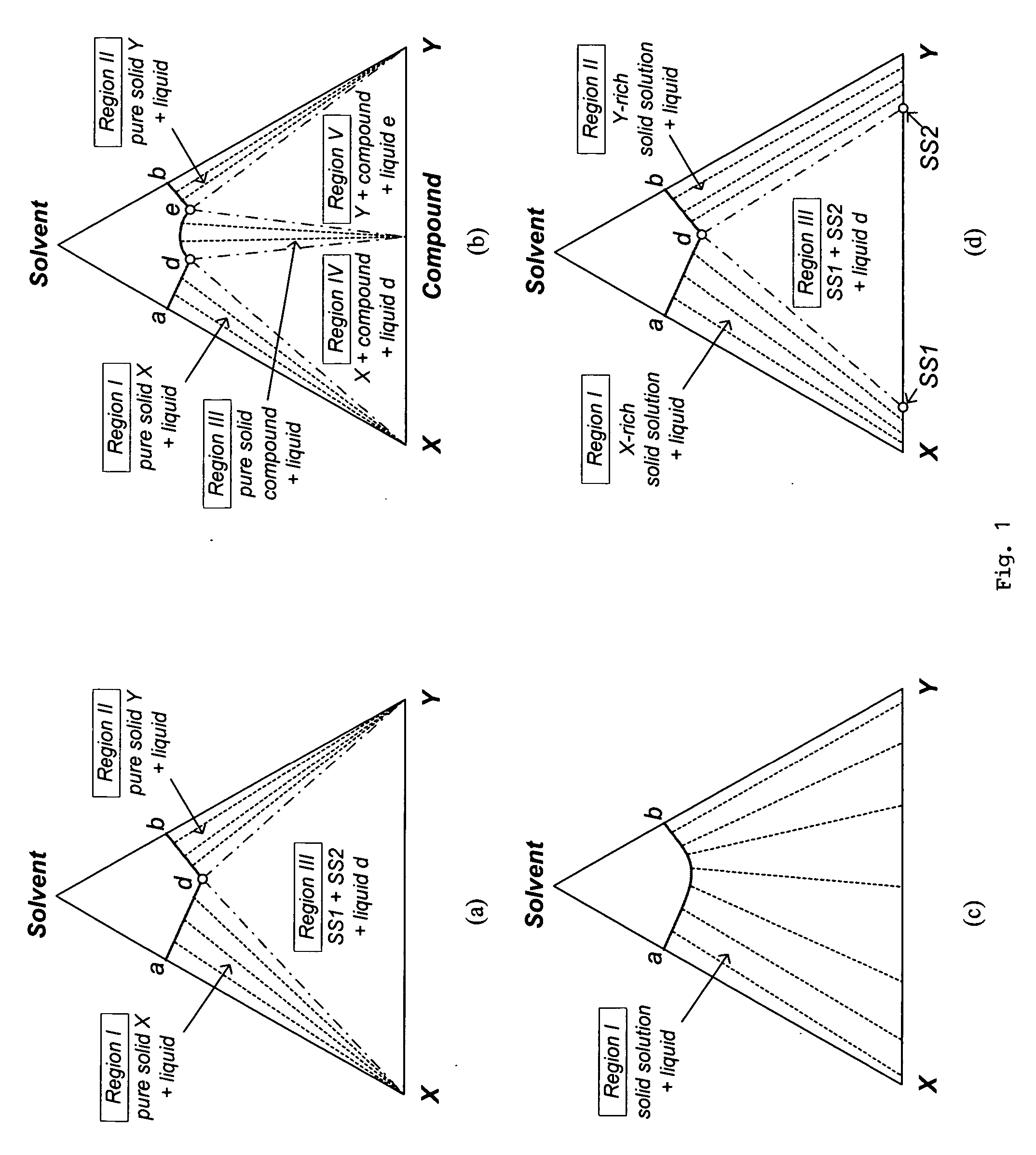

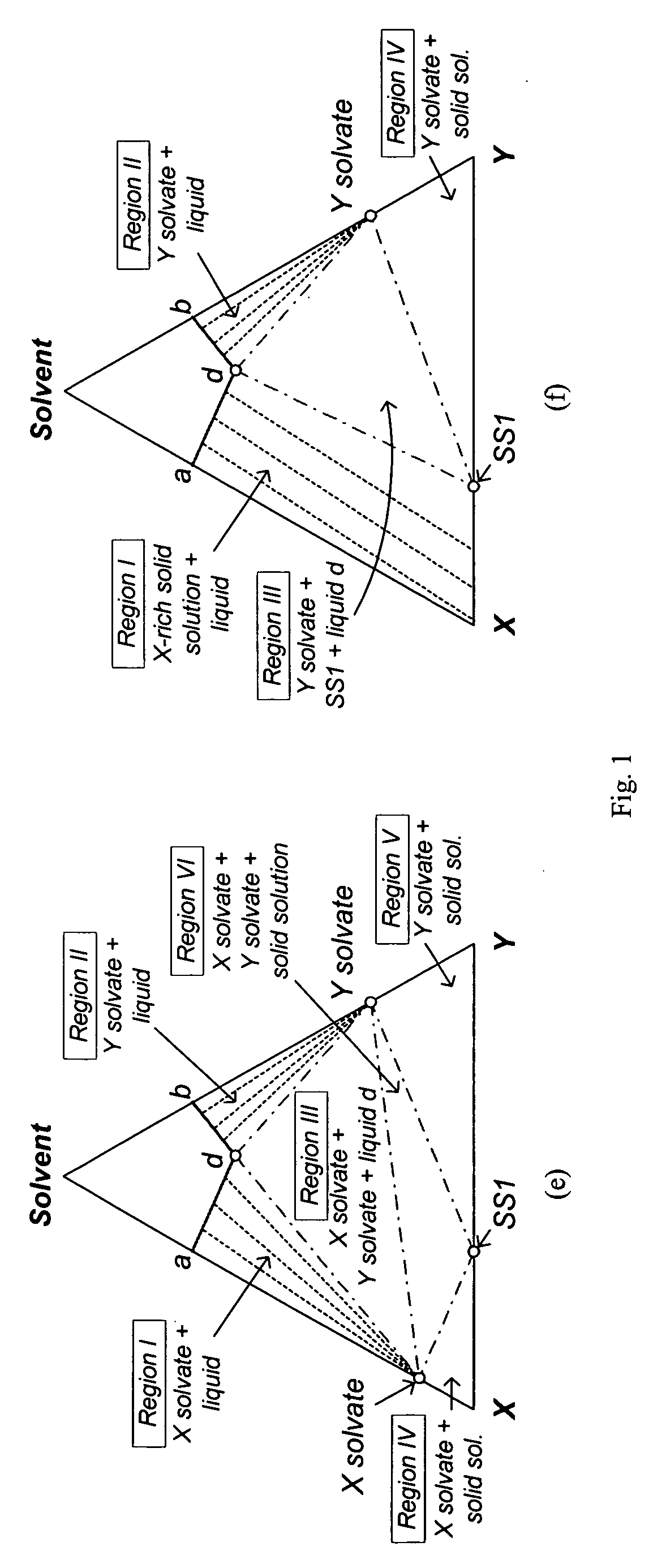

Separation of fullerene C60 and C70 using crystallization

ActiveUS20070274894A1Low productionLow separationMaterial nanotechnologyFullerenesSolid solutionFullerene

The present invention provides a method for separating two highly pure fullerenes from a mixture of fullerenes comprising crystallizing a first fullerene component and a second fullerene component, wherein the phase equilibrium behavior of the mixture fed to a crystallizer is characterized by a region(s) where a pure fullerene of the two fullerenes or the solid solution or solvate thereof can be crystallized out. In particular, the present invention provides a method for simultaneously separating two highly pure fullerenes from a mixture of fullerenes via crystallization, which comprises (i) adjusting the amount of a solvent in the mixture fed to a first crystallizer to obtain a phase equilibrium behavior such that a first fullerene components of the two fullerenes, in the form of a pure crystal, a solid solution crystal, or a solvate crystal is obtained during crystallization; (ii) adjusting the amount of a solvent in the mixture fed to a second crystallizer, operating at a different temperature compared to the first crystallizer, to obtain a phase equilibrium behavior such that a second fullerene component of the two fullerenes, in the form of a pure crystal, a solid solution crystal, or a solvate crystal is obtained during crystallization; and additionally (iii) purifying the solid solution or the solvate into a highly pure fullerene, when the solid product from the crystallizers is in the form of a solid solution or a solvate. The method according to the present invention allows to obtain up to 99.990% pure fullerenes, with relatively low production and separation cost. The method can be applied for various two fullerenes-solvent systems.

Owner:THE HONG KONG UNIV OF SCI & TECH

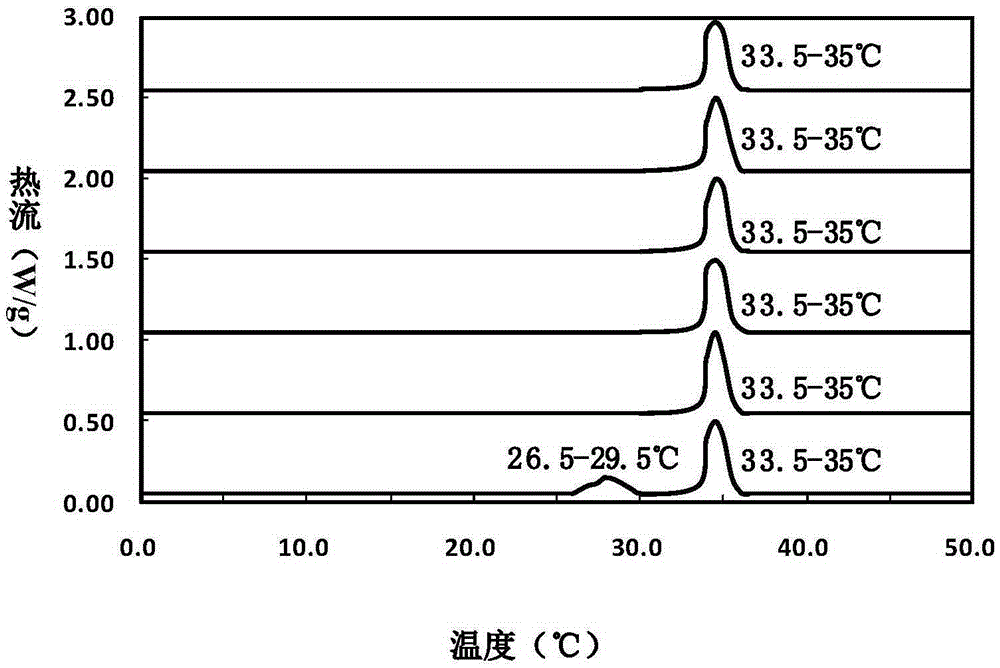

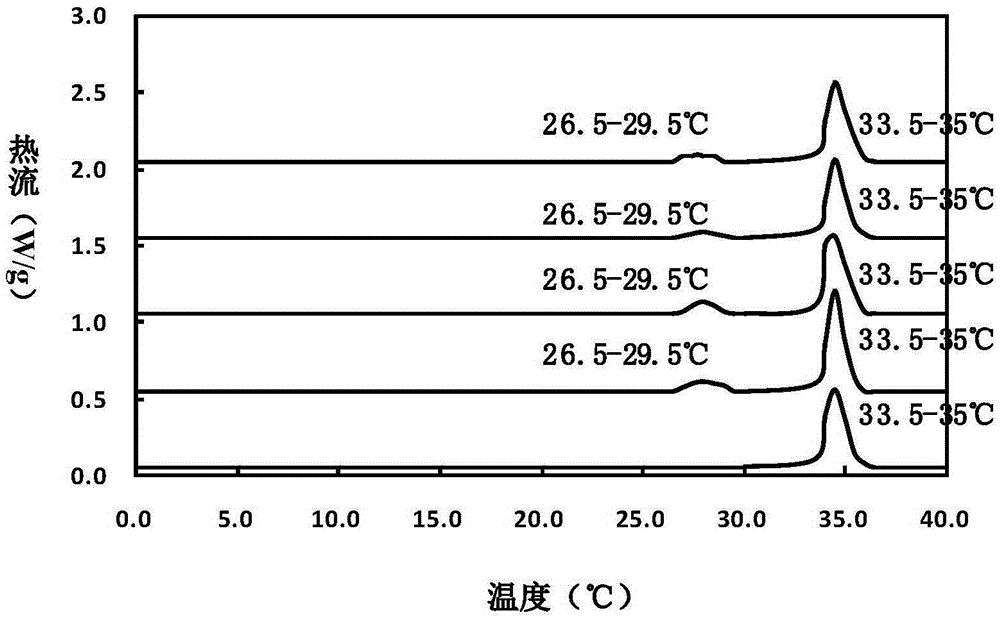

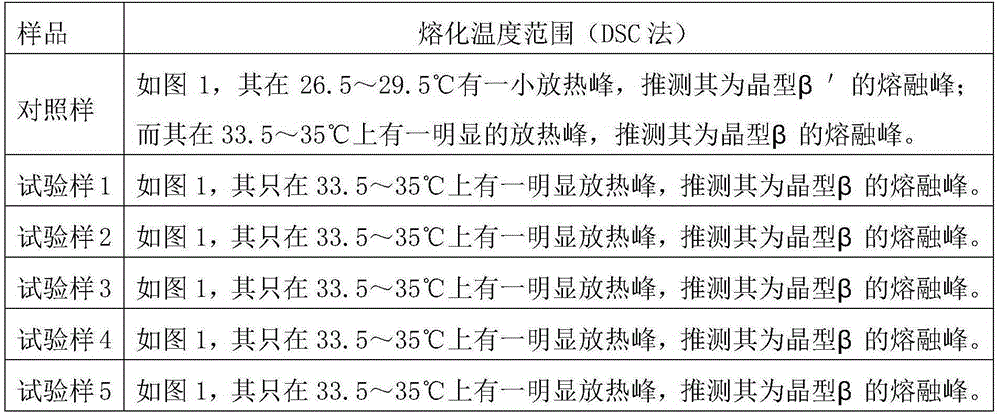

Mellow chocolate, preparation method and application of chocolate to preparation of chocolate decorating part

The invention aims to provide mellow chocolate. Cocoa butter can be separated out in the pure crystal form beta, slurry is uniformly dispersed and free of coking, gelatinization and the like during processing, the mellow chocolate can be placed stably and free of frosting, and the preparation process is not rigorous. The mellow chocolate comprises components in parts by weight as follows: 30-40 parts of white granulated sugar, 30-40 parts of cocoa butter, 1-5 parts of a cocoa mass, 10-20 parts of alkalized cocoa powder, 1-10 parts of whole milk powder, 1-5 parts of black cocoa powder, 0.15-1 part of PGPR, 0.3-2.5 parts of lecithin, 0.03-0.2 parts of vanillin, 0.015-0.1 parts of Span and 0.02-0.1 parts of GMS (glycerin monostearate). The invention further discloses a preparation method of the mellow chocolate. The method comprises steps as follows: preprocessing of raw and auxiliary materials, fine grinding, refining, temperature regulation and casting. The method is simple and effective, common people can also prepare qualified mellow chocolate with the method, and post-processing, such as production of a chocolate decorating part, of the chocolate is facilitated.

Owner:HANGZHOU QIAOZHIHE FOOD

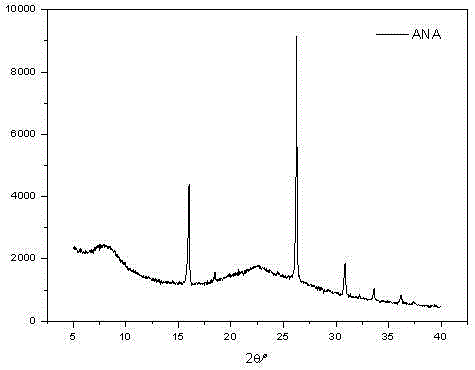

Nano-scale ultra-fine analcime preparation method

ActiveCN106672991APrevent crystallizationReduce dosageMaterial nanotechnologyCrystalline aluminosilicate zeolitesUltra fineCrystallinity

The present invention discloses a nano-scale ultra-fine analcime preparation method, wherein an alkali source, a silicon source, an aluminum source, water and N-methylpyrrolidine are adopted as reaction raw materials and crystallization is performed for 5-200 h under autogenous pressure and 140-200 DEG C hydrothermal condition to obtain the small grain nanometer analcime. According to the present invention, the obtained nano-scale ultra-fine analcime has characteristics of simple process, pure crystal phase, high crystallinity, large specific surface, low cost and the like, and has wide application prospects in ion adsorption and purification.

Owner:CHINA PETROLEUM & CHEM CORP +1

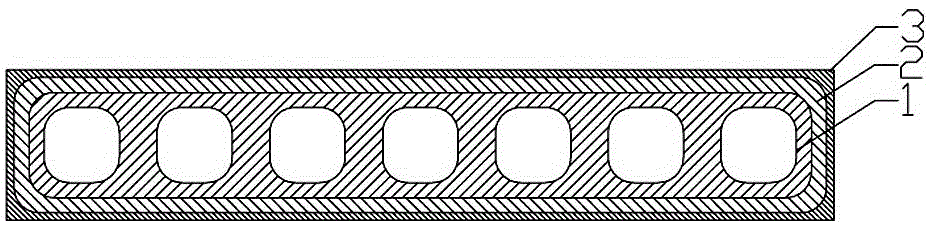

Method for preparing high-performance pure crystal silicon carbide nano flat ceramic membrane

ActiveCN106431415AControl Aperture SizeGive full play to physical and chemical propertiesSemi-permeable membranesSeawater treatmentPure crystalEnergy conservation

The invention discloses a method for preparing high-performance pure crystal silicon carbide nano flat ceramic membrane. The method comprises the following steps: first, selecting high-purity 6H-SiC powder as a basic material, carrying out medium airflow shaping on materials of a support layer, a transition layer and an upper membrane layer, squeezing a green body of the support layer by adopting a piston-type squeezer and curing the green body of the support layer with a crawler-type vacuum microwave drying machine; squeezing pug of the transition layer onto the cured support layer, placing the pug into the crawler-type vacuum microwave drying machine, and then curing and sintering at high temperature; finally, spraying pug of the upper membrane layer on the transition layer by a plasma method. The preparation method disclosed by the invention can realize continuous production, the effects of energy conservation and environmental protection are obvious, the working environment is good, the aperture size, the flux permeability and the particle removal rate of the ceramic membrane can be excellently controlled, and no additive is remained after sintering; the finished product ceramic membrane can give full play to the own advantages of the physical and chemical properties of silicon carbide under the working conditions of high temperature, high salinity and strong corrosion, the separation accuracy is high, the regeneration capacity is strong, the service life is strong, and the ceramic membrane can be reused.

Owner:河南晟道科技有限公司

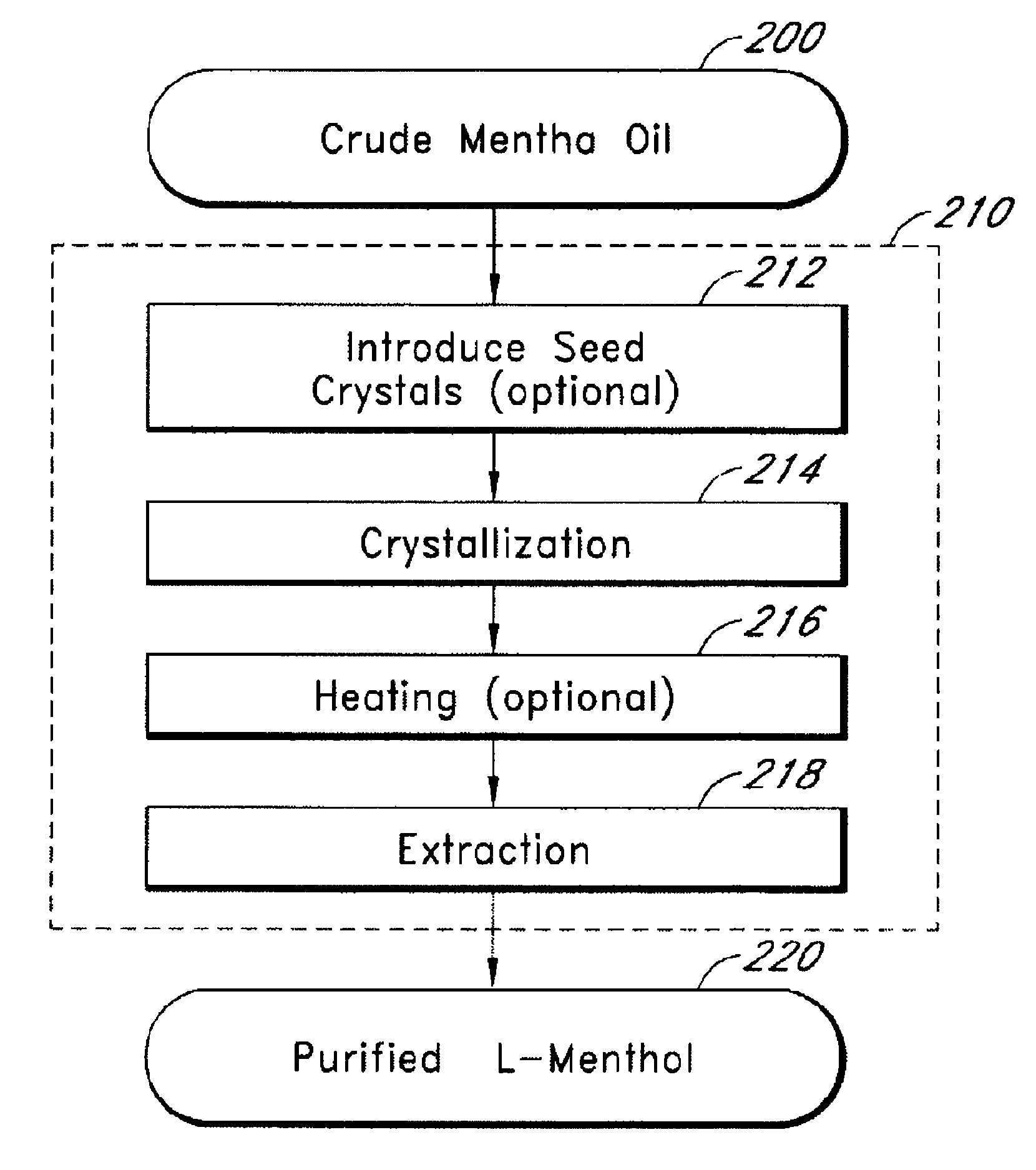

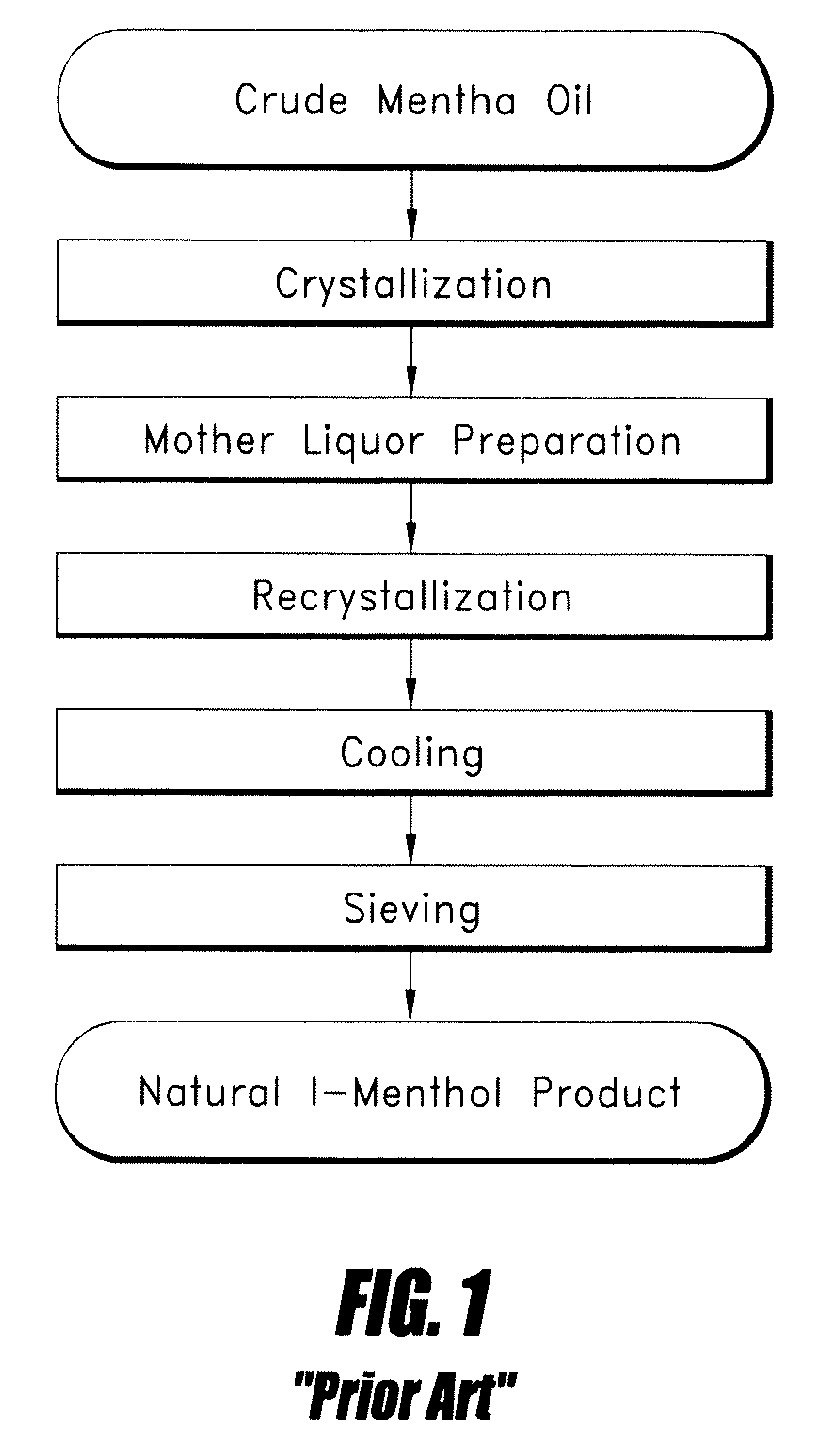

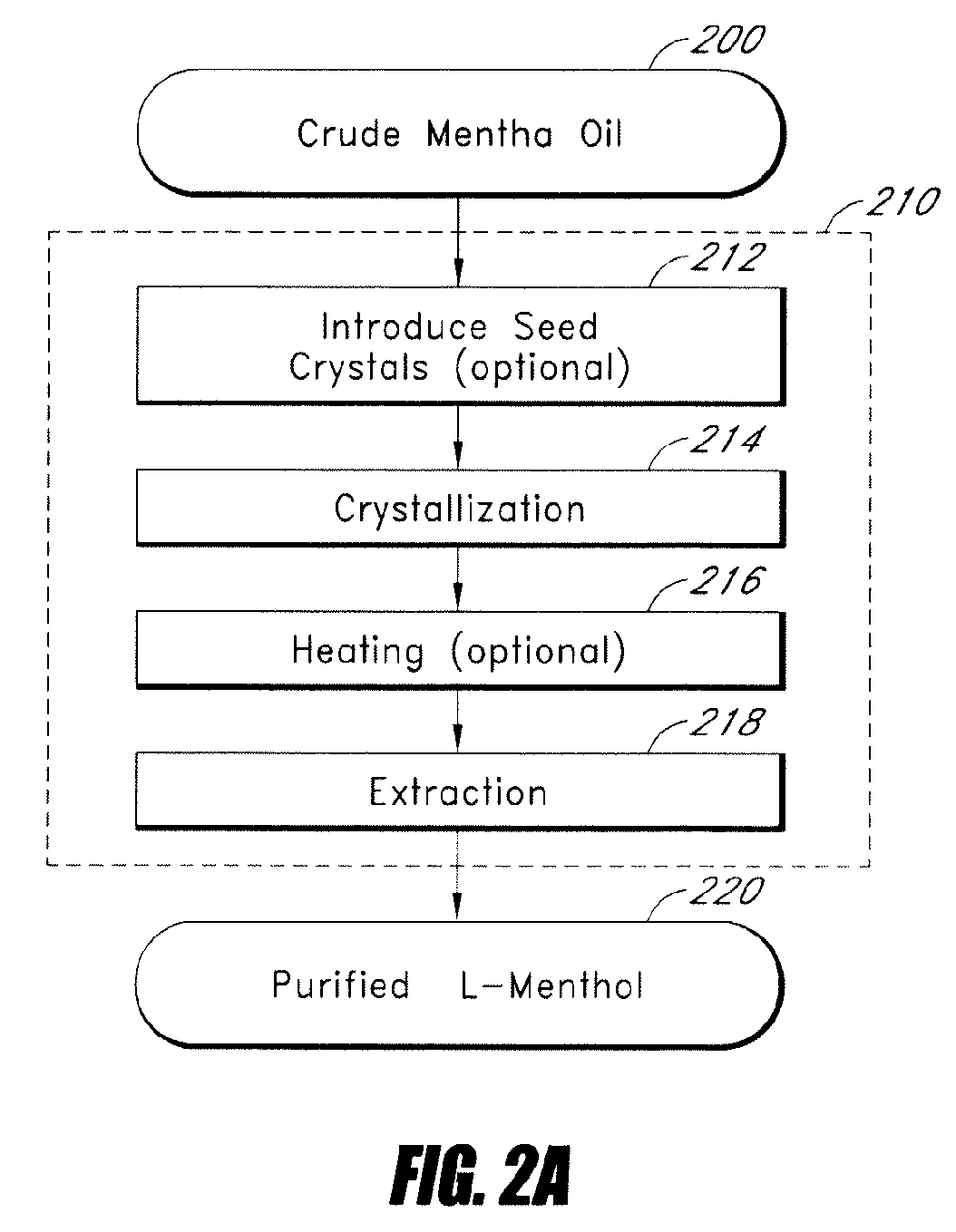

Methods and apparatus for production of natural L-menthol

Embodiments are provided that provide for efficient production of highly pure natural I-menthol. In some embodiments, a method for preparing natural I-menthol involves providing crude mentha oil in a crystallizer and gradually reducing the temperature of the crystallizer in a step-wise manner, thereby producing highly pure crystals in less than two weeks. The methods disclosed herein are suitable for pharmaceutical GMP.

Owner:NAGAOKA

Thermistor chip and preparation method thereof

ActiveCN105575569AHigh resistance precisionImprove stabilityNegative temperature coefficient thermistorsSlurrySolvent

The invention provides a thermistor chip and a preparation method of the thermistor chip. The thermistor chip is prepared from the following raw materials in percentage by mass: 40 to 60 percent of manganese nitrate, 20 to 35 percent of cobalt nitrate, 10 to 20 percent of nickel nitrate and 5 to 10 parts of aluminum nitrate, wherein the raw materials are all chemical pure crystals. The preparation method comprises the following steps of dissolving the crystals into deionized water to prepare a mixed solution; carrying out thermal decomposition on the mixed solution to obtain mixed powder; mixing the mixed powder with a solvent, a binding agent, a dispersing agent and a plasticizing agent to prepare slurry; carrying out wet film casting on the slurry to obtain a block; carrying out the technologies of drying, cutting, adhesive discharging, sintering, polishing-grinding, silver coating and scribing on the block, thus obtaining the thermistor chip. The electrical resistivity of the thermistor chip provided by the invention is 20 Kohm.mm to 30 Kohm.mm, and a material B value is 4100 K to 4700 K; the preparation method of the thermistor chip is simple, a process of settling and standing or gelating is not needed, and the thermistor chip has the characteristics of high sensitivity, less energy consumption and short production period.

Owner:SHENZHEN GUDIAN ELECTRONICS

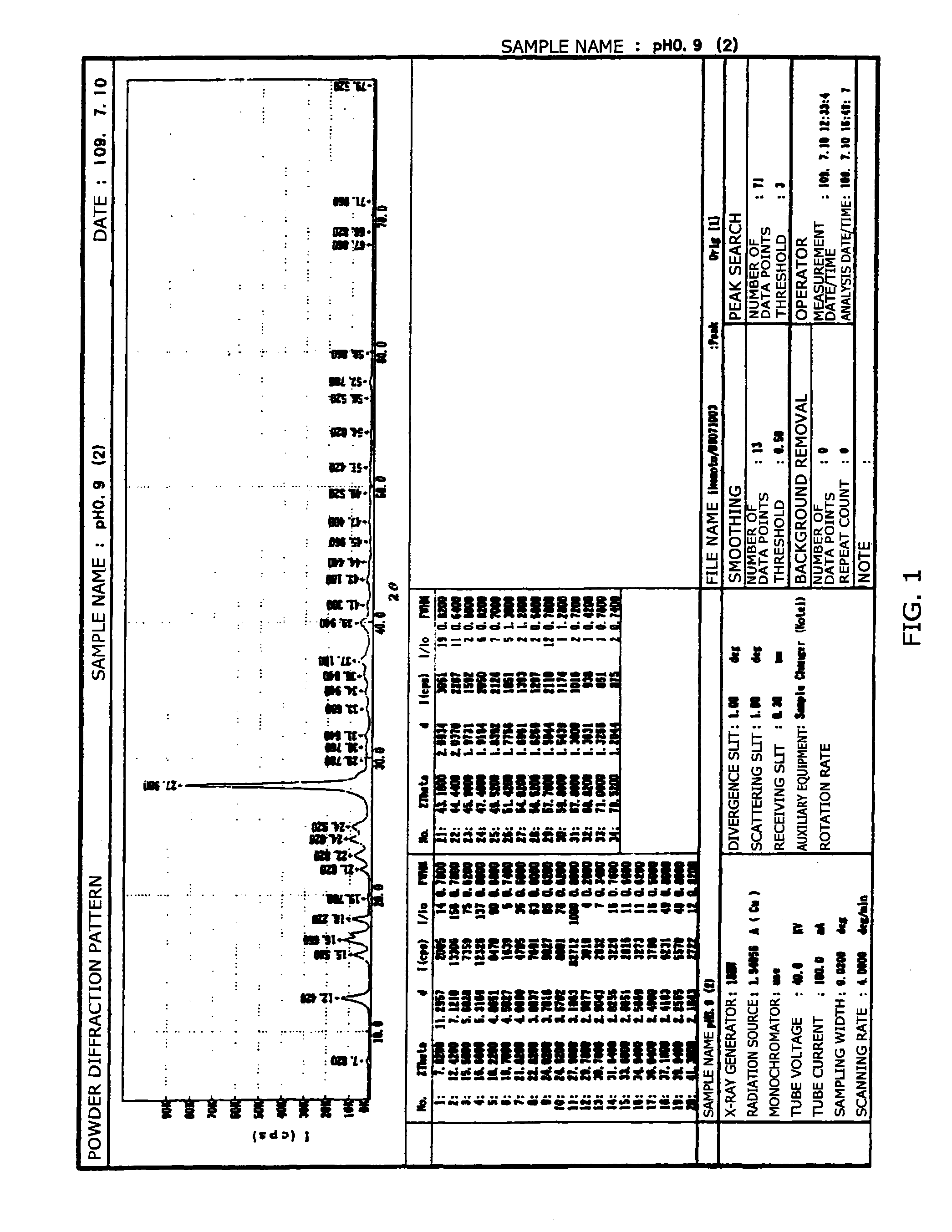

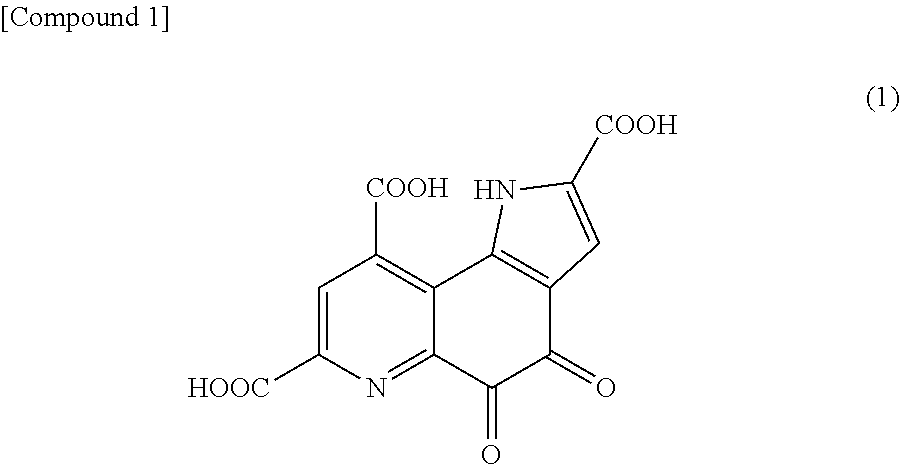

Pyrroloquinoline quinone in free form

InactiveUS20120226045A1High purityReduce alkali metal contentOrganic chemistryOrganic solventFree form

An object of the present invention is to provide a method for conveniently producing pyrroloquinoline quinone in the free form without any organic solvent or ion-exchange resin and highly-pure crystals thereof. According to the present invention, there is provided a production method of pyrroloquinoline quinone in the free form and highly-pure crystals thereof, wherein the production method comprises preparing a solution having a pH of 1.5 or less by dissolving an alkali metal salt of pyrroloquinoline quinone to obtain a precipitate.

Owner:MITSUBISHI GAS CHEM CO INC

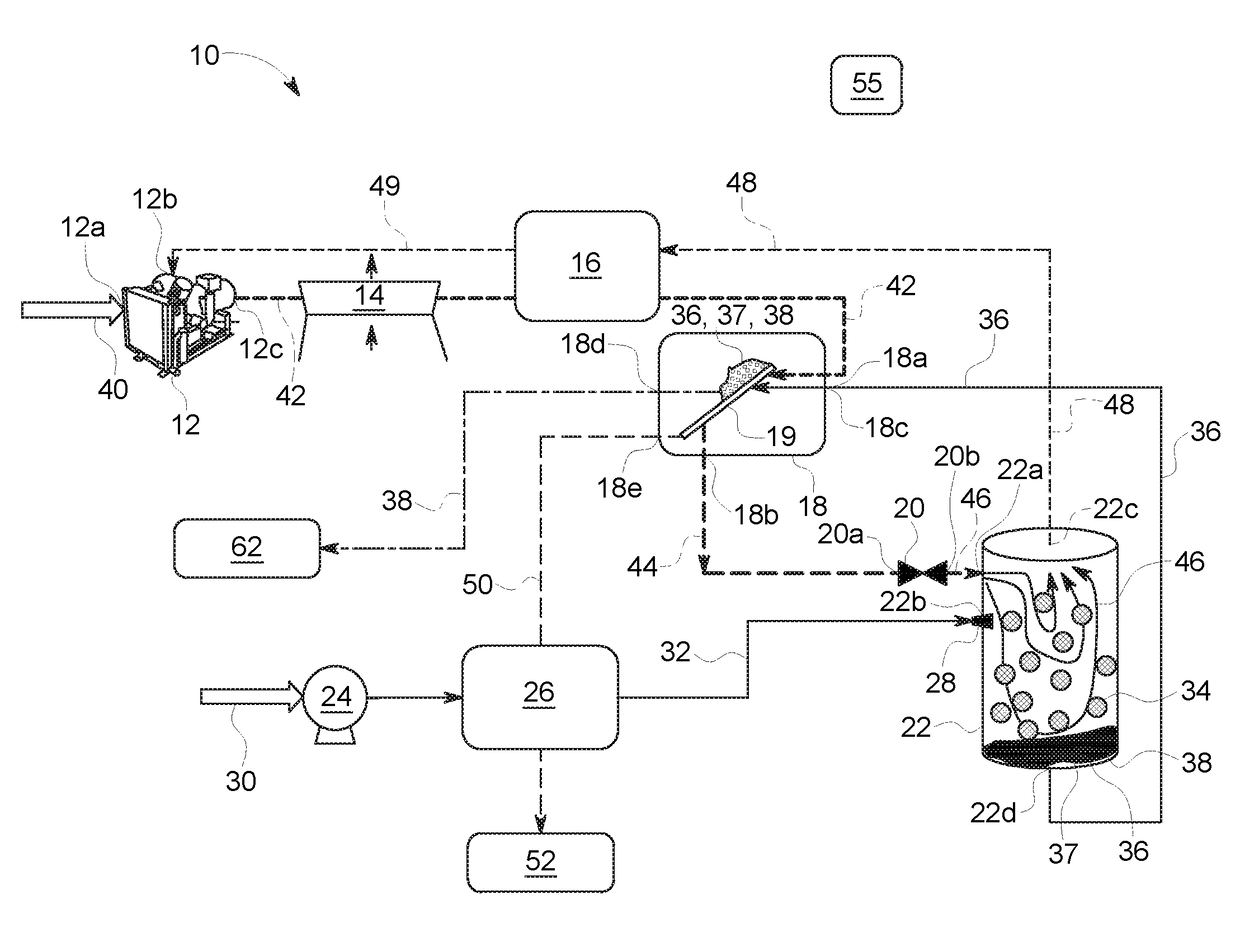

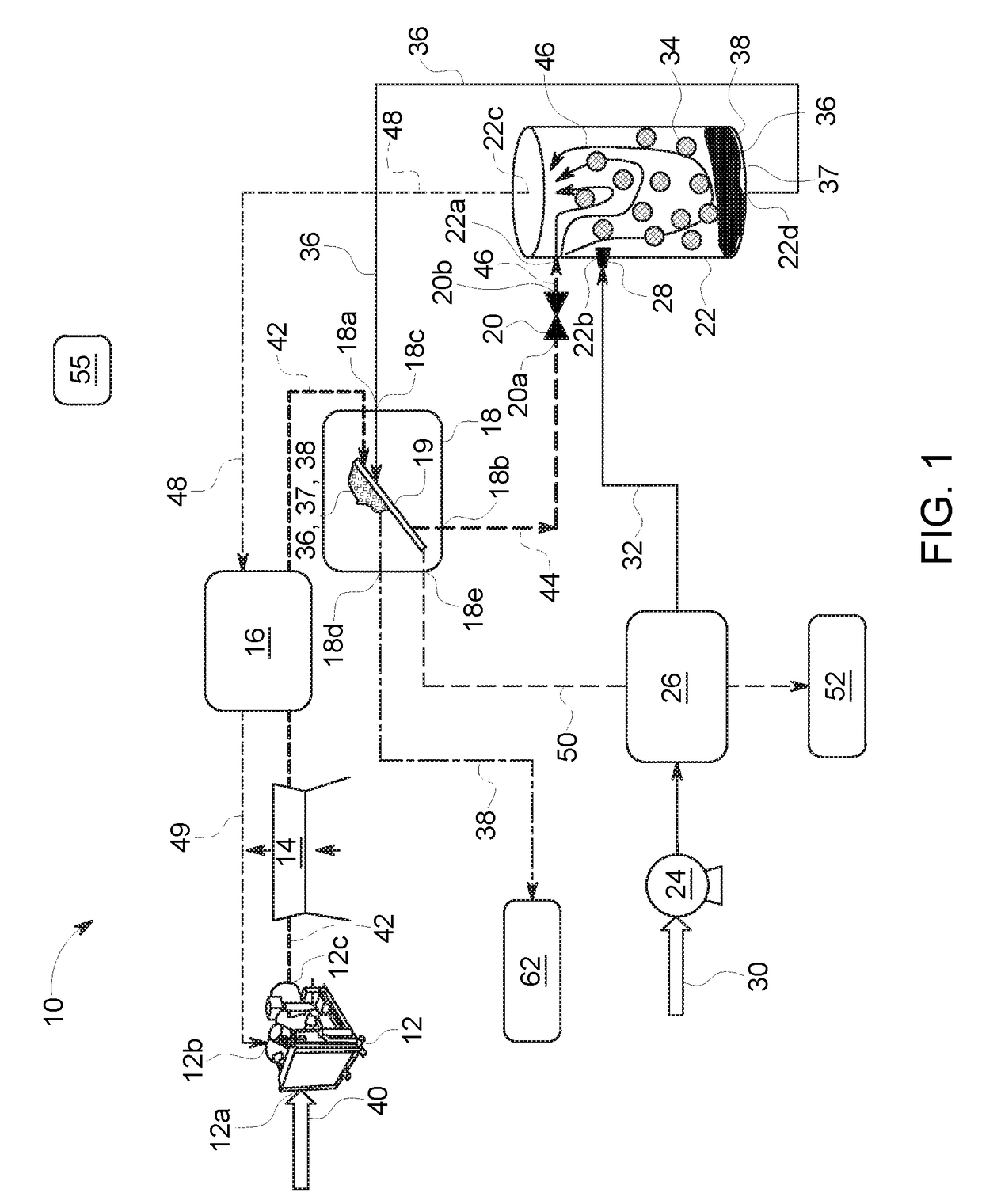

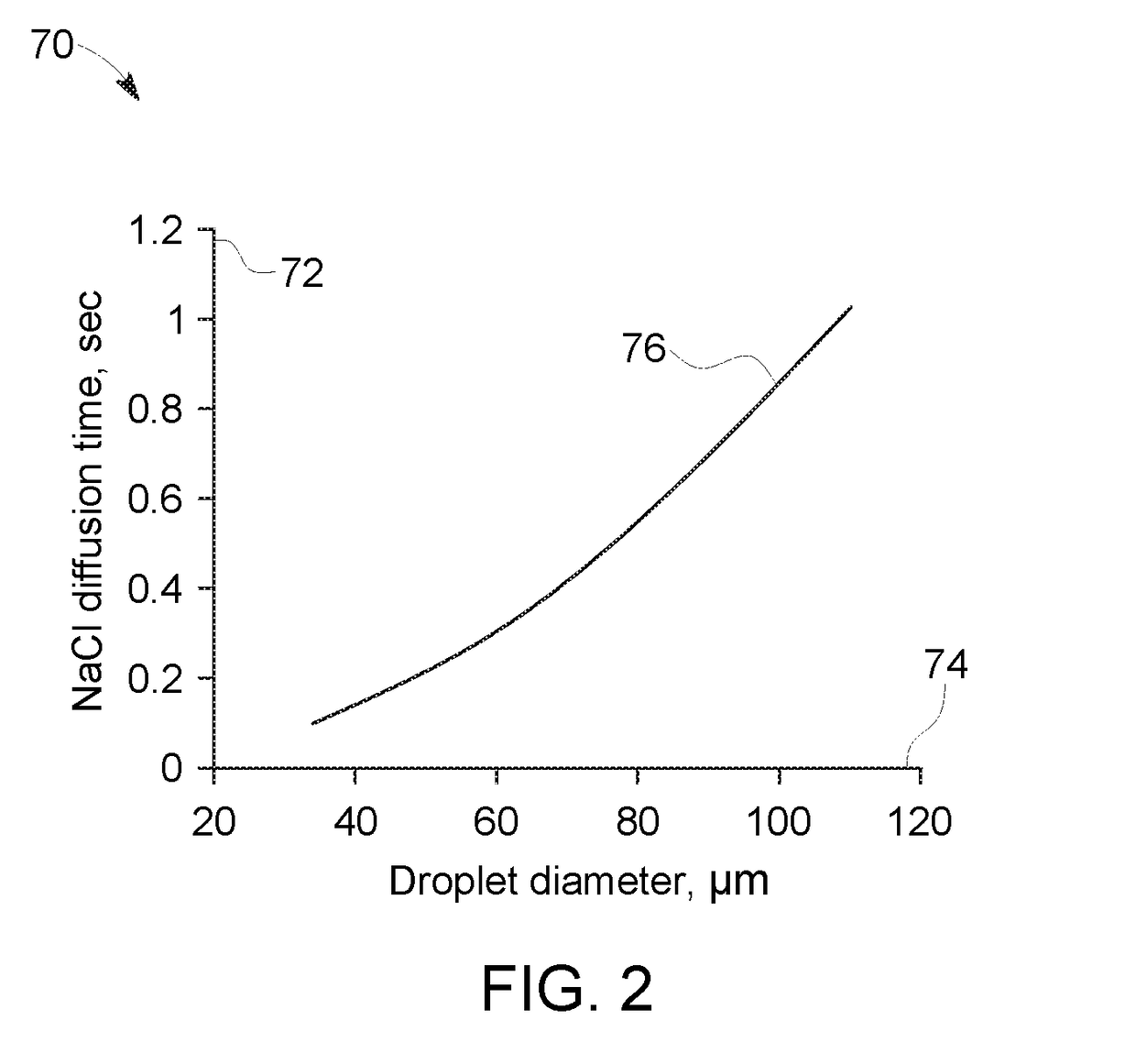

Water desalination system and method for fast cooling saline water using fast freeze process

InactiveUS20180141826A1General water supply conservationSeawater treatmentSaline waterWater desalination

A desalinating system and process is disclosed. The desalination system comprises using a freeze or fast-cooling process to freeze saline water droplets in a controlled manner that provides for diffusion of salt ions to a center of each frozen saline water droplet and formation of salt crystals surrounded by pure water crystals. The pure water crystals and salt crystals are subsequently separated in an ice melter using heat exchange to form a pure water stream.

Owner:GENERAL ELECTRIC CO

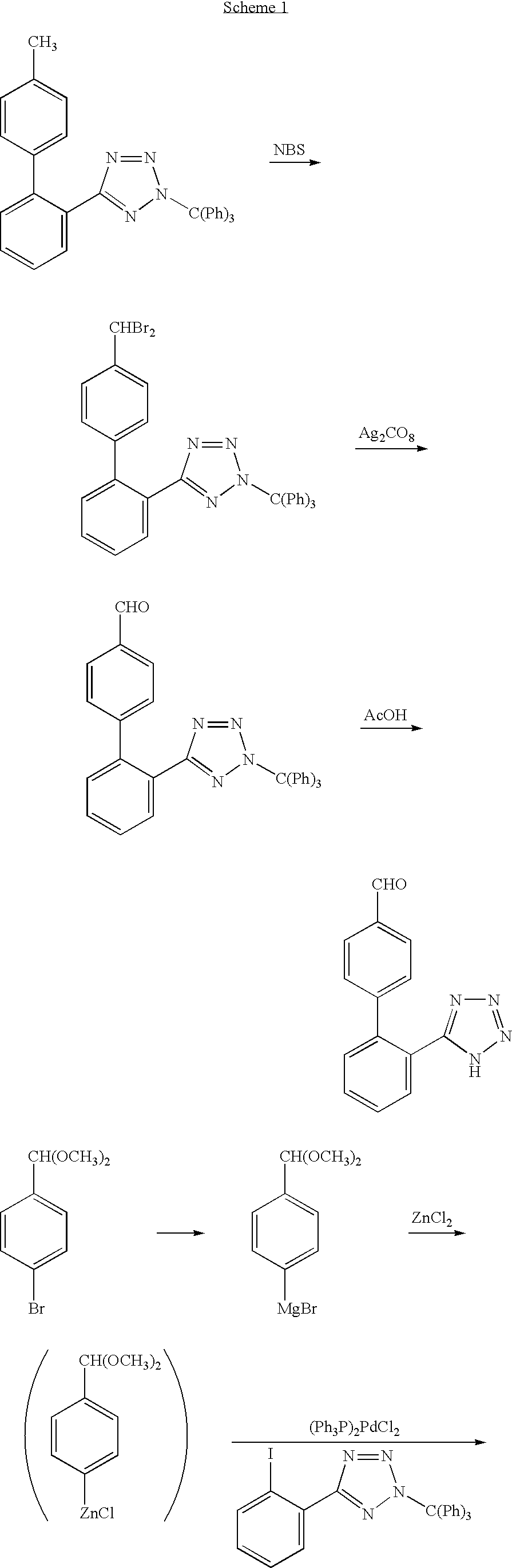

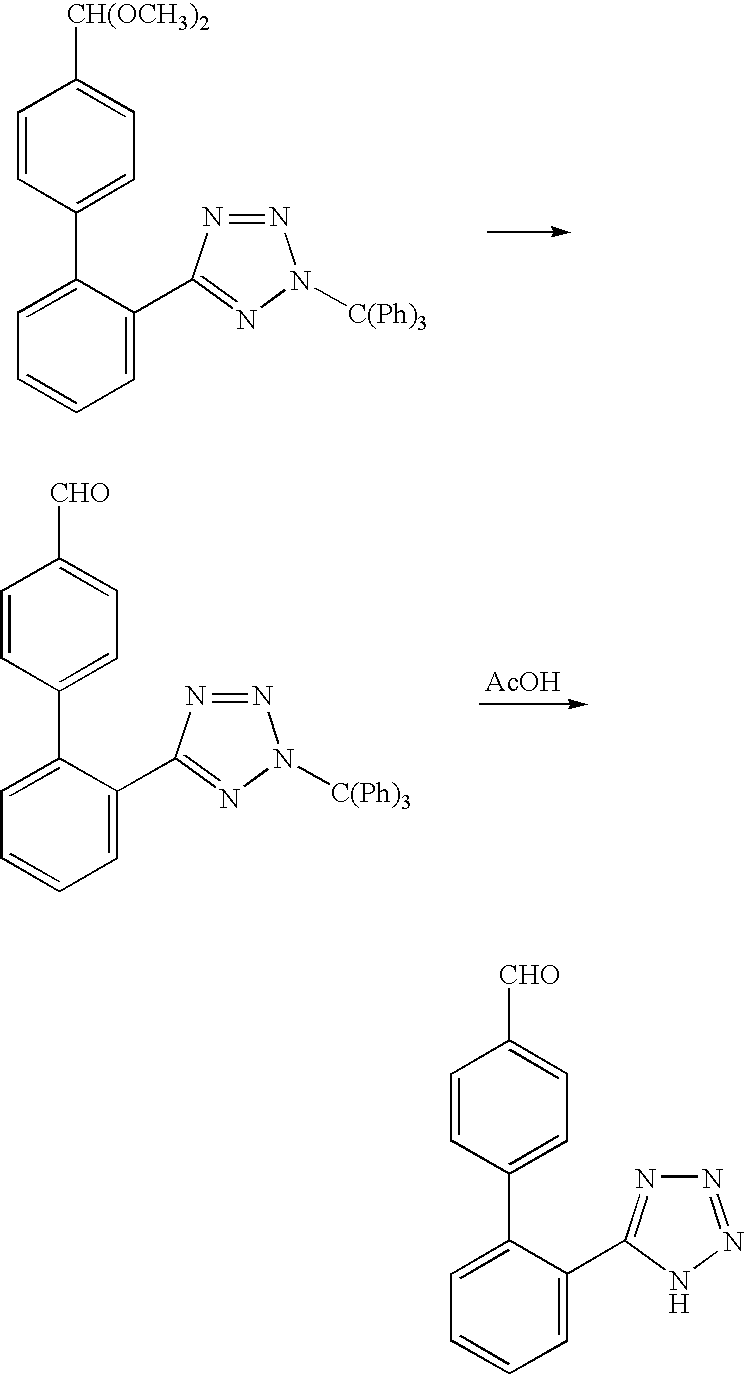

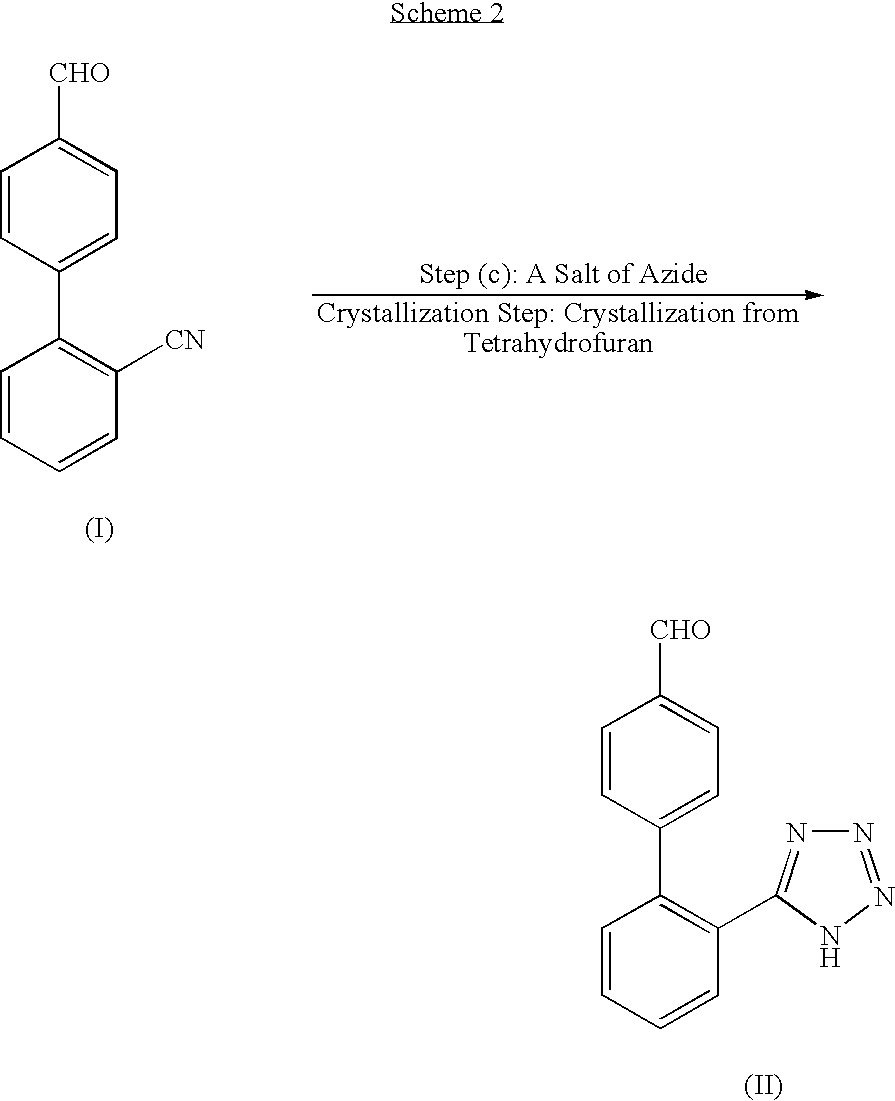

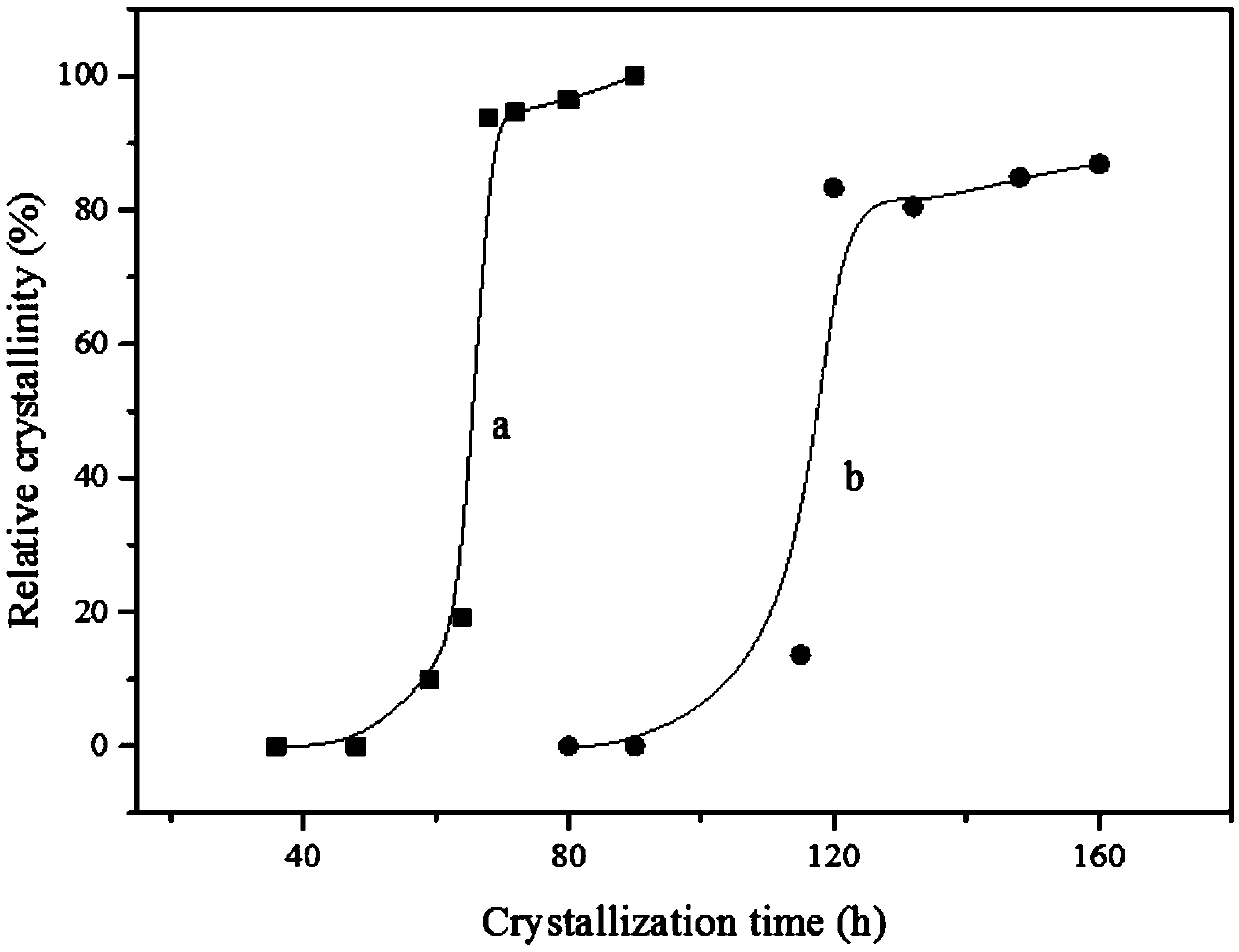

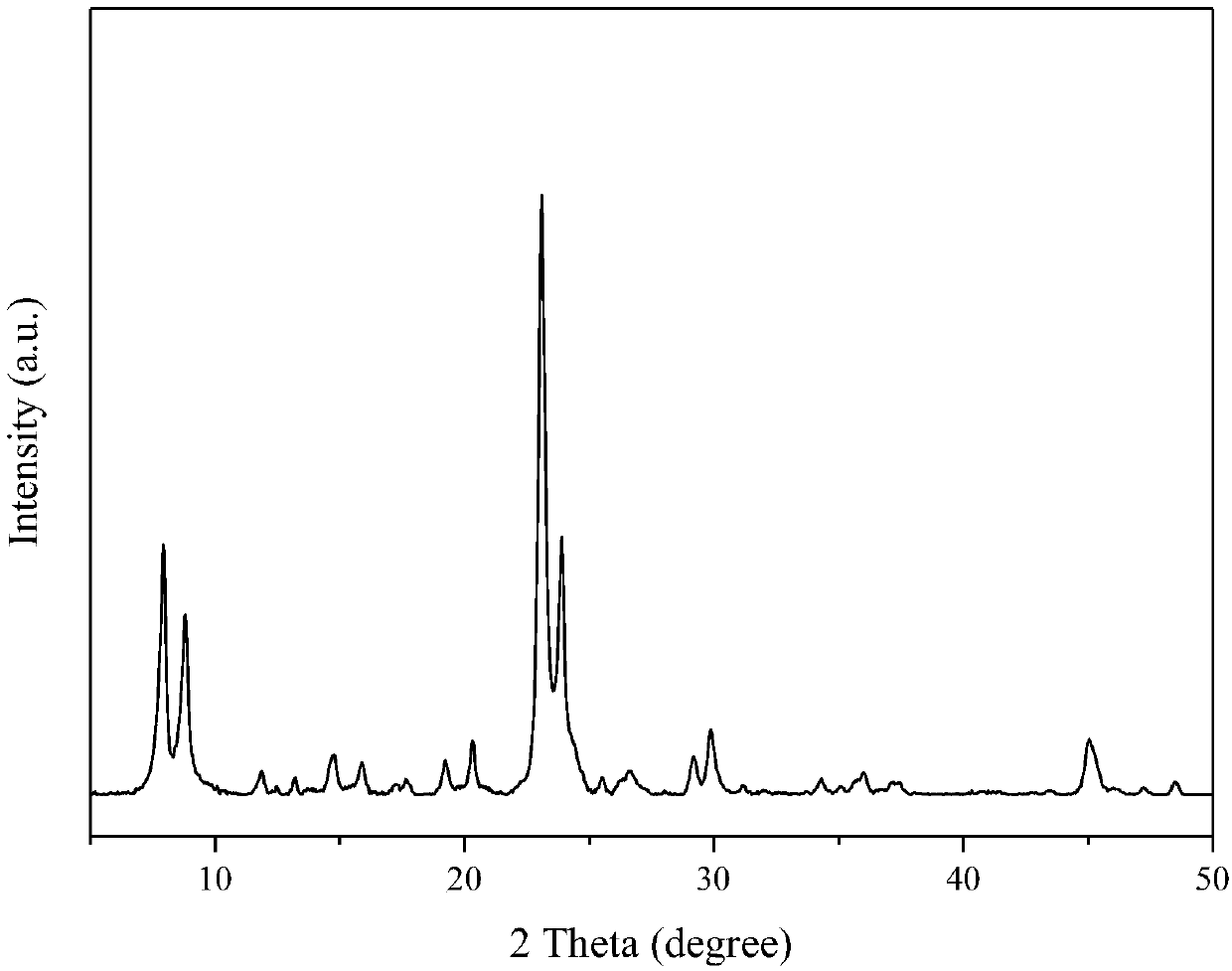

Process for producing 2'-(1h-tetrazol-5-yl)biphenyl-4-carbaldehyde

The present invention provides a process for producing 2′-(1H-tetrazol-5-yl)biphenyl-4-carbaldehyde which comprises reacting 2′-cyanobiphenyl-4-carbaldehyde with a salt of azide; a process for producing a highly pure crystal of 2′-(1H-tetrazol-5-yl)biphenyl-4-carbaldehyde which comprises reacting 2′-cyanobiphenyl-4-carbaldehyde with a salt of azide, obtaining a crystal of 2′-(1H-tetrazol-5-yl)biphenyl-4-carbaldehyde, dissolving said crystal obtained and recrystallizing a highly pure crystal in tetrahydrofuran; and the like. According to the present process, 2′-(1H-tetrazol-5-yl)biphenyl-4-carbaldehyde which is useful as a synthetic intermediate of medicines can be produced in a short process at high yield and high purity.

Owner:SUMITOMO CHEM CO LTD

Method for promoting synthesis of ZSM-11 molecular sieve

ActiveCN110817899AShort crystallization timeLower crystallization temperaturePentasil aluminosilicate zeoliteMolecular sieveIsopropyl

The invention provides a method for promoting the synthesis of a ZSM-11 molecular sieve. The method comprises the steps that a silicon source, an aluminum source, an inorganic base, a microporous templating agent and a crystal growth promoter R are sufficiently mixed, and obtained gel is subjected to short-time hydrothermal crystallization to rapidly prepare the ZSM-11 molecular sieve. The synthesis process is rapid, specifically, crystallizing is directly carried out at a suitable temperature for 10-90 hours, and the used crystal growth promoter is 2-pyrrolidone, N-methyl-2-pyrrolidone, N-ethyl-2-pyrrolidone, N-isopropyl-2-pyrrolidone or a mixture thereof. The ZSM-11 molecular sieve with high crystallinity, pure crystal phase, controllable particle size and wide range is quickly preparedby using the low-cost crystal growth promoter and through a one-step method, the method is instead of a traditional method to quickly obtain the ZSM-11 molecular sieve, and the method is an economicaland fast method to obtain the ZSM-11 molecular sieve.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

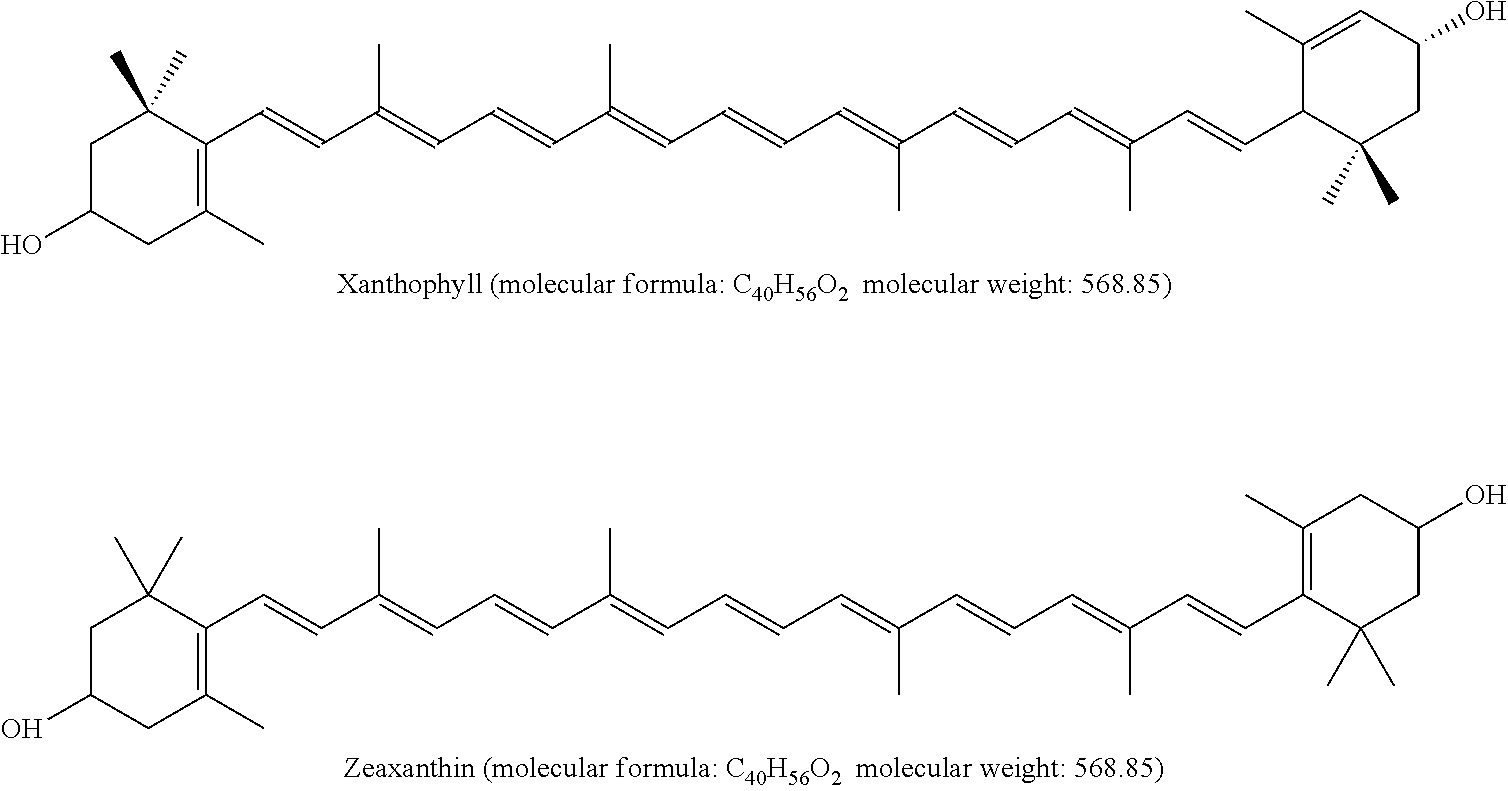

Preparing Method for Xanthophyll Crystals with Higher Content of Zeaxanthin from Plant Oleoresin

ActiveUS20120296126A1Reduce probabilityImprove solubilityPreparation by isomerisationOrganic compound preparationIsomerizationFiltration

The invention makes public a preparing method for xanthophyll crystals with higher content of zeaxanthin from plant oleoresin. The current methods generally are to get quite pure crystal forms of xanthophyll or zeaxanthin, and they refer to several separation steps. The invention mixes the xanthophyll diester-containing plant oleoresins and food grade alcohol solvents to form even solution, and then soap-dissolve the solution under an alkaline environment; then replenish organic solvents and emulsifiers into the reaction solution and drop some alkali solution into the solution to make partial xanthophyll crystals be transformed to be zeaxanthin through epimerization reaction; after the reaction is finished, add the mixed solvents of alcohol solvent and water to separate out the crystals; use the method of centrifugation or filtration to get the crystals; wash the crystals several times with the mixed solution of deionized water and alcohols to remove the impurities among the crystals; recrystallize the gained crystals with absolute ethyl alcohol, and then dry the crystals to get the products. The invention can gain mixture crystals that contain xanthophyll and zeaxanthin at one time in quite high collection rate, and it is convenient for the followed product application.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

Method for refining edoxaban

The invention belongs to the field of medicinal chemistry, and relates to a refined method for edoxaban. The crude edoxaban is first stirred and dissolved in an ethanol pure aqueous solution, then a mixed solution of ethers and ketones is added, and the mixture is stirred and crystallized; Washing, vacuum drying to obtain pure edoxaban crystals, the yield is over 90%, the purity (HPLC) reaches 99.4%, and the impurities are reduced to about 0.1%.

Owner:TIANJIN HANKANG PHARMA BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com