Wear-resistant hooking lock for point rails of external-locking turnout

A turnout and anti-wear technology, applied in roads, tracks, buildings, etc., can solve the problems of excessive waste of equipment resources, changes in size wear, wear of lock hooks and core rails, etc., to save resources, reduce replacement times, reduce The effect of the number of maintenance replacements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

[0028] In order to further understand the content, characteristics and effects of the present invention, the following embodiments are listed hereby, and are described in detail in conjunction with the accompanying drawings as follows:

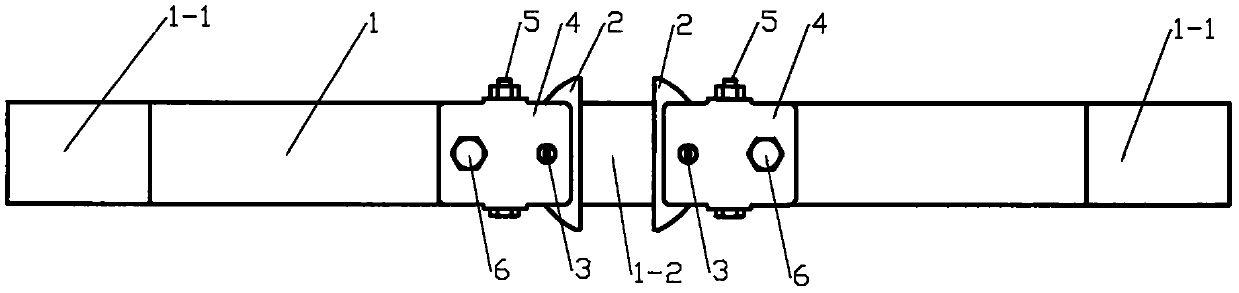

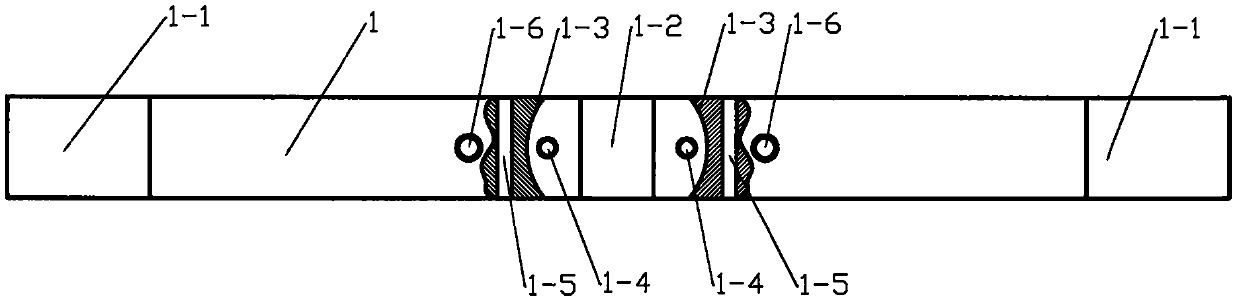

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 Shown, the present invention is made of lock hook (1) and anti-wear block (2) and bearing pin (3), buckle plate (4), bolt pin (5), bolt ( 6) is formed, the two ends of the U-shaped mouth (1-2) in the middle part of the lock hook (1) are respectively equipped with anti-wear blocks (2) along the arc surface (1-3), and the two pin shafts (3) pass through the two pins respectively. The waist-shaped hole (2-3) vertically through of a wear-resistant block (2) is screwed in the threaded hole (1-4) on the bottom plane at the two ends of the U-shaped mouth (1-2), and the two buckle plates (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com