Rotary cutting bionic intelligent corn harvesting divider

A technology of rotary cutting and grain dividing device, which is applied in the field of rotary cutting bionic intelligent corn harvesting and dividing device, which can solve the problems of slow movement, increased feeding loss, and uneven grain division of corn, so as to reduce soil adhesion, The effect of improving structural strength and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

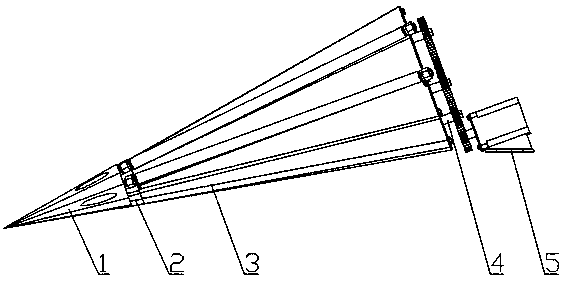

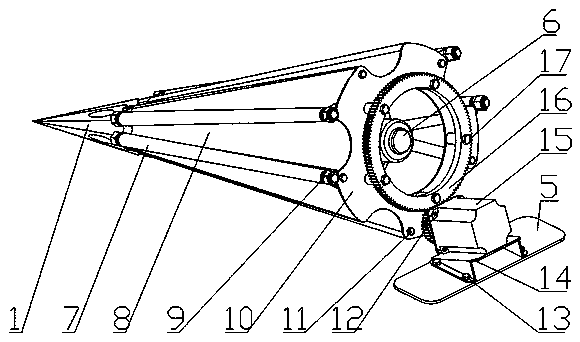

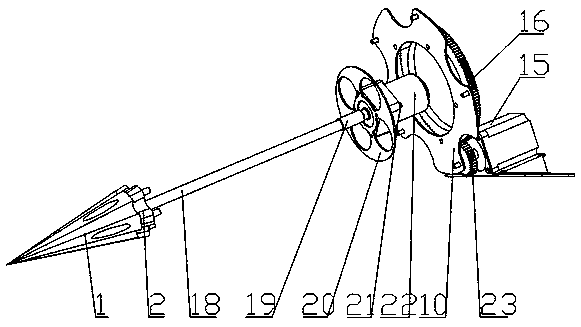

[0019] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the present invention includes a grain-dividing cone 1, a grain-dividing shoulder 2, a grain-dividing body 3, a reversing mechanism 4, a header frame 5 and a speed regulating mechanism 6, and the grain-dividing cone 1 is fixed on the grain-dividing cone by a drive shaft 18. The top of the shoulder 2, the split shoulder 2 is fixed on the top of the split body 3 through the stud 28, the reversing mechanism 4 is fixed on the header frame 5 through the third bolt 13, and the speed regulating mechanism 6 is fixed on the header frame 5 through the fifth bolt. 21 is fixed on the second support 20; the bottom of the grain-dividing cone 1 is evenly distributed with light holes 24, and the outside of the grain-dividing cone 1 is distributed with a cone concave surface 29 and a cone convex surface 30; the grain-dividing body 3 includes a grain-dividing roller 7 and a corrugated shell Body 8, nut 9, ring g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com