Patents

Literature

201 results about "Linear channel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

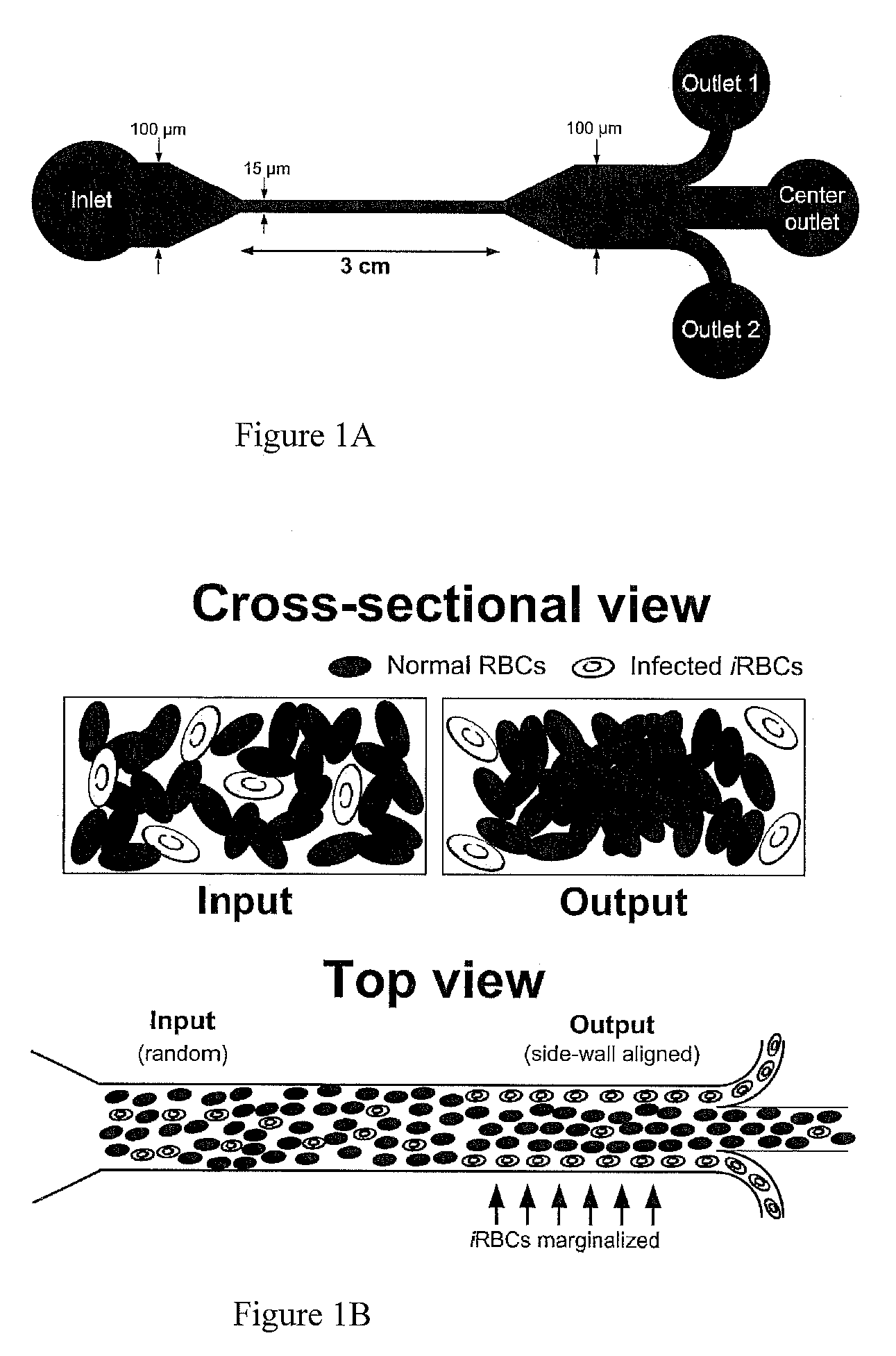

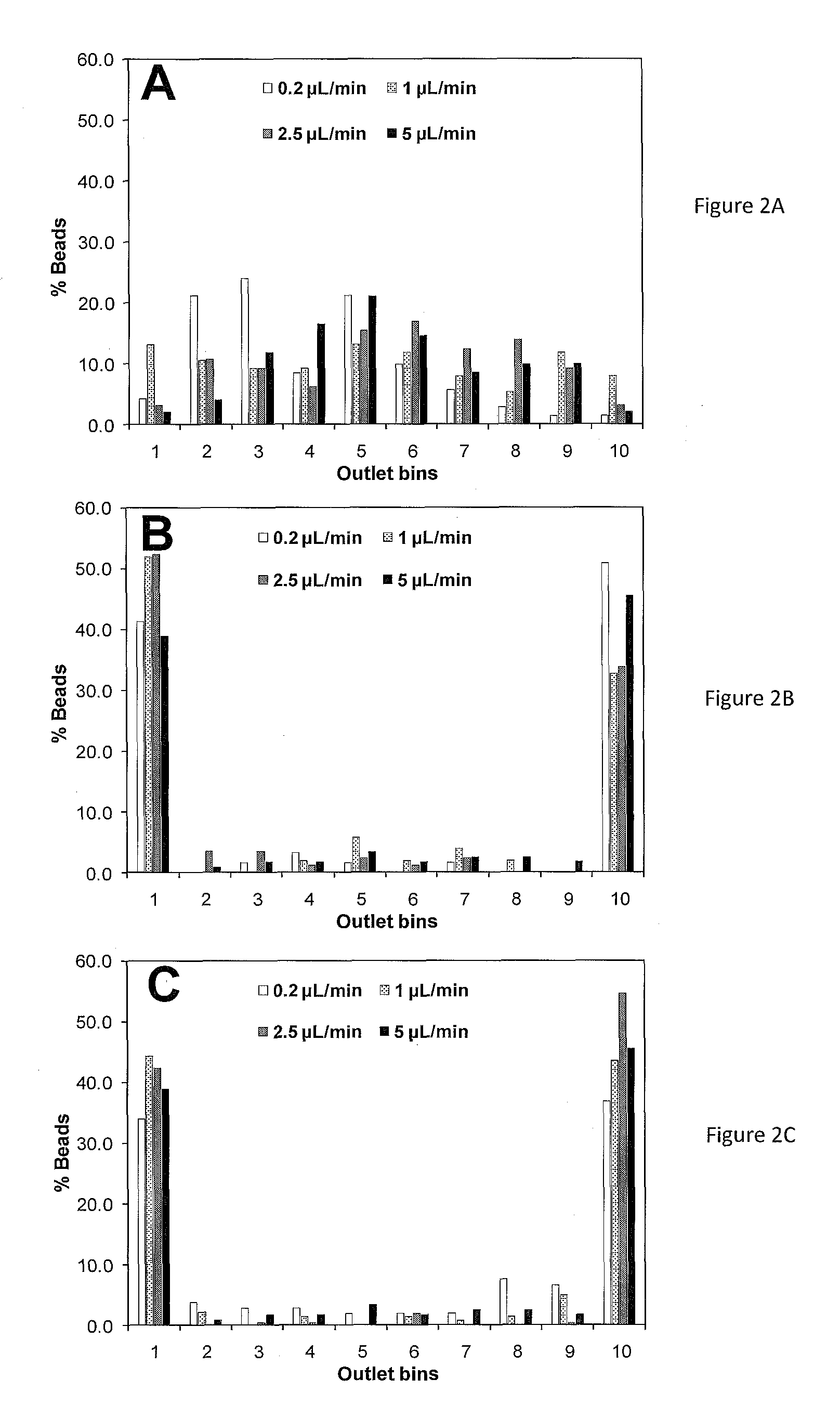

Microfluidics Sorter For Cell Detection And Isolation

ActiveUS20130130226A1Easy to handleLow costMicrobiological testing/measurementLaboratory glasswaresMicrofluidicsCell based

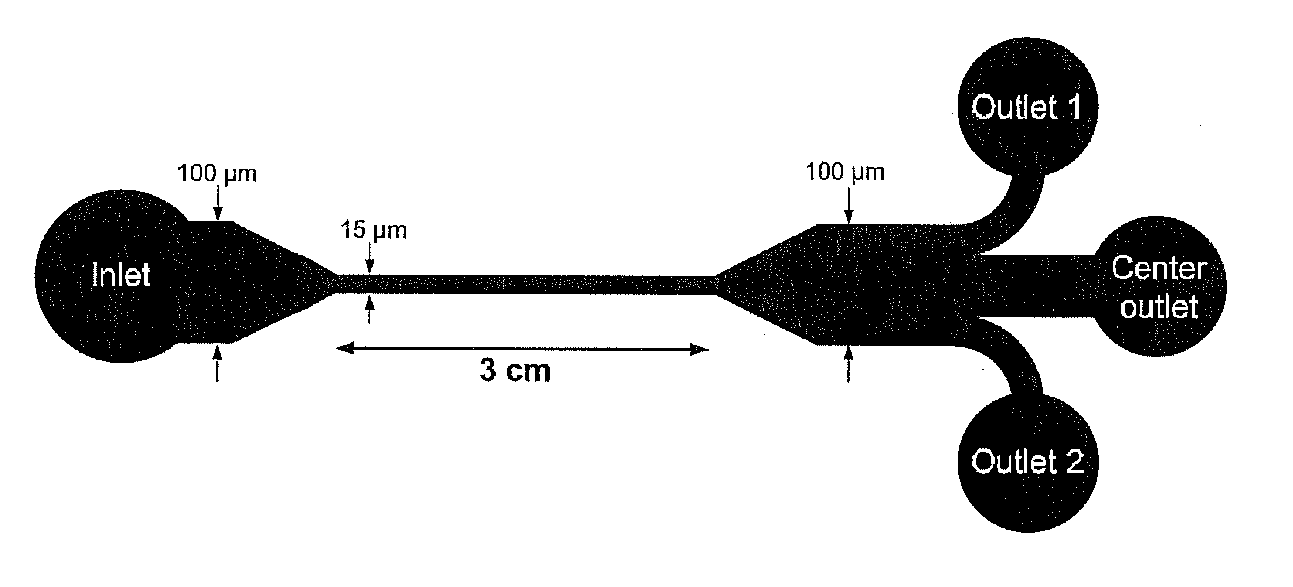

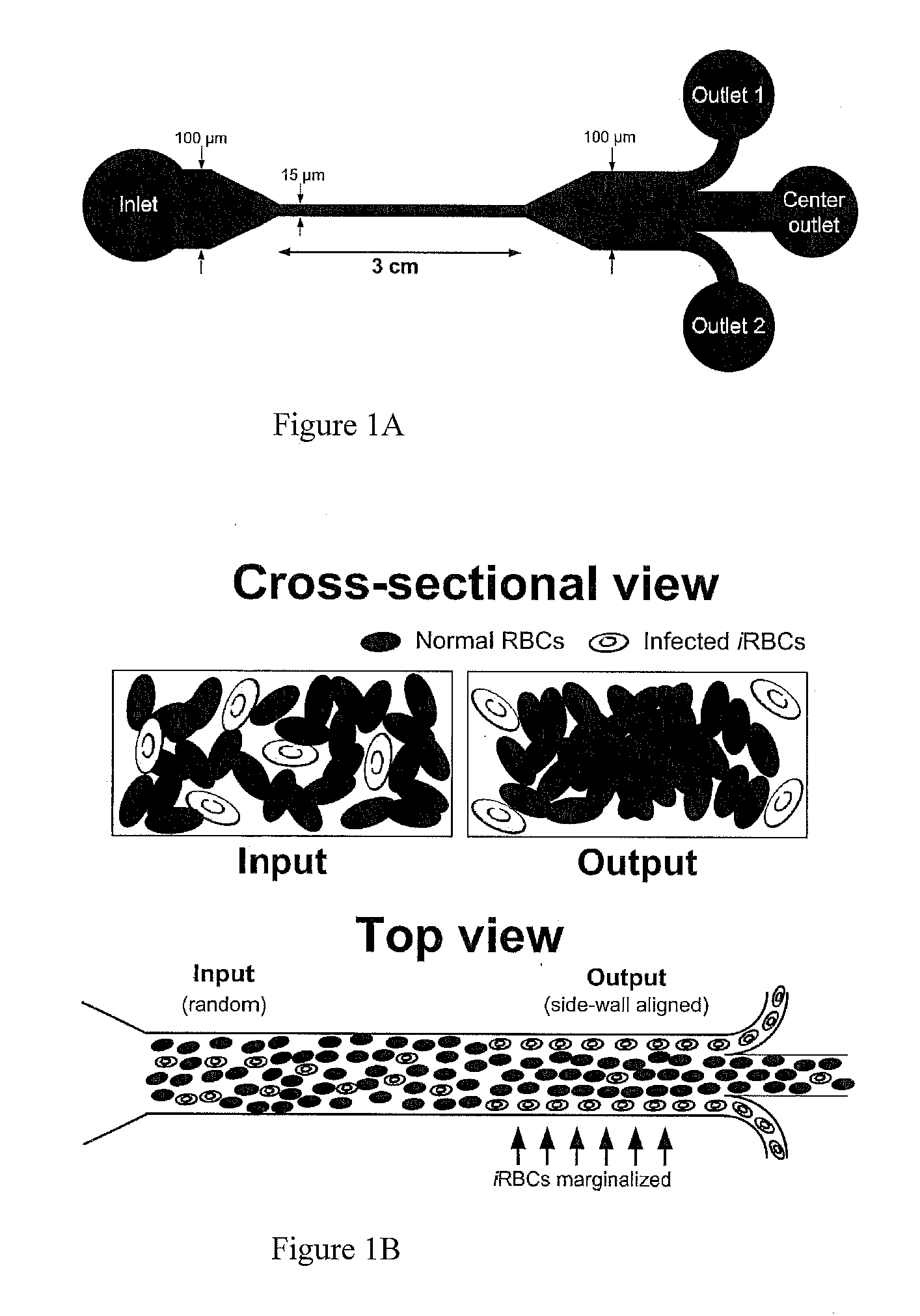

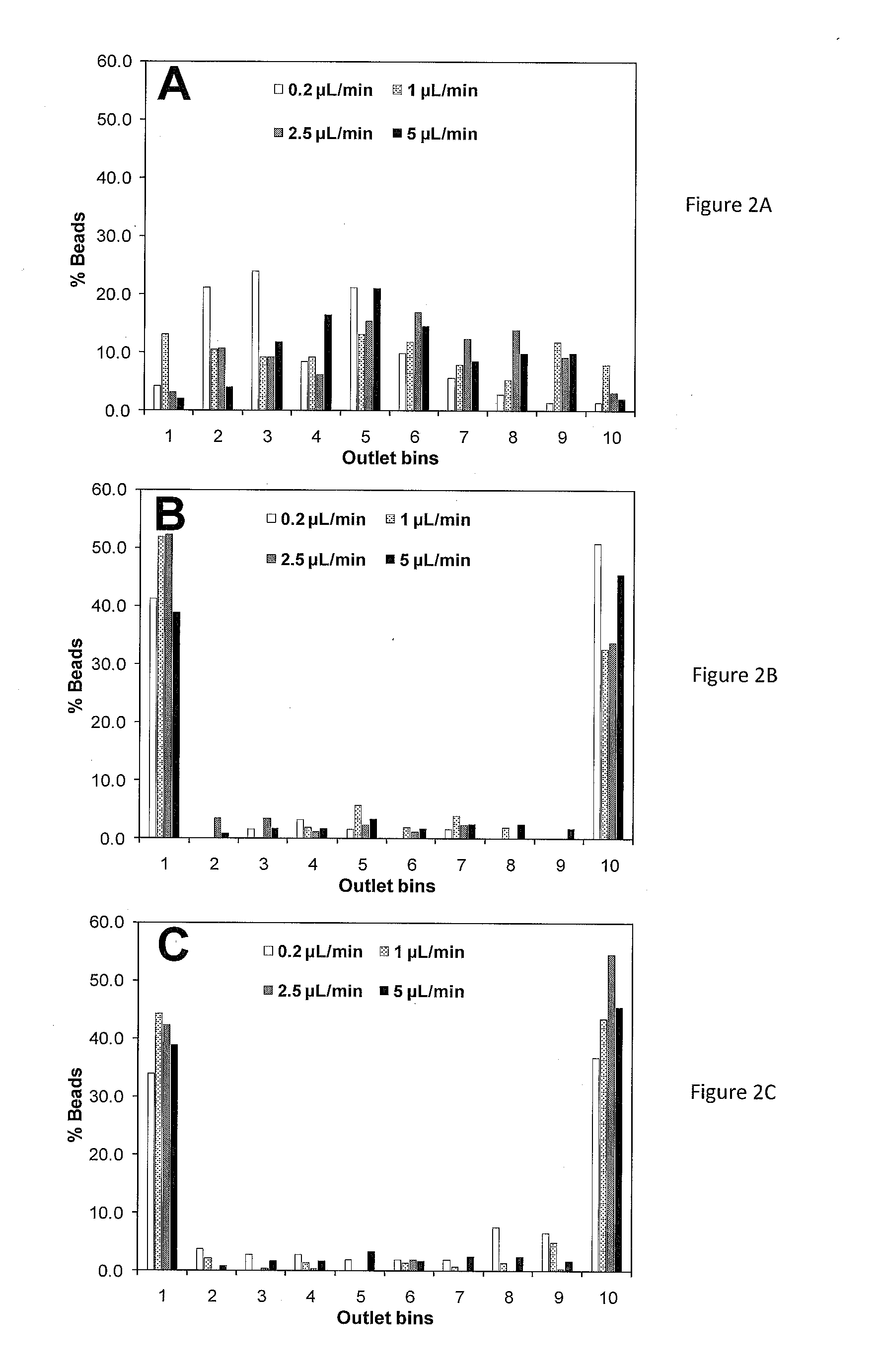

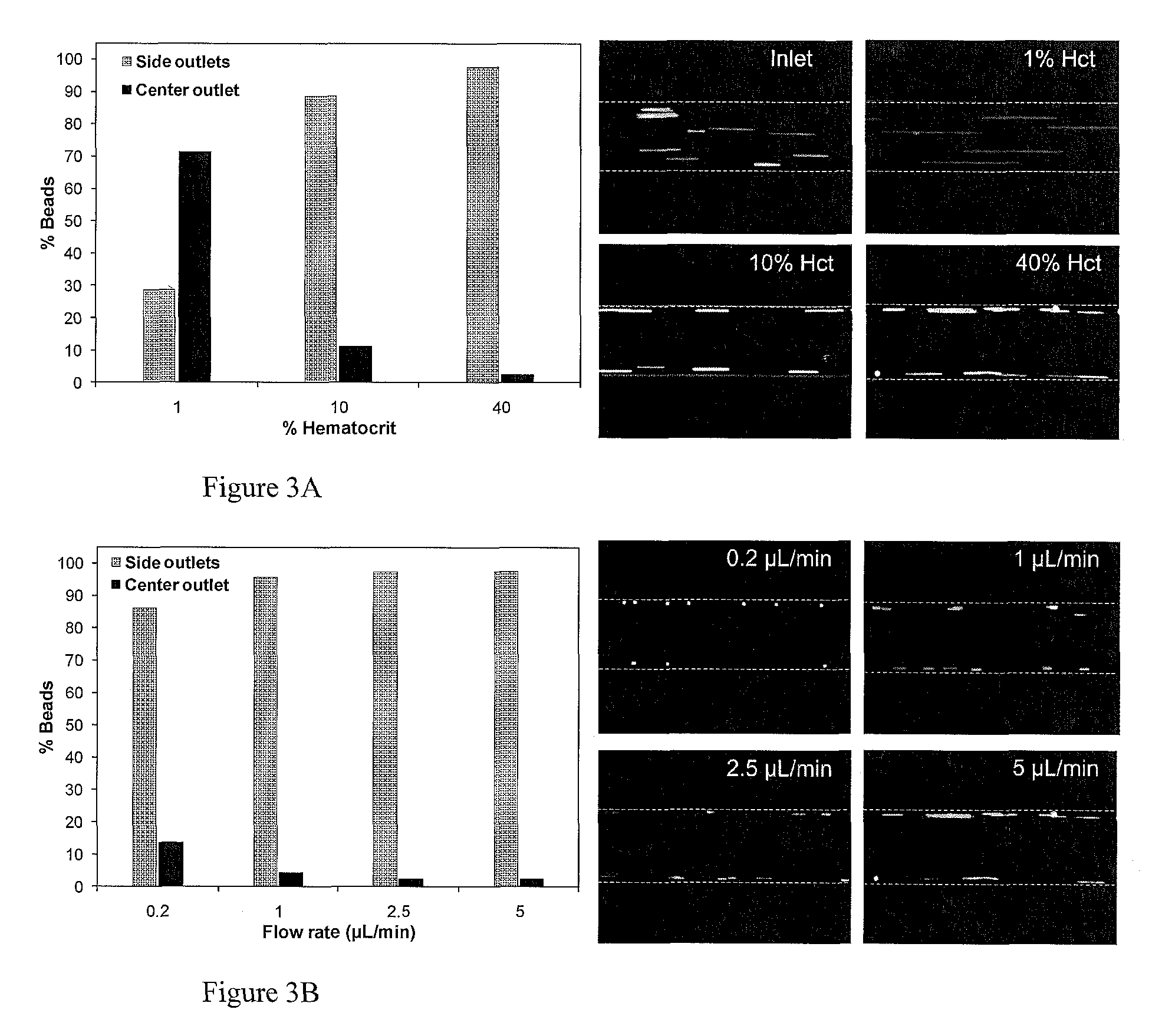

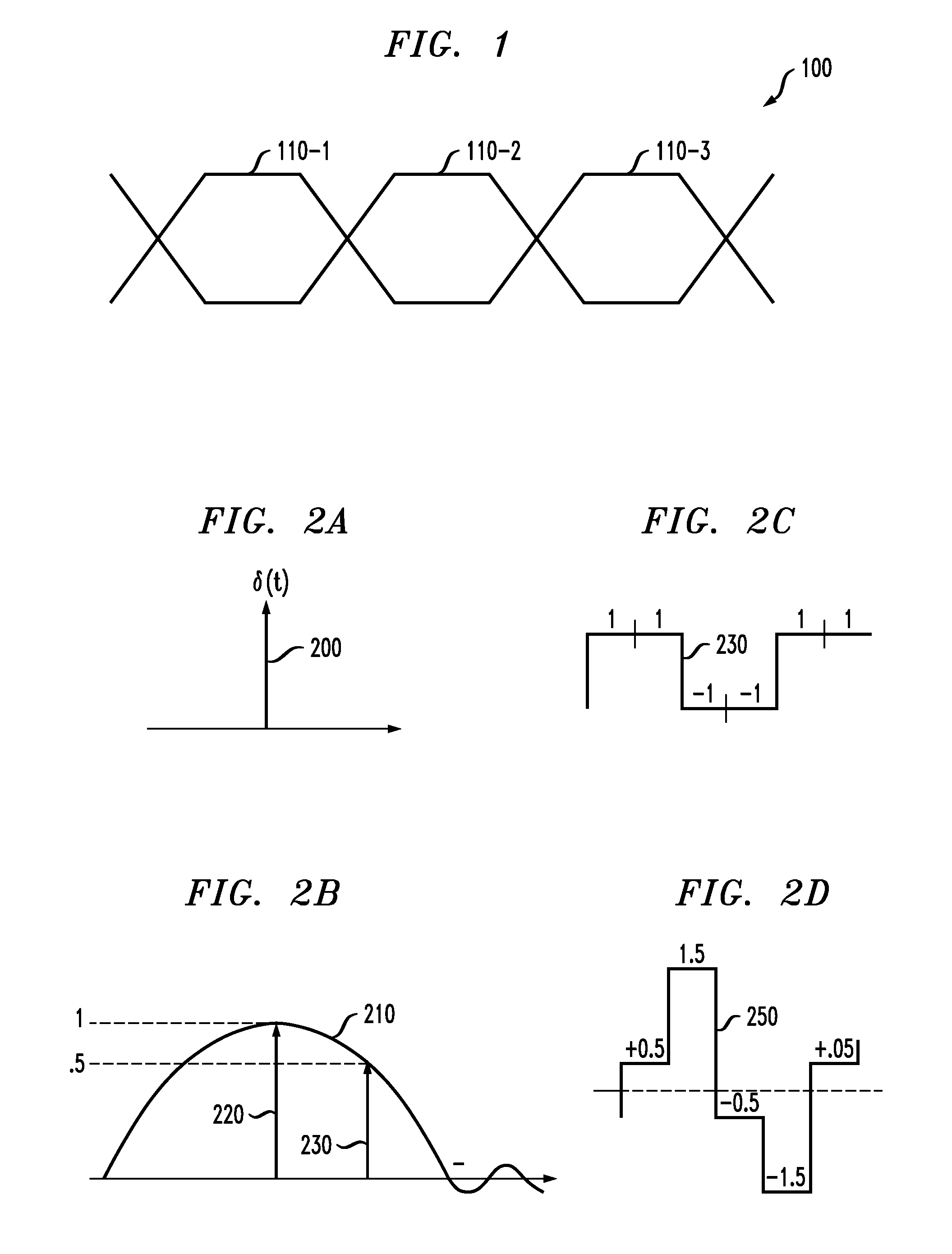

A method of detecting one or more diseased blood cells in a blood sample includes introducing a blood sample into at least one inlet of a microfluidic device comprising one or more linear channels wherein each channel has a length and a cross-section of a height and a width defining an aspect ratio adapted to isolate diseased blood cells along at least one portion of the cross-section of the channel based on reduced deformability of diseased blood cells as compared to non-diseased blood cells, wherein diseased blood cells flow along a first portion of the channel to a first outlet and non-diseased blood cells flow along a second portion of the channel to a second outlet. The one or more channels can be adapted to isolate cells along portions of the cross-section of the channel based on cell size. In some embodiments, the one or more channels can be spiral channels.

Owner:MASSACHUSETTS INST OF TECH +1

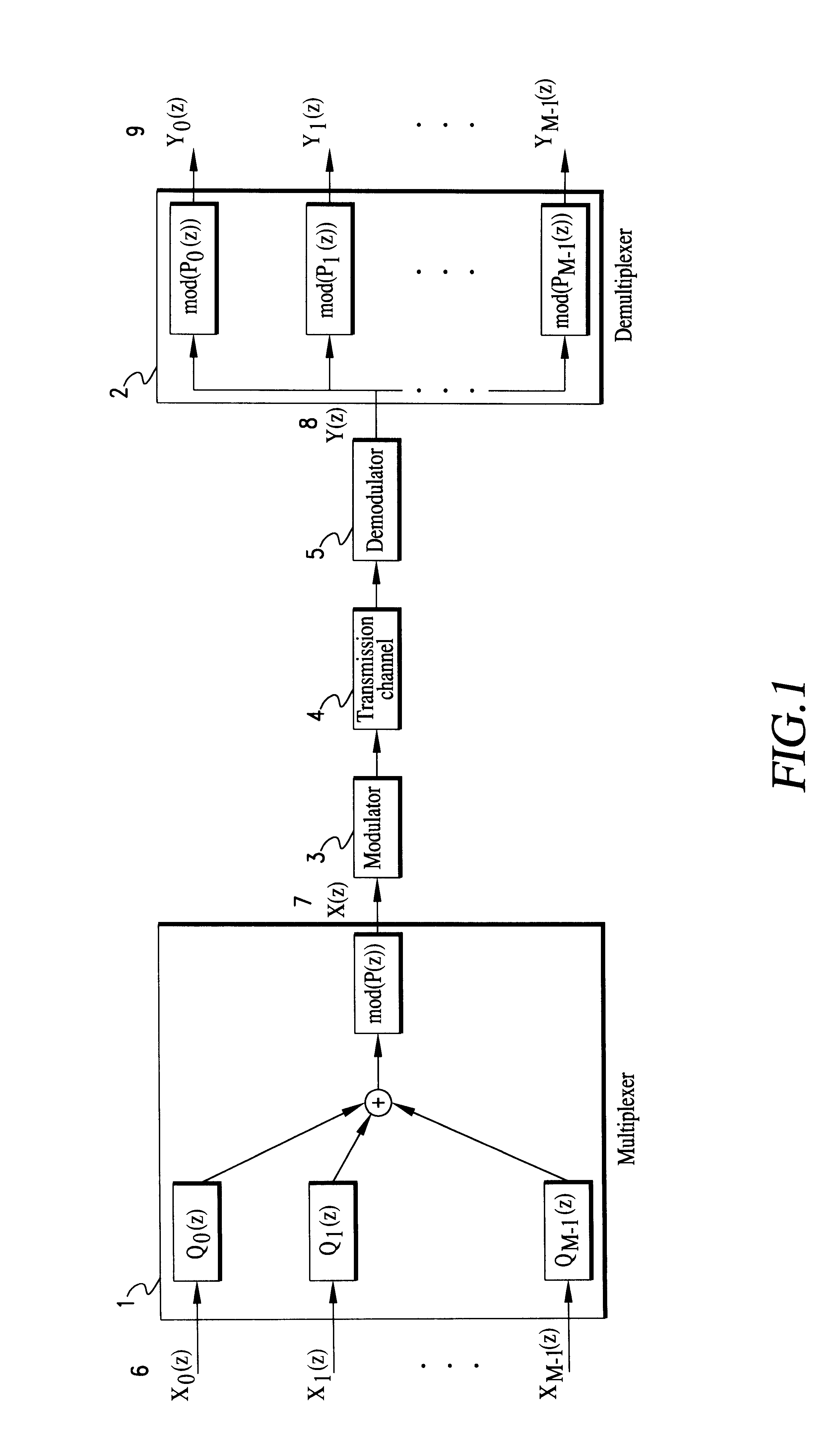

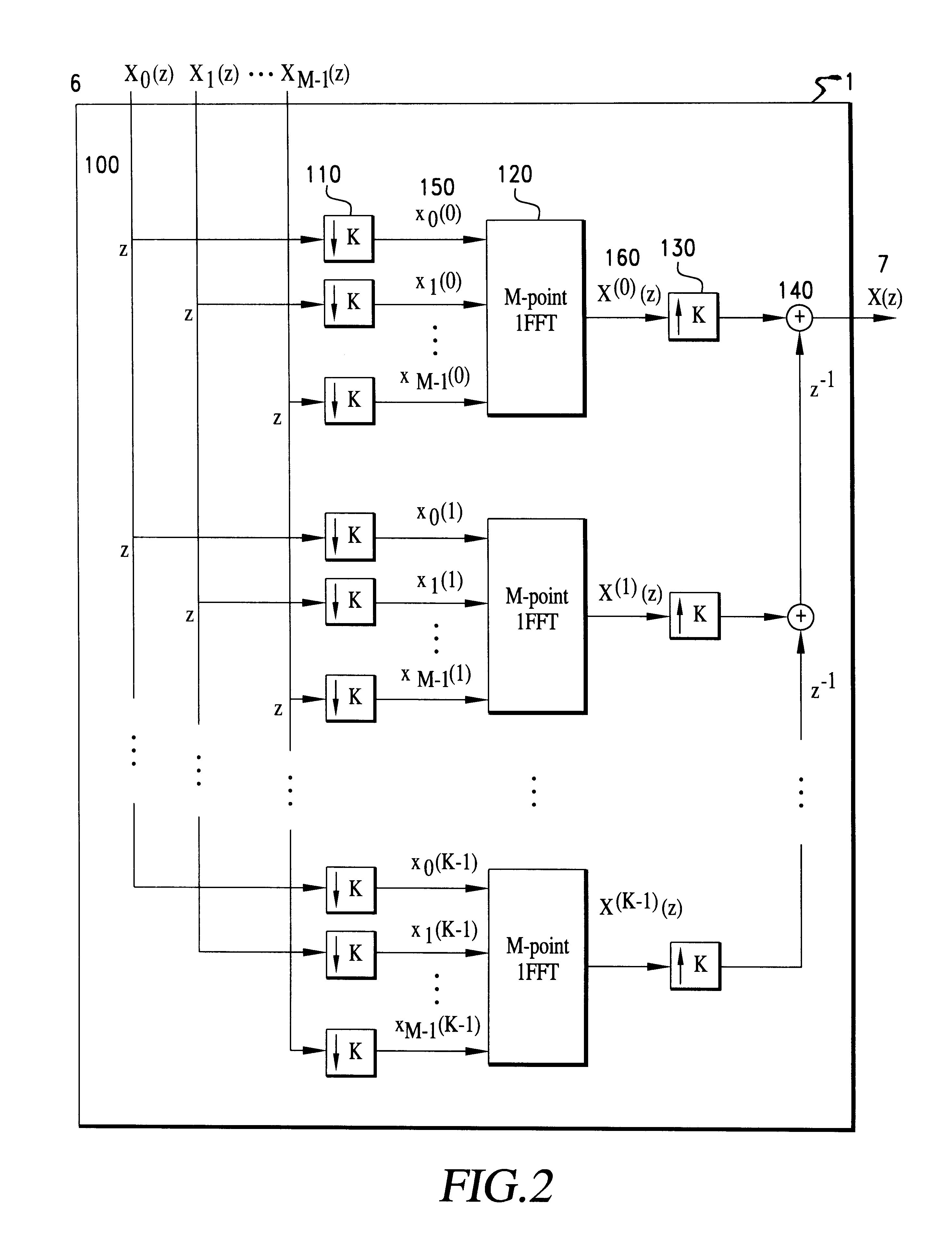

Residue division multiplexing system and apparatus for discrete-time signals

InactiveUS6317409B1Easy to useSimple structureFrequency-division multiplexAmplitude-modulated carrier systemsDiscrete-time signalEngineering

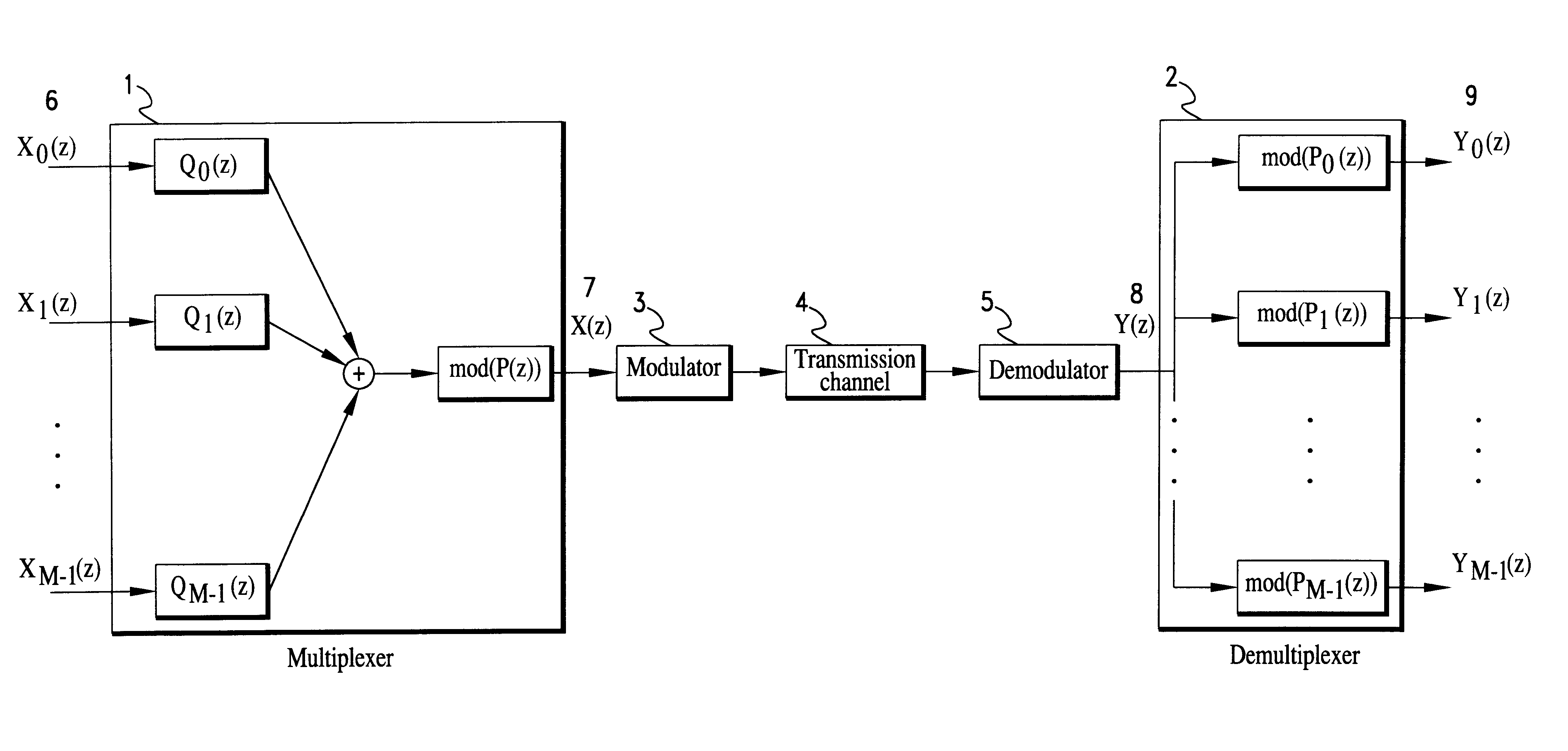

A multiplexing system utilizes the whole transmission bandwidth without inducing interchannel interference for a linear channel with additive noise. Using the multiplexing system, the linear distortion channel is decomposed into independent linear distortion subchannels. Treating z-transforms as polynomials, a multiplexer at a receiver utilizes the Chinese remainder procedure to combine subchannel signals into a multiplexed signal to be transmitted through a single transmission channel. A demultiplexer at a receiver recovers the transmitted subchannel signals by taking residue polynomials on the factor polynomials used in the Chinese remainder procedure. The multiplexer that combines M subchannel signals of length K may be implemented by K M-point IFFT processors using 1-ej2pim / Mz-K (m=0 to M-1) as relatively prime polynomials required in the Chinese remainder procedure. Samples from the subchannel signals are arranged in K groups of M samples such that each group contains samples at the same position in the subchannel signals, M-point inverse DFTs of the arranged samples are computed for all of the groups, and finally the multiplexed signal is obtained by performing polyphase composition of the inverse DFT outputs. Reversing the process of multiplexing, the demultiplexer is implemented by K M-point FFT processors. Another class of the system is a multiplexing system using (1-ej2pim / Mr0z-1) (1-ej2pim / Mr1z-1) . . . (1-ej2pim / MrK-1z-1) (m=0 to M-1) as relatively prime polynomials, wherein ri is a non-zero complex number (i=0 to K-1). The multiplexer obtains the multiplexed signal by applying the Chinese remainder procedure recursively, starting with the subchannel signals Xm(z) regarding them as residue polynomials on mod((1-ej2pim / Mr0z-1) (1-ej2pim / Mr1z-1) . . . (1-ej2pim / MrK-1z-1)) (m=0 to M-1).

Owner:MURAKAMI HIDEO

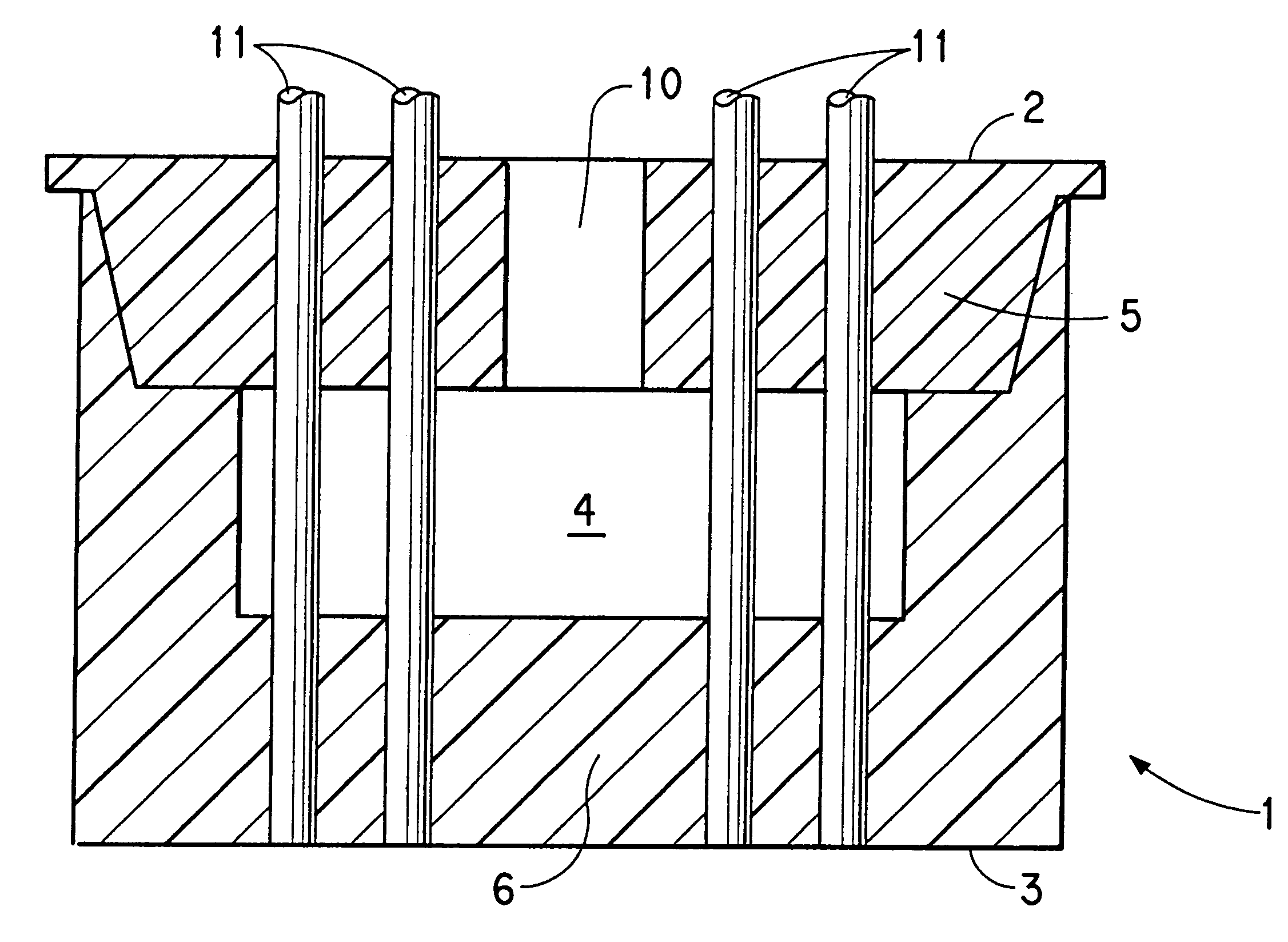

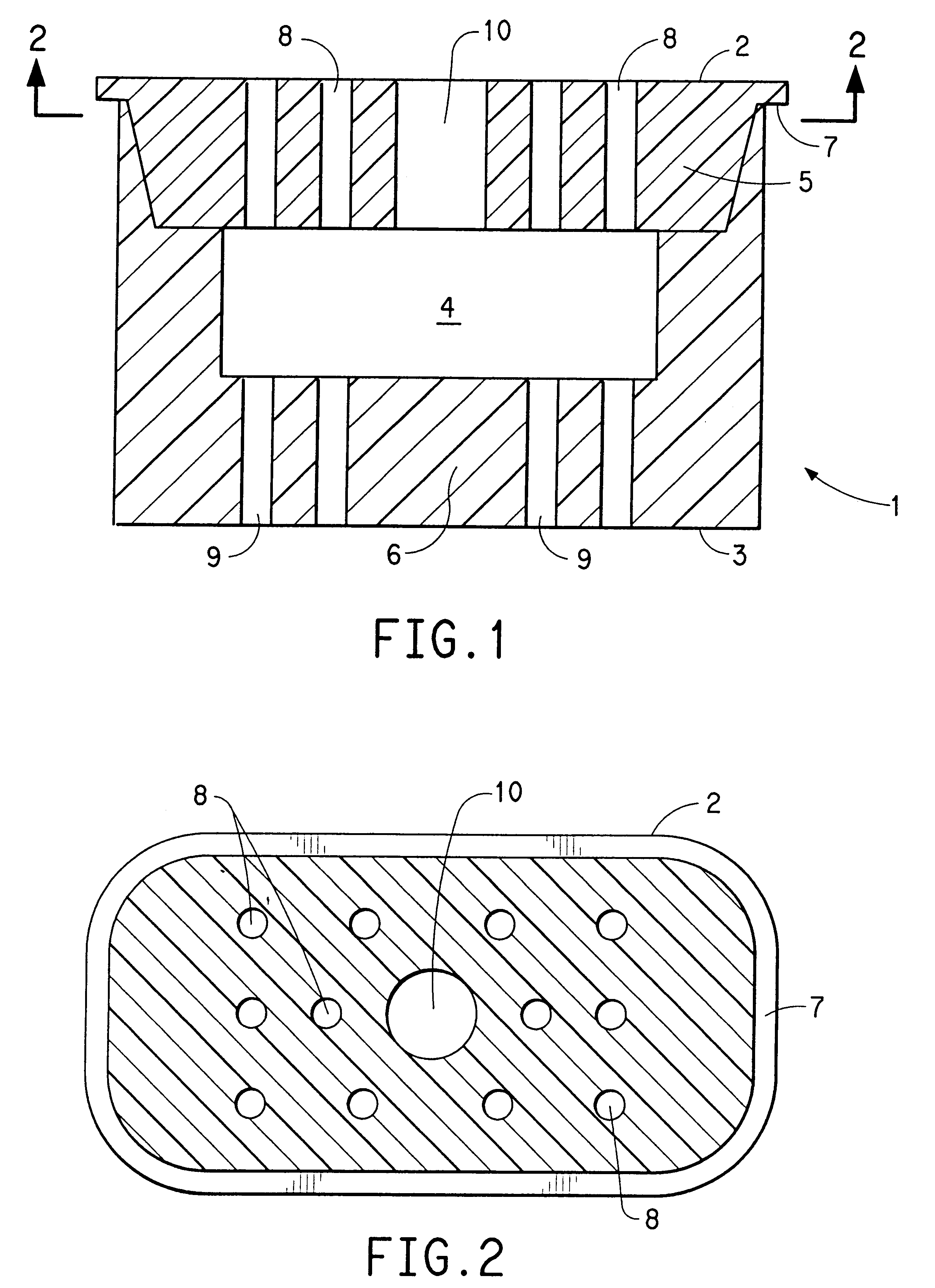

Method for bonding of tubes of thermoplastics polymers

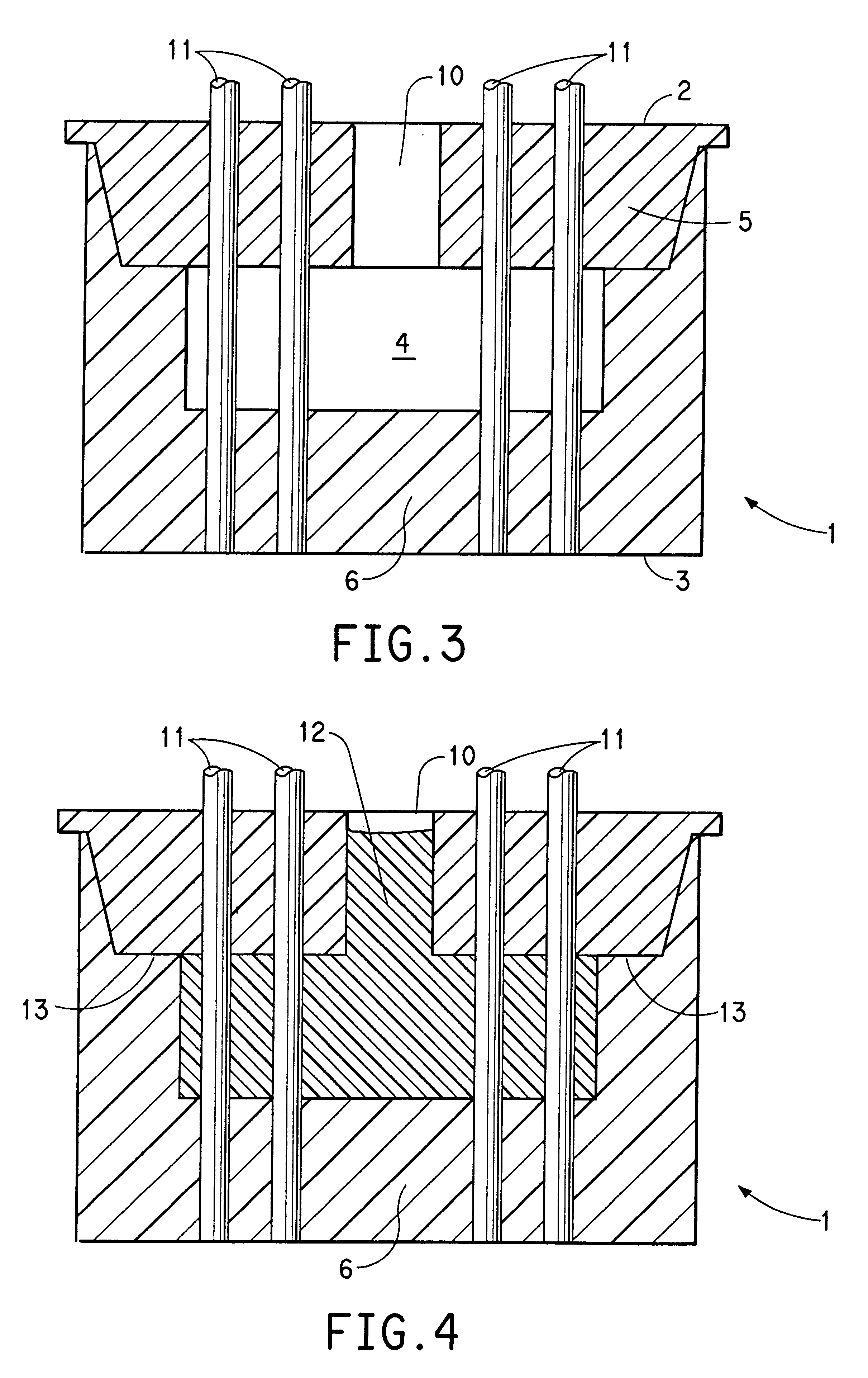

A method for bonding a tube into a device each of which is formed from a thermoplastic polymer. The device has first and second solid members in spaced apart relationship to form a hollow cavity therebetween. At least one linear channel extends through each of said solid members in an aligned relationship, such that a tube may be passed through in sliding engagement, including through the hollow cavity. Molten polymeric composition is injected into the hollow cavity at a temperature lower than the melting point of the thermoplastic polymer so as to bond to the thermoplastic polymer and to the tube to form fluid-tight bonds therewith.

Owner:JOSEPH ANTHONY CESARONI

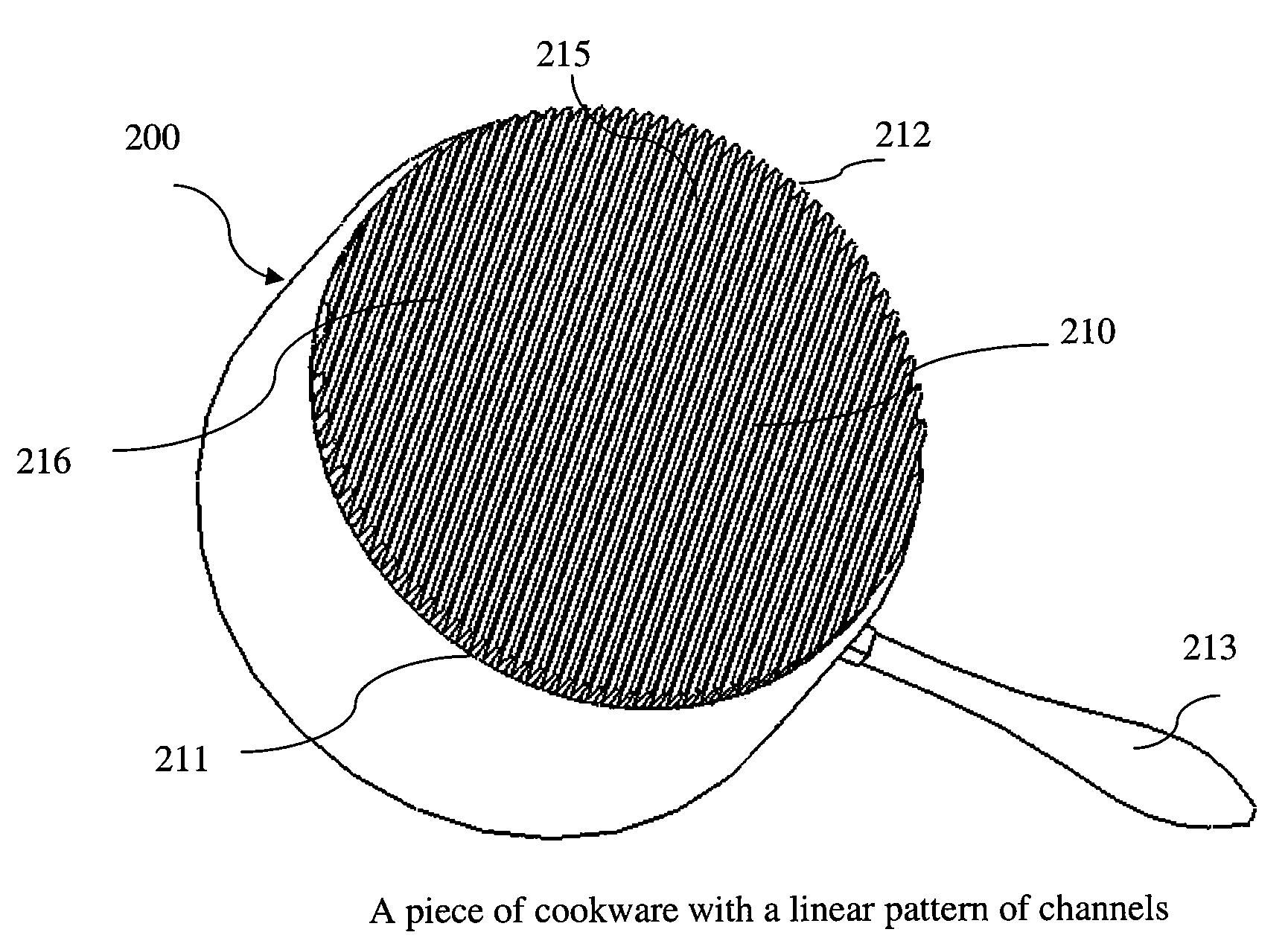

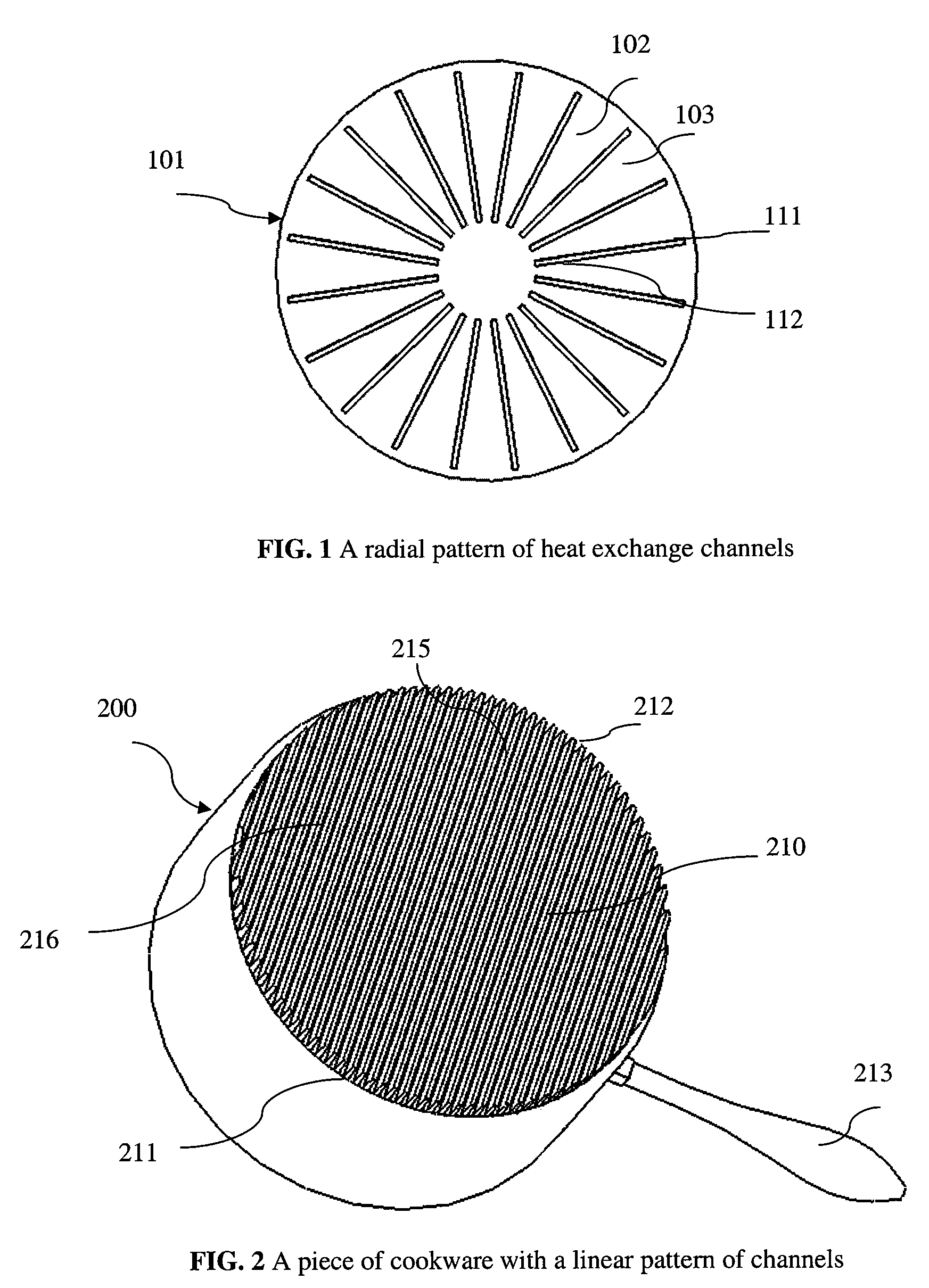

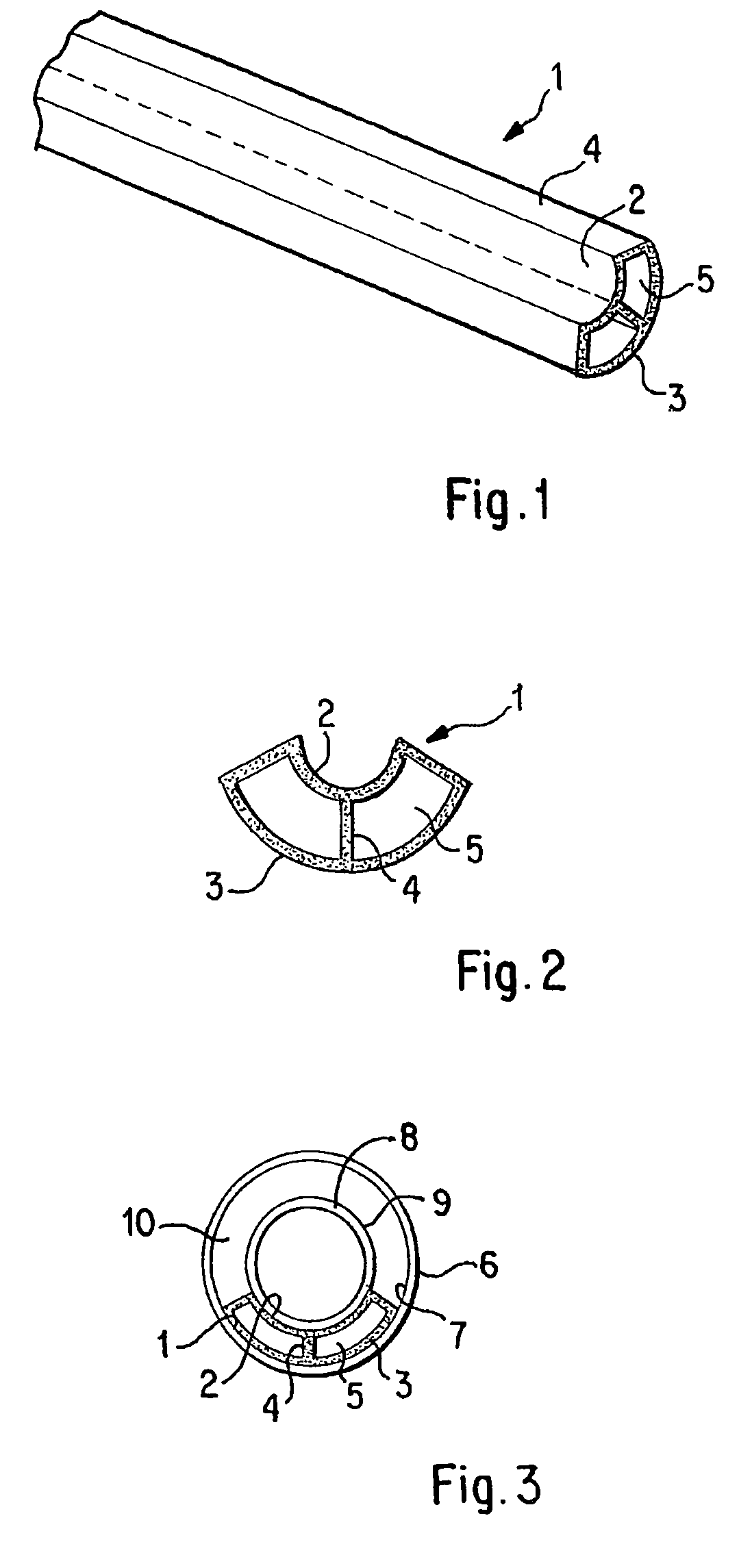

Energy Efficient Cookware

InactiveUS20080223359A1Improve heat transfer performanceMinimize mixingCooking-vessel materialsEnlarged heating surface vesselsEngineeringUltimate tensile strength

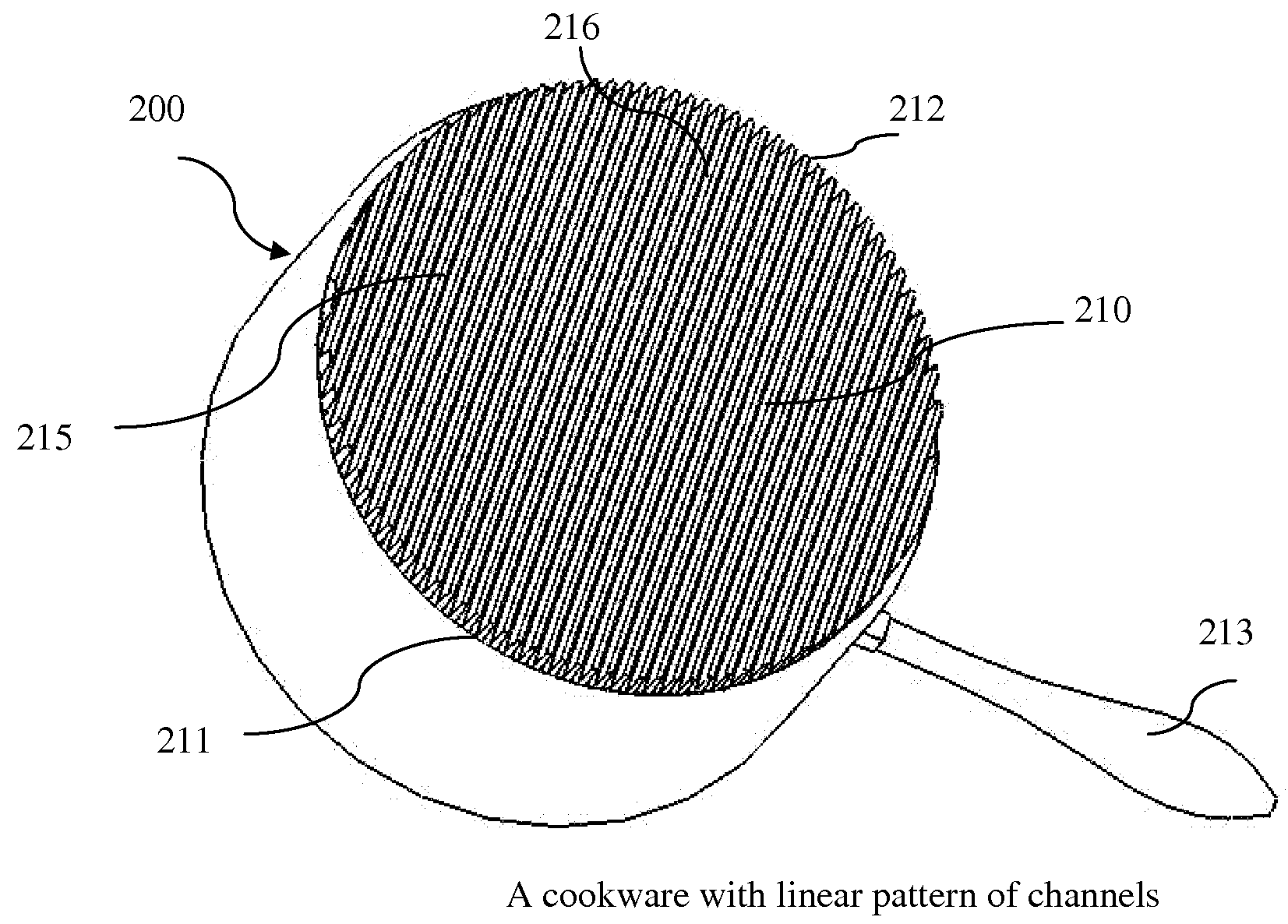

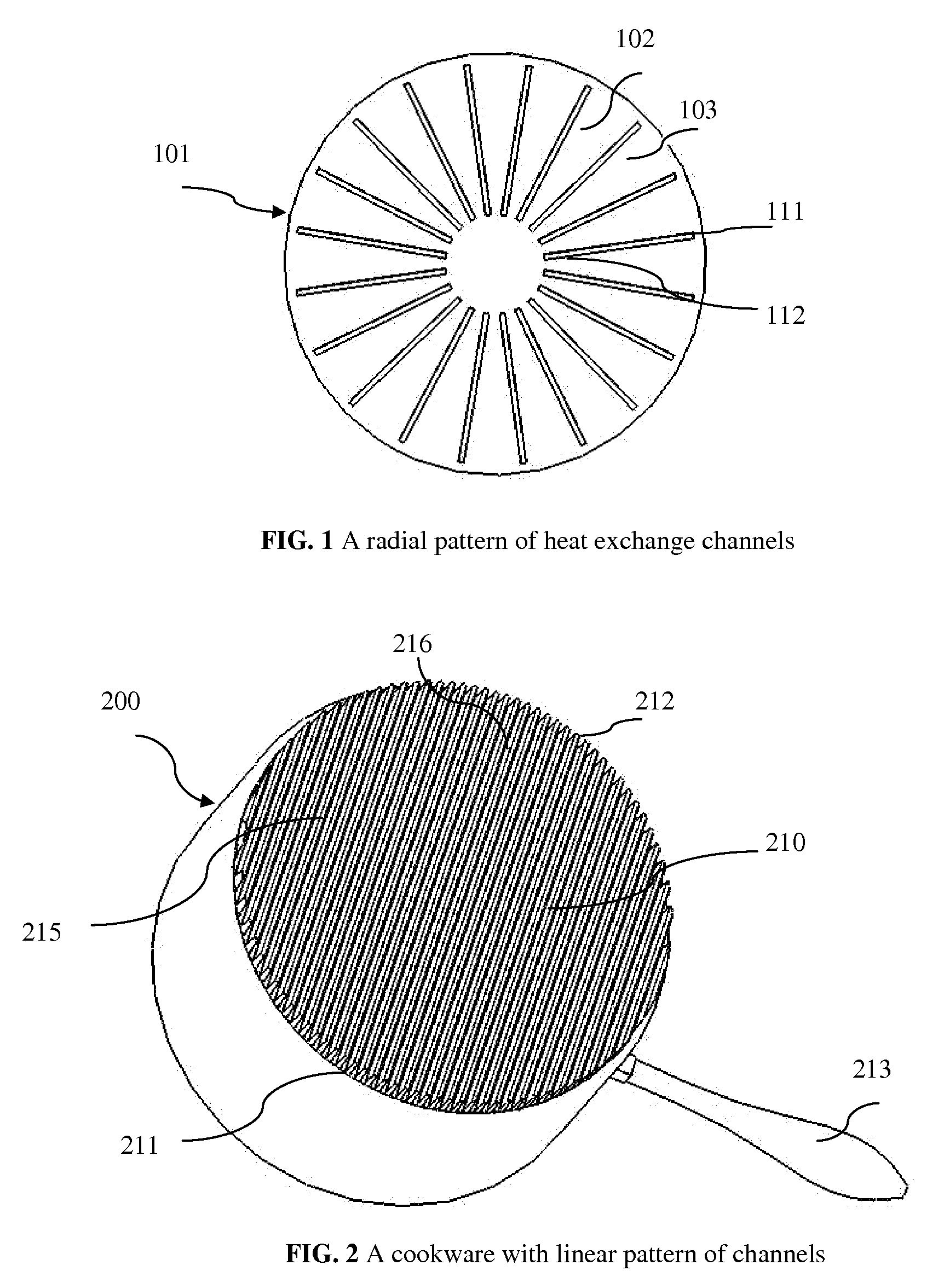

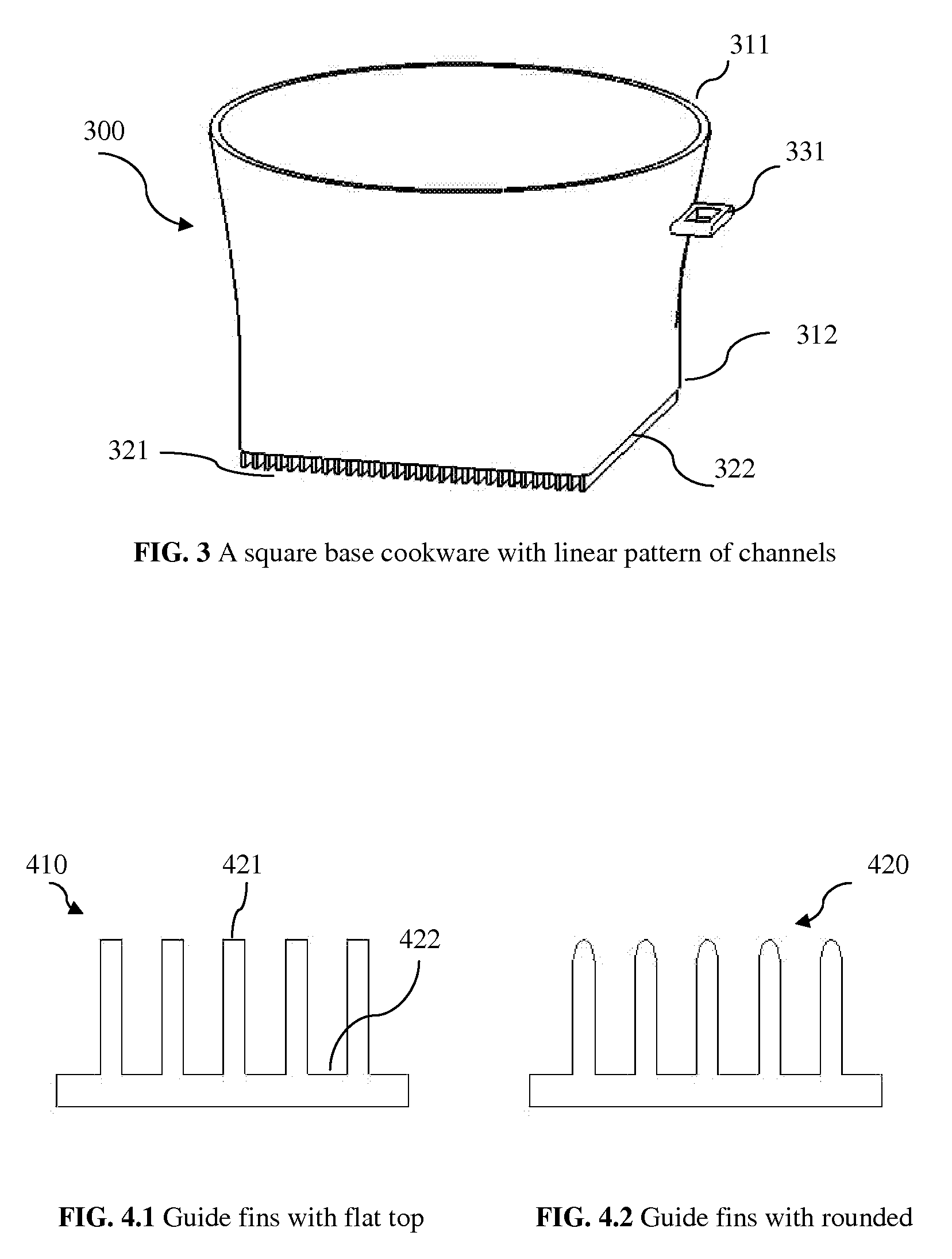

Energy efficient cookware is provided includes a base and a wall, a linear pattern of flame guide channels connected to the base bottom. The guide channels accept a flame and guides it to the perimeter from the central region resulting efficient heat exchange; The linear channel profiles provides maximum the surface enhancement from a given plain area on the bottom to improve heat transfer while provides even heating, and mechanical strength to the cookware; The impedance to entrance of flame flow into the channels is minimized to allow easy entrance of the flame into the channels; A square base further extends the linear channel length to gain extra efficiency. A method of making the efficient cookware is provided involving welding an extruded channel base to a wall.

Owner:ENERON

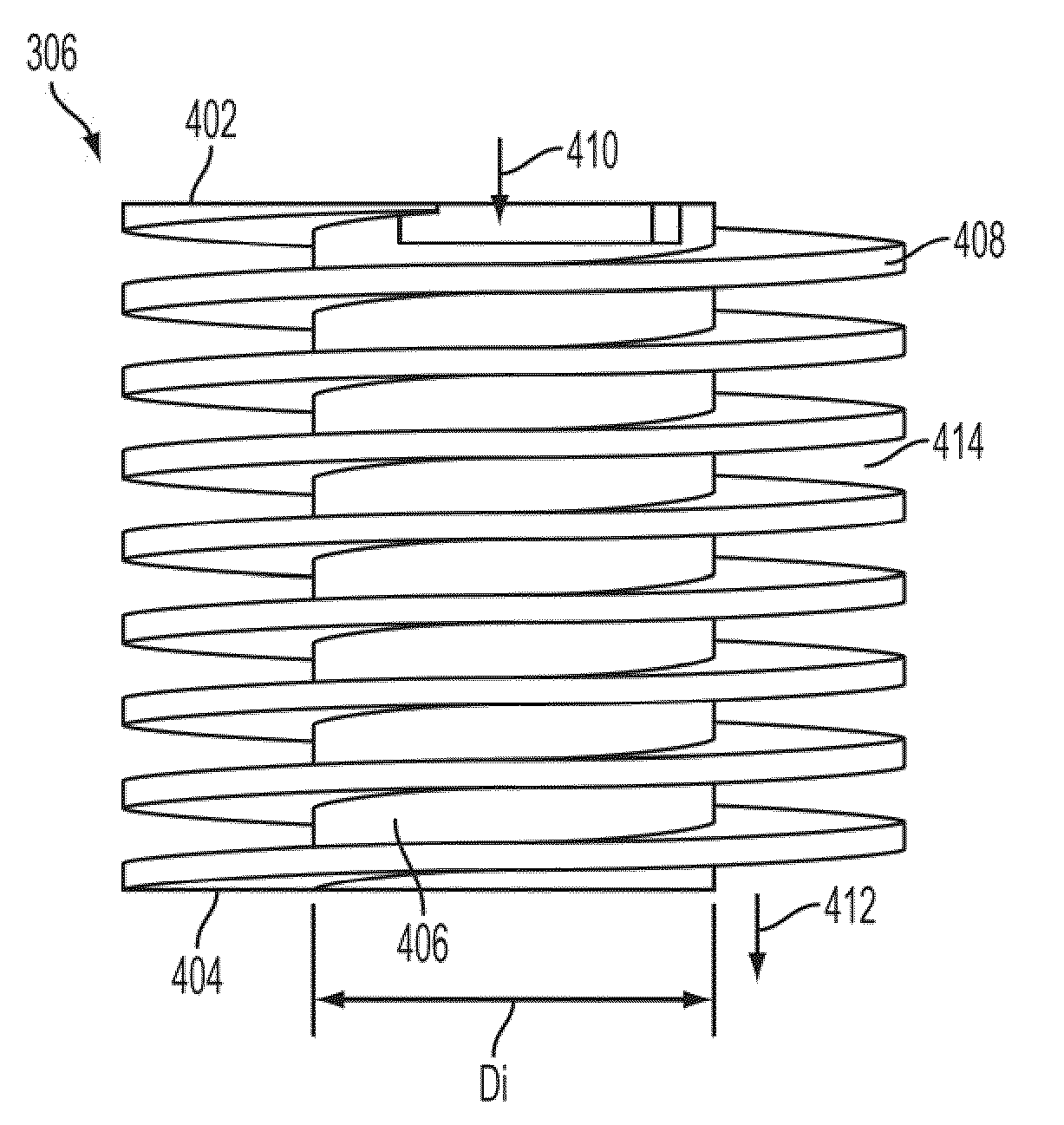

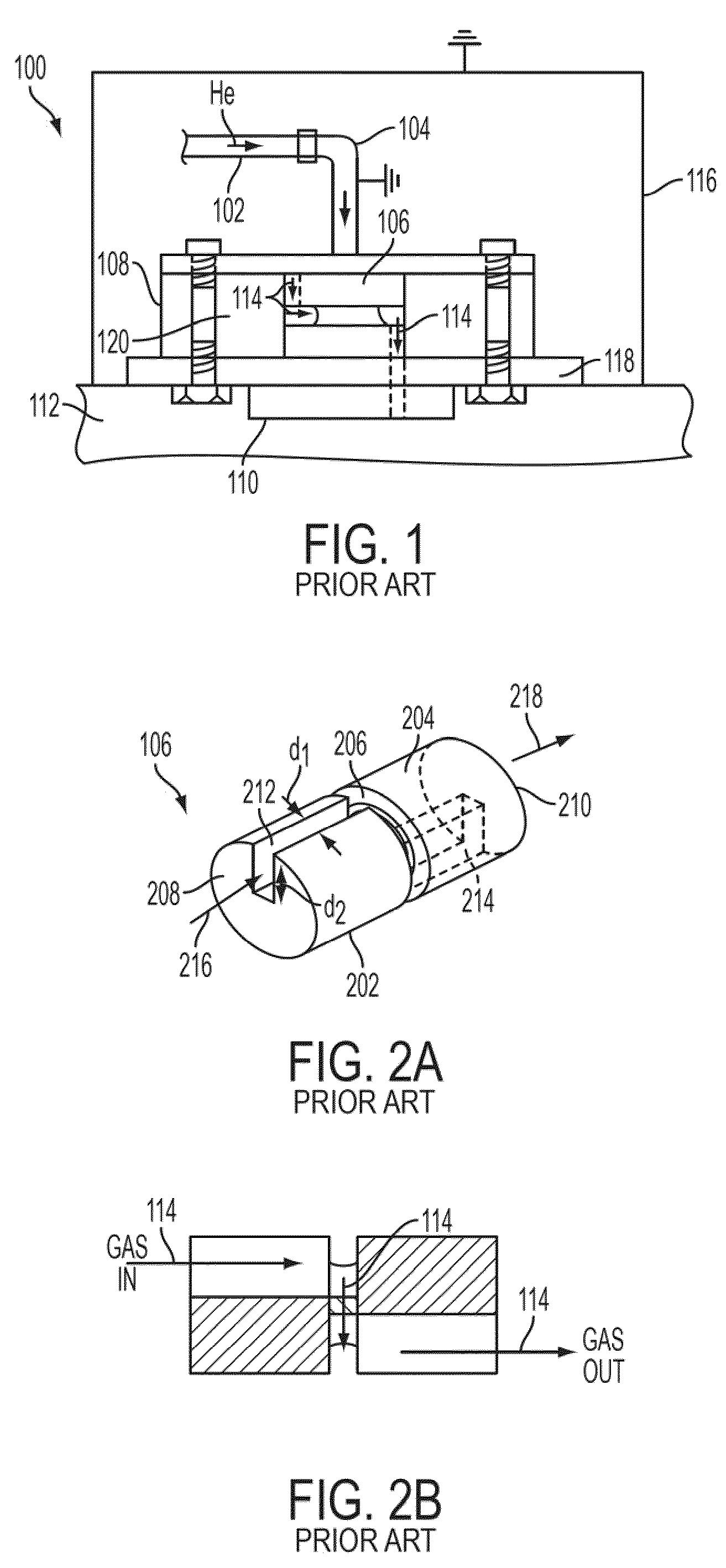

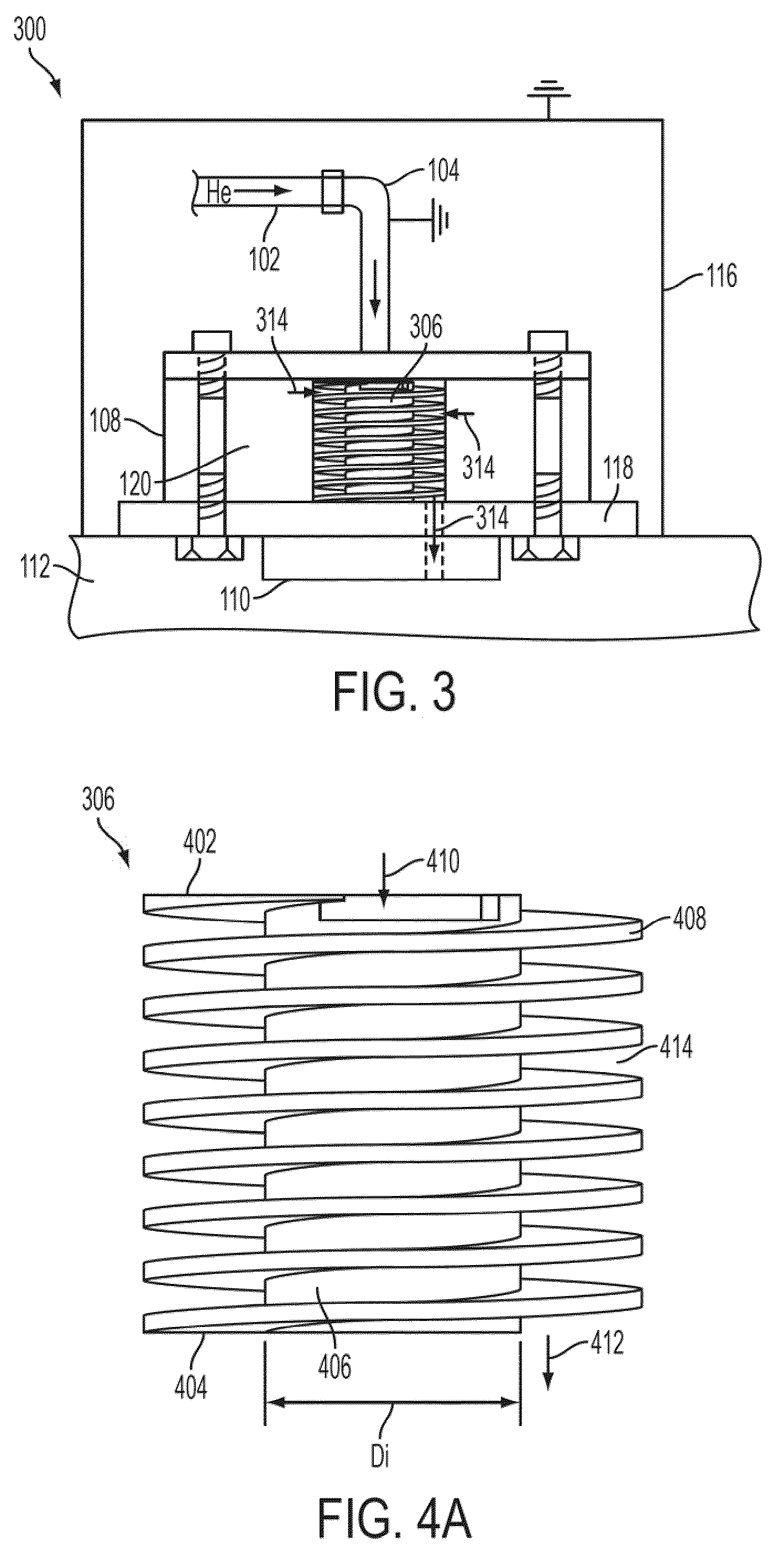

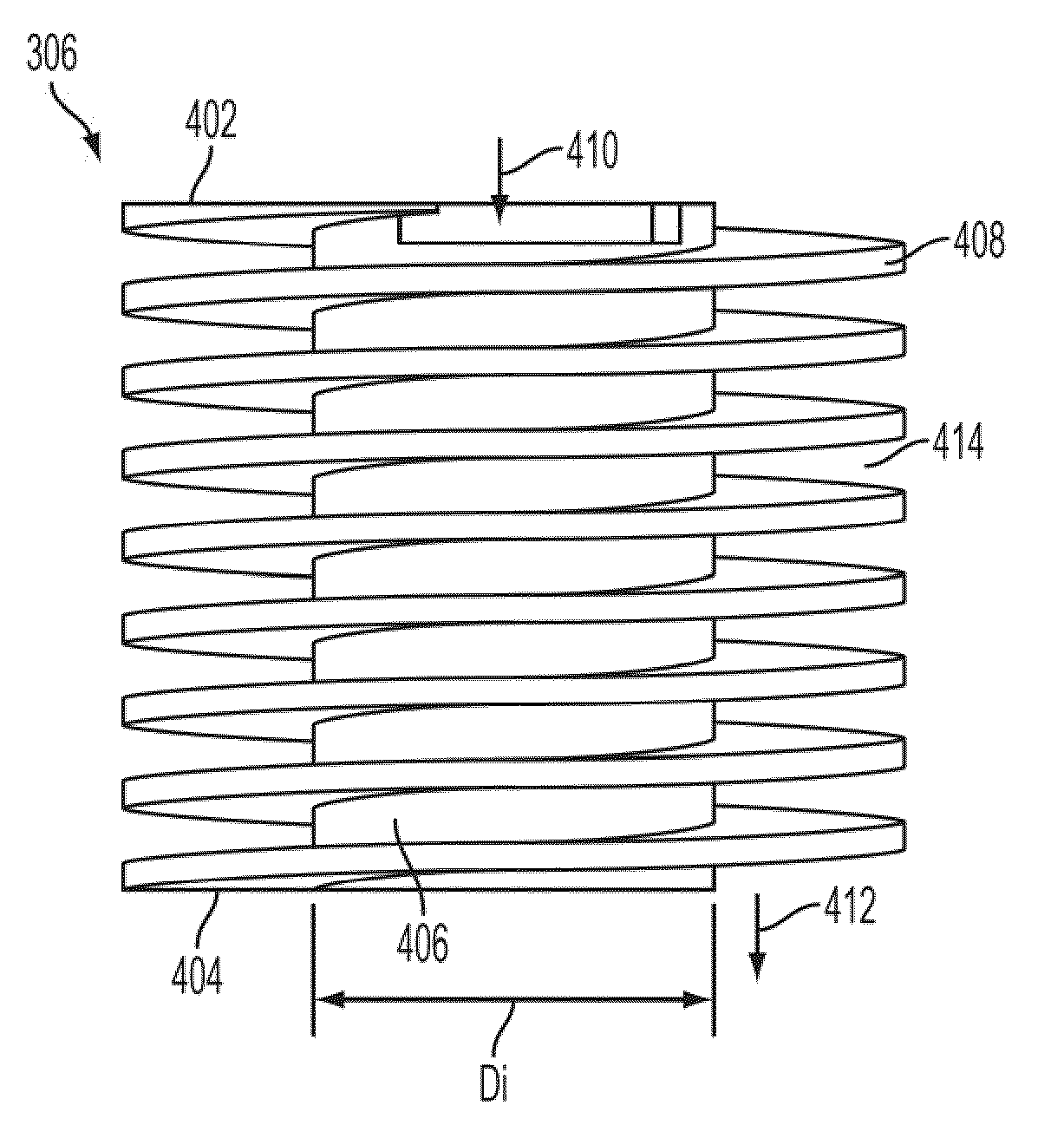

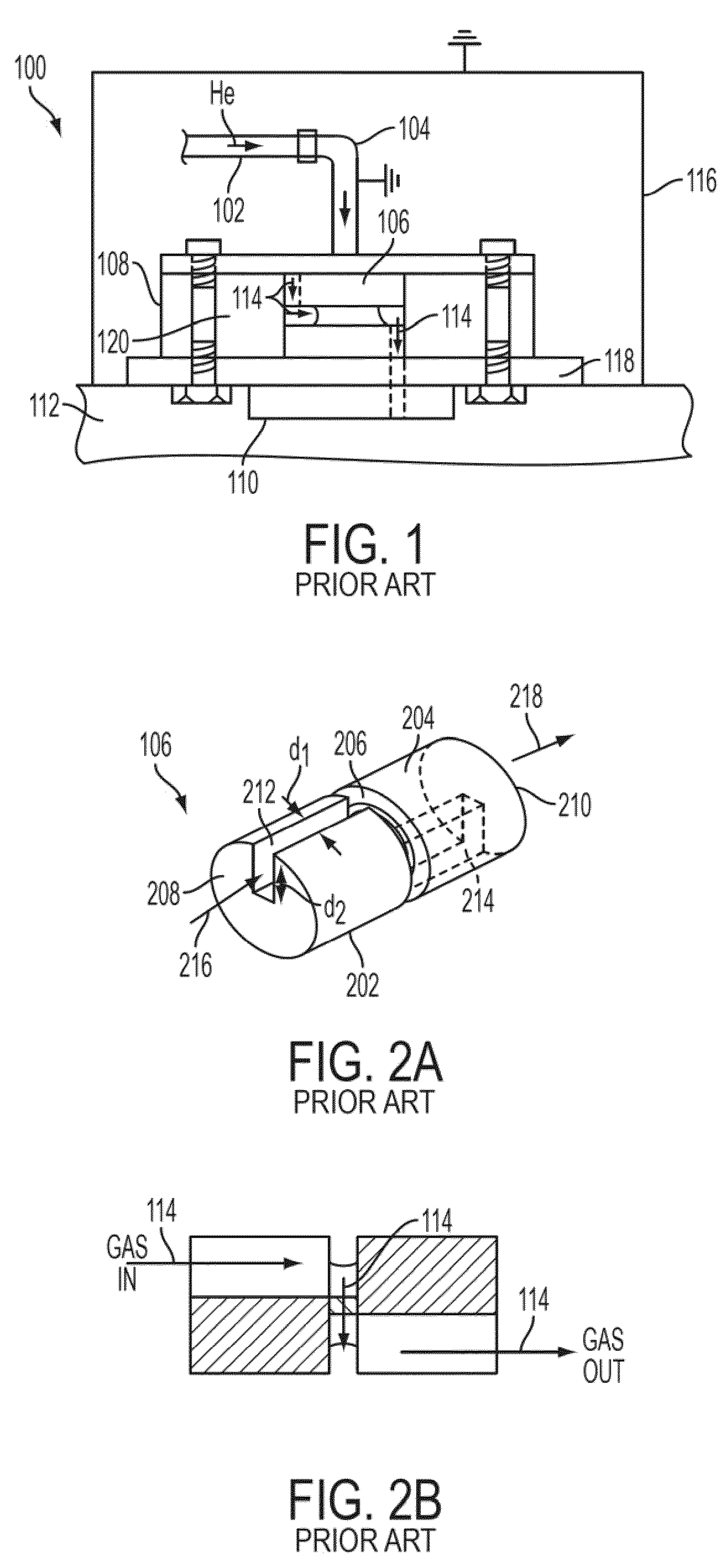

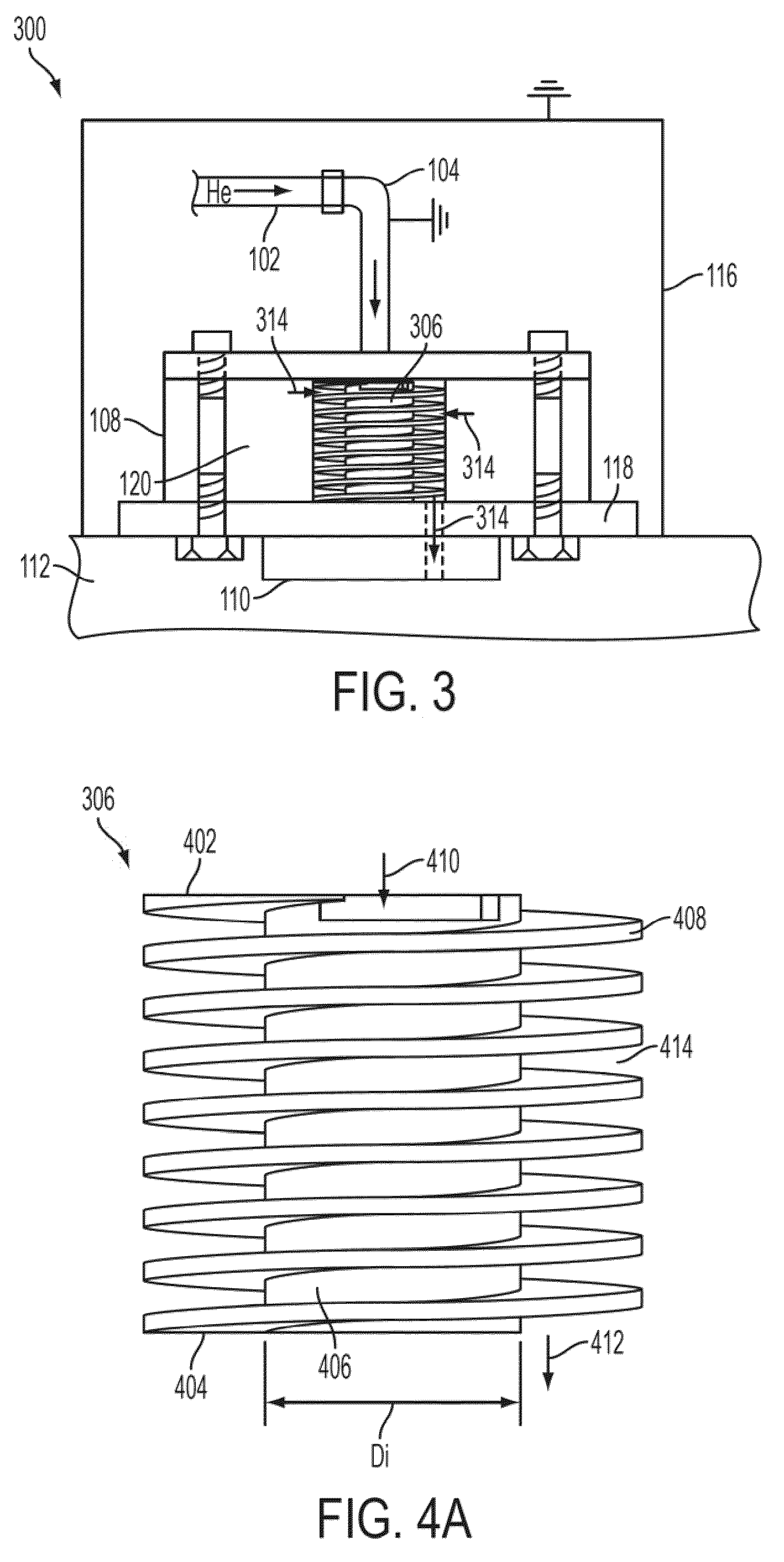

Plasma arrestor insert

ActiveUS20110075313A1Decreases likelihood of arcing and plasma generationEmergency protective arrangement detailsSemiconductor/solid-state device manufacturingDielectricProcess engineering

A dielectric arrestor insert for use in a chamber wafer processing system having a gas input line, an arrestor housing and a wafer processing space. The input line is able to provide gas to the arrestor housing. The arrestor housing is able to house the dielectric arrestor insert. The dielectric arrestor insert comprises a gas entry portion, a non-linear channel and a gas exit portion. The gas entry portion is arranged to receive the gas from the input line. The non-linear channel is arranged to deliver the gas from the gas entry portion to the gas exit portion. The gas exit portion is arranged to deliver the gas from the non-linear channel to the wafer processing space.

Owner:LAM RES CORP

Energy efficient griddle plate

InactiveUS20100083949A1Improve heat transfer performanceMinimize mixingCooking-vessel materialsEnlarged heating surface vesselsThermal energyCombustor

An energy efficient griddle plate is provided that includes a base and a pattern of flame guide channels connected to or constructed on the base. The guide channels can accept flames and guide the flames and heated air to the perimeter of the base while fins extending from the base absorb thermal energy; Linear channel profiles provide a substantial surface area enhancement from a given area on the bottom so as to improve heat transfer while providing even heating and mechanical strength to the plate; A flame entrance opening can be provided in as along as the flame guiding channels to allow easy entrance of the flame into the channels. Further, a burner pattern is given to improve the temperature uniformity on the flat surface of the plate. A method of making the efficient cookware involving extrusion is provided.

Owner:ENERON

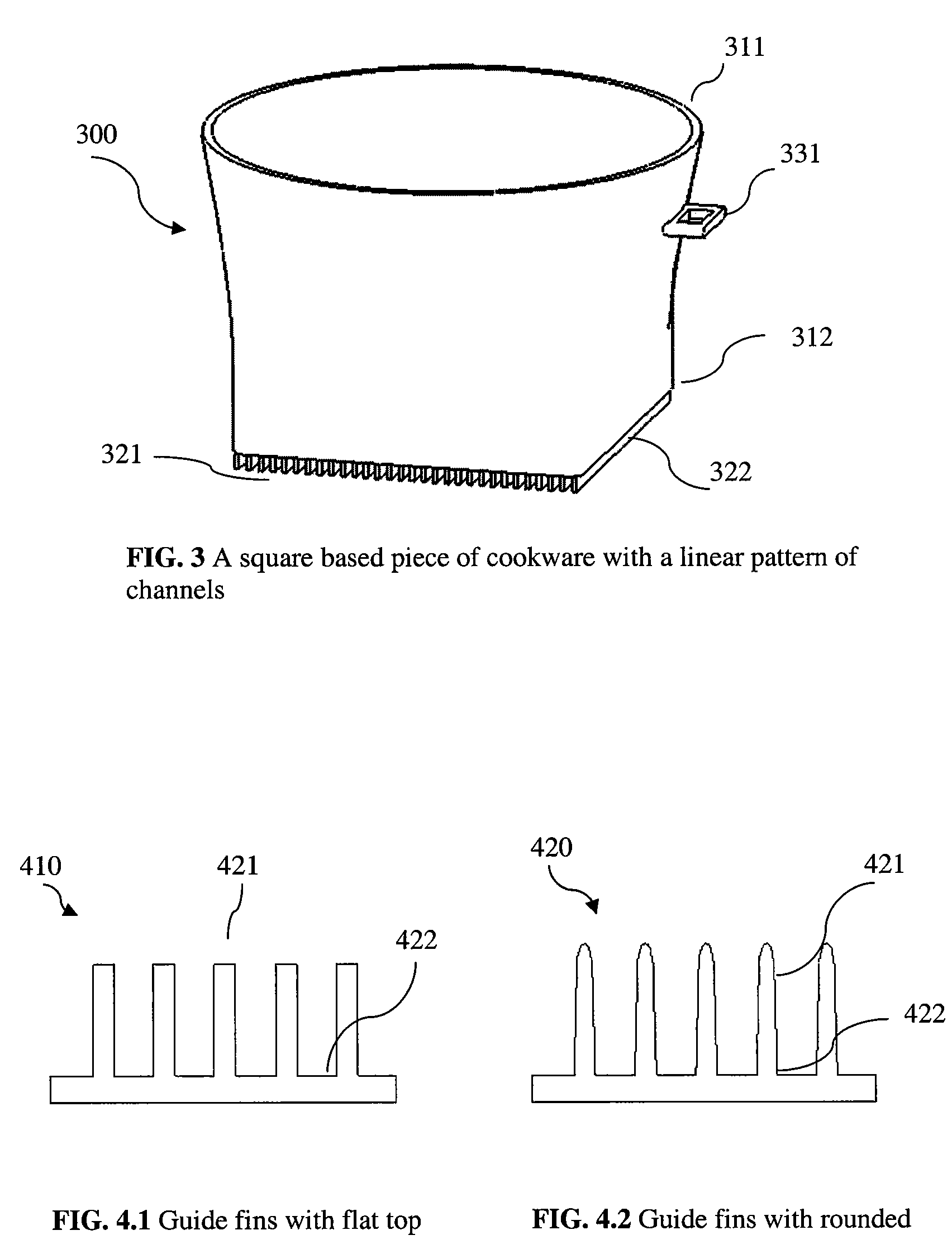

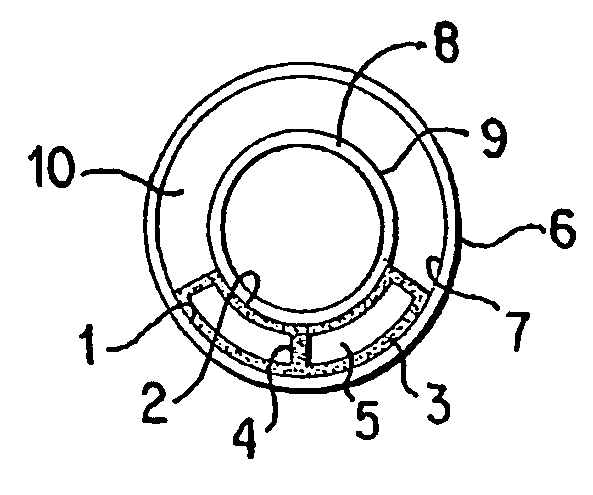

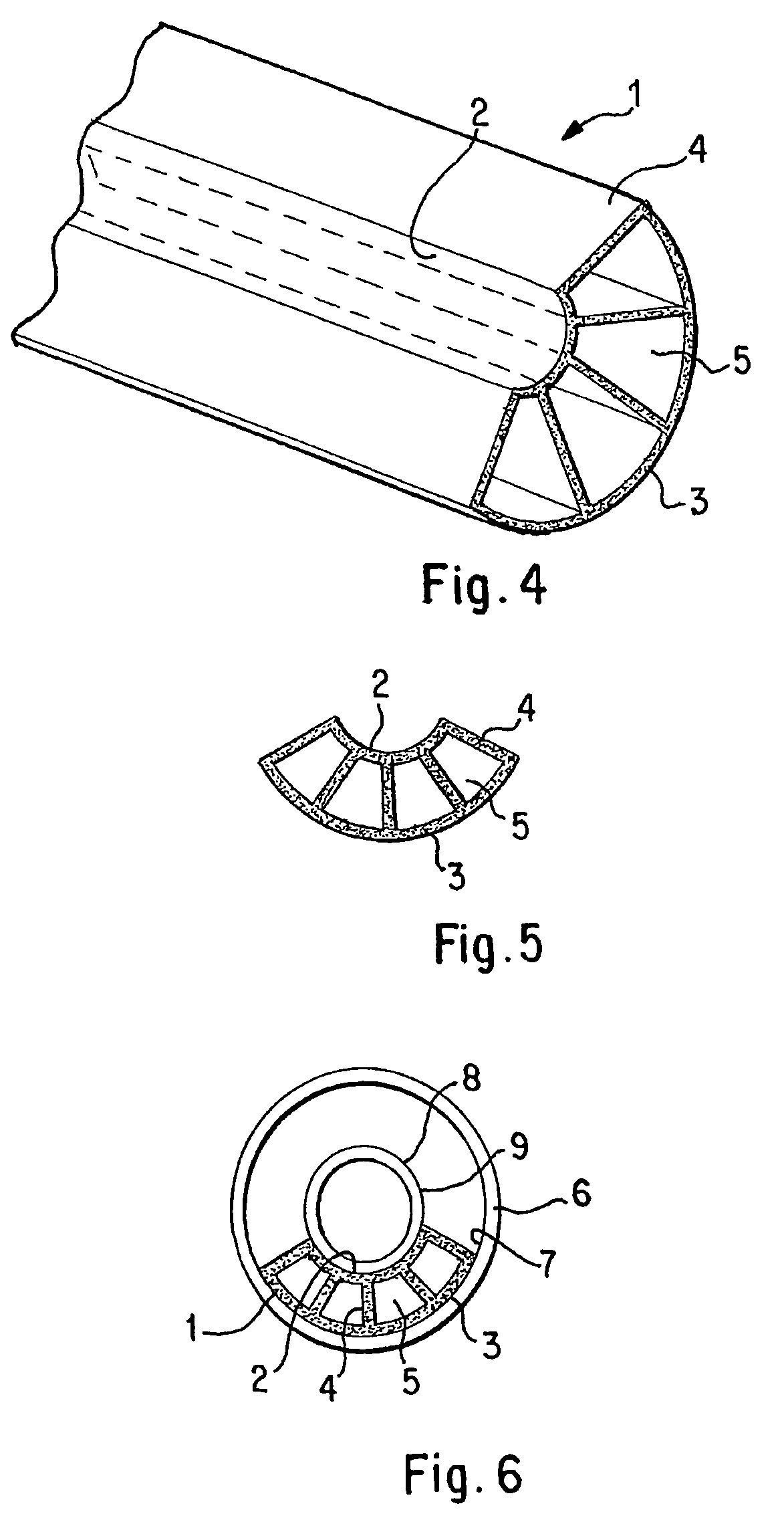

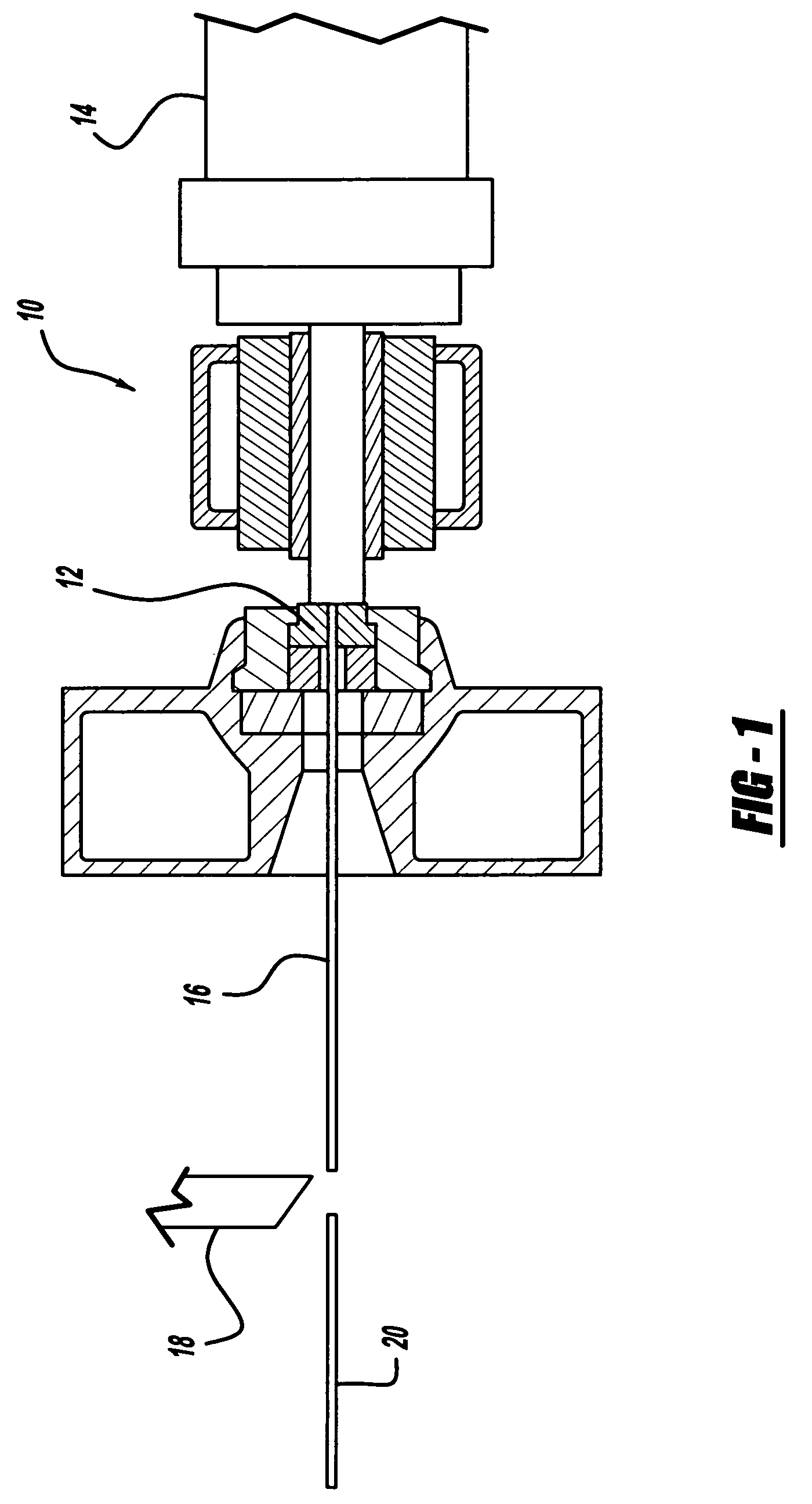

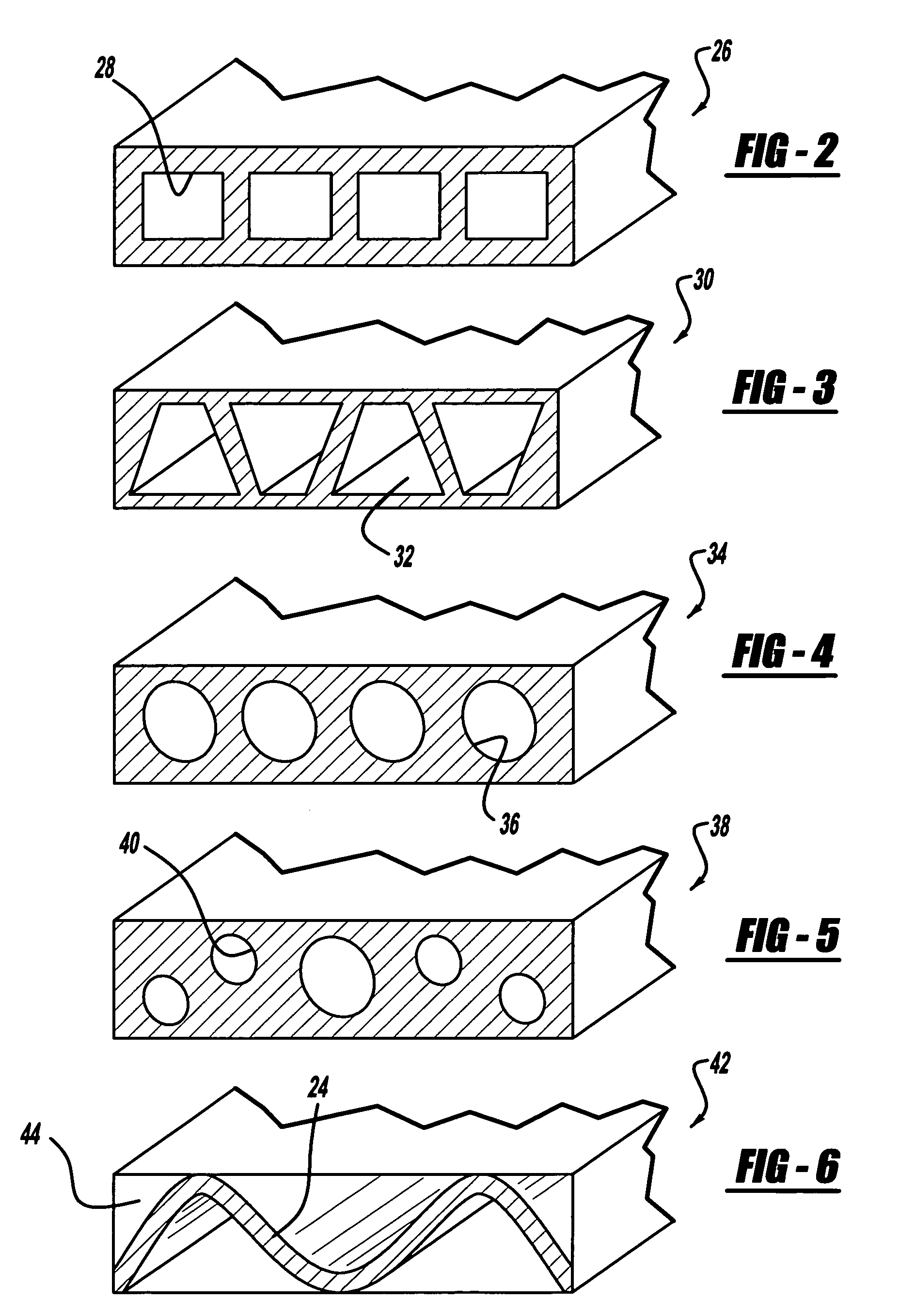

Pipe insert and pipe assembly formed therewith

InactiveUS7156126B2Easy to manufactureEasy to installPipe supportsInsulated cablesEngineeringSynthetic resin

A synthetic resin pipe insert for insertion in an existing pipe or for use in the manufacture of new pipe to form a multi-channel pipe. The insert has a curved cross sectional configuration which defines a segment of a circle with a convexly curved radially outer wall and a concavely curved radially inner wall and a plurality of radial walls extending between the curved, radially inner and outer walls to form at least two linear channels. A curved inner pipe member may optionally be fitted against the concavely curved radially inner wall. The pipe insert of the invention facilitates multiple utility connections, such as cable TV and sewer, in a single pipe assembly.

Owner:PIPELINE INSERT TECH

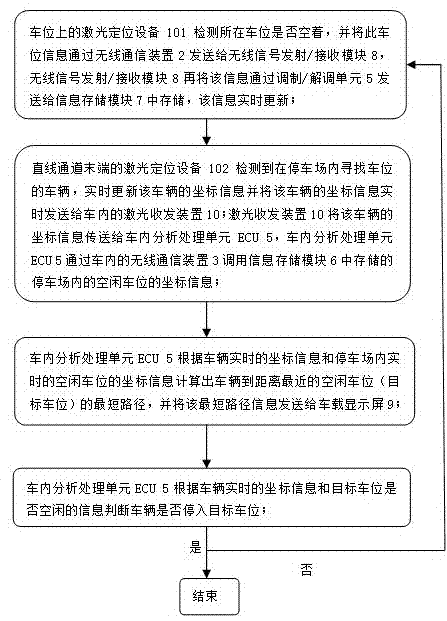

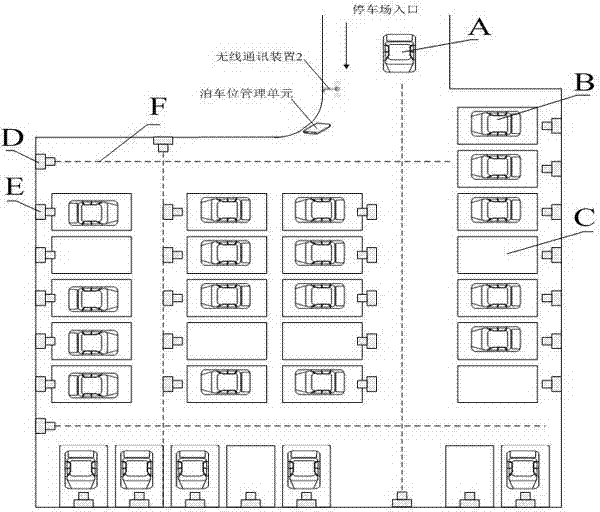

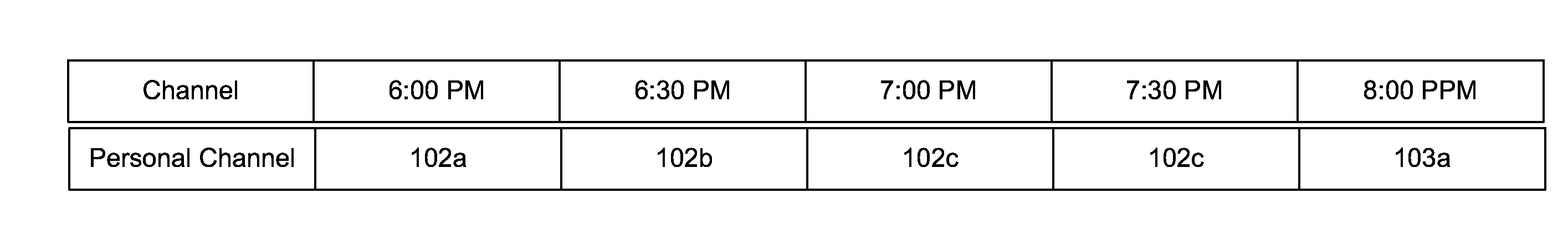

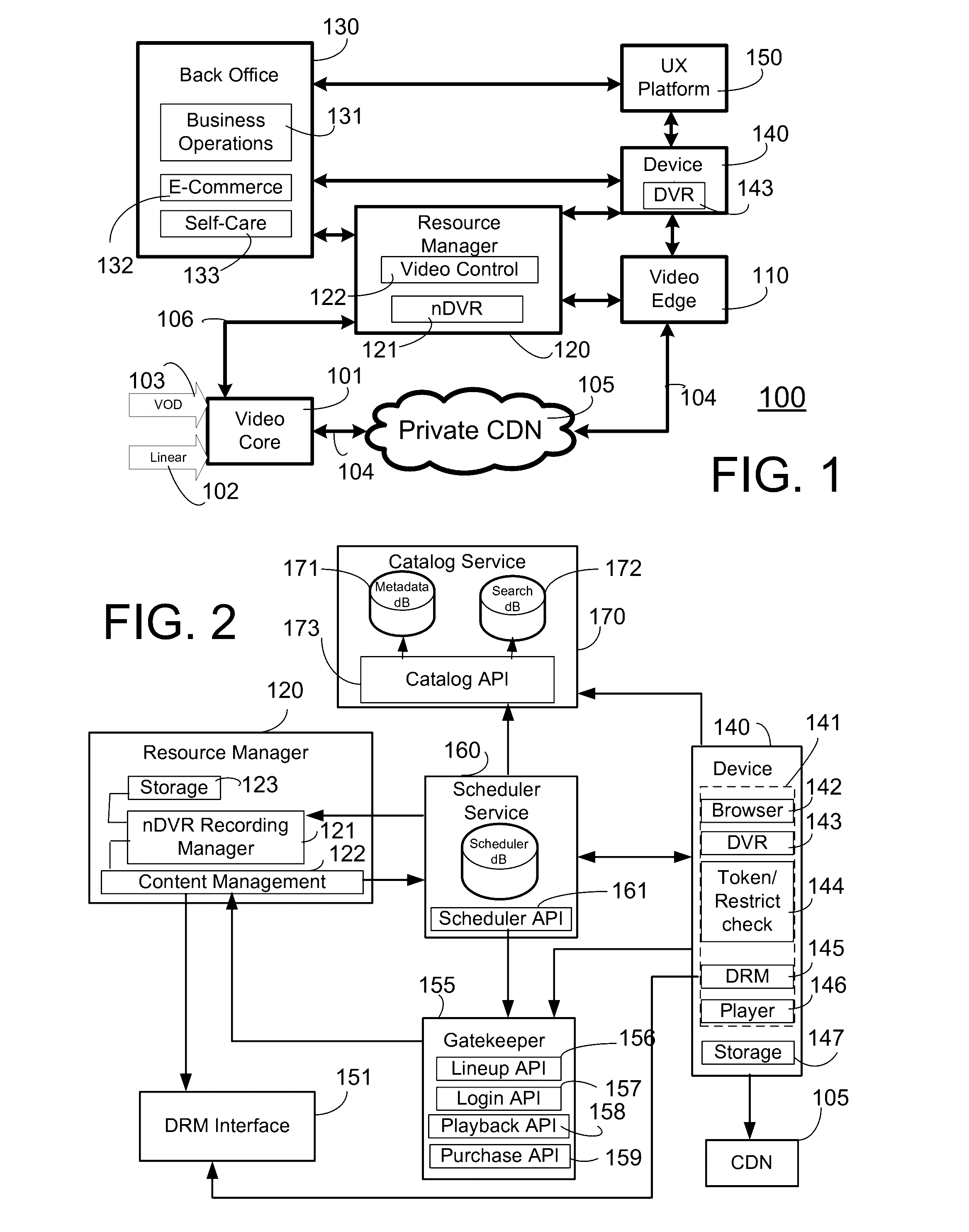

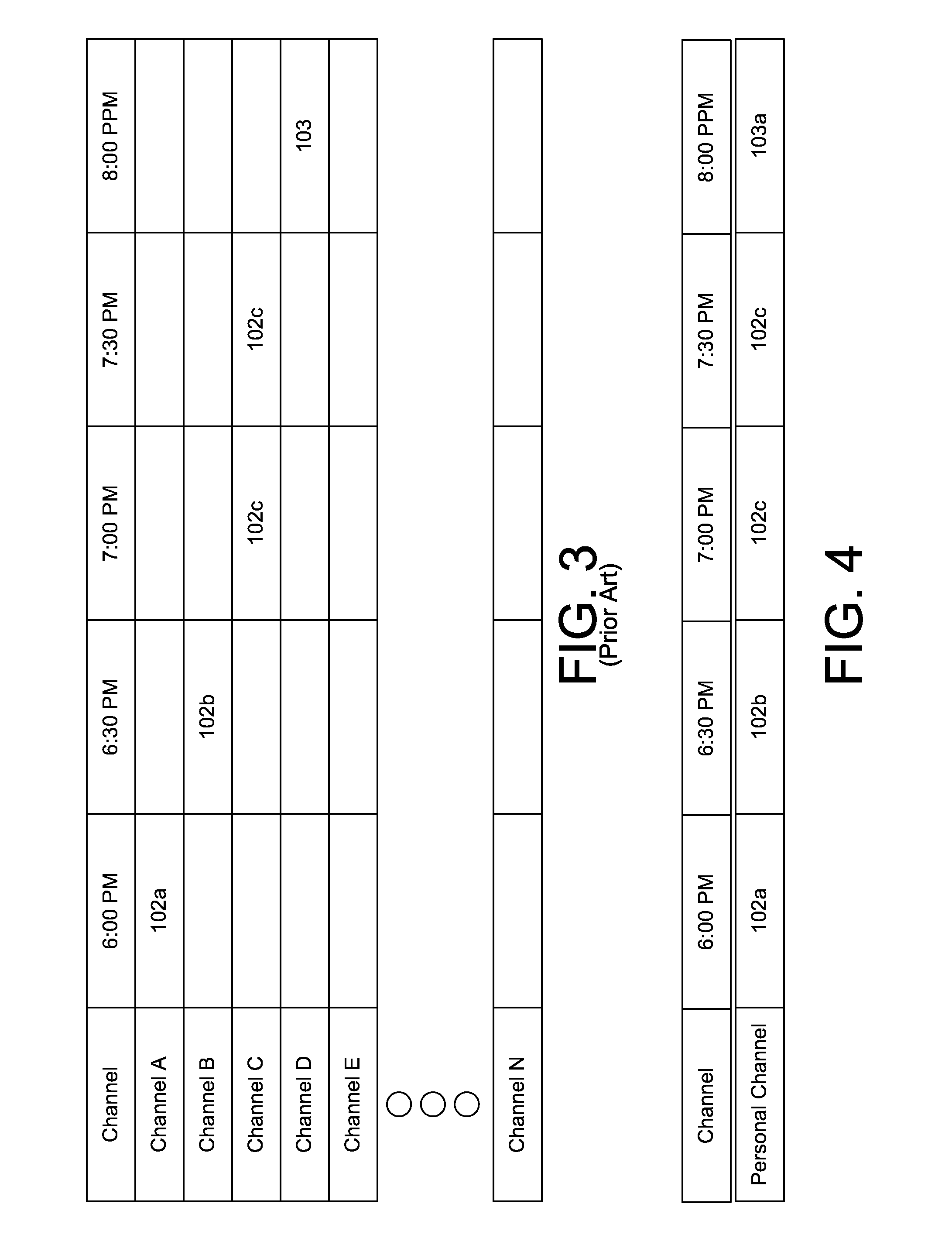

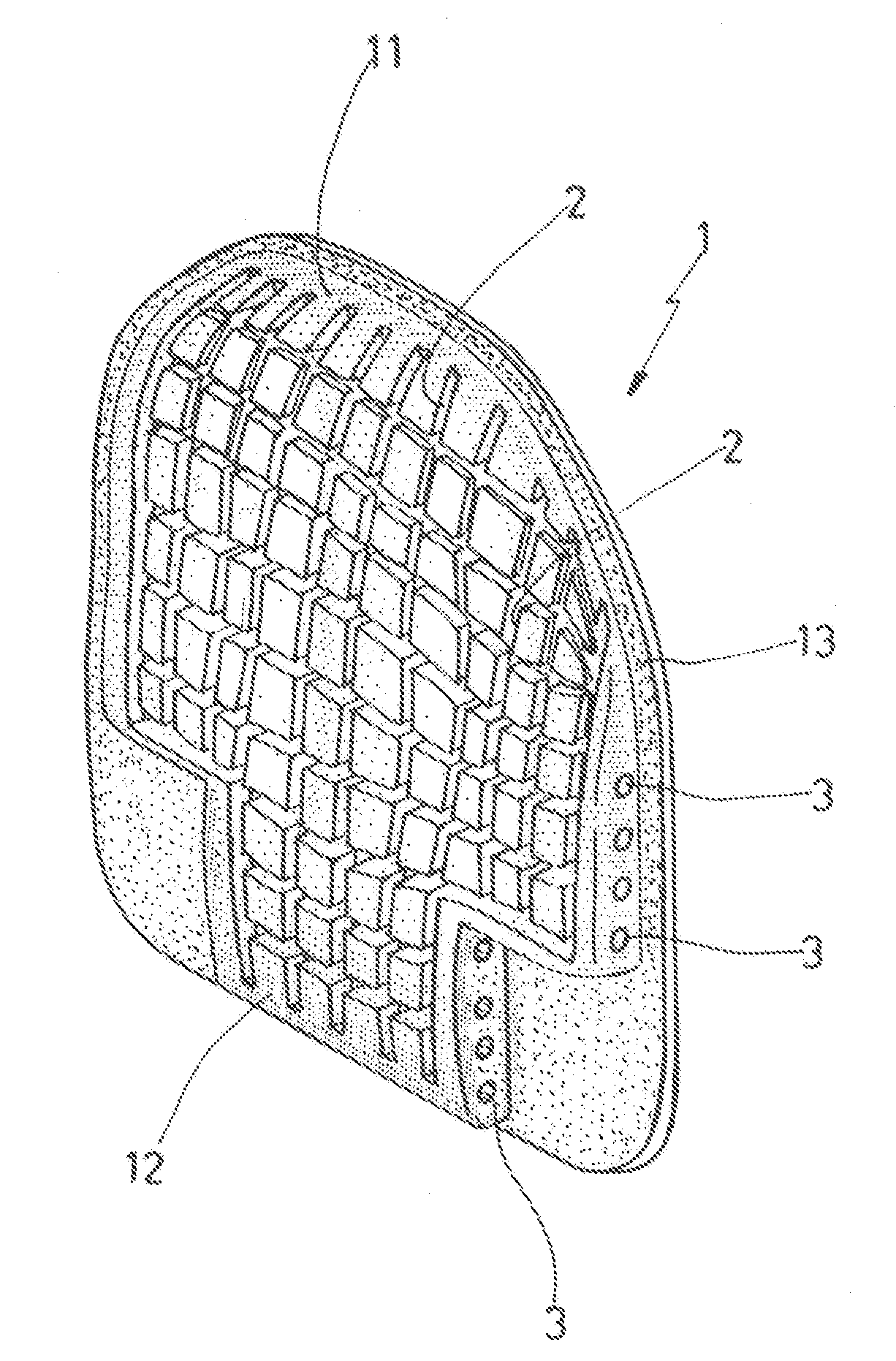

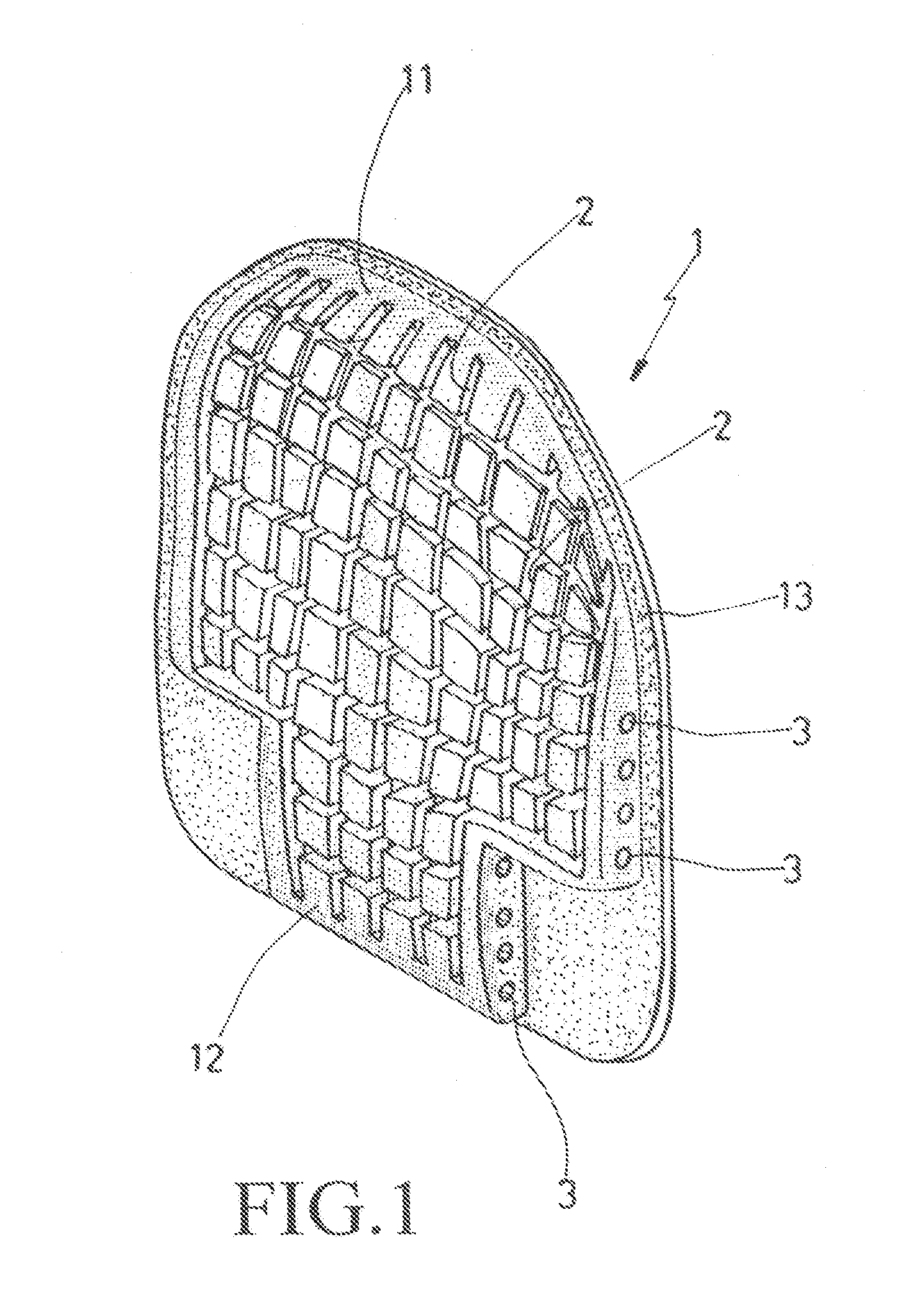

System and method for content delivery by subscriber personal channel

InactiveUS20160337704A1Increase flexibilityOvercome disadvantagesSelective content distributionPersonalizationResource management

The present invention relates to an improved system and method for providing a personal channel of linear programming to a subscriber in a content delivery network (CDN). The system and method of creates a linear channel for a subscriber in a predetermined arrangement of program scheduling from file information corresponding to media content data in predetermined arrangement of program scheduling to optimize the playback and the user experience. The predetermined arrangement of program scheduling is determined from one or more user characteristics based on service requests from the user or subscriber's interaction with a resource manager, a scheduler service and / or catalog service. According to methods of the present invention the personal channel for channel creation may be based on content provider, who will structure channels for a particular area, subscriber or other grouping of any available program scheduling. The personal channel of linear programming may be configured to use media content that has been predetermined for a particular personalized channel, whereby such a personalized channel may also change content from program to program, so that a version of the channel would be similar but unique to the viewer, such that a linear channel may be the basis service but individual programs will be swapped out from file information for the desired media content e.g. VOD, DVR, NDVR or other file based sources from said CDN.

Owner:LAYER3 TV INC

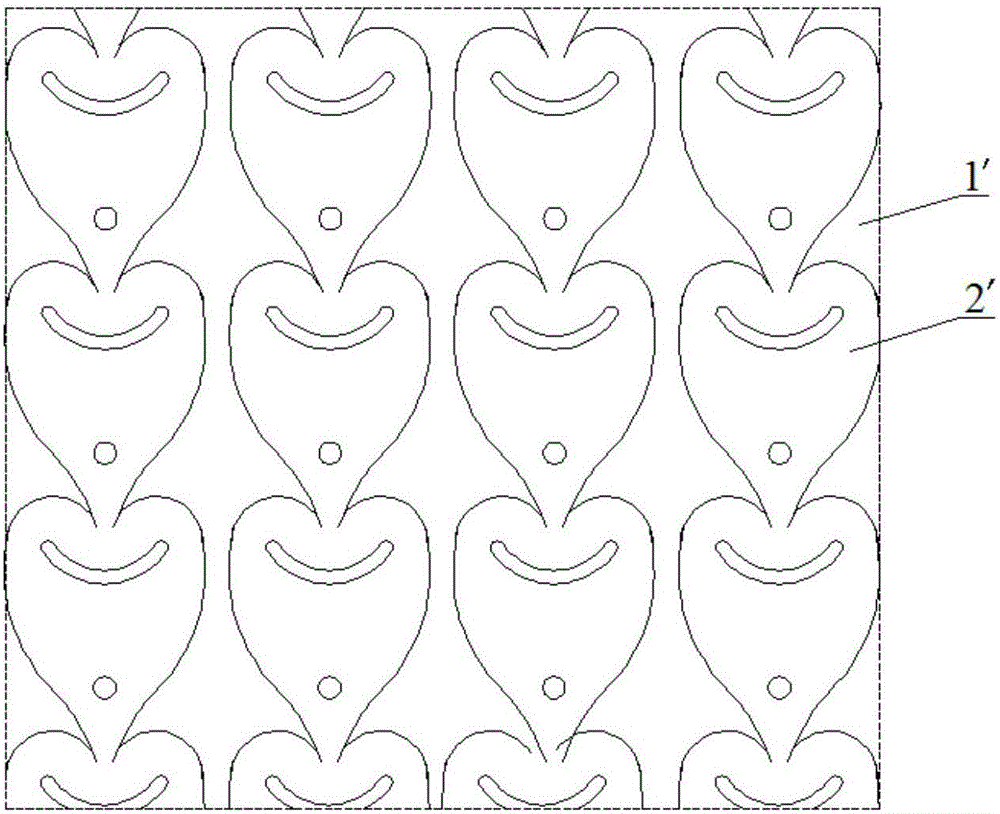

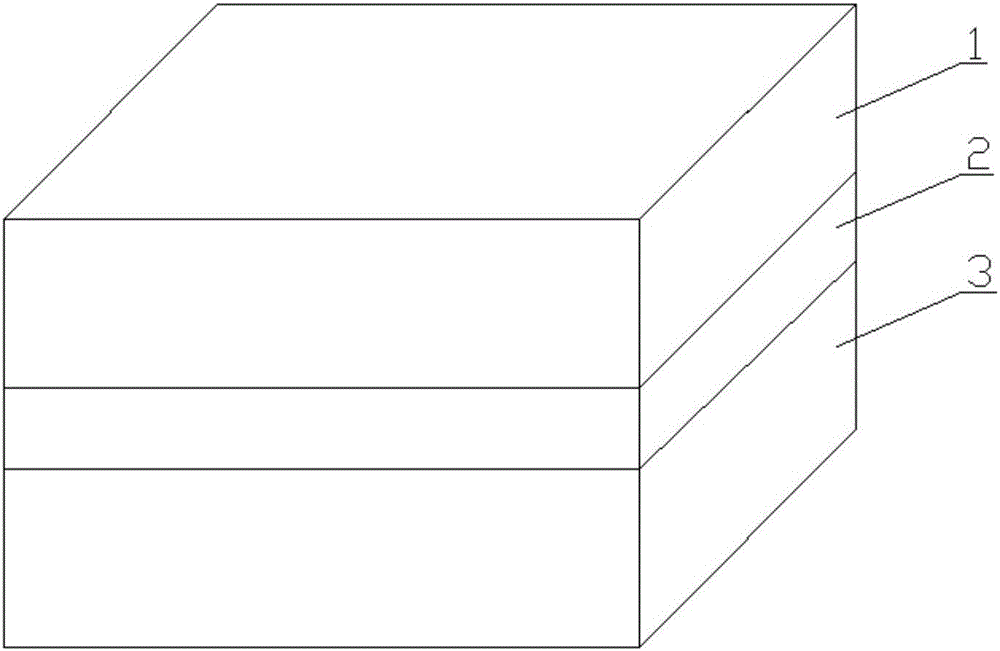

Three-dimensional ventilating pad for backpack

Owner:YANG FU YUAN

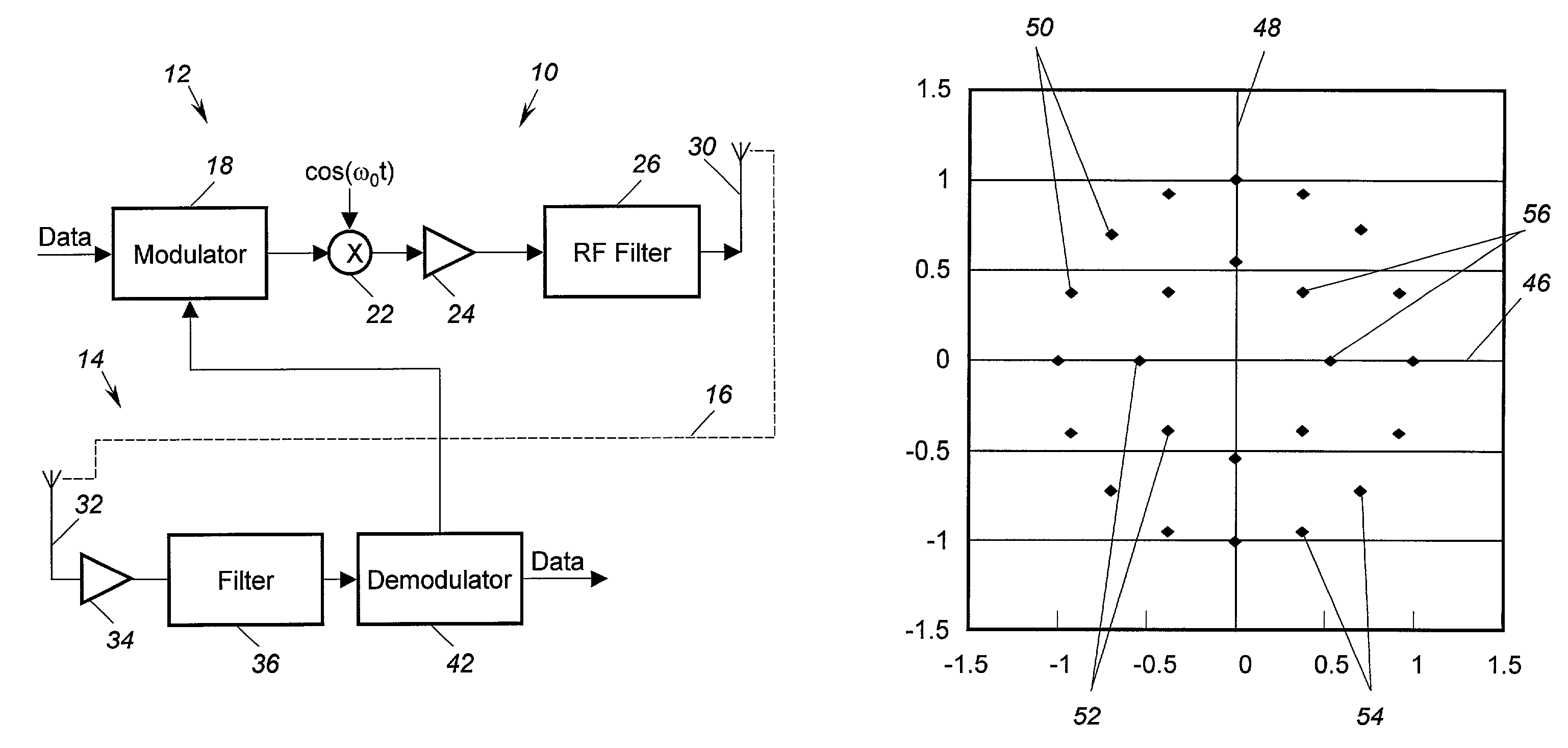

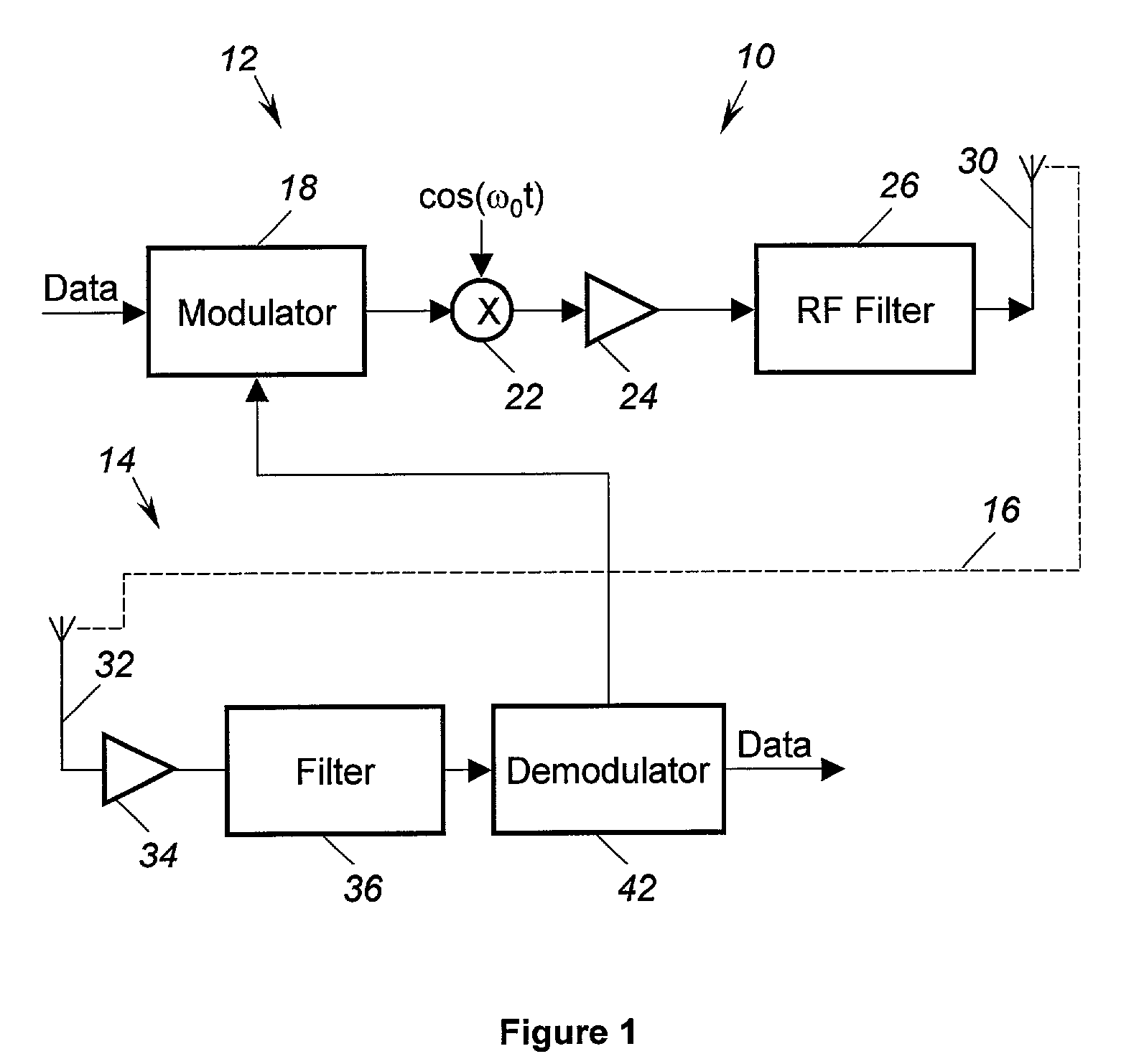

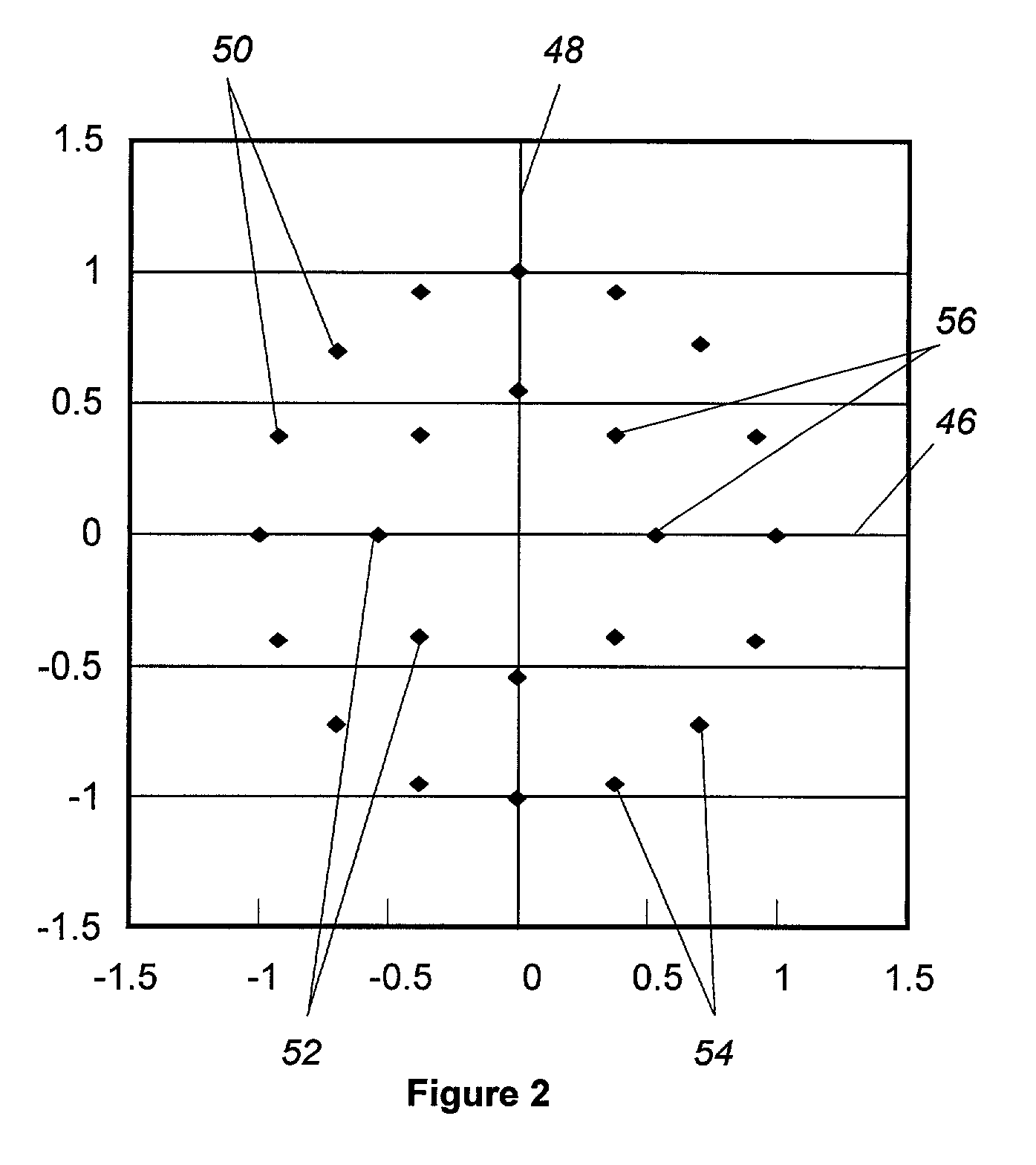

M-ary signal constellations suitable for non-linear amplification

InactiveUS7039126B2Secret communicationPhase-modulated carrier systemsCommunications systemPower efficient

A communications system (10) which utilizes an M-ary QAM signal constellation suitable for non-linear applications. The communications system includes a modulator (18) for utilizing the M-ary constellation to implement the modulation. The M-ary constellation is a circular constellation which provides a simplified amplitude predistortion by utilizing the subject M-ary constellations, enabling more efficient communications can then be achieved through a peak-power-limited non-linear channel (16). Such non-linear channels (16) are more power efficient at creating RF energy from DC energy.

Owner:NORTHROP GRUMMAN SYST CORP

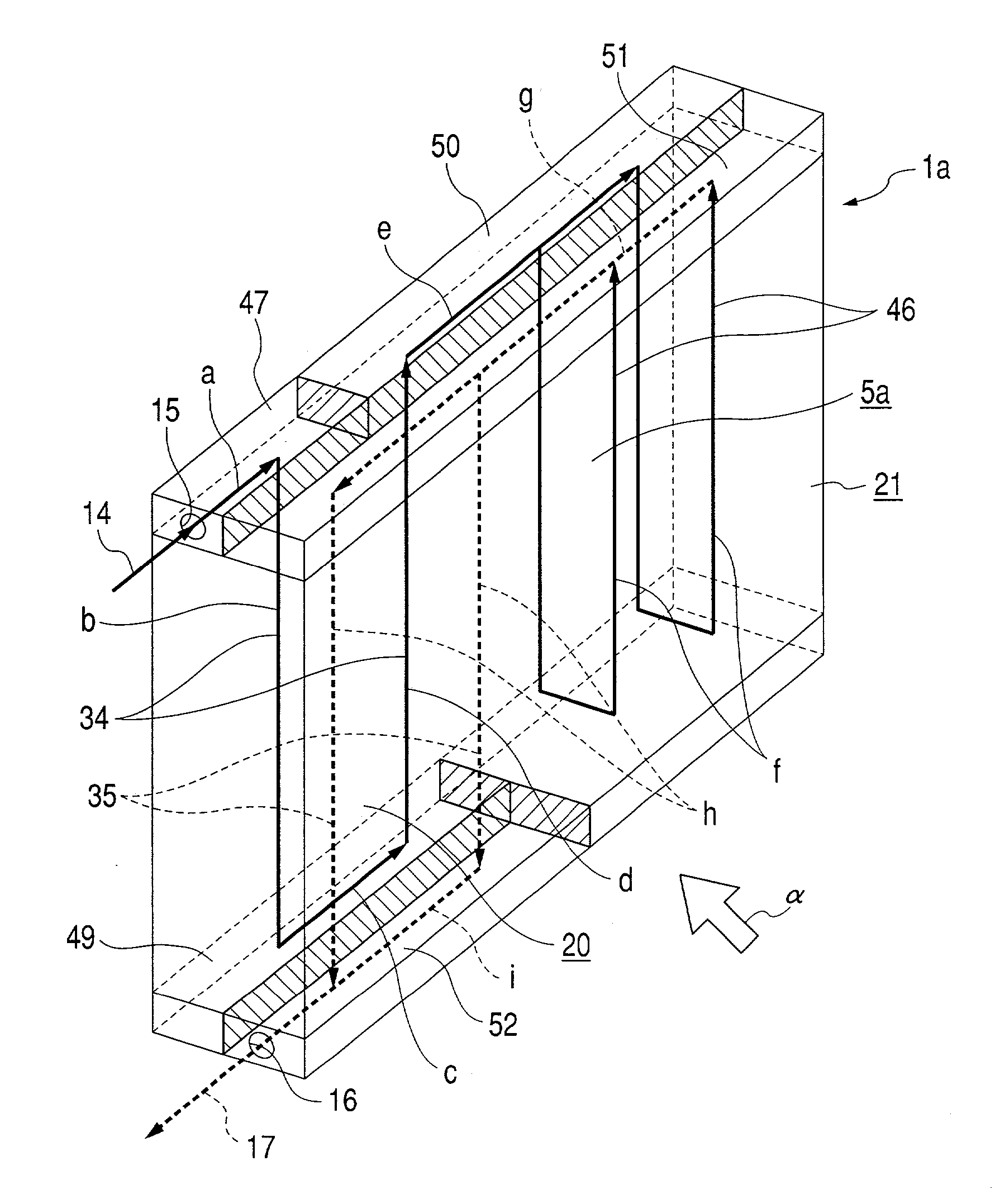

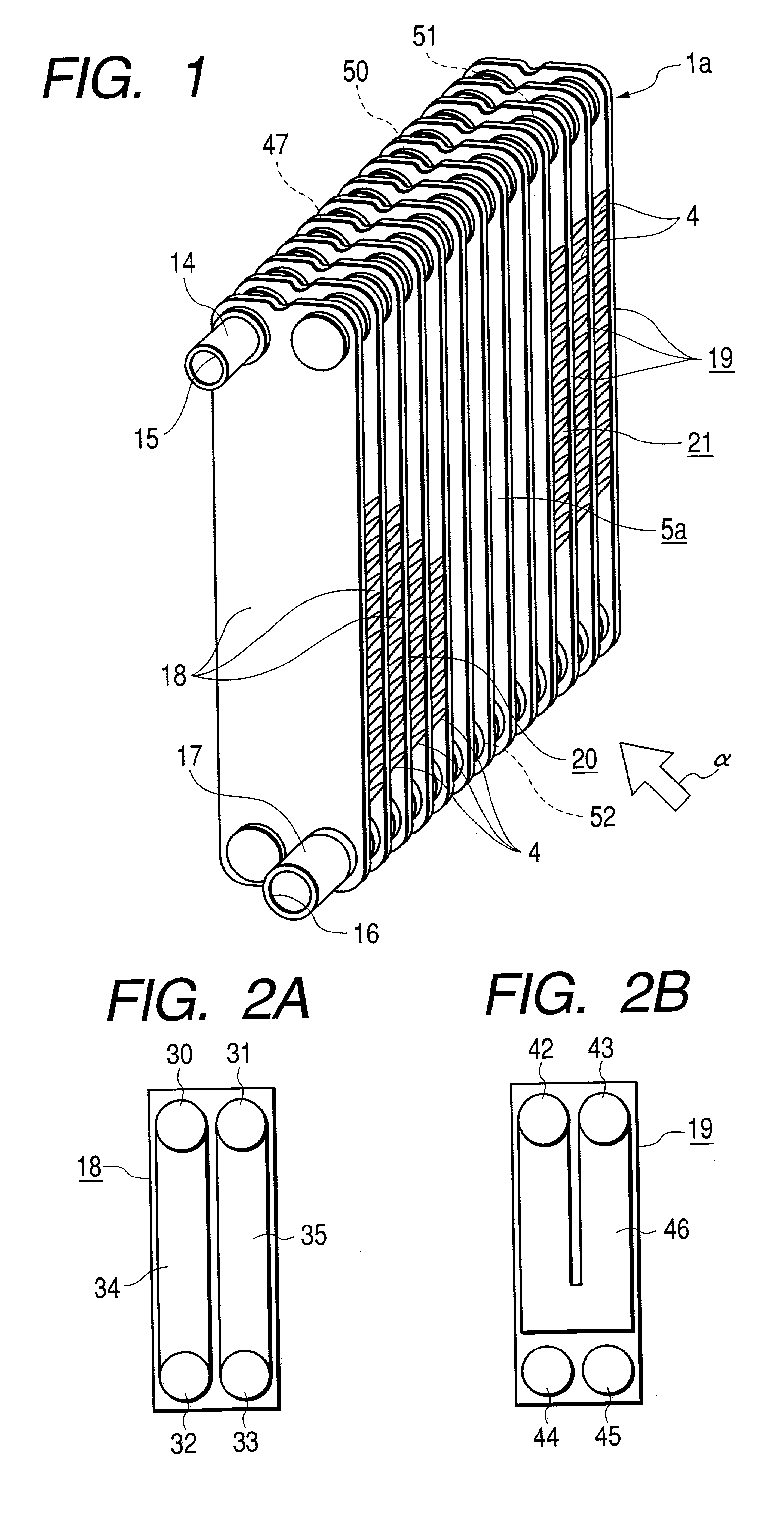

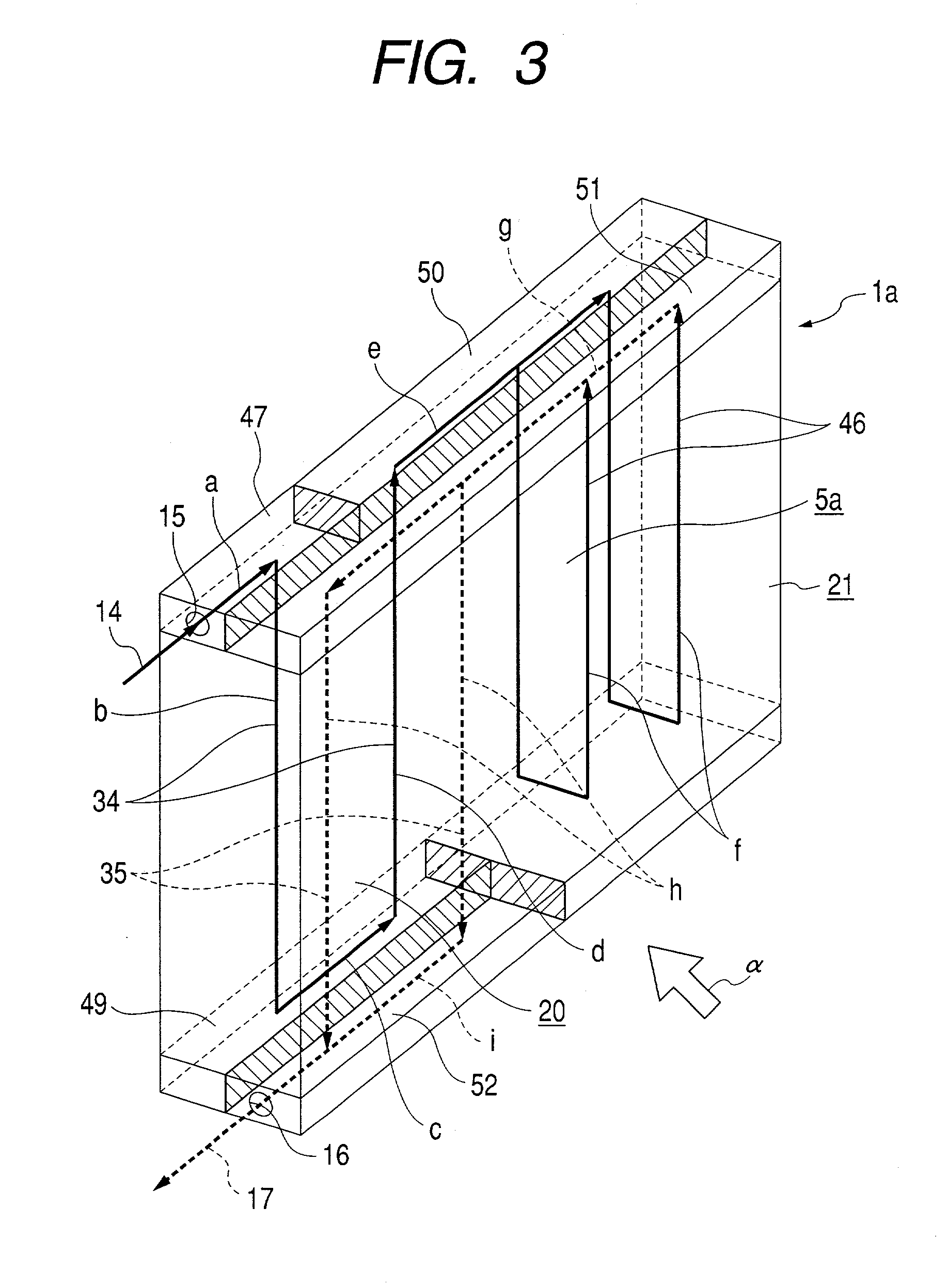

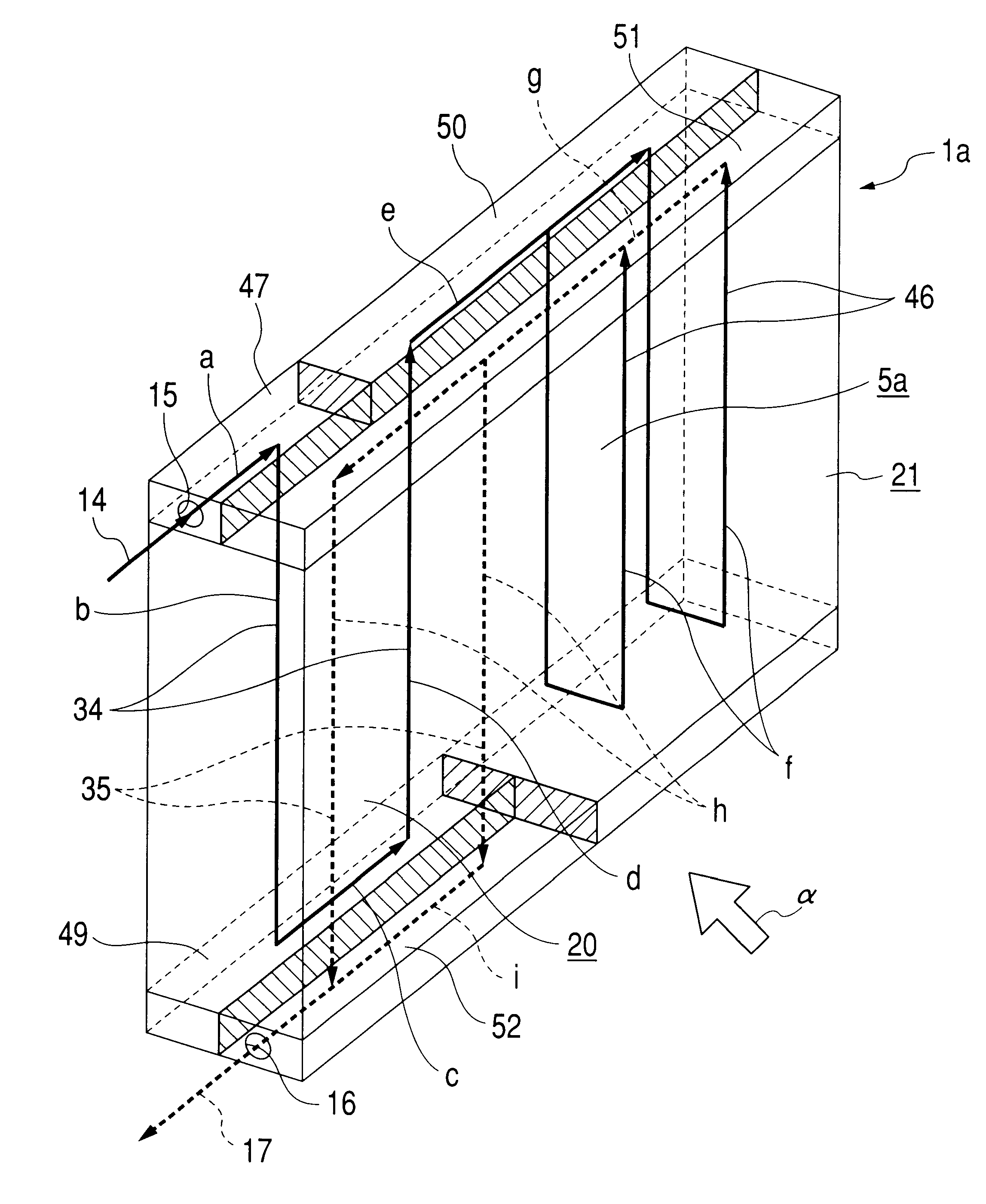

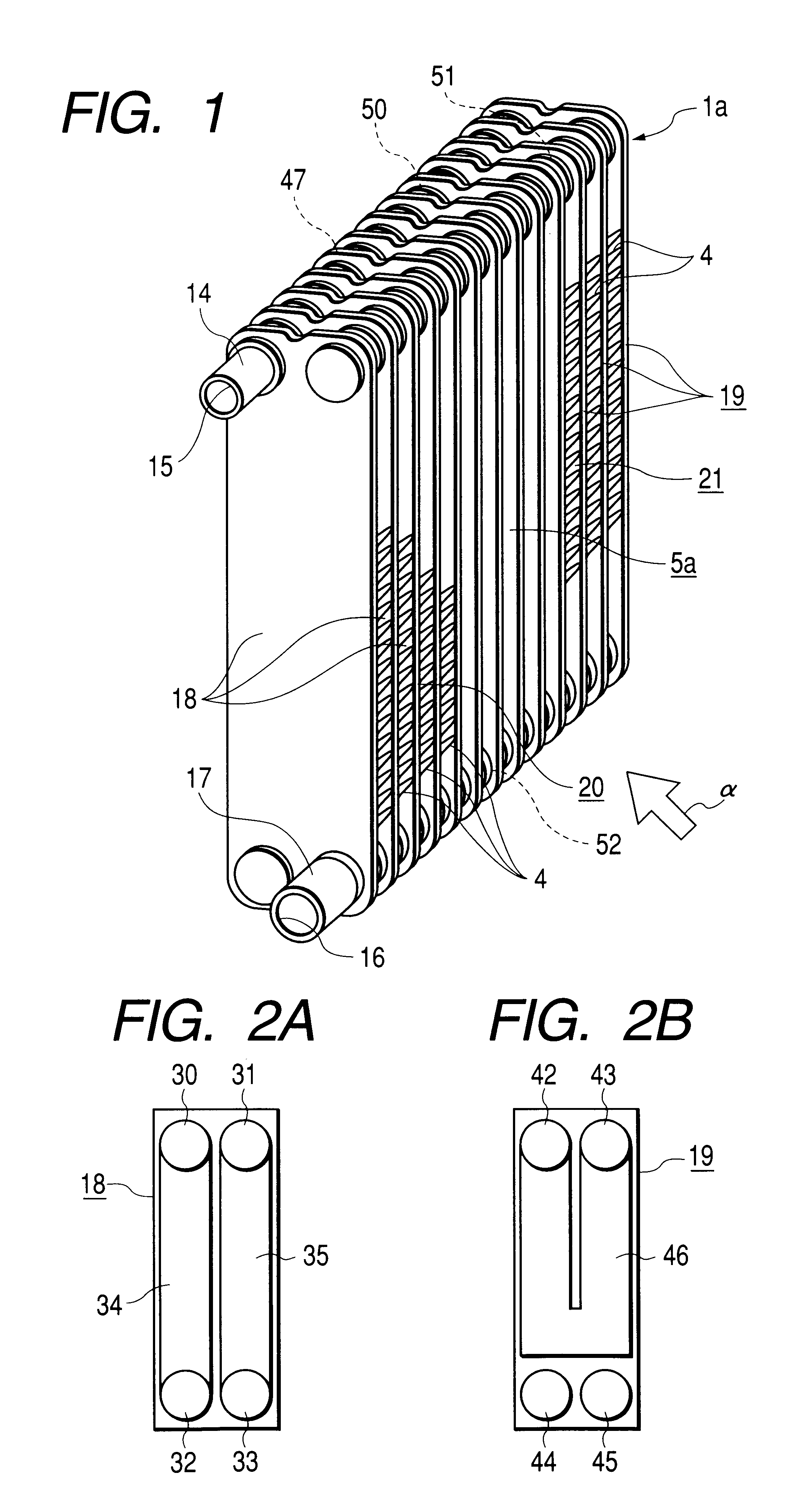

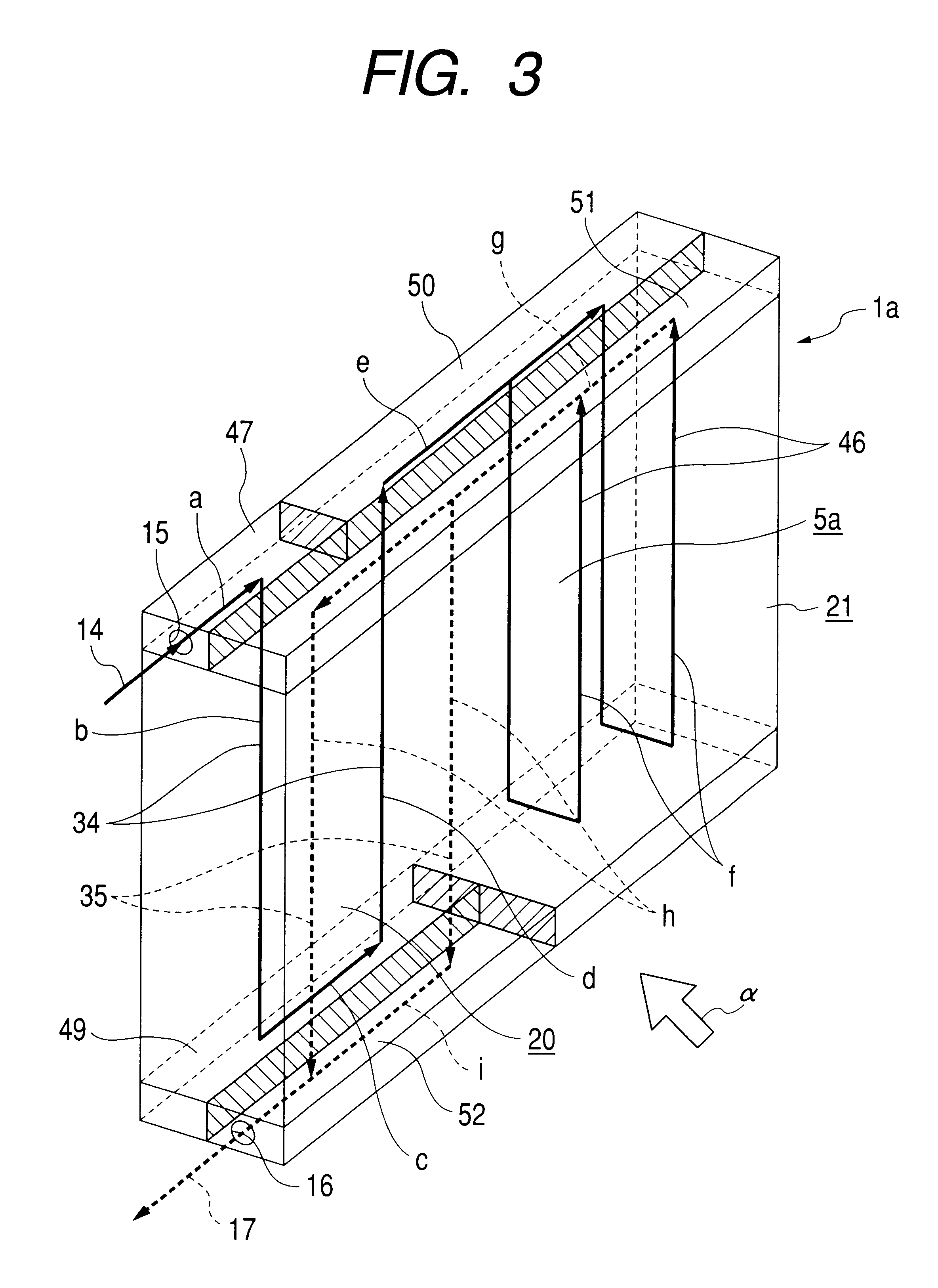

Stacked-type evaporator

A widthwise one half portion of a core section 5a is constituted by a first section 20 formed by stacking a plurality of first elements having first and second linear channels 34 and 35 inside them and fins, and a widthwise other half portion thereof is similarly constituted by a second section 21 formed by stacking a plurality of second elements respectively having U-shaped channels 46 inside them and fins. The number of times the refrigerant fed into a thicknesswise one half portion on an inlet tank 47 side of the first section 20 is turned back in an opposite direction concerning a longitudinal direction of the first linear channels 34 inside this thicknesswise one half portion is made more numerous than the number of times the refrigerant fed into a thicknesswise other half portion on an outlet tank 52 side of the first section 20 is turned back in the opposite direction concerning the longitudinal direction of the second linear channels 35 inside this thicknesswise other half portion.

Owner:CALSONIC KANSEI CORP

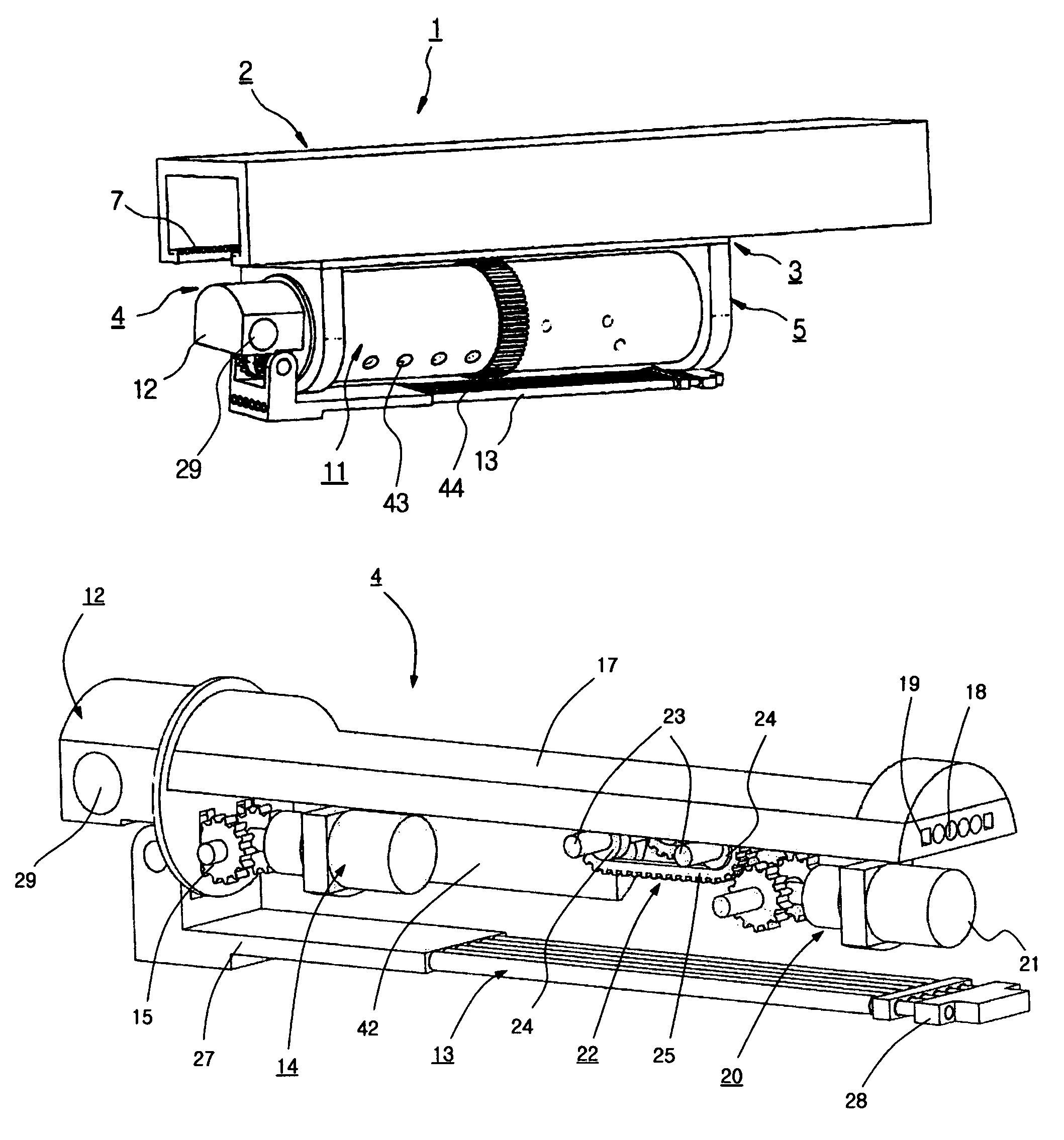

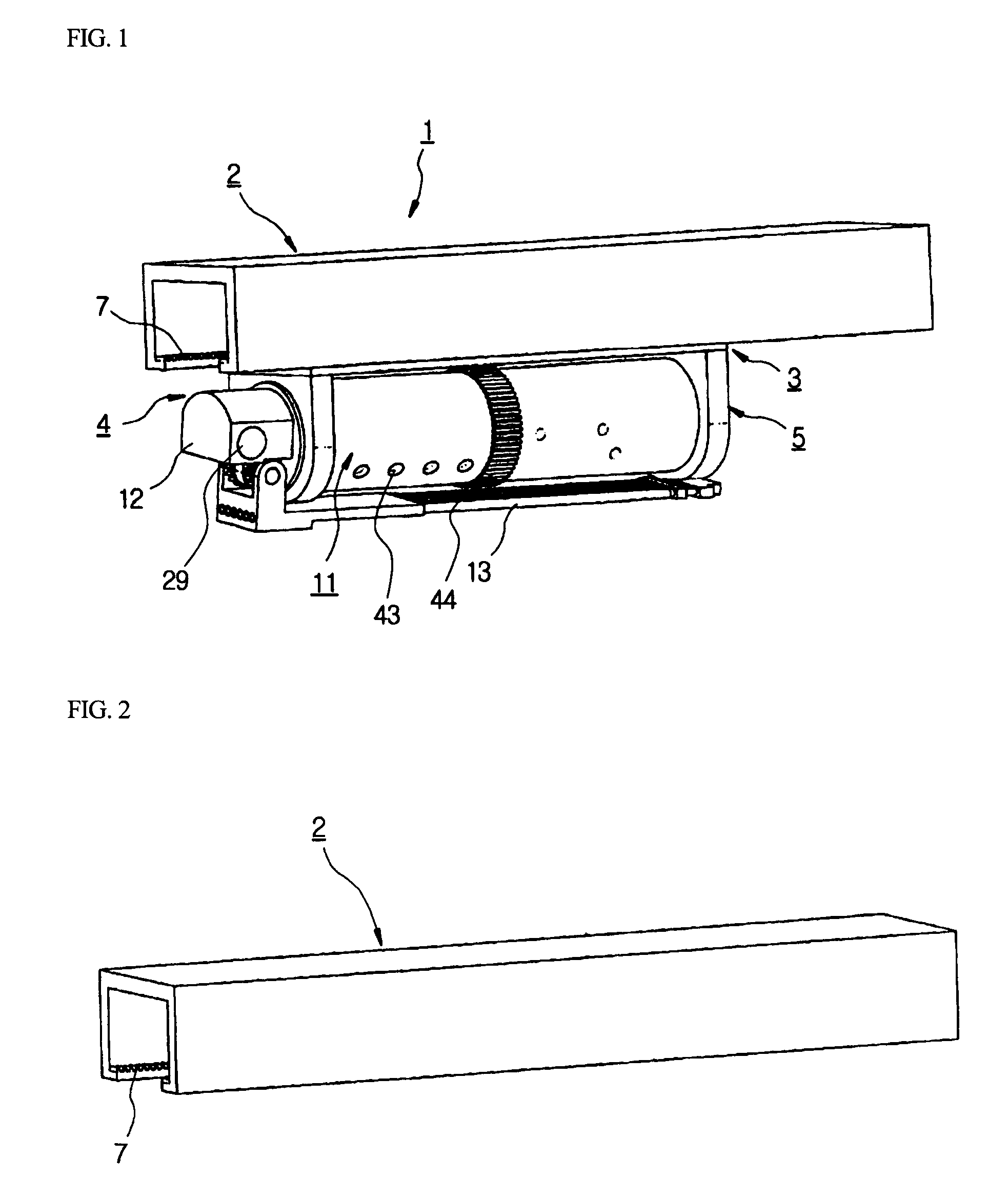

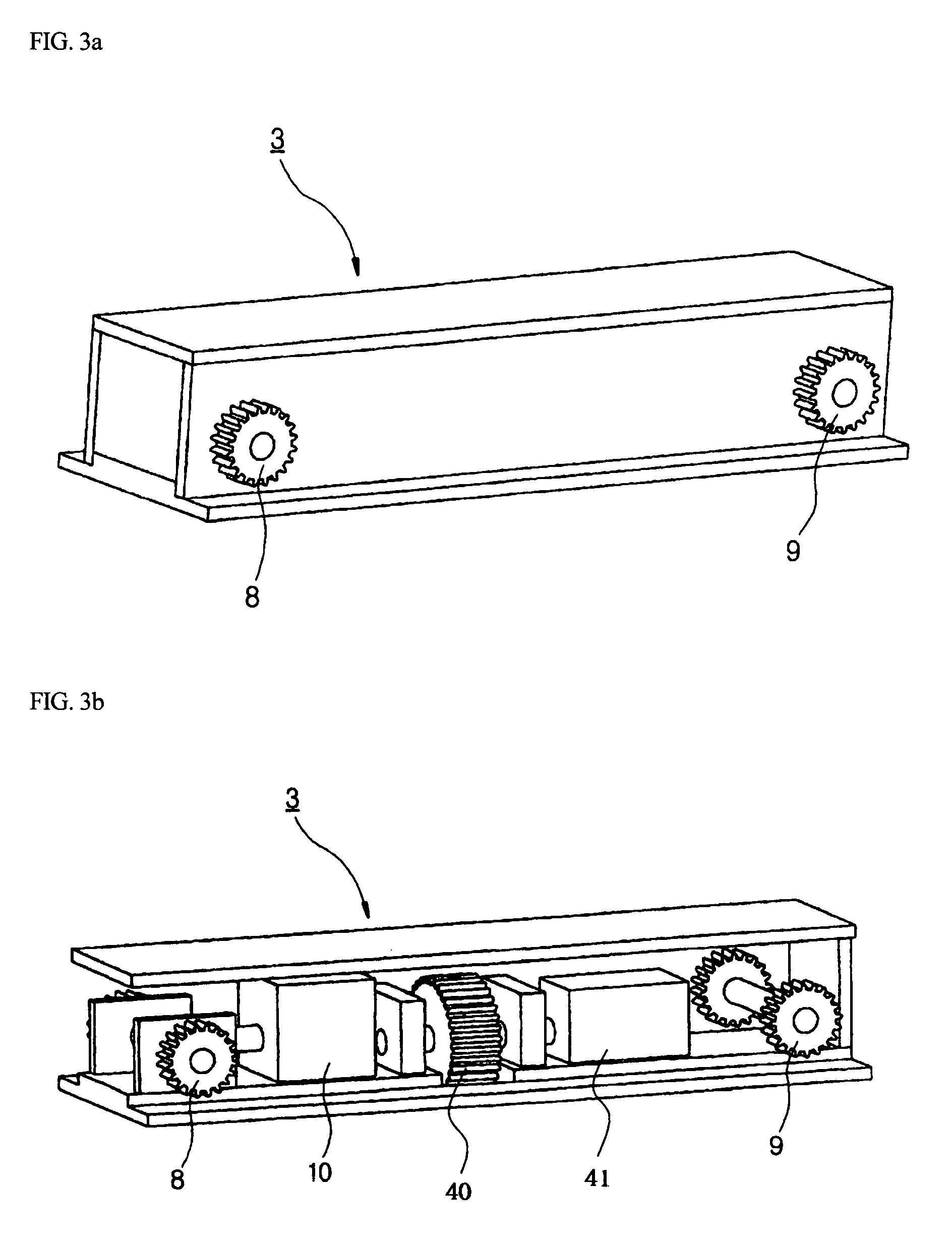

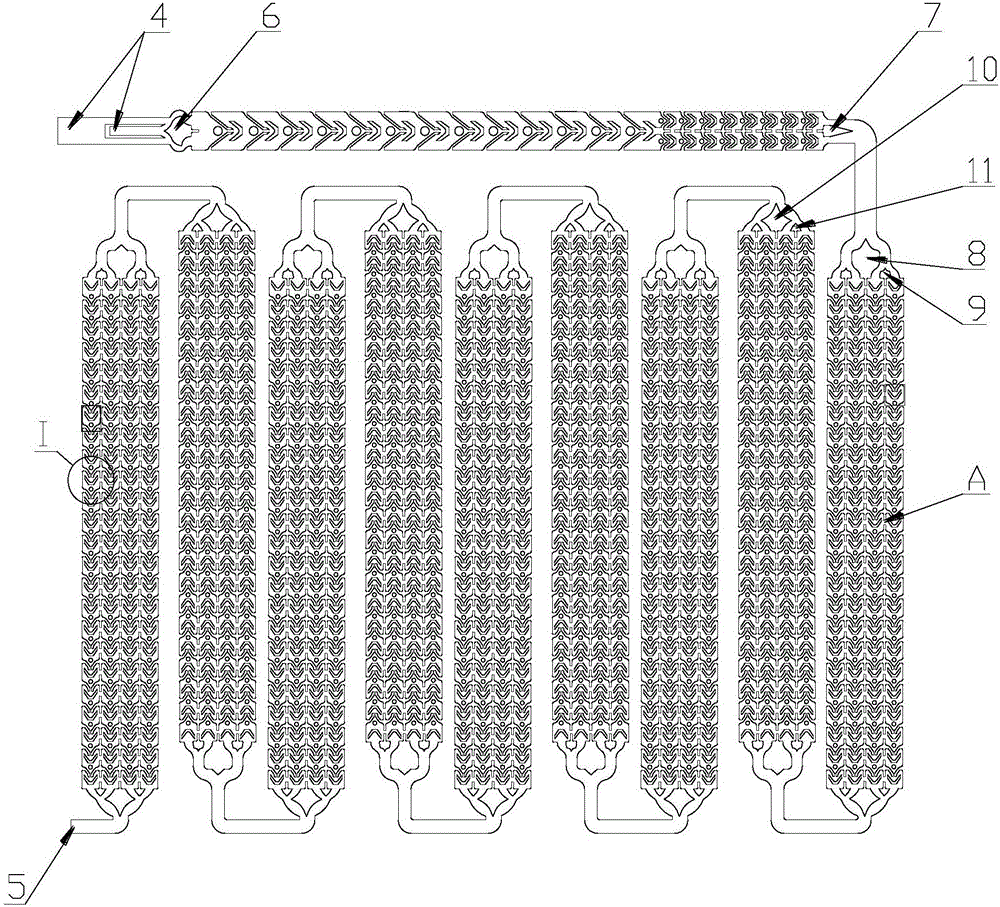

Lance system for inter-tube inspecting and lancing as well as barrel spraying of heat transfer tubes of steam generator in nuclear power plant

Disclosed is a lance system for inter-tube inspecting and lancing as well as barrel spraying of heat transfer tubes of a steam generator in a nuclear power plant, so that foreign substances piled up around heat transfer tubes in the steam generator are removed using high-pressure water. The lance system includes a rigid guide support rail positioned above a Blow Down Lane (BDL) at the center of the steam generator, a locomotion box including a motor drive unit for inducing a rectilinear motion of a lance body and a motor drive unit for inducing a rotational motion of the lance body centering on a horizontal axis, the lance body including a circular barrel including a motor drive unit for vertically erecting or horizontally laying down a multistage circular pole assembly, and a flat plate provided with linear passages for passing high-pressure water hoses, an optical cable and control rods therethrough, a circular drum assembly for stably connecting the high-pressure water hoses, the optical cable and the control rods, and the multistage circular pole assembly being extensible and contractible by the movement of the control rods obtained by engaging teeth of a toothed belt unit, driven by a motor and positioned in the circular barrel, with gear teeth of the control rods, and two nozzle blocks, for barrel spraying, provided with barrel spray nozzles fixedly assembled therewith, symmetrically fixed to the inner surface of the circular barrel, wherein the multistage circular pole assembly is vertically erected in the operation of inter-tube lancing and inspecting, in which the lance system approaches inner parts of the heat transfer tubes and sprays the high-pressure water thereto, and is maintained in a horizontally laid-down position in the operation of barrel spraying.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

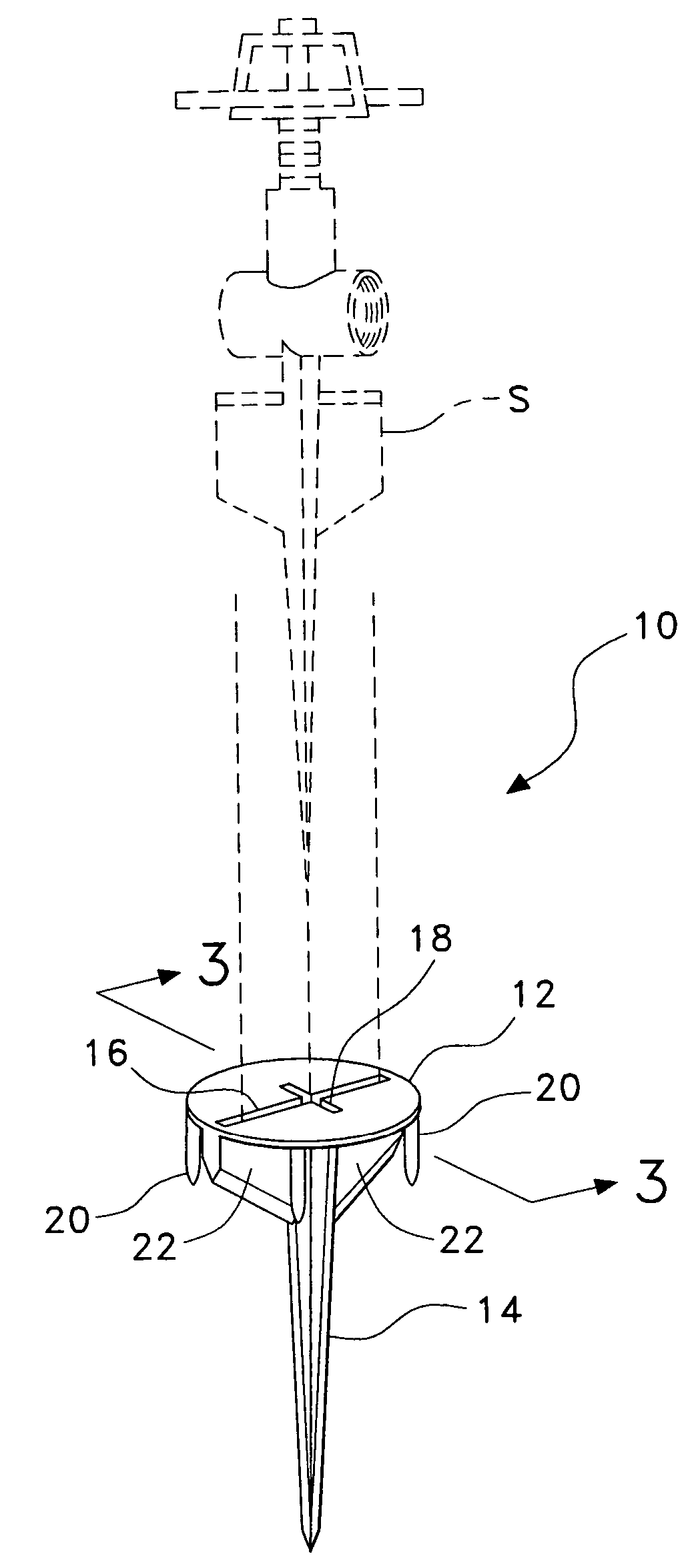

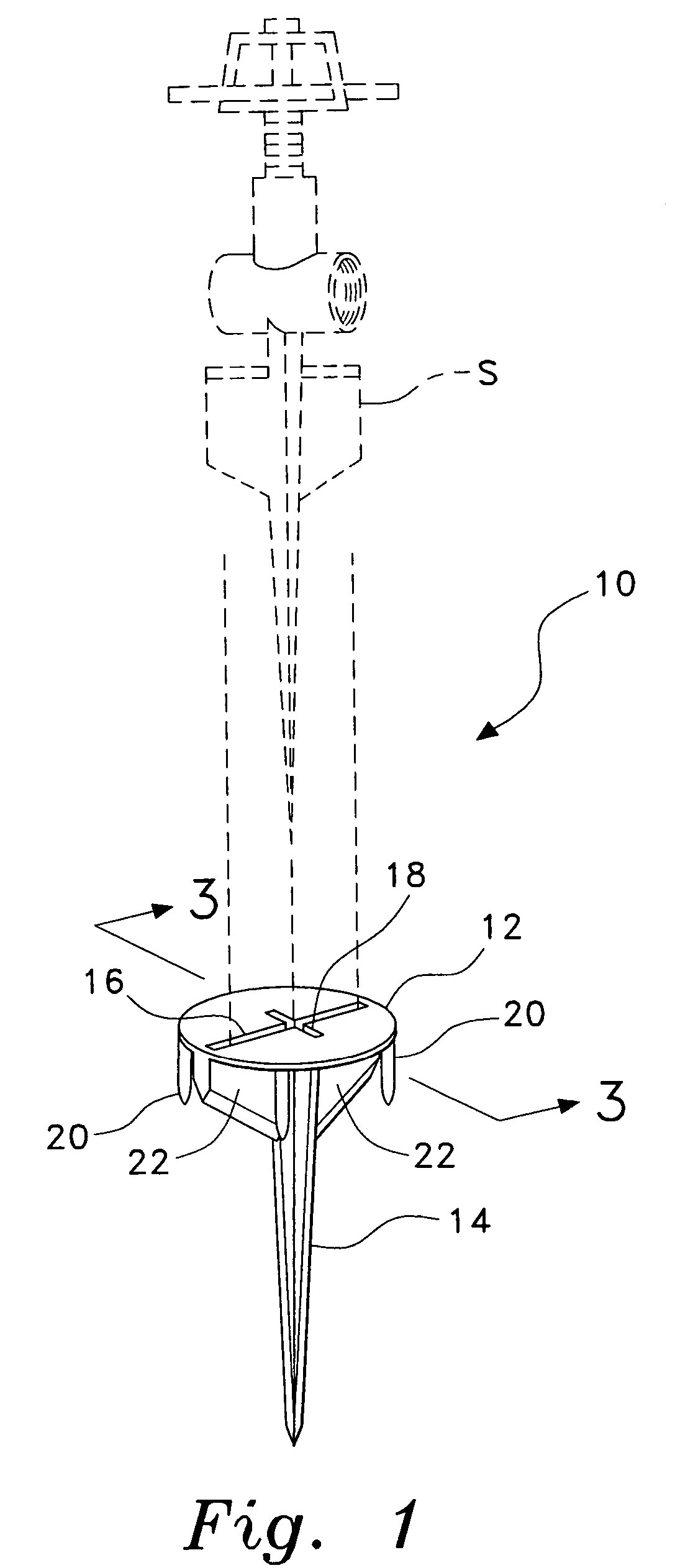

Sprinkler anchor

Owner:MAYORGA PETE

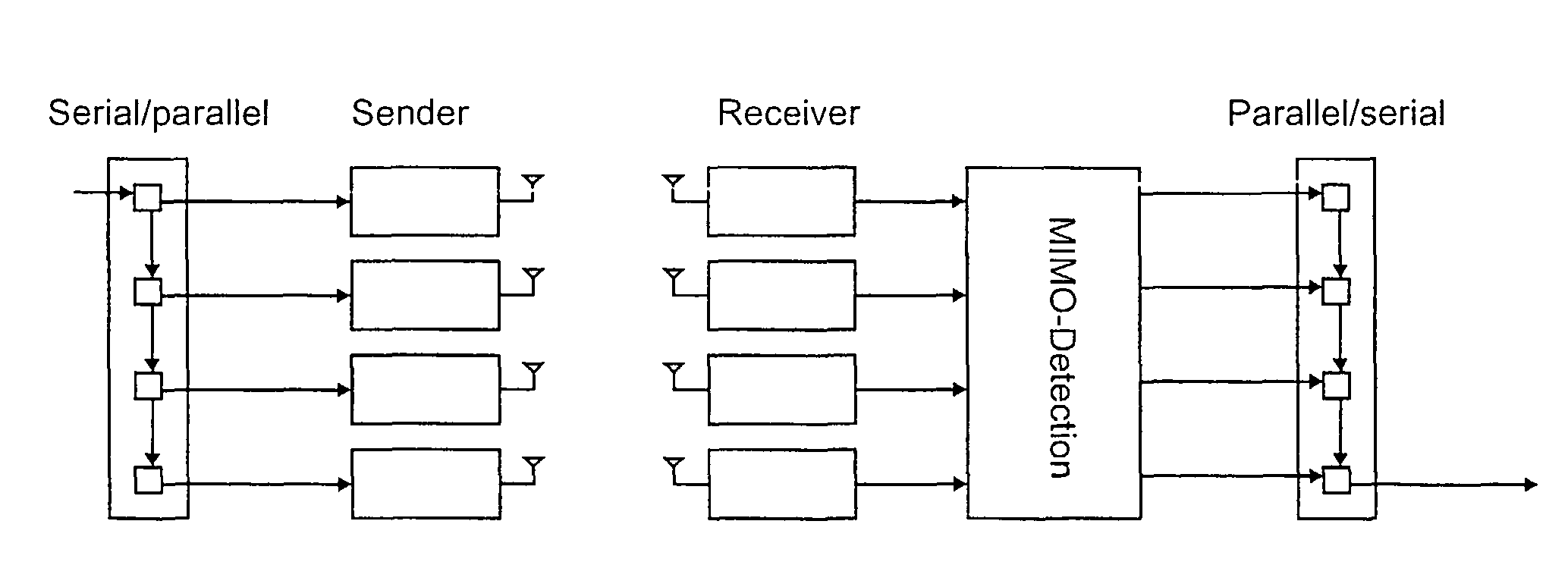

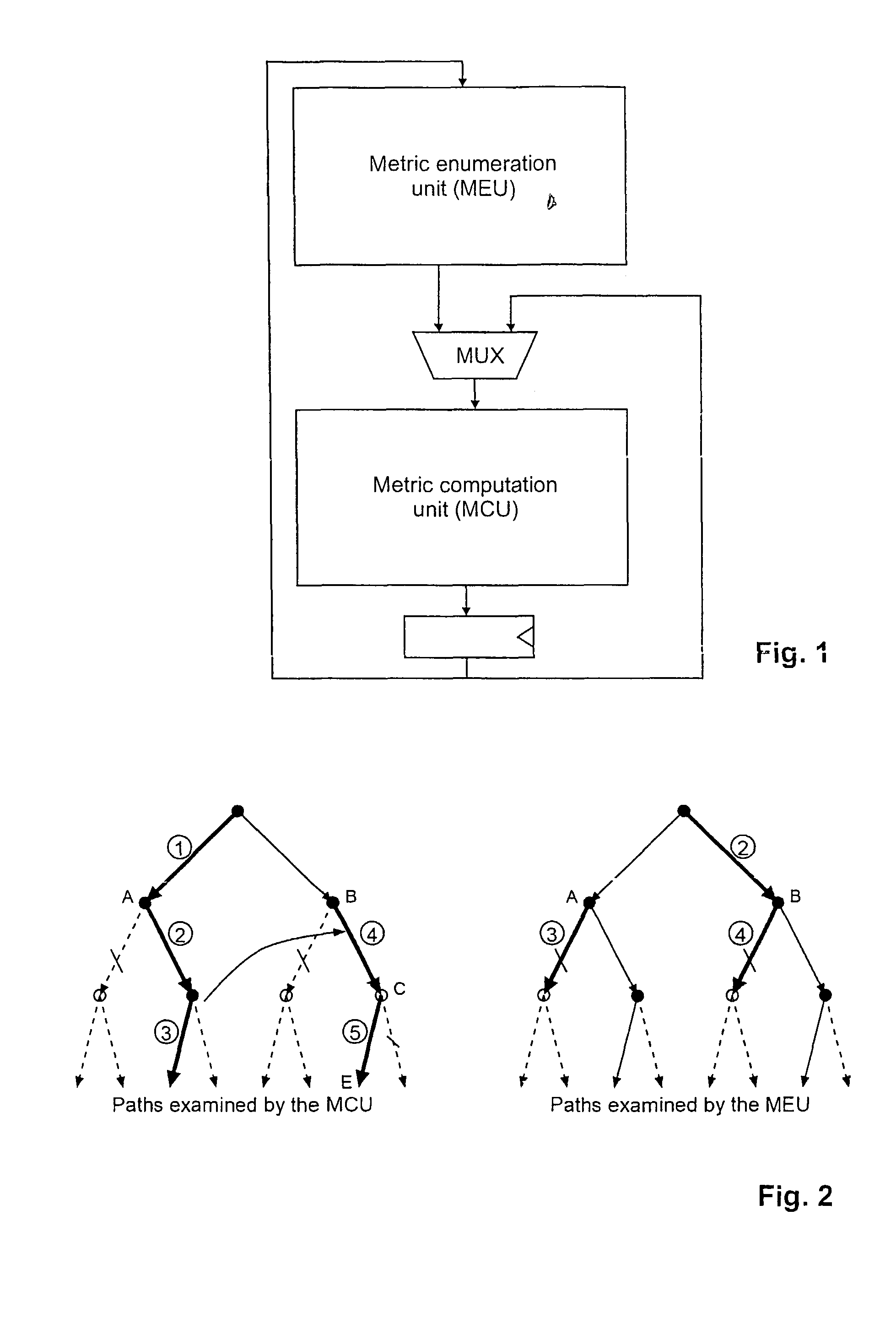

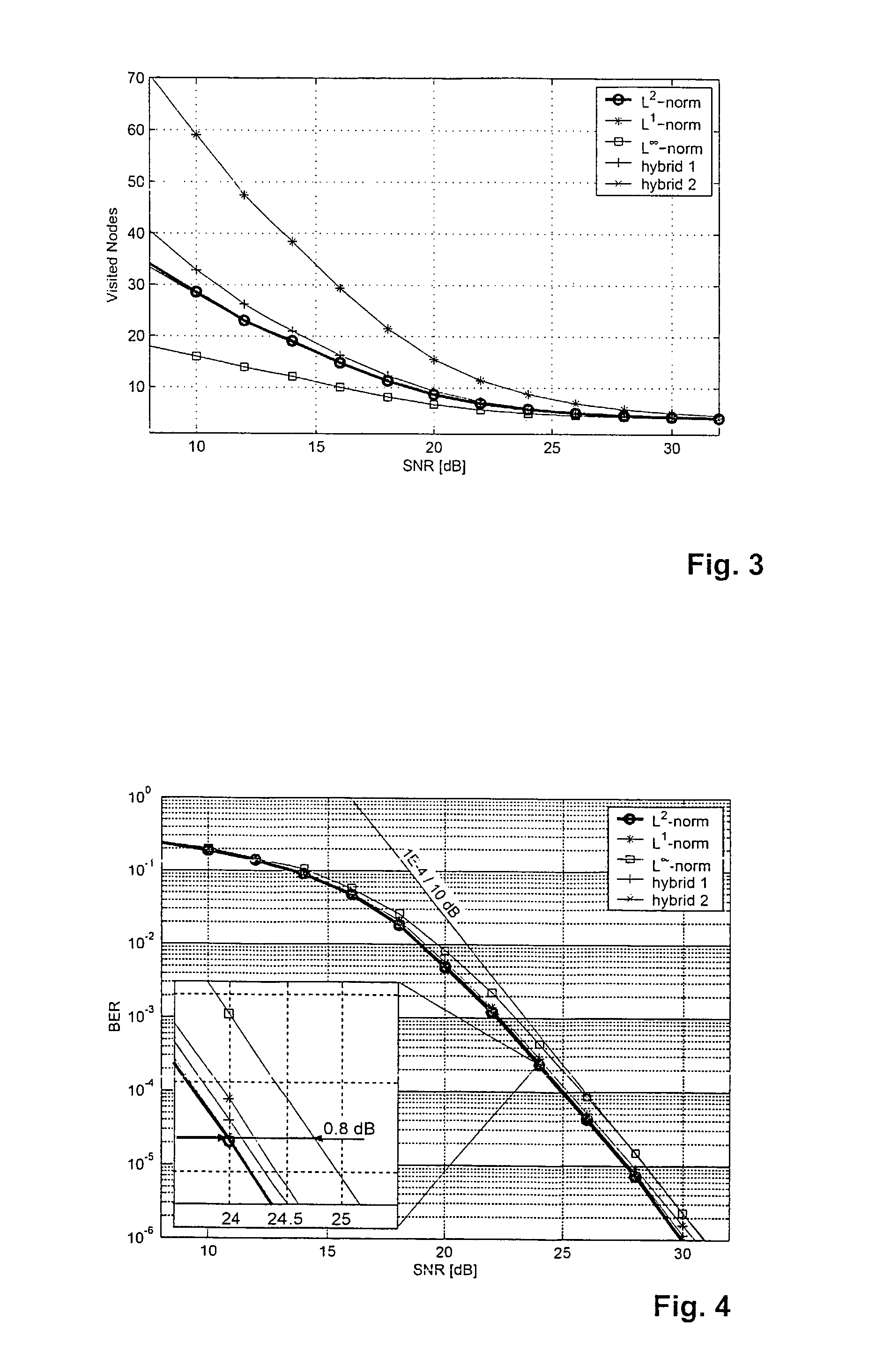

Method and device for decoding a signal of multiple input/multiple output system

InactiveUS7782971B2Efficient implementationReduce error rateDiversity/multi-antenna systemsBaseband systemsQR decompositionDecision boundary

The method for decoding a received signal in a multiple input / multiple output system uses QR-decomposition of the linear channel matrix, but then applies a non-Euclidean norm during tree traversal. Two separate hardware units, namely an MCU and a MEU, art provided for concurrent operation. The MCU determines a next child node, while the MEU determines next best parent nodes on the previously processed tree levels, which makes it possible to retrace the path to a next starting node without investing dedicated processing steps (e.g., cycles). On each tree level, the possible coordinates are grouped into several circular sets in the complex plane, and a series of decision boundaries is calculated for each set that allows a quick evaluation of the optimum coordinate in each set.

Owner:ETH ZZURICH

Micro-reactor

ActiveCN106423033AReduce areaKeep for a long timeChemical/physical/physico-chemical microreactorsChemical/physical/physico-chemical stationary reactorsMicroreactorEnergy consumption

The invention discloses a micro-reactor. The micro-reactor is provided with a reaction channel; the reaction channel is provided with a plurality of reaction cavities (12), and each reaction cavity (12) is internally provided with a diversion body (15) and a spoiler body (16); all the reaction cavities (12) are respectively in a rectangle; an outlet of each reaction cavity (12) comprises a V-shaped channel (17) and a linear channel (18), wherein the widths of the V-shaped channels (17) are reduced gradually, and the widths of the linear channels (18) are the same as one another; the widths a of the linear channels (18) are 0.002-6mm, and the ratios of distances b between the spoiler bodies (16) and two sides of the V-shaped channels (17) to the widths a of the linear channels (18) are equal to 0.93-2.2. The micro-reactor has a high specific surface area so as to augment and strengthen a reaction process, thus further increasing liquid holdup and handling capacity, effectively improving the conversion rate and yield of products and remarkably improving coefficient of heat conduction and heat exchange effect; furthermore, when a medium passes through a channel, the pressure drop is greatly reduced, so that the micro-reactor is beneficial to accurate control of reaction conditions and reduction of energy consumption.

Owner:SHANDONG HIMILE CHEM TECH

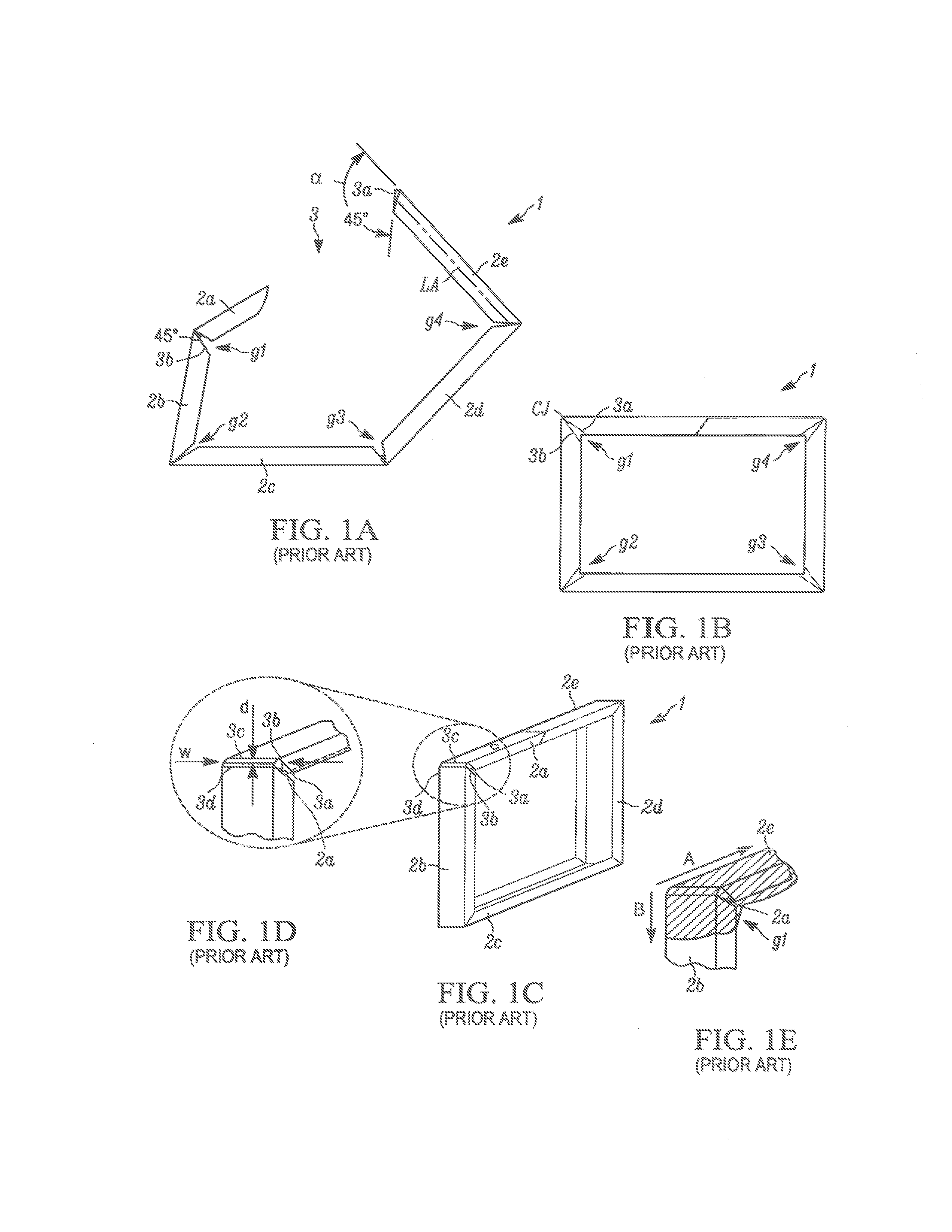

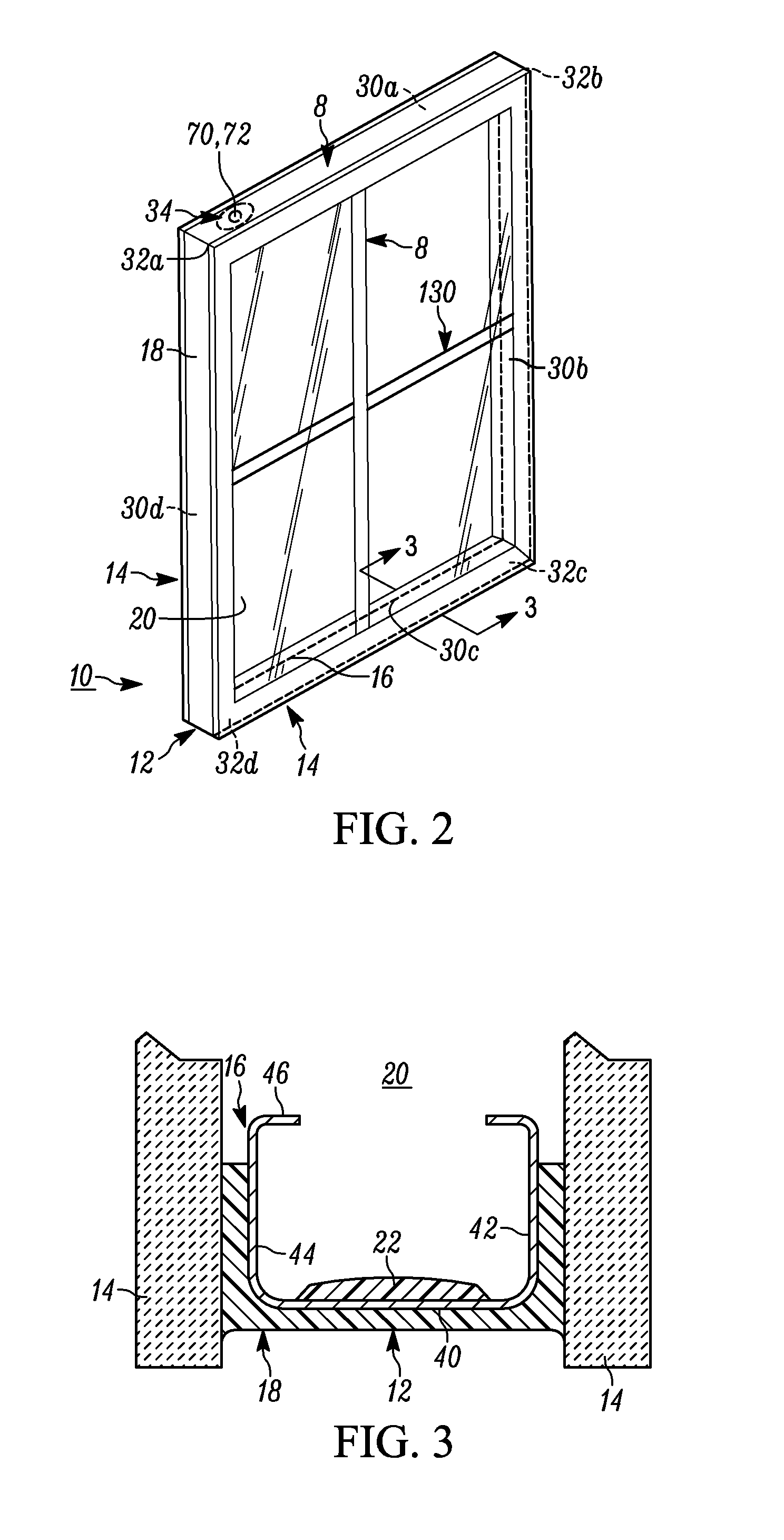

Spacer frame and method of making same

Owner:GED INTEGRATED SOLUTIONS

Microfluidics sorter for cell detection and isolation

ActiveUS9458489B2Easy to handleIncrease flow rateMicrobiological testing/measurementDead animal preservationMicrofluidicsCell based

A method of detecting one or more diseased blood cells in a blood sample includes introducing a blood sample into at least one inlet of a microfluidic device comprising one or more linear channels wherein each channel has a length and a cross-section of a height and a width defining an aspect ratio adapted to isolate diseased blood cells along at least one portion of the cross-section of the channel based on reduced deformability of diseased blood cells as compared to non-diseased blood cells, wherein diseased blood cells flow along a first portion of the channel to a first outlet and non-diseased blood cells flow along a second portion of the channel to a second outlet. The one or more channels can be adapted to isolate cells along portions of the cross-section of the channel based on cell size. In some embodiments, the one or more channels can be spiral channels.

Owner:MASSACHUSETTS INST OF TECH +1

Symmetrical self-closing mechanism for a drawer slide

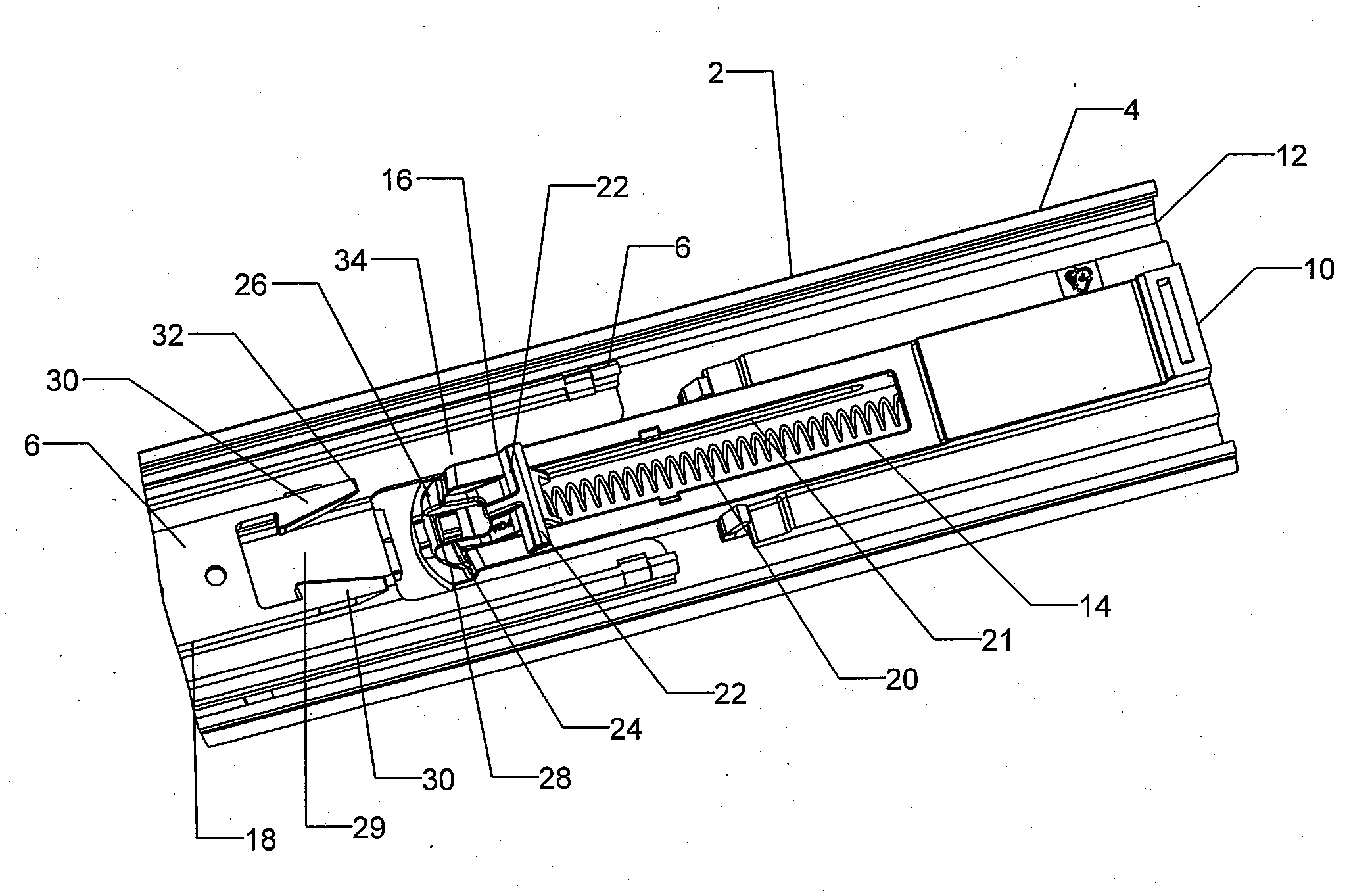

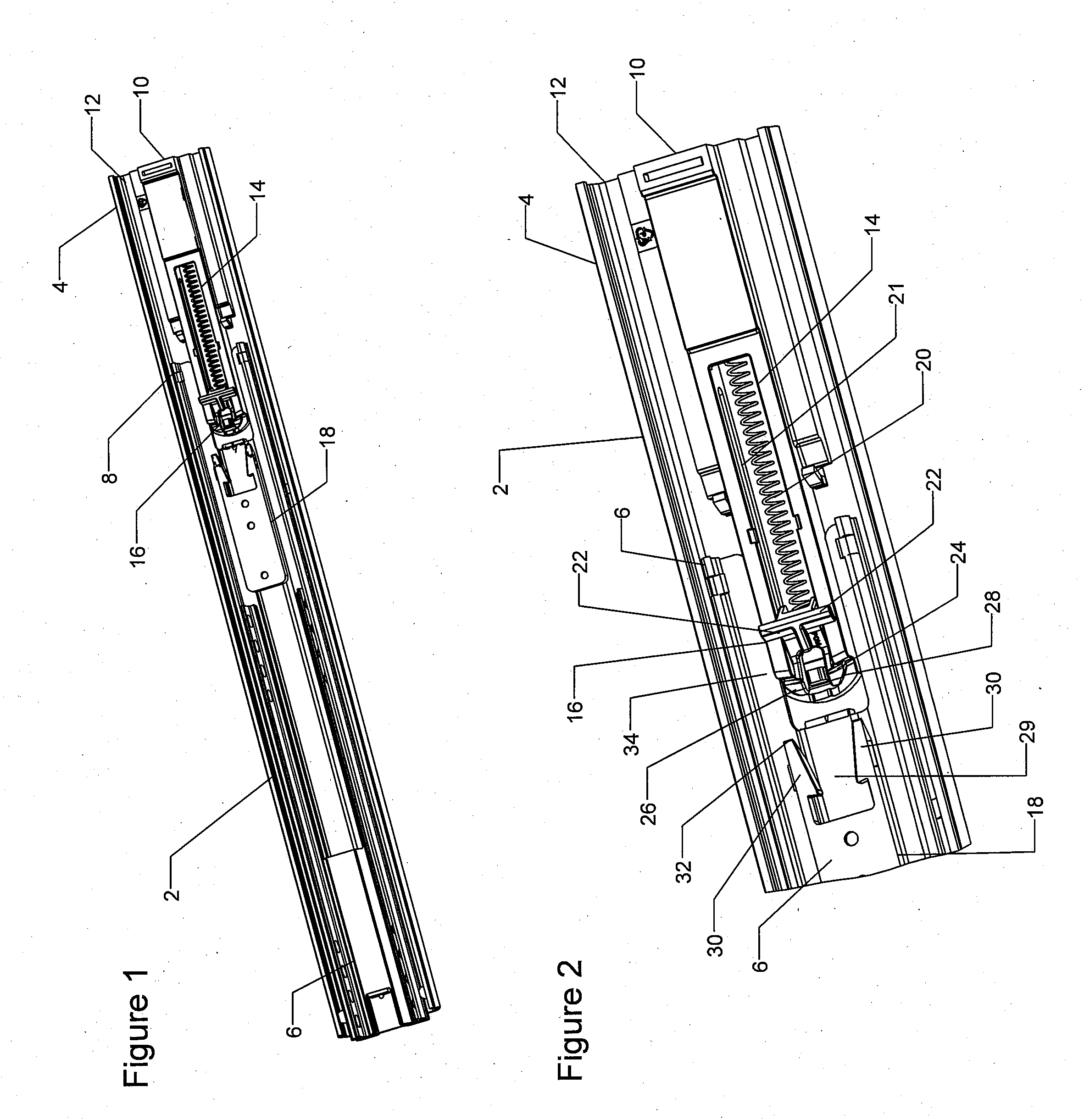

ActiveUS20090026902A1Easy to operateReduce manufacturing costDrawersFittingEngineeringMechanical engineering

A self-closing drawer slide has a housing with a linear channel extending therein at an inner end of an outer longitudinal section. A catch is slidably mounted within the channel and has pivot pins 36 extending out either side thereof (only one side is shown) into corresponding slots in the sides of the channel. The catch is symmetrical about a longitudinal centre line of the housing and rocks rearward to unlock and engage a latch on an inner longitudinal section and forward to lock and release the latch. The catch is biased to slide to an inner end of the channel when the catch is unlocked and there are no external forces on the slide.

Owner:WATERLOO FURNITURE COMPONENTS

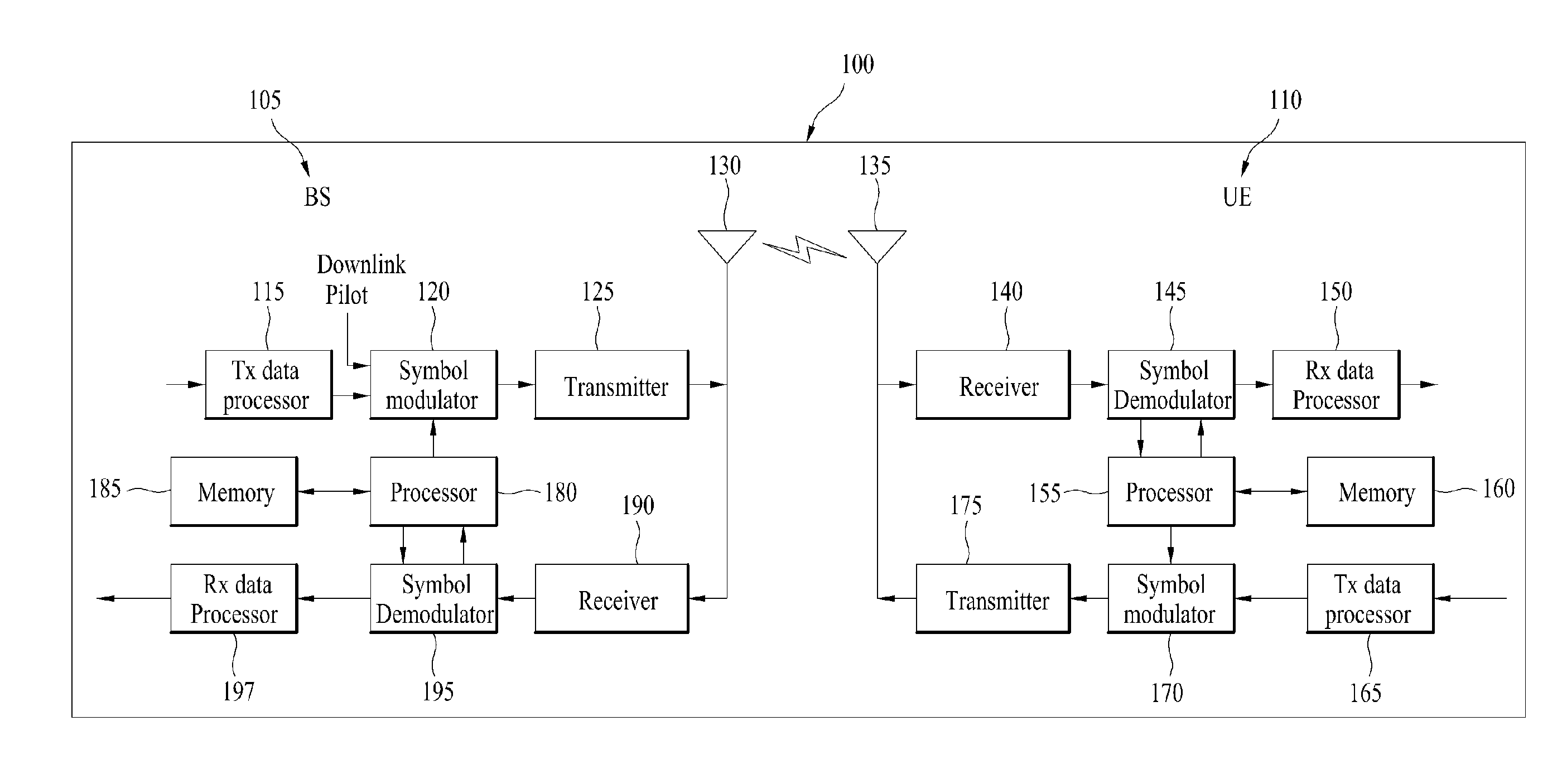

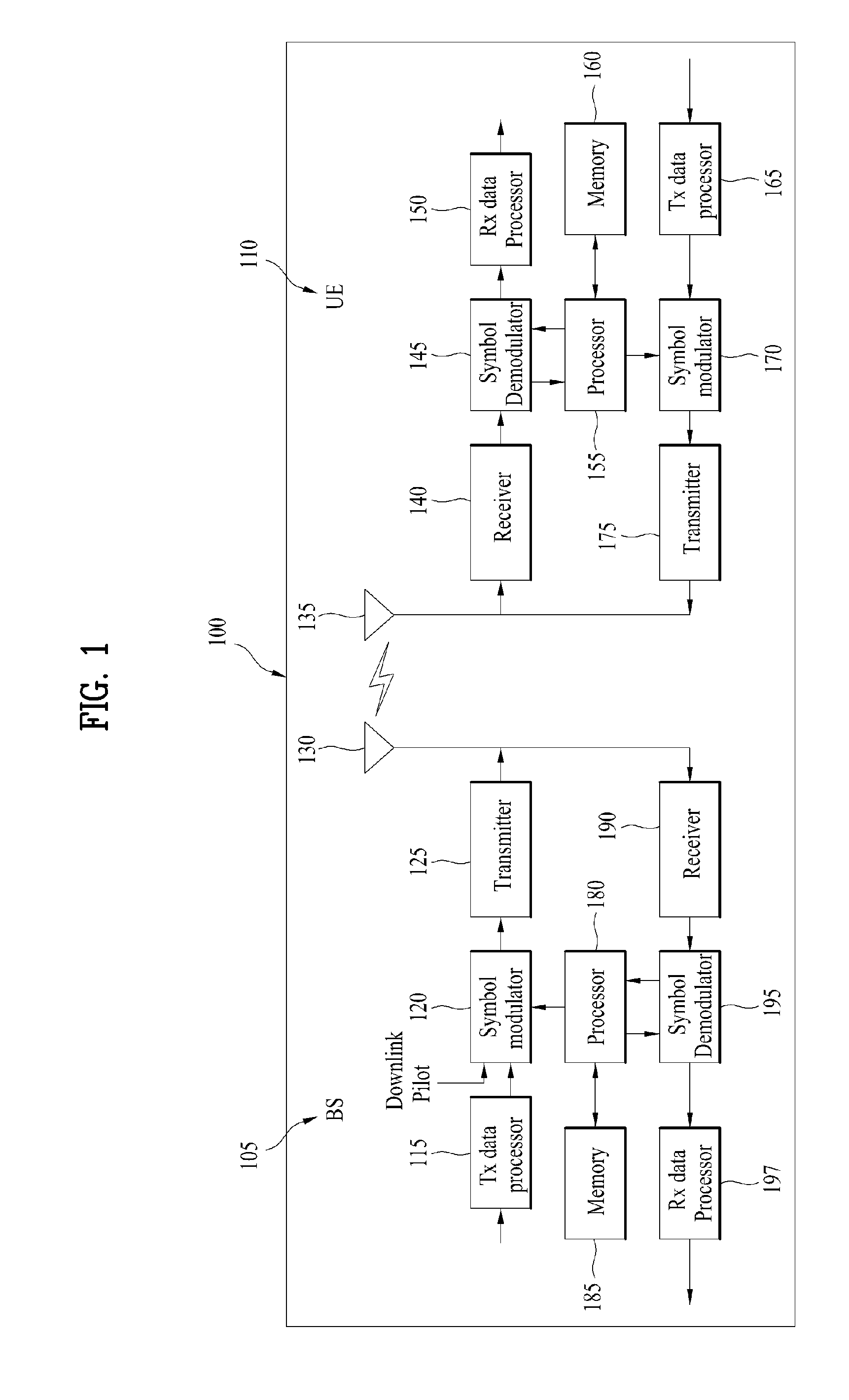

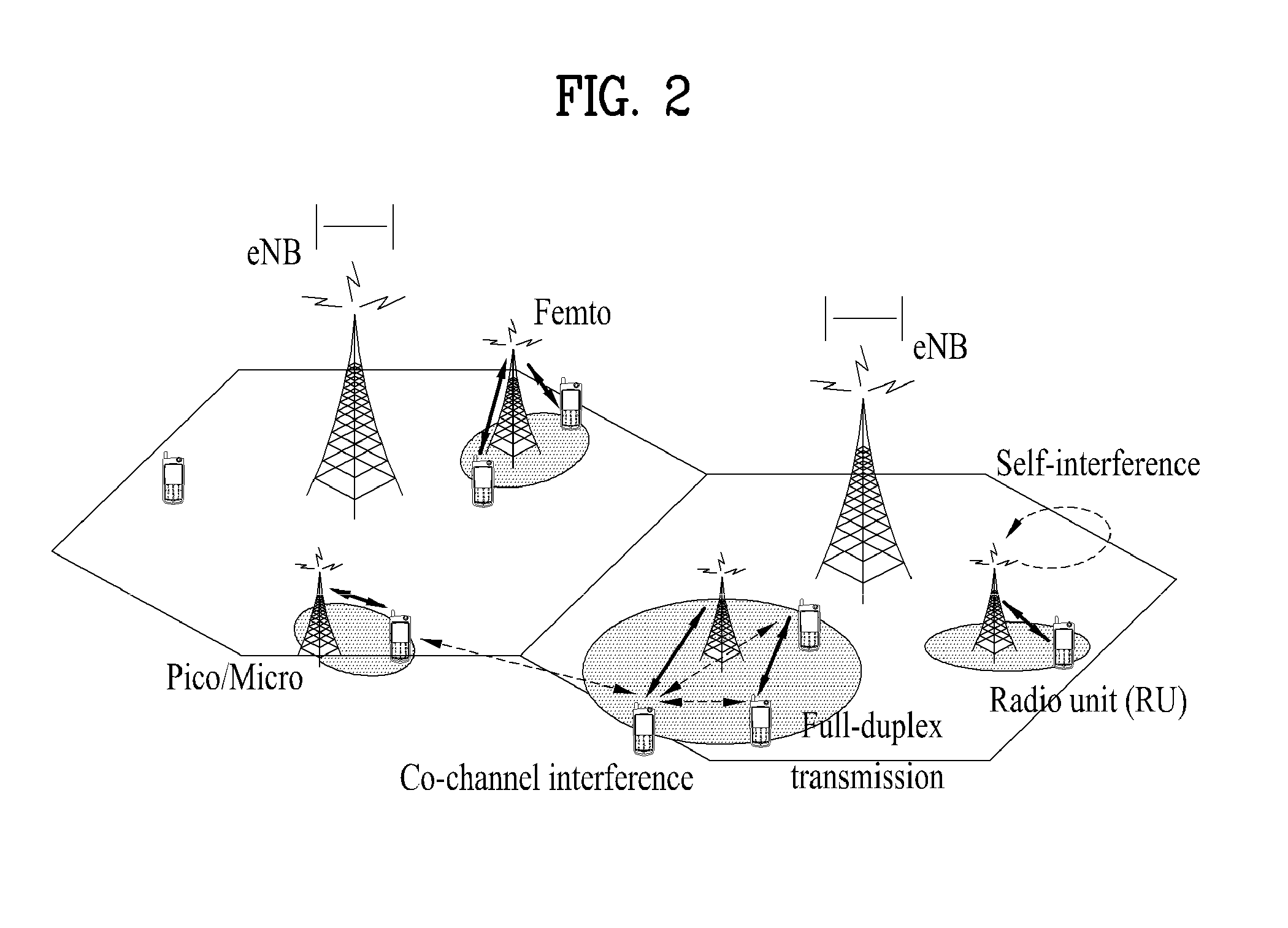

Method and apparatus for cancelling self-interference signal between transmission antenna and reception antenna

ActiveUS20150311985A1Site diversityRadio transmission for post communicationSelf interferenceSignal cancellation

An apparatus for cancelling a self-interference signal between a transmission antenna and a reception antenna is disclosed. The apparatus includes a first self-interference signal cancellation unit for cancelling a self-interference signal in consideration of a linear channel between the transmission antenna and the reception antenna, a second self-interference signal cancellation unit for cancelling a self-interference signal in consideration of nonlinear channel characteristic between the transmission antenna and the reception antenna or linear characteristic of a radio channel, and a controller for comparing a transmitted signal output from the transmission antenna and a received signal received by the reception antenna to provide a first coefficient to be applied to self-interference signal cancellation of a linear device in the first self-interference signal cancellation unit and a second coefficient to be applied to self-interference signal cancellation of a nonlinear device in the second self-interference signal cancellation unit.

Owner:LG ELECTRONICS INC

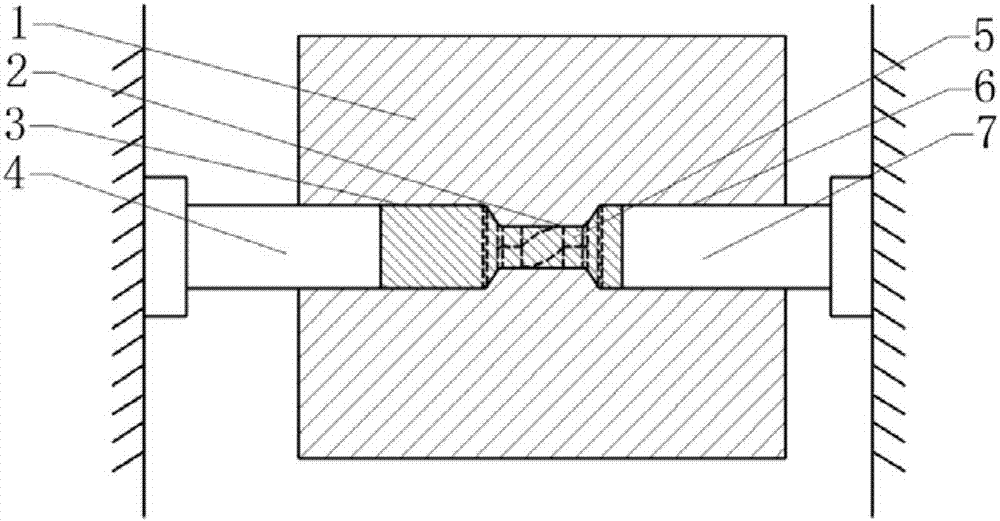

Blocked type variable cross-section reciprocating squeezing, twisting and upsetting forming method for ultra-fine grain bars

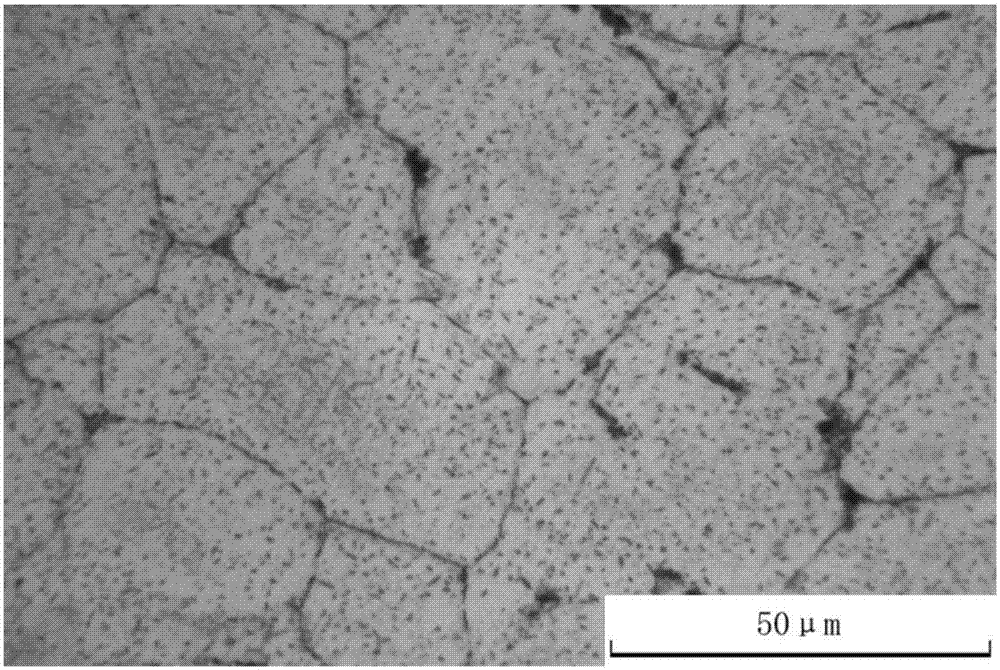

InactiveCN107282671ASolve uneven stressImprove uniformityMetal-working apparatusUltra fineEngineering

The invention discloses a blocked type variable cross-section reciprocating squeezing, twisting and upsetting forming method for ultra-fine grain bars. On the basis of a three-way hydraulic forming machine, the die assembly force is provided through an upper slide block, and pressure required for forming of punches at the two ends is provided through a left slide block and a right slide block. A die inner cavity is a linear channel formed by sequentially connecting a first squeezing channel, a middle twisting channel and a second squeezing channel on the same straight line. The section area of the middle twisting channel is smaller than the section area of the first squeezing channel and the section area of the second squeezing channel. The punches at the two ends are located at the two ends of the linear channel in a one-to-one correspondence manner, and a blocked variable section cavity is formed through the reciprocating punches at the two ends. By means of reciprocating of the punches at the two ends, the reciprocating squeezing, twisting and upsetting process of a to-be-processed blank in the linear channel is achieved, and preparation of the ultra-fine grain bars is completed through multi-pass forming. By means of the blocked type variable cross-section reciprocating squeezing, twisting and upsetting forming method, bar grains can be effectively refined, the forming limit of the bars is improved, and the blocked type variable cross-section reciprocating squeezing, twisting and upsetting forming method is easy to operate, high in applicability and capable of being easily applied in an engineered manner.

Owner:HEFEI UNIV OF TECH

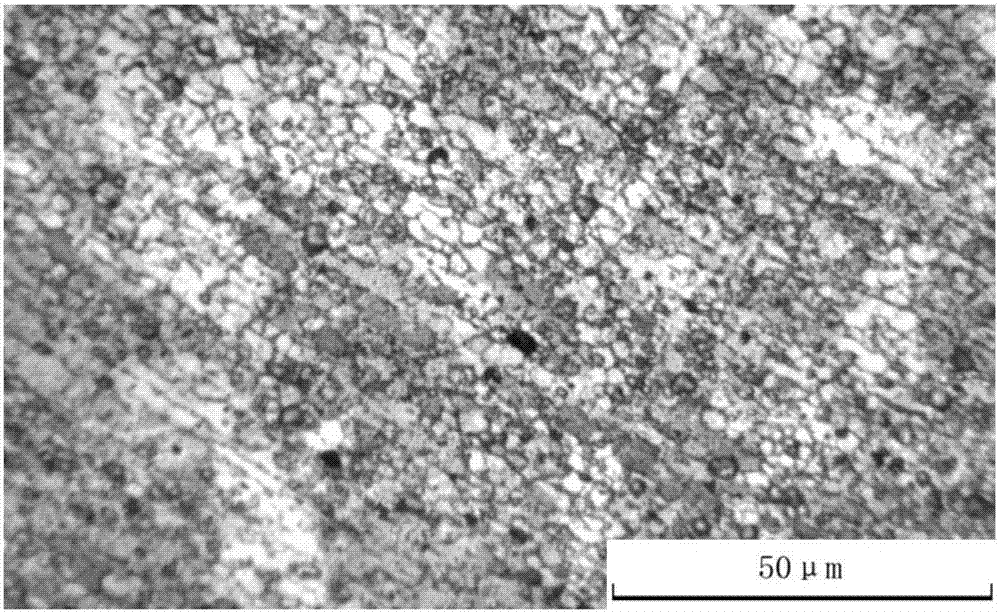

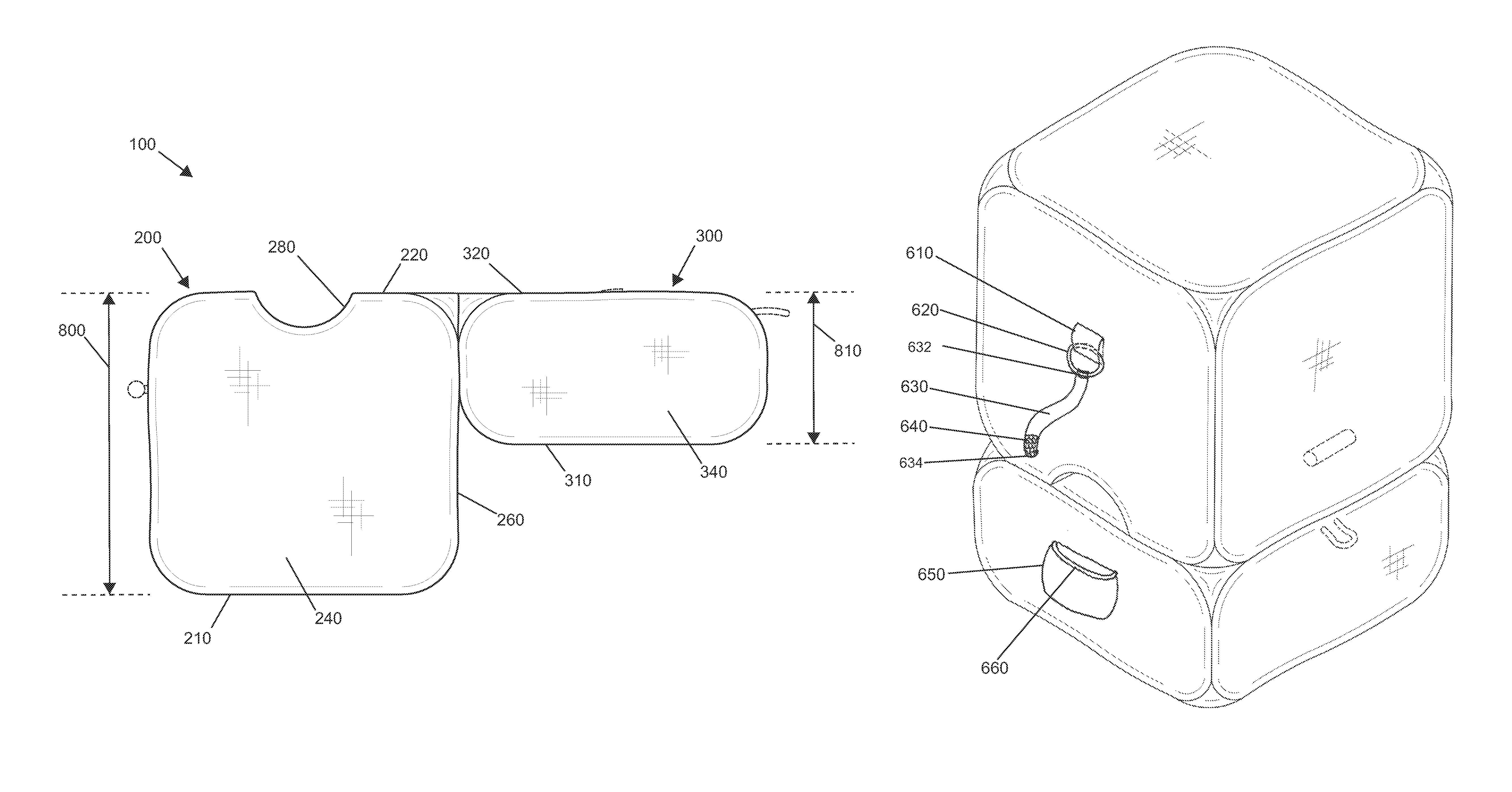

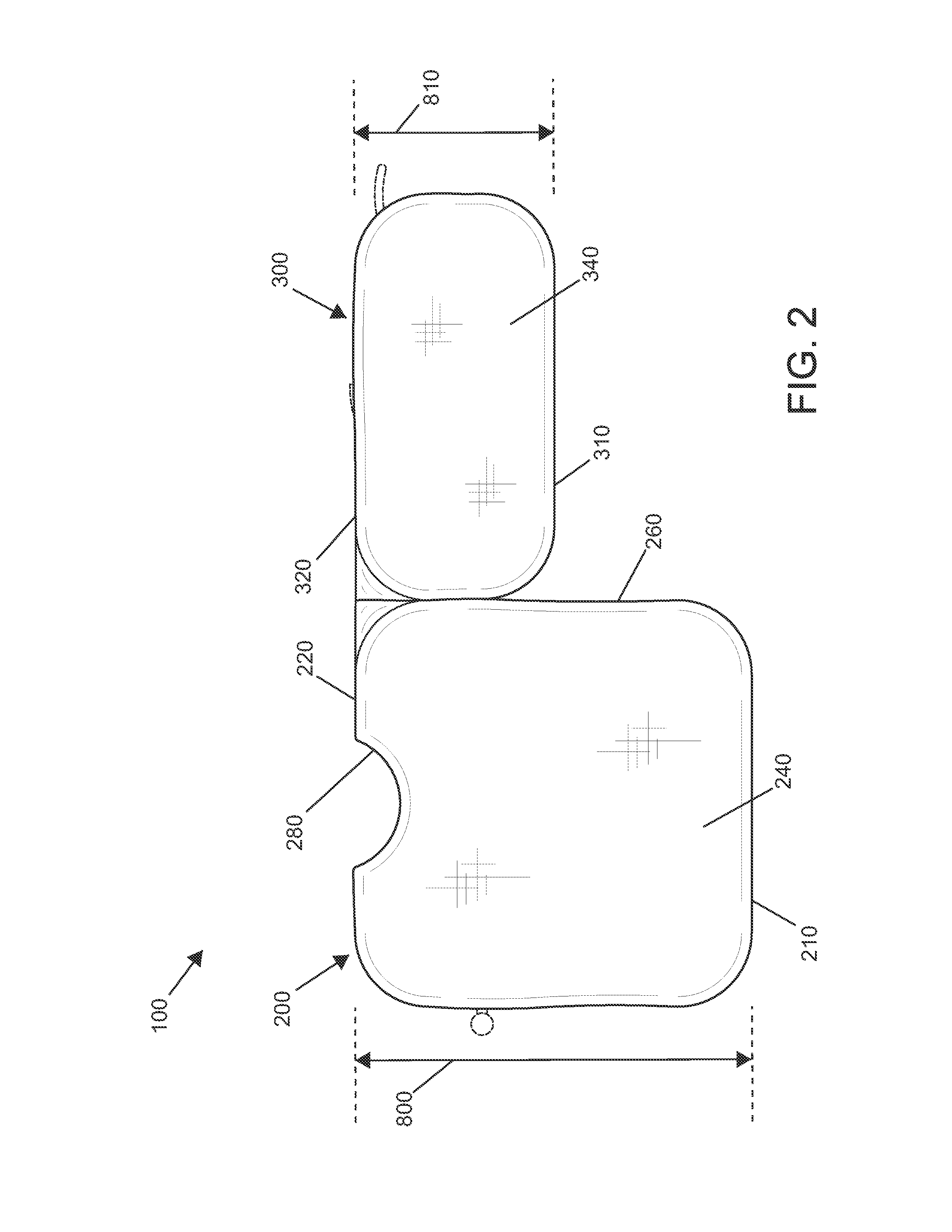

Bi-elevation pillow system

A bi-elevation pillow system for allowing two users to lie side by side with each of their heads respectively positioned at a different elevation by using the pillow system has a base pillow member with a general shape of a rectangular prism. The base pillow member has a cavity with a cushion component located inside. A base pillow bottom surface has a linear channel located on it. The system has a secondary pillow member with a general shape of a rectangular prism with a cavity having a cushion component located inside. In a first position for storage, the base pillow bottom surface is rotated against and interfaces with a secondary pillow bottom surface. In a second position for use, the secondary pillow is rotated about a hinge 180 degrees in an open configuration and placed on a ground surface for use.

Owner:KVITEK KYLE M

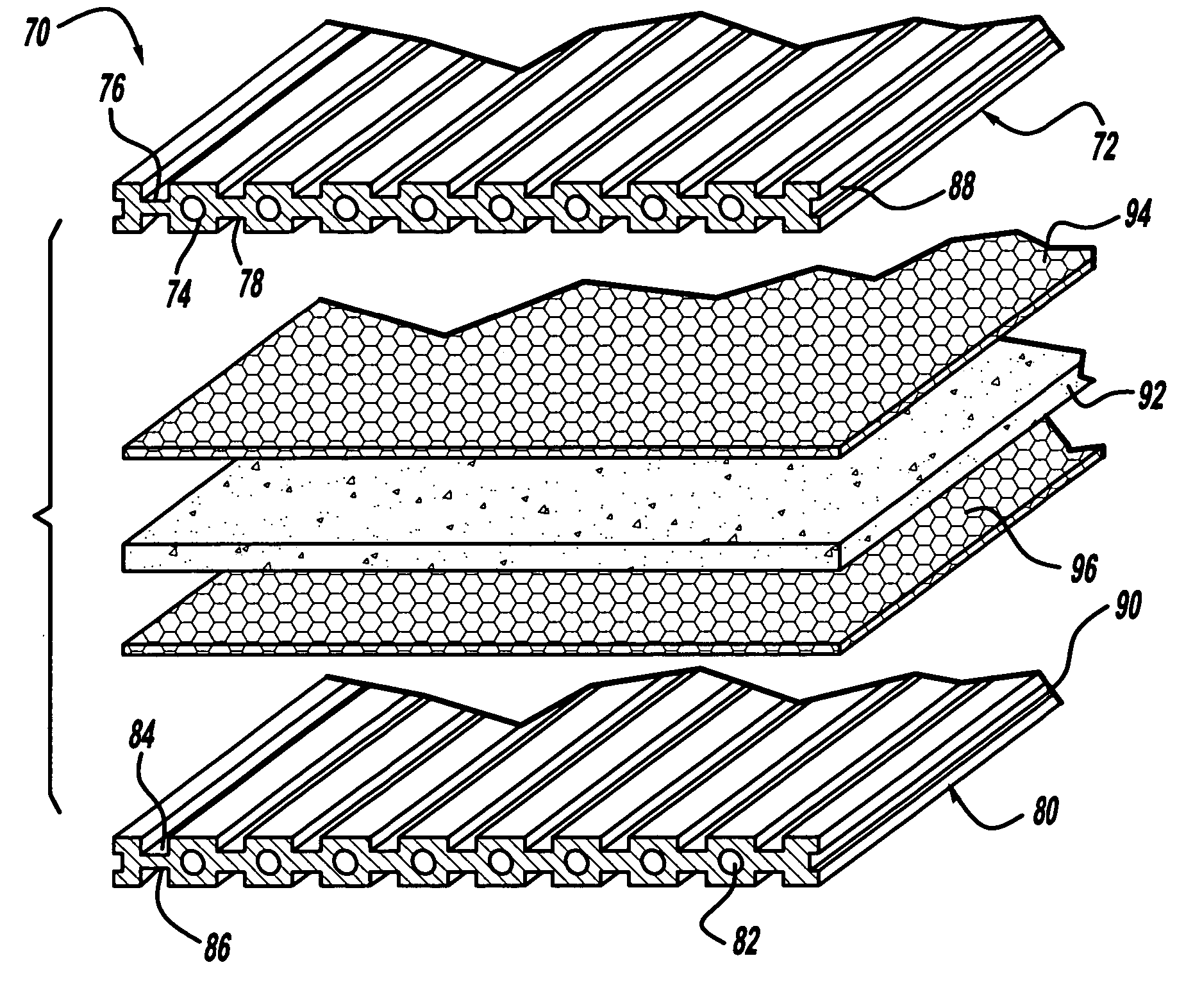

Extruded bipolar plates

An extruded bipolar plate for a fuel cell. The bipolar plate is fabricated by an extrusion process so that the extruder die forms linear channels in the extrusion for the flow channels in the plate. A variety of different shapes can be provided for the flow channels. In one design, the flow channels for the cooling fluid extend through the center of the bipolar plates, and flow channels for the anode and cathode fluids are provided on the outside of the bipolar plate. Further, the sides of the bipolar plate can be formed with a recess to receive end caps to secure the plates together. In addition, the end cap can include flow channels to control the flow of the fluids to the plates when the fuel cell stack is assembled.

Owner:GM GLOBAL TECH OPERATIONS LLC

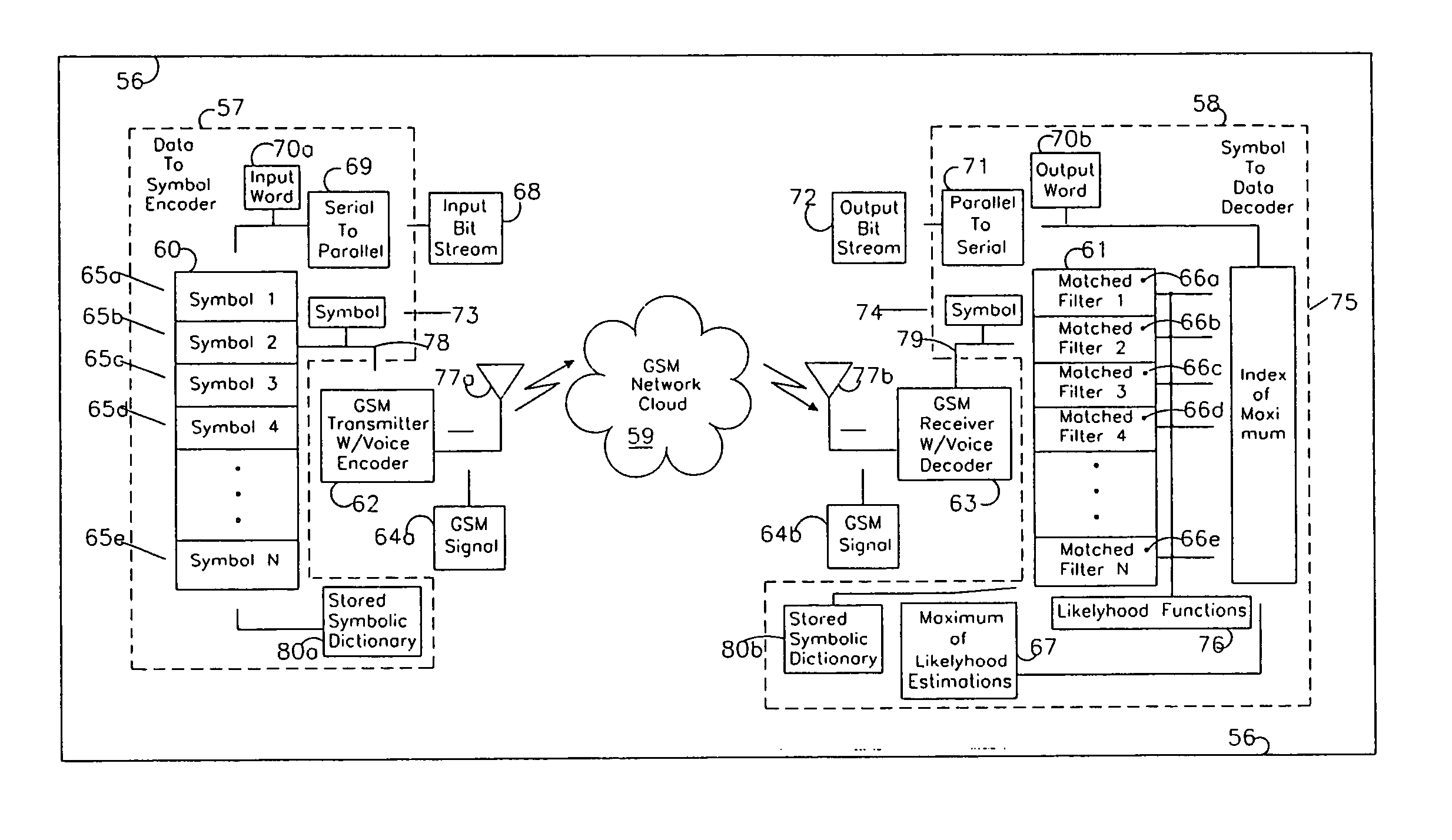

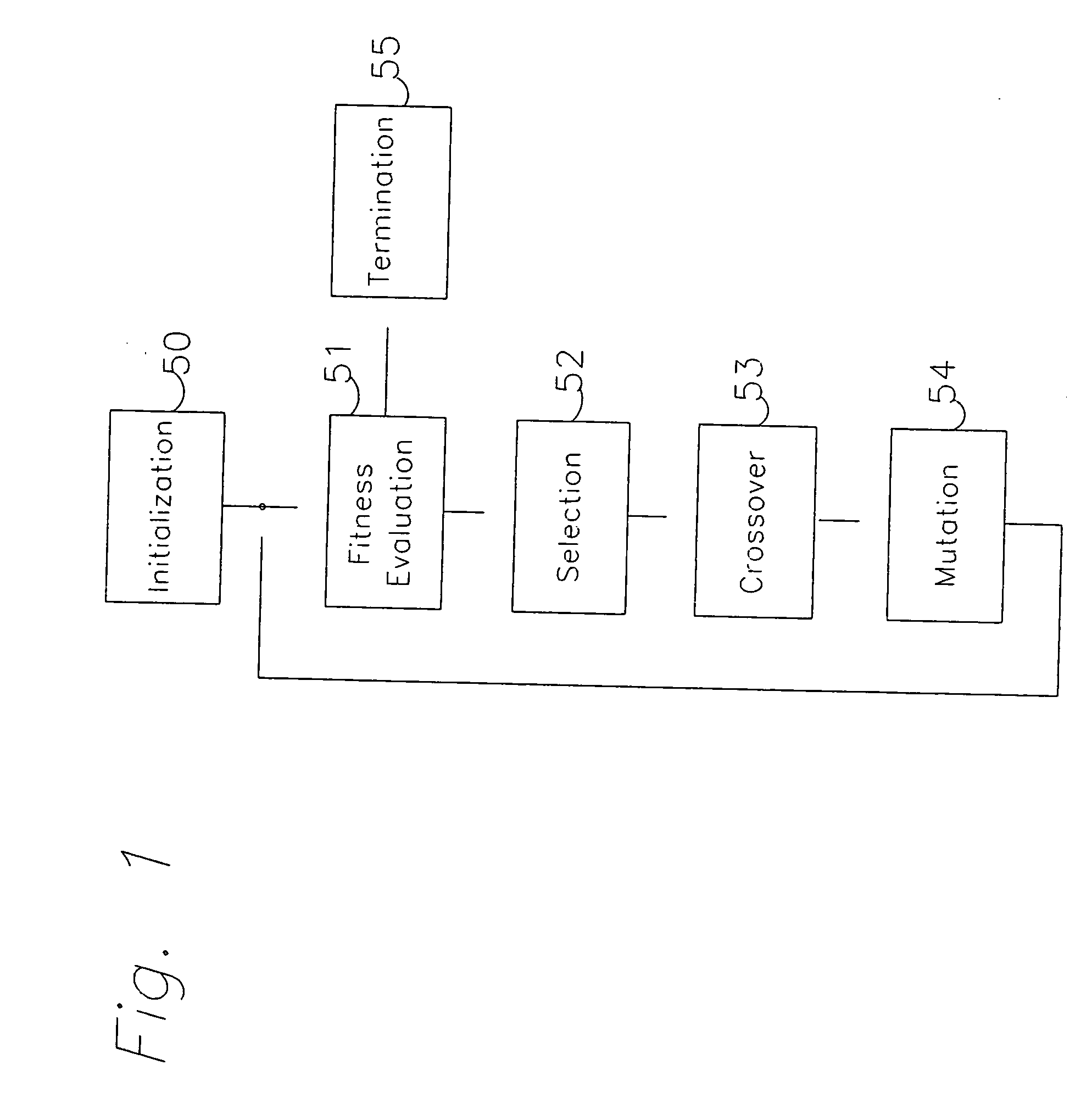

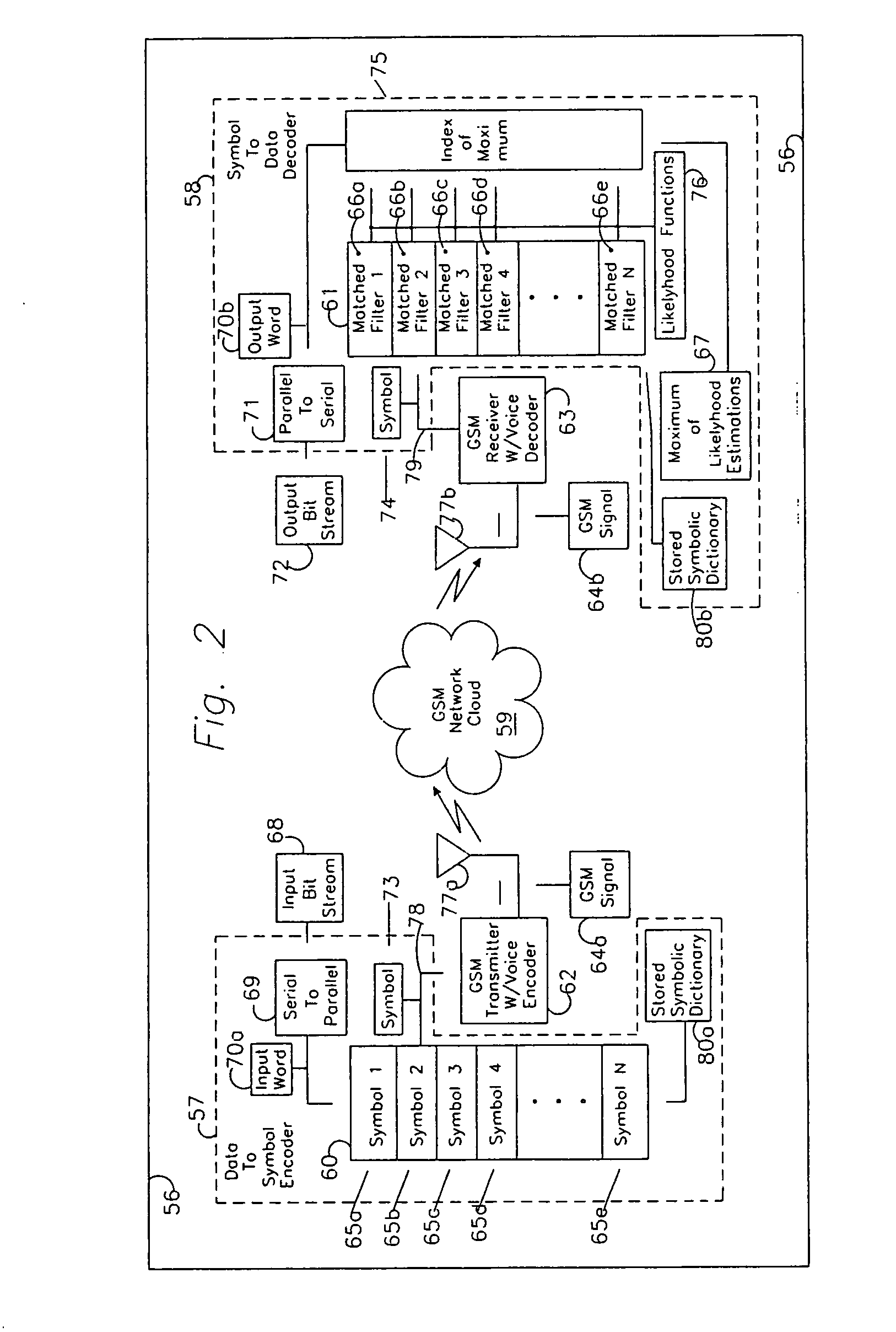

Evolutionary synthesis of a modem for band-limited non-linear channels

InactiveUS20060293045A1Maintain separabilitySmall sizeData switching by path configurationSource coding adaptationModem deviceNerve network

A method of selecting optimized encoding symbols and decoding parameters for a communications neural network using a genetic algorithm. A population of individuals representing the symbols and parameters of the communications neural network is evolved through successive generations to create increasingly effective neural network characteristics. In one embodiment, the final optimized neural network is implemented on a band-limited non-linear channel of a communication network.

Owner:SYMSTREAM TECH HLDG PTY LTD

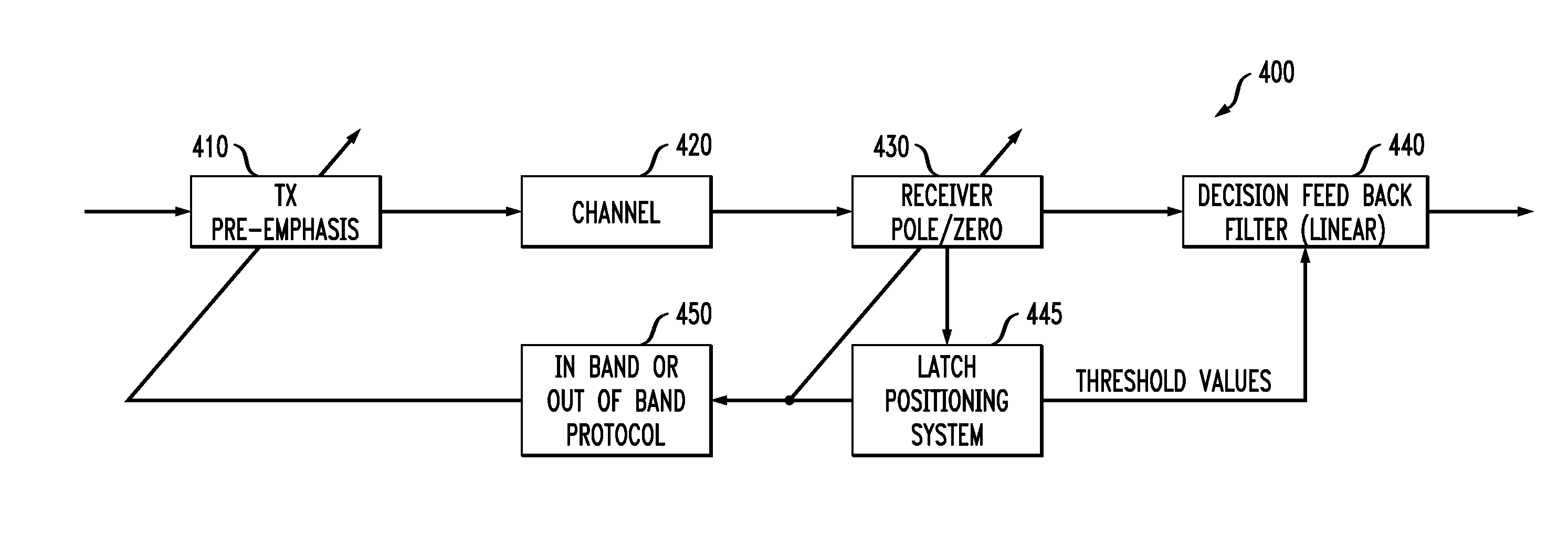

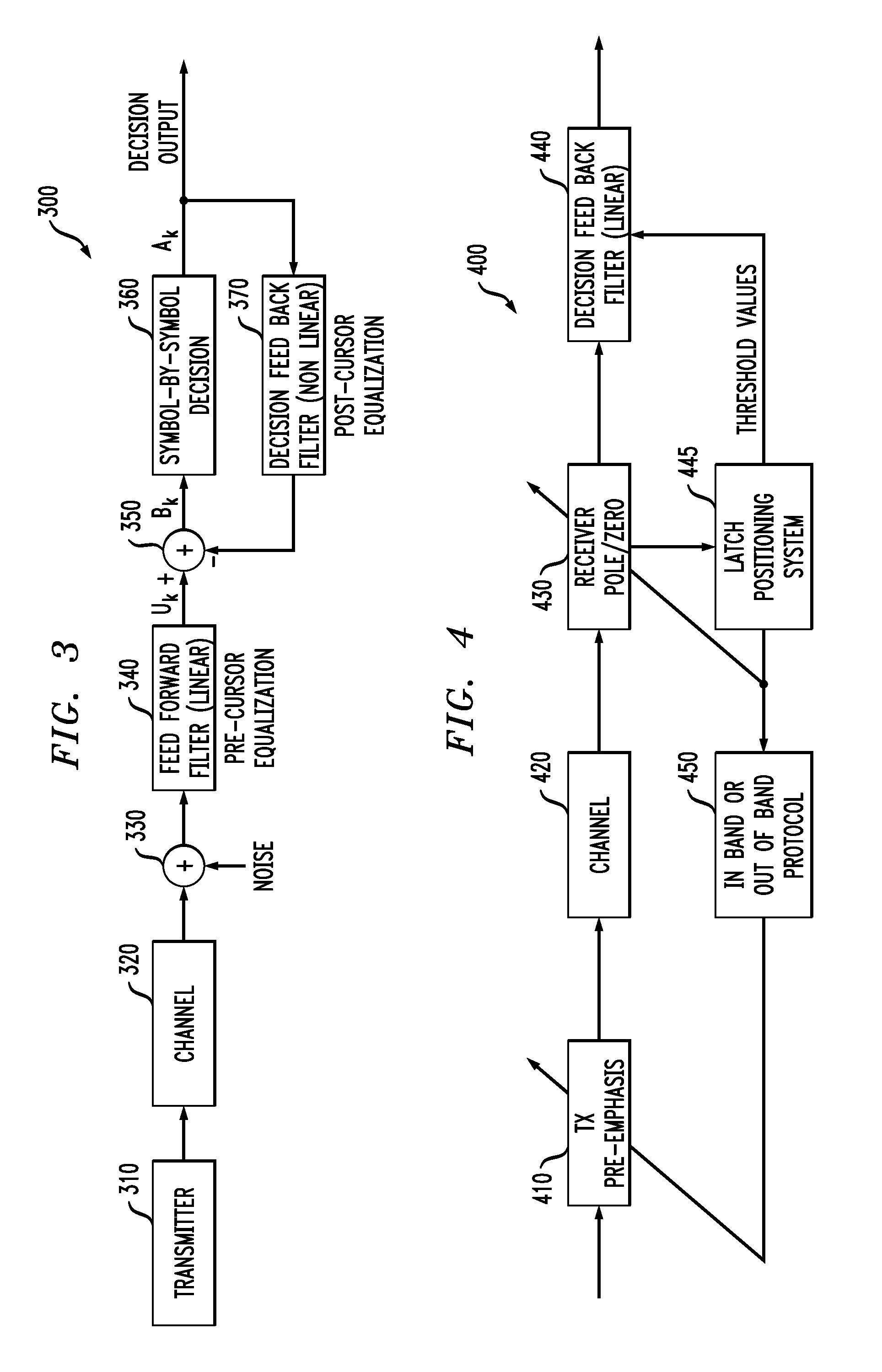

Method and apparatus for non-linear decision-feedback equalization in the presence of asymmetric channel

InactiveUS20080080609A1Improve immunityMultiple-port networksDelay line applicationsEngineeringEqualization

Methods and apparatus are provided for determining the threshold position of one or more latches employed for decision-feedback equalization in the presence of a non-linear channel. A latch employed by a decision-feedback equalizer is positioned by constraining input data such that the input data only contains transitions from a first binary value; obtaining a plurality of samples of a single-sided data eye associated with the constrained input data; determining a threshold position of the latch based on the samples; and transforming the determined position to address the non-linearity of the channel. For example, a non-linear mapping table can map measured threshold values to transformed threshold values based on distance.

Owner:AVAGO TECH INT SALES PTE LTD

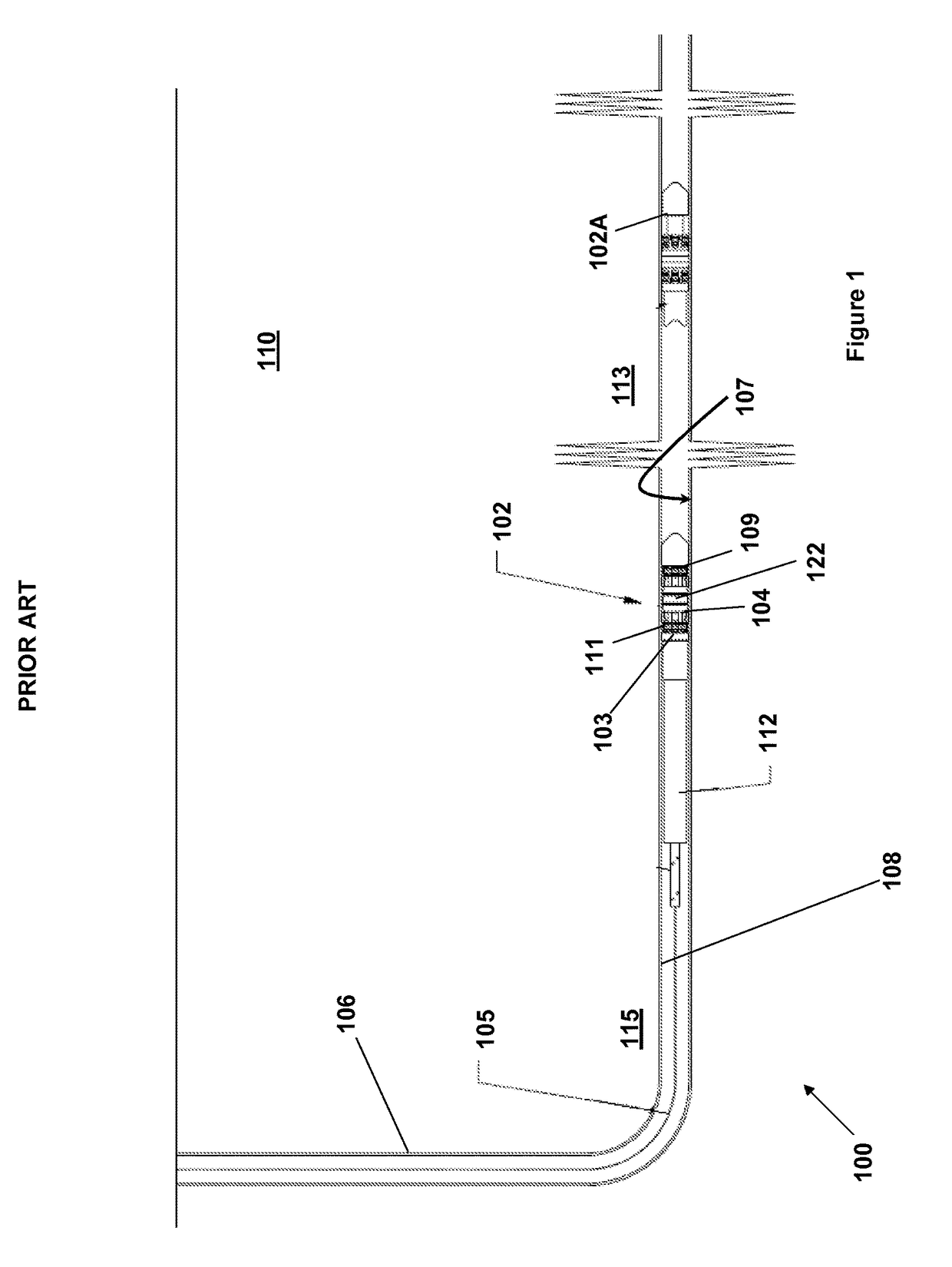

Downhole system for isolating sections of a wellbore

Owner:THE WELLBOSS CO LLC +1

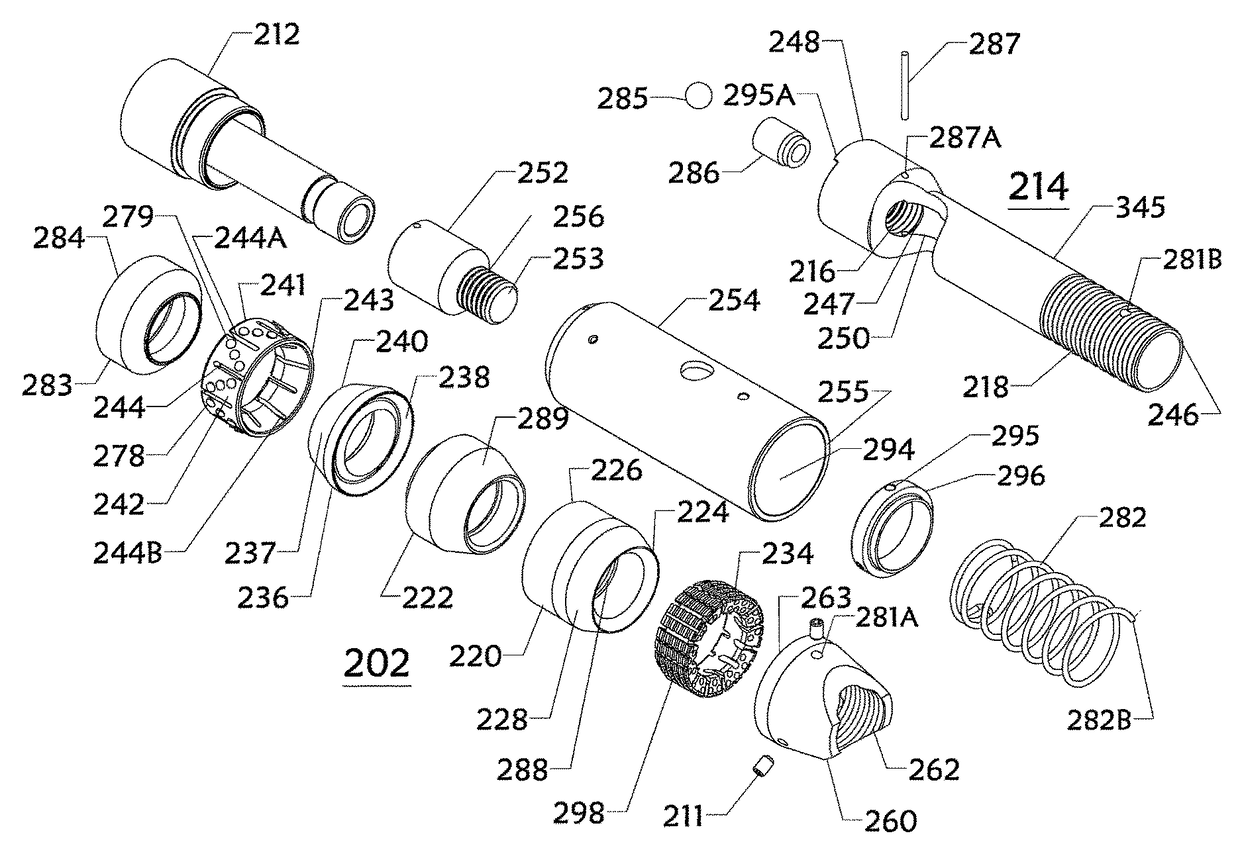

Piercing tip for scrap shear

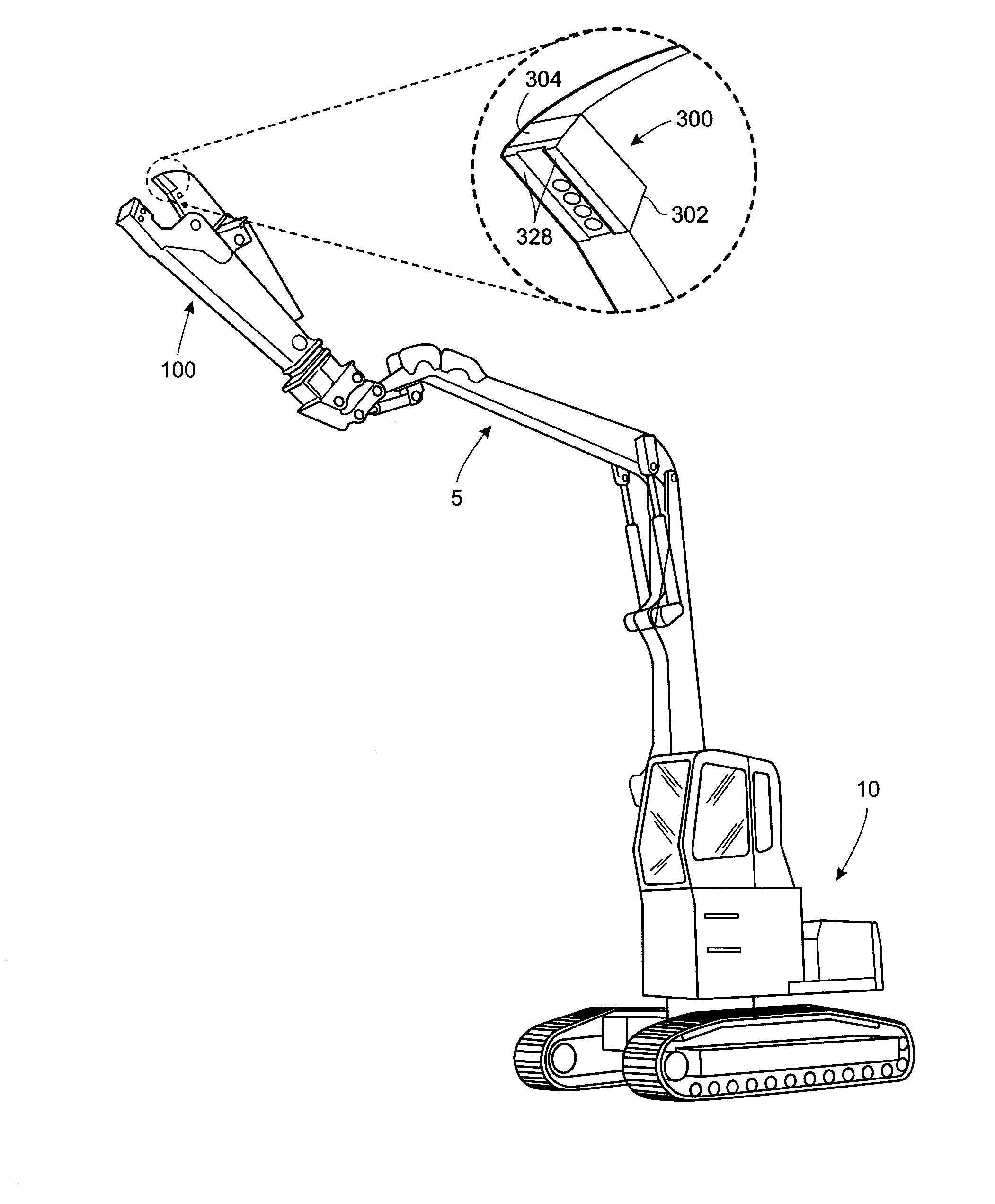

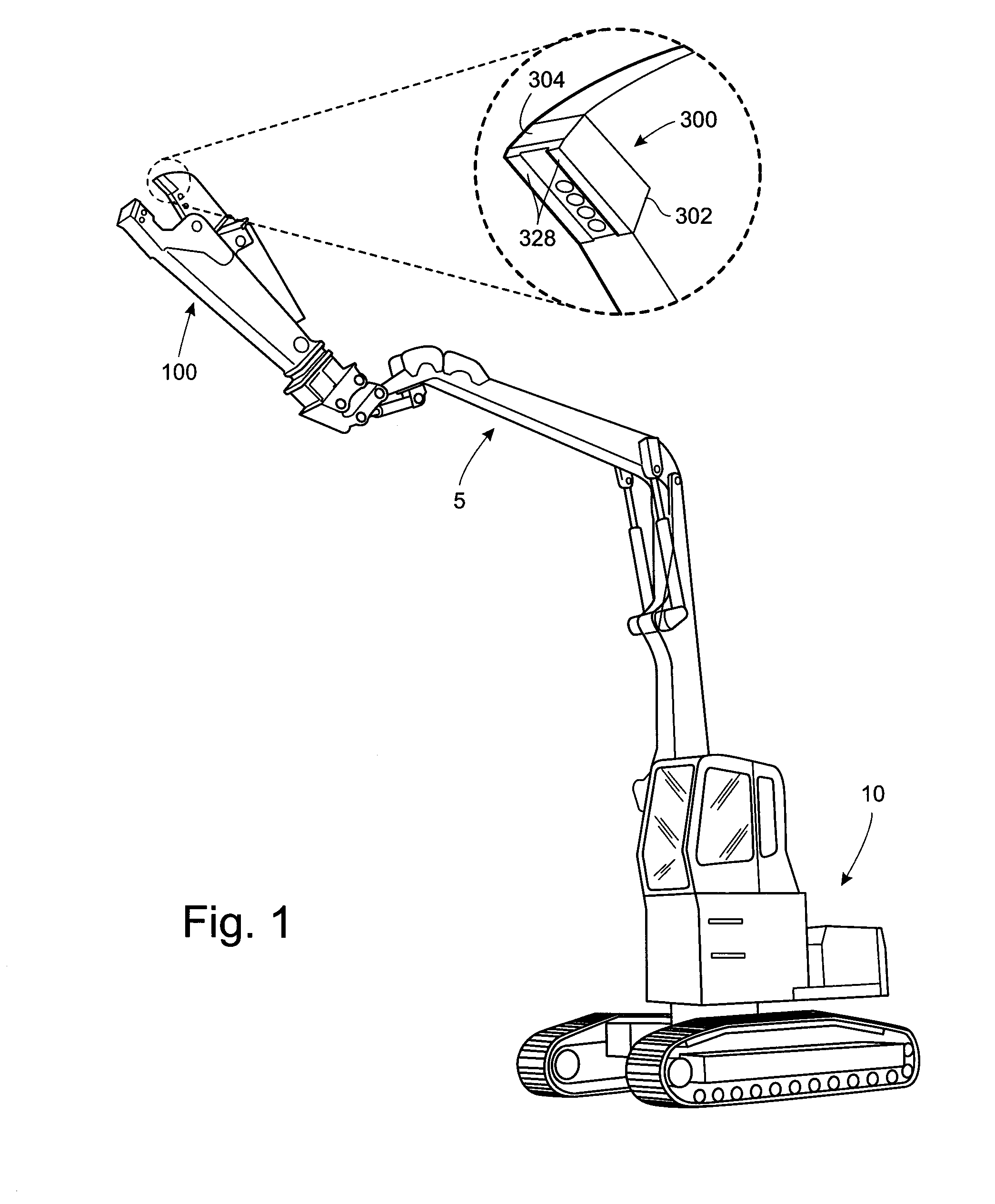

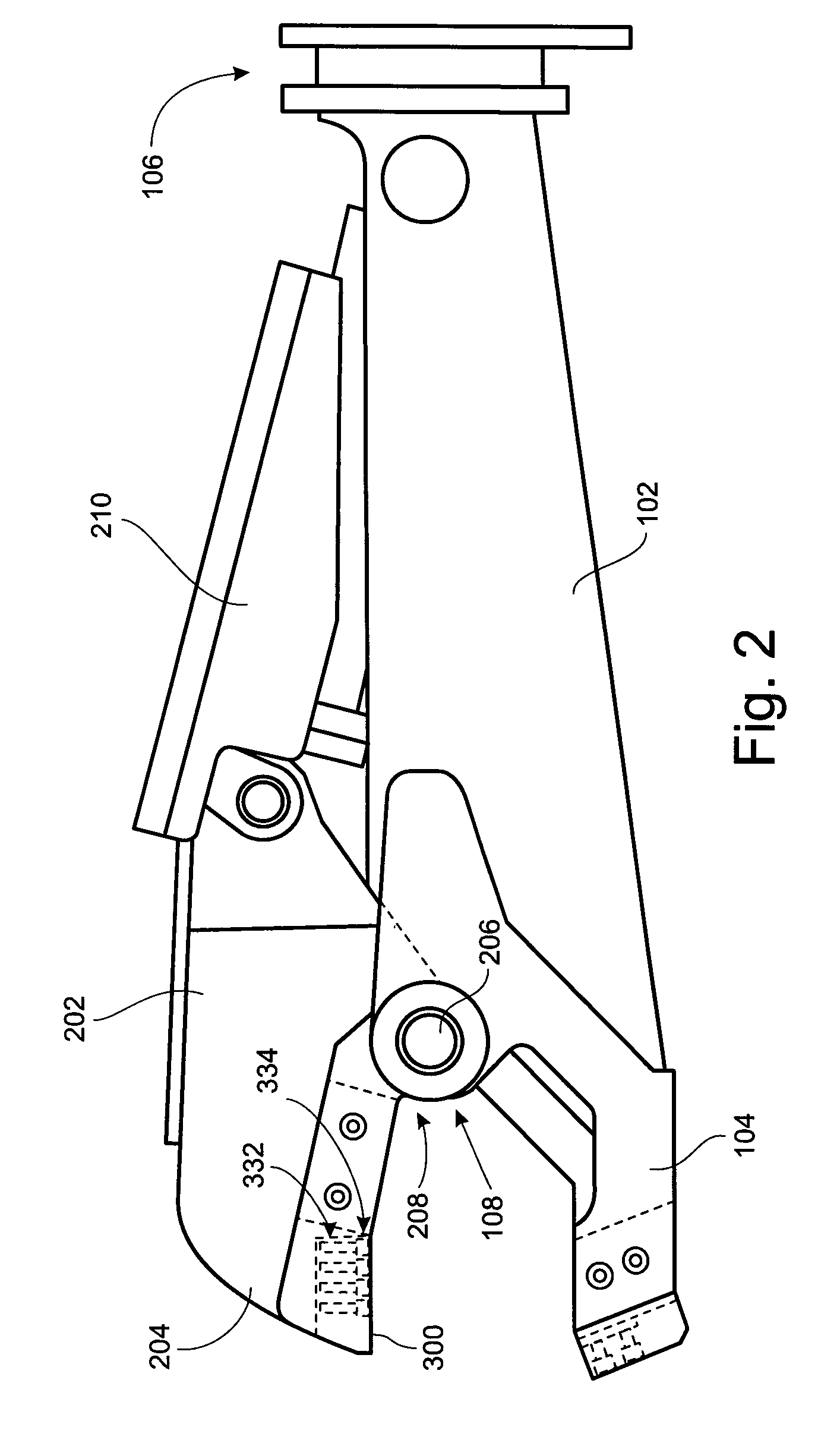

InactiveUS20110146469A1Reduce decreaseMaintain engagementShearing machinesMetal working apparatusMaterial PerforationLinear channel

A piercing tip for a jaw of a shearing apparatus includes a main body having an open linear slot formed therein, and a complementary linear channel formed in the main body parallel to and open to the slot to capture within the channel an enlarged elongate head of a jaw of a shearing apparatus. A jaw for a shearing apparatus includes a raised rail, an enlarged elongate head positioned along the raised rail, and a piercing tip for piercing the scrap material upon movement of the jaw to the closed position. The piercing tip has a slot formed therein for receiving the raised rail and a widened channel formed in the slot for receiving the enlarged elongate head to maintain the engagement of the piercing tip with the second jaw.

Owner:PURSER BRIAN

Plasma arrestor insert

ActiveUS8503151B2Decreases likelihood of arcing and plasma generationSemiconductor/solid-state device manufacturingEmergency protective arrangement detailsDielectricProcess engineering

A dielectric arrestor insert for use in a chamber wafer processing system having a gas input line, an arrestor housing and a wafer processing space. The input line is able to provide gas to the arrestor housing. The arrestor housing is able to house the dielectric arrestor insert. The dielectric arrestor insert comprises a gas entry portion, a non-linear channel and a gas exit portion. The gas entry portion is arranged to receive the gas from the input line. The non-linear channel is arranged to deliver the gas from the gas entry portion to the gas exit portion. The gas exit portion is arranged to deliver the gas from the non-linear channel to the wafer processing space.

Owner:LAM RES CORP

Stacked-type evaporator

A widthwise one half portion of a core section 5a is constituted by a first section 20 formed by stacking a plurality of first elements having first and second linear channels 34 and 35 inside them and fins, and a widthwise other half portion thereof is similarly constituted by a second section 21 formed by stacking a plurality of second elements respectively having U-shaped channels 46 inside them and fins. The number of times the refrigerant fed into a thicknesswise one half portion on an inlet tank 47 side of the first section 20 is turned back in an opposite direction concerning a longitudinal direction of the first linear channels 34 inside this thicknesswise one half portion is made more numerous than the number of times the refrigerant fed into a thicknesswise other half portion on an outlet tank 52 side of the first section 20 is turned back in the opposite direction concerning the longitudinal direction of the second linear channels 35 inside this thicknesswise other half portion.

Owner:CALSONIC KANSEI CORP

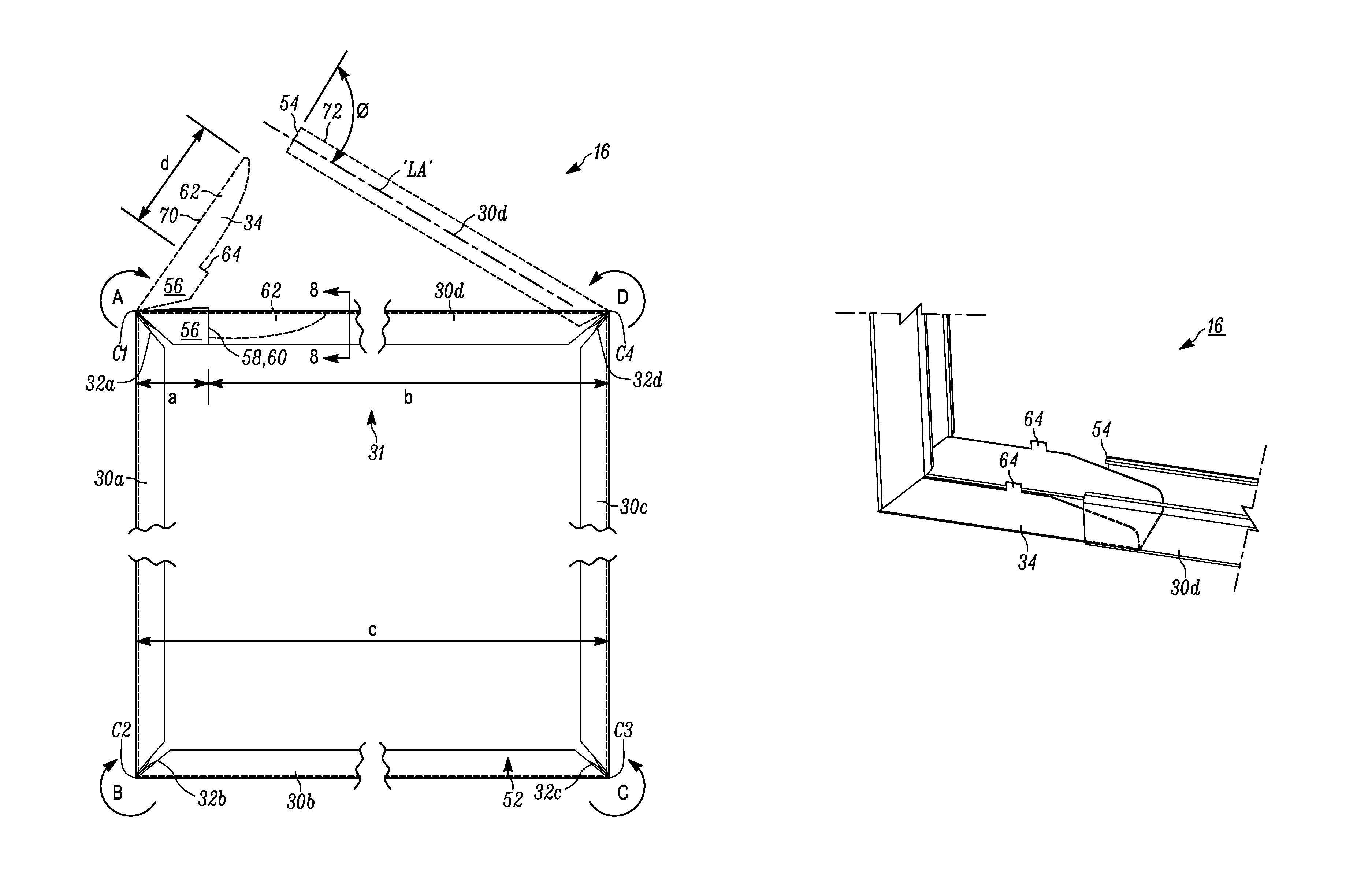

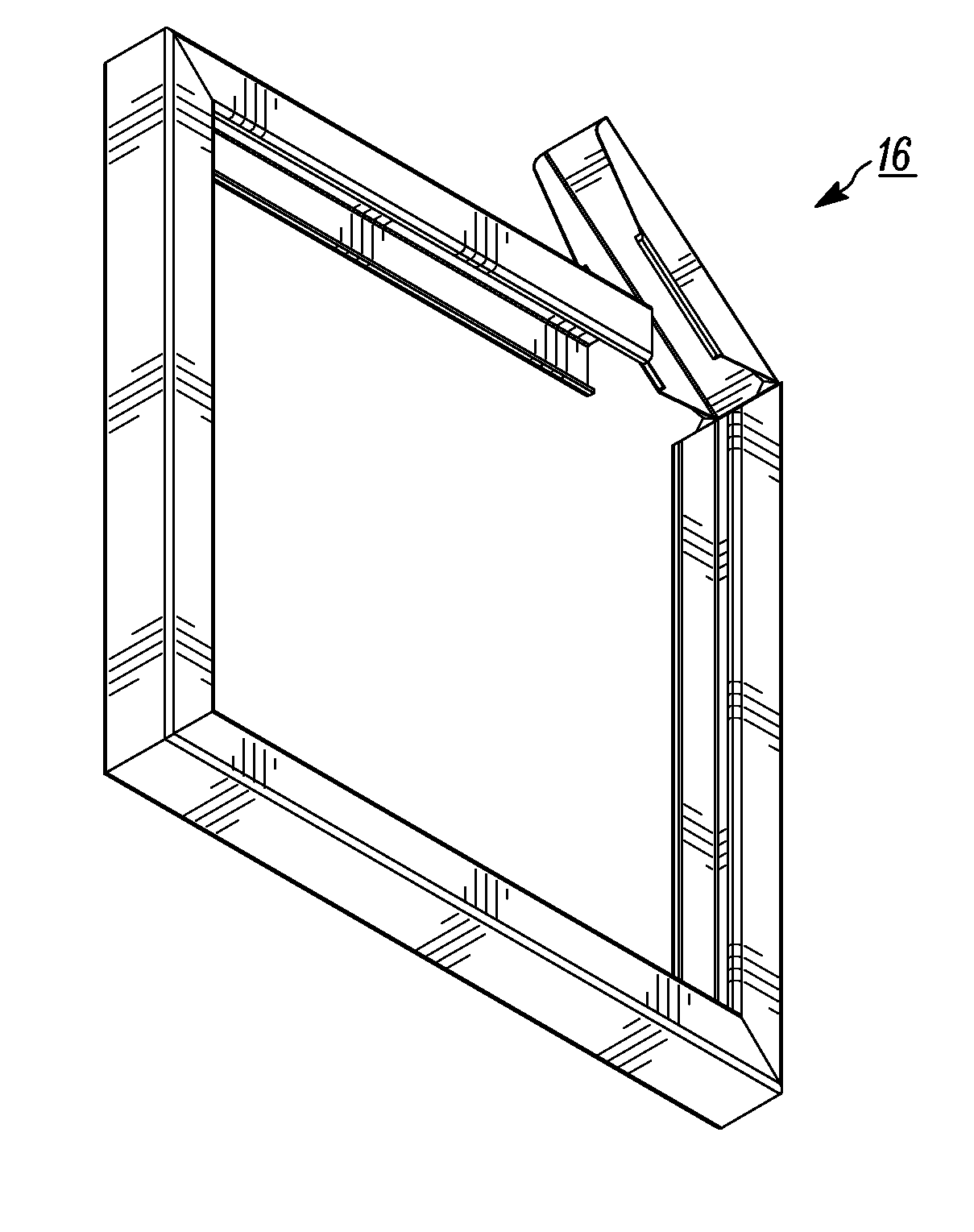

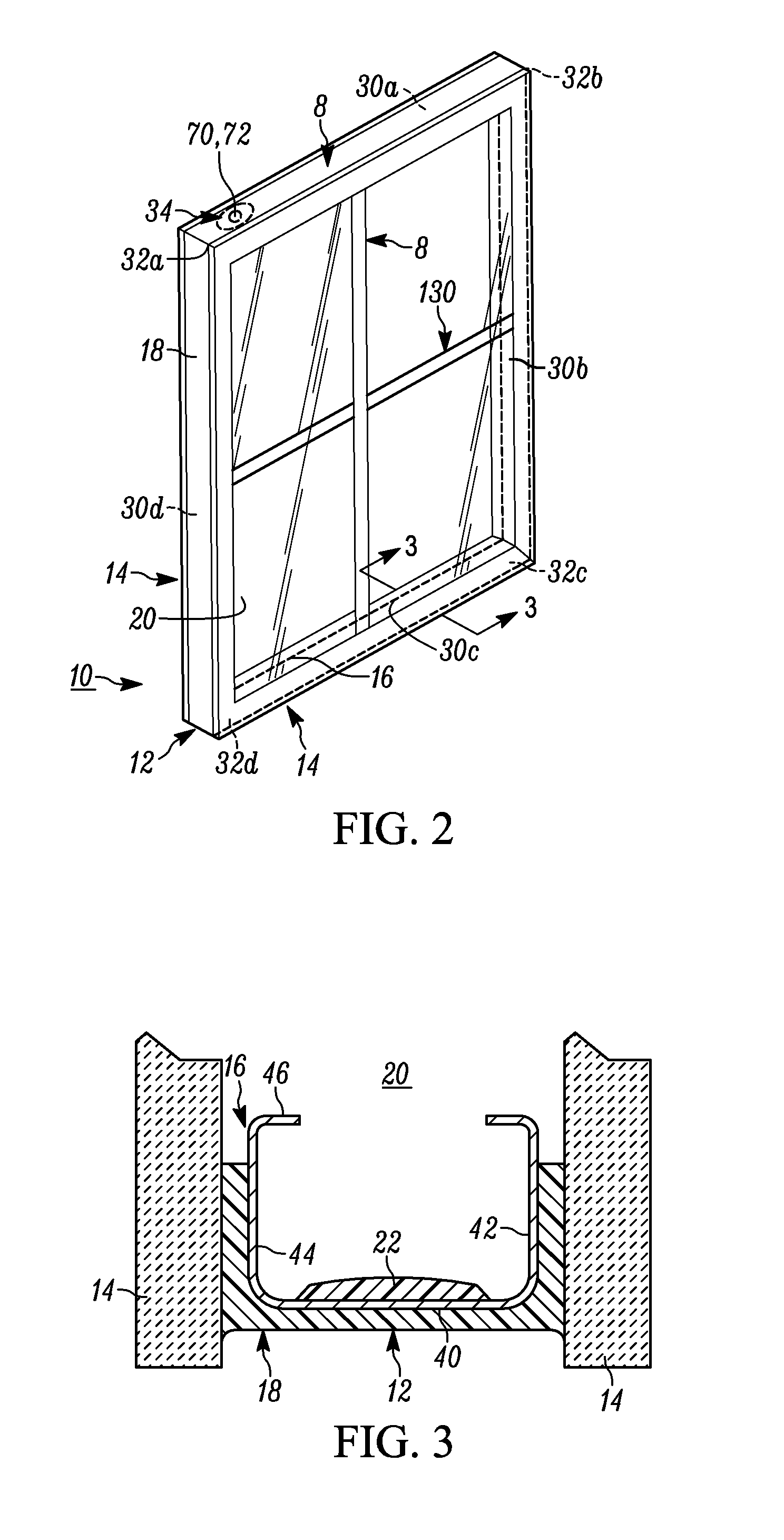

Spacer frame and method of making same

A spacer frame assembly and method of assembly includes a substantially linear channel having first and second ends. The substantially linear channel that when assembled includes at least four sides and corresponding corners between each of the sides. The spacer frame assembly also has a connecting structure located at one of the first and second ends and an opposite frame end located at the other of the one of first and second ends. The opposite frame end has an inner channel for receiving a nose portion of the connecting structure. The spacer frame assembly also includes a stop extending from the connecting structure for locating the opposite frame end when in the assembled position.

Owner:GED INTEGRATED SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com