High-salt-content organic waste water treatment system and method

A technology for organic wastewater treatment and organic wastewater, applied in multi-stage water treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve problems such as difficult to handle, aggravate the economic burden of enterprises, and secondary pollution of the environment, and achieve easy Achieve the effect of good water quality and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

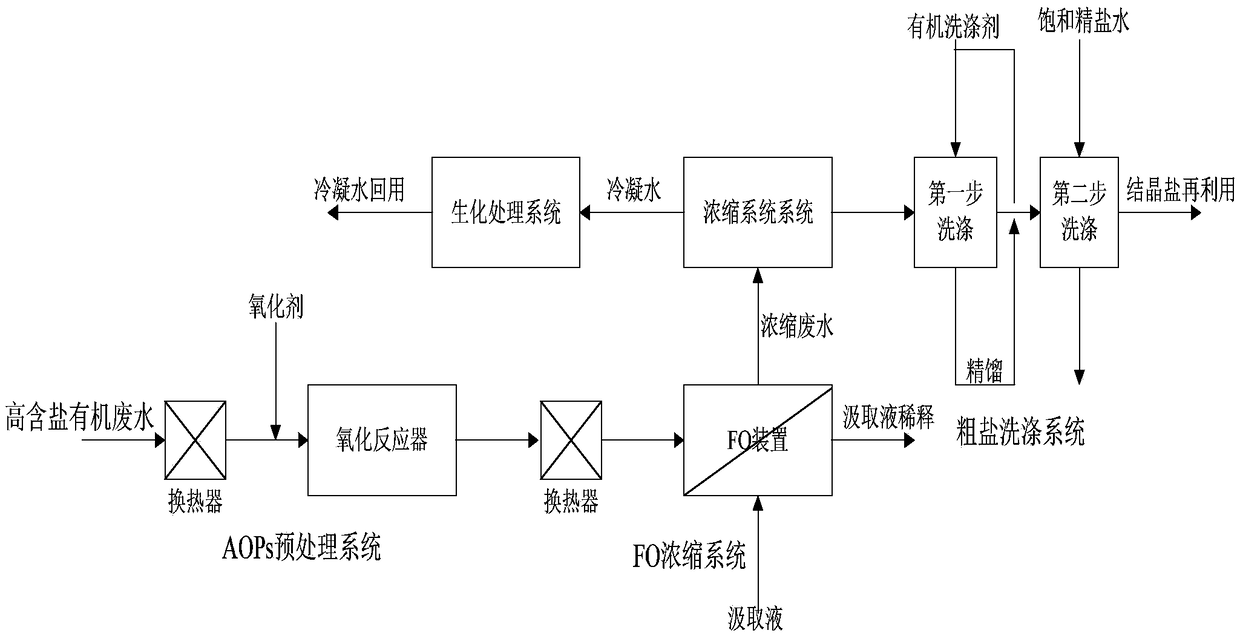

[0080] The water quality of hydrazine hydrate wastewater produced by an enterprise is shown in Table 1. In this example, AOPs pretreatment system, FO concentration system, concentration crystallization system, coarse salt washing system and biochemical treatment system were selected.

[0081] Such as Figure 4 As shown, the method includes the following steps:

[0082] (1) Utilize hydrochloric acid (volume fraction 31%) to adjust the pH of the hydrazine hydrate wastewater of pH=12 at 4, control the hydrazine hydrate wastewater flow rate at 40m 3 / h enters the plate heat exchanger, and the waste water is heated by 0.4MPa steam and controlled at 65°C.

[0083] (2) The waste water is sent to the AOPs pretreatment system after heat exchange. The AOPs pretreatment system uses a UV oxidation reactor, in which the wavelength of the ultraviolet lamp is 400nm, and the number of ultraviolet lamps in the equipment is 3. According to the ratio of 1.5 times of the COD value in the waste...

Embodiment 2

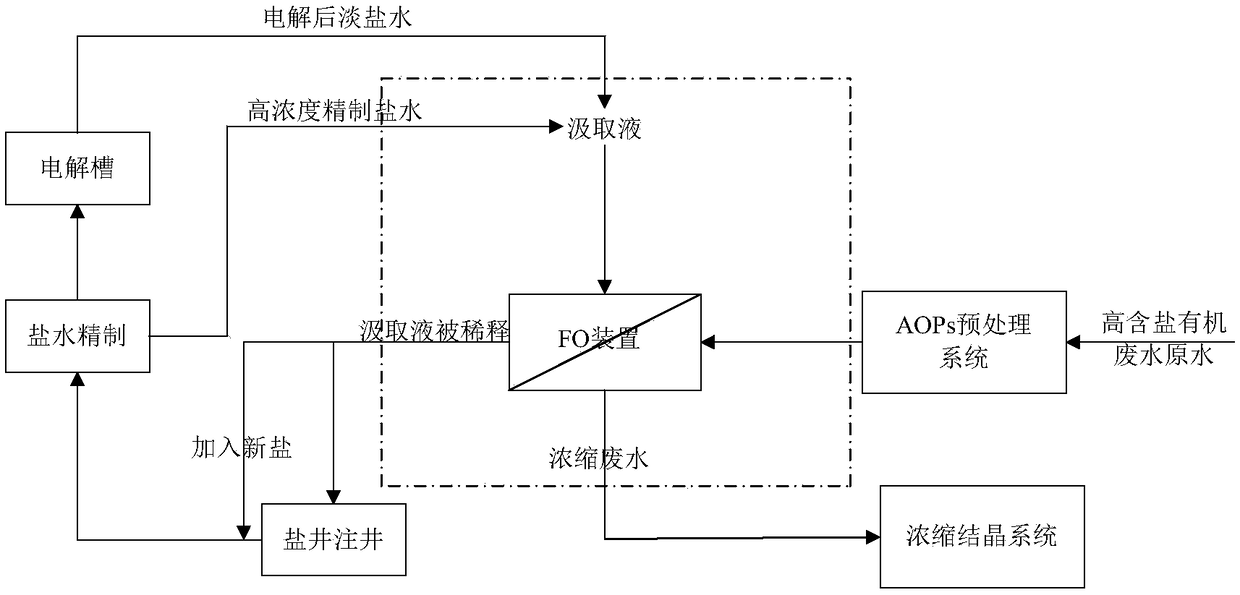

[0094] Table 2 shows the water quality of wastewater after mercury removal in a calcium carbide process PVC production process in a factory. In this embodiment, AOPs pretreatment system, FO concentration system, concentration and crystallization system, coarse salt washing system are selected. Wastewater treatment process such as Figure 5 shown. Include the following steps:

[0095] (1) The wastewater has a pH of 8, enters the plate heat exchanger at 5t / h, heats the wastewater through 0.3MPa steam and maintains it at 75°C, and enters the AOPs pretreatment system after heating.

[0096] (2) The AOPs pretreatment system of this embodiment adopts a UV oxidation reactor, wherein the wavelength of the ultraviolet lamp is 180nm, and the number of ultraviolet lamps in the equipment is 2. According to the ratio of 5 times of the COD value in the wastewater, the oxidant is introduced, and the oxidant is selected as 30% H 2 o 2 solution, H 2 o 2 (30%) solution is added in the wa...

Embodiment 3

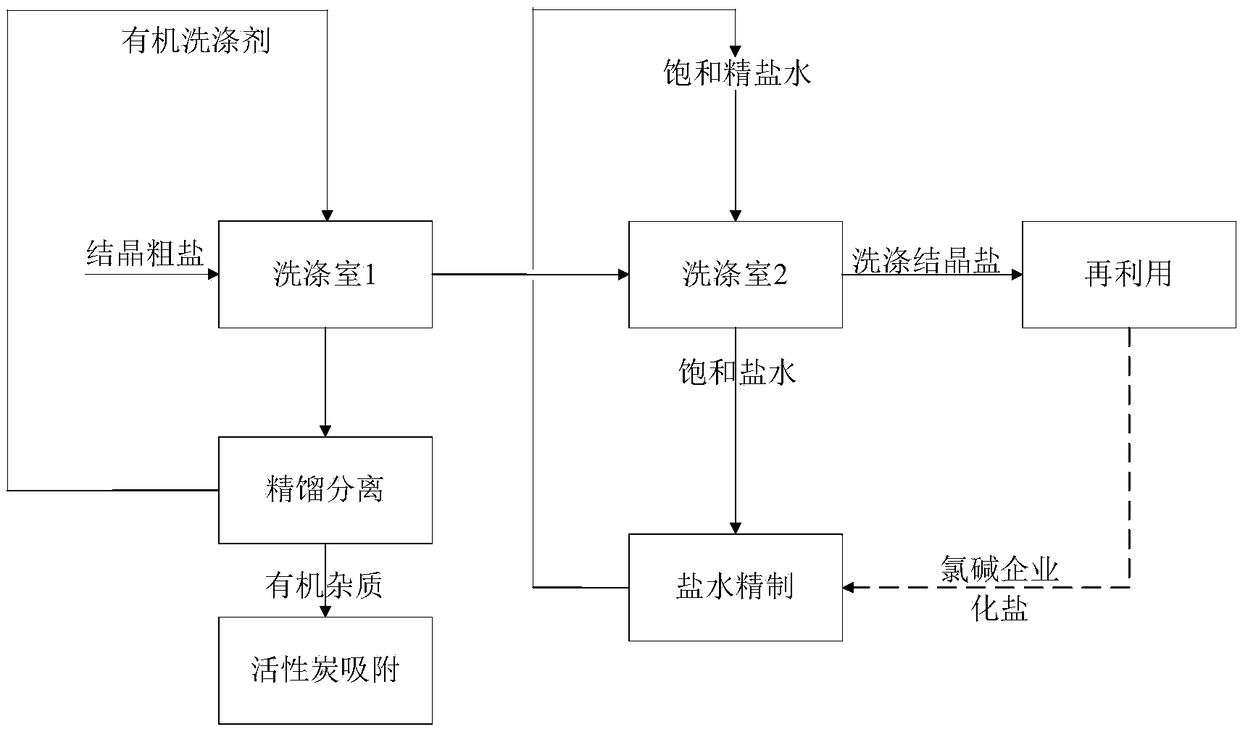

[0107] Table 3 shows the water quality of diphenylmethane diisocyanate (MDI) wastewater produced by a polyurethane company. In this embodiment, only AOPs pretreatment system and FO concentration system are selected. Wastewater treatment process such as Figure 6 shown. Include the following steps:

[0108] (1) Use high-purity hydrochloric acid (31%) to adjust the pH value of MDI wastewater to 6, and raise the temperature of the wastewater to 70°C through a plate heat exchanger, and enter the AOPs pretreatment system after heating.

[0109] (2) MDI waste water is 10m 3 / h enters the AOPs pretreatment system, and the AOPs pretreatment system uses a UV oxidation reactor, in which the wavelength of the ultraviolet lamp is 150nm, and the number of ultraviolet lamps in the equipment is 2. The temperature of the UV reactor is maintained at 80°C, and the reaction time is 60 minutes. The oxidant is fed in a ratio of 3 times the COD value in the wastewater. The oxidant is ozone, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com