Composite joints and jibs

A technology of composite joints and jibs, which is applied to cranes and other directions, can solve problems such as uneven force on the jib section, and achieve the effect of improving the force transmission effect, improving performance, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0045] The following will be based on Figure 9 and Figure 10 The composite joint 26 of the first embodiment of the present invention will be described in detail.

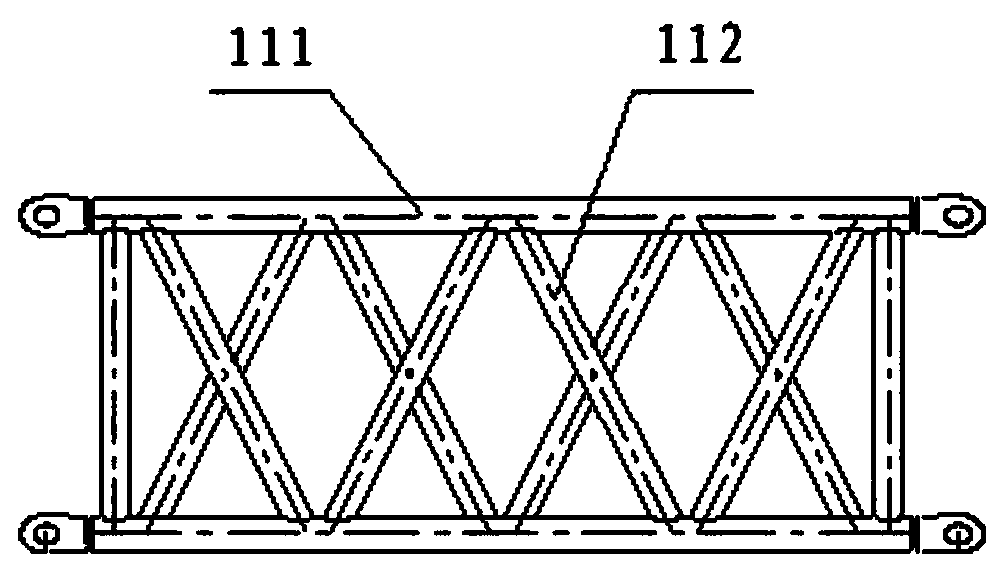

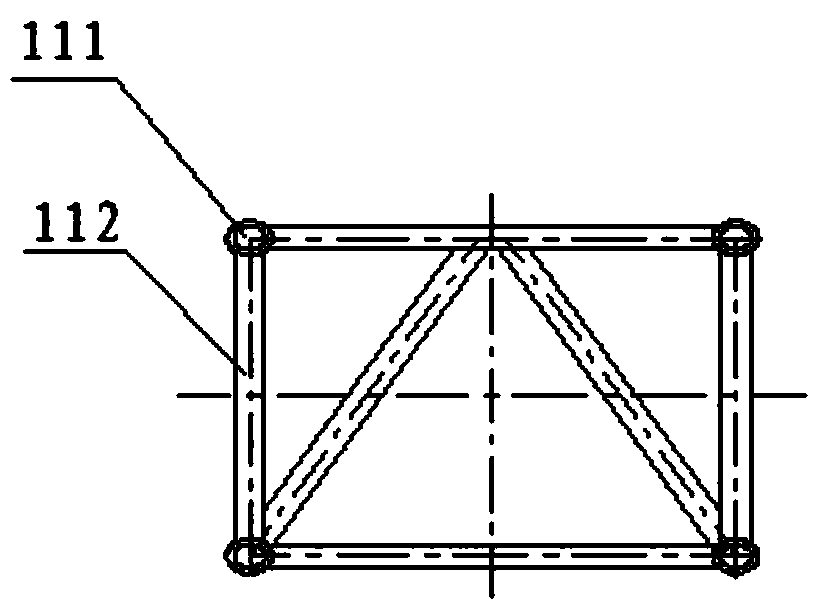

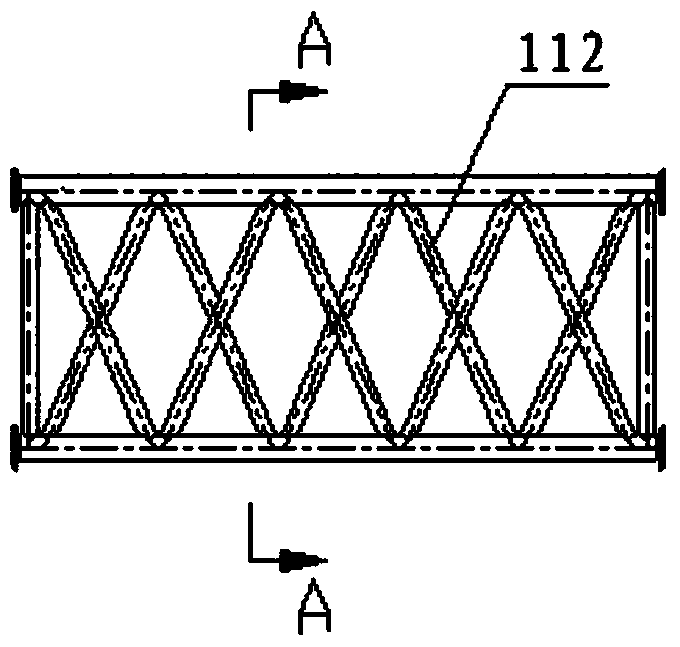

[0046] Such as Figure 9 As shown, the composite main chord of the jib section 21 is composed of two main chords 211 arranged in parallel in the longitudinal direction. The composite main chords of adjacent boom sections are connected with composite joints 26 . A lug joint 211A is correspondingly provided on the side of the two main chords of each composite main chord corresponding to the composite joint 26 .

[0047] Such as Figure 10 As shown, the composite joint 26 of the first embodiment includes a seat 261 . The seat body 261 has a first side and a second side ( Figure 10 The left side and the right side shown), the first side and the second side of the seat body 261 are fixedly connected with lug type taps 262 . The lug-type tap 262 in this embodiment is a multi-lug-type tap, and multiple lugs of ea...

no. 2 example

[0055] The following will be based on Figure 11 and Figure 12 The composite joint 26 of the second embodiment of the present invention will be described in detail.

[0056] Such as Figure 12 As shown, in the compound joint 26 of the second embodiment, the lug type tap 262 is also a multi-lug type tap. Different from the compound joint 26 of the first embodiment, the number of lugs of the lug type tap 262 arranged on the first side of the compound joint 26 in the second embodiment is different from that of the lug type tap 262 arranged on the second side. The connectors 262 have the same number of lugs.

[0057] Specifically, as Figure 12 As shown, the number of lugs of the lug tap 262 on both the first side and the second side of the compound joint 26 of the second embodiment is three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com