Blocked type variable cross-section reciprocating squeezing, twisting and upsetting forming method for ultra-fine grain bars

A technology of ultra-fine grain and variable cross-section, which is applied in the direction of metal processing equipment, etc., and can solve the problems that it is difficult to meet the requirements of the preparation process of ultra-fine grain rods, it is impossible to prepare large-size ultra-fine grain materials, and the deformation amount of multi-directional forging is limited. , to achieve a significant effect of grain refinement, reduce the inhomogeneity of strain distribution, and be easy for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In this example, the closed variable cross-section reciprocating extrusion and torsion forming method for preparing ultra-fine-grained materials is based on a three-way hydroforming machine, and the upper slider of the three-way hydroforming machine provides mold clamping force for the mold with the upper and lower mold forms. , the left slider and the right slider provide the pressure required for punch forming at both ends.

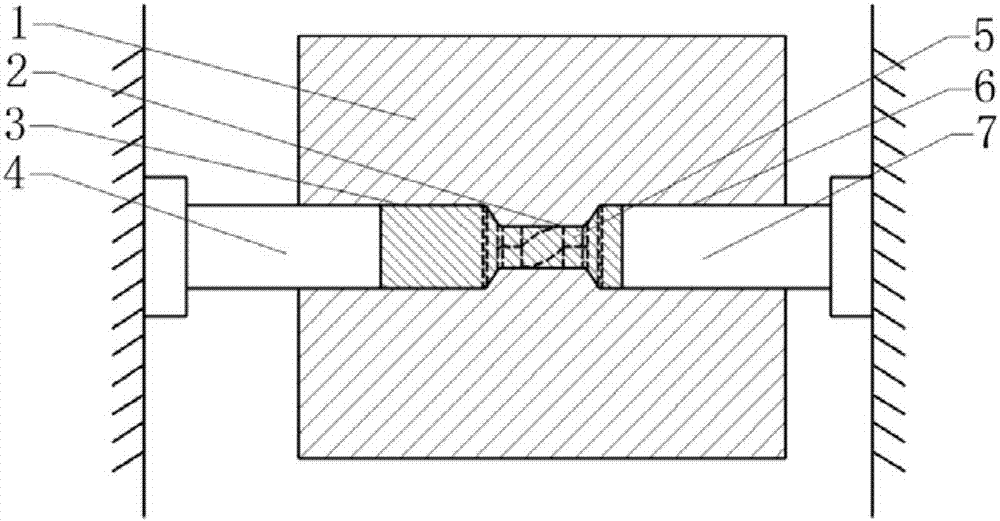

[0019] Such as figure 1 As shown, the inner cavity of the mold is set to be a "one" channel formed by sequentially connecting the first extrusion channel 3, the middle twisting channel 2 and the second extrusion channel 6 on the same straight line, and the cross-sectional area of the middle twisting channel 2 is smaller than that of the first The cross-sectional area of the first extrusion channel 3 and the second extrusion channel 6; the punches at both ends are located at the two ends of the "one" channel one by one, figure 1 Shown in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com