Method for promoting synthesis of ZSM-11 molecular sieve

A ZSM-11, molecular sieve technology, applied in the field of catalytic chemistry, to achieve the effects of high crystallinity, short crystallization time and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

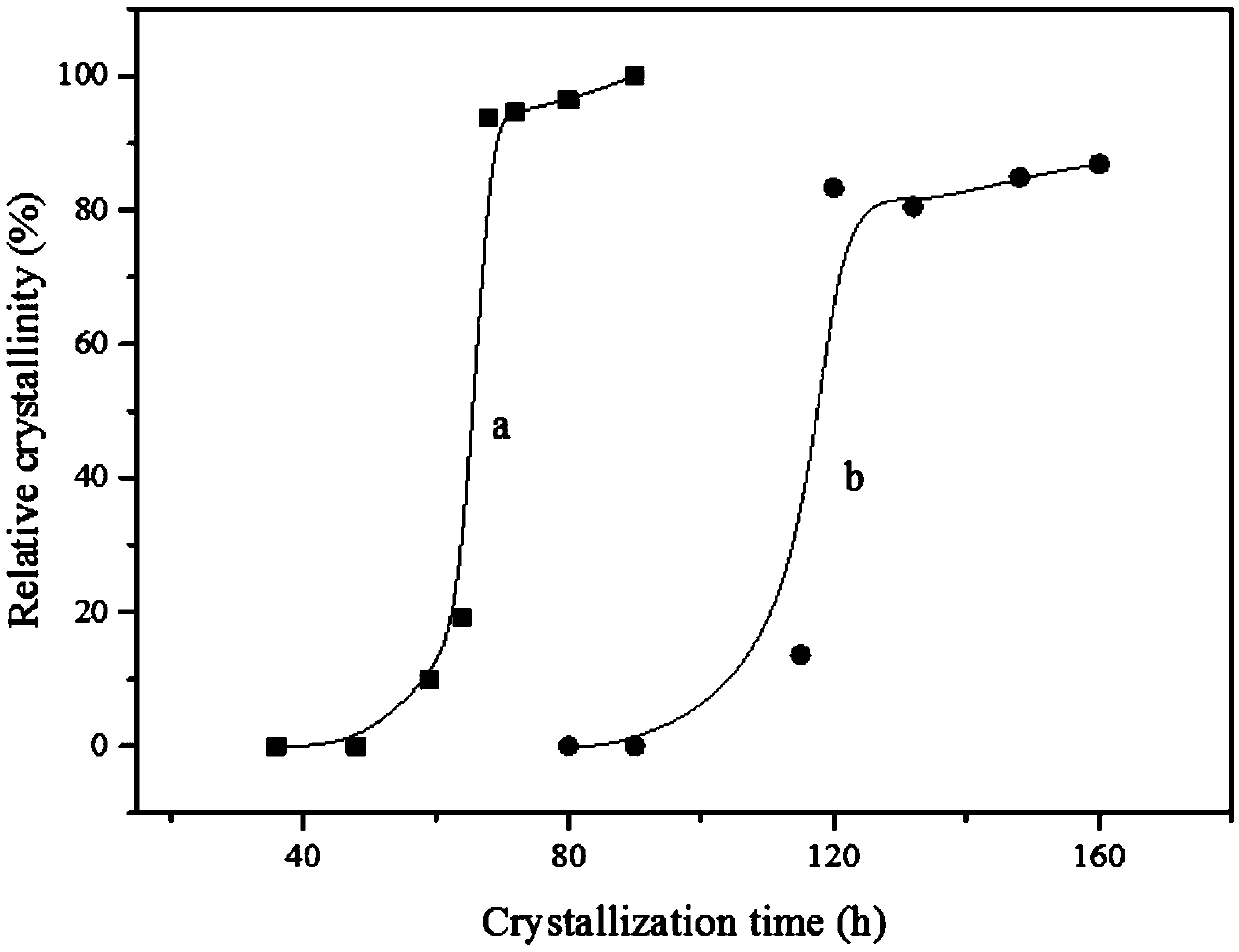

[0033] Under stirring conditions, 9.83g silica sol (30.57wt.% SiO 2 , 0.327wt.% Na 2 O, 0.033wt.%Al 2 o 3 , 6 9.01wt.%H 2 O), 0.54g aluminum sulfate (≥99wt.%), 0.58g sodium hydroxide (96.0wt.%NaOH), 3.22g tetrabutylammonium bromide (TBABr, purity≥99wt.%), 7.51g N-methyl Base-2-pyrrolidone (NMP, ≥99wt.%) and 28.90 g of deionized water were added to the reaction kettle in a certain order. The molar composition of the raw material mixture is: SiO 2 / Al 2 o 3 =60,Na 2 O / SiO 2 = 0.15, TBA + / SiO 2 =0.2,H 2 O / SiO 2 =40, NMP / SiO 2 = 1.5. Stir for 10 minutes to make it fully mixed and seal the synthesis kettle. Directly crystallize dynamically (40 rpm) at 130°C for 0-90h. The reaction was quenched with tap water and centrifuged to obtain a solid product. Then wash with deionized water until neutral. Dry overnight at 120°C to obtain molecular sieve powder. figure 1 (a) is the change curve of the crystallinity of the crystallized product with the crystallization time....

Embodiment 2

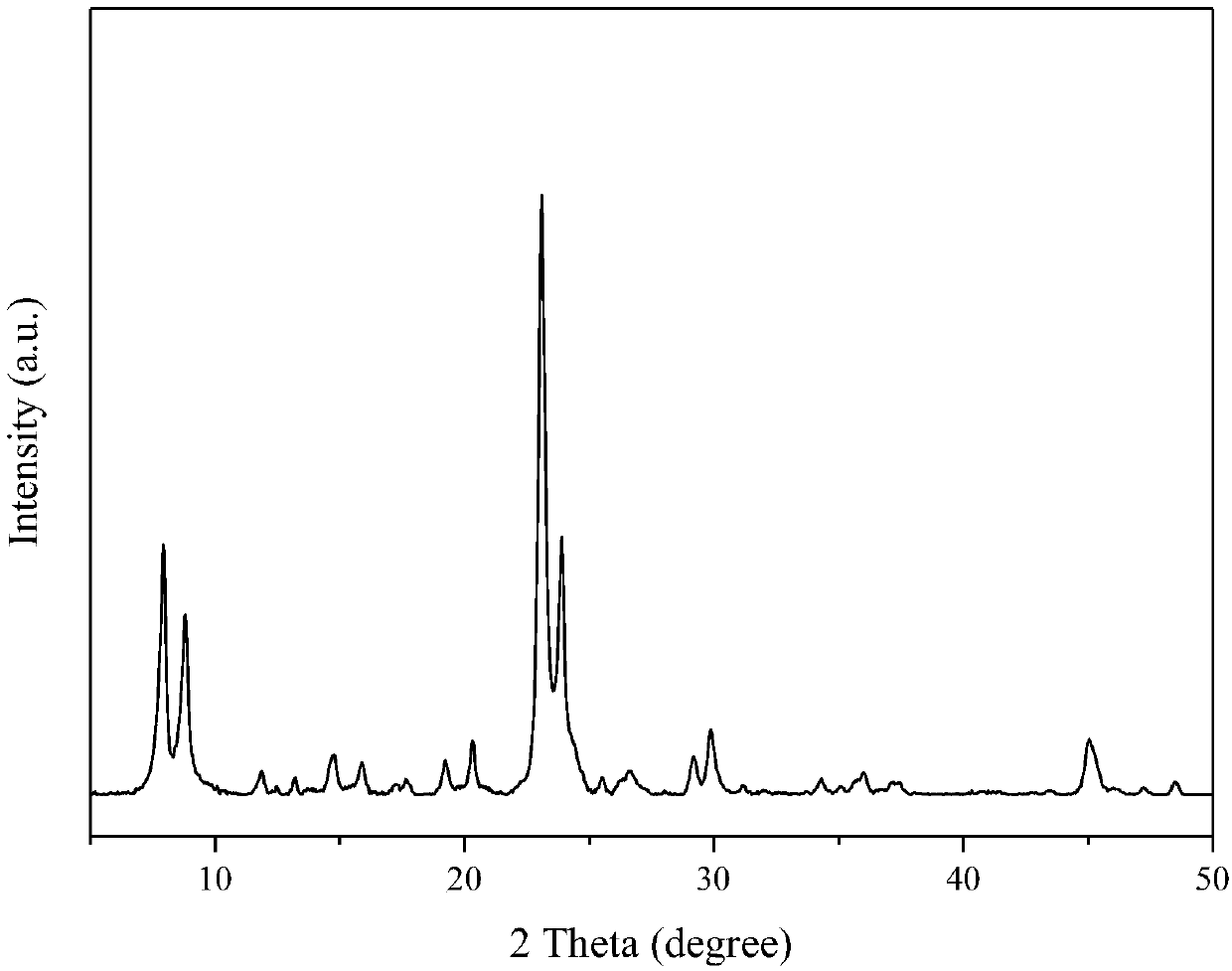

[0037] In embodiment 1, silica sol is changed into white carbon black, aluminum sulfate is changed into aluminum powder, sodium hydroxide is changed into potassium hydroxide (≥99wt.%), tetrabutylammonium bromide is changed into tetrabutyl chloride Aqueous ammonium solution (purity ≥ 35wt.%) is added to the reactor in the same order under stirring conditions, and the molar composition of the raw material mixture is: SiO 2 / Al 2 o 3 =100,K 2 O / SiO 2 = 0.2, TBA + / SiO 2 =0.4, NMP / SiO 2 = 2.0, H 2 O / SiO 2 =15. Stir for 30 minutes to make it fully mixed and seal the synthesis kettle. Directly crystallize dynamically (30 rpm) at 150°C for 25h. The reaction was quenched with tap water and centrifuged to obtain a solid product. Then wash with deionized water until neutral. Dry overnight at 120°C to obtain molecular sieve powder. The XRD spectrum pattern of gained ZSM-11 product and figure 2 Similarly, the particle size is about 0.6um.

Embodiment 3

[0039] In embodiment 1, silica sol is changed into orthosilicate ethyl ester (≥99wt.%), aluminum sulfate is changed into aluminum chloride (≥99wt.%), tetrabutylammonium bromide is changed into tetrabutylammonium hydroxide, N-methyl-2-pyrrolidone is changed to N-ethyl-2-pyrrolidone (NEP, ≥99wt.%), and under stirring conditions, it is added to the reactor in the same order, and the molar composition of the raw material mixture is: SiO 2 / Al 2 o 3 =80,Na 2 O / SiO 2 = 0.4, TBA + / SiO 2 =0.1, NEP / SiO 2 = 1.0, H 2 O / SiO 2 =30. Stir for 30 minutes to make it fully mixed and seal the synthesis kettle. Directly crystallize dynamically (20 rpm) at 170°C for 18h. The reaction was quenched with tap water and centrifuged to obtain a solid product. Then wash with deionized water until neutral. Dry overnight at 120°C to obtain molecular sieve powder. The XRD spectrum pattern of gained ZSM-11 product and figure 2 Similarly, the particle size is about 0.7um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com