Maize straw three-dimensional returning machine

A technology of corn stalks and straw pulverizers, which is applied to loaders, harvesters, crop processors, etc., can solve the problems of polluting the atmosphere, wasting resources, destroying the ecological environment, etc., so as to enhance soil fertility, ensure compaction, improve The effect of feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

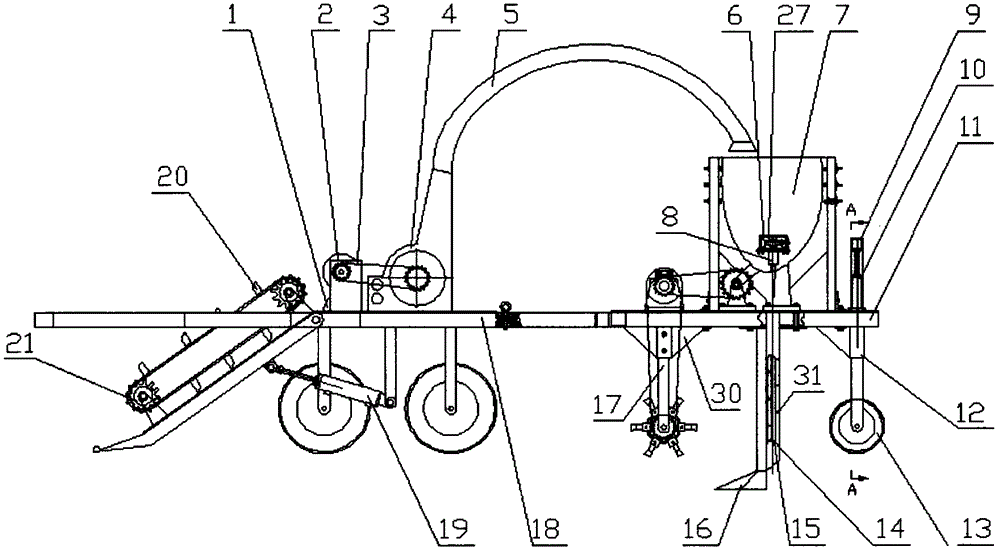

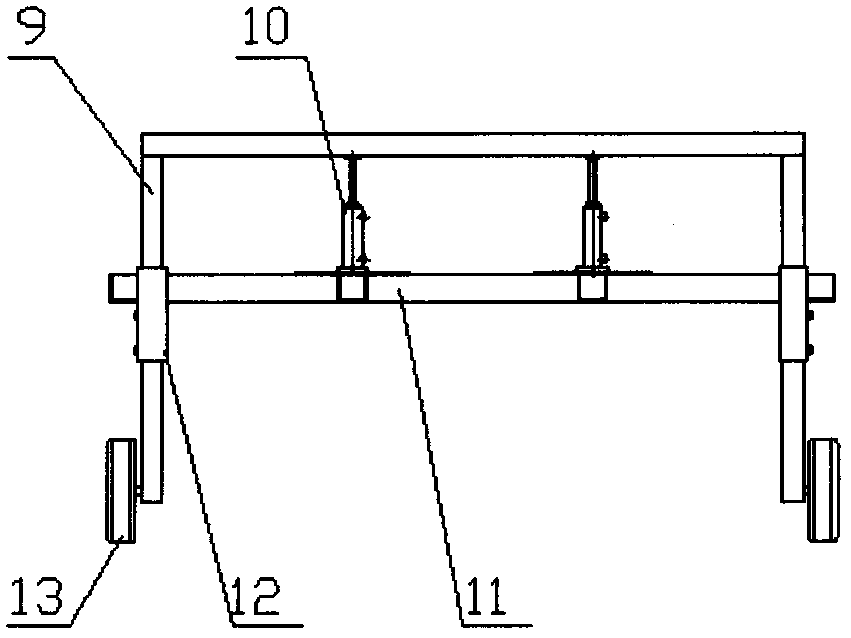

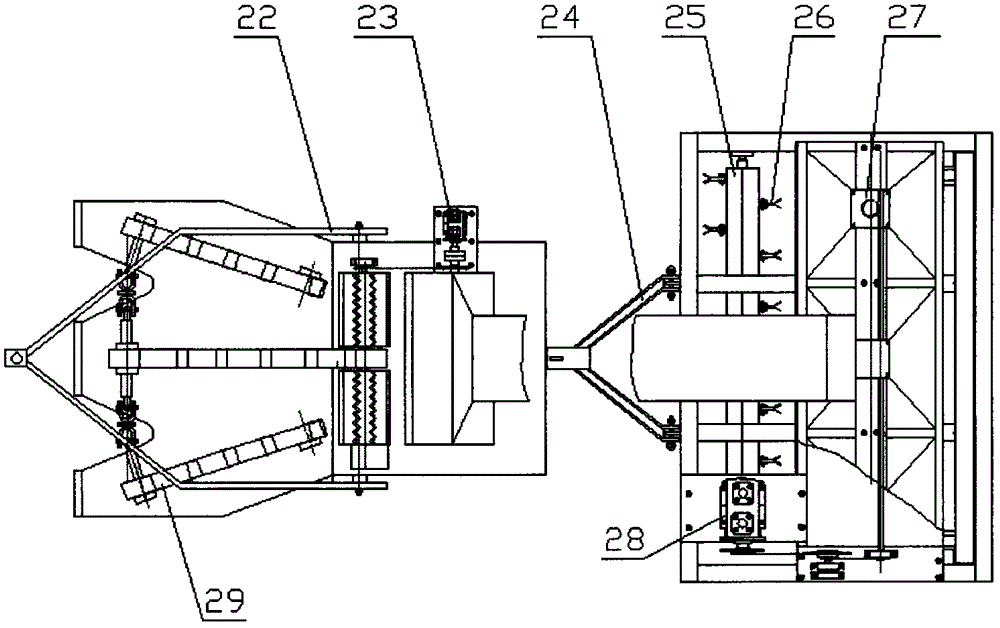

[0028] A three-dimensional corn stalk returning machine, mainly including a front frame 18, a rear frame 11, a straw picking device, a straw feeding device, a straw grinder 4, a stubble removal mechanism, a straw deep application device, a hydraulic control depth limiting mechanism and a hydraulic pressure control mechanism. Control system assembly, etc., the front frame 18 is connected to the rear frame 11 through the connecting frame 24, the front end of the front frame 18 is provided with a straw picking device, and the straw picking device includes a height adjustment An oil cylinder 19, a straw feeding device is arranged above the front frame 18, and the straw feeding device includes an automatic feeding gap adjustment mechanism 3, an upper feeding roller 2 and a lower feeding roller 1, between the two feeding rollers The front of the gap between the gaps is aligned with the exit of the straw picking device, and the rear is aligned with the entrance of the straw grinder 4....

Embodiment 2

[0030] The sprocket 21 of the straw picking device is arranged on the front part of the front frame 18, and the picking conveyor chain 29 is wound on the sprocket 21 and the sprocket coaxial with the upper feeding roller 2, and the rear motor 23 drives the upper The feeding roller 2 rotates, and the coaxial sprocket wheel of the feeding roller 2 drives the pick-up conveyor chain 29 to rotate, and the pick-up conveyor chain 29 drives the straw pick-up teeth 20 uniformly distributed on the pick-up conveyor chain 29 to complete the straw pick-up operation, and the pick-up height is adjusted by the oil cylinder 19 are hinged on both sides below the front frame 18 middle part, can change the push rod expansion and contraction amount of the height adjustment oil cylinder 19 by the hydraulic control system, realize the adjustment of the working height of the straw picking mechanism.

Embodiment 3

[0032] The straw feeding device is arranged in the middle of the front frame 18, the feeding gap automatic adjustment mechanism 3 includes a traveling gear and a pin connecting rod, and the feeding gap automatic adjustment mechanism 3 is arranged on the upper feeding roller 2 and the lower feeding roller 1 on both sides, when working, the rear motor 23 drives the upper feed roller 2 to rotate, the upper feed roller 2 drives the lower feed roller 1 to rotate, and the gap between the upper feed roller 2 and the lower feed roller 1 faces The outlet of the quasi-straw picking device is aligned with the entrance of the straw pulverizer 4. When the thickness of the straw layer changes, the upper feeding roller 2 can move up and down to adjust the size of the feeding gap, and ensure that the upper feeding roller 2 and the lower feeding roller The entering roller 1 turns in the opposite direction, so that the straw enters the straw grinder 4 smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com