Method for promoting Beta molecular sieve synthesis

A molecular sieve and accelerator technology, applied in the field of catalytic chemistry, can solve the problems of low product yield, cumbersome preparation process, low preparation reproducibility, etc., and achieve the effects of excellent catalytic performance, simple preparation method and low crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Under stirring conditions, 5.3g of white carbon black (95.0wt.% SiO 2 , 5.0wt.%H 2 O), 0.4g sodium aluminate (49.0wt.%Al 2 o 3 , 38.0 wt.% Na 2 O, 13.0 wt.% H 2 O), 0.13g sodium hydroxide (96.0wt.% NaOH), 22.3g tetraethylammonium hydroxide aqueous solution (TEAOH, purity ≥ 35wt.%), 16.7g N-methyl-2 pyrrolidone (NMP, ≥ 99wt. %), 9g deionized water are added in the reactor in a certain order. The molar composition of the raw material mixture is: SiO 2 / Al 2 o 3 =43.5,Na 2 O / SiO 2 = 0.048, TEA + / SiO 2 =0.636, NMP / SiO 2 = 2.0, H 2 O / SiO 2=16. Stir for 30 minutes to make it fully mixed and seal the synthesis kettle. Directly crystallize dynamically (30 rpm) at 140°C for 0-60h. The reaction was quenched with tap water and centrifuged to obtain a solid product. Then wash with deionized water until neutral. Dry overnight at 80°C to obtain molecular sieve powder.

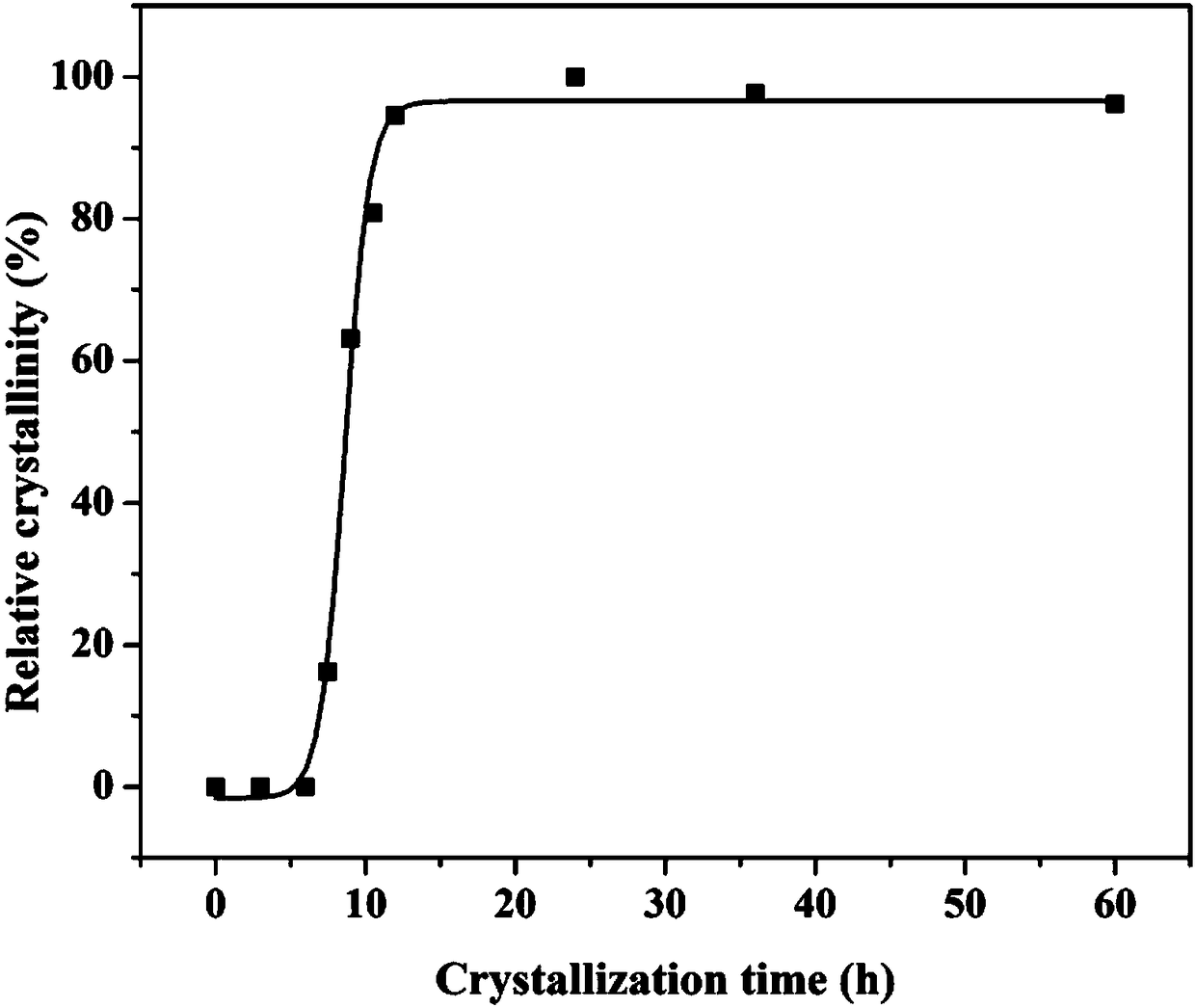

[0037] figure 1 It is the change curve of the crystallinity of the crystallization product wi...

Embodiment 2

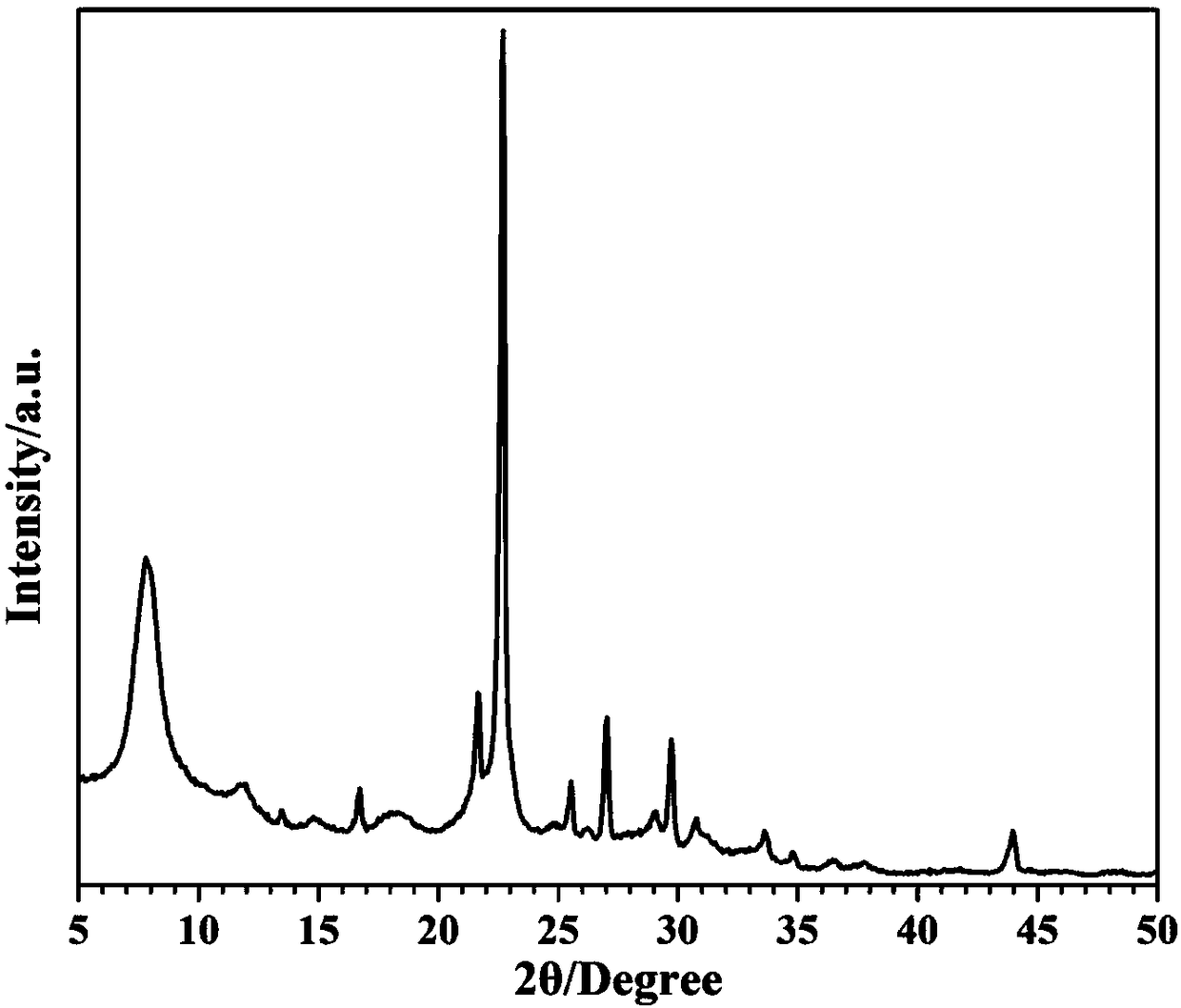

[0043] Under stirring condition, 19.5g water glass (26wt.%SiO 2 , 8.2 wt.% Na 2 O, 65.8 wt.% H 2 O), 5.6g aluminum sulfate (≥99wt.%), 1.9g potassium hydroxide (≥99wt.%), 25g tetraethylammonium chloride aqueous solution (TEACl, purity ≥35wt.%), 16.7g N-methyl -2 Pyrrolidone is added to the reaction kettle in a certain order. The molar composition of the raw material mixture is: SiO 2 / Al 2 o 3 =10,K 2 O / SiO 2 = 0.2, TEA + / SiO 2 =0.636, NMP / SiO 2 = 2.0, H 2 O / SiO 2 =16. Stir for 30 minutes to make it fully mixed and seal the synthesis kettle. Directly crystallize dynamically (100 rpm) at 95°C for 60h. The reaction was quenched with tap water and centrifuged to obtain a solid product. Then wash with deionized water until neutral. Dry overnight at 80°C to obtain molecular sieve powder. The XRD spectrum pattern of gained Beta product and figure 1 Similar, the particle size is about 346nm, N 2 The BET surface area of the adsorption and desorption test is 721m ...

Embodiment 3

[0045] Under stirring conditions, mix 17.4g ethyl orthosilicate (≥99wt.%), 0.2g aluminum chloride (≥99wt.%), 2.7g sodium hydroxide, 3.5g tetraethylammonium hydroxide aqueous solution, 9.5g N-ethyl-2-pyrrolidone (NEP, ≥99wt.%) and 9 g of deionized water were added into the reaction kettle in a certain order. The molar composition of the raw material mixture is: SiO 2 / Al 2 o 3 =200,Na 2 O / SiO 2 = 0.4, TEA + / SiO 2 =0.1, NEP / SiO 2 = 1.0, H 2 O / SiO 2 =16. Stir for 30 minutes to make it fully mixed and seal the synthesis kettle. Directly crystallize dynamically (80 rpm) at 120°C for 18h. The reaction was quenched with tap water and centrifuged to obtain a solid product. Then wash with deionized water until neutral. Dry overnight at 80°C to obtain molecular sieve powder. The XRD spectrum pattern of gained Beta product and figure 1 Similar, the particle size is about 389nm, N 2 The BET surface area of the adsorption and desorption test is 692m 2 / g, the total pore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com