Patents

Literature

45results about How to "Solve uneven stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

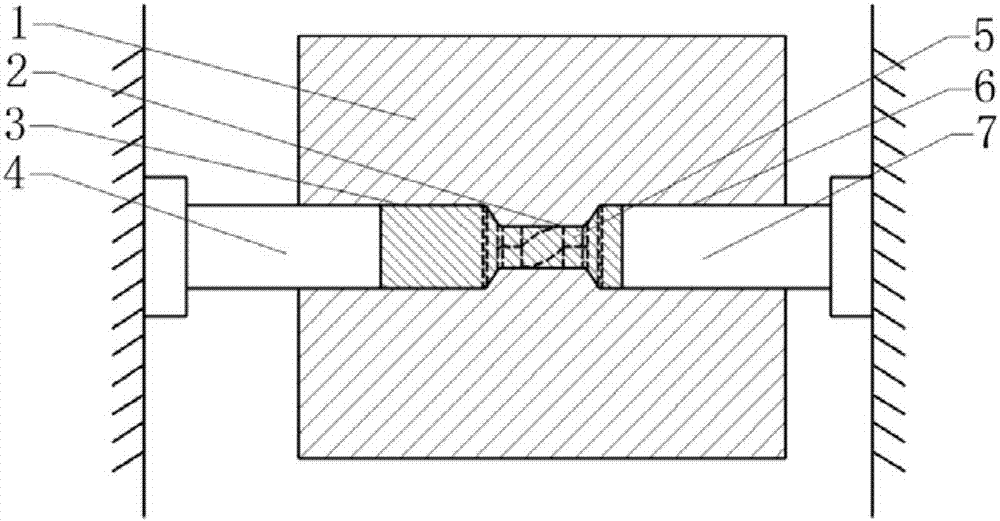

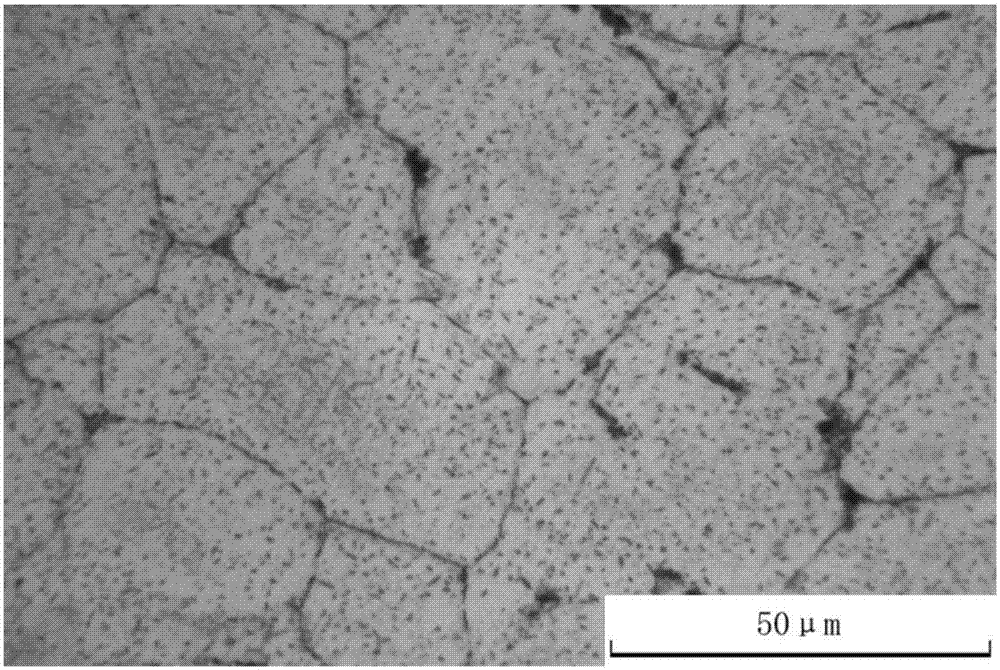

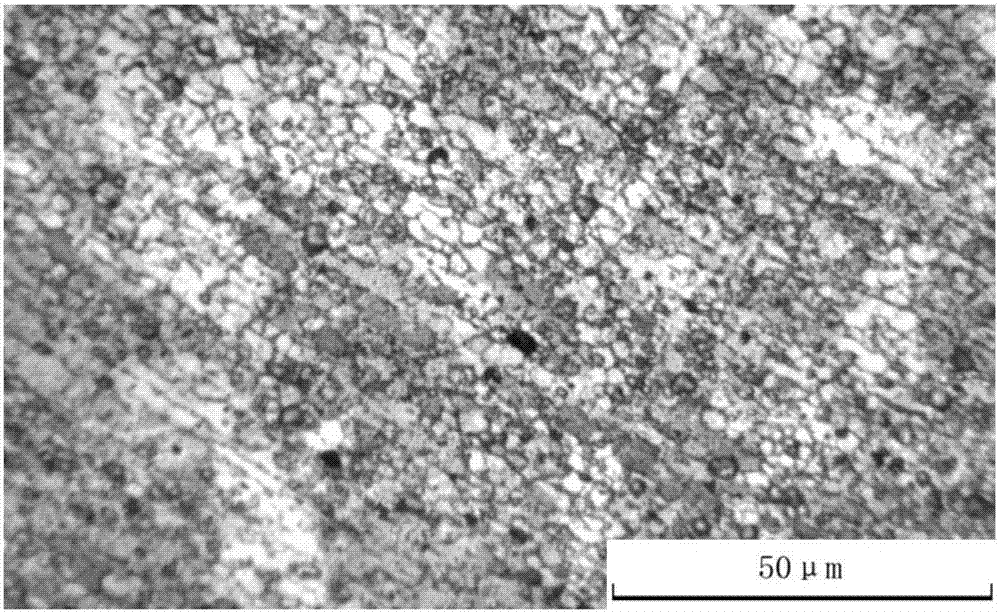

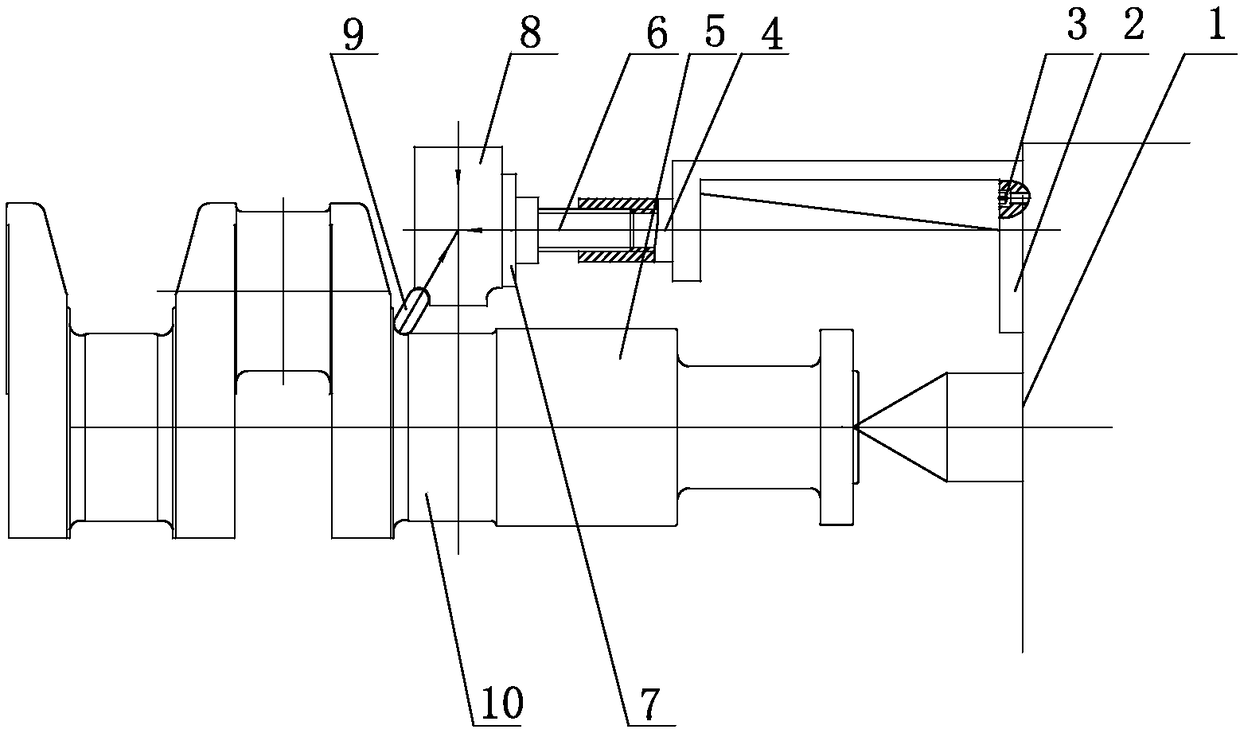

Blocked type variable cross-section reciprocating squeezing, twisting and upsetting forming method for ultra-fine grain bars

InactiveCN107282671ASolve uneven stressImprove uniformityMetal-working apparatusUltra fineEngineering

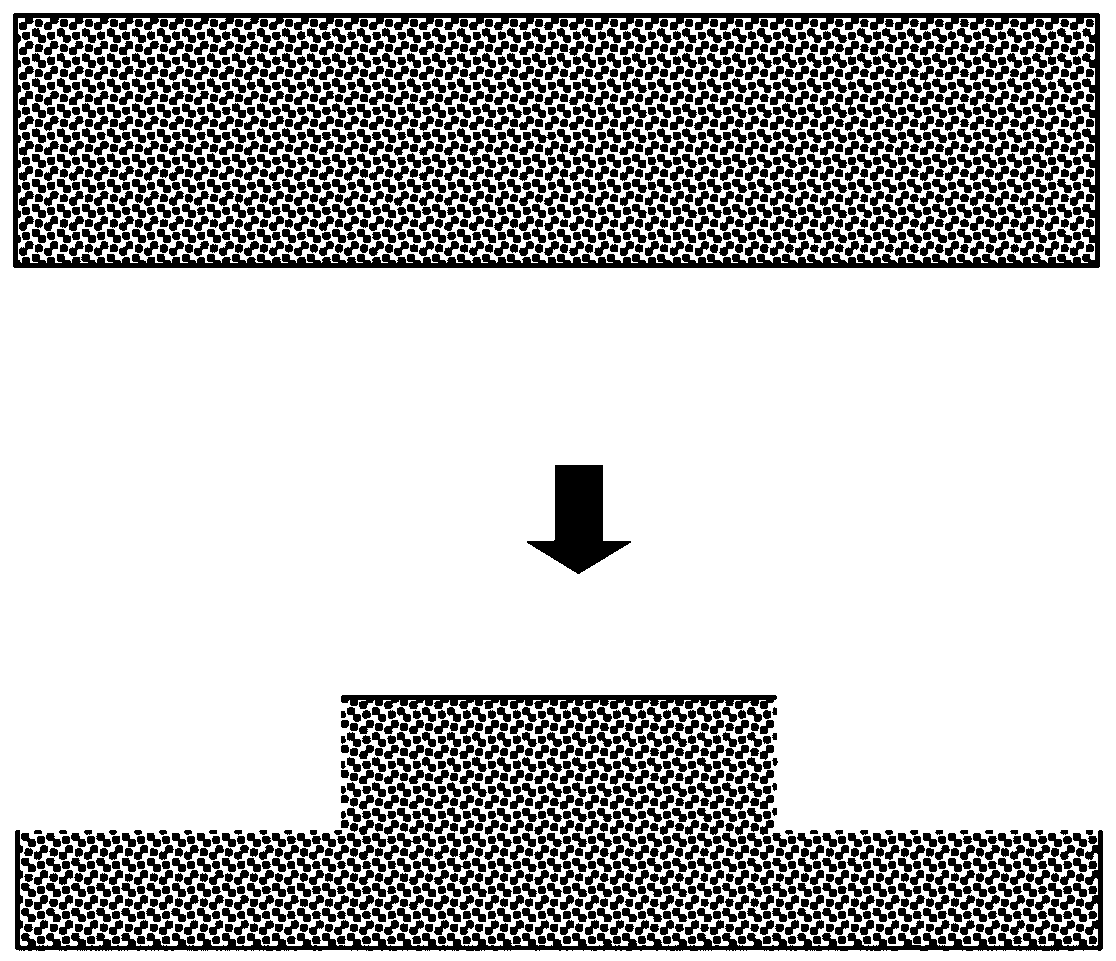

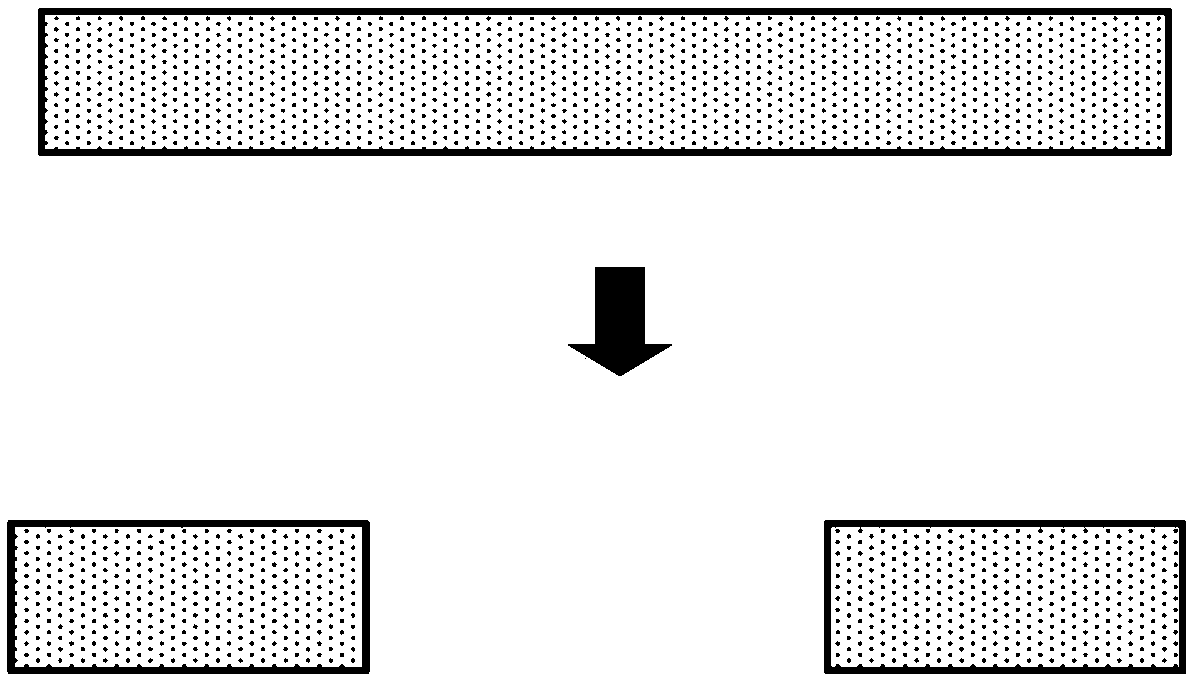

The invention discloses a blocked type variable cross-section reciprocating squeezing, twisting and upsetting forming method for ultra-fine grain bars. On the basis of a three-way hydraulic forming machine, the die assembly force is provided through an upper slide block, and pressure required for forming of punches at the two ends is provided through a left slide block and a right slide block. A die inner cavity is a linear channel formed by sequentially connecting a first squeezing channel, a middle twisting channel and a second squeezing channel on the same straight line. The section area of the middle twisting channel is smaller than the section area of the first squeezing channel and the section area of the second squeezing channel. The punches at the two ends are located at the two ends of the linear channel in a one-to-one correspondence manner, and a blocked variable section cavity is formed through the reciprocating punches at the two ends. By means of reciprocating of the punches at the two ends, the reciprocating squeezing, twisting and upsetting process of a to-be-processed blank in the linear channel is achieved, and preparation of the ultra-fine grain bars is completed through multi-pass forming. By means of the blocked type variable cross-section reciprocating squeezing, twisting and upsetting forming method, bar grains can be effectively refined, the forming limit of the bars is improved, and the blocked type variable cross-section reciprocating squeezing, twisting and upsetting forming method is easy to operate, high in applicability and capable of being easily applied in an engineered manner.

Owner:HEFEI UNIV OF TECH

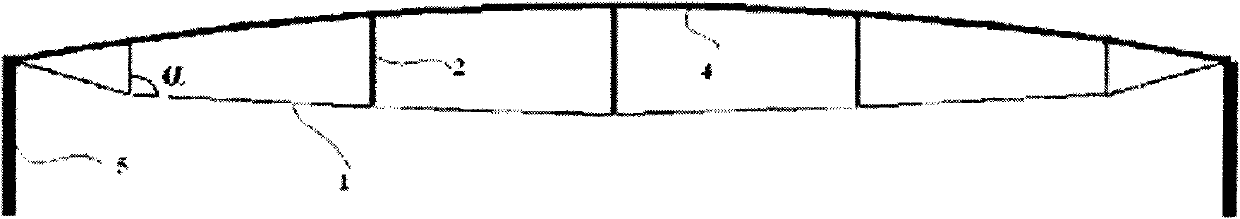

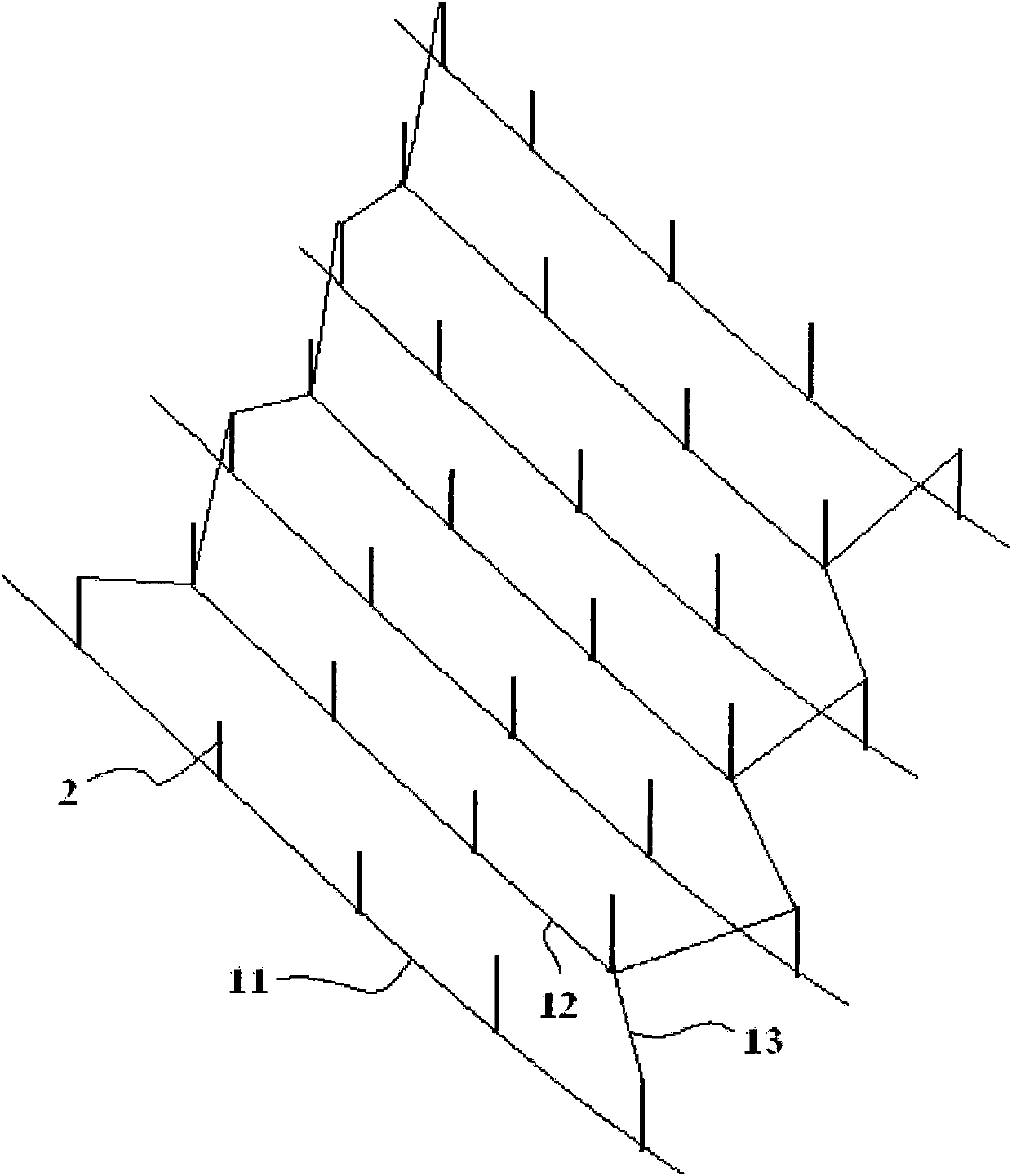

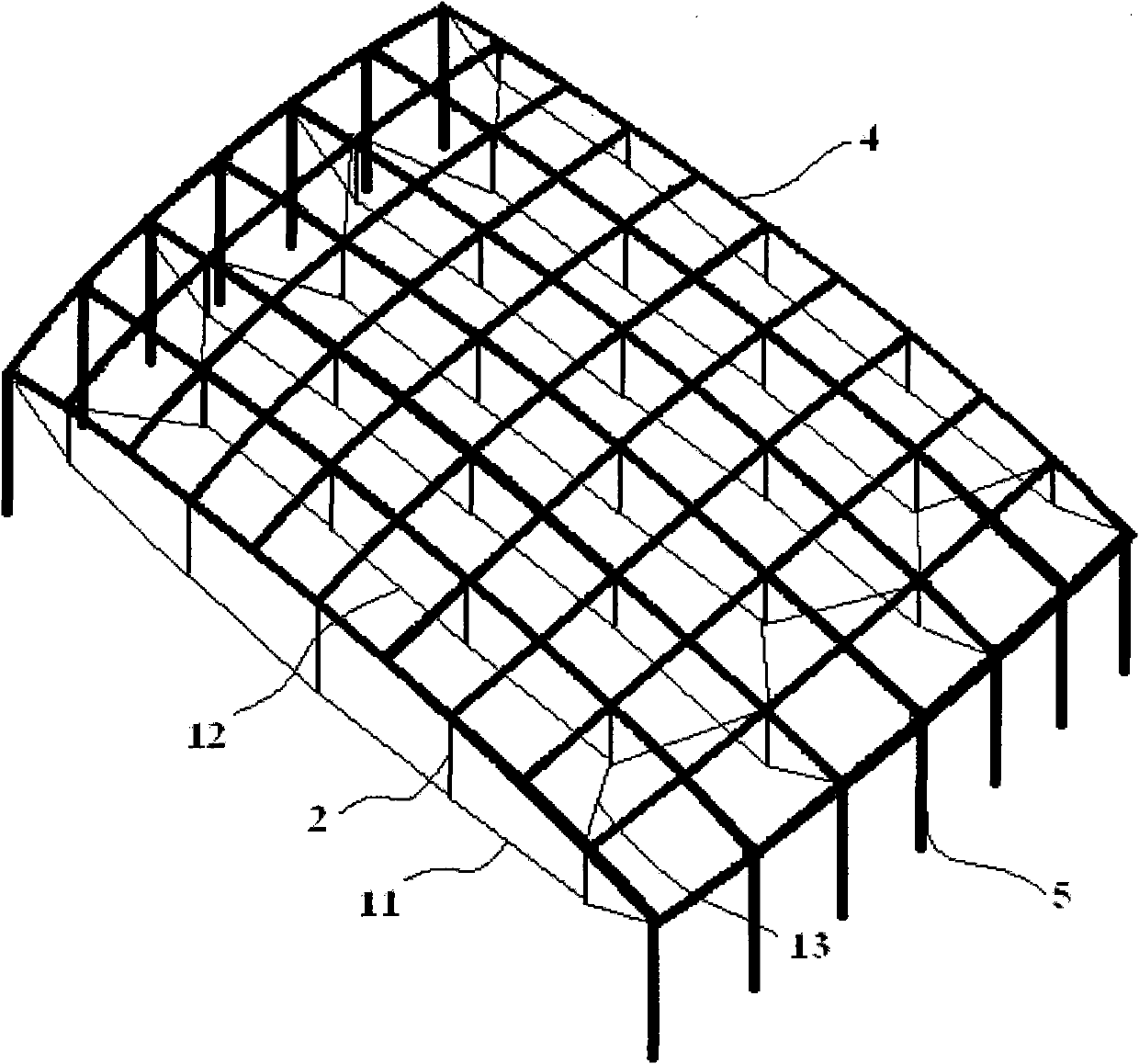

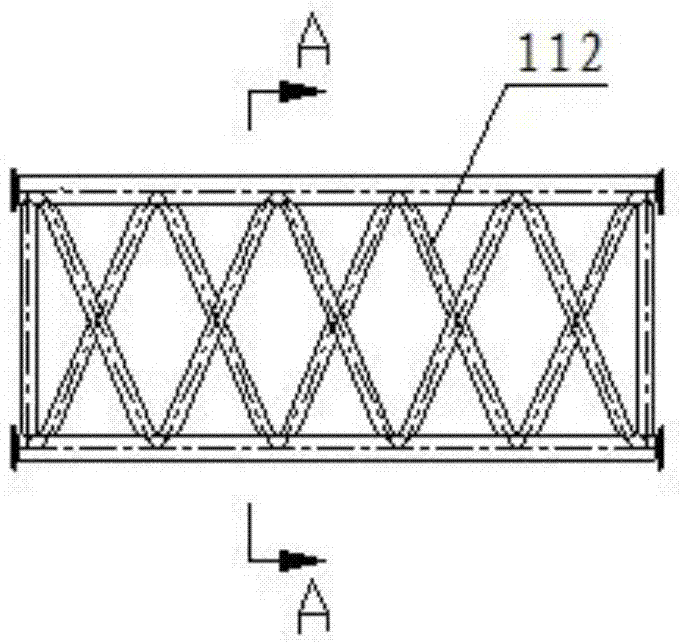

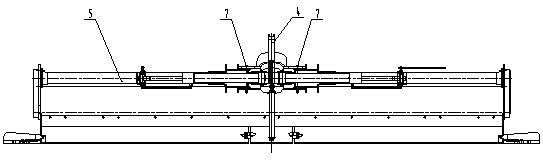

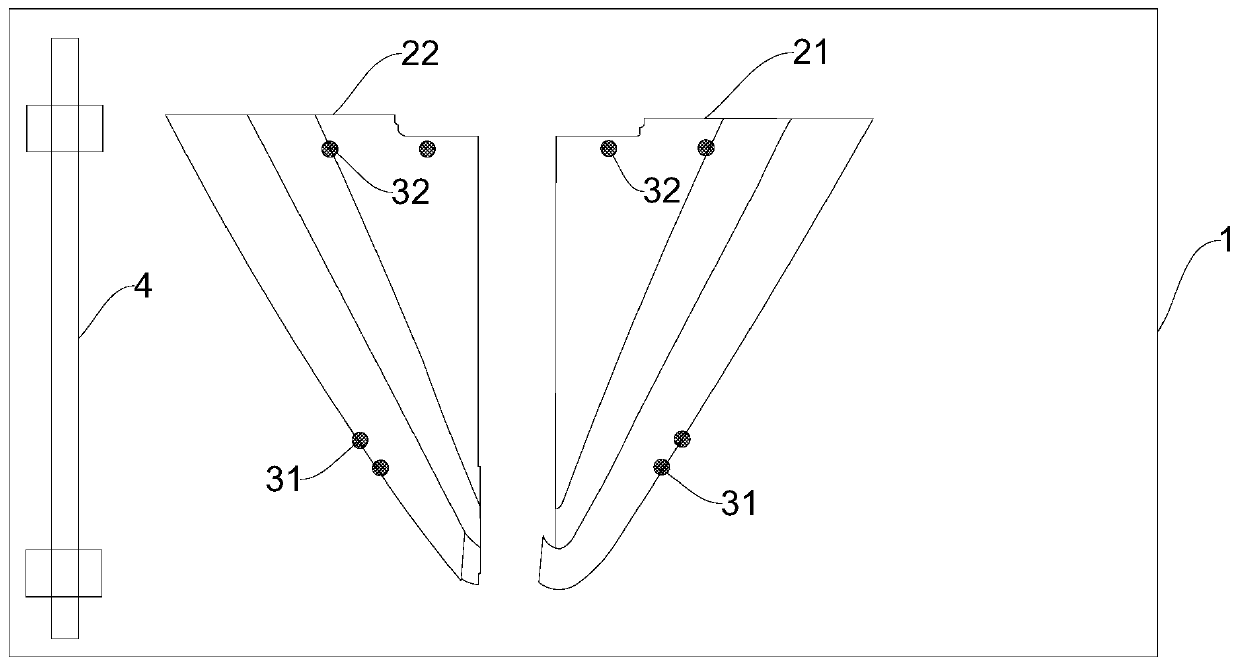

Truss string structure

Relating to the field of engineering design, the invention provides a truss string structure which can provide a solution to the problem of uneven distribution of stress existing in present truss string structures. In the truss string structure provided in the invention, a grid beam is connected to vertical members or horizontal members; the lower ends of struts are in connection with main cables or secondary cables, and the upper ends are in connection with the grid beam; projections of the main cables on a horizontal surface are in parallel with a first direction, and each main cable is connected to at least two struts, and the main cable ends are connected to the grid beam ends or the vertical member top or the horizontal member; projections of the secondary cables on a horizontal surface are in parallel with the first direction, and the two ends of each secondary cable are connected to at least one strut respectively, with the connected parts between a secondary cable and two struts also in connection with the lower ends of two inclined cables respectively, and the upper ends of the inclined cables are connected to the grid beam or the vertical member tops or the horizontal members; on a horizontal surface, projections of angles between the inclined cables and the secondary cables are greater than 90 degrees and less than 180 degrees. Thus, the truss string structure of the invention can be used in large-span space structures.

Owner:CCDI INT SHENZHEN DESIGN CONSULTANTS

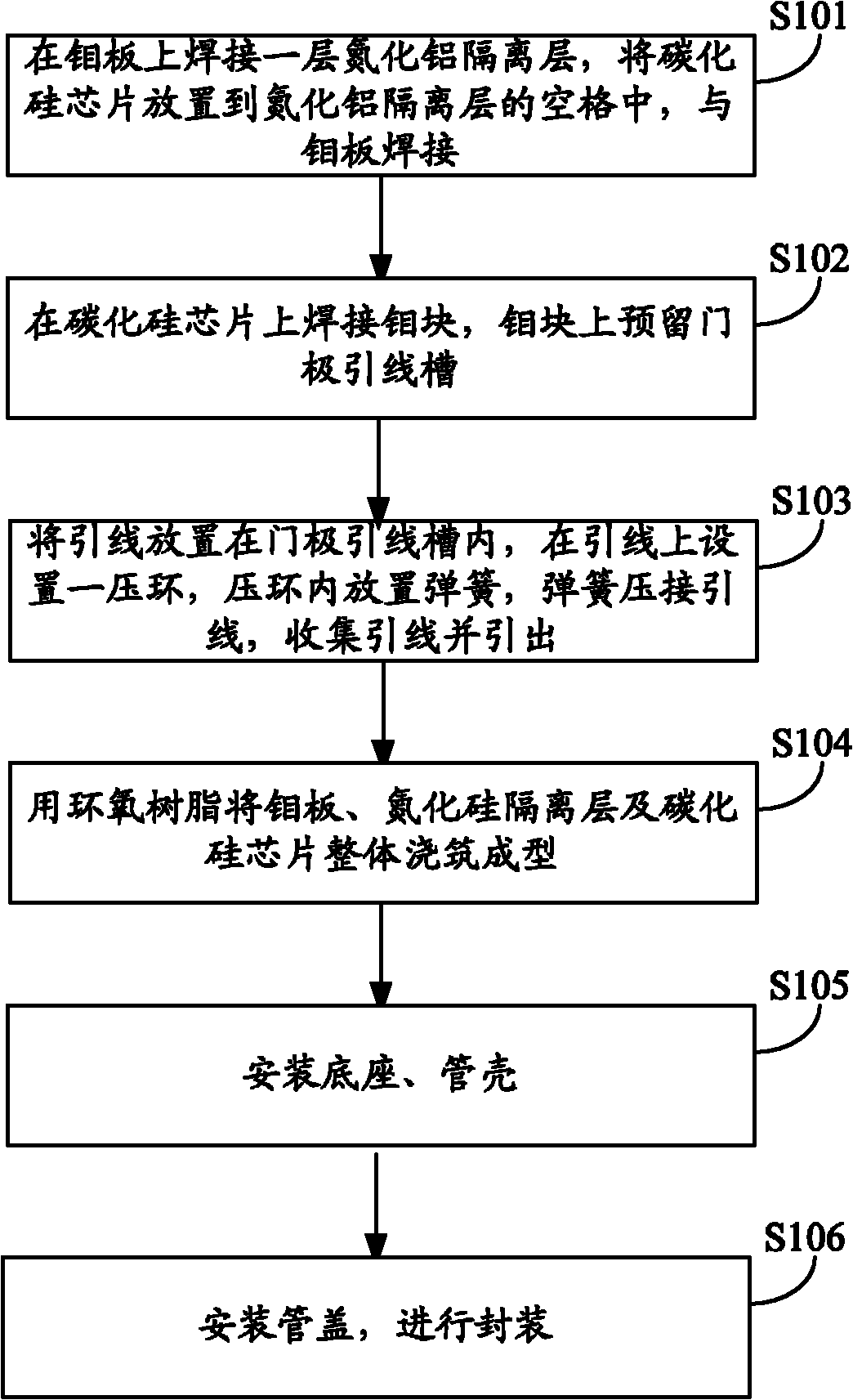

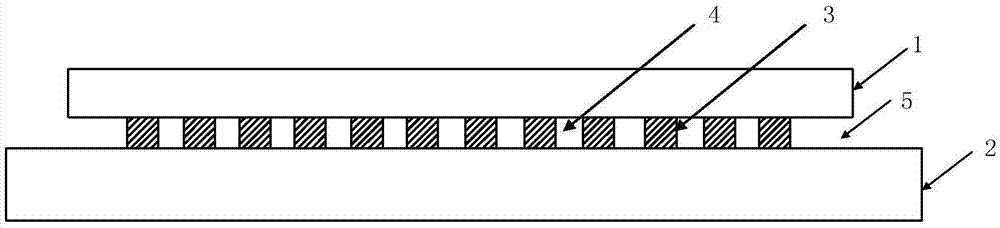

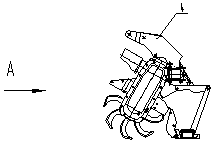

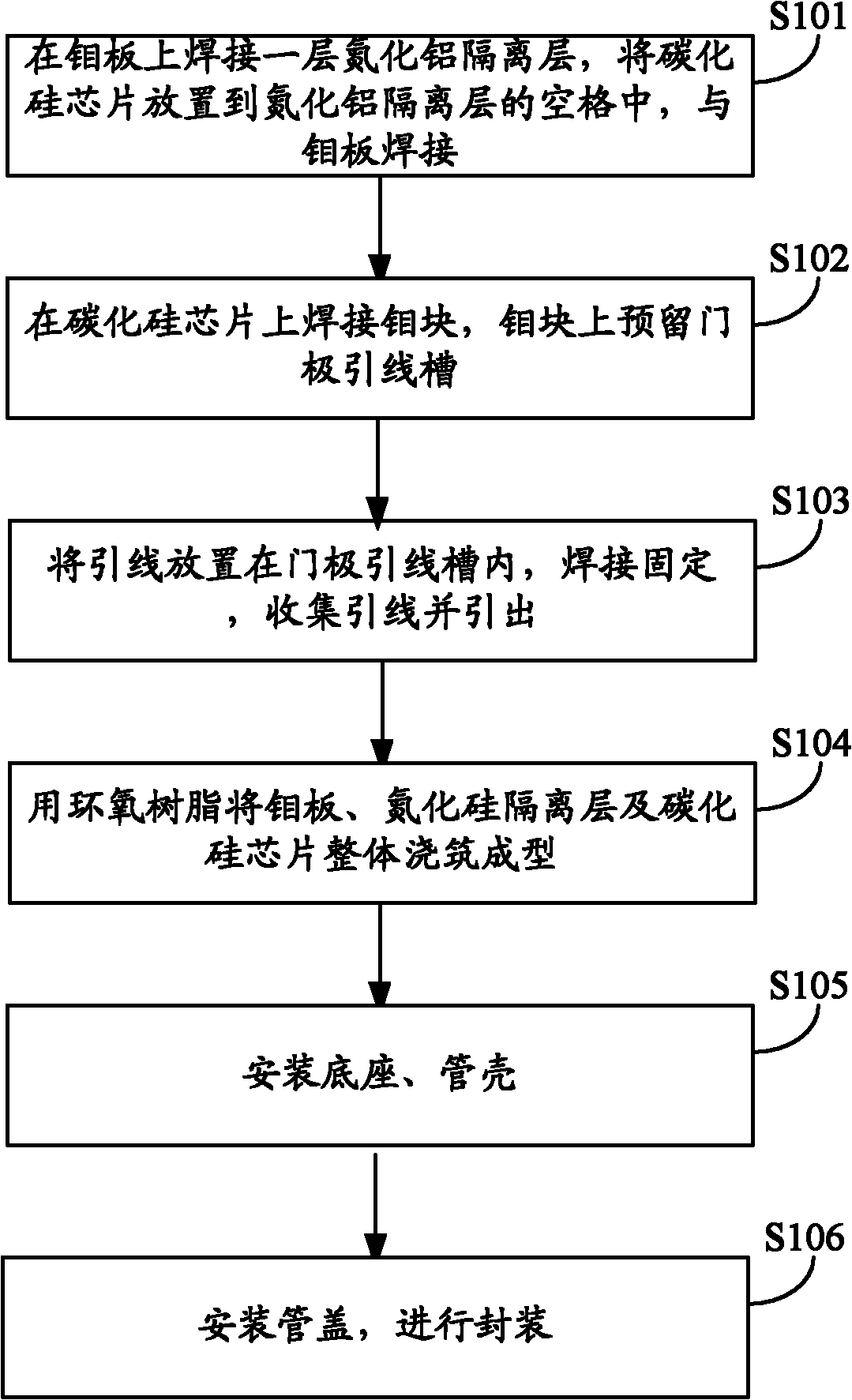

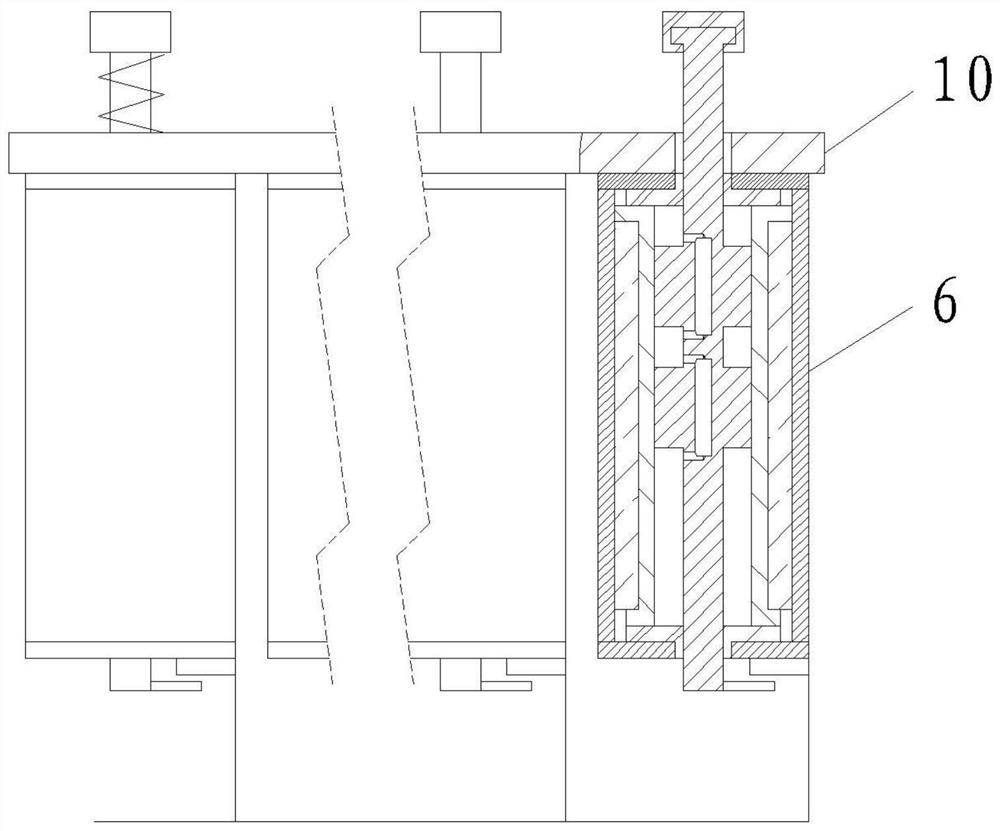

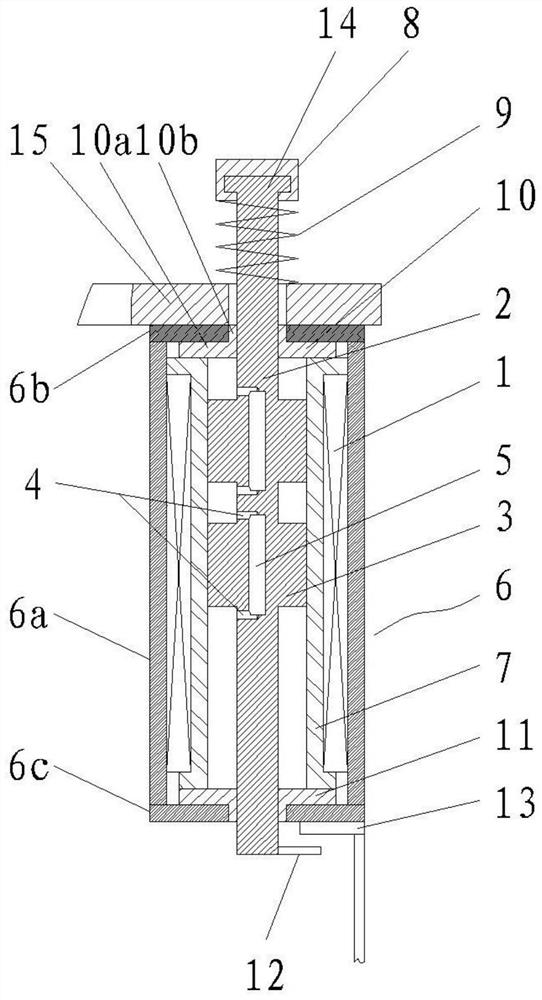

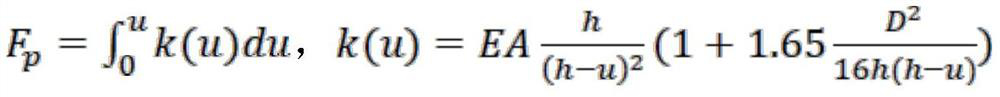

Silicon carbide power module and packaging method thereof

ActiveCN102130021AAvoid thermal shockImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEpoxyIsolation layer

The invention relates to a packaging method of a silicon carbide power module. The packaging method comprises the following steps of: welding an aluminum nitride isolation layer on a molybdenum plate, placing a silicon carbide chip in a blank of the aluminum nitride isolation layer, and welding the silicon carbide chip with the molybdenum plate; welding a molybdenum block on the silicon carbide chip, and reserving a gate electrode lead slot on the molybdenum block; placing a lead in the gate electrode lead slot, arranging a compression ring on the lead, placing a spring used for crimping in the compression ring, and collecting and leading out the lead; and carrying out integral casting forming on the molybdenum plate, the silicon carbide isolation layer and the silicon carbide chip through using epoxy resin, installing a base, a tube shell and a tube cap, and packaging. The invention also discloses a silicon carbide power module. The invention ensures that the silicon carbide power module has higher reliability and stronger thermal cycle capacity under the working conditions of high power and high temperature.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD +1

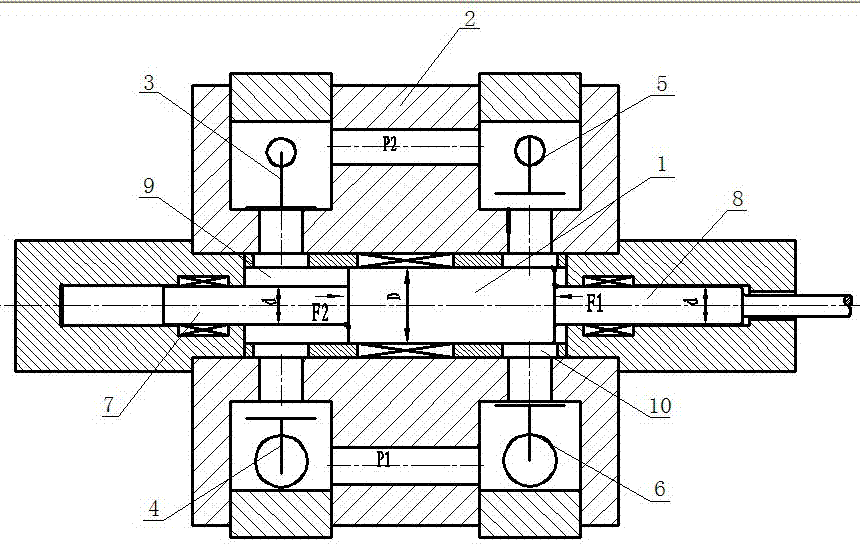

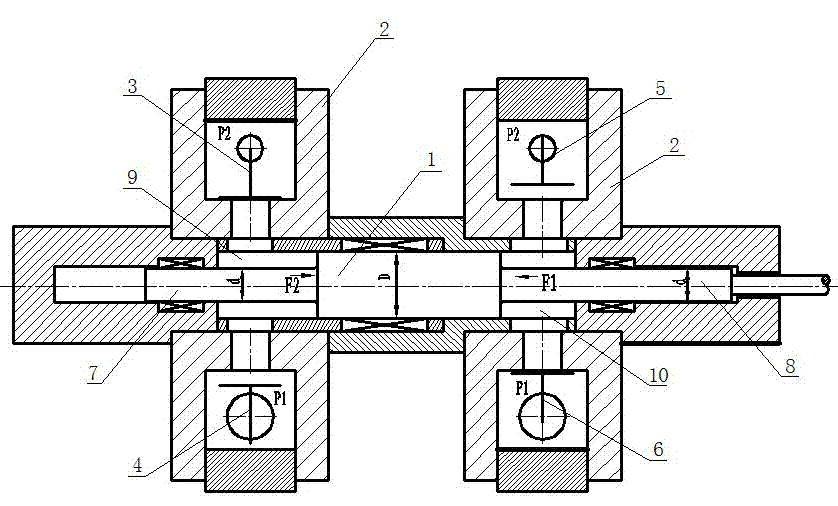

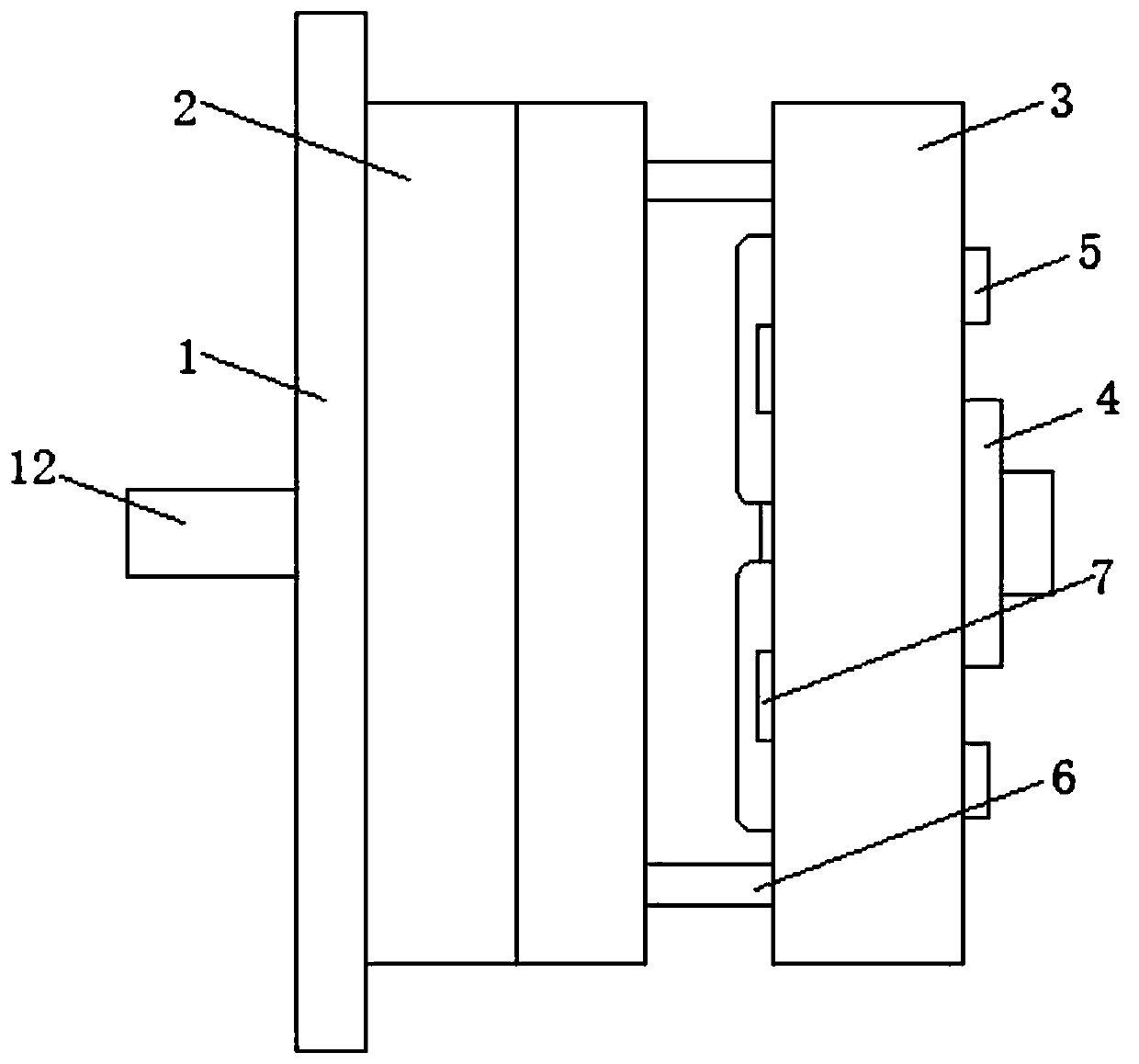

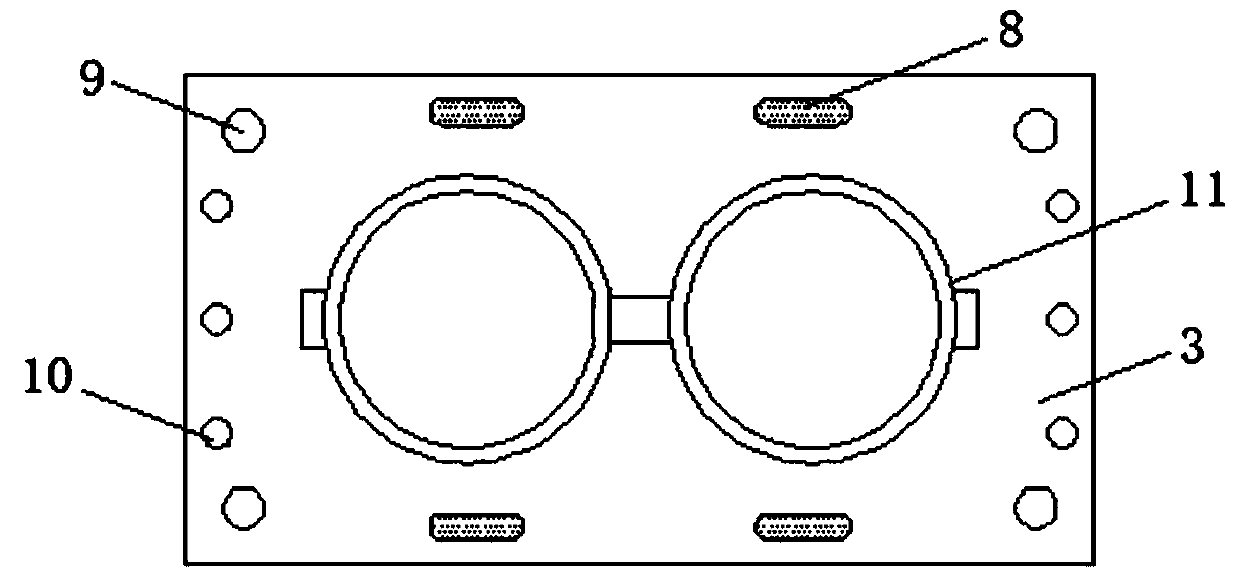

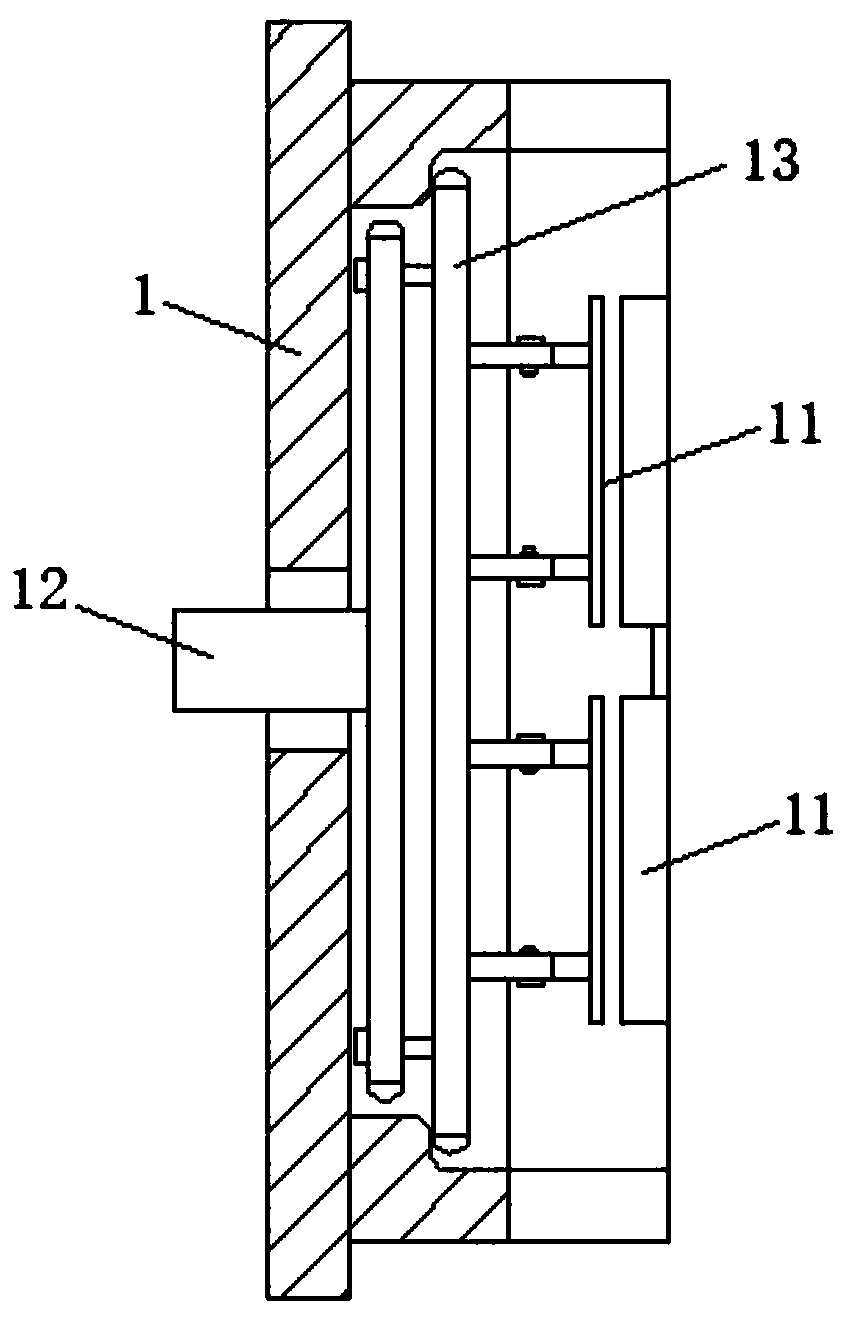

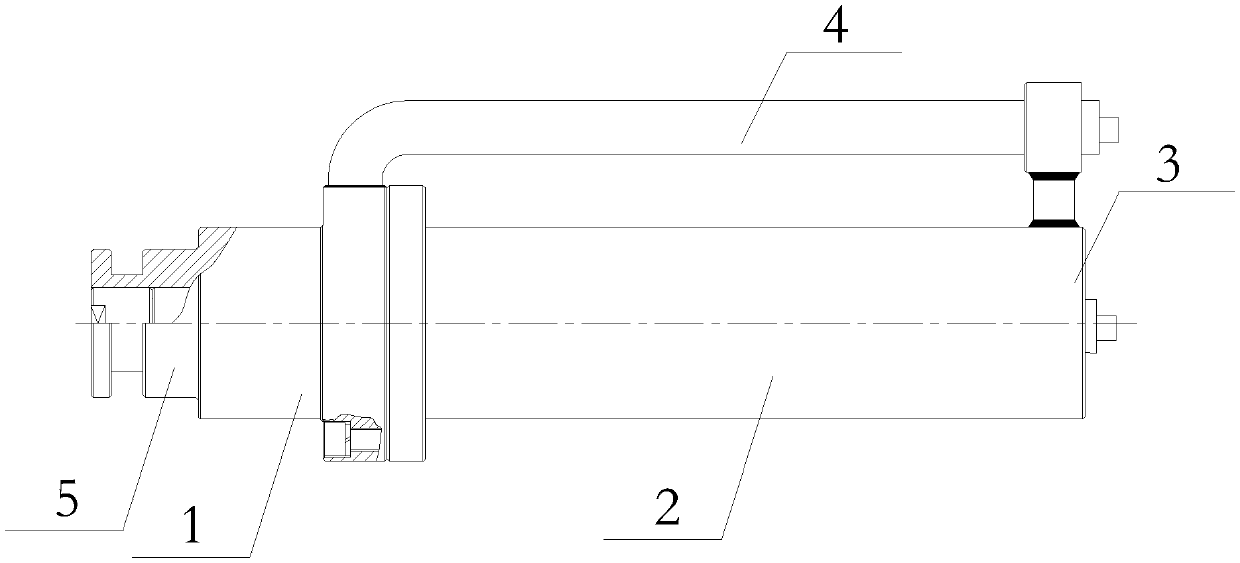

Double-acting reciprocating booster pump

InactiveCN102758772ANovel structural designSolve uneven stressPositive displacement pump componentsLiquid fuel engine componentsReciprocating motionEngineering

The invention provides a double-acting reciprocating booster pump and belongs to the technical field of reciprocating pumps. The double-acting reciprocating booster pump is composed of a double-step plunger piston and a pump body. A left volume cavity and a right volume cavity are arranged on the pump body, a suction valve assembly I and a discharge valve assembly I are installed in the left volume cavity, and a suction valve assembly II and a discharge valve assembly II are installed in the right volume cavity. The double-step plunger piston and a sealing assembly of the double-step plunger piston are installed between the left volume cavity and the right volume cavity and separate the left volume cavity and the right volume cavity. The double-acting reciprocating booster pump is novel in structural design, has two flow discharging strokes in one reciprocating motion stroke of the double-step plunger piston and increases discharge flows in a multiplied mode. In addition, stress on two sides of the double-step plunger piston in the suction and discharge strokes are the same. The double-acting reciprocating booster pump always provides same acting force for a power end and solves the problem that the stress of a conventional booster pump in the suction and discharge strokes are uneven.

Owner:JINTUO PETROLEUM MACHINERY MANUFACTRING CO LTD

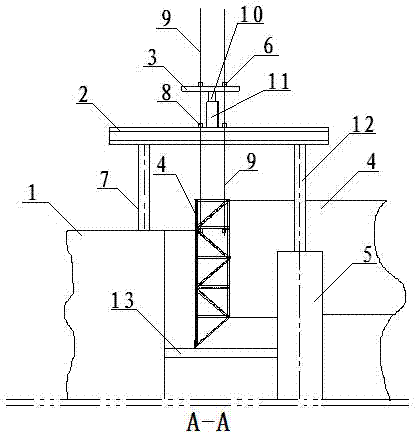

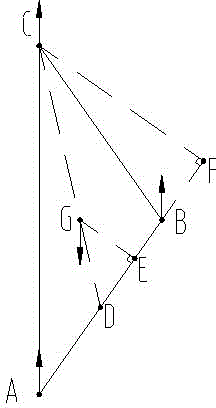

Method for synchronously controlling sinking double-wall steel cofferdam by jack

The invention discloses a method for synchronously controlling a sinking double-wall steel cofferdam by a jack. A steel pipe pile, a synchronous jack, finish rolling screw thread steel rods, a shoulder pole beam and a coupled I-shaped steel girder are fully utilized. The method is characterized by comprising the following steps of: building a portal, arranging the shoulder pole beam, two finish rolling screw thread steel rods and screw caps, primarily lifting the cofferdam, and secondarily lifting the cofferdam and sinking the cofferdam and other steps. According to the method, the problem of uneven stress in a cofferdam sinking process caused by anthropic factors and the like is effectively solved by combination of the synchronous jack and the portal; security in the cofferdam sinking process is ensured, and the method is suitable for building roads, bridges or buildings in water.

Owner:SHANGHAI CIVIL ENG GRP FIFTH

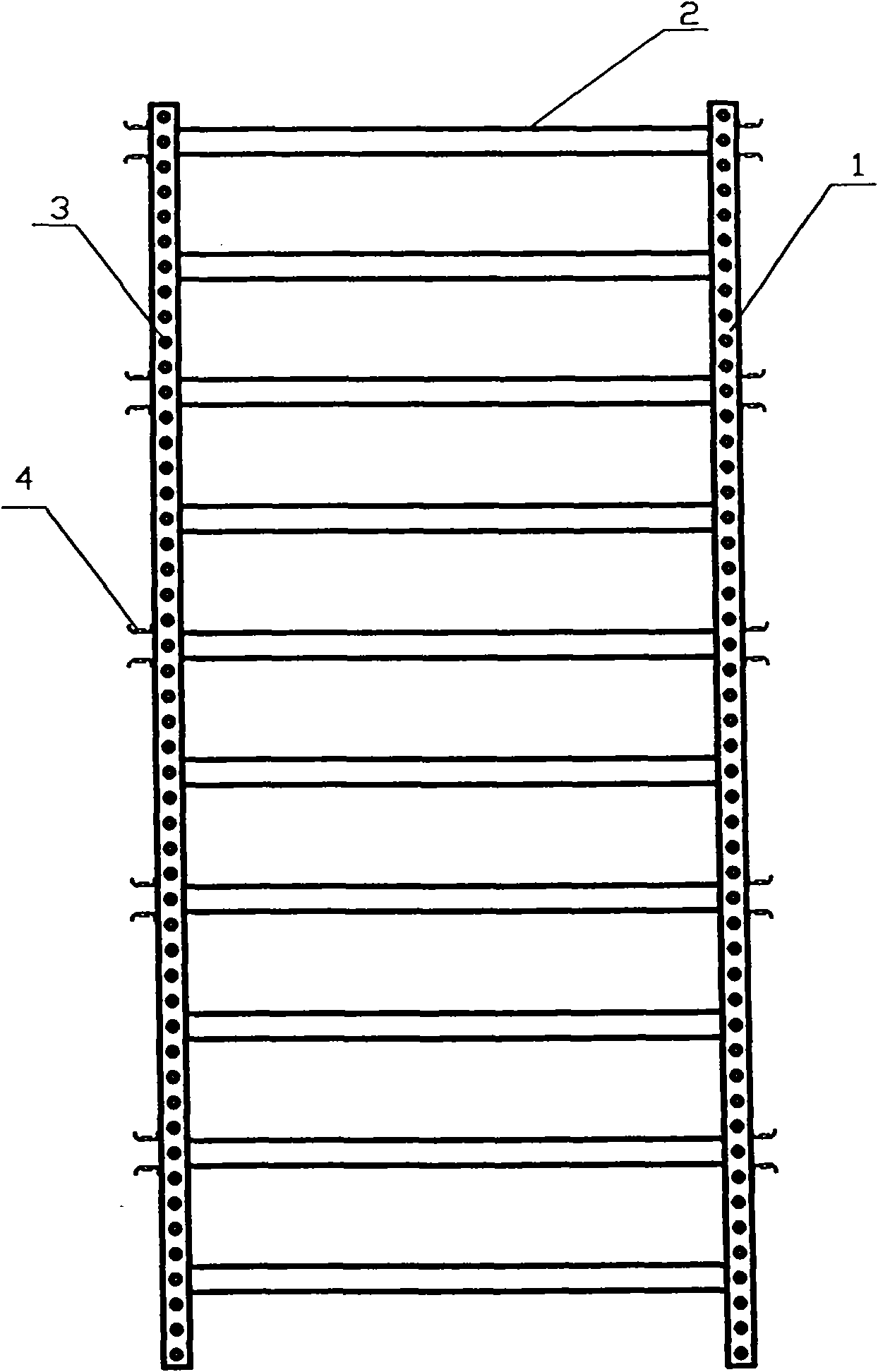

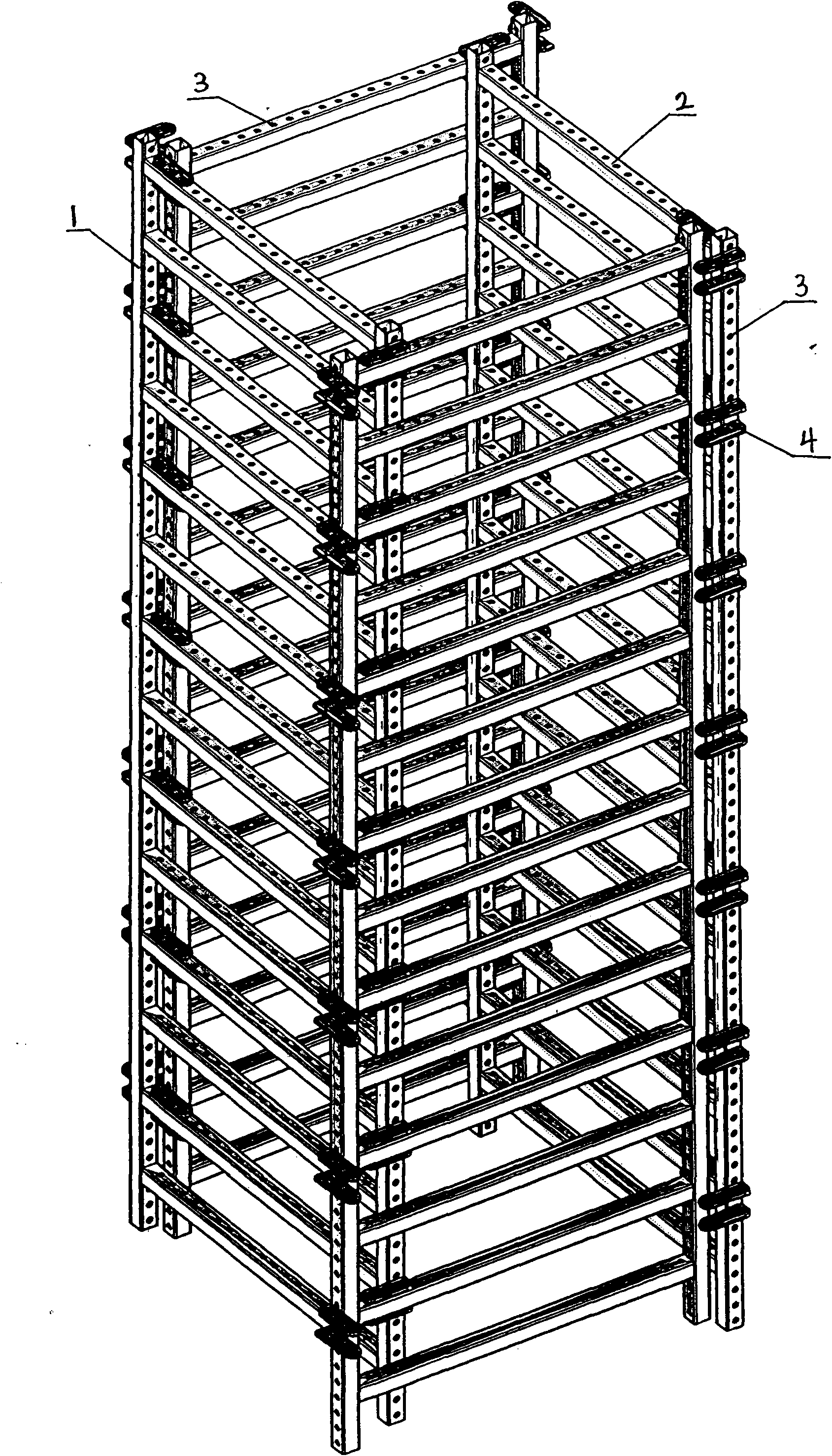

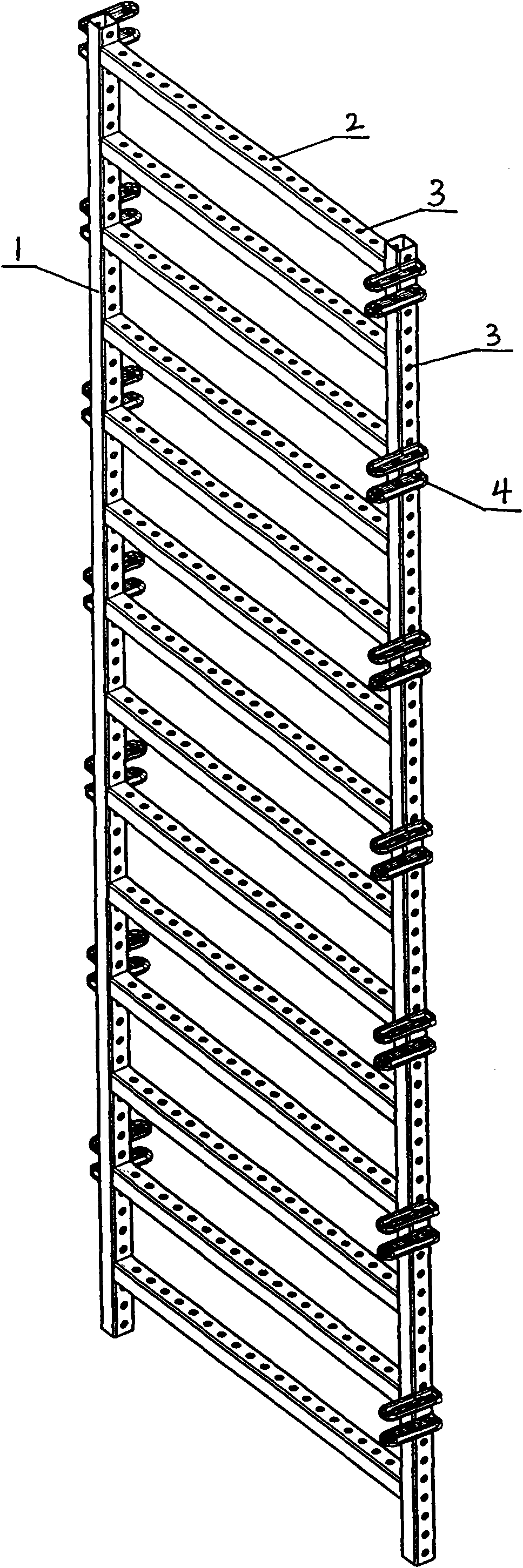

Precise building mold support frame system for reinforcing building templates and use method thereof

ActiveCN102400553ARealize the constructionStable supportAuxillary members of forms/shuttering/falseworksCable stayedArchitectural engineering

The invention relates to the field of buildings and particularly relates to a precise building mold support frame system for reinforcing building templates and a use method thereof. The precise building mold support frame system for reinforcing the building templates comprises a line frame unit, a beam bottom support frame, a stress clamping device, a loquat support frame, a cable stayed frame and a moving device capable of being braked. The precise building mold support frame system for reinforcing the building templates can conveniently realize the support and fixing effects on various templates built in the building construction, simultaneously, the structure is simple, the efficiency is high, and the practicability is realized.

Owner:王亚运

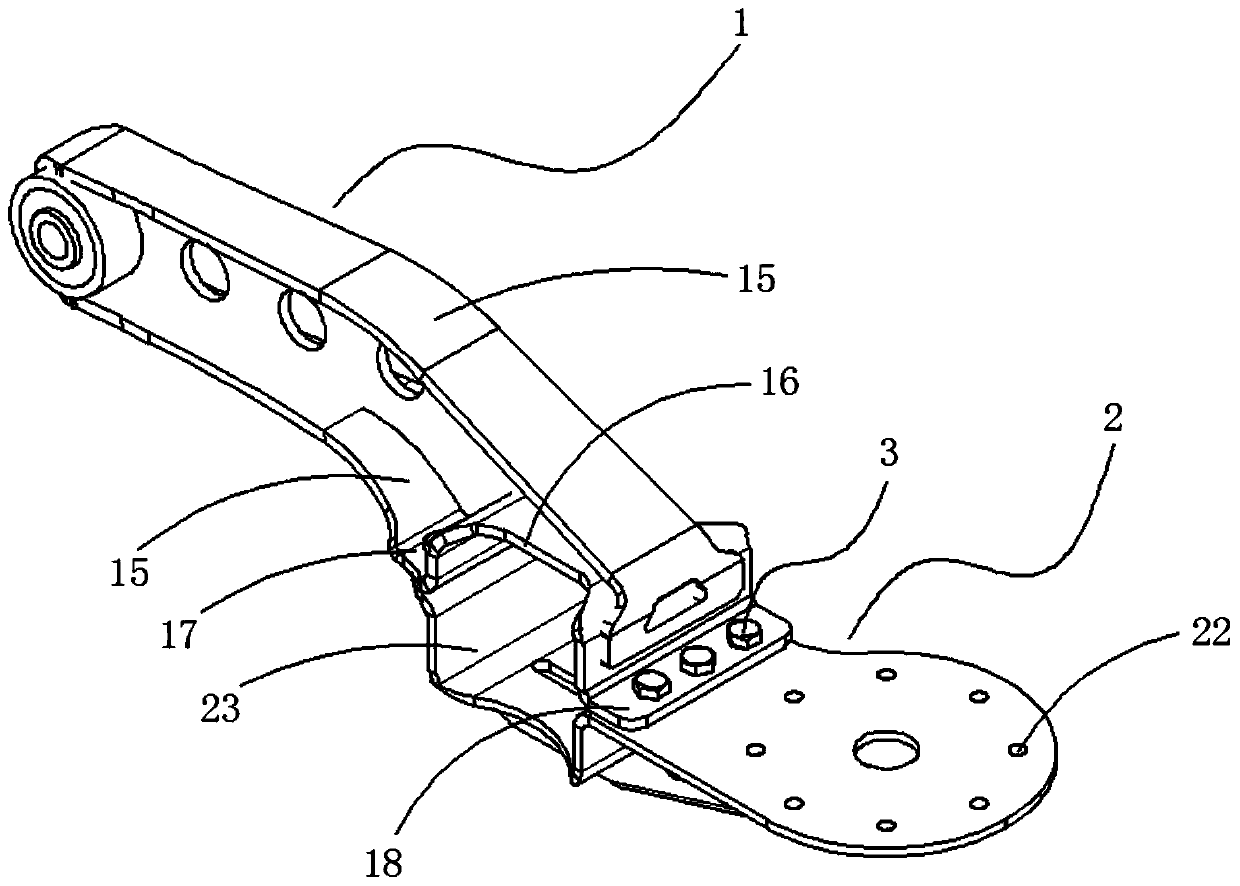

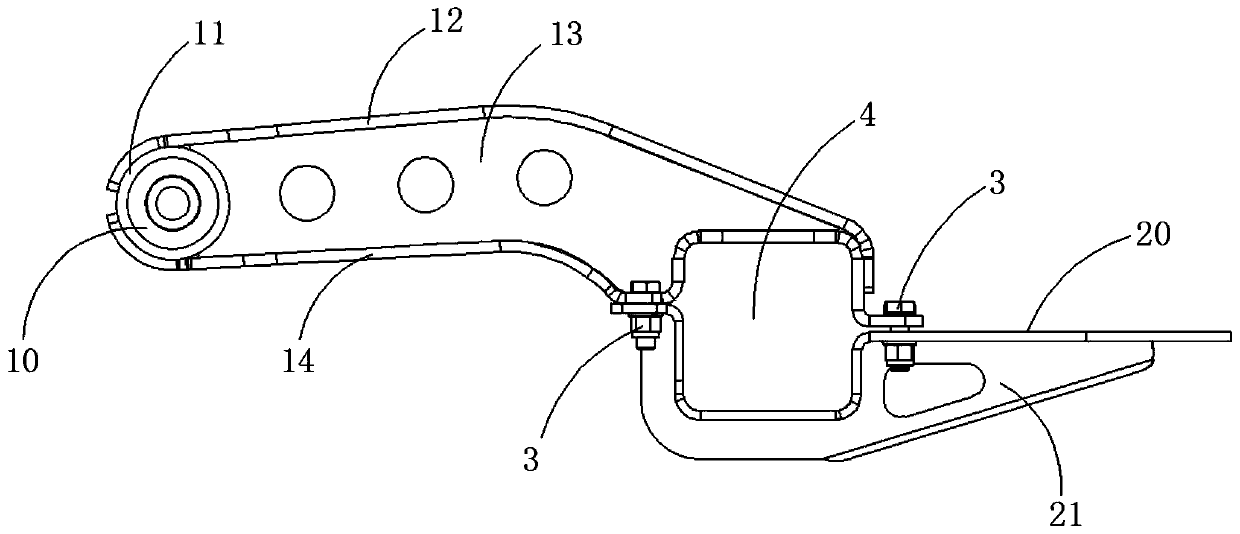

Novel air suspension guide arm and automobile comprising same

PendingCN110435374AImprove securityLarge installation spaceResilient suspensionsVehicle springsControl armEngineering

The invention relates to a novel air suspension guide arm and an automobile comprising the same. The invention discloses the novel air suspension guide arm, and the novel air suspension guide arm comprises a control arm, wherein the control arm comprises an upper side plate, a lower side plate, a vertical plate and a torsion sleeve, and is characterized in that the torsion sleeve is connected withone or any of the upper side plate, the vertical plate or the lower side plate, the vertical plate is positioned between the upper side plate and the lower side plate, and one end, far away from thetorsion sleeve, of the control arm is connected with a first axle fixing plate. The beneficial effects are as follows: the air suspension guide arm consists of the upper side plate, the lower side plate and the vertical plate, and the air suspension guide arm has simple structure, safety and reliability and reasonable structure. Compared with the control arm of the existing metal plate structure,the novel air suspension guide arm is more stable, higher in strength and better in safety. The lower side plate is of a structure which gradually narrows and then widens from one end of the torsion sleeve, and can bear larger force and is more durable.

Owner:SHANDONG LUOXIANG AUTOMOBILE MFG CO LTD

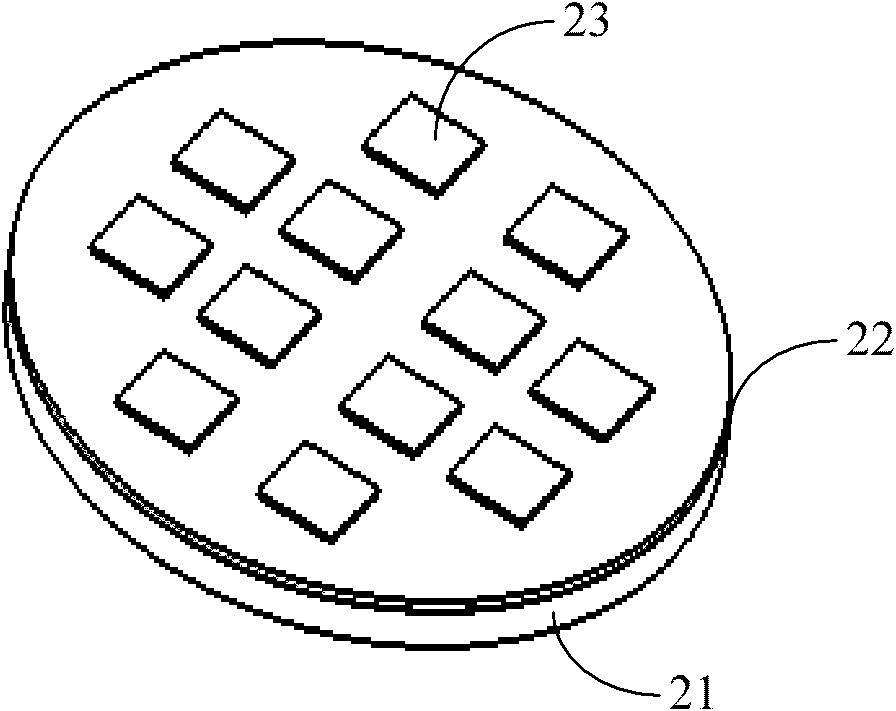

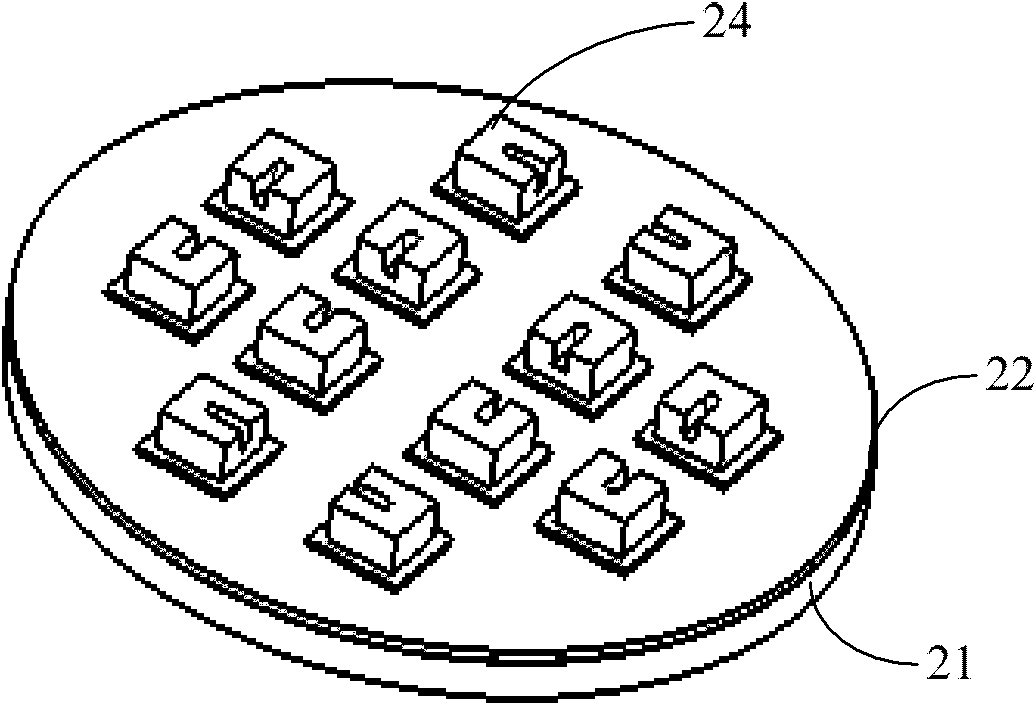

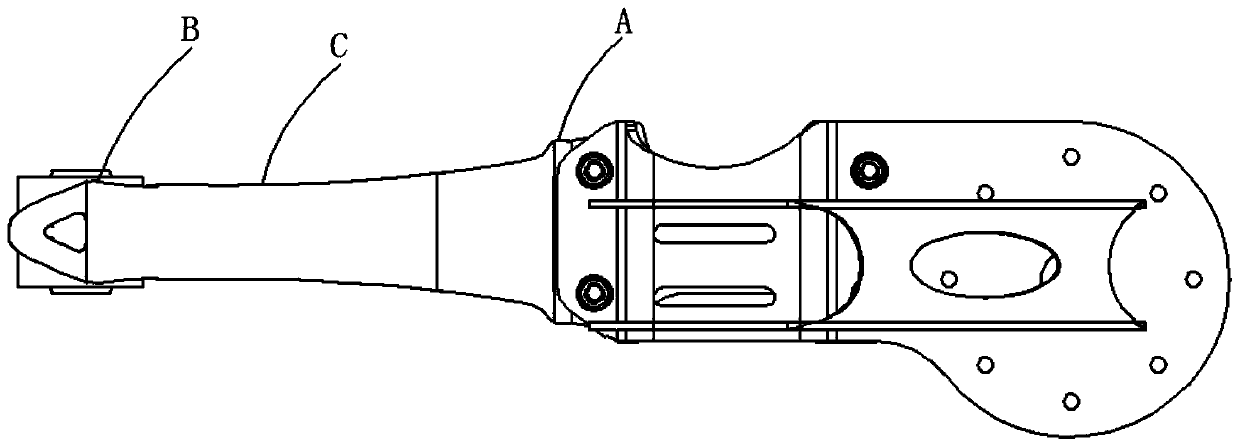

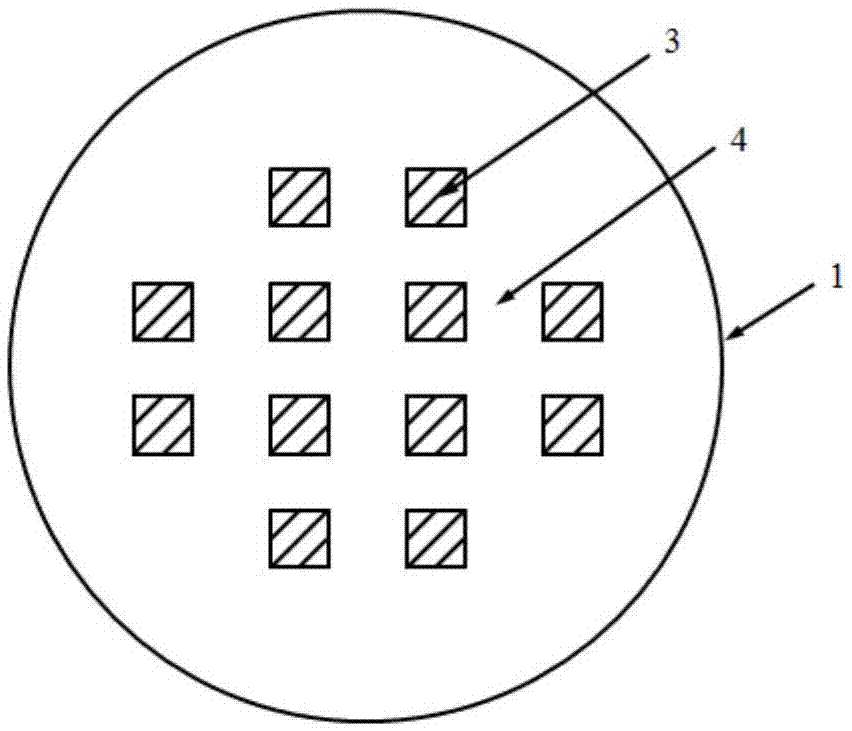

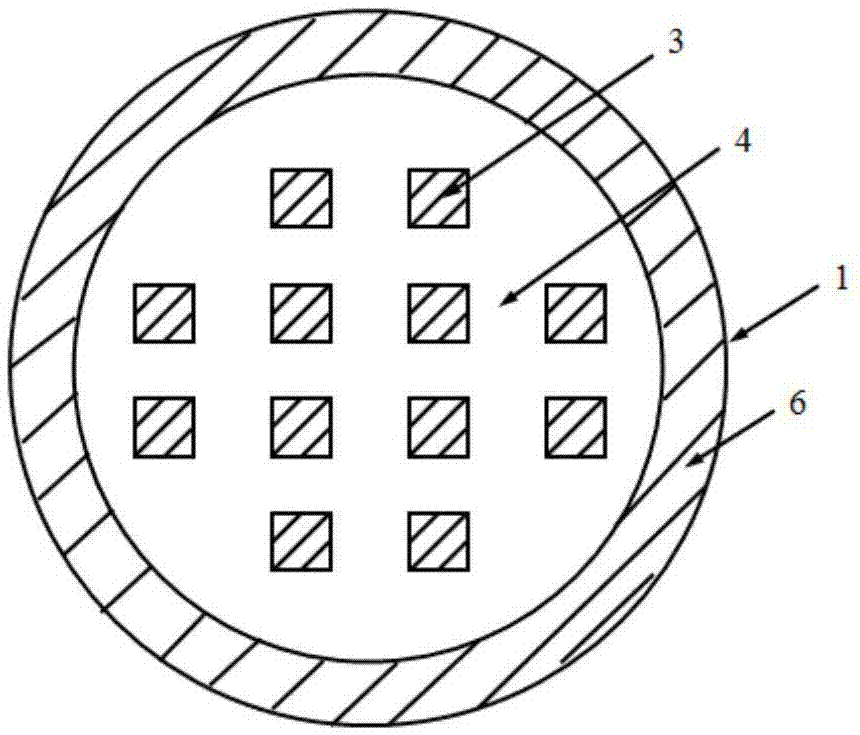

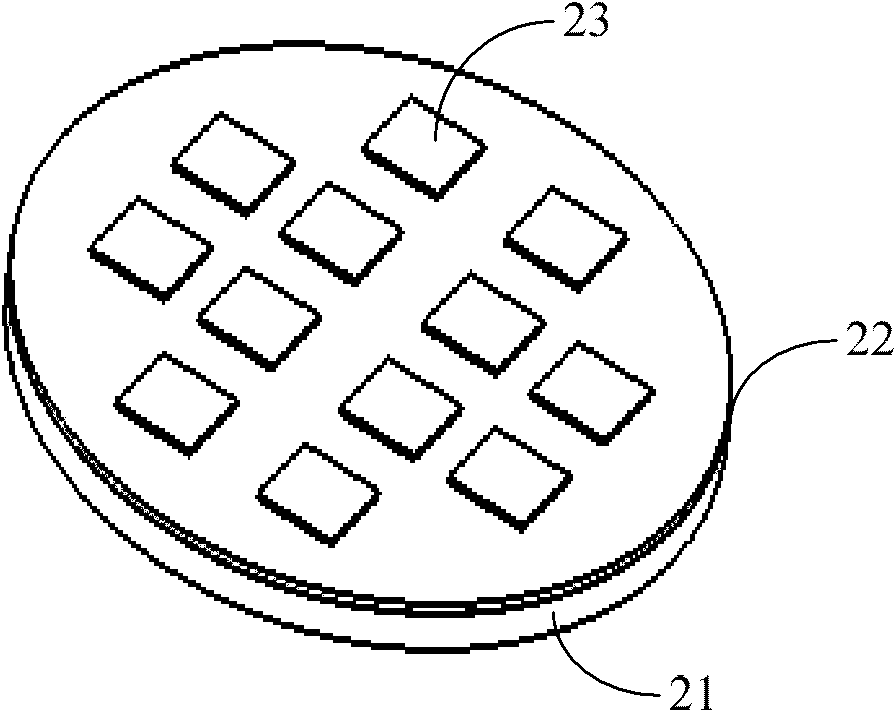

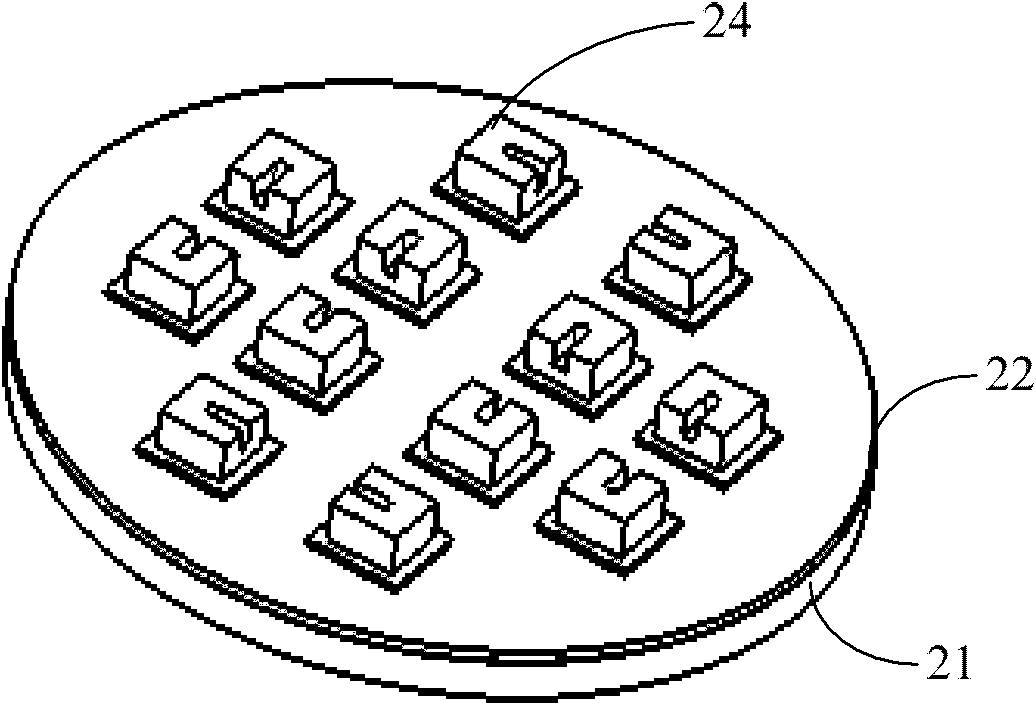

Wafer metal coating structure adapted to thinned back and toolings thereof

ActiveCN105448669AEliminate uneven stressSolve uneven stressSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentMetal coatingEngineering

The invention provides a wafer metal coating structure adapted to a thinned back and toolings (photoetched plates and wafer clamps) thereof. In the wafer metal coating structure, the middle part of the wafer metal coating is provided with a plurality of isolated metal zones used for realizing chip functions, and marked as chip active zones overall, and the difference from the existing technology is as follows: the peripheries of the chip active zones are provided with isolated metal ring belts, wherein the thickness of the metal ring belts is the same as that of the metal zones. When the wafer is thinned at the back, since metal exists at the wafer edge, the edge gap is eliminated, thus the problem that the edge stress of the wafer is uneven can be solved, and the risks of fracture and bending can be eliminated; meanwhile, since the edge gap is eliminated, a supporting carrier of the wafer edge can be totally fitted with the front, so that the probability that the thinned particles enter the wafer front can be eliminated and the problem of wafer surface contamination can be solved.

Owner:XIAN LIXIN PHOTOELECTRIC SCI & TECH

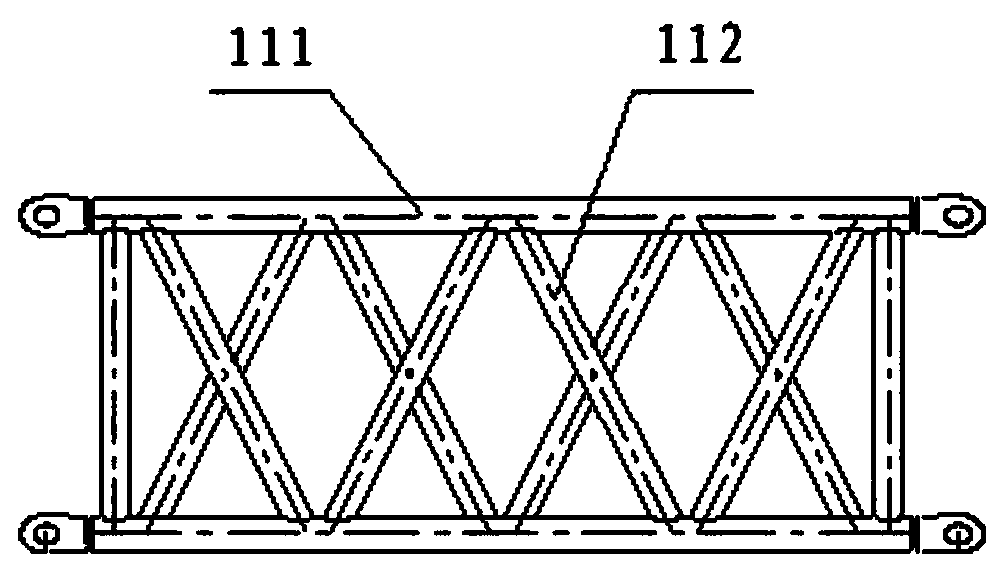

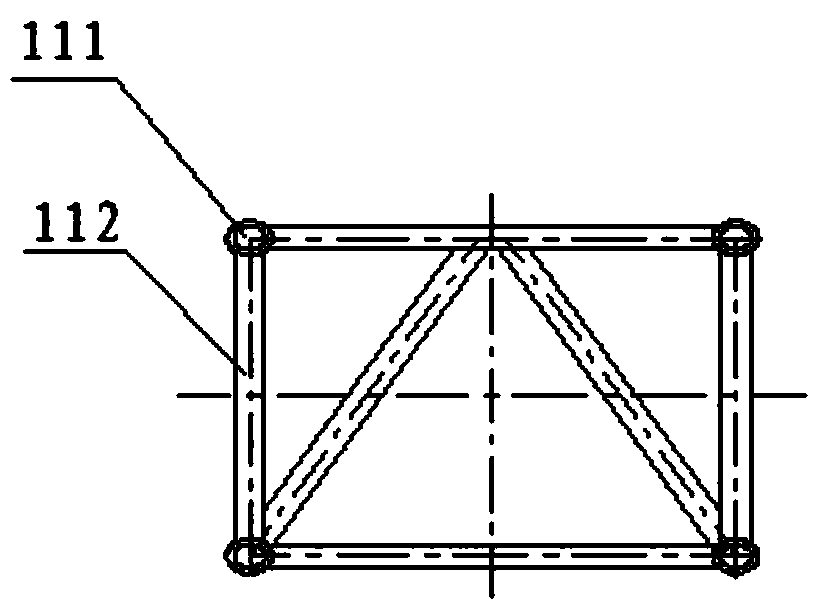

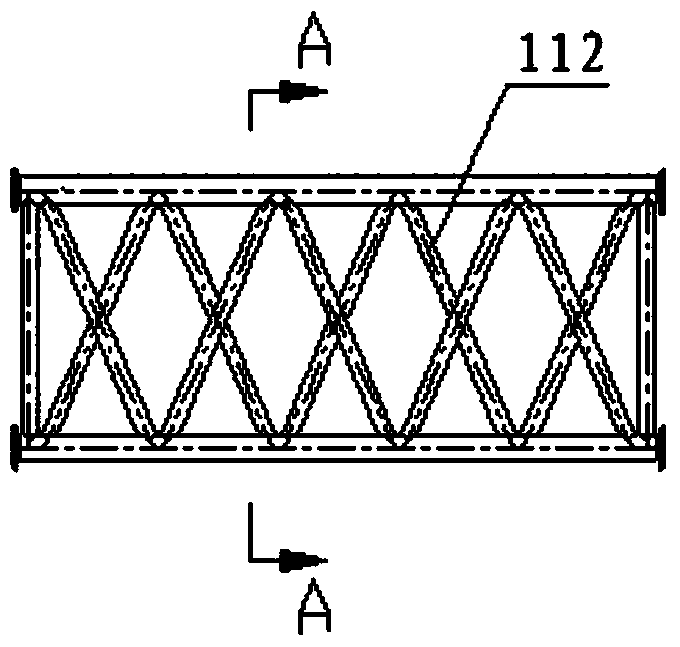

Composite connector and cantilever crane

The invention discloses a composite connector and a cantilever crane. The composite connector comprises a base body and multiple ear plate-type sub connectors; the base body is provided with a first side surface and a second side surface which are oppositely arranged; and the multiple ear plate-type sub connectors are separately arranged on the first side surface and the second side surface of the base body and are fixedly connected with the base body, wherein at least one of the first side surface and the second surface is provided with more than two ear plate-type sub connectors. Jib sections provided with composite type main chords are connected to form the cantilever crane through the above composite connectors; the stress applied to the main chords can be transferred to the main chords on different planes through the base bodies; and the stress transferring effect among the main chords is improved, so that the stress among the multiple jib sections is more uniform, and the performance of the cantilever crane is improved.

Owner:XCMG CONSTR MACHINERY

Balanced hoisting mechanism for hoisting heavy piece

Owner:CHINA RAILWAY JIUJIANG BRIDGE ENG +1

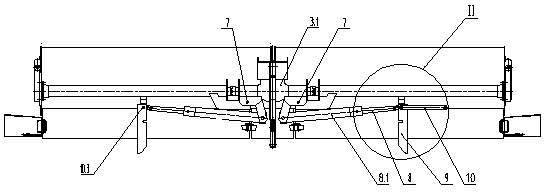

Efficient folding type cultivator

ActiveCN103404262AEnable connectivityAchieve foldingAgricultural undercarriagesAgricultural engineeringTillage

The invention discloses an efficient folding type cultivator comprising a machine frame, a rotary tillage mechanism, a transmission system, a hanging assembly and a dragging plate assembly. The machine frame comprises a middle machine frame body and side machine frame bodies, wherein the side machine frame bodies are connected to the side faces of the middle machine frame body in a hinged mode through pin shafts. The transmission system comprises a center gearbox and side gearboxes, wherein the center gearbox is fixedly connected with the middle of the middle machine frame body, and the side gearboxes are fixedly connected with the side faces of the side machine frame bodies. The rotary tillage mechanism comprises a rotary tillage shaft, a cutter base and a rotary tillage blade. An output shaft of the center gearbox is connected with input shafts of the side gearboxes through jaw clutches. The rotary tillage mechanism comprises a left rotary tillage mechanism body and a right rotary tillage mechanism body, wherein left rotary tillage mechanism body and the right rotary tillage mechanism body are connected with the two side machine frame bodies respectively. The cultivator can be folded to remarkably reduce the transverse size during walking or transportation, and facilitates walking or transportation. The rotary tillage mechanism is uniform in stress, safe and reliable, and long in service life. The phenomenon that the cultivator is entangled by grass and straw is effectively prevented, power consumption is remarkably reduced, and work efficiency is remarkably improved.

Owner:泰州樱田农机制造有限公司

Silicon carbide power module and packaging method thereof

ActiveCN102148169AAvoid thermal shockImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEpoxyComputer module

The invention relates to a packaging method of a silicon carbide power module, comprising the following steps of: welding an aluminium nitride isolated layer on a molybdenum plate, placing silicon carbide chips into empty spaces of the aluminium nitride isolated layer to be welded with the molybdenum plate; welding molybdenum blocks on the silicon carbide chips, reserving gate lead slots on the molybdenum blocks; placing leads into the gate lead slots, welding and fixing, collecting the leads and leading the leads out; casting and moulding the molybdenum blocks, the silicon nitride isolated layer and the silicon carbon chips in an integrating way, mounting a base, a tube shell and a tube cap, and packaging. The invention also provides a silicon carbide power module. By adopting the method provided by the invention, the silicon carbon power module has higher reliability and stronger thermal cycle capability under the working conditions of high power and high temperature.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

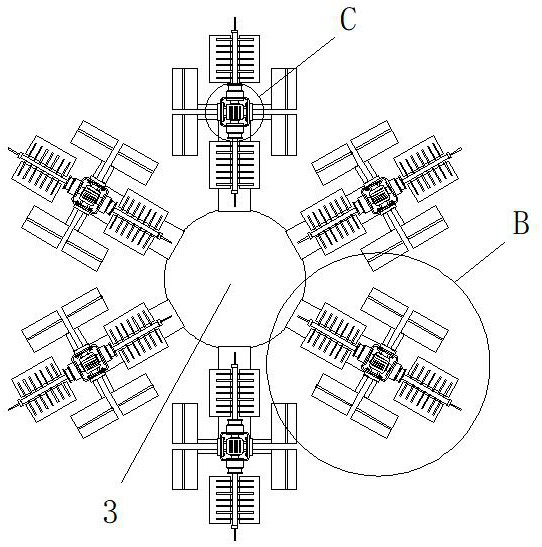

Anti-interference intelligent error correction communication system in complex electromagnetic environment

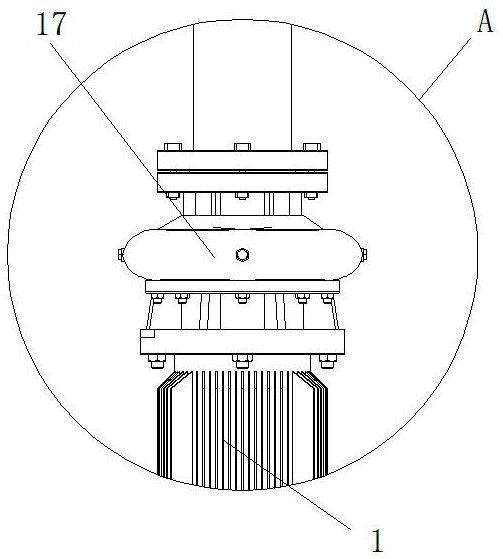

InactiveCN113451745AImprove adjustabilityImprove support stabilityMagnetic/electric field screeningAntenna supports/mountingsCommunications systemInterference resistance

The invention discloses an anti-interference intelligent error correction communication system in a complex electromagnetic environment, and relates to the technical field of intelligent error correction communication. In allusion to the problems that the communication system is interfered and the communication effect is influenced in the complex electromagnetic environment, the invention proposes the following scheme: the anti-interference intelligent error correction communication system comprises a driving motor, the output end of the driving motor is fixedly connected with a gearbox through a flange, a transmission shaft is welded to the output end of the gearbox, a sleeve is welded to the end, which is away from the gearbox, of the transmission shaft, a rotating disc is welded to the top of the sleeve, six fixing rods are evenly welded to the periphery of the rotating disc, a sealing box body is welded to the end, which is away from the rotating disc, of the fixing rod, and symmetrical mounting bases are arranged in an inner cavity of the sealing box body. The system is wide in application scene, convenient to use, and the anti-interference effect in the complex electromagnetic environment is effectively and directly achieved by using the principle of a frequency hopping antenna. Meanwhile, the system is low in use cost, good in error correction effect and suitable for being widely popularized.

Owner:袁利卿

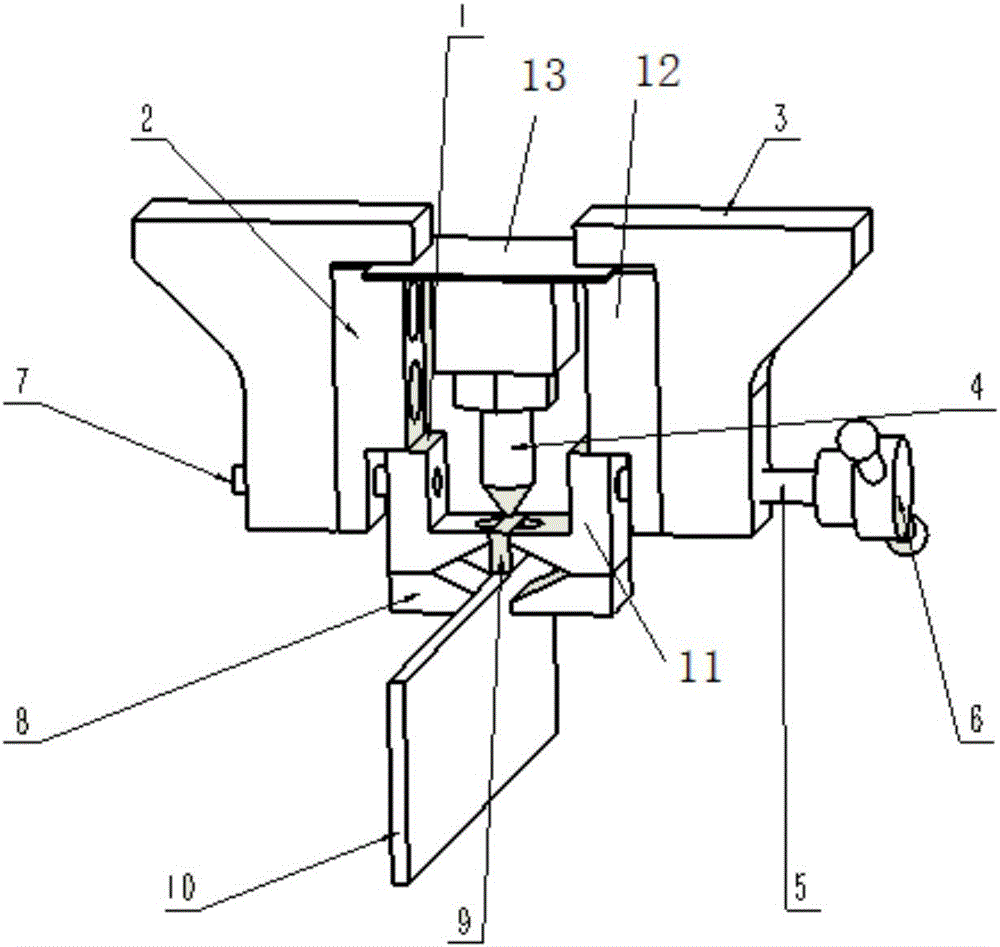

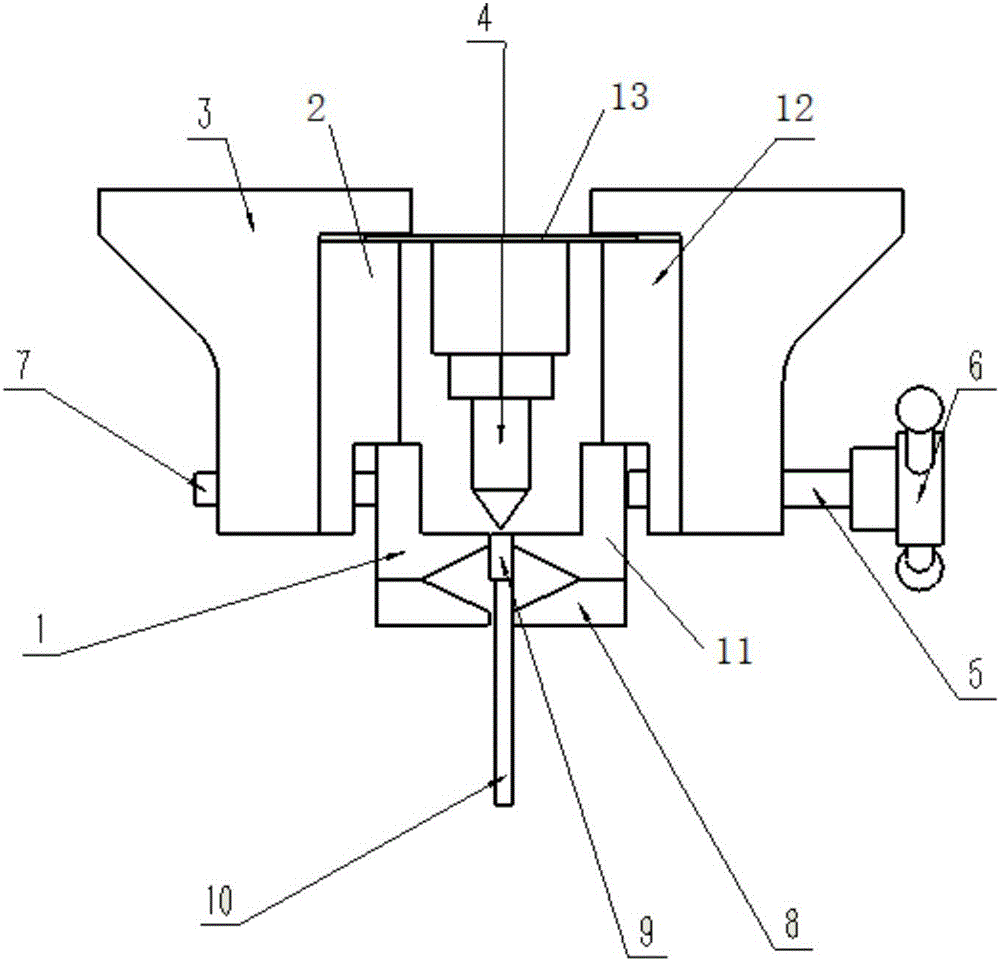

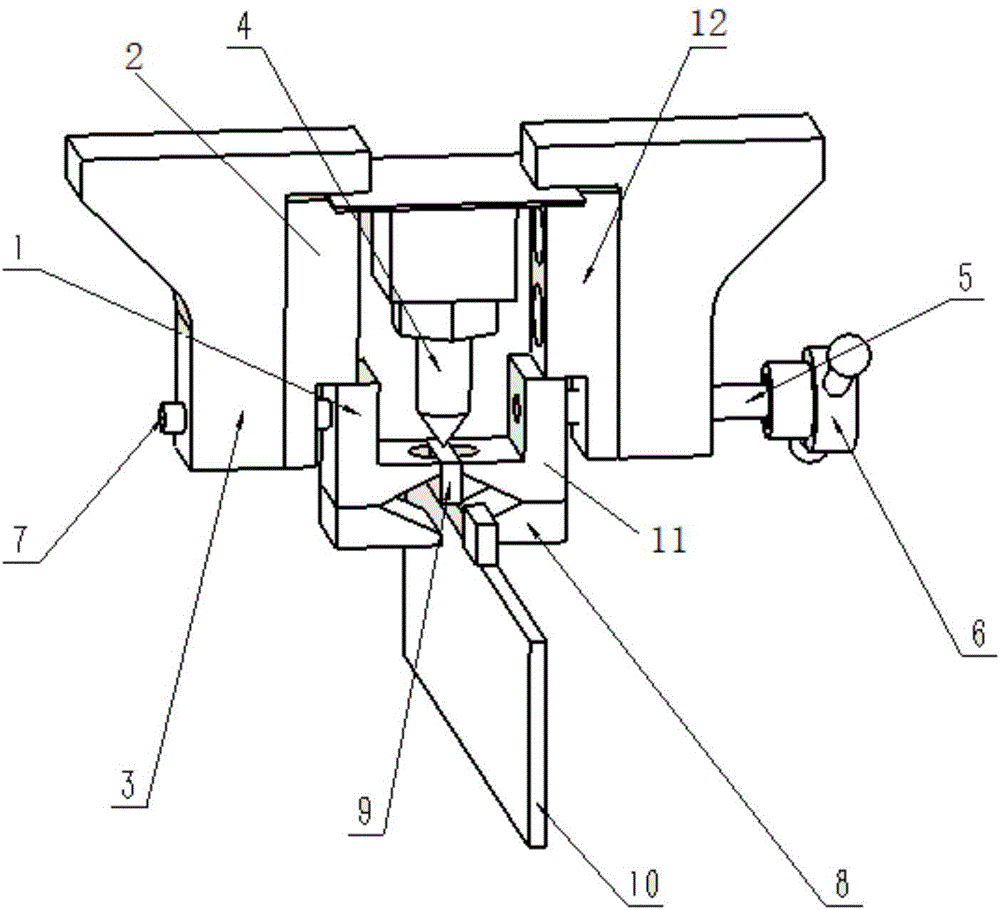

Diamond tool bit welding device and method

ActiveCN106736199AReduce positioning errorsImprove welding efficiencyMetal sawing tool makingWelding/cutting auxillary devicesTool bitReciprocating motion

The invention discloses a diamond tool bit welding device and a method, solves the problem of incapability of guaranteeing the welding precision of a diamond tool bit in the prior art, and uses a reference positioning block for positioning a saw blade and the tool bit on the same one reference surface to effectively reduce the positioning error. The diamond tool bit welding device comprises a fixture; the fixture includes a first clamping base and a second clamping base; reference positioning blocks are respectively arranged at the lower parts of the first clamping base and the second clamping base; the side part of the first clamping base is matched with a sliding device; the sliding device drives the first clamping base to move to enable the first clamping base and the second clamping base to clamp the tool bit; the side part of the second clamping base is matched with a reciprocating motion mechanism; and the reciprocating motion mechanism drives the fixture to move so as to enable the reference positioning block to tightly bond on a first side surface or a second side surface of the saw blade.

Owner:SHANDONG UNIV

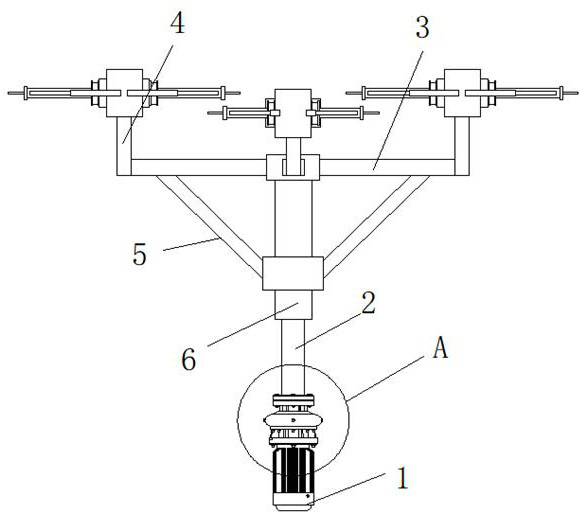

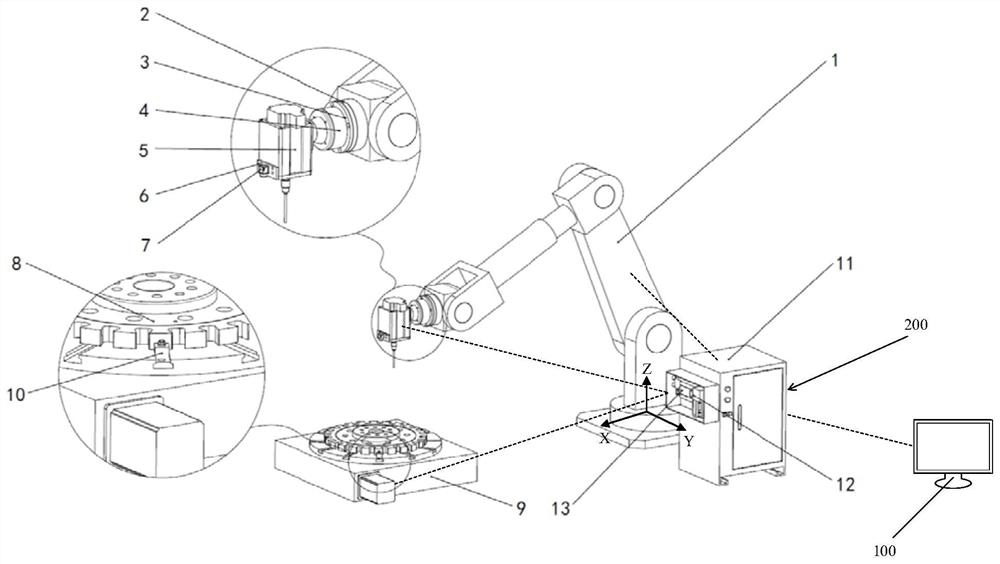

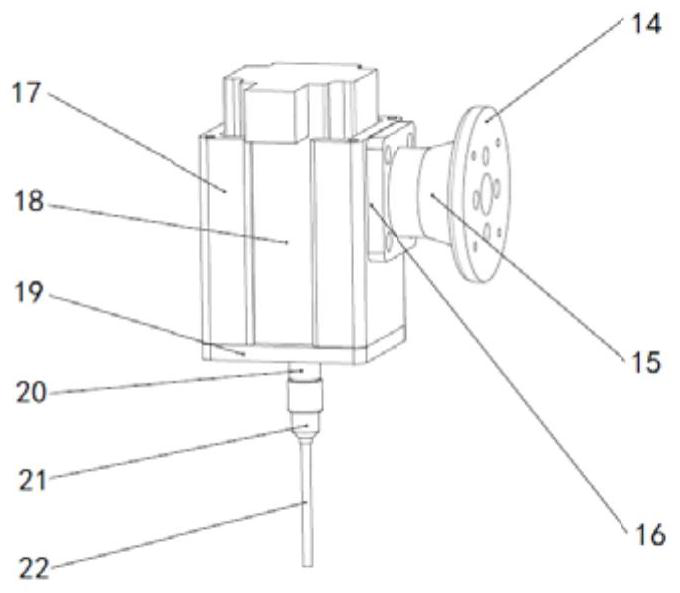

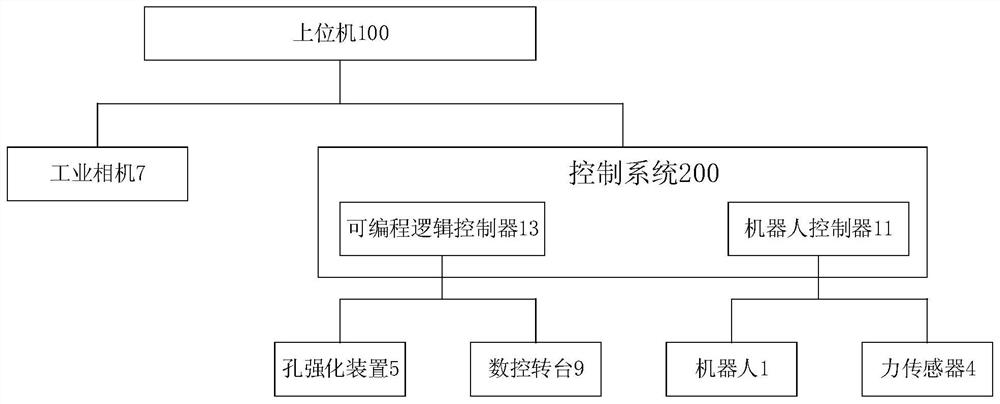

Aero-engine turbine disc bolt hole intelligent strengthening system and control method thereof

PendingCN112045677AExtended service lifeReal-time monitoring of contact forceProgramme-controlled manipulatorPlaning/slotting machinesNumerical controlMachine control

The invention relates to an aero-engine turbine disc bolt hole intelligent strengthening system and a control method thereof. The aero-engine turbine disc bolt hole intelligent strengthening system comprises a robot, a numerical control rotary table, a control system and an upper computer; a hole strengthening device is fixed to the robot and the robot drives the hole strengthening device to move,the hole strengthening device is connected with a force sensor, and an industrial camera is arranged on the hole strengthening device; the numerical control rotary table is used for fixing a turbinedisc to be machined, and a fixing mechanism is arranged on the numerical control rotary table; the control system is in communication connection with the robot, the force sensor, the hole strengthening device and the numerical control rotary table; and the upper computer is in communication connection with the control system and the industrial camera. According to the aero-engine turbine disc bolthole intelligent strengthening system and the control method thereof, a method that the robot clamps the hole strengthening device is adopted, matched with the numerical control rotary table, the force sensor and the industrial camera, the industrial camera is used for guiding the robot to move, and flexible machining control is carried out according to stress monitored by the force sensor, so that intelligent machining of aero-engine turbine disc bolt holes is achieved.

Owner:EAST CHINA UNIV OF SCI & TECH +1

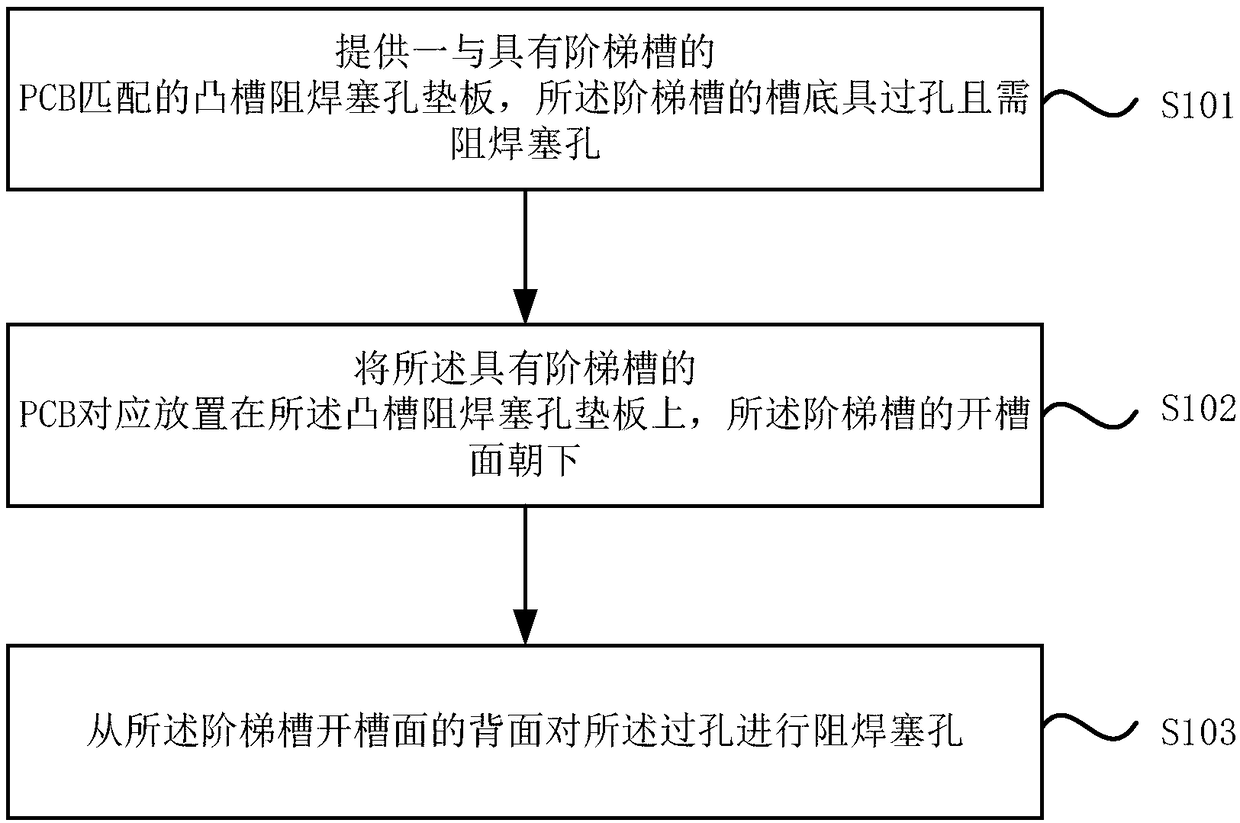

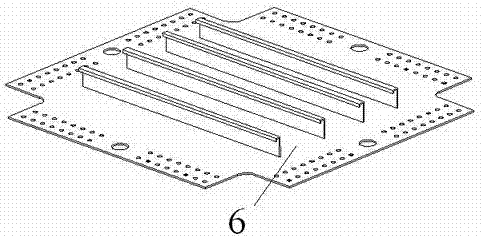

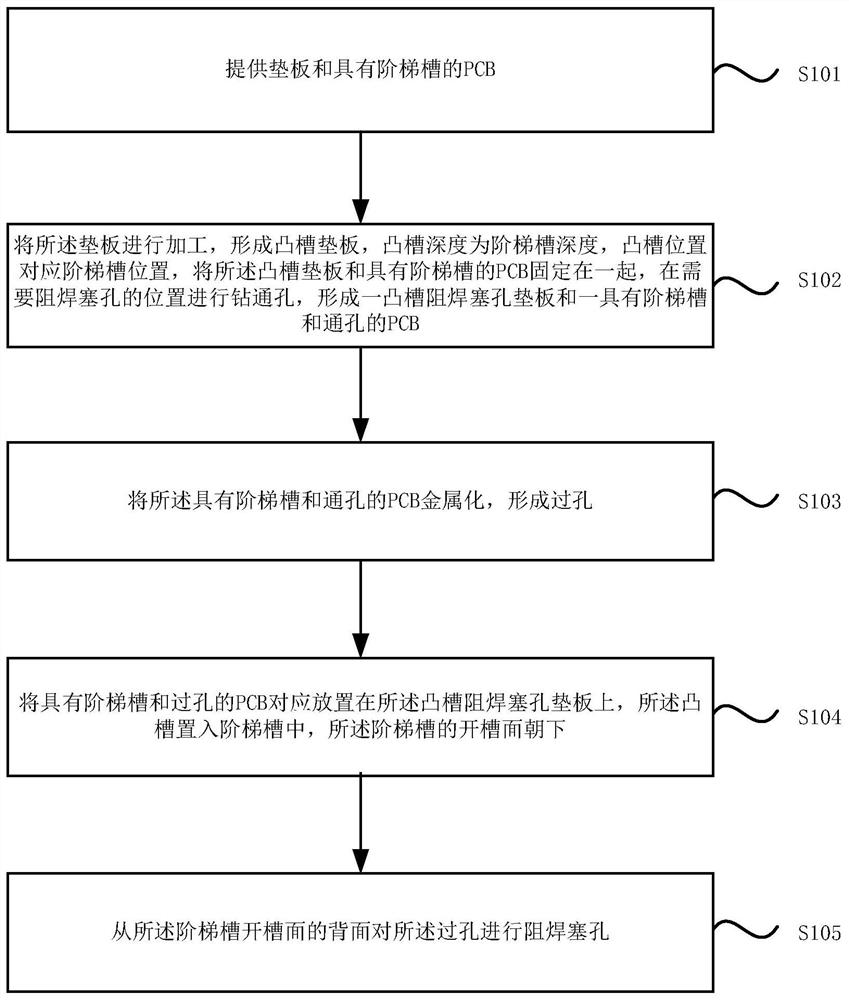

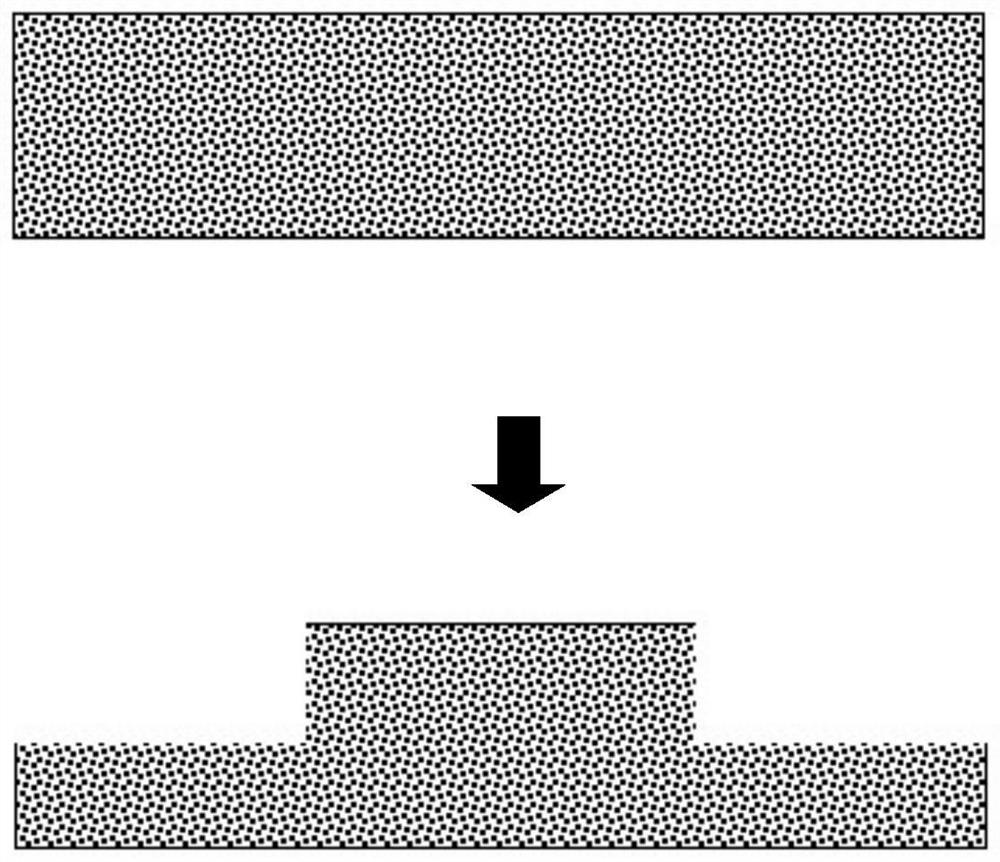

Slot bottom via hole solder resist plugging-based manufacturing method and PCB

ActiveCN108834321AEvenly oilySolve uneven stressPrinted circuit aspectsPrinted circuit manufactureResistEngineering

The embodiments of the present invention disclose a slot bottom via hole solder resist plugging-based manufacturing method and a PCB. The method includes the following steps that: a protruding slot solder resist plug base plate matched with a PCB having a stepped trench is provided, a via hole is formed in the slot bottom of the stepped slot, wherein the via hole requires to be plugged with solderresist; the PCB having the stepped slot is correspondingly arranged on the protruding slot solder resist plug base plate with the slotted surface of the stepped slot facing downwards; and the via hole is plugged with the solder resist from the back surface of the slotted surface of the stepped slot. With the manufacturing method provided by the technical schemes provided by the embodiments of theinvention adopted, a problem that the bottom of the slot and the exterior of the slot are unevenly stressed during hole plugging can be solved; uniform oil bleeding in hole plugging can be ensured; and the problems of long production process, low production efficiency and high production cost of a resin hole plugging technique can be solved. The method of the invention has the advantages of simple production technique and suitability for batch production.

Owner:DONGGUAN SHENGYI ELECTRONICS

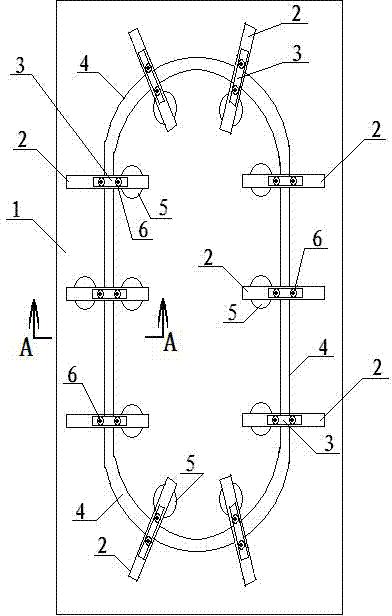

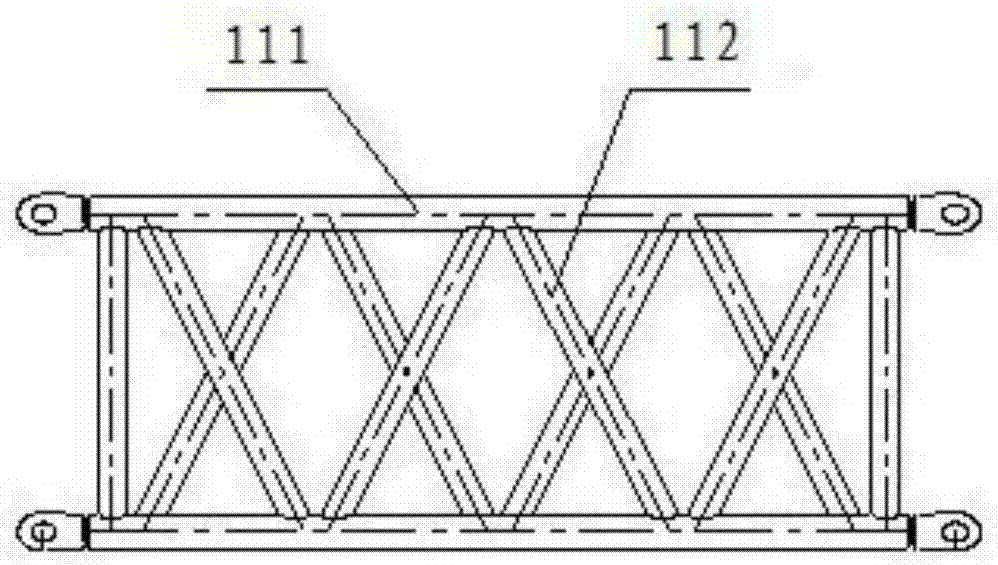

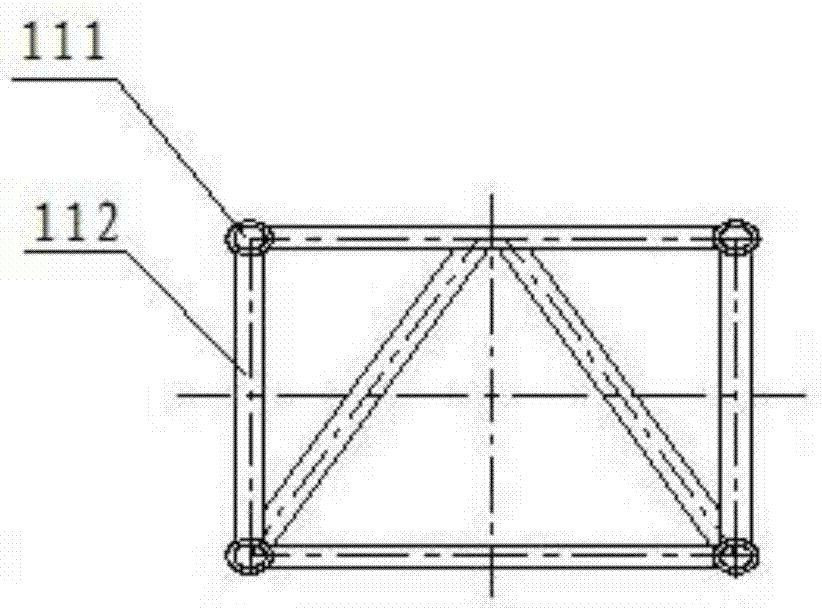

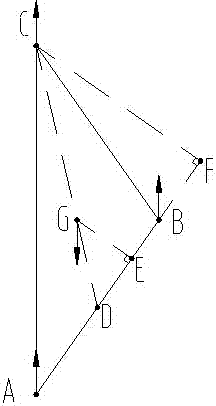

Stiffened plate shear test loading device

ActiveCN107036910ASolve uneven stressWeight reductionMaterial strength using steady shearing forcesAir bearingEngineering

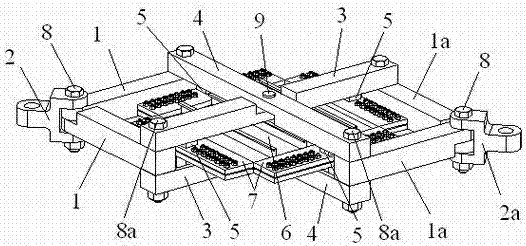

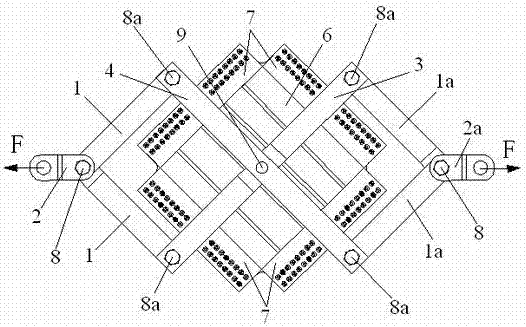

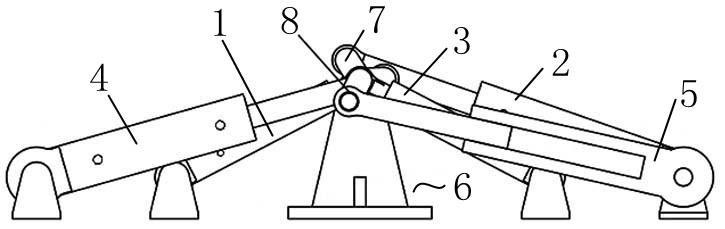

A stiffened plate shear test loading device belongs to the technical field of bearing test for aviation stiffened plates. The stiffened plate shear test loading device is characterized in that loading lug forks are hinged to pull plates, the other ends of the pull plates are connected to mutually perpendicular and intersecting slide rails through hinges, the mutually perpendicular and intersecting slide rails are connected in the middle through a pin hinge, and square sliders at two ends of a slider structure mate with slide channels of the slide rails; when force F is loaded to the loading lug forks, component force of the force F is transmitted to the pull plates, the pull plates pull the slide rails to rotate around pins, and inner rail channels of the slide rails apply force parallel to the pull plates to cubes at the top and bottom of the slider structure; during loading, shear force is applied to the middle of peripheral loading segments of a stiffened plate, the shear force is transmitted through a small area and is distributed evenly around a test piece, the stress-bearing state of the test piece is very close to pure shear stress state, and the problem that the loading segments bear stress non-uniformly is solved effectively.

Owner:DALIAN UNIV OF TECH

Self-adaptive flexible clamp

PendingCN111745572AManufacturing shortLow costWork holdersFluid-pressure actuator componentsElectromagnetic lockMagnetorheological fluid

The invention discloses a self-adaptive flexible clamp which comprises a plurality of electromagnetic locking devices arranged in an array, wherein each electromagnetic locking device comprises a cylinder barrel assembly, a sliding assembly hermetically and slidably mounted in the cylinder barrel assembly in a fit manner, a magnet exciting coil arranged on the cylinder barrel assembly, a clampingpart connected to the sliding assembly and extending outside the cylinder barrel assembly and a magnetorheological fluid filling the cylinder barrel assembly. The sliding assembly at least divides thecylinder barrel assembly into two chambers in a sliding direction, an overflow channel through which the magnetorheological fluid flows in each chamber is arranged on the sliding assembly, and the magnet exciting coil controls the viscosity of the magnetorheological fluid, so that the sliding assembly is in a locked state or a sliding state. The clamp is designed as the electromagnetic locking devices by means of the magnetorheological fluid and the electromagnetic locking devices are combined to form the array clamp to clamp a precision workpiece with a complex surface contour. The self-adaptive flexible clamp is self-adaptive to various complex surface contours.

Owner:CHONGQING UNIV

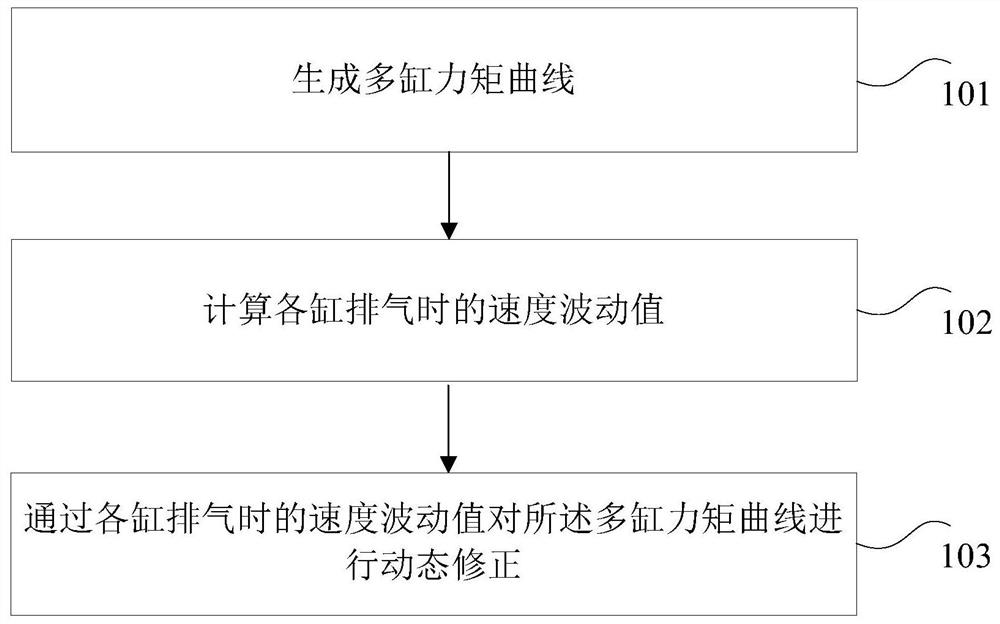

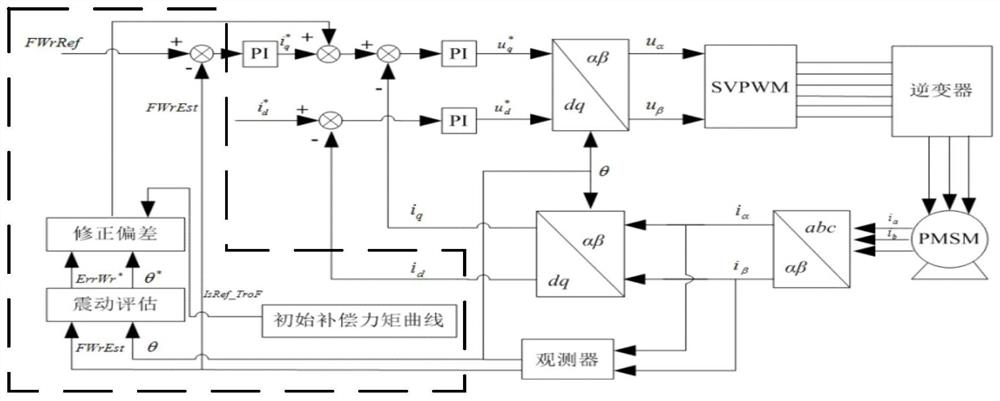

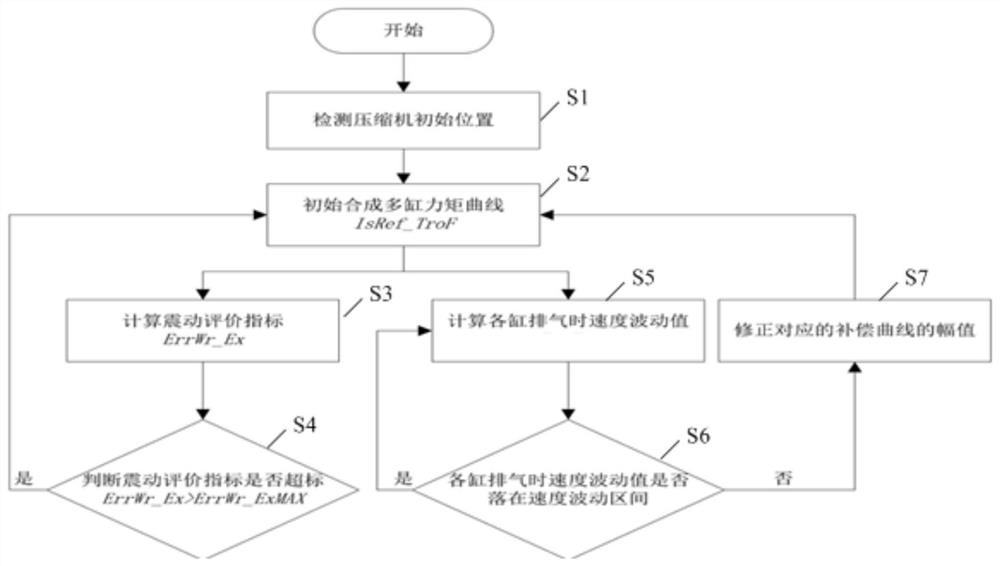

Compressor torque compensation method and device

ActiveCN111800046ASolve uneven stressStable speedElectronic commutation motor controlAC motor controlEngineeringMechanical engineering

Owner:GREE ELECTRIC APPLIANCES INC

A kind of bow section hoisting method

ActiveCN109052171BSmall footprintSolve the problem of fragmentationLoad-engaging elementsField conditionsMarine engineering

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

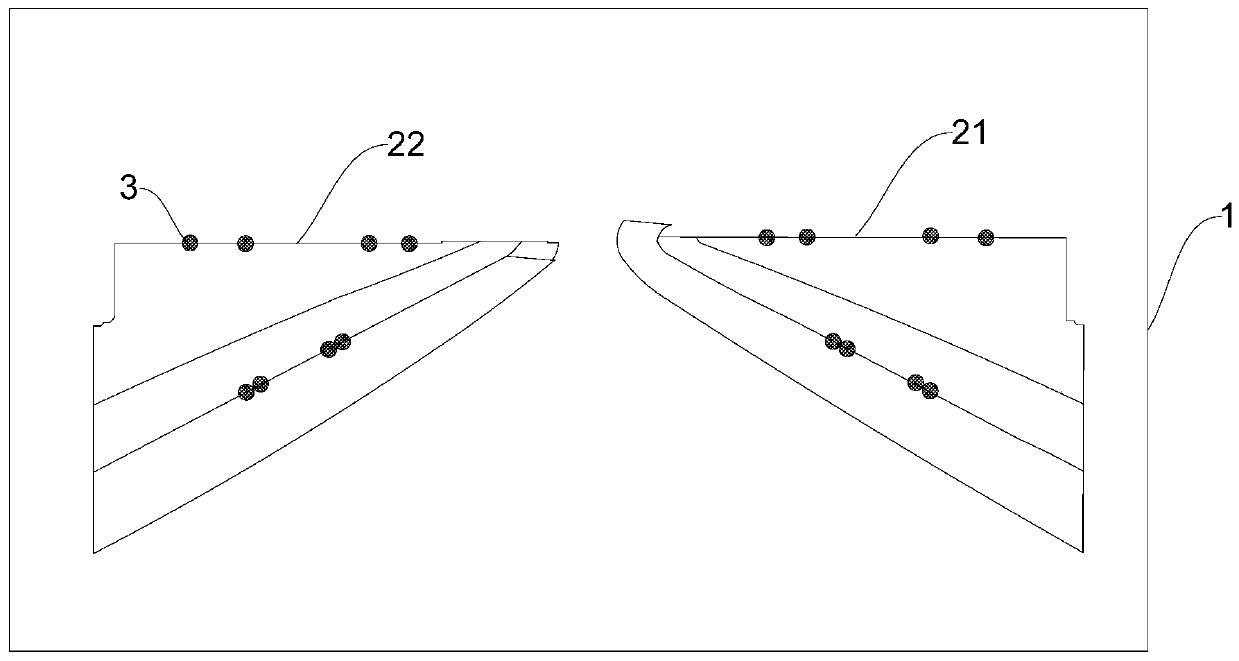

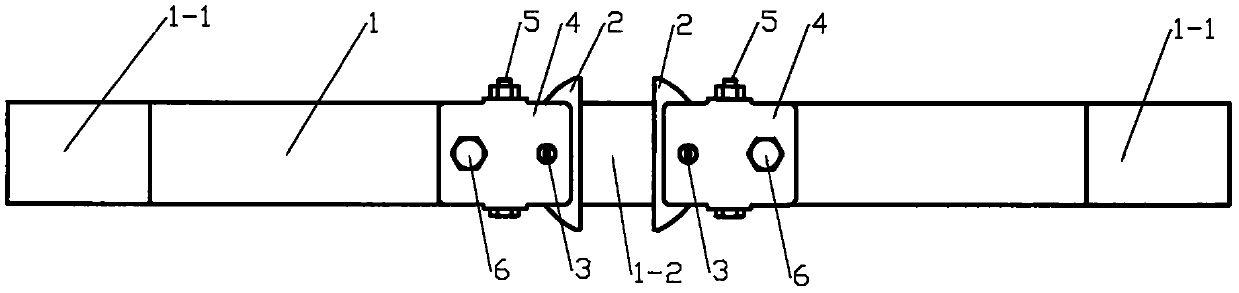

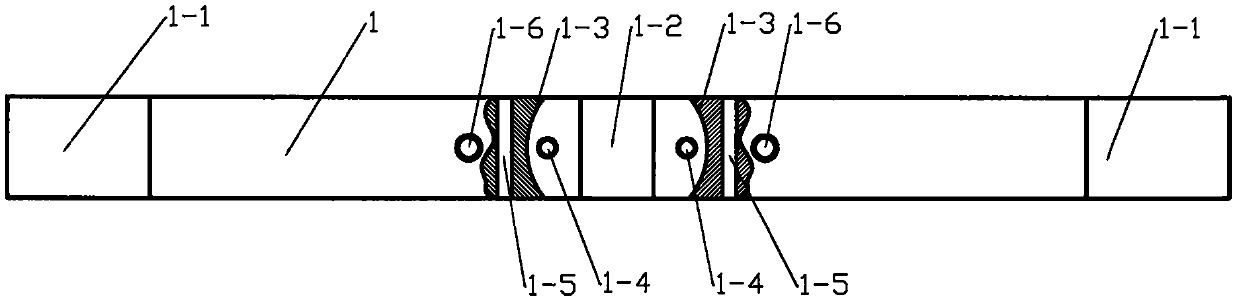

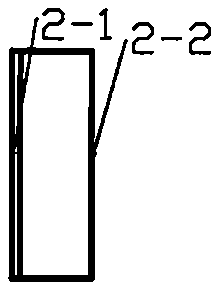

Wear-resistant hooking lock for point rails of external-locking turnout

A wear-resistant hooking lock for point rails of an external-locking turnout mainly consists of a hooking lock (1), wear-resistant blocks (2) and pin shafts (3) arranged at both ends of a U-shaped opening at the middle of the hooking lock, fastening and pressing plates (4), pin bolts (5) and bolts (6). The wear-resistant blocks (2) are respectively mounted along cambered surfaces (1-3) at both ends of the U-shaped opening (1-2) at the middle of the hooking lock (1). When planes (2-1) of the wear-resistant blocks (2) are in close contact with bottom surfaces of the point rails and stressed to generate torsion angles, cambered surfaces (2-2) of the wear-resistant blocks (2) can automatically rotate along the vertical cambered surfaces (1-3) at both ends of the U-shaped opening (1-2), so thatthe planes (2-1) of the wear-resistant blocks (2) can be always in plane contact with the bottom surfaces of the point rails and the wear of the hooking lock to the point rails is reduced. When the size of the wear-resistant blocks (2) on the hooking lock changes because of the wear during the using process and is not in conformity with the requirements, the excessively worn wear-resistant blocks(2) which are arranged at both ends of the U-shaped opening of the hooking lock can be replaced quickly and conveniently to recover a standard state of the hooking lock, so that the safety performance of equipment and the reliability for use are improved and the disturbance to the running of trains is reduced.

Owner:张振坤 +2

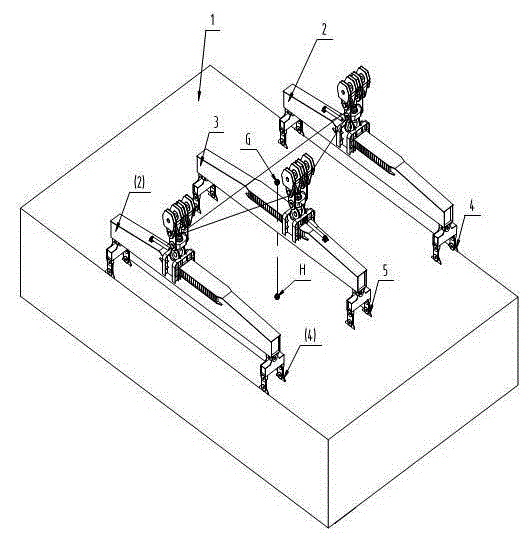

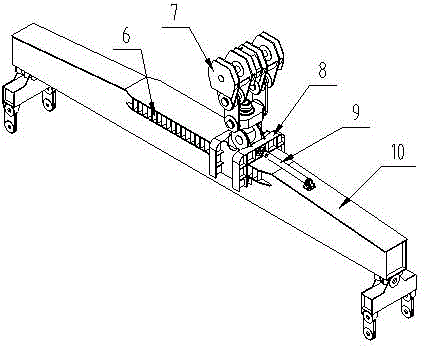

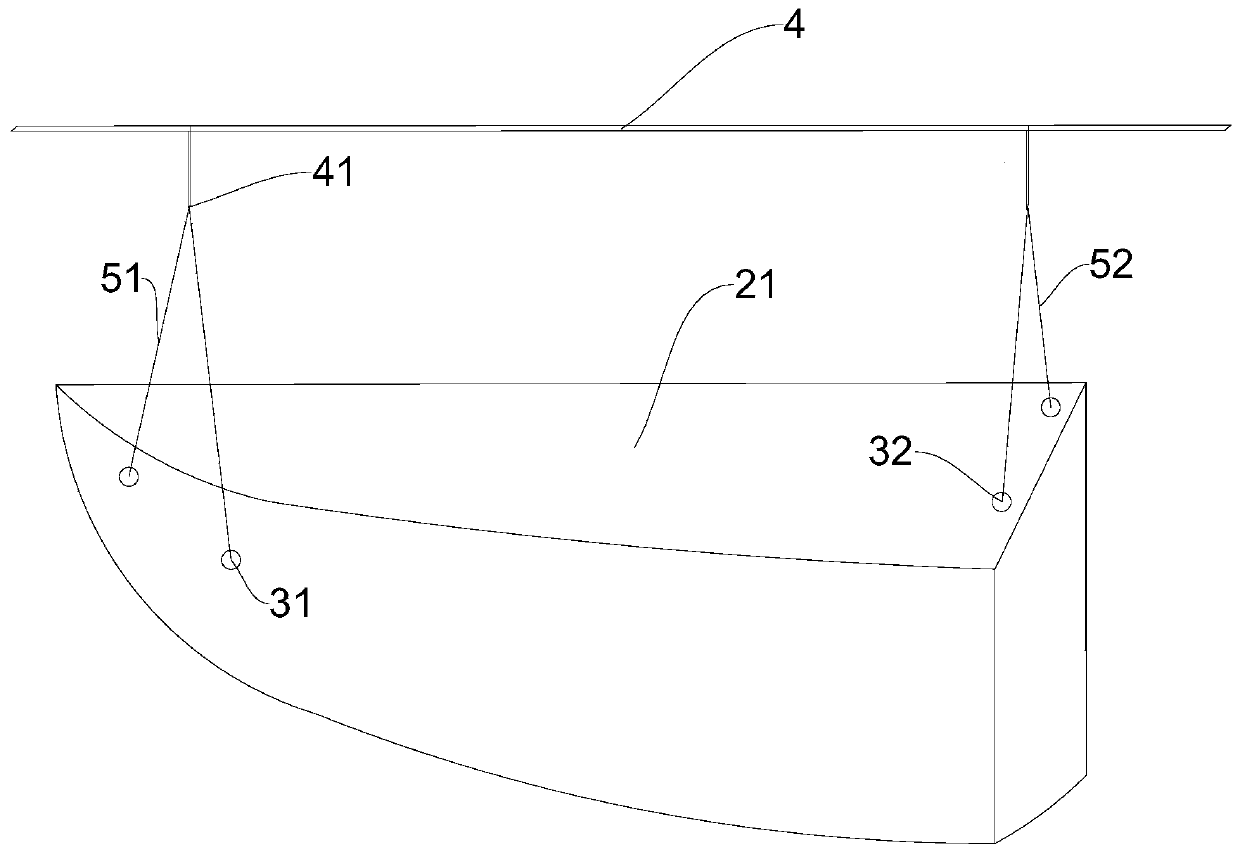

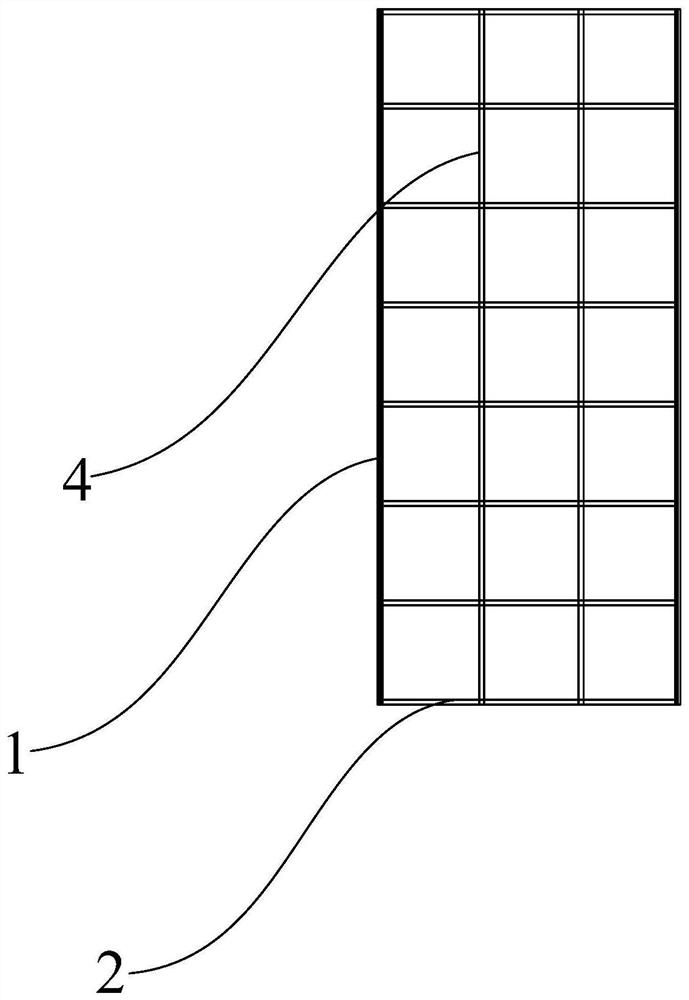

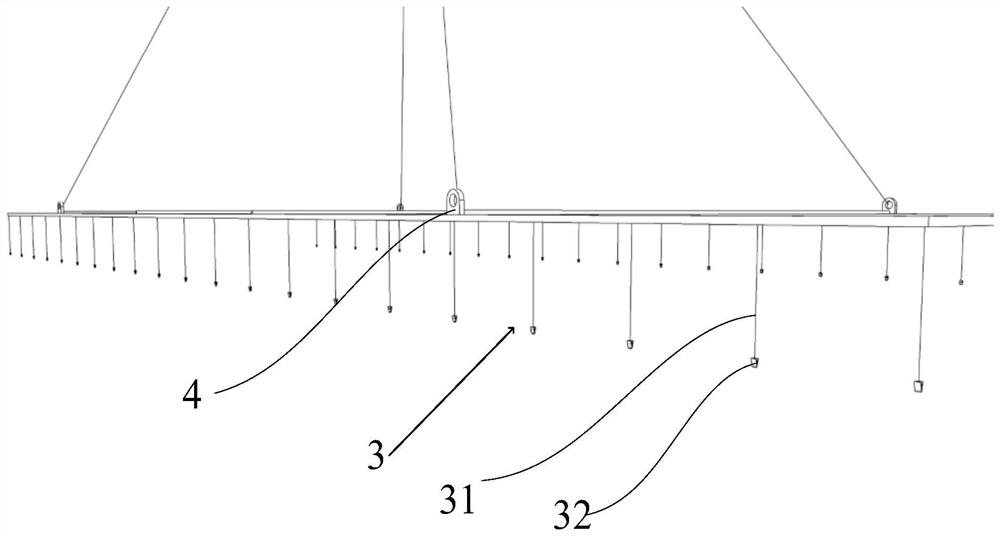

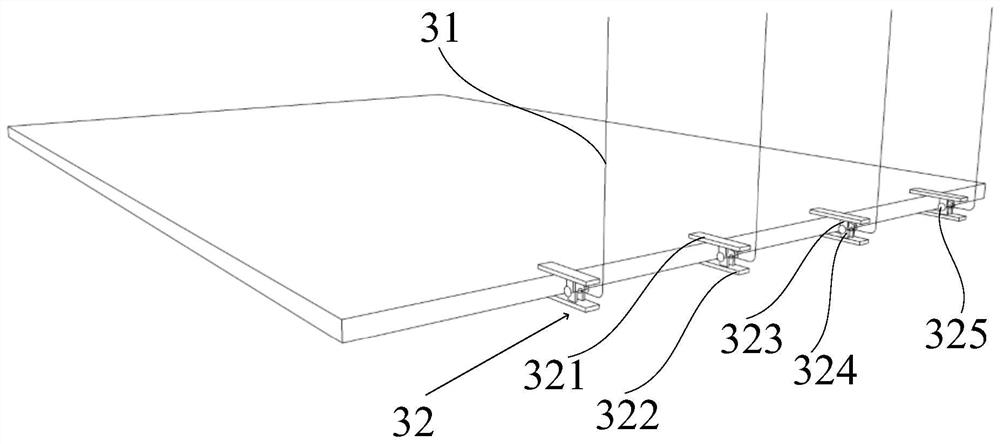

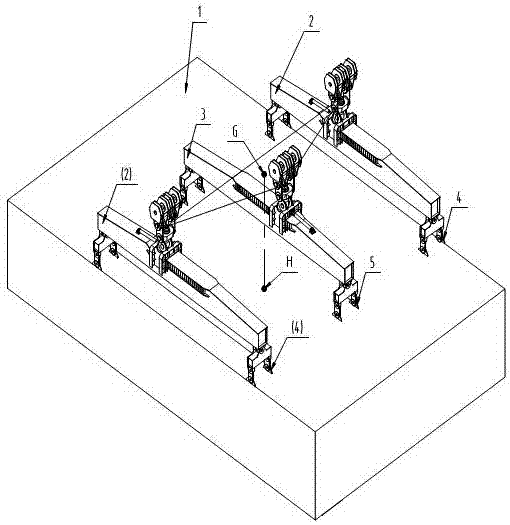

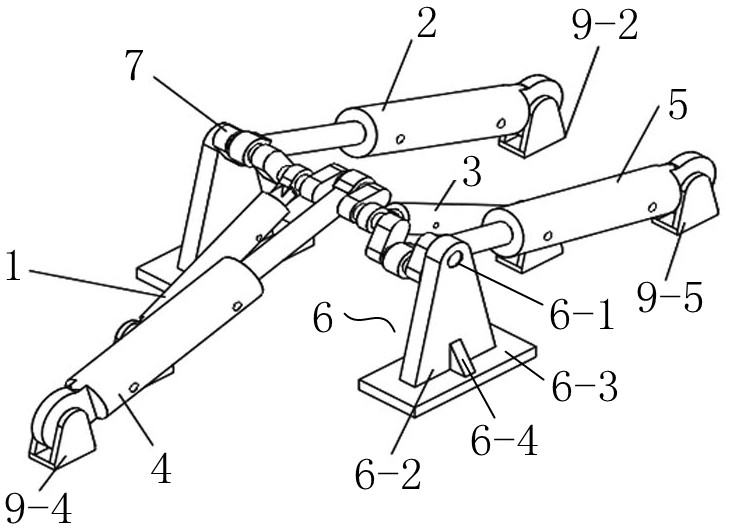

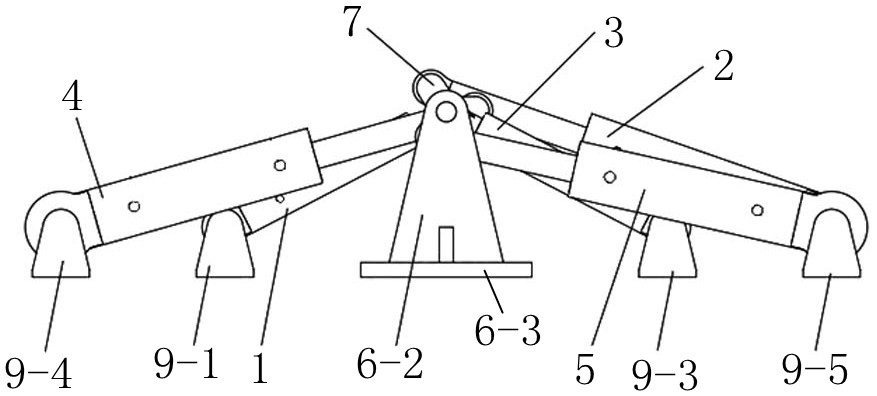

Hoisting tool for ceiling of cruise ship prefabricated cabin and assembling method of hoisting tool

InactiveCN113443094ASolve uneven stressImprove the uniformity of forcePrefabricated cabinsHull structureStructural engineering

The invention discloses a hoisting tool for a ceiling of a cruise ship prefabricated cabin and an assembling method of the hoisting tool, and belongs to the field of cruise ship hull structure manufacturing. The hoisting tool for the cruise ship prefabricated ceiling comprises a pair of longitudinal beams arranged in parallel; a plurality of cross beams, of which both ends are fixedly connected with the two longitudinal beams respectively; a plurality of clamping assemblies that are evenly distributed in the extending direction of the two longitudinal beams, wherein the distances from the clamping ends of the clamping assemblies to the longitudinal beams are equal; a plurality of hoisting pieces with hoisting holes, which are fixedly connected with the longitudinal beams or the cross beams. The problem that the ceiling is uneven in stress in the transportation process is solved. After the ceiling is assembled, the hoisting tool completes the hoisting work at a time, and therefore in the transportation process, the stress uniformity of the ceiling is improved. According to the structure, the ceiling is effectively prevented from being broken in the transportation process.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

A Balanced Hoisting Mechanism for Hoisting Heavy Parts

Owner:CHINA RAILWAY JIUJIANG BRIDGE ENG +1

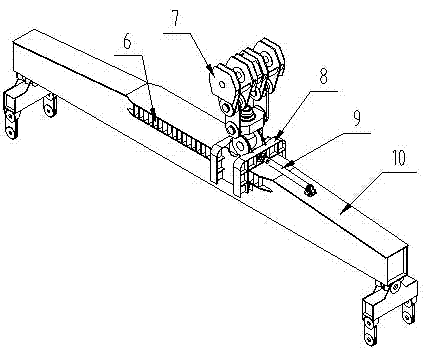

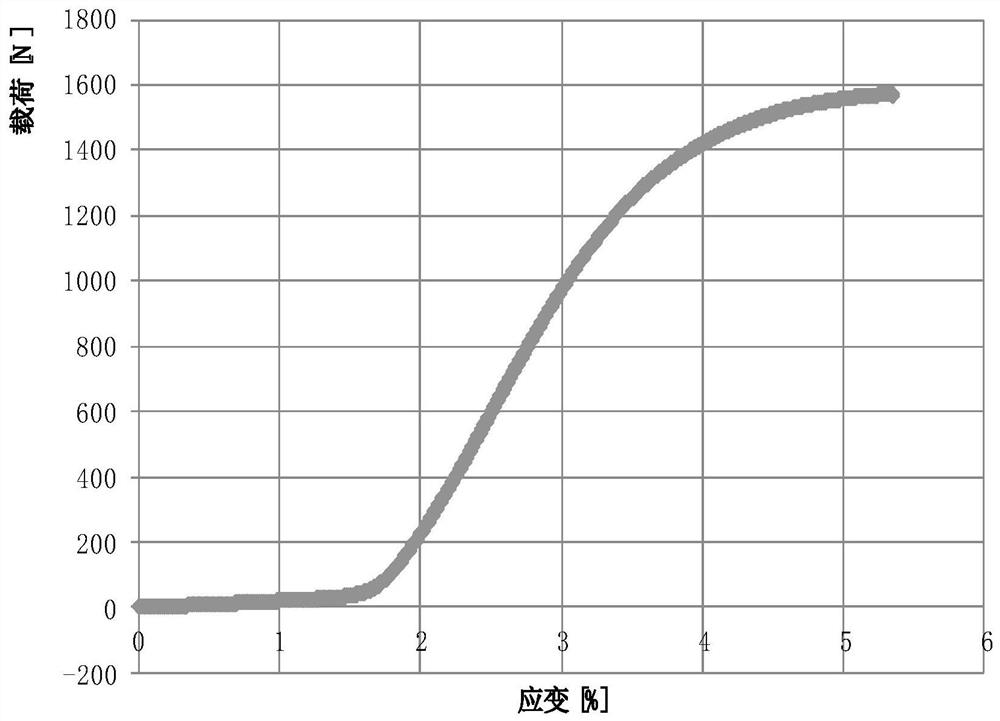

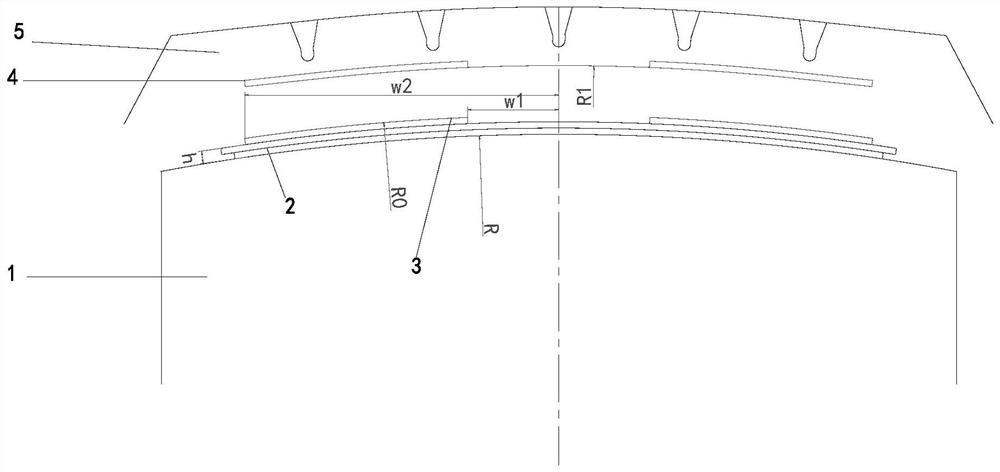

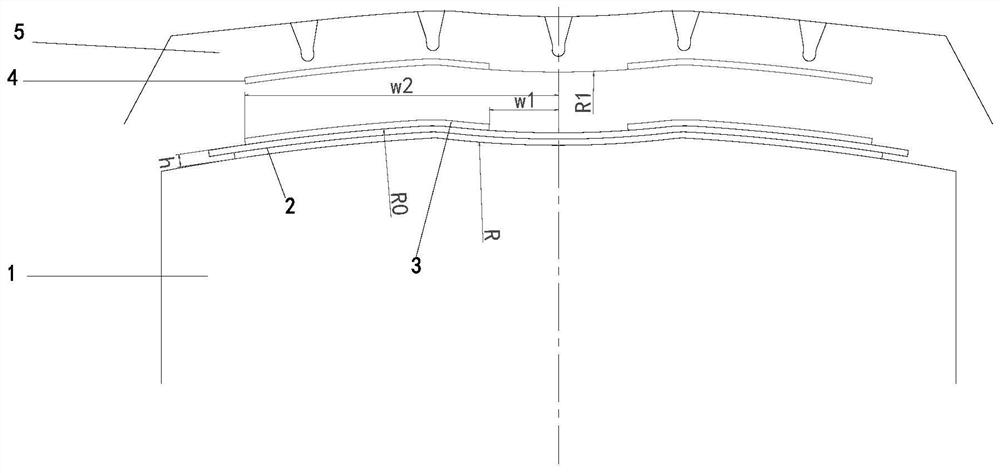

Curved surface fitting drum design method and curved surface fitting drum

PendingCN112848807ASolve uneven stressPneumatic tyre reinforcementsEngineeringMechanical engineering

The invention discloses a curved surface fitting drum design method and a curved surface fitting drum. The method comprises the following steps: determining a pre-stretching rate based on a preset stretching characteristic curve graph of a 0-degree reinforced cord fabric layer; determining the radius of the curved surface fitting drum based on the material thickness and the radius of a 0-degree reinforced cord fabric layer in the tire structure of the tire, wherein the material thickness is the material thickness between the 0-degree reinforced cord fabric layer and the curved surface fitting drum; generating the curve fitting drum on the basis of the radius of the curved surface fitting drum and the pre-stretching rate, so that the 0-degree reinforced cord fabric layer is located in a material stretching area of the preset stretching characteristic curve graph, the tension of the reinforced cord fabric layer is controlled through the curved surface fitting drum, and therefore the problem that a tire crown assembly is uneven in stress is solved.

Owner:SHANDONG LINGLONG TIRE

Bushing friction and wear test device

ActiveCN111982731ASimple structureReduce testing costsInvestigating abrasion/wear resistanceMechanical engineeringCrankshaft

The invention belongs to the technical field of workpiece wear test devices. The invention particularly relates to a bushing friction and wear test device which comprises a crankshaft and crankshaft mounting seats supported at two ends of the crankshaft, a plurality of eccentric parts are arranged on the crankshaft; the crankshaft is formed by detachably connecting a plurality of eccentric parts into a whole; each eccentric part of the crankshaft is sequentially and uniformly deflected and distributed in the circumferential direction; the number of eccentric parts of the crankshaft is not lessthan three; the two end parts of the crankshaft are coaxial; the end part of the crankshaft is mounted in the mounting hole of the crankshaft mounting seat; each eccentric part of the crankshaft is provided with a test oil cylinder, the test oil cylinders are arranged on the two sides of the crankshaft in a crossed mode, a force application oil cylinder is installed on the concentric part, between every two adjacent test oil cylinders, of the crankshaft, the force application oil cylinders are arranged on the two sides of the crankshaft in a crossed mode, and the test oil cylinders and the force application oil cylinders are hinged and fixed through corresponding oil cylinder mounting bases. The test device can be used for carrying out a wear test on a plurality of bushings at one time, so that the working efficiency is greatly improved.

Owner:XCMG EXCAVATOR MACHINERY

Composite joints and jibs

The invention discloses a composite connector and a cantilever crane. The composite connector comprises a base body and multiple ear plate-type sub connectors; the base body is provided with a first side surface and a second side surface which are oppositely arranged; and the multiple ear plate-type sub connectors are separately arranged on the first side surface and the second side surface of the base body and are fixedly connected with the base body, wherein at least one of the first side surface and the second surface is provided with more than two ear plate-type sub connectors. Jib sections provided with composite type main chords are connected to form the cantilever crane through the above composite connectors; the stress applied to the main chords can be transferred to the main chords on different planes through the base bodies; and the stress transferring effect among the main chords is improved, so that the stress among the multiple jib sections is more uniform, and the performance of the cantilever crane is improved.

Owner:XCMG CONSTR MACHINERY

Auxiliary device for unilateral fillet rolling of bent axle

The invention is mainly applied to the technical field of diesel engine component machining and particularly relates to an auxiliary device for unilateral fillet rolling of a bent axle. The device comprises a connecting support and a single-wheel rolling head. Connecting holes are formed at one end of the connecting support, and an adjustment thread sleeve is arranged at the other end of the connecting support. A roller is arranged at the position of a base angle of one end of the single-wheel rolling head, and an adjustment bolt is arranged at the other end of the single-wheel rolling head ina manner that the adjustment bolt is corresponding to the adjustment thread sleeve. According to the auxiliary device for unilateral fillet rolling of the bent axle, rolling force can be disintegrated; and the problem of uneven force bearing is solved. By means of the device, the problem that rolling cannot be conducted on unilateral fillets of two ends of the bent axle can be solved; thus filletrolling of each portion of the bent axle is completed more comprehensively; and integral performance of the bent axle is improved. The structure is simple and reasonable; and the device is easy to use.

Owner:ZICHAI POWER CO LTD

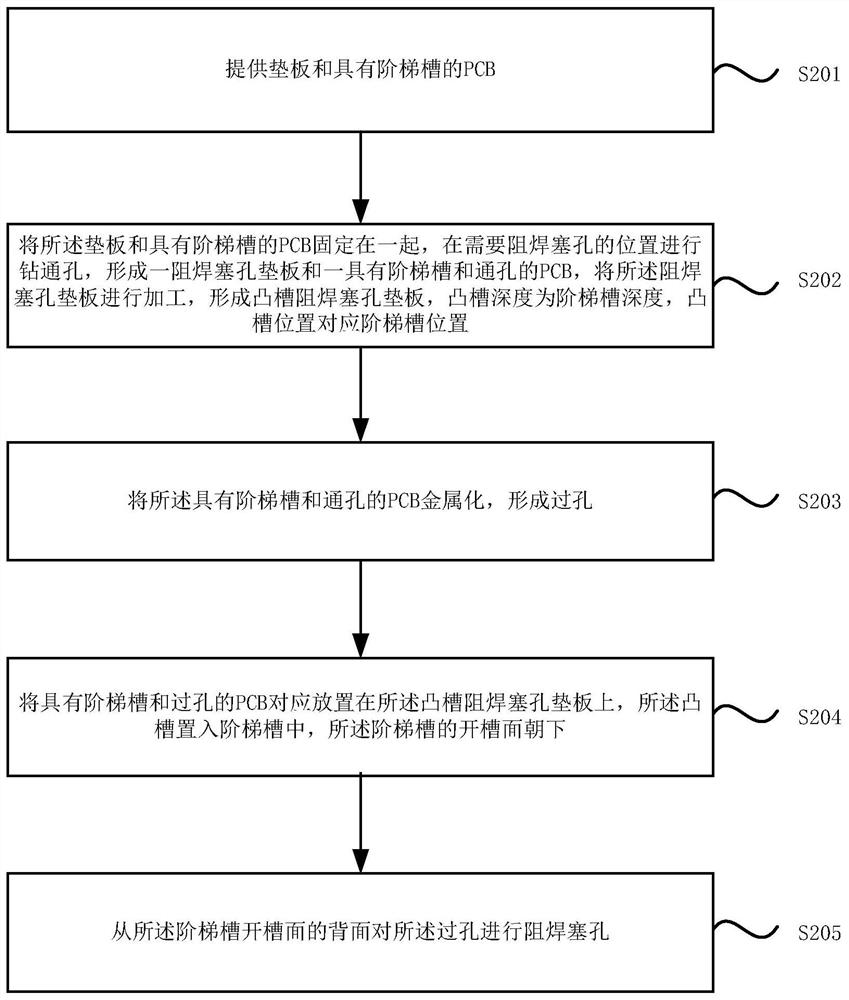

A kind of manufacturing method and pcb of slot bottom via hole solder resistance plug

ActiveCN109041433BEvenly oilySolve uneven stressPrinted circuit aspectsPrinted element electric connection formationSolder maskStructural engineering

Owner:DONGGUAN SHENGYI ELECTRONICS

Processing mold for cellulose acetate plastic sheet glasses

The invention discloses a processing mold for cellulose acetate plastic sheet glasses. The processing mold comprises a base, an ejection mechanism, a support rod and an ejection piece, wherein a lowermold is arranged on the right side of the base, the lower mold is connected to the outside of the base in a welding mode, the right side of the lower mold is fixedly connected with an upper mold, a cavity is formed inside the lower mold, an ejection mechanism is mounted inside the cavity, and a push plate is arranged on the right side of the ejection mechanism. According to the processing mold for the cellulose acetate plastic sheet glasses, the ejection piece with the same size as a plastic sheet workpiece is arranged outside the ejection mechanism, and when the workpiece is ejected out, theejection piece can be attached to the bottom of the workpiece with a maximum area, so that the problem of uneven stress caused by small contact area with the workpiece when the workpiece is ejected out by a traditional ejection rod is solved; and after the plastic sheet workpiece is processed well, the circular-ring-shaped ejection piece can cover the bottom of the workpiece well and push the workpiece in combination with the push rod, so that the workpiece is stripped intact, the stripping yield is high, the overall structure is simple, and the practicability is high.

Owner:浙江中塑胶板有限公司

Novel bloom continuous casting machine emergency shutdown oil cylinder

PendingCN109676100AImprove safety and reliability performanceImprove safety and reliability performance, service lifeIntegrated designCylinder block

The invention discloses a novel bloom continuous casting machine emergency shutdown oil cylinder and relates to the field of metallurgy. The novel bloom continuous casting machine emergency shutdown oil cylinder comprises an oil cylinder upper flange, a cylinder body and an oil cylinder lower flange, wherein the oil cylinder upper flange, the cylinder body and the oil cylinder lower flange are fixedly connected with one another. An oil cylinder hanging lug is fixedly mounted at the end close to the oil cylinder upper flange. A piston is arranged inside the oil cylinder upper flange, the cylinder body and the oil cylinder lower flange in a penetrating manner. According to the novel bloom continuous casting machine emergency shutdown oil cylinder, the oil cylinder upper flange and the oil cylinder hanging lug are of integrated design, and the defect that in the process of site secondary assembling, seal damage is possibly caused is overcome; in addition, a connected threaded rod is stressed more uniformly, and the strength is more reliable; a countersunk head screw thread does not need to be exposed, an arc-shaped groove is large in mounting clearance, and mounting is easier and moreconvenient to conduct; the novel oil cylinder is optimized from original five main components into the three main components, a seal is reduced, the oil leakage risk is lowered, use safety and reliability performance of the oil cylinder is improved, and the service life is remarkably prolonged; and the repair cost of spare parts and the labor intensity of workers are greatly lowered.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com