Patents

Literature

406 results about "Depth limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

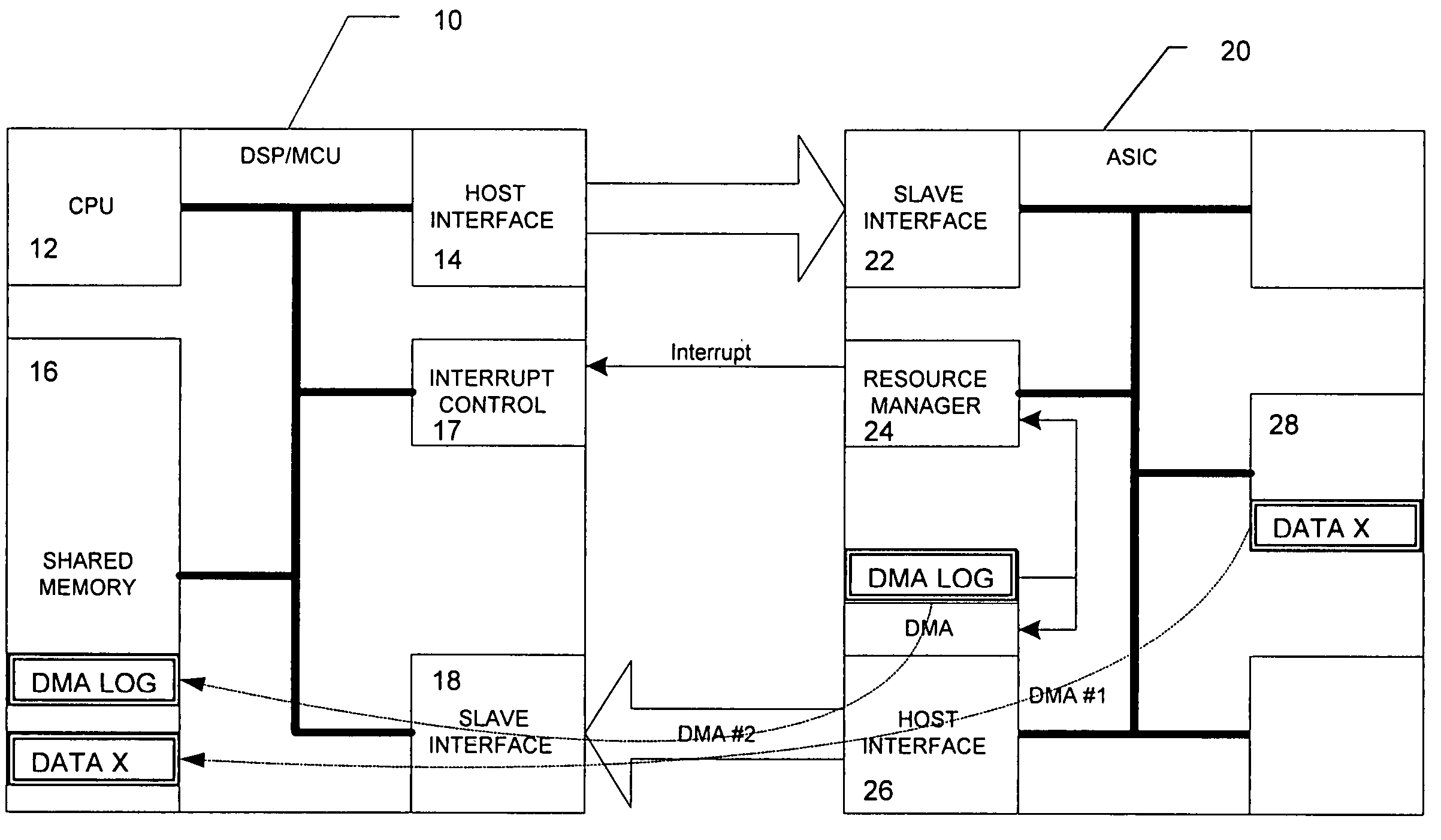

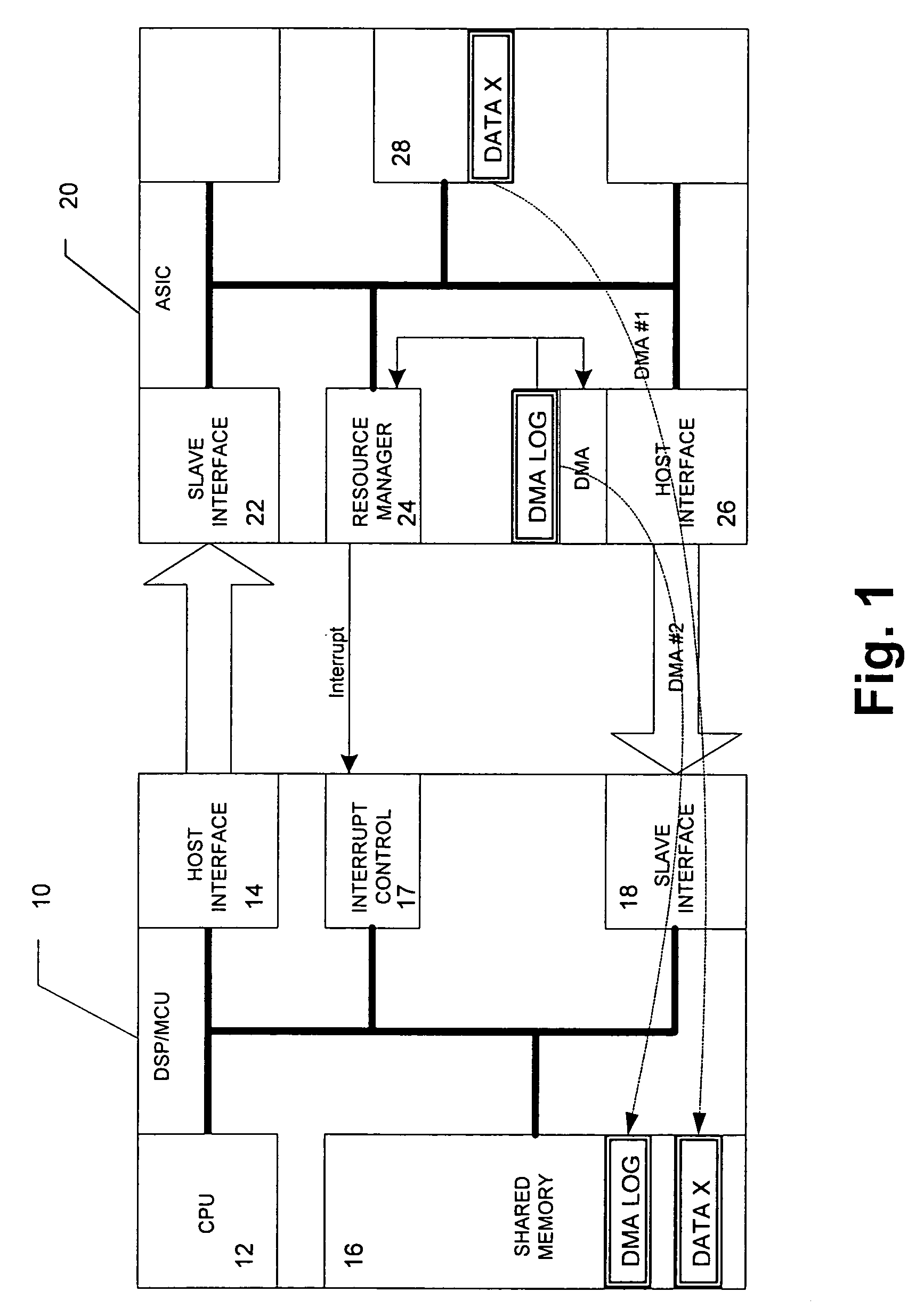

DMA data transfer between low-overhead processor and connected external circuitry using transactions log

InactiveUS7293119B2Reduce loadReduce overheadDigital computer detailsSpecific program execution arrangementsTransaction logData transmission

Owner:NOKIA SOLUTIONS & NETWORKS OY

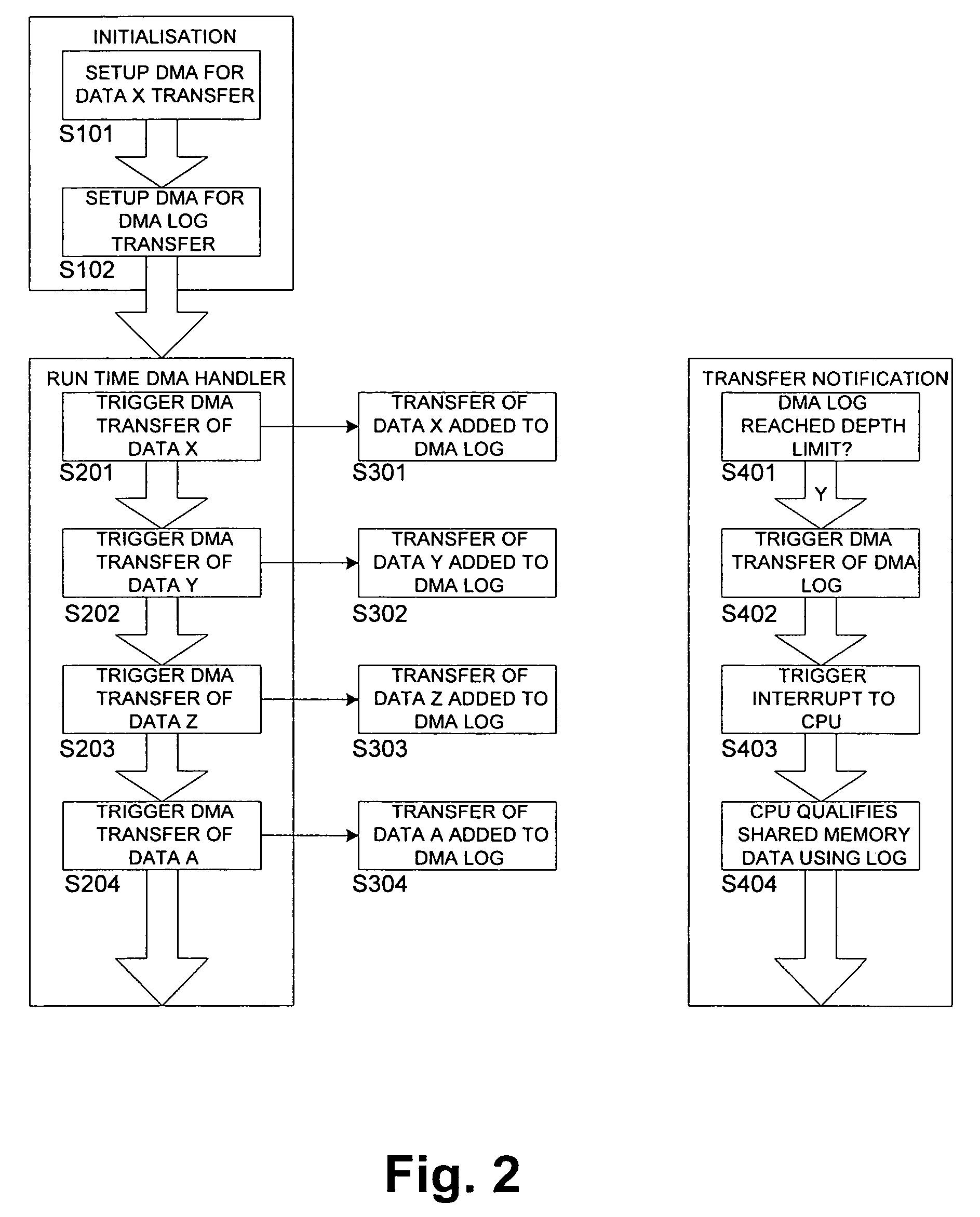

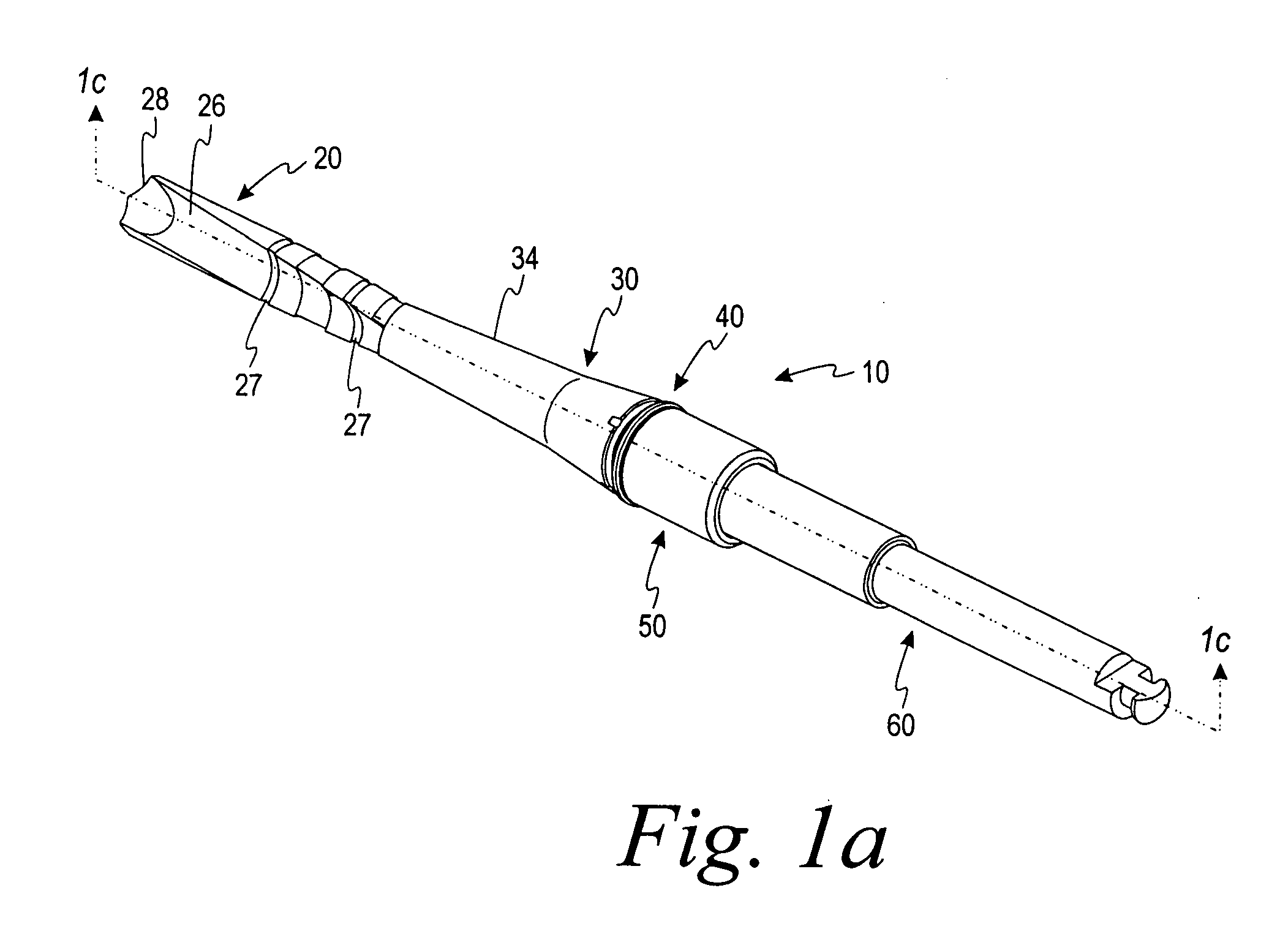

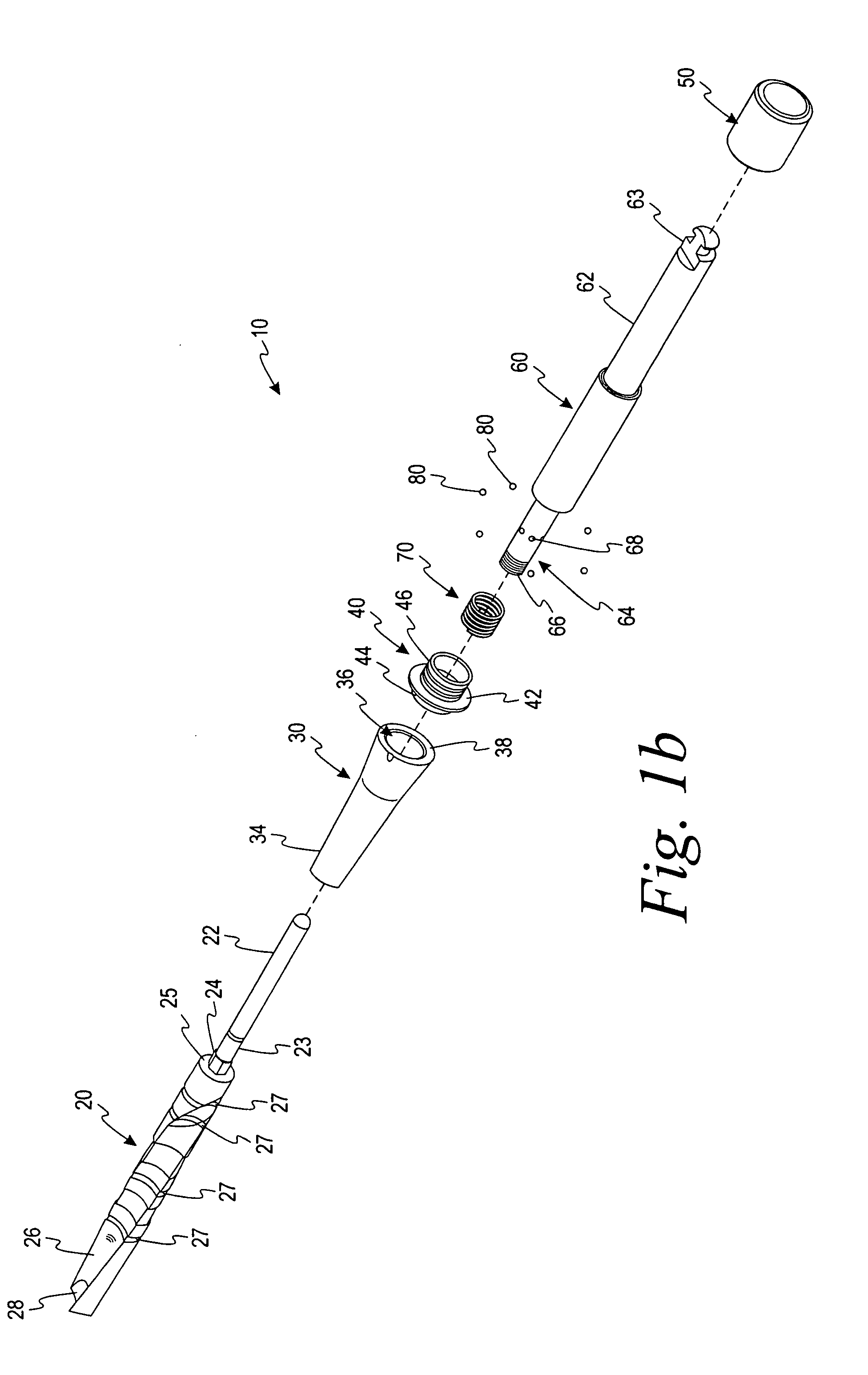

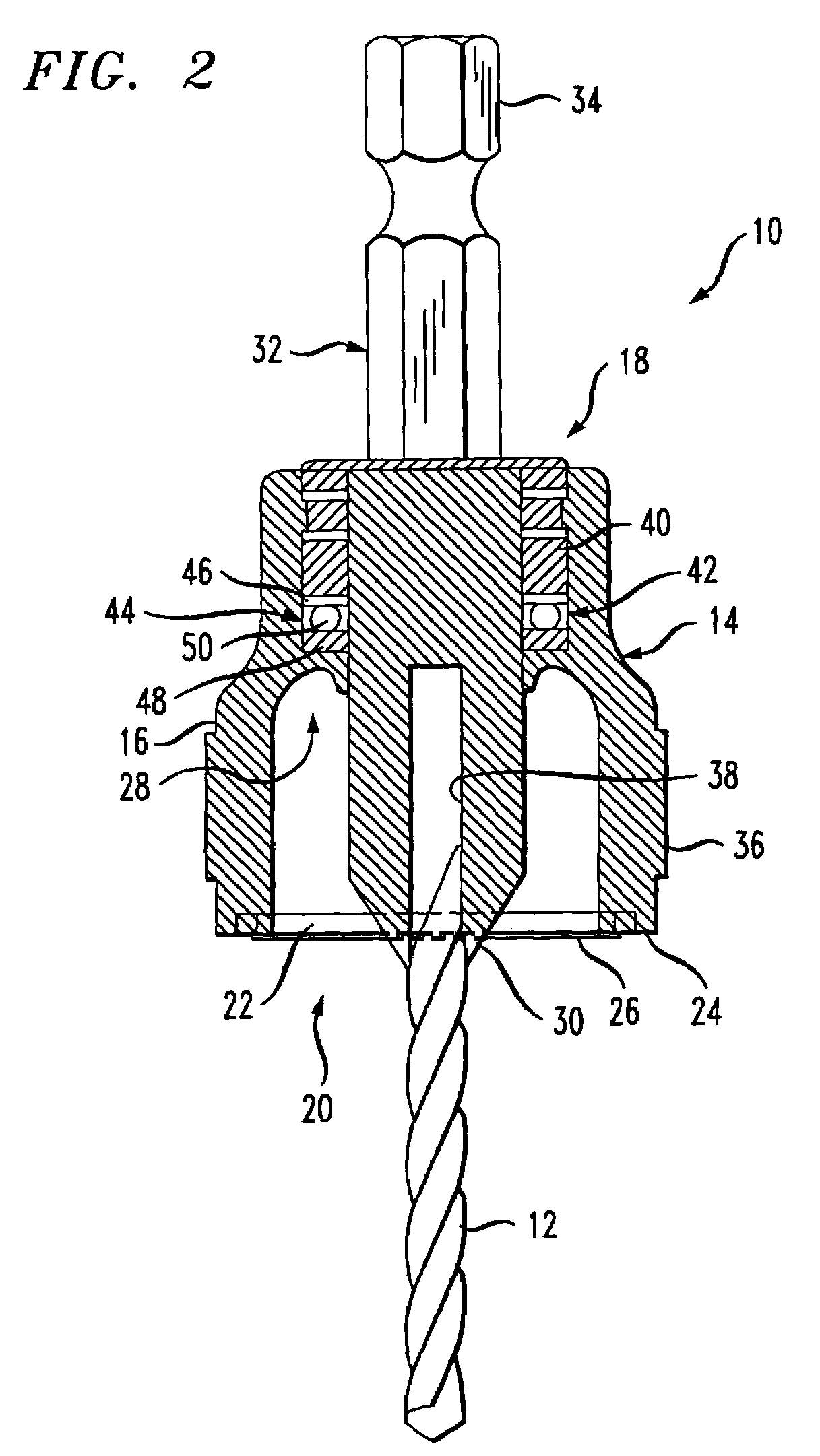

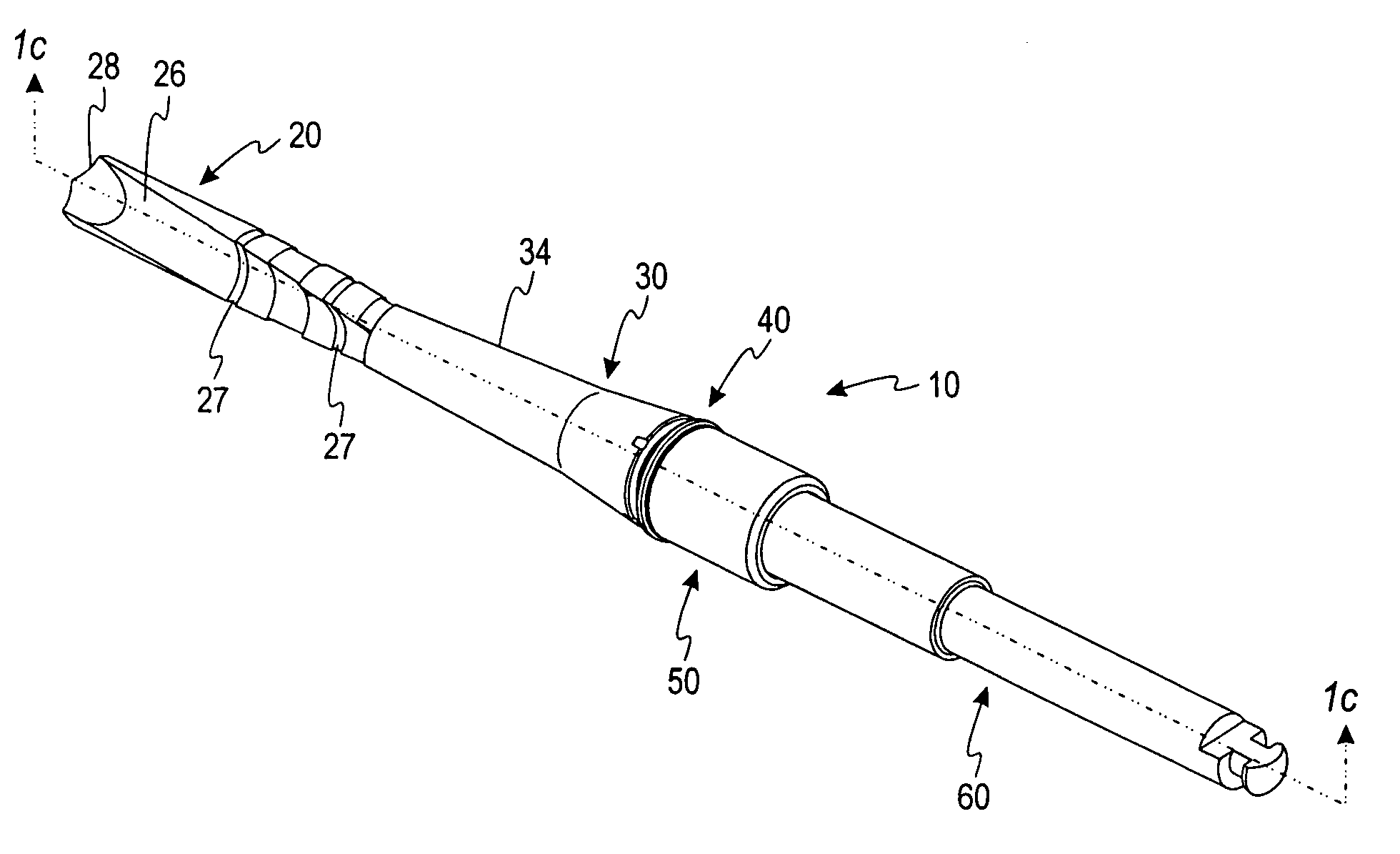

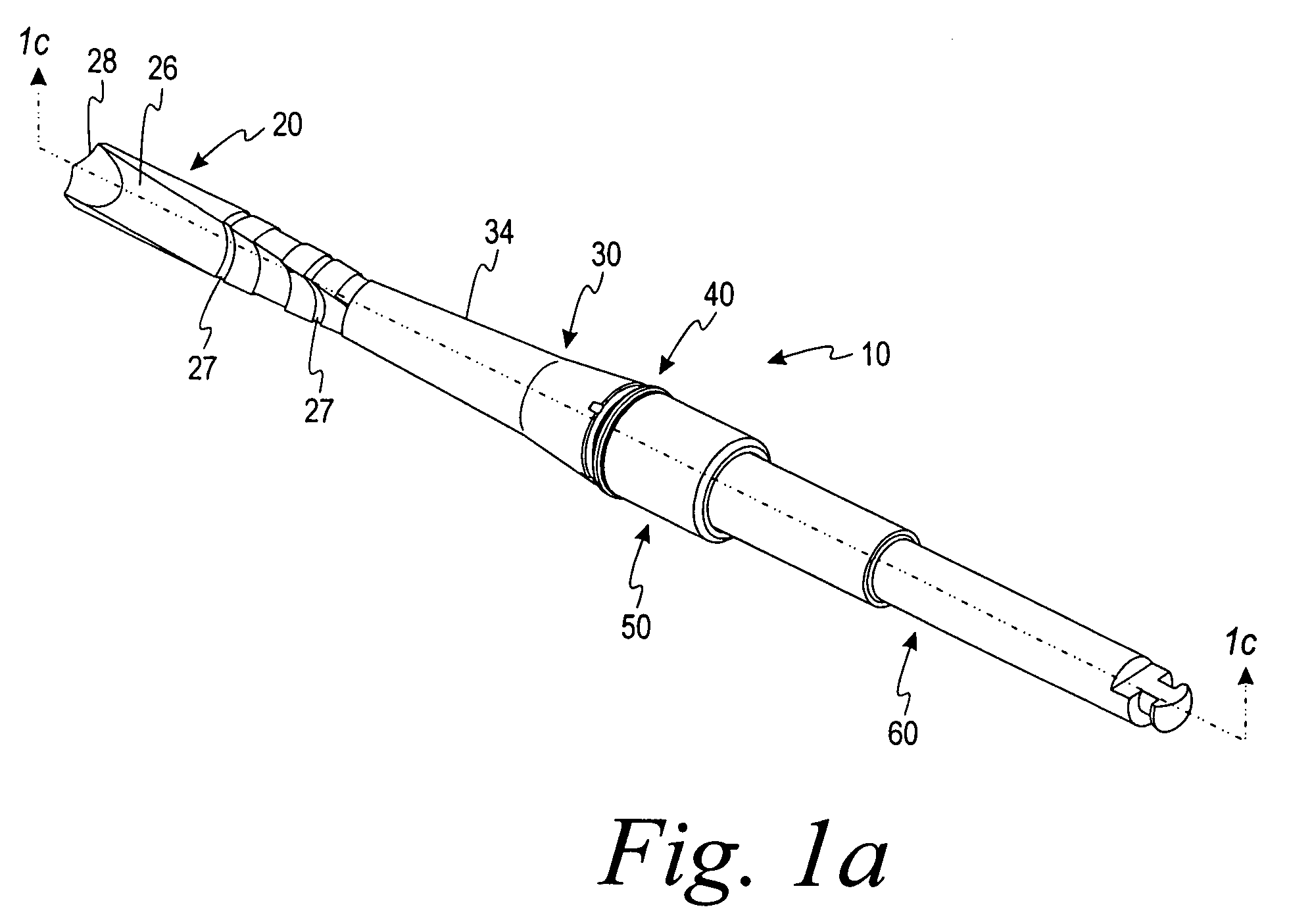

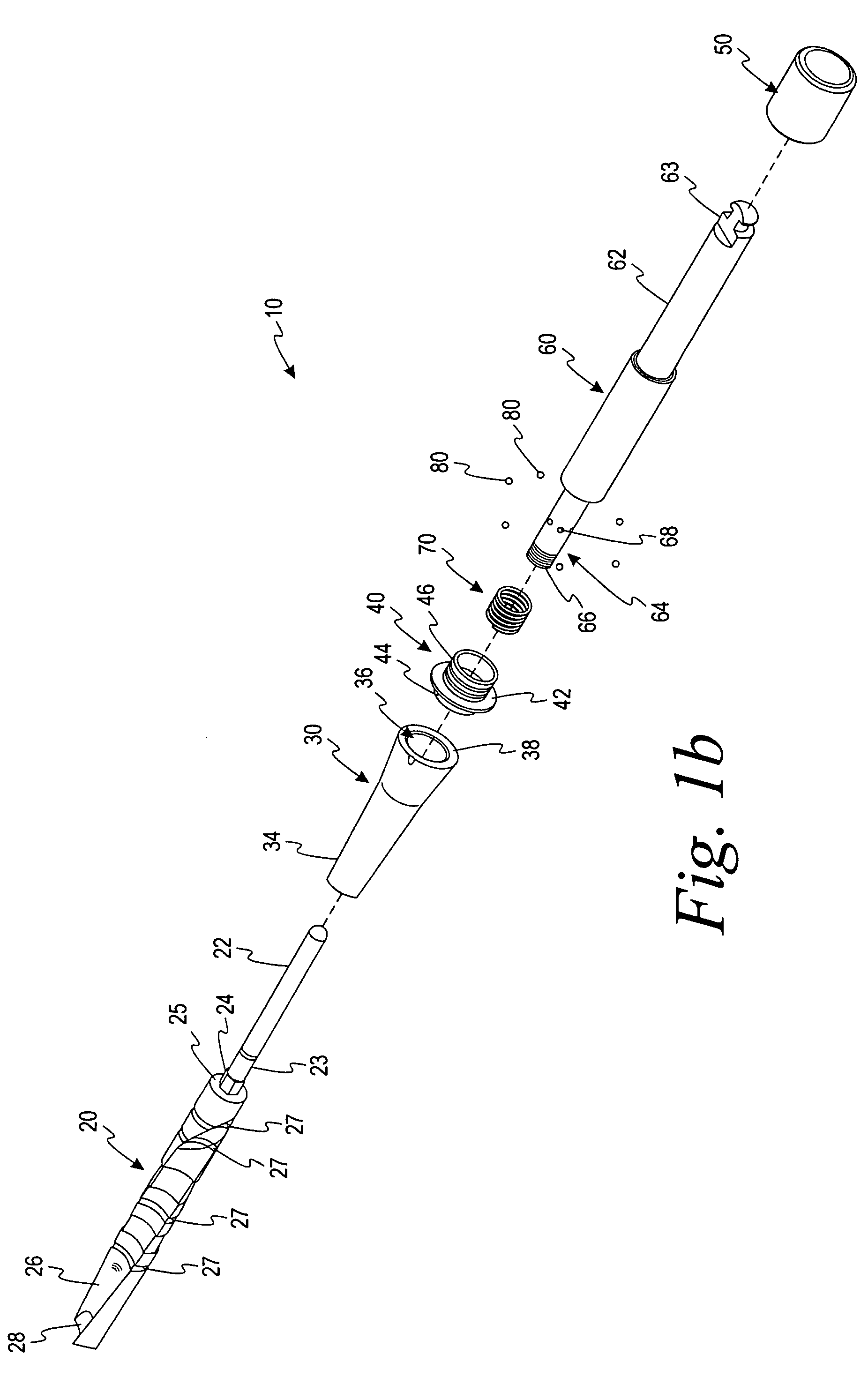

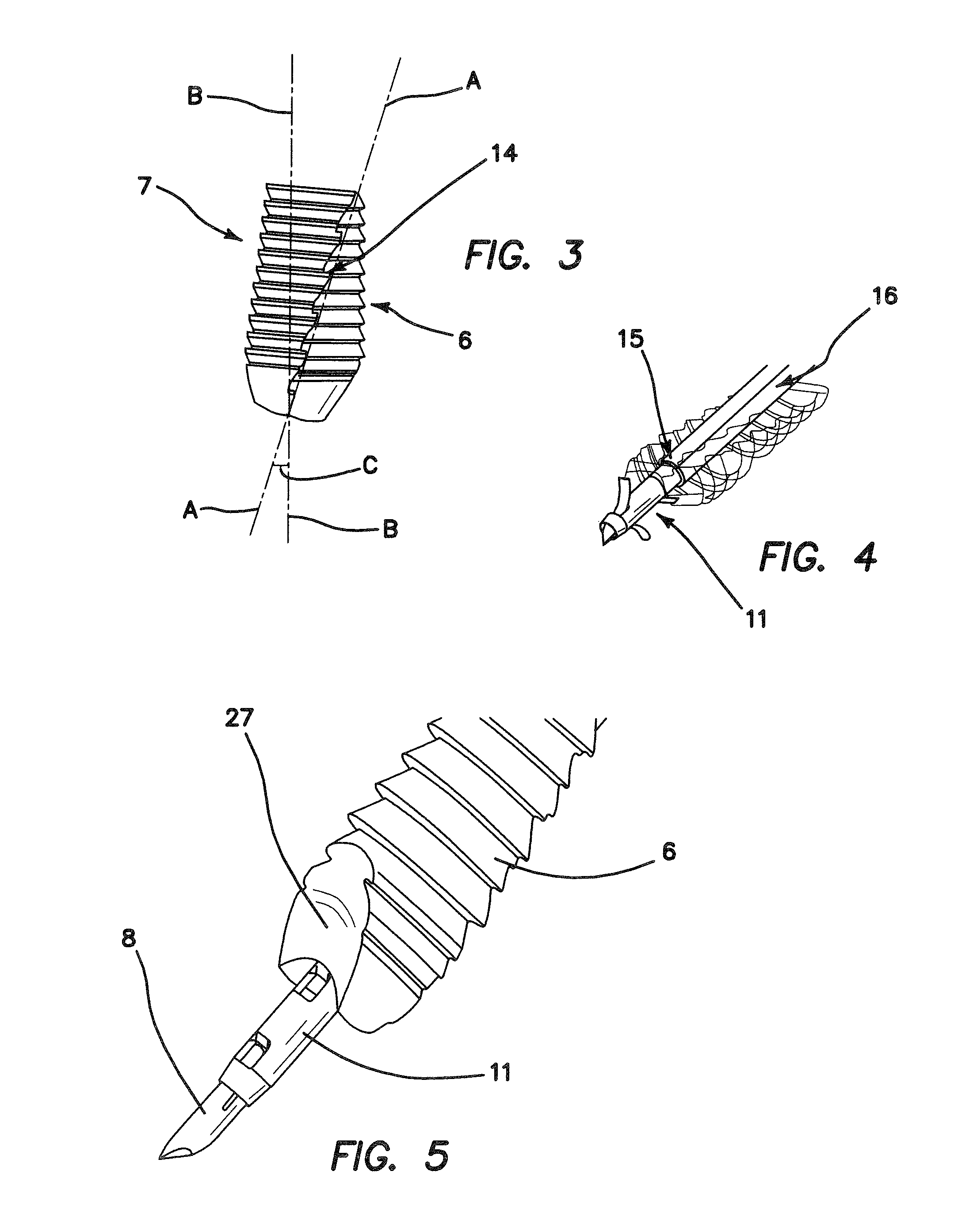

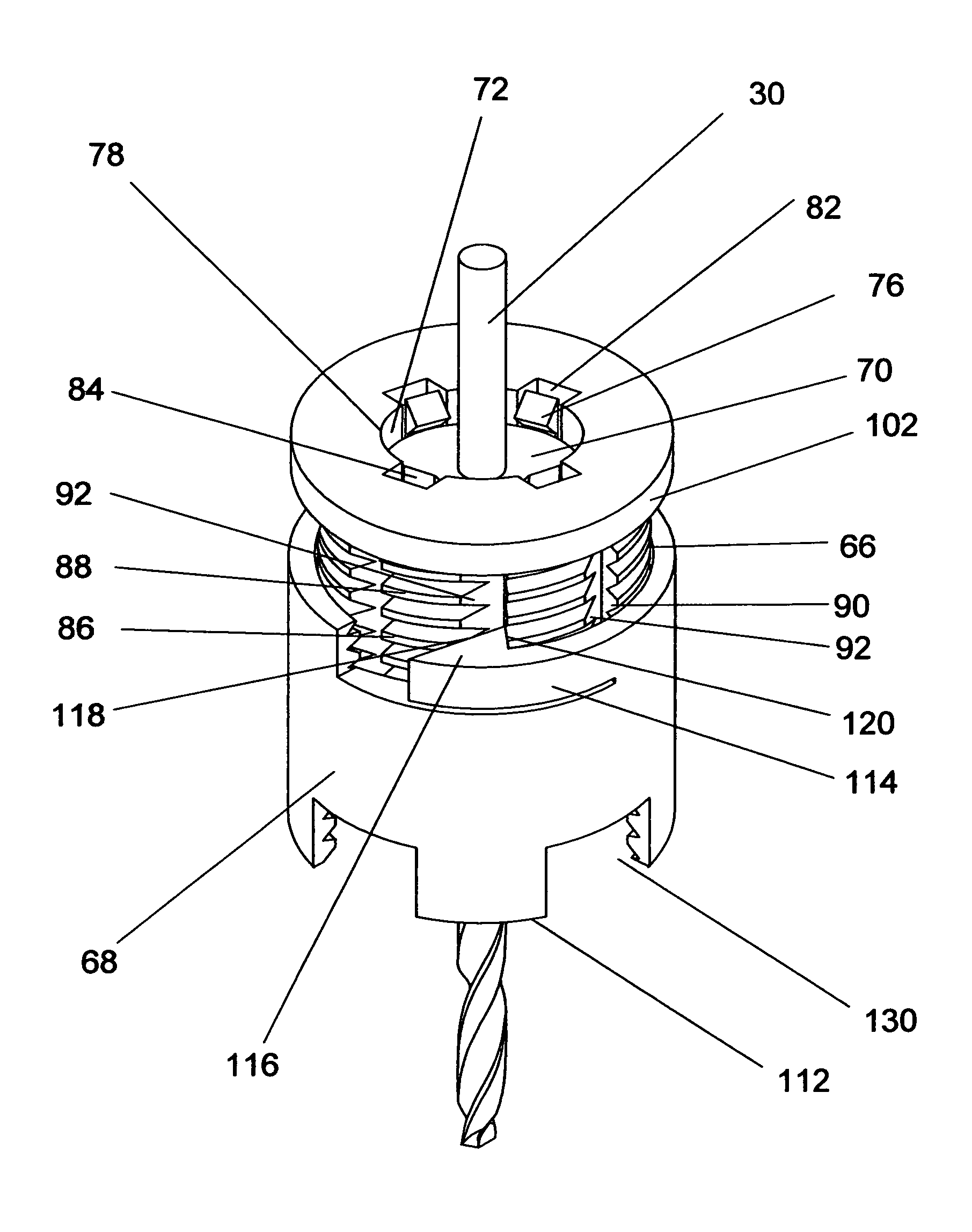

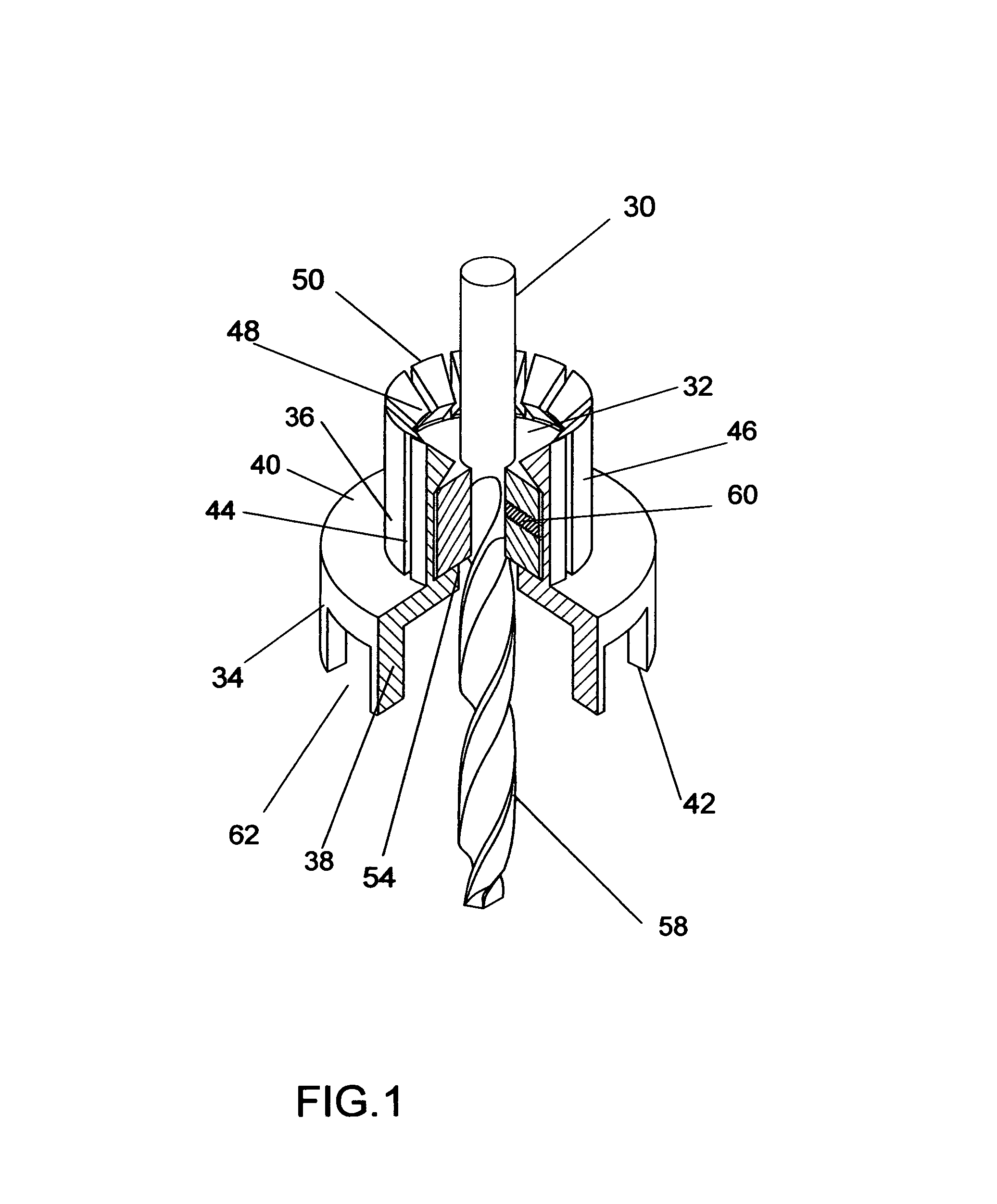

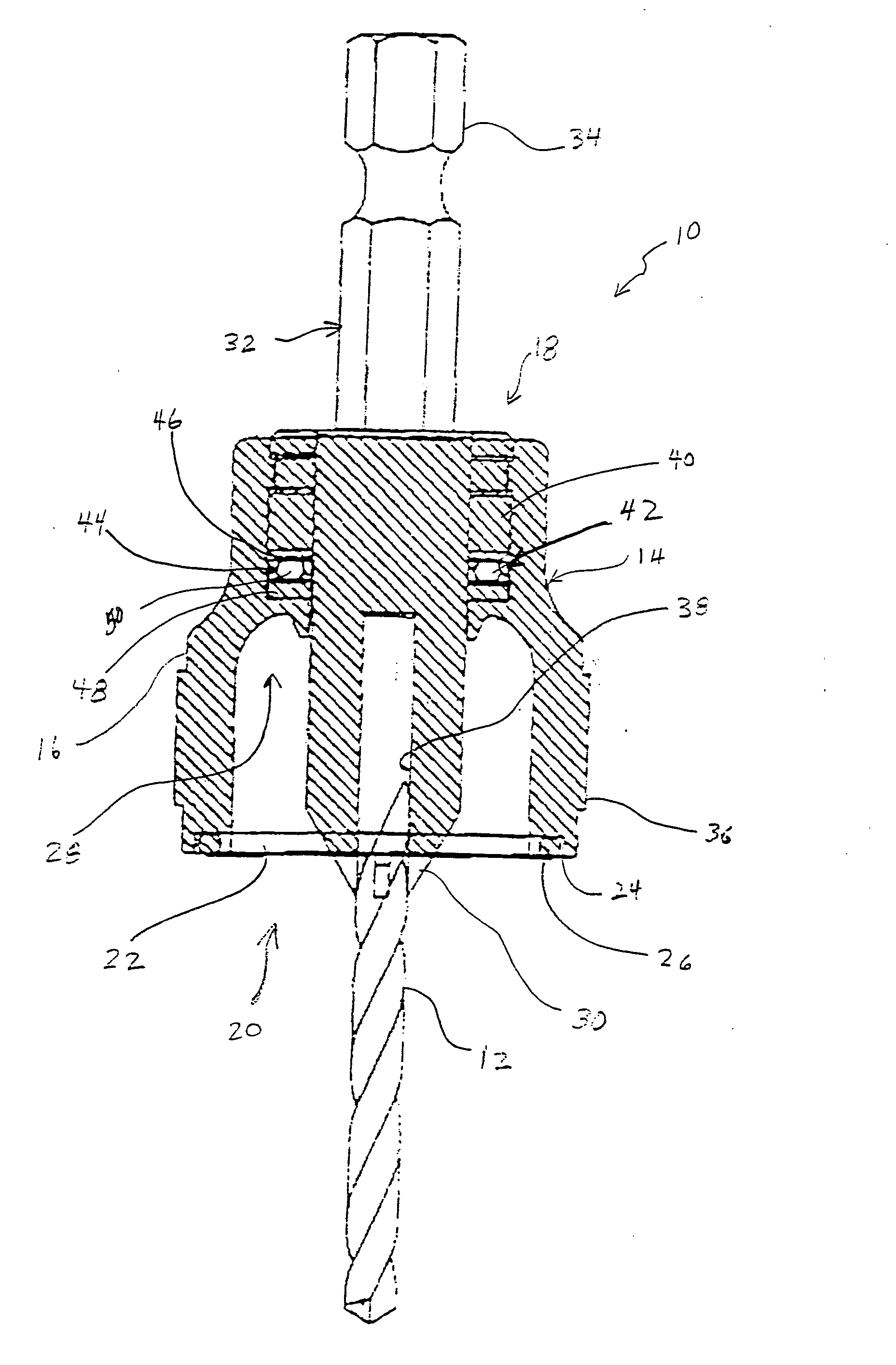

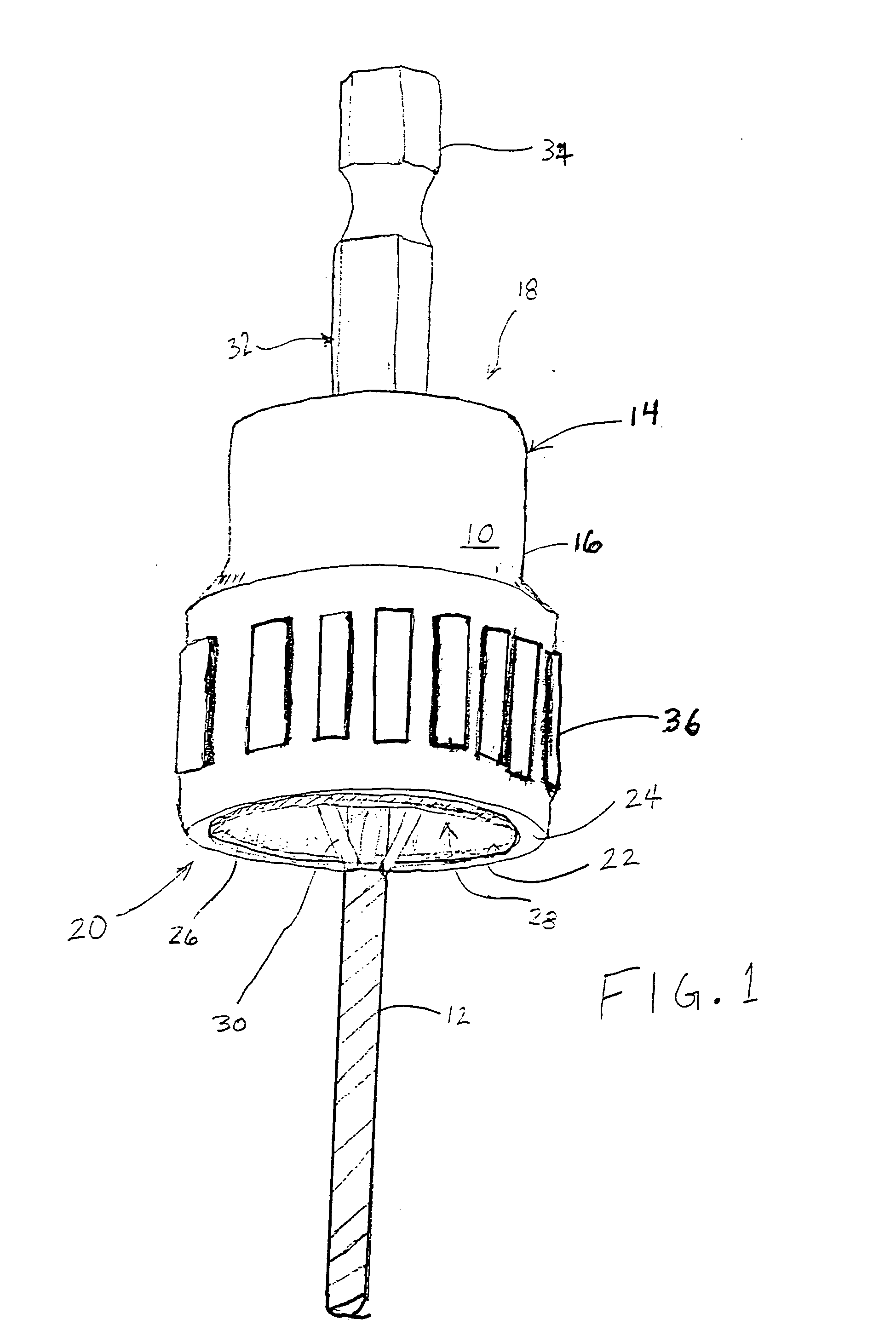

Drill bit assembly for bone tissue including depth limiting feature

A drill assembly for creating a bore in living bone comprises a drill bit, a collet-nose drill stop, a collet sleeve, a collet body, a concealment collar, a retaining spring, and a plurality of retaining balls. The drill bit inserts into the collet body and is retained in the collet body by the plurality of retaining balls. The collet-nose drill stop extends over a portion of the drill bit to limit the depth of the bore formed by the drill bit. The collet body has a drive shank and a connection region. The connection region of the collet body is adapted to receive a portion of the drill bit. The plurality of retaining balls are adapted to longitudinally secure the drill bit to the collet body.

Owner:BIOMET 3I LLC

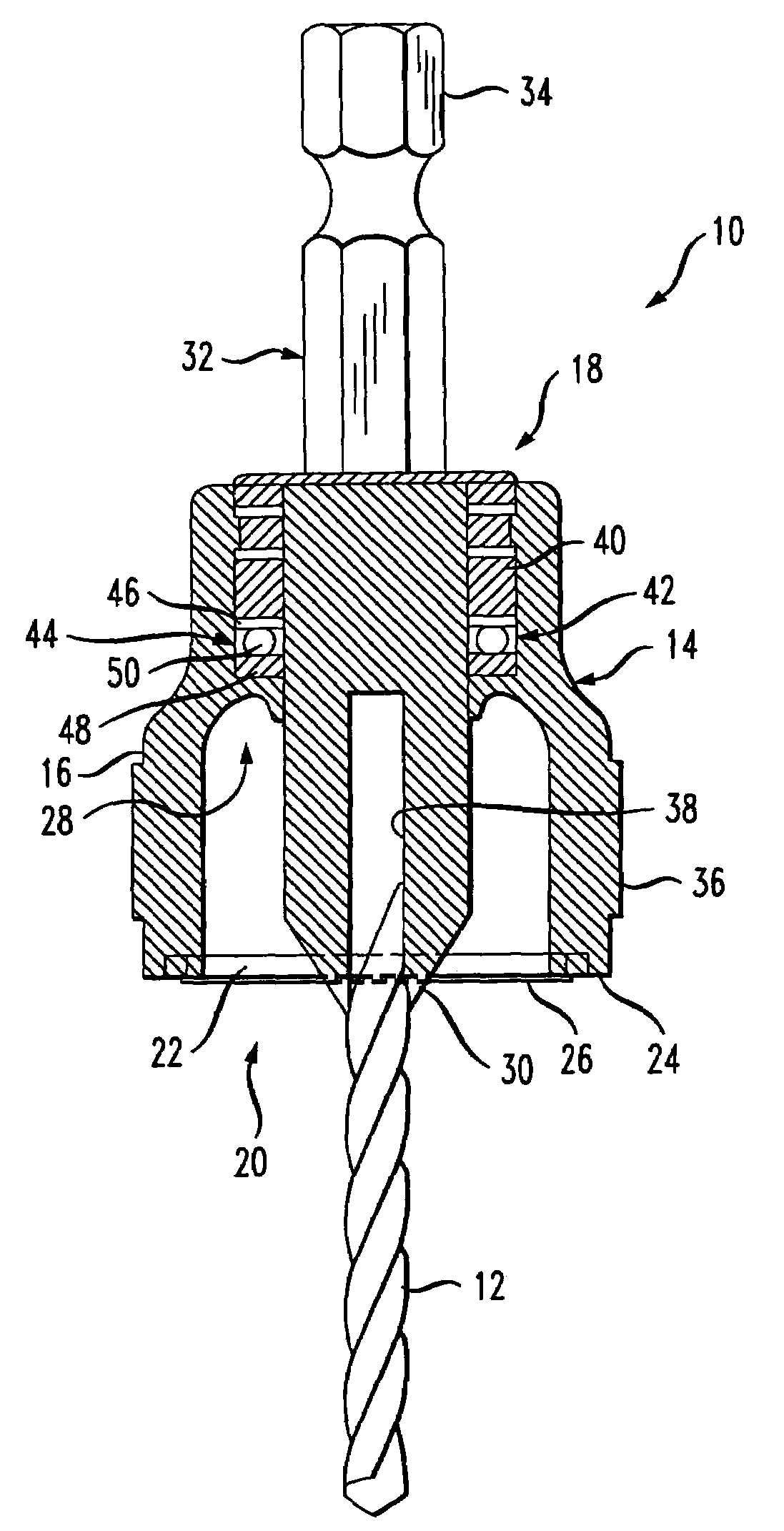

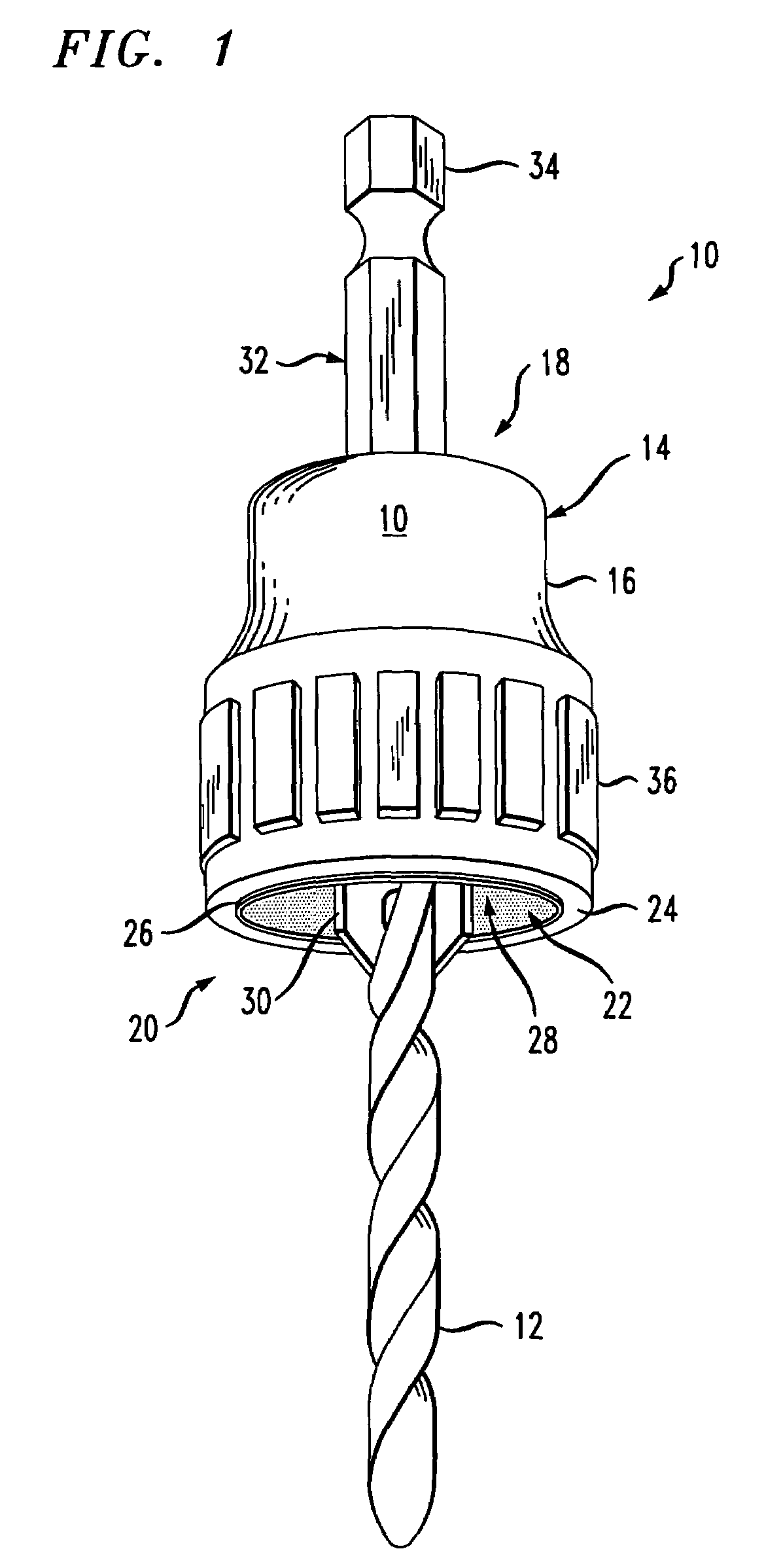

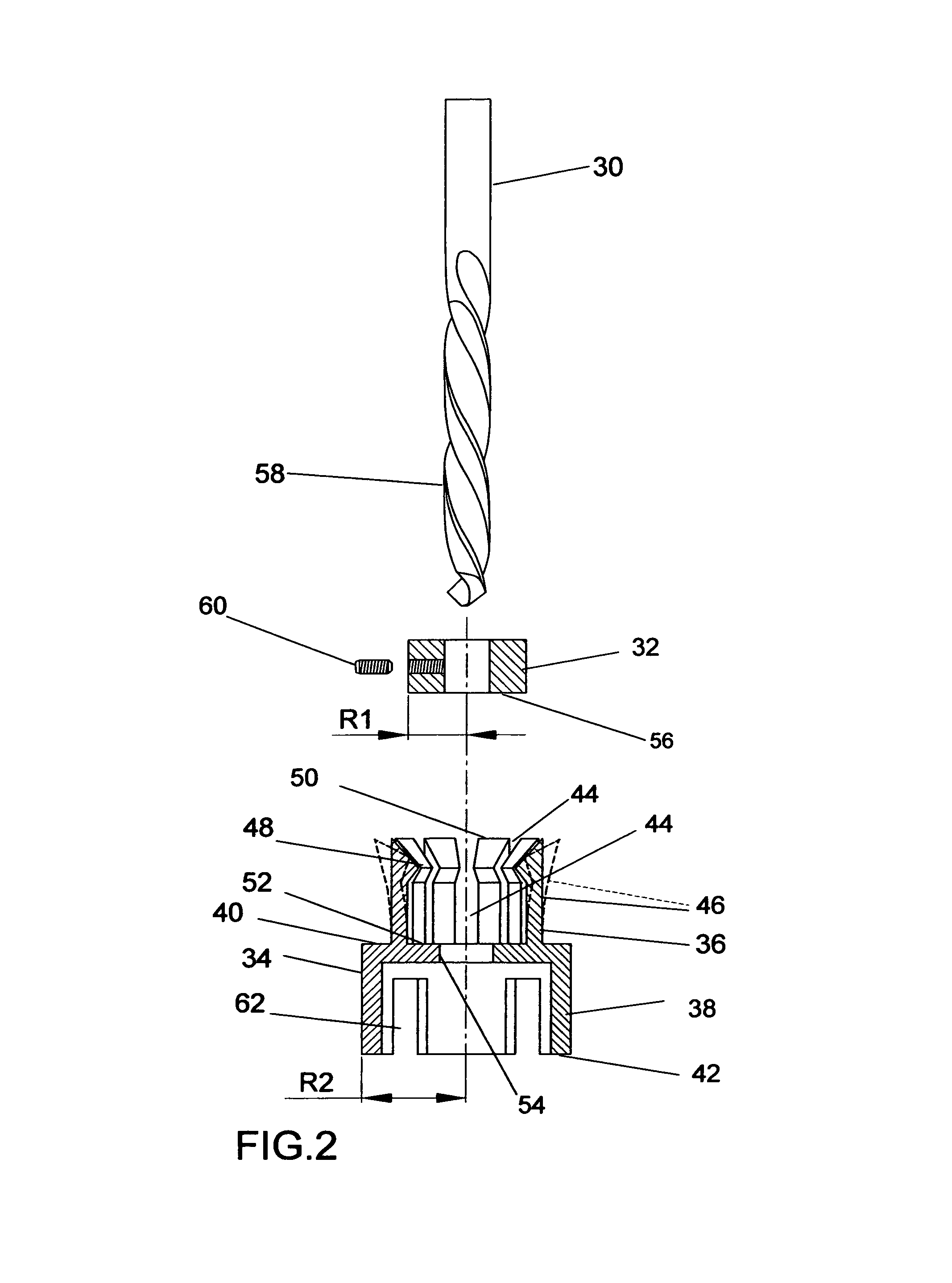

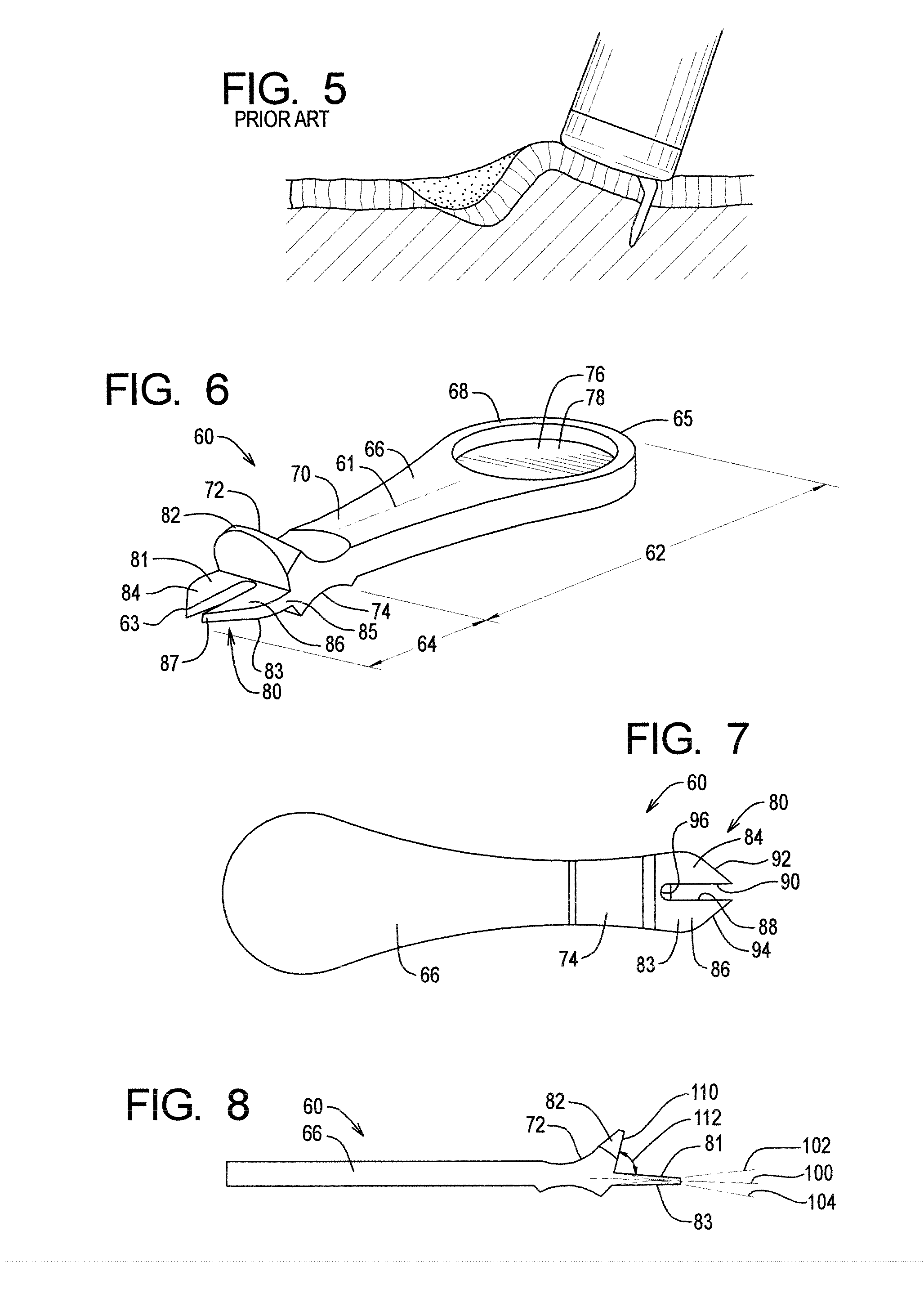

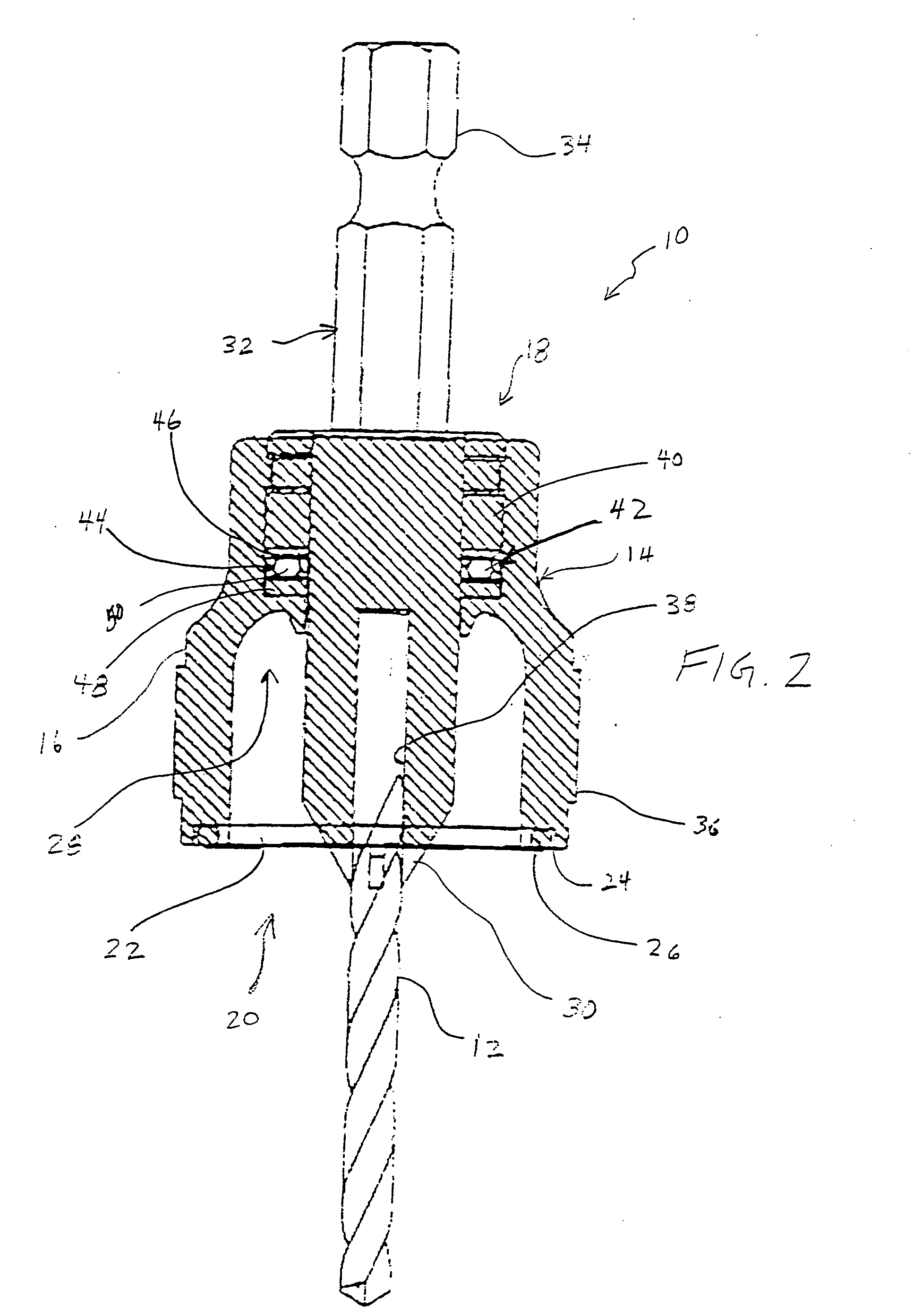

Depth limiting device and hole forming apparatus containing the same

ActiveUS7258513B2Facilitates and promotesAvoid damageThread cutting toolsDrilling/boring measurement devicesEngineeringMechanical engineering

A depth limiting device includes a stop collar having a an open end portion and an workpiece engaging portion extending along the open end portion thereof for contacting a workpiece; a spindle extending axially through the shell, the spindle including a first end extending from the exterior of the stop collar for attachment to a hole forming apparatus, and an second end interior to the stop collar for attachment to a hole forming bit, wherein the attached hole forming bit projects through the open end portion of the stop collar at a predetermined length corresponding to the desired depth of the hole in the workpiece; and a bearing assembly operatively associated with the stop collar and the spindle for isolating the rotation of the spindle from the stop collar whereby the stop collar ceases to rotate when contacting the workpiece without generating sufficient frictional contact to mar or otherwise damage the workpiece.

Owner:FAR NORTH

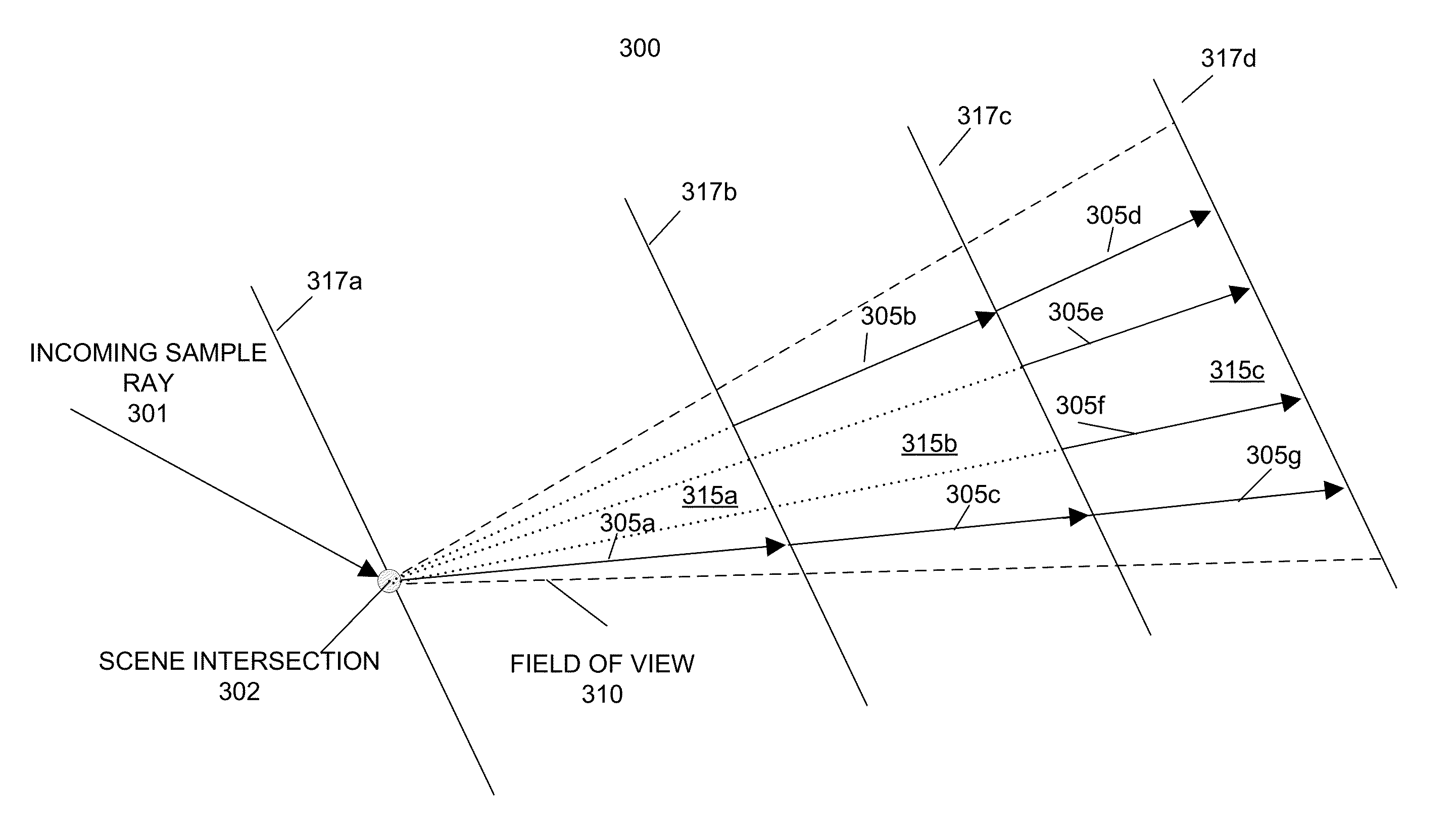

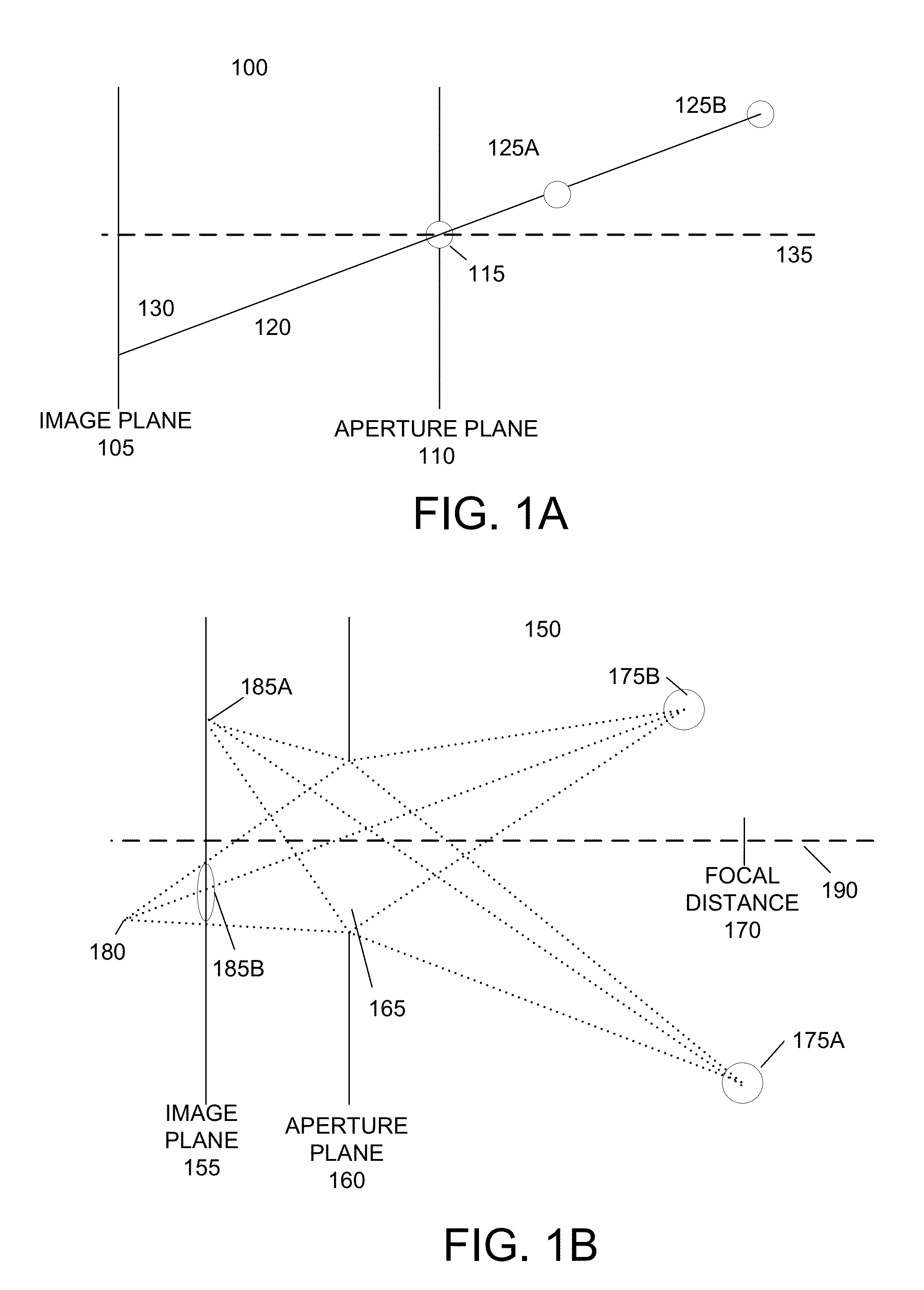

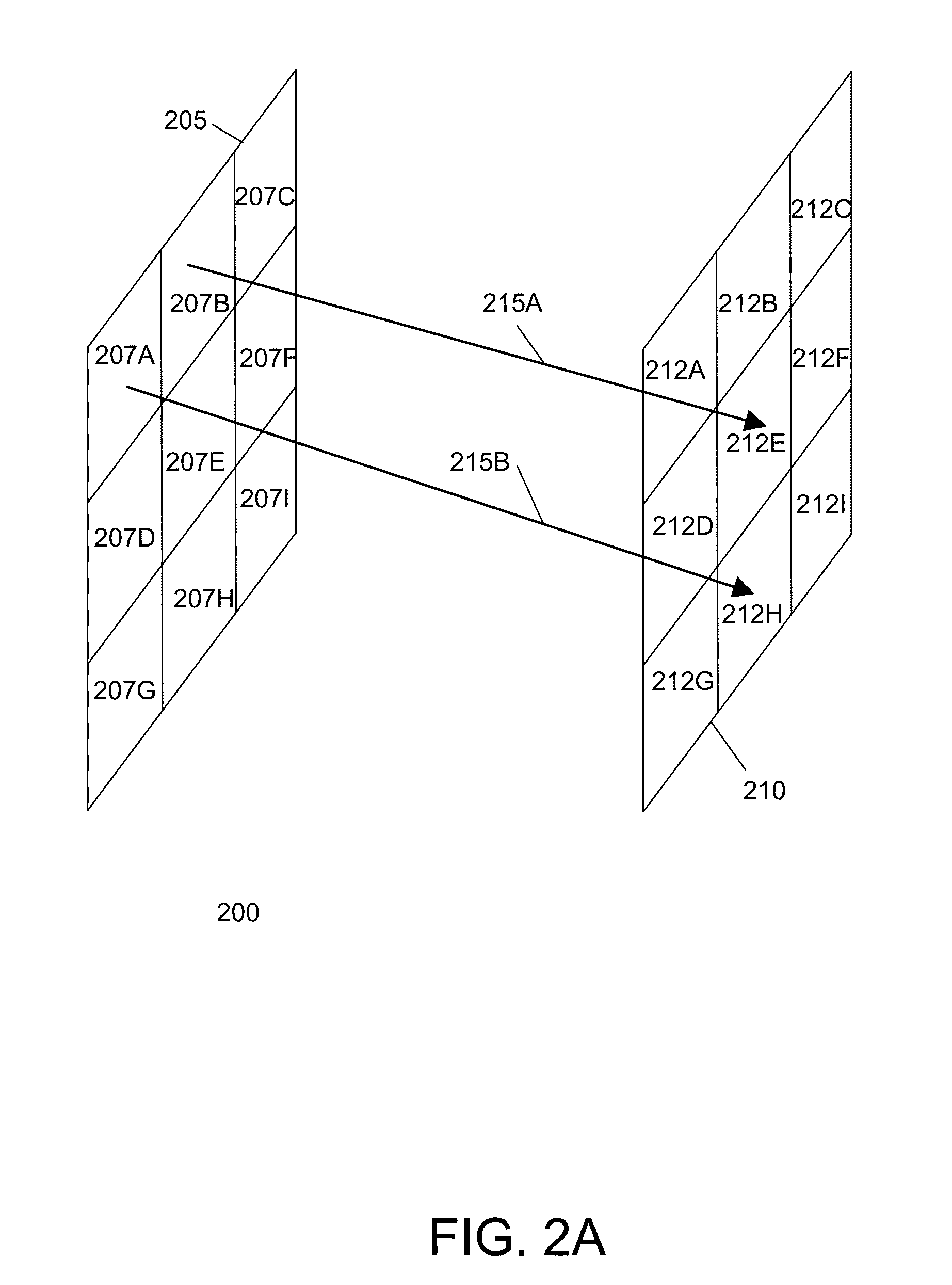

Adaptive depth of field sampling

ActiveUS8493383B1Increase the number ofDetails involving antialiasingCathode-ray tube indicatorsDepth of fieldSelf adaptive

Adaptive sampling alleviates aliasing by partitioning the field of view of an image sample point into depth regions. Portions of the scene are sampled within a depth region using sample rays. If a sample ray is not completely occluded in the depth region, corresponding sample rays are evaluated in adjacent depth regions. Sample rays can be recursively evaluated in further depth regions until all the subsamples intersect opaque objects or a depth limit or transparency threshold is reached. The value of an image sample point is the weighted combination of sample rays. The number of sample rays in each depth region may increase monotonically with distance along a line of sight from an image sample point for effects such as reflection, refraction, and illumination. The number of sample rays in each depth region may increase monotonically with distance from a focal plane for effects such as depth of field.

Owner:PIXAR ANIMATION

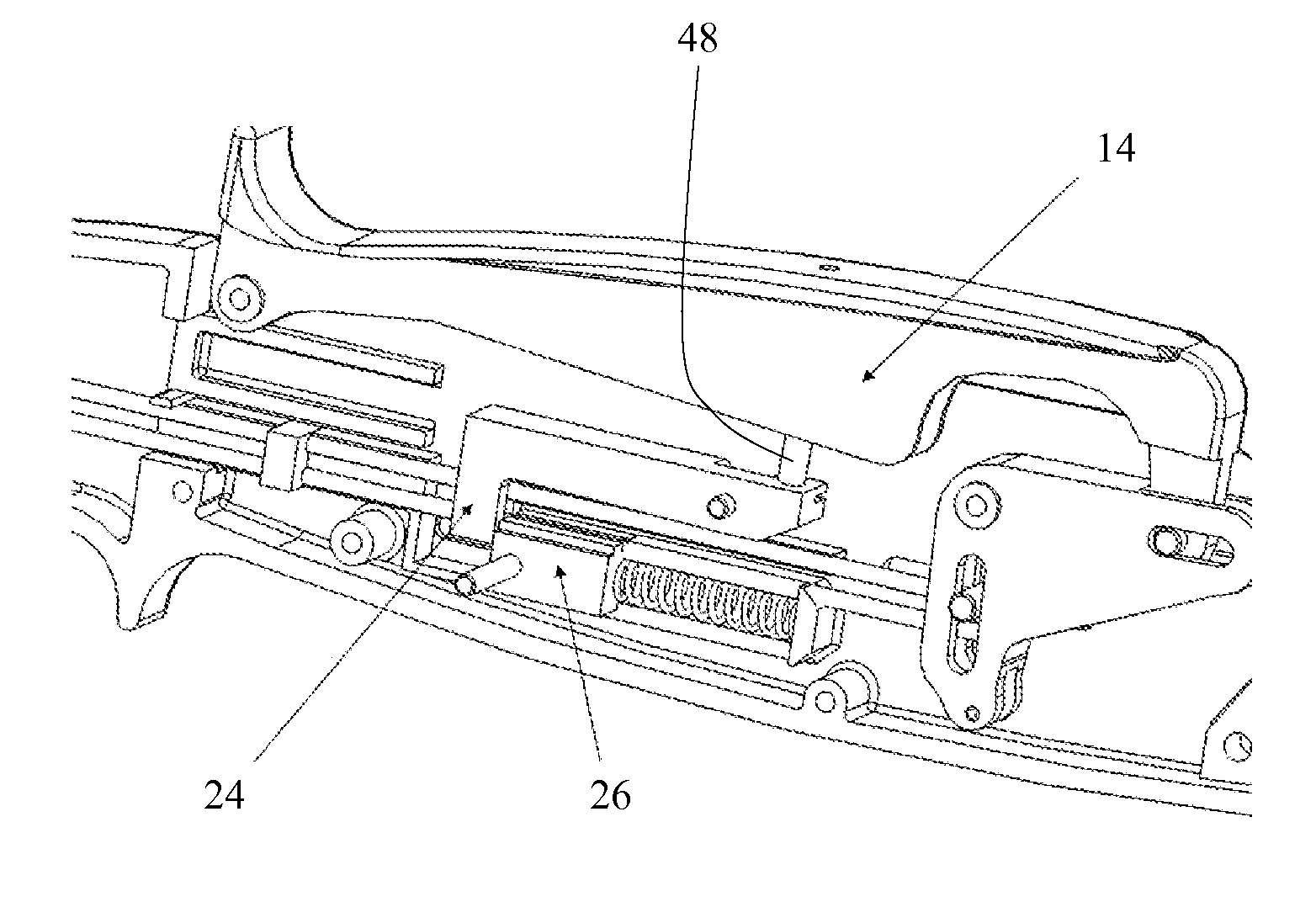

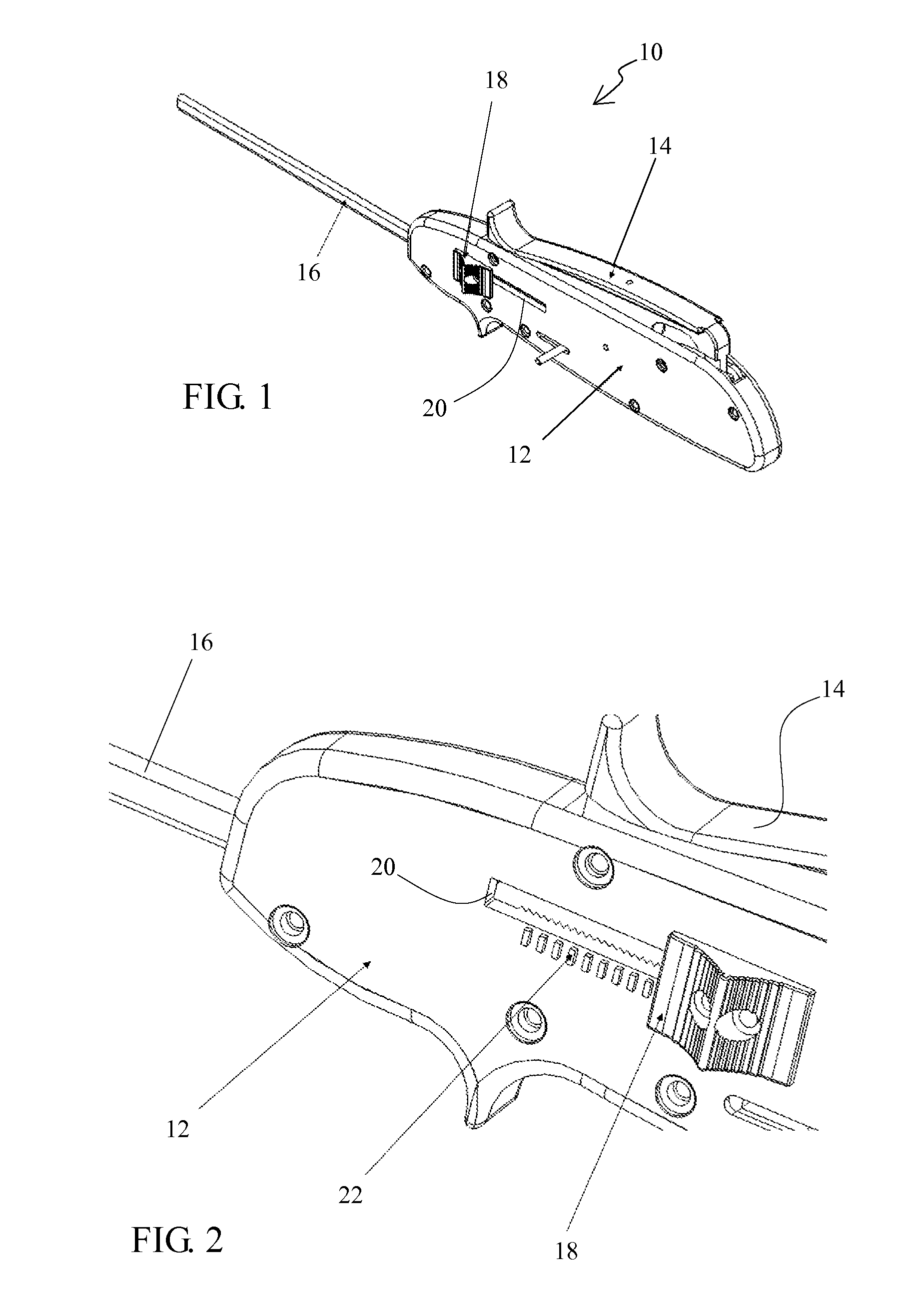

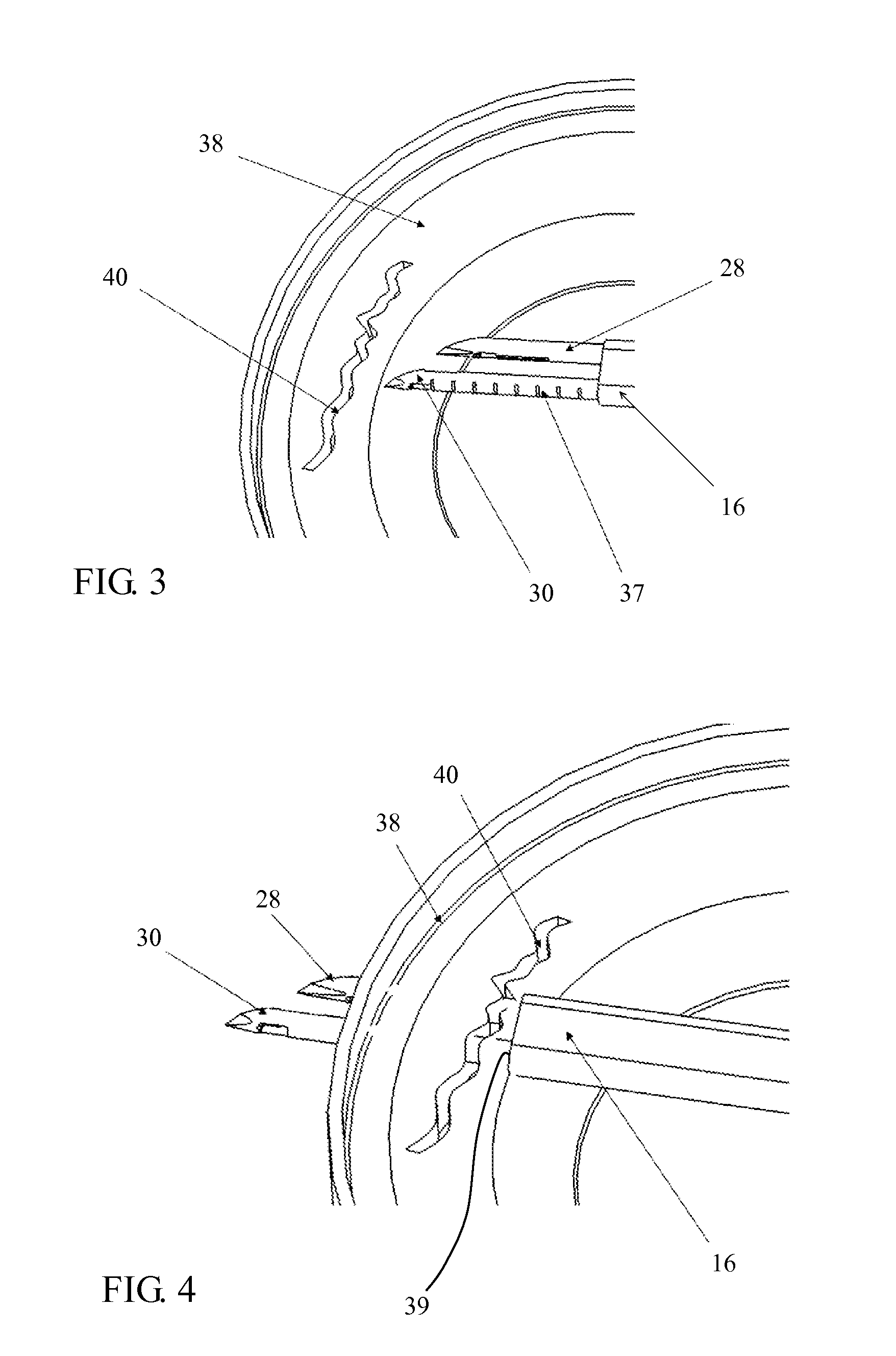

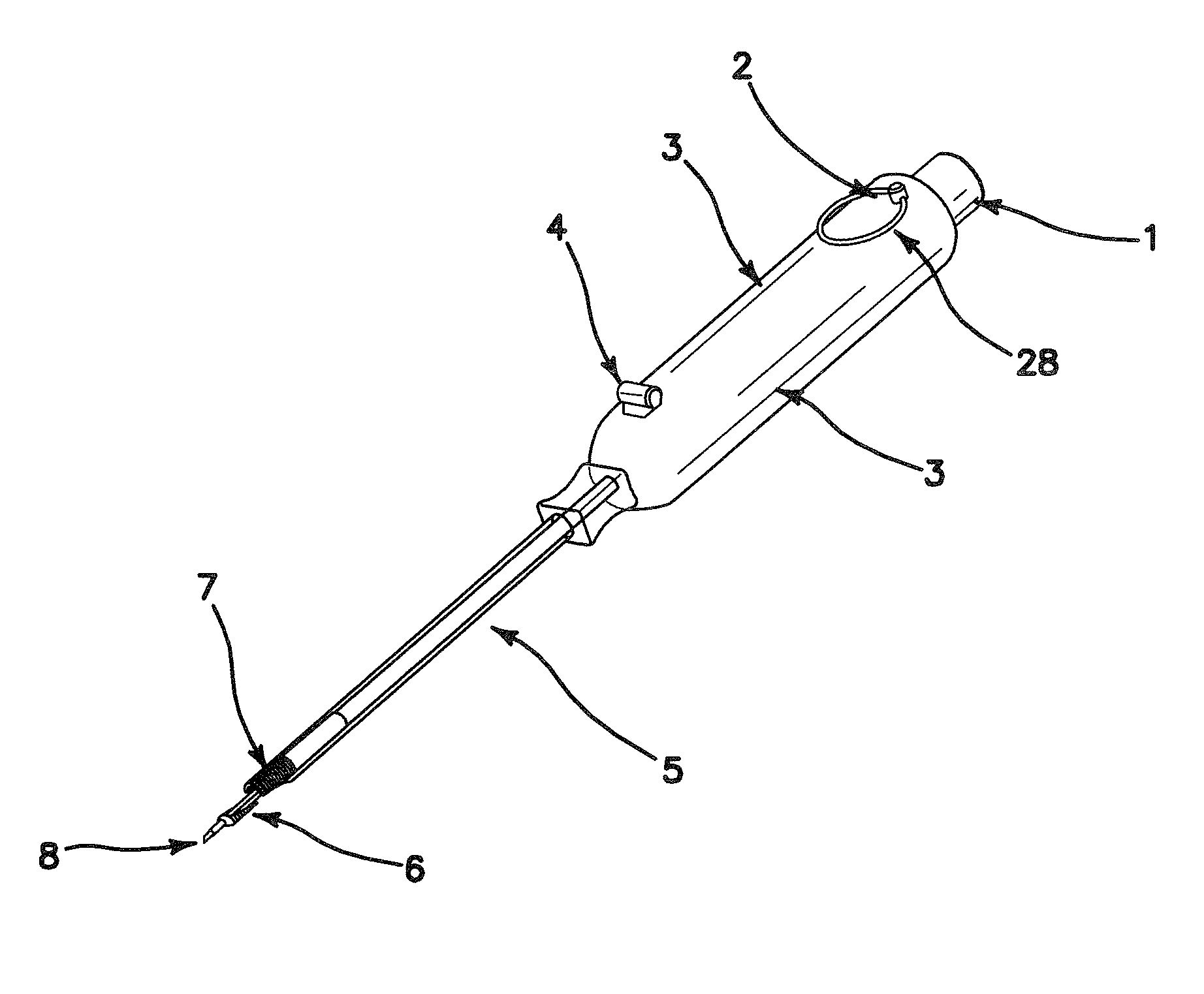

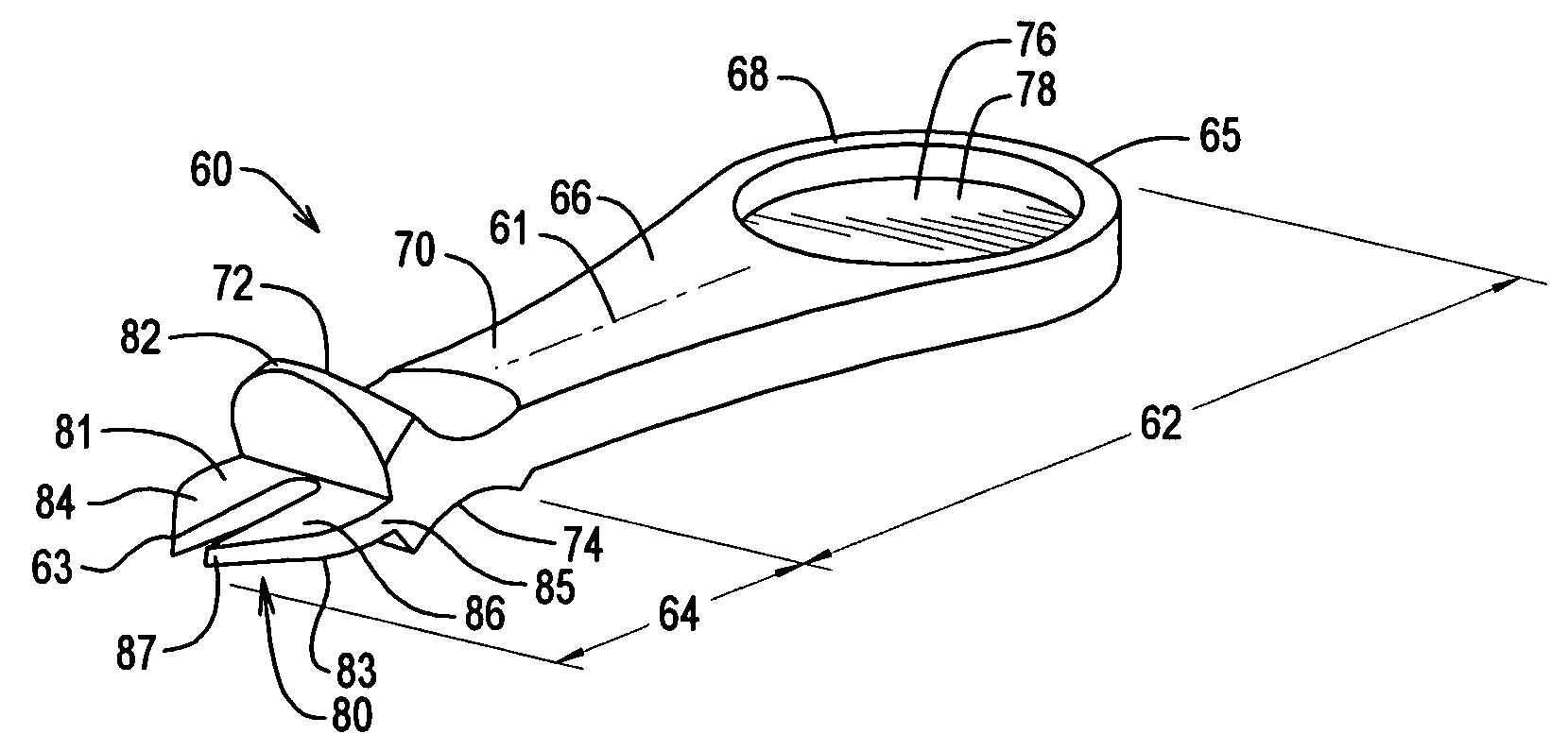

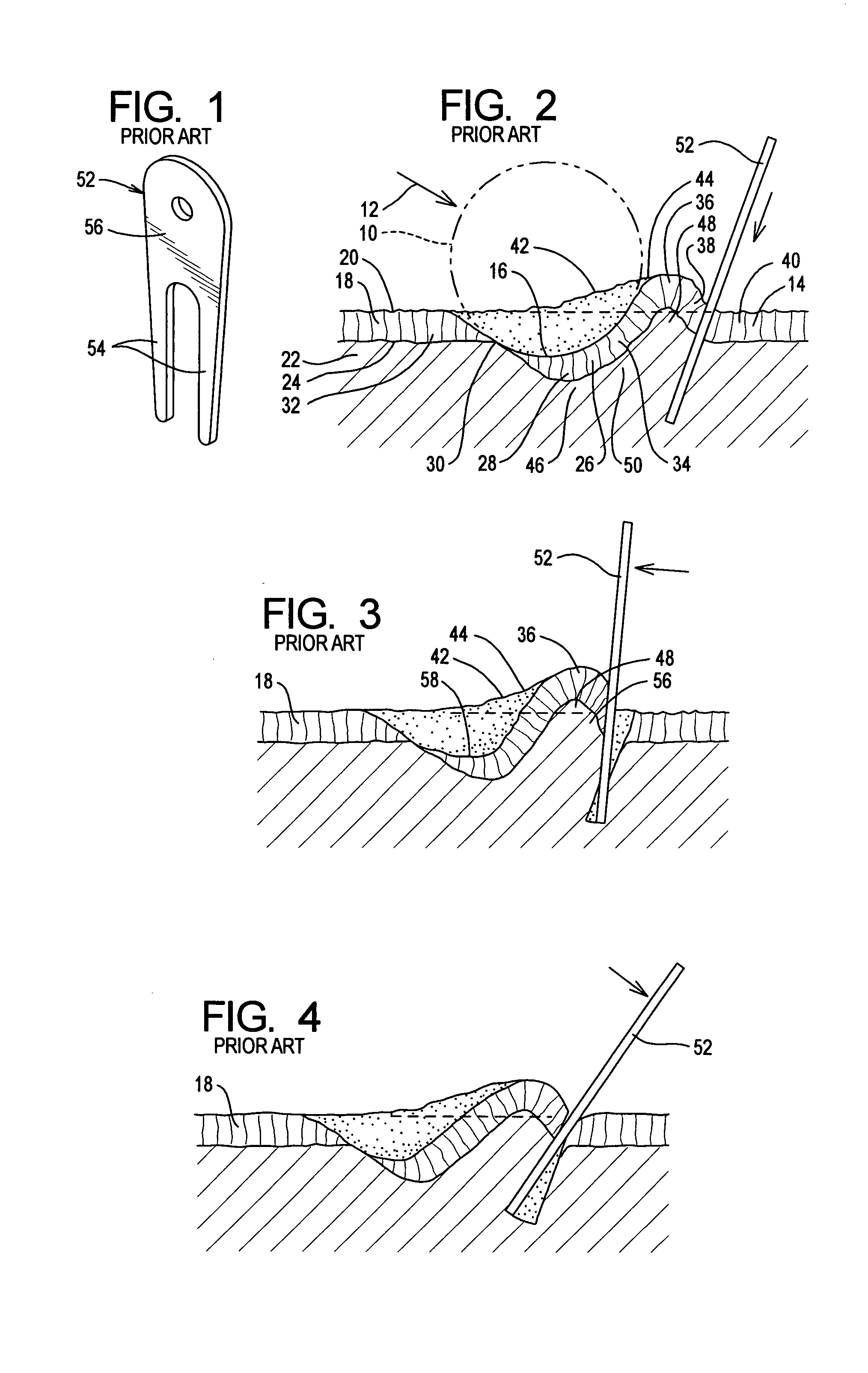

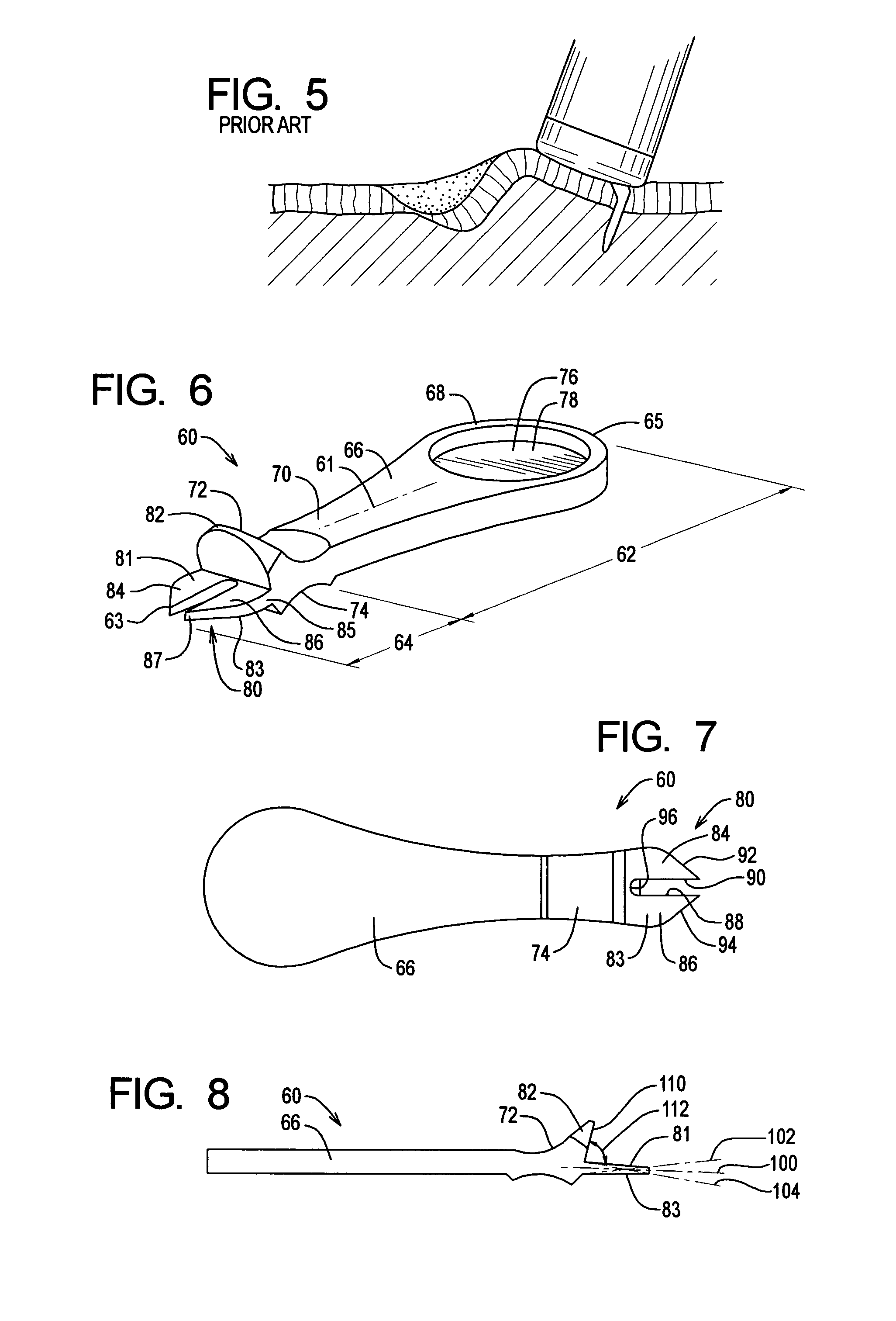

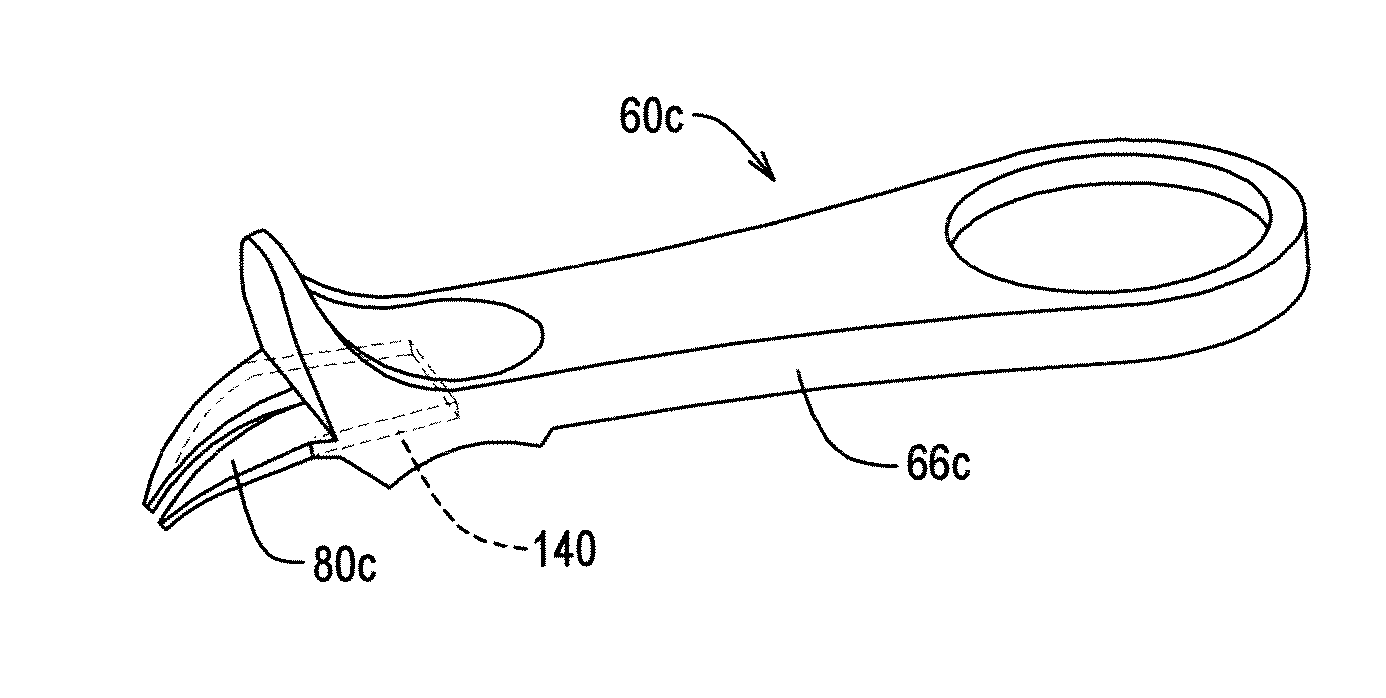

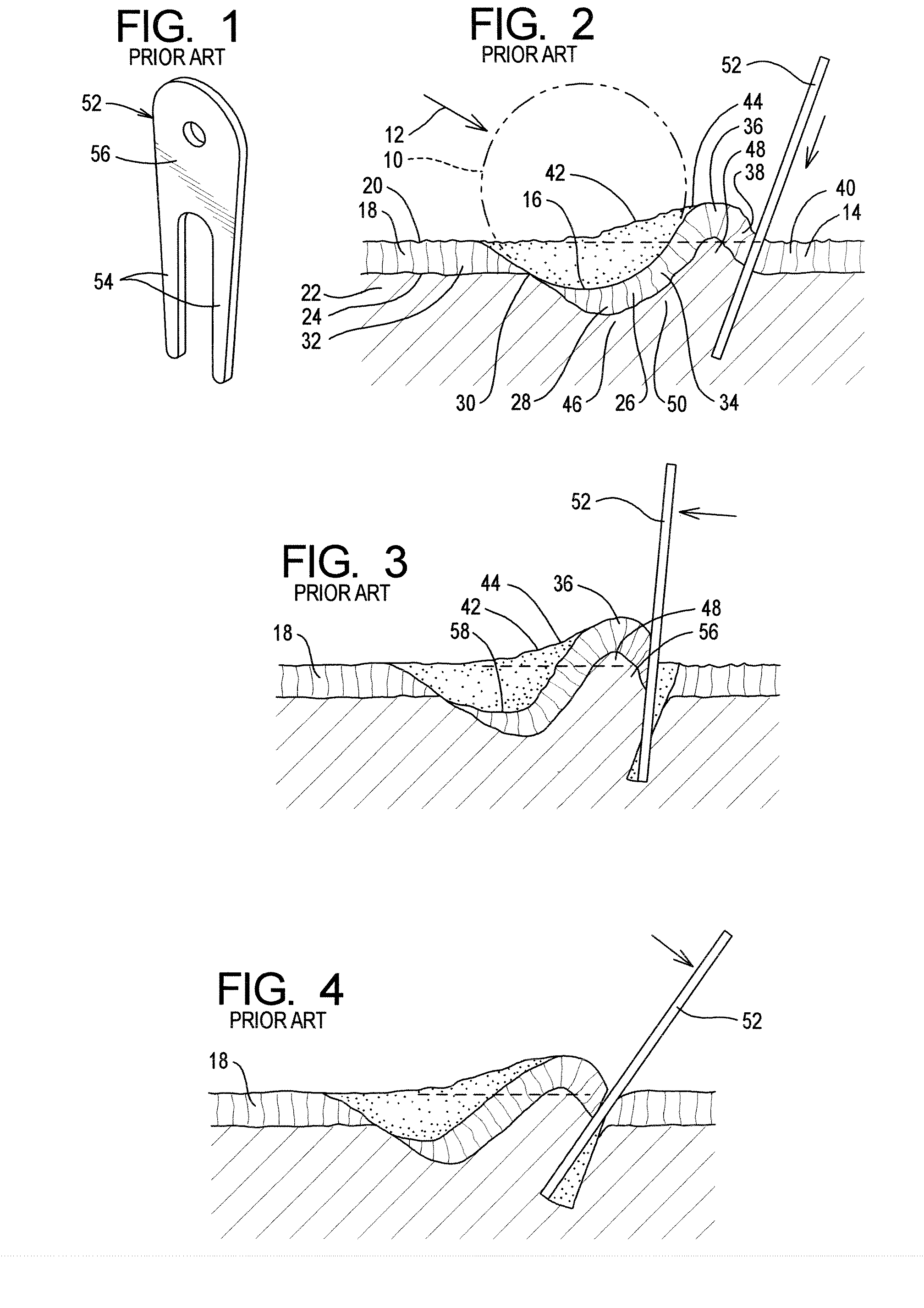

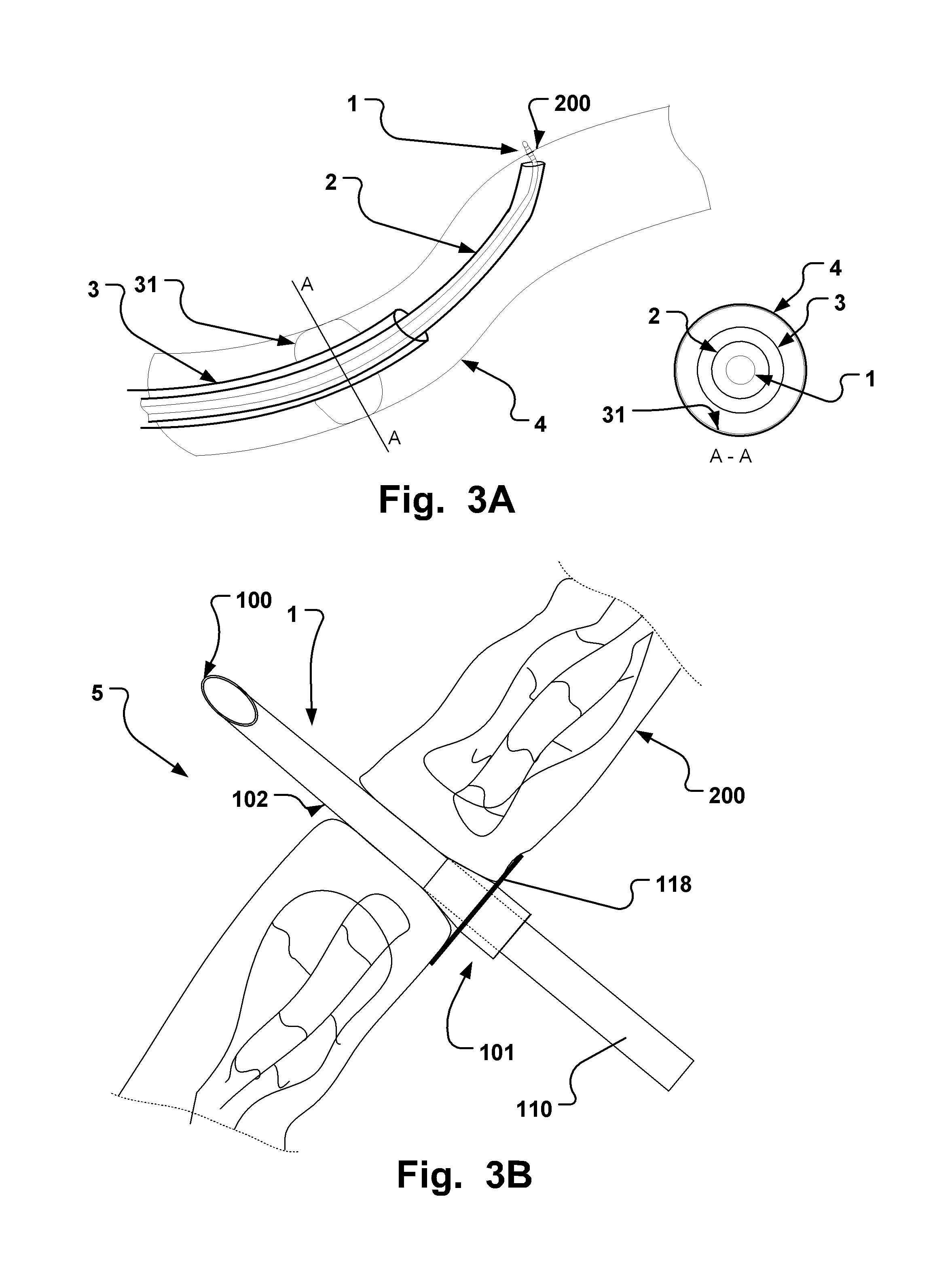

Meniscal repair systems and methods

A device for repairing a tear in a portion of tissue comprises a proximal actuator portion, a transfer needle extending distally from the proximal actuator portion and a catch needle extending distally from the proximal actuator portion. A suture needle is disposed in the transfer needle, and is extendable from the transfer needle toward the catch needle and retractable from the catch needle toward the transfer needle. An extendable catch plunger is disposed in the catch needle for capturing suture therein when it is transferred from the transfer needle. A retractable insertion sheath is provided for covering the transfer needle and the catch needle when the device is inserted into a procedural site. A depth limiting apparatus limits the depth of insertion of the needle into the procedural site.

Owner:CAYENNE MEDICAL INC

Drill bit assembly for bone tissue including depth limiting feature

A drill assembly for creating a bore in living bone comprises a drill bit, a collet-nose drill stop, a collet sleeve, a collet body, a concealment collar, a retaining spring, and a plurality of retaining balls. The drill bit inserts into the collet body and is retained in the collet body by the plurality of retaining balls. The collet-nose drill stop extends over a portion of the drill bit to limit the depth of the bore formed by the drill bit. The collet body has a drive shank and a connection region. The connection region of the collet body is adapted to receive a portion of the drill bit. The plurality of retaining balls are adapted to longitudinally secure the drill bit to the collet body.

Owner:BIOMET 3I LLC

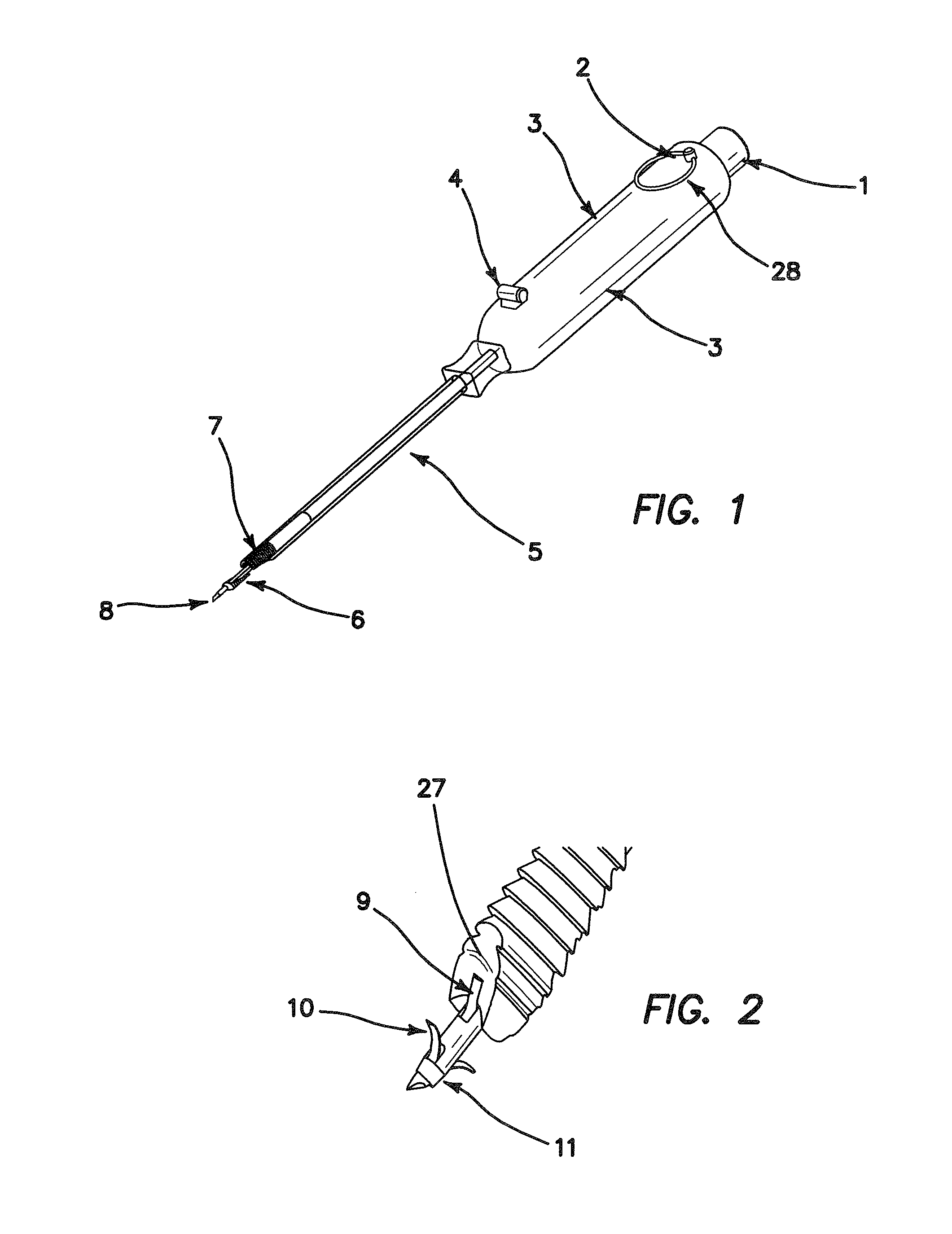

Tenodesis implant and inserter and methods for using same

The present invention provides a novel split barbed fixation device for tenodesis, soft tissue reattachment of tendons and ligaments to bones. The insertion device is adapted for an entirely arthroscopic approach while achieving fixation strength with ultimate pullout resistance comparable to interference screws. The device includes an integrated tendon grasper that provides for easy manipulation of the tendon arthroscopically while eliminating the need for external whip stitching of the tendon, thereby reducing preparation time. The device further includes elements that prevent the fixation implant from being destabilized or rotating during deployment and manipulation, including: a depth limiting sheath, a first implant retainer, a first implant retaining step, a tendon grasping needle tube, and an implant keyway for mating the implant to the tube. The implant itself comprises two separate portions mating along a diagonal and having barbed surface features in opposite directions, only one of which contacts the tendon.

Owner:CAYENNE MEDICAL INC

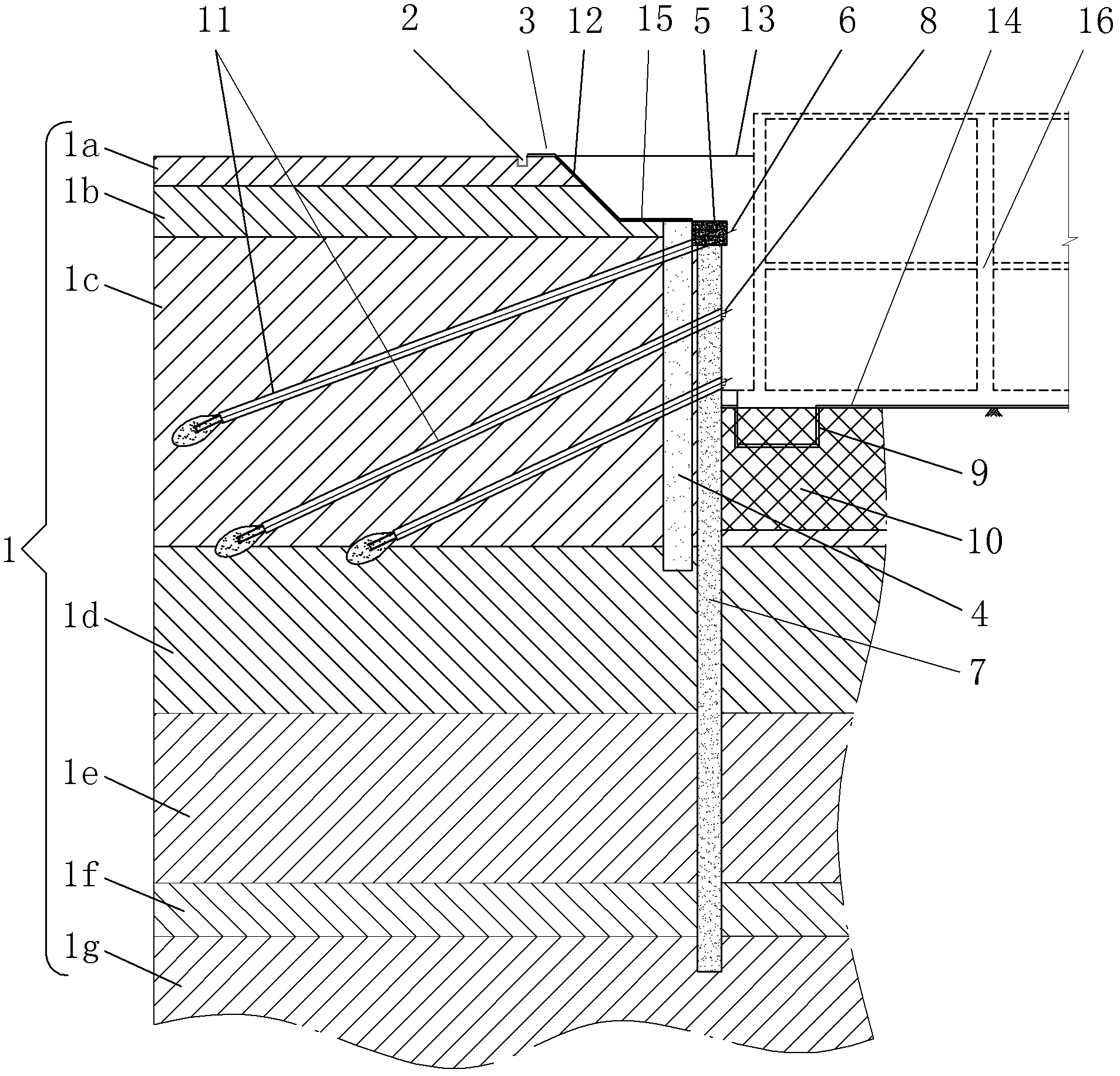

Foundation pit support construction method combining horizontal rotary jet-grouting soil bolting and bore concrete piles

ActiveCN102518135AOutstanding and Beneficial Technical EffectsControl deformation valueExcavationsBulkheads/pilesEngineeringDeformation control

The invention belongs to the technical field of foundation pit supporting for high-rise buildings, in particular to a foundation pit support construction method combining horizontal rotary jet-grouting soil bolting and bore concrete piles, which includes steps: firstly, constructing water-stop mixed piles and bored concrete piles according to a preset foundation pit; and secondly, performing soil excavation and soil bolting layer by layer and section by section. The foundation pit support construction method has the advantages that the foundation pit support constructed by the method is high in deformation control performance and stability and especially applicable to projections with high requirements on foundation pit deformation, and the method is applicable to mega-area foundation pit supporting in soft soil areas with failure of using internal support structures, limited slope reduction conditions and excavation depth limited within 15m, and meets the requirement that development and utilization of urban underground space continue to develop.

Owner:BIAOLI CONSTR GROUP

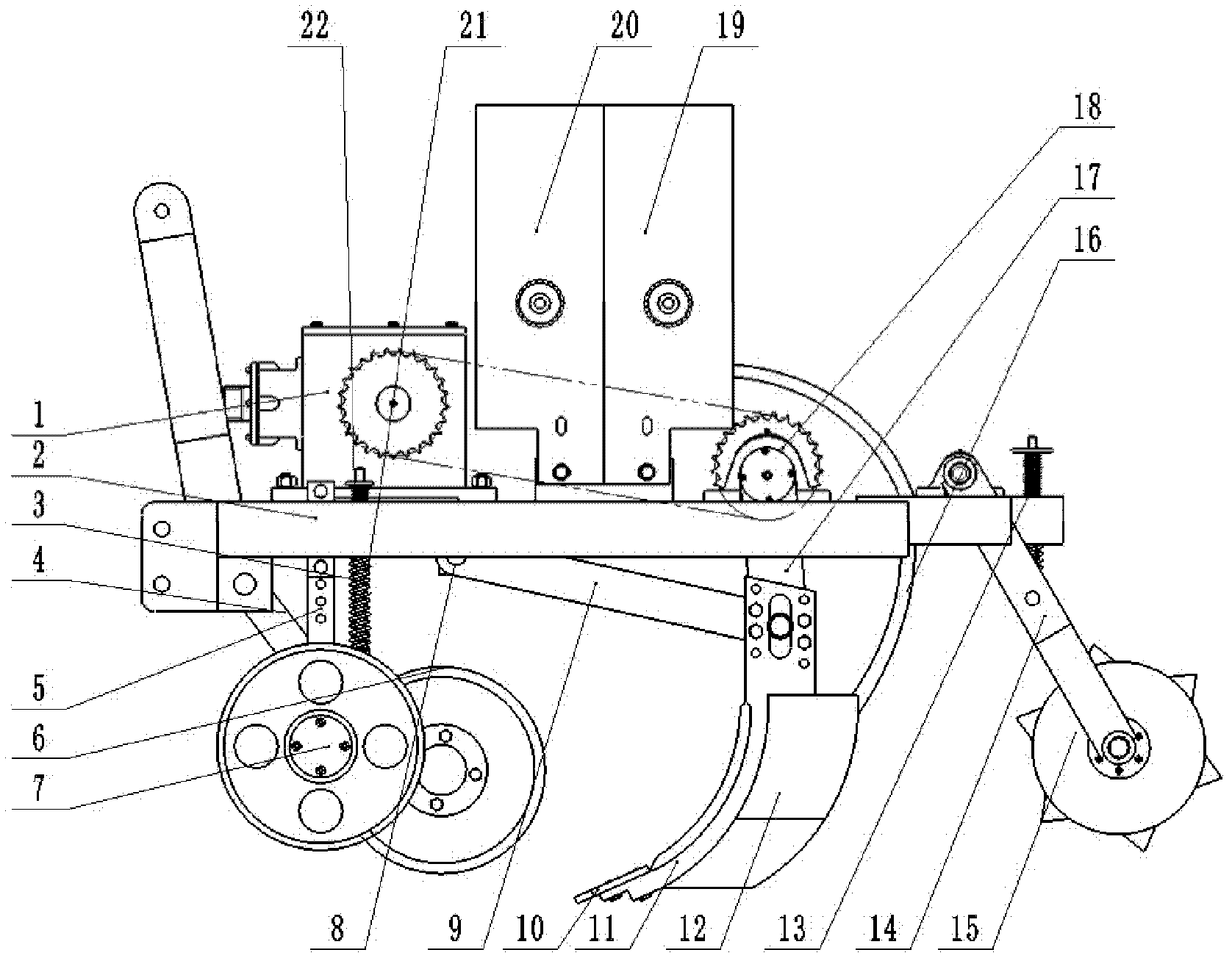

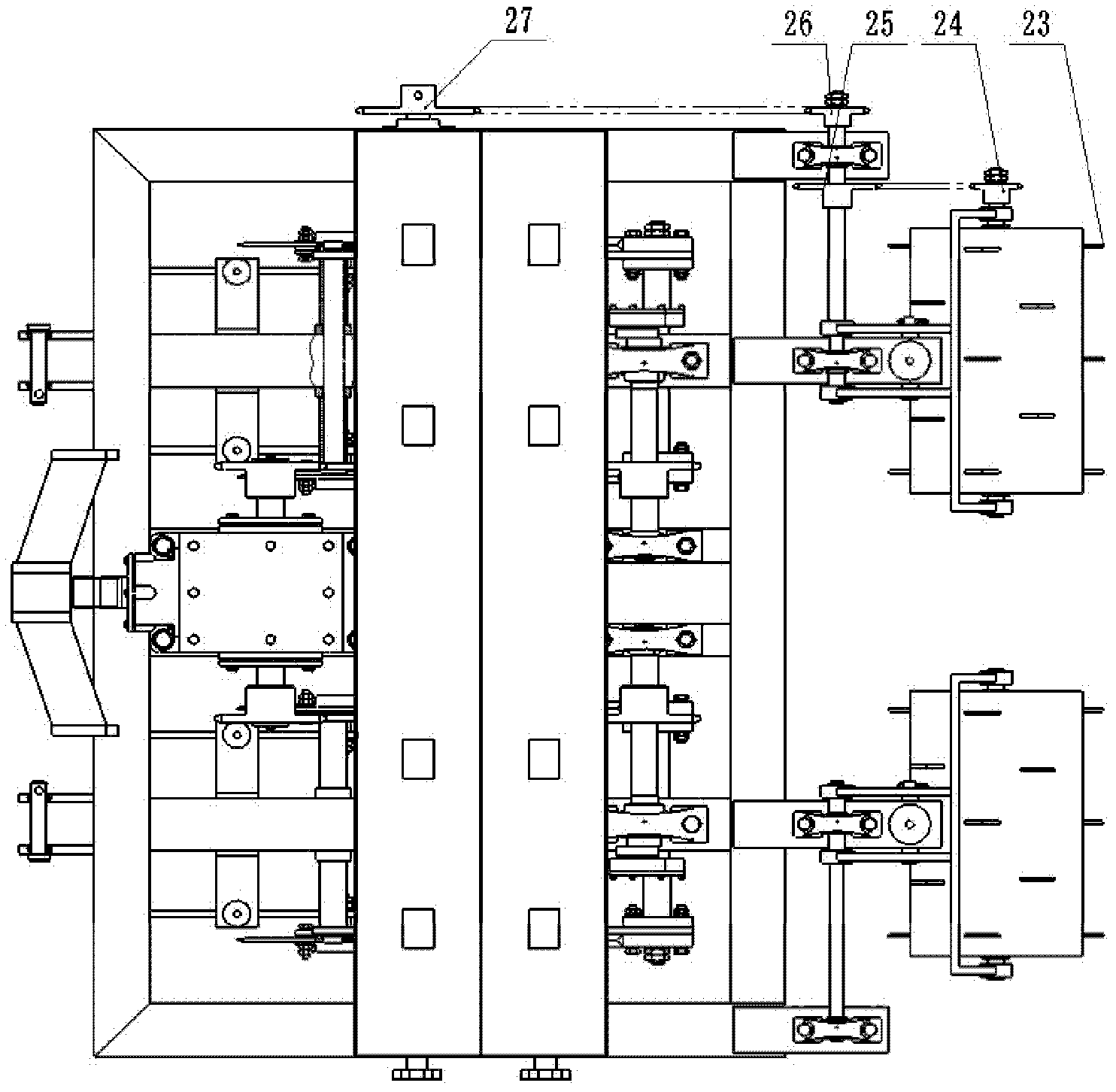

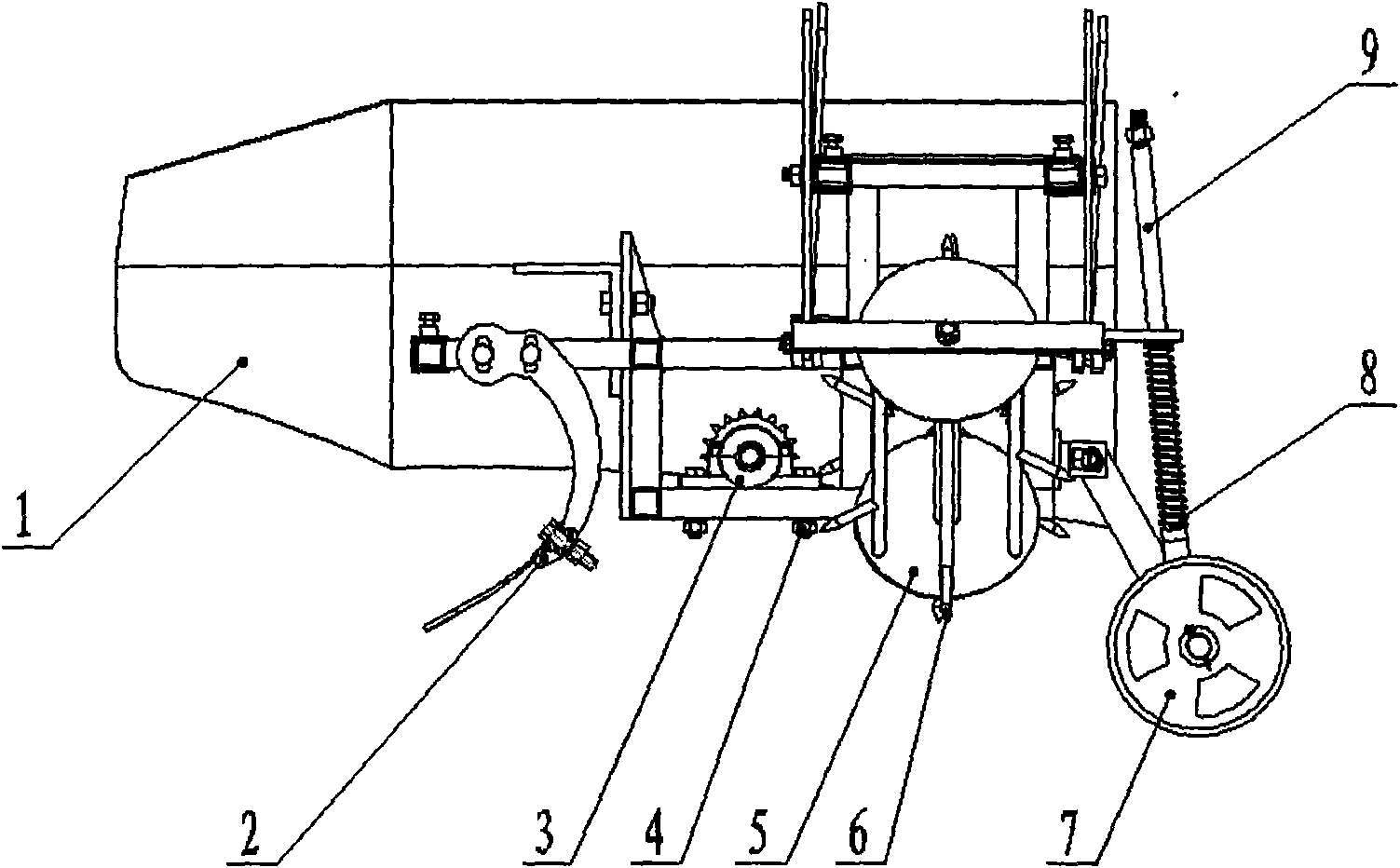

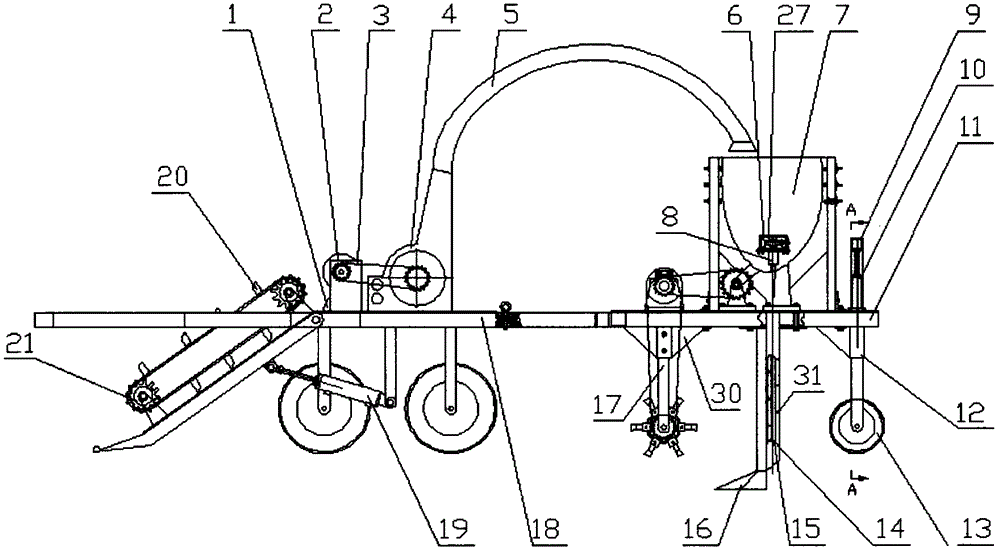

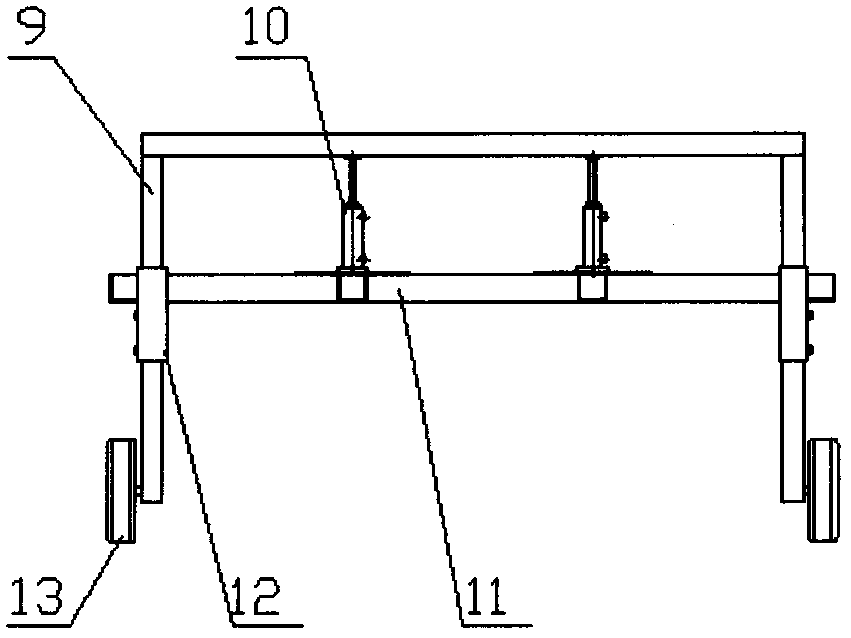

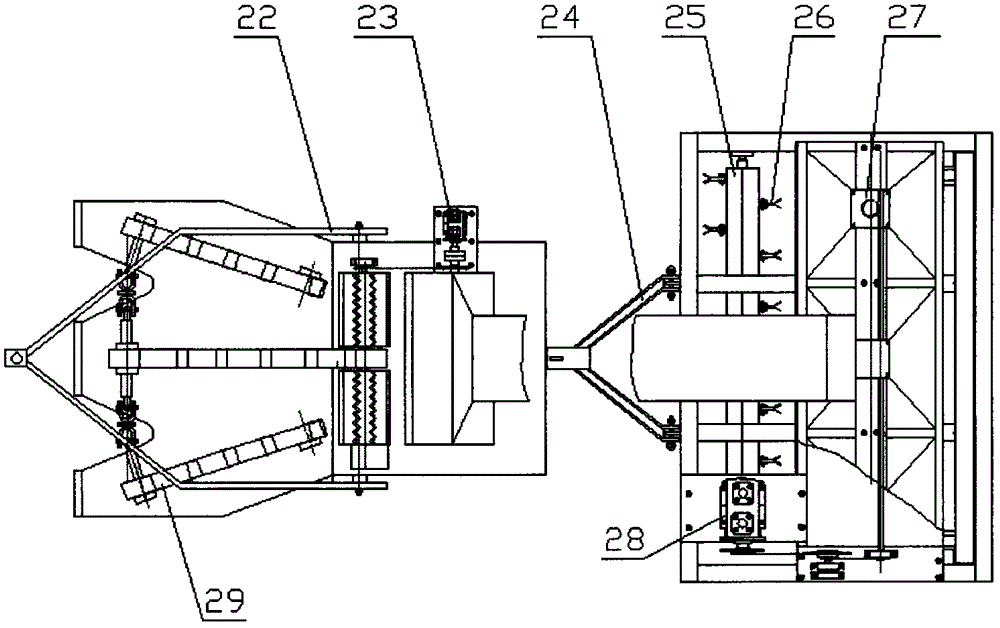

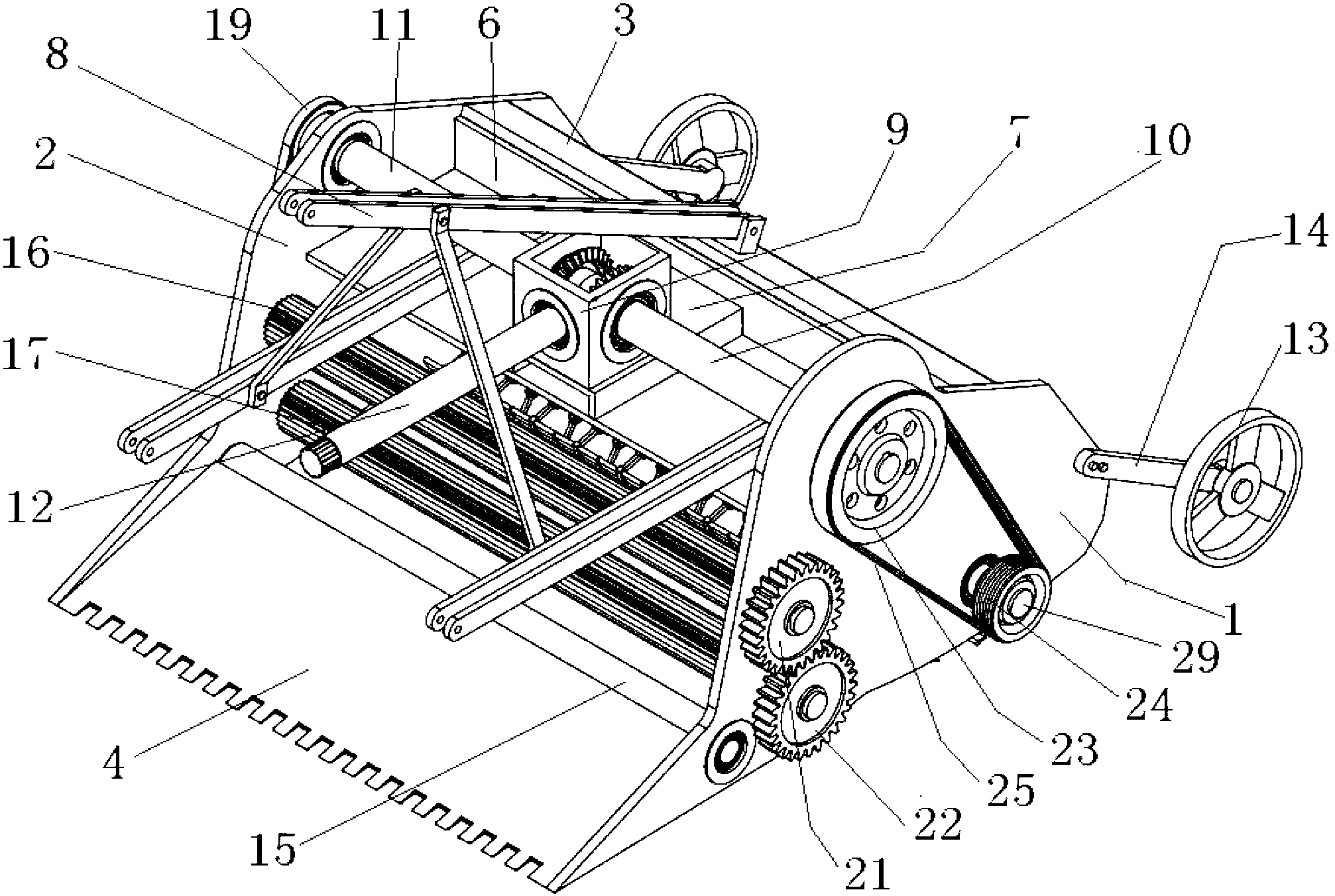

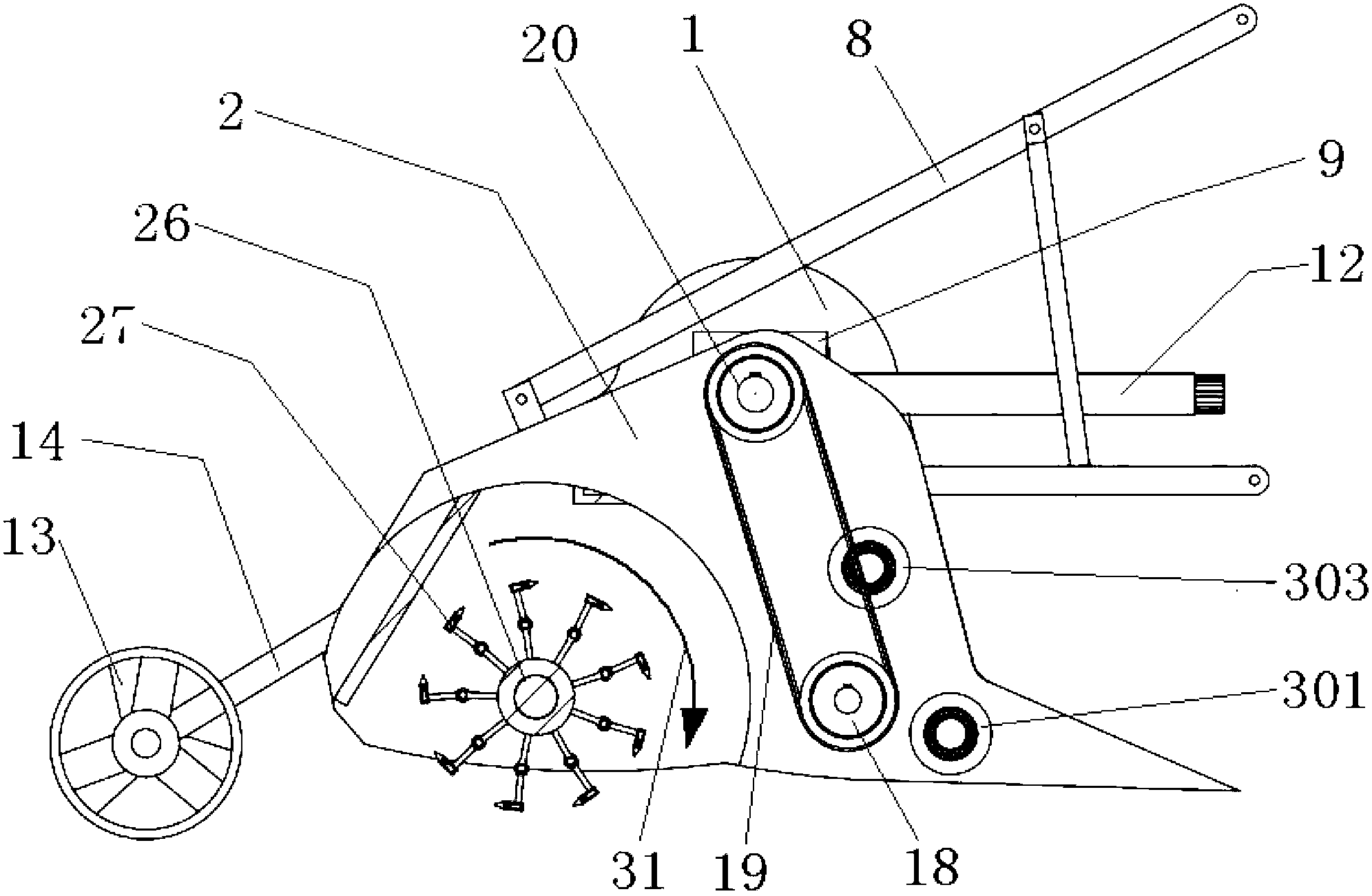

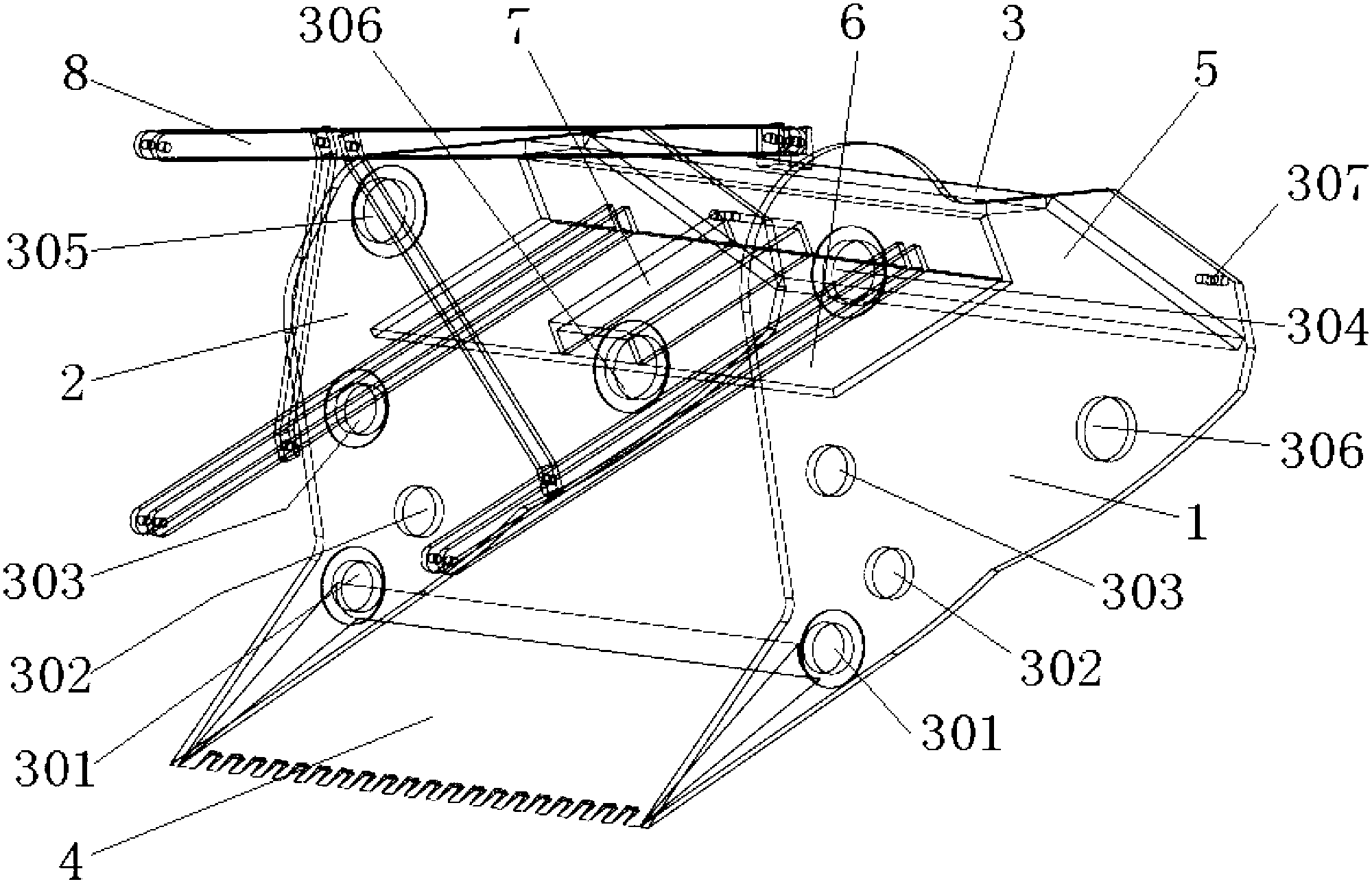

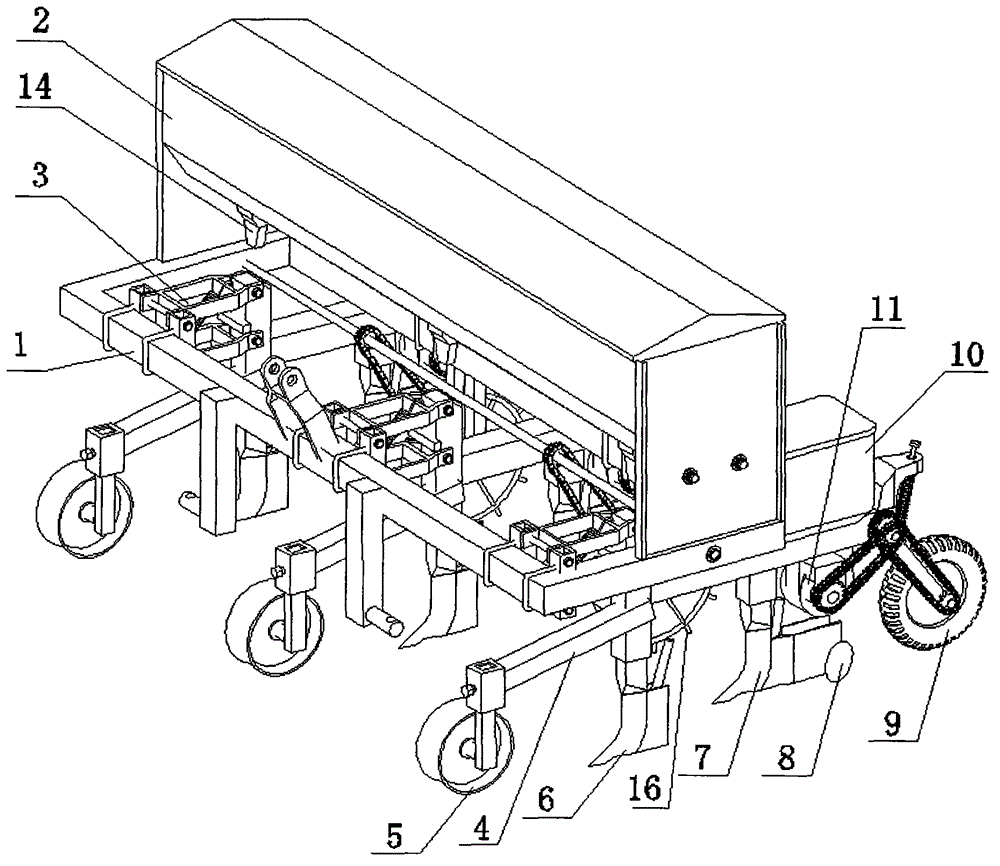

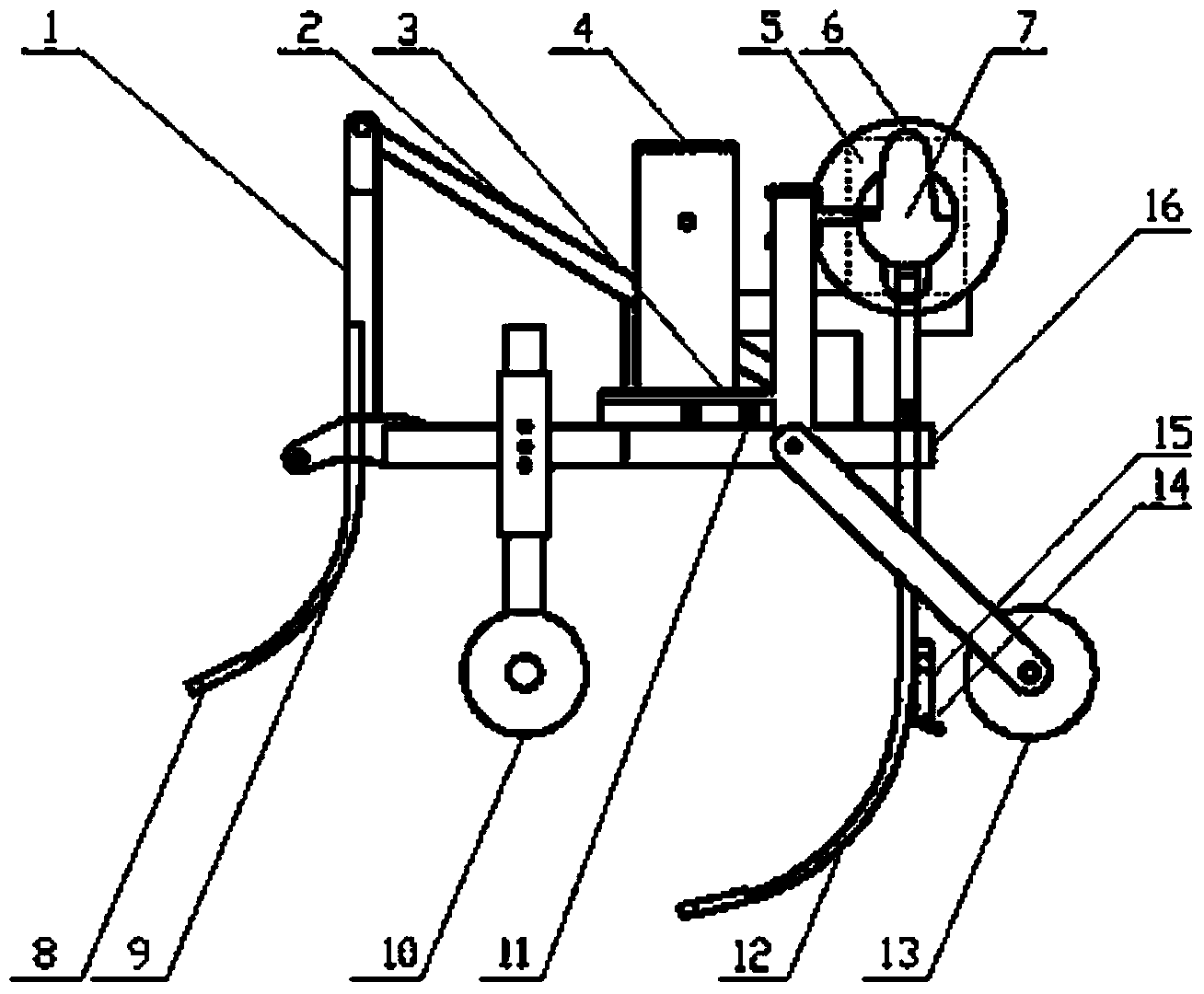

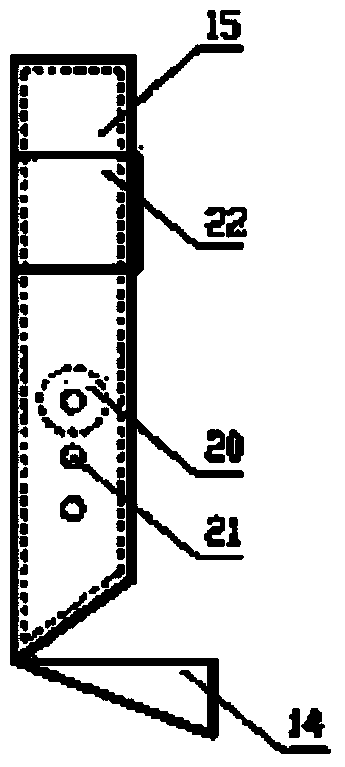

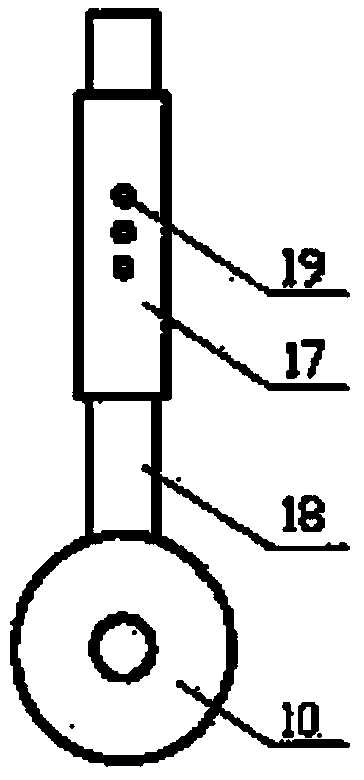

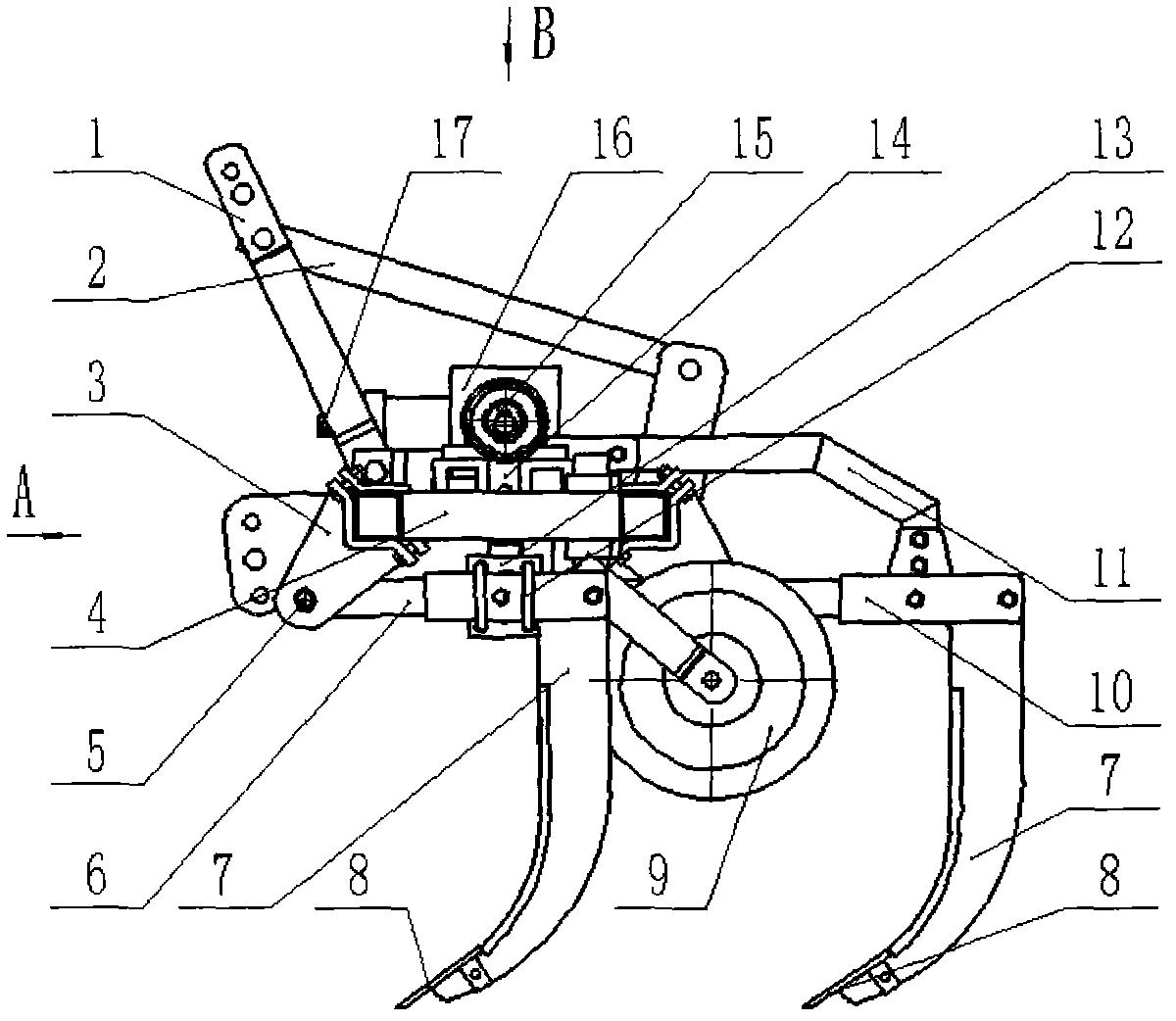

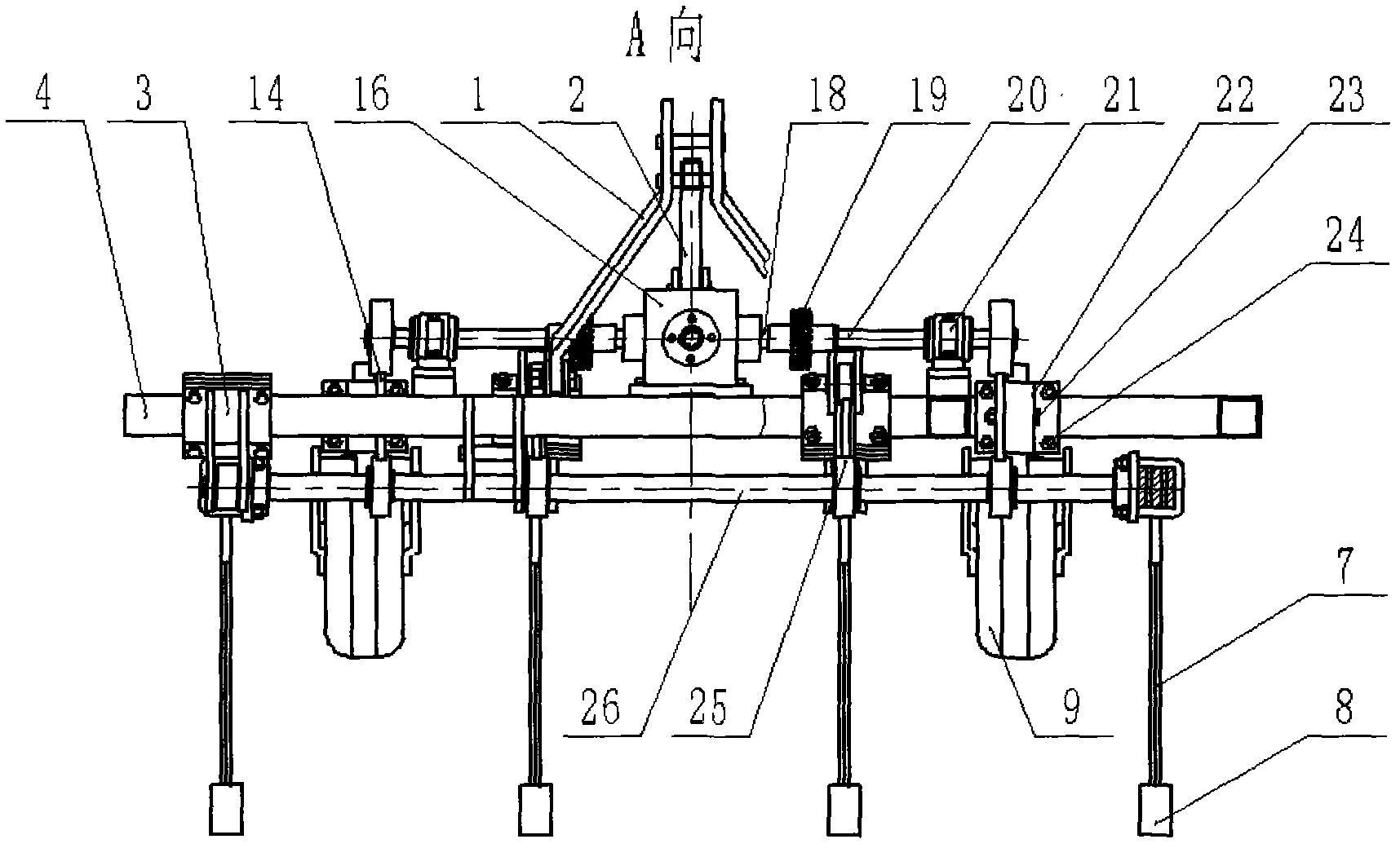

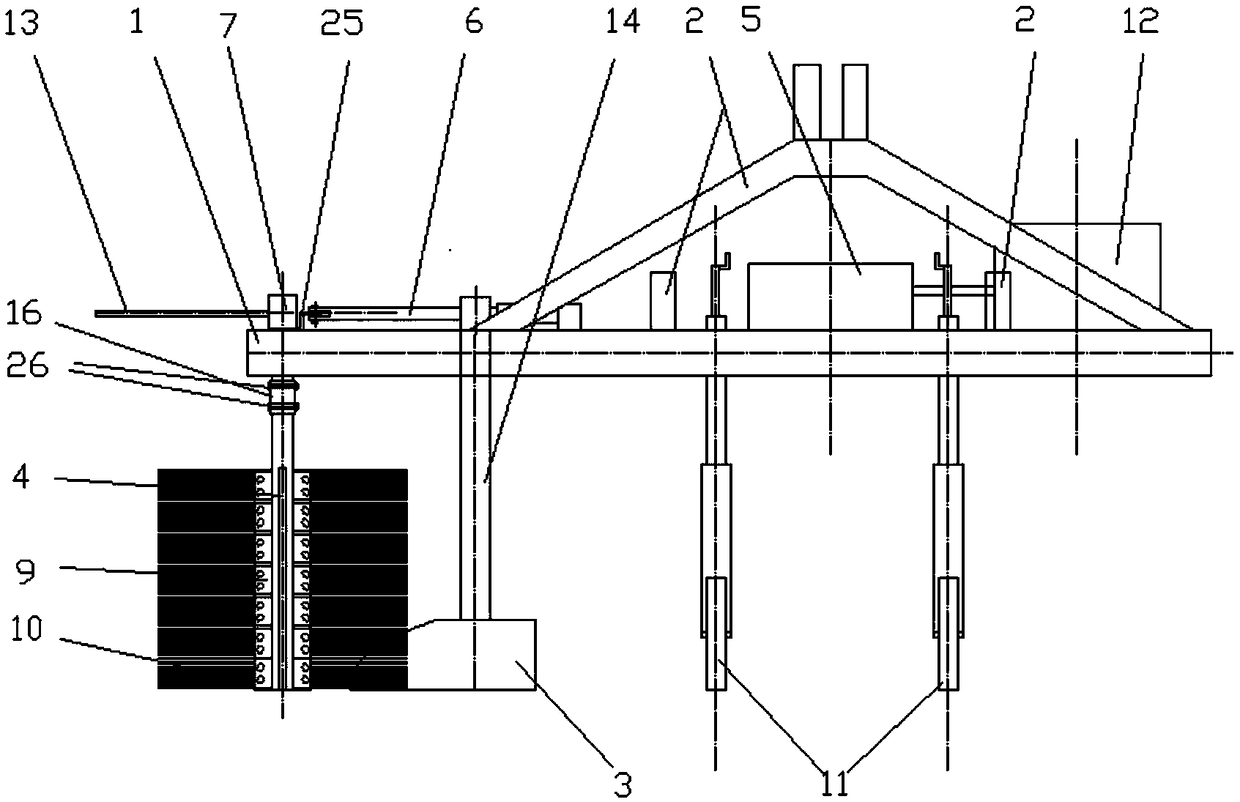

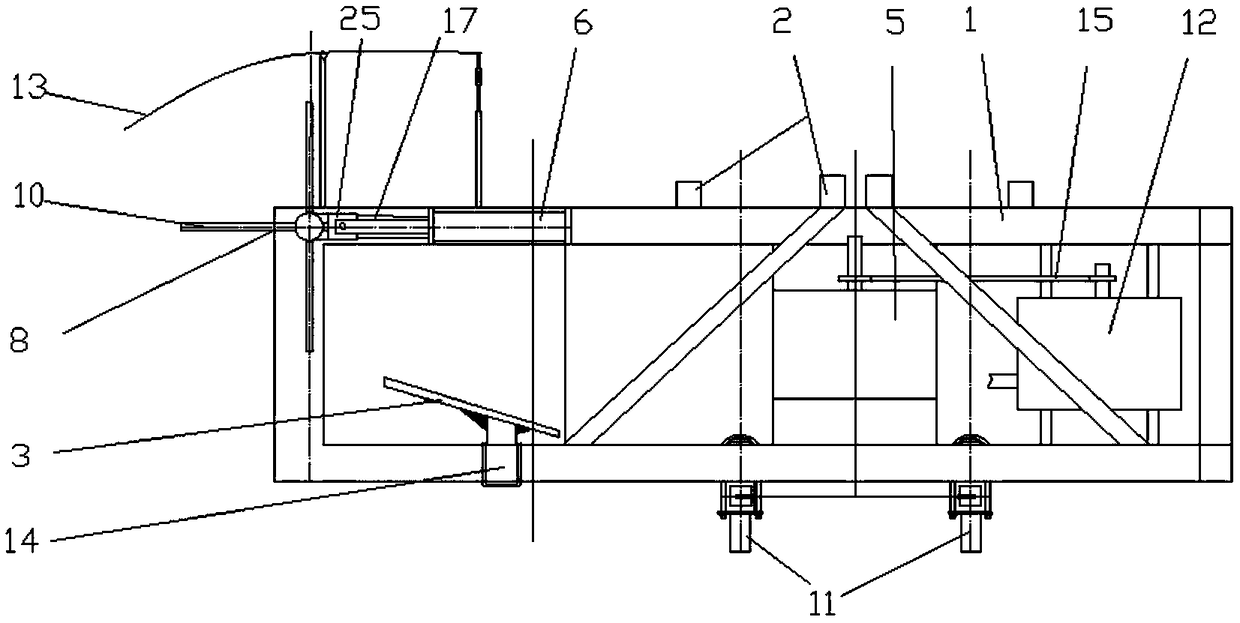

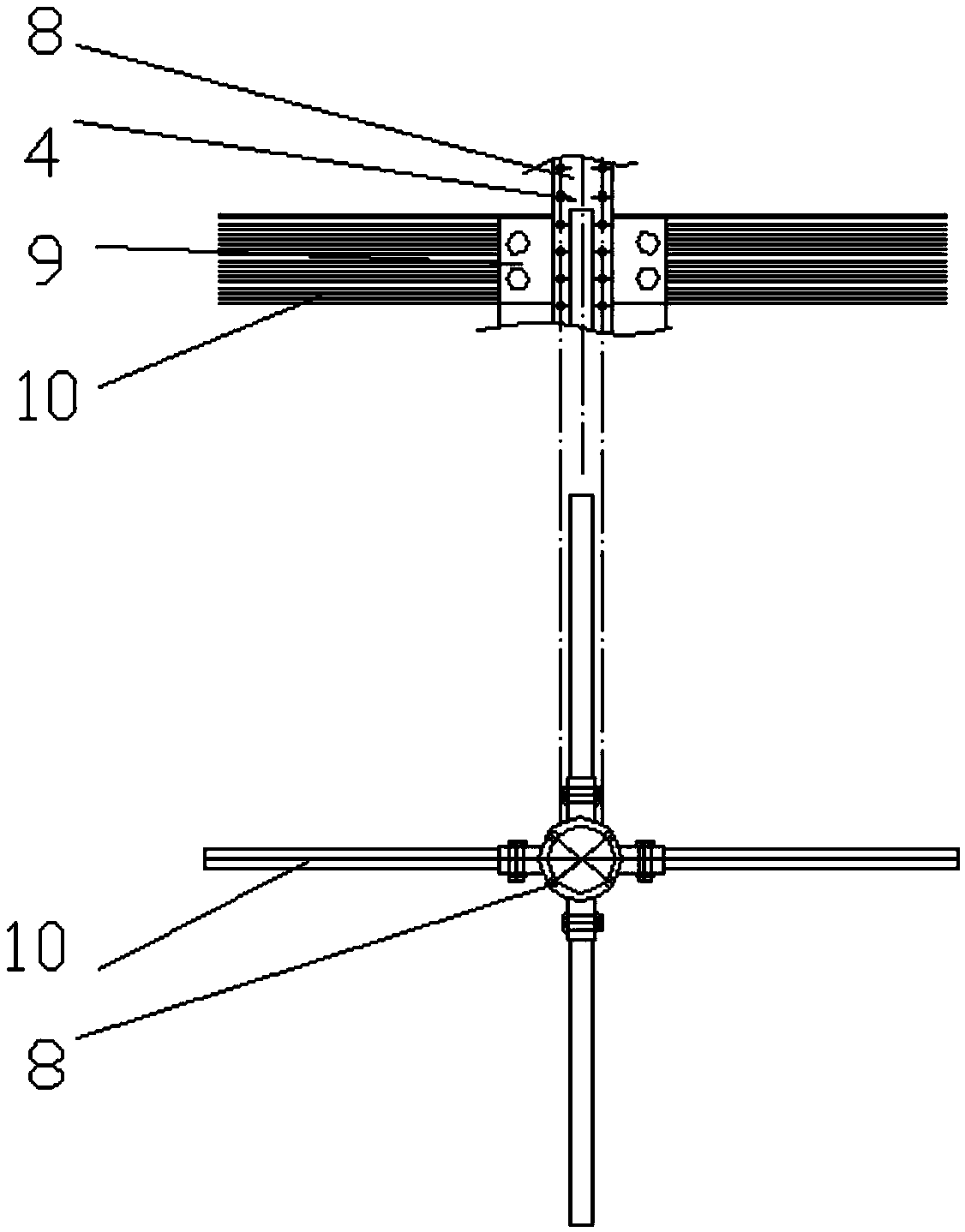

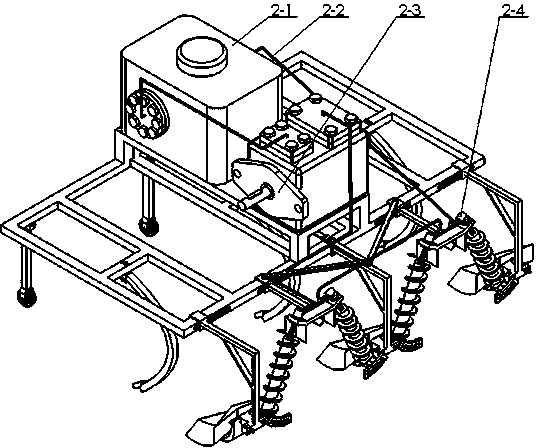

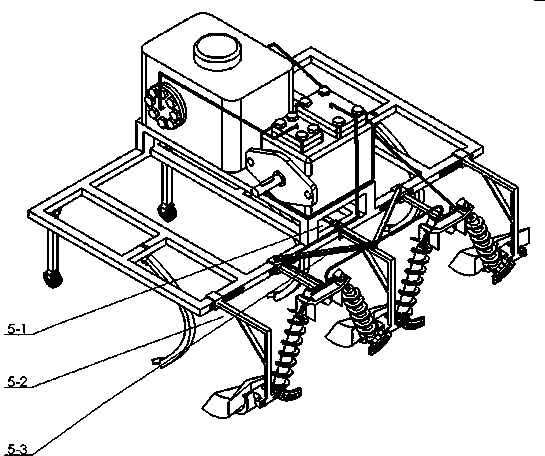

Combined remediation method for deteriorated grasslands and special grassland operating machine

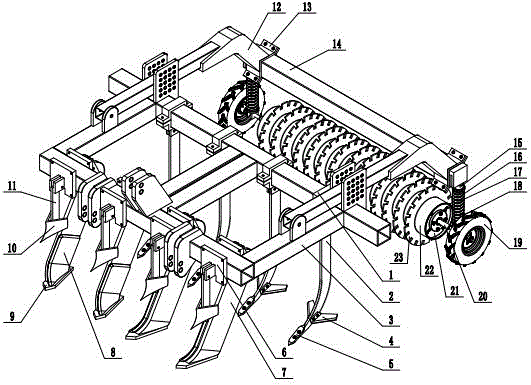

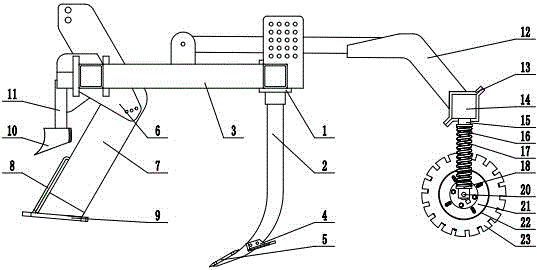

The invention belongs to the technical field of the mechanized remediation of grasslands, and relates to a combined remediation method for deteriorated grasslands and a special grassland operating machine. The method comprises the following steps of: cutting roots of grass on the grasslands to be remediated, and loosening soil underground and forming seed furrows and fertilizer furrows in the soil along cutting joints; sowing and fertilizing alternately, and applying seeds and fertilizers into the corresponding furrows; and compacting the furrows. The special grassland operating machine comprises a cutting assembly, a vibratory soil loosening and furrowing assembly, a seed and fertilizing applying assembly, a compaction assembly and a depth limit assembly. By the combined remediation method and the special grassland operating machine, the root cutting, vibratory soil loosening and furrowing, sowing, fertilizer application and compaction are combined, and multiple remediation modes are combined, so the combined remediation method and the special grassland operating machine are suitable for the sowing for fertilizer application and fertilizing for resowing in the process of remediating the deteriorated grasslands with high compactness and are also applicable to farmlands with poor soil texture, and can better remediate grasslands deteriorated naturally or due to man factor.

Owner:CHINA AGRI UNIV

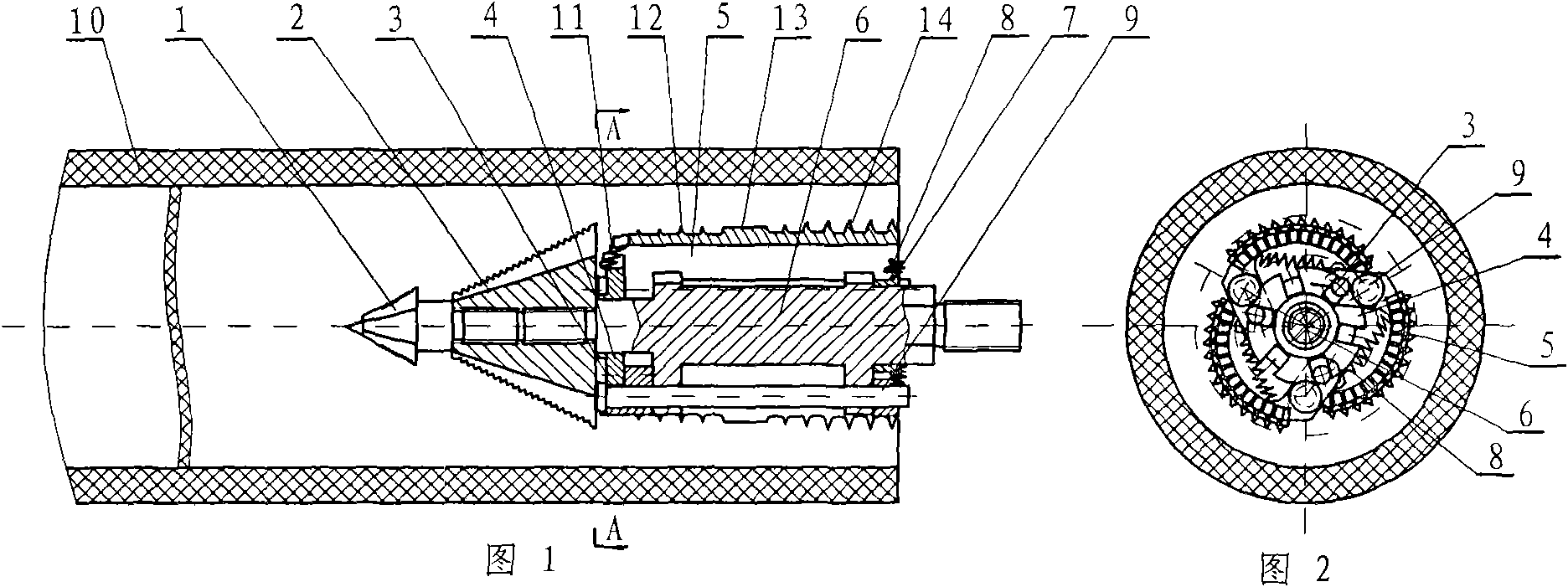

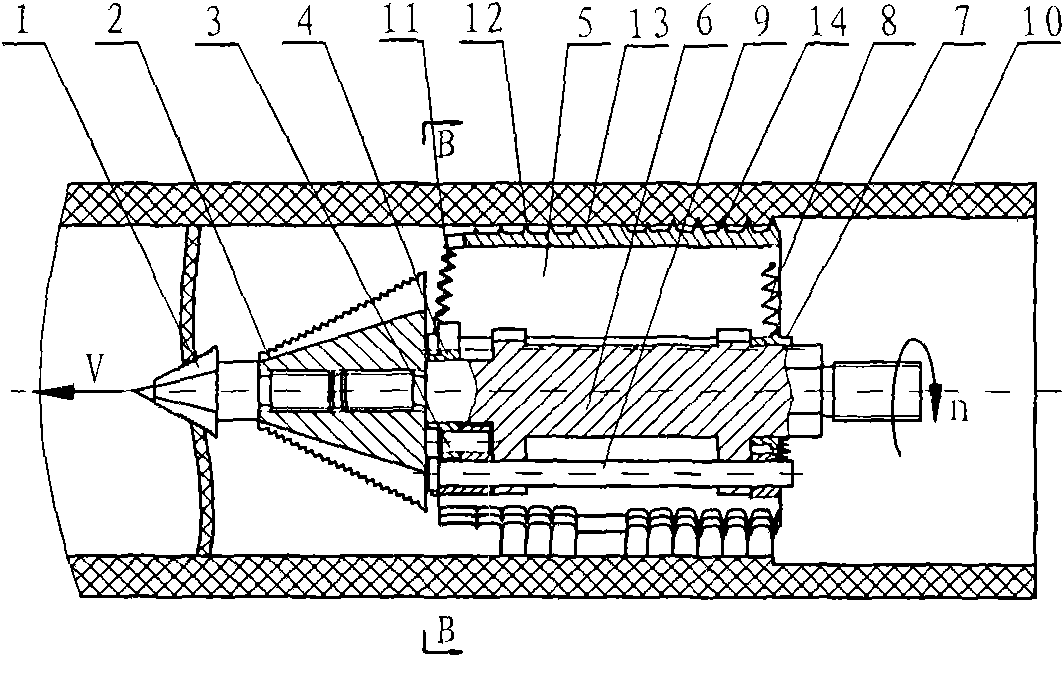

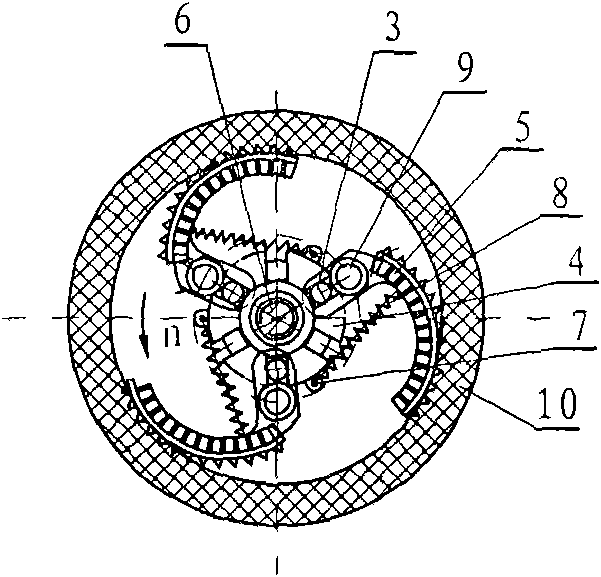

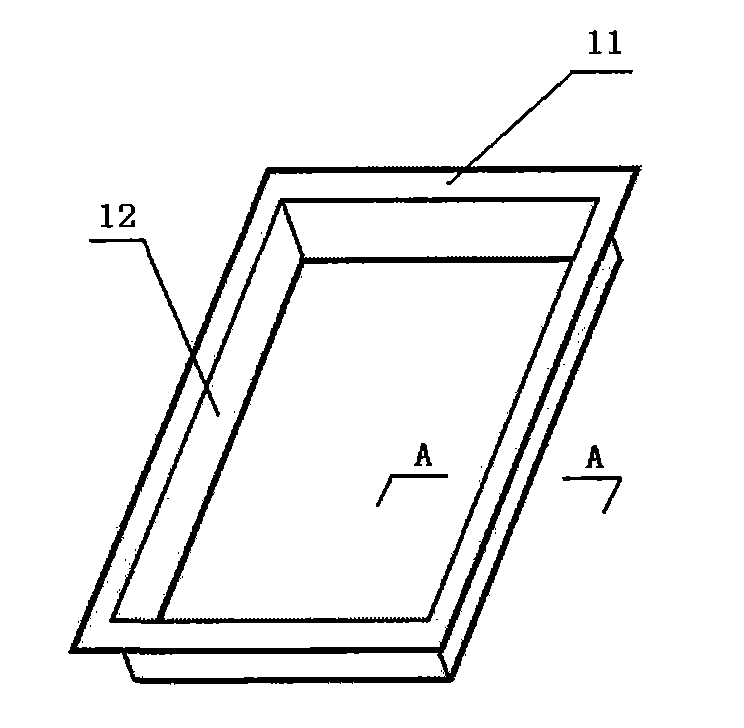

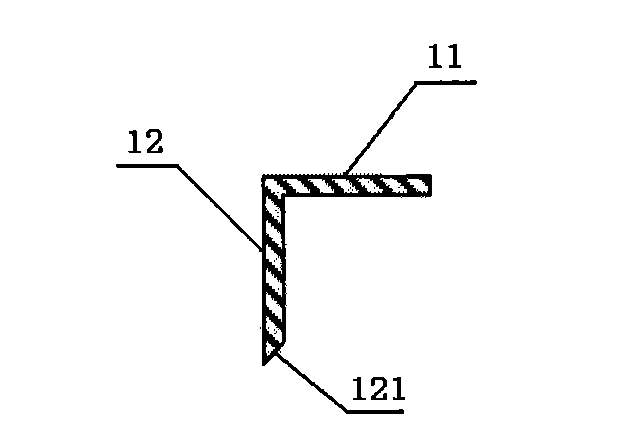

Combined cutting tool for taking inner bamboo joints and tabasheers out of intact bamboo tube

InactiveCN101670601AGuaranteed uniformityImprove cutting efficiencyRotary cutting toolsEngineeringCentrifugal force

The invention discloses a combined cutting tool for taking inner bamboo joints and tabasheer out of an intact bamboo tube. When the combined cutting tool rotates and moves in axial direction, three tabasheer cutting blades 5 synchronously open and cling to the inner wall of the bamboo tube under action of centrifugal force, plural rear cutter teeth 14 on the external curved surface of the tabasheer cutting blades 5 take the tabasheer out, at the same time, the inner bamboo joints are taken out by a small wimble 1, a large wimble 2, an end face tooth 11 on the front end face of the tabasheer cutting blades 5 and the plural front cutter teeth 12 on the external curved surface thereof; a section of depth limiting face 13 without cutter teeth is arranged in the middle of the external curved surface of the tabasheer cutting blades 5 and is used for limiting the depth of tabasheer cutting; each tabasheer cutting blade is provided with a synchronizing pin 3; the synchronizing pin 3 can slidein the radial groove of a synchronizing grooved pulley 4, thus ensuring that the three tabasheer cutting blades 5 can synchronously open under action of centrifugal force and can synchronously retractunder action of a resetting spring 8.

Owner:NANJING FORESTRY UNIV

Soil layering scraping sampler

InactiveCN101832883APrecise control of layer thicknessAvoid squeezingWithdrawing sample devicesComputer scienceDepth limit

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

Golf green repair device method and apparatus

Owner:GREENFIX GOLF

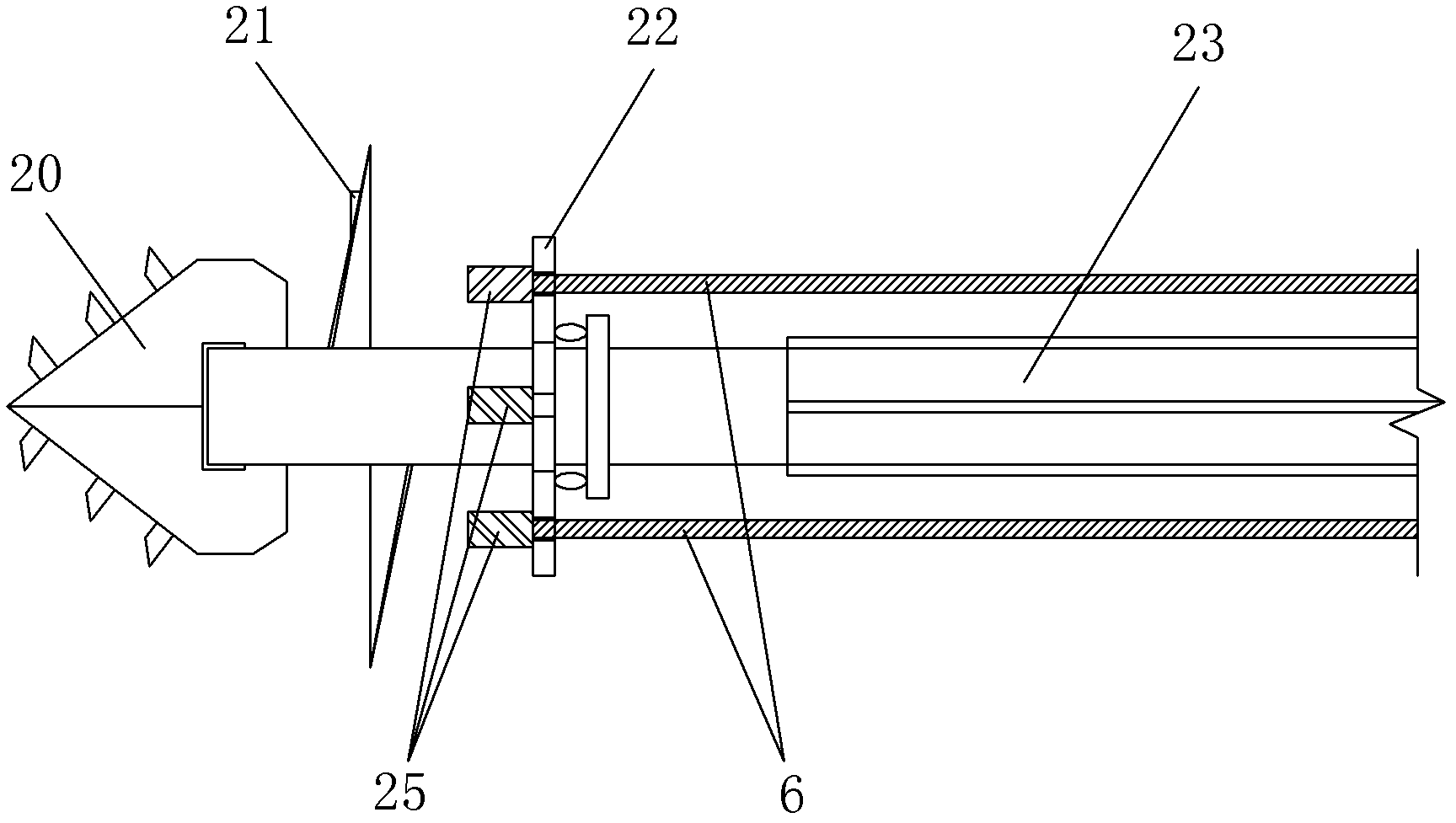

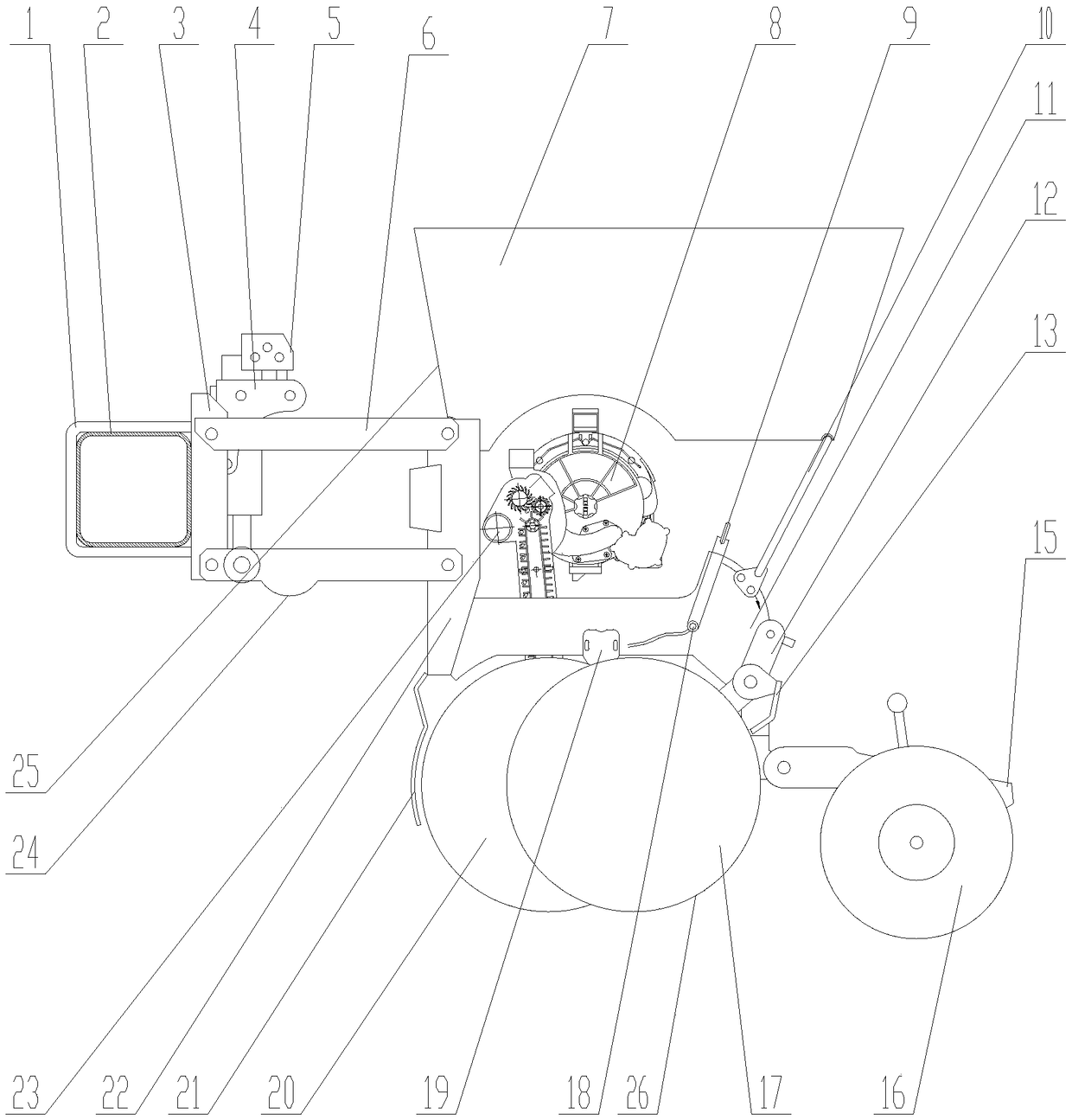

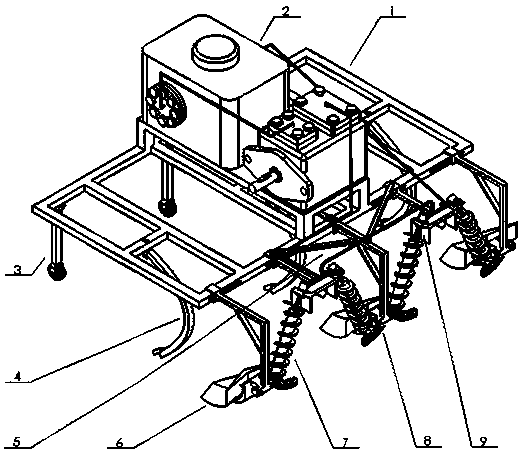

Mini type mulching film recovery machine of tobacco in seedling stage

InactiveCN101658087ASolve the problem of working at a height that cannot enter the groundSolve the problem of profiling and picking filmGatherer machinesDrive wheelGear wheel

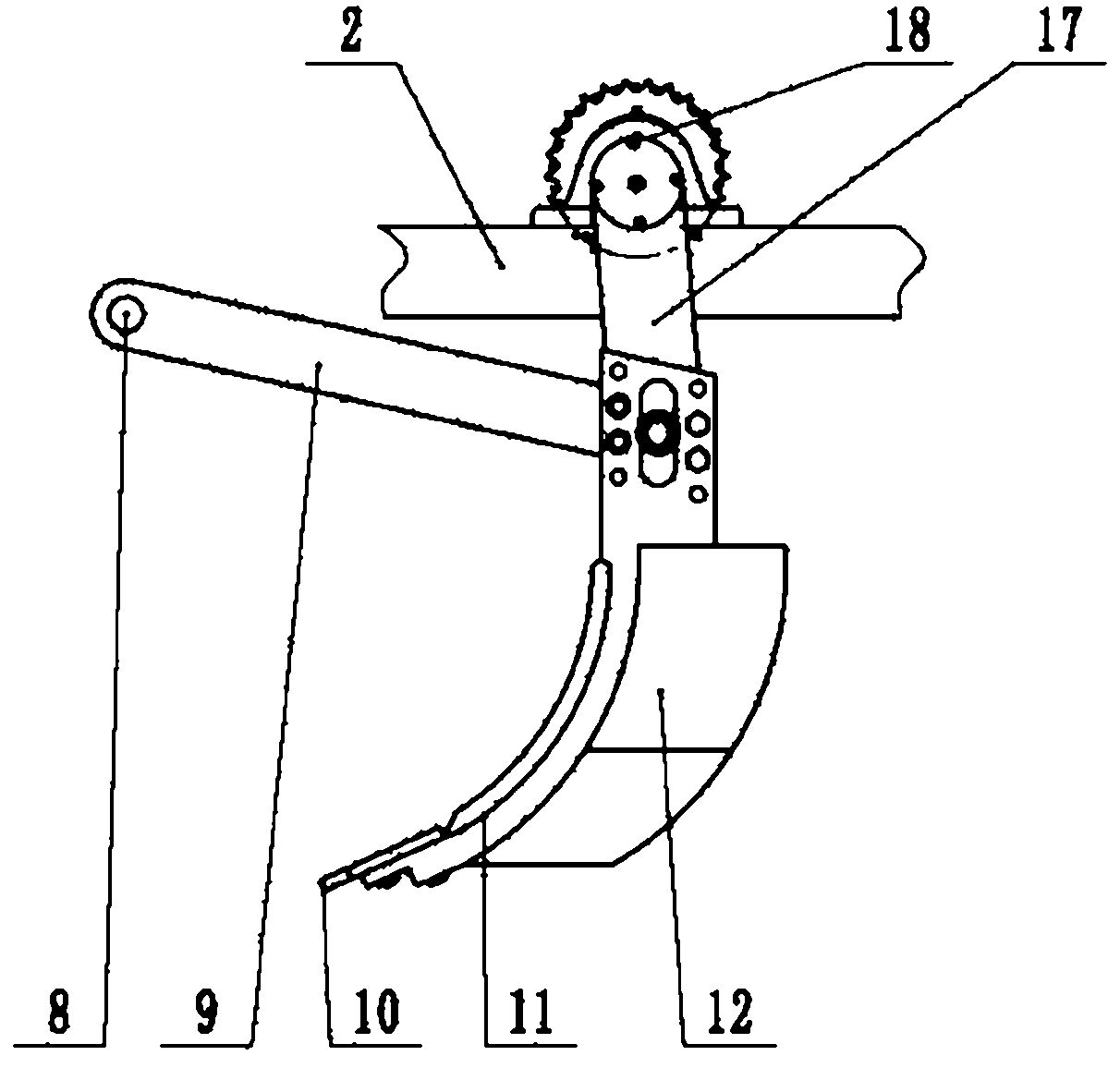

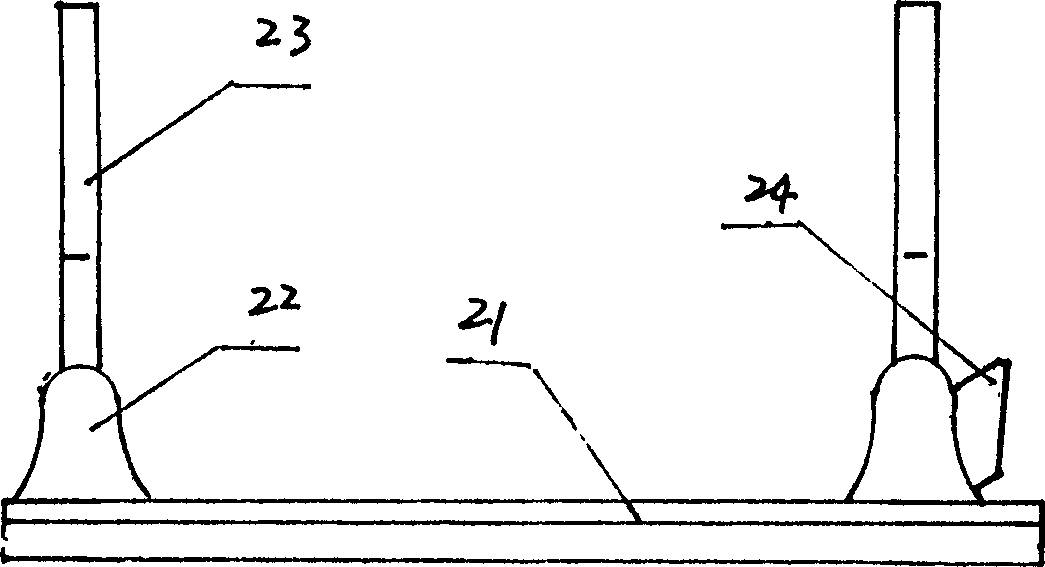

The invention relates to a mini type mulching film recovery machine of tobacco in seedling stage, which mainly comprises a seedling protective plate (1), a depth limiting land wheel (7), a break shovel (2), a stander (11), a large chain wheel (13), a small chain wheel (17), a gear wheel (18), a pinion (22), a film rolling roll (15), a universal joint (16), a position horizontal adjusting rod (20)of the film rolling roll and an angle vertical adjusting rod (25) of the film rolling roll. The gear wheel (18) and the pinion (22) are meshed to make the film rolling roll (15) and a driving wheel toreversely rotate to roll the film, so earth rolling is avoided; the inclined angle of the film rolling roll (15) can be adjusted by the universal joint (16), the angle vertical adjusting rod (25) ofthe film rolling roll and the position horizontal adjusting rod (20) of the film rolling roll according to the inclined angle of a tobacco ribbing surface; and the film rolling roll (15) is always well attached to the inclined plane of tobacco ribbing by the depth limiting land wheel (7) under the action of a depth limiting spring (8). The small tobacco seedling stage mulching recovery machine isused for recovering mulching films of seedling-stage tobacco planted in ridge culture, belongs to field tending machinery and is also suitable for recovering mulching films of cotton and other flat planting crops.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Depth limiting device for a boring tool

InactiveUS8876444B1Preventing work-piece from being marredPrevent rotationThread cutting toolsDrilling/boring measurement devicesEngineeringScrew thread

A depth limiting device for a boring tool having stop collar includes housing and a sleeve. The housing provides snap on attachment onto the stop collar, allowing for a free axial rotation of the said housing around the body of the stop collar. The housing and the sleeve have a threaded engagement for adjusting position relative to one another and thereby adjusting length of the working portion of boring tool. Coupled housing and sleeve are freely rotatable with respect to the body of the stop collar and cease to rotate when operator achieves desirable depth of drilling and the device is pressed against the work-piece surface. The structural interrelationship prevents marring of the surface of the work-piece.

Owner:CHANTURIDZE BESARION

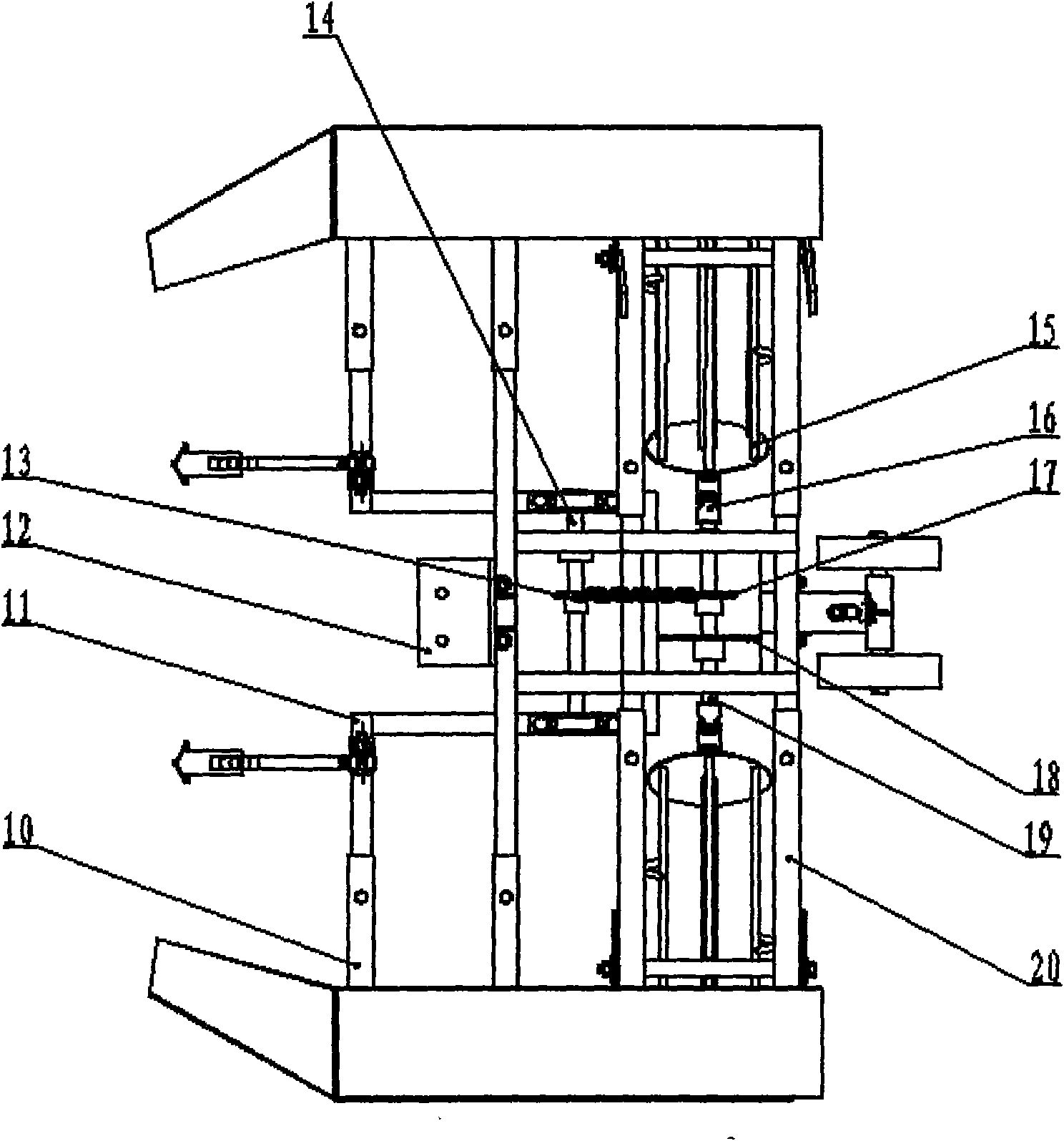

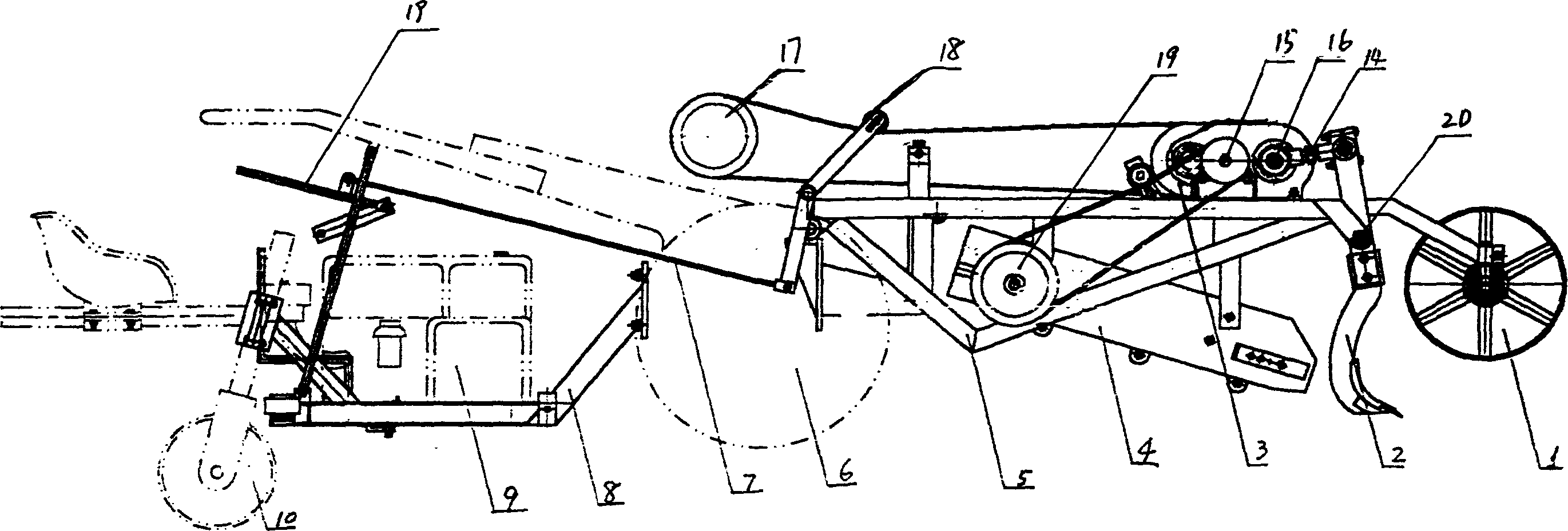

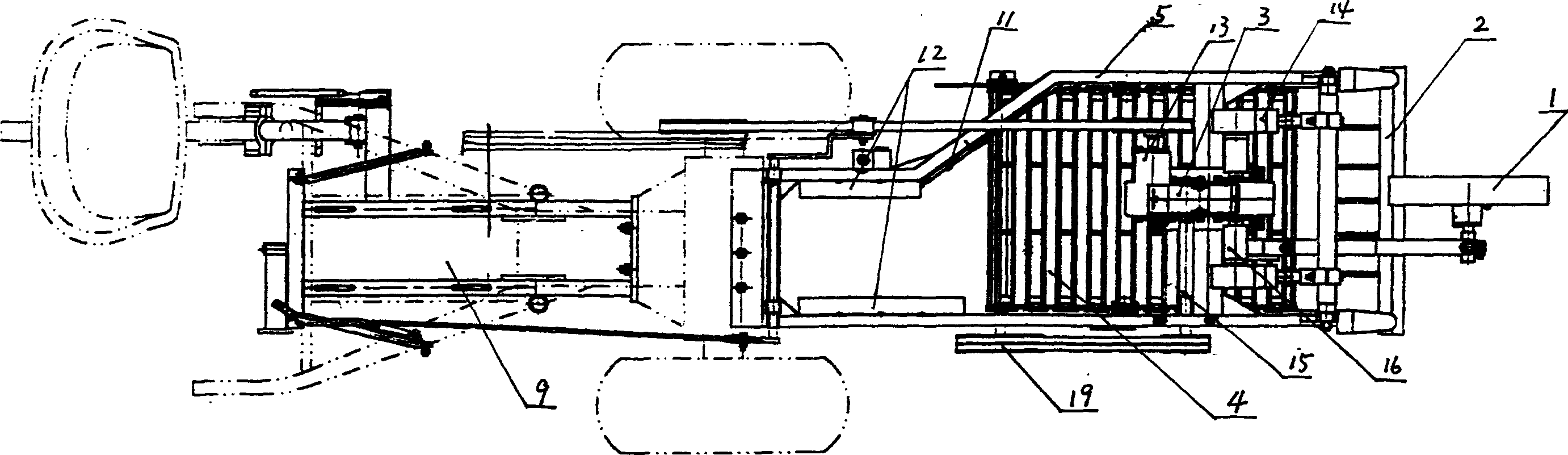

Maize straw three-dimensional returning machine

InactiveCN105210571AGood physical propertiesImprove fertilityLoadersCrop conditionersControl systemAgricultural engineering

The invention relates to a maize straw three-dimensional returning machine which mainly comprises a front frame, a rear frame, a straw picking device, a straw feeding device, a straw crusher, a stubble cleaning mechanism, a straw deep placement device, a hydraulic control depth-limiting mechanism, a front motor, a rear motor, a hydraulic control system assembly and the like. The straw picking device is assembled at the front end of the front frame, the straw feeding device is assembled on the front part of the front frame, the straw crusher is assembled in the rear part of the front frame, the stubble cleaning mechanism is assembled below the front part of the rear frame, the straw deep placement device is assembled in the middle part of the rear frame, the hydraulic control depth-limiting mechanism is assembled in the rear part of the rear frame, the front motor is arranged on the front frame, the rear motor is arranged on the rear frame, and power is provided to the pre-posed motor and the post-posed motor by a hydraulic output system of a tractor. The maize straw three-dimensional returning machine during work is pulled by the tractor, and picks, crushes and deeply places the maize straws in a field as the tractor moves and meanwhile cleans stubbles, so that operations of ground mulching return to field, reclaimed soil return to field and soil deep placement return to field on the maize straws are realized.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Rolling and chopping combined banana straw crushing and returning machine

InactiveCN103229635APromote production increaseImprove crushing effectCrop conditionersMowersEngineeringDepth limit

The invention belongs to the agricultural machinery technical field and relates to a rolling and chopping combined banana straw crushing and returning machine. A feeding device, a rolling and water squeezing device, a chopping device and a depth limiting device are sequentially arranged on a machine frame from the front to the rear; a power transmission device allocates power supplied by a tractor to the rolling and water squeezing device and the chopping device; the tractor draws the rolling and chopping combined banana straw crushing and returning machine through a three-point suspension frame which is fixedly connected to the upper portion of the machine frame; and high speed rotation of a chopped knife drum is employed to drive a hammer claw type chopped knife to chop banana straws after rolling and water squeezing processing in the chopping device. The rolling and chopping combined banana straw crushing and returning machine has the advantages of employing two working procedures namely rolling and water squeezing and hob chopping to directly crush the banana straws in a banana growing field and directly discharge into the field to serve as fertilizers, preventing the environmental pollution, being compact in complete machine structure and good in crushing effect of the banana straws, promoting increase production of bananas and being applicable to crushing and returning operation of the banana straws in main producing areas of the bananas.

Owner:HAINAN UNIVERSITY

Golf green repair device method and apparatus

Owner:GREENFIX GOLF

Depth limiting device and hole forming apparatus containing the same

ActiveUS20060257220A1Promotes and facilitates precise drillingPromotes and facilitates and boringThread cutting toolsDrilling/boring measurement devicesEngineeringMechanical engineering

A depth limiting device includes a stop collar having a an open end portion and an workpiece engaging portion extending along the open end portion thereof for contacting a workpiece; a spindle extending axially through the shell, the spindle including a first end extending from the exterior of the stop collar for attachment to a hole forming apparatus, and an second end interior to the stop collar for attachment to a hole forming bit, wherein the attached hole forming bit projects through the open end portion of the stop collar at a predetermined length corresponding to the desired depth of the hole in the workpiece; and a bearing assembly operatively associated with the stop collar and the spindle for isolating the rotation of the spindle from the stop collar whereby the stop collar ceases to rotate when contacting the workpiece without generating sufficient frictional contact to mar or otherwise damage the workpiece.

Owner:FAR NORTH

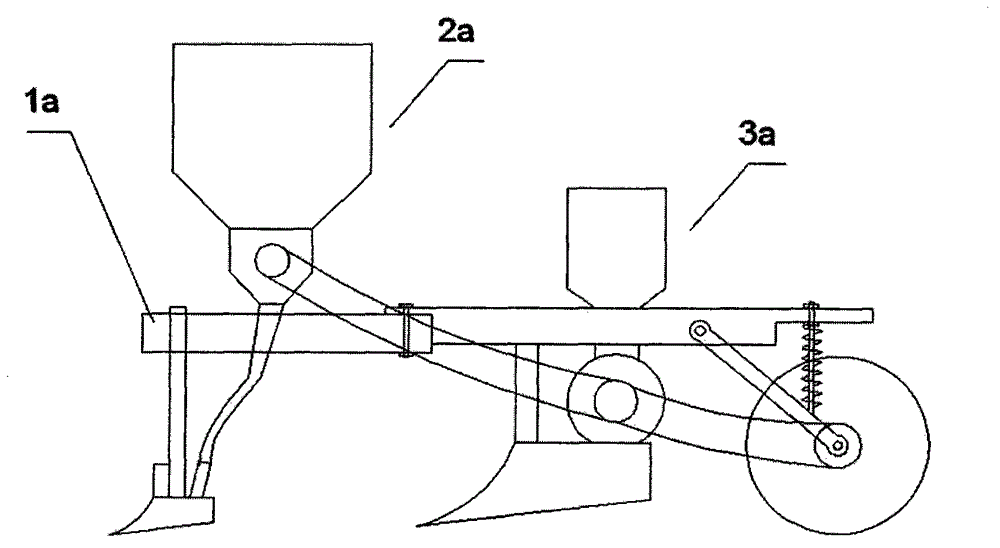

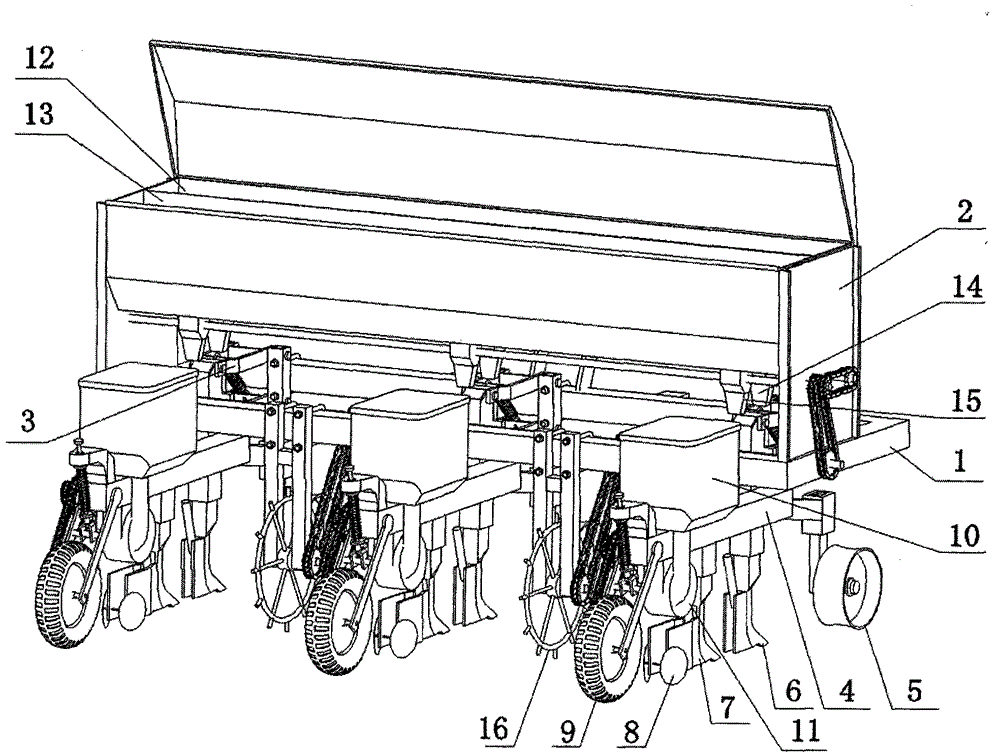

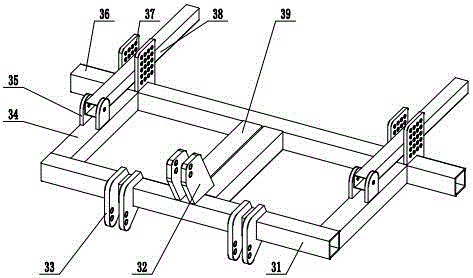

No-tillage profiling precision seeder

InactiveCN102714954AEnsure consistencyPrevent jumpingAgriculture gas emission reductionSeed depositing seeder partsSeederAgricultural engineering

The invention discloses a no-tillage profiling precision seeder, which comprises a main rack. A fertilizer box is arranged on the main frame. A seeding rack is fixedly arranged in each seeding row below the main rack through a profiling four-link mechanism. A depth limiting wheel, a base fertilizer furrow opener, a seed furrow opener, a soil covering device, a compaction wheel, a seed box and a seed feeder are installed on each seeding rack. The internal part of the fertilizer box is divided into a front base fertilizer hopper and a rear seed fertilizer hopper. Base fertilizer feeders and seed fertilizer feeders are arranged at the bottoms of the front base fertilizer hopper and the rear seed fertilizer hopper at positions corresponding to each seeding row. Fertilizer feeding pipes below the base fertilizer feeders are communicated with the base fertilizer furrow openers. Fertilizer feeding pipes below the seed fertilizer feeders are communicated with the seed furrow openers. The no-tillage profiling precision seeder can adapt to and meet the requirements on seeding operation on sloping farmlands or uneven lands, can realize no-tillage precision seeding, and has the characteristics of consistent depth, high operation quality, strong adaptability, few fault and high use safety and reliability.

Owner:赵玉茹

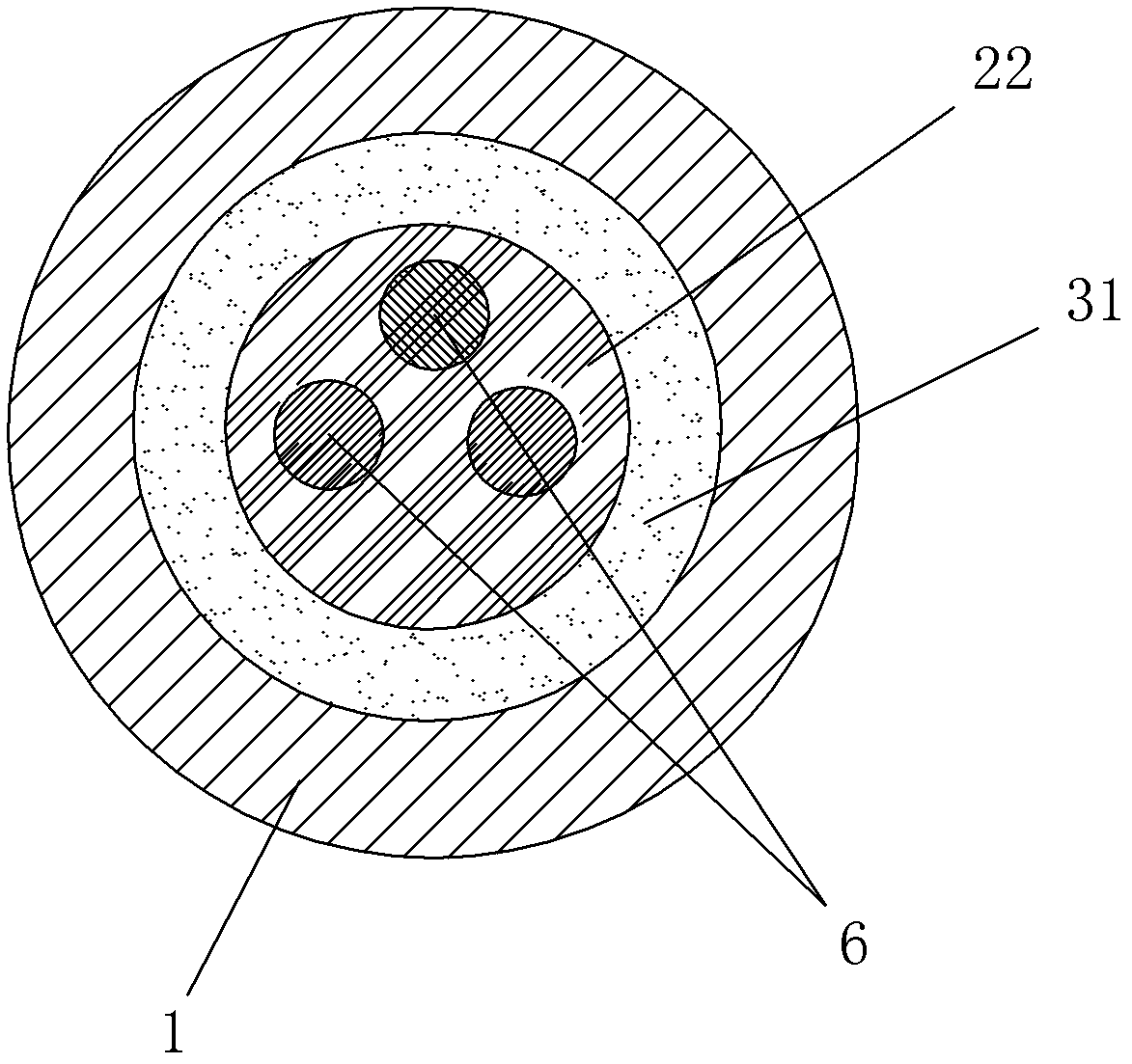

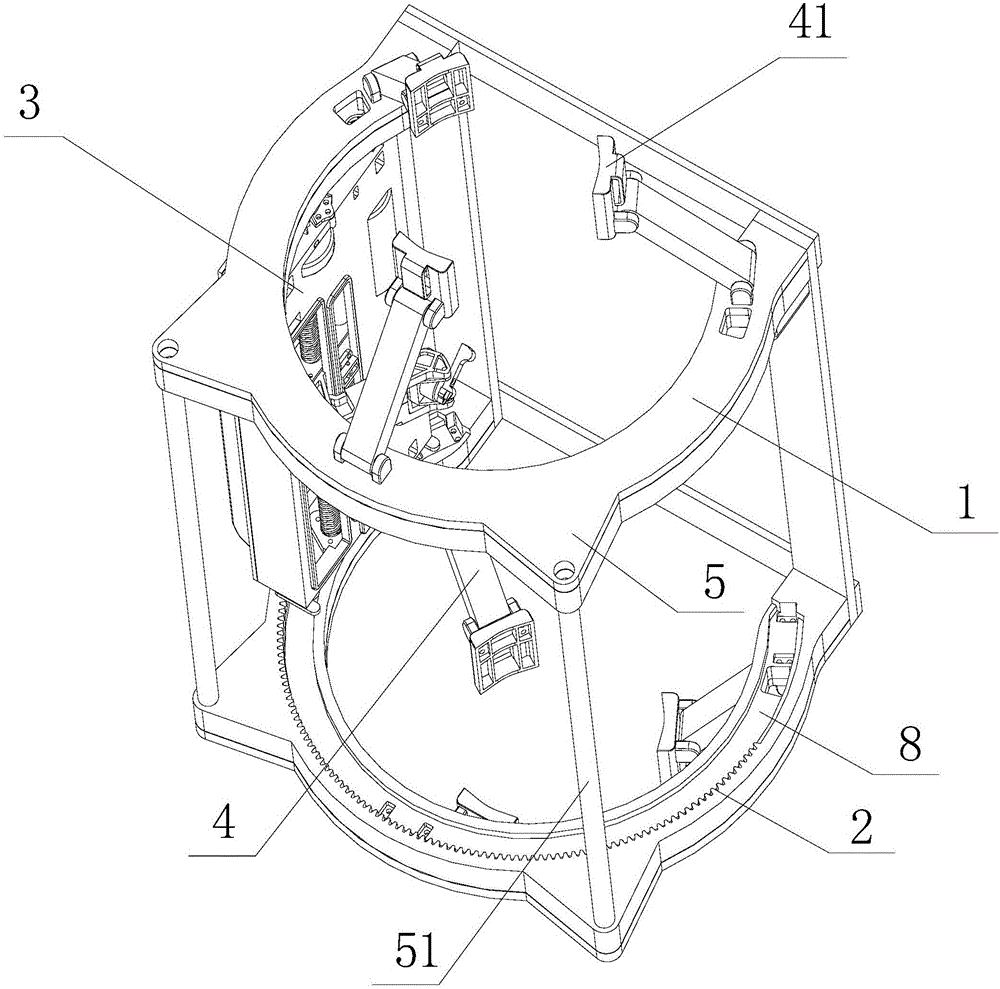

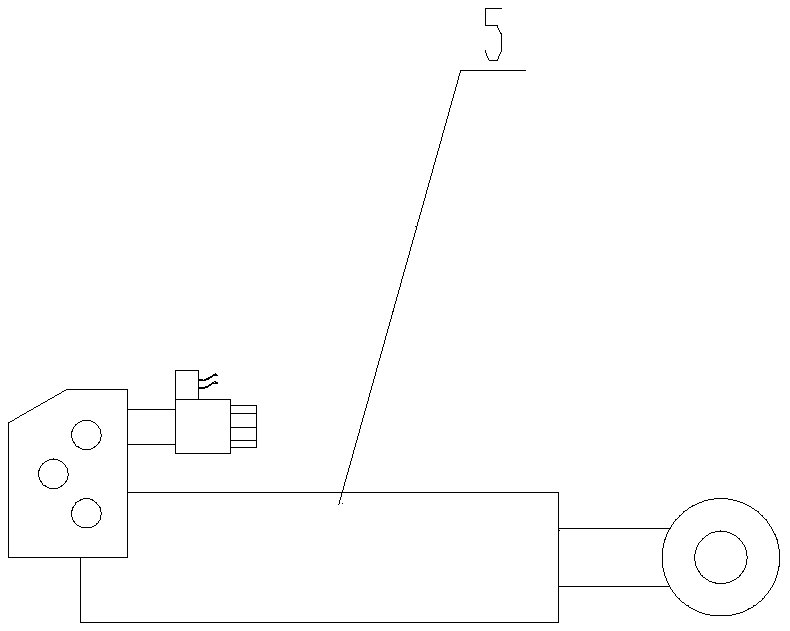

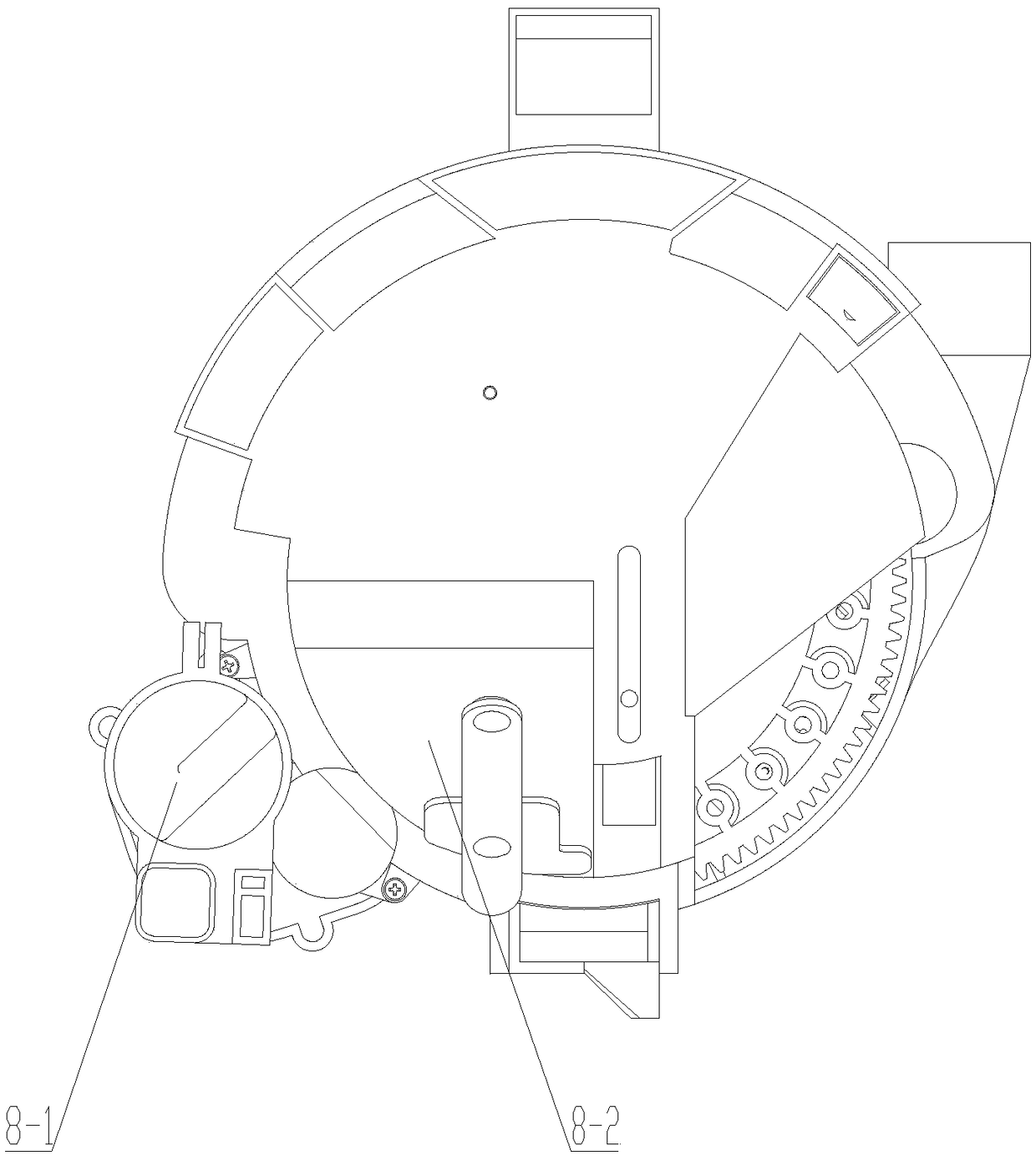

Rubber tapping machine and rubber tapping method

ActiveCN106034978ASolve labor intensitySolve the problem of insufficient fineness of manual tappingForestryEngineeringUltimate tensile strength

The invention discloses a rubber tapping machine and a rubber tapping method. The rubber tapping machine comprises a fixation frame, the top surface and the bottom surface of the fixation frame are respectively provided with annular planet gears in opposite arrangement, a knife rest assembly is installed between the top surface and the bottom surface of the fixation frame, the knife rest assembly is internally provided with a leading screw along a vertical direction, a rubber tapping assembly is installed on the leading screw and can be driven by the leading screw to vertically move along the leading screw, the rubber tapping assembly comprises a knife rest which is installed on the leading screw and can move vertically along the leading screw, one side of a cutter head swing arm is hinged to the knife rest through a torsion spring, the other side is hinged to a swing seat, the swing seat is provided with a cutter head angle adjustment seat, the top end of the cutter head angle adjustment seat is provided with a cutter head and a knife depth limiting member, and the knife rest is also provided with a knife collecting assembly which can overcome an elastic force of the torsion spring to draw the cutter head swing arm to the knife rest. The rubber tapping machine disclosed by the invention replaces labor with automatic machinery, realizes unmanned automatic rubber tapping for rubber trees, and solves the problems of large manual rubber tapping labor intensity and low manual rubber tapping precision to the maximum degree.

Owner:NINGBO CIHEVEA TECH CO LTD

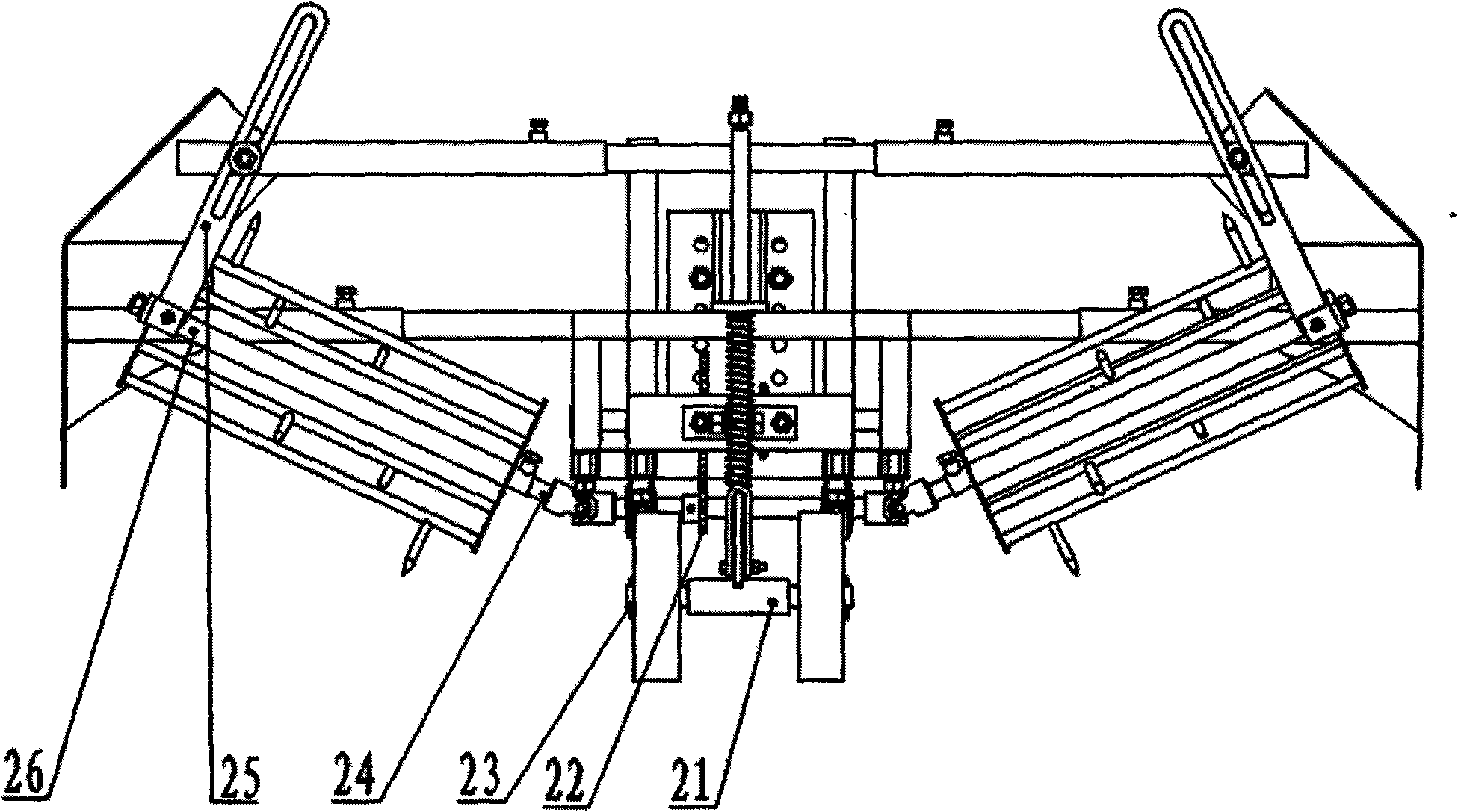

Alternate vibratory subsoiling and fertilizing all-in-one machine

InactiveCN103477741AAchieve loose but not overturned effectFully compactedSpadesPloughsAgricultural engineeringDepth limit

The invention discloses an alternate vibratory subsoiling and fertilizing all-in-one machine, which comprises a vibratory subsoiling device, a depth controller, a fertilizing device and a traction device, which are arranged on a rack; the traction device comprises a hanging support, the hanging support is arranged on the middle part of the front end part of the rack, a subsoiler of the vibratory subsoiling device comprises a half subsoiler, a full subsoiler and an alternate vibration generating device, the alternate vibration generating device comprises a plurality of groups of crank necks arranged on a rotating shaft at intervals, the back side of the full subsoiler is provided with a vertical fertilizer discharge pipe, the fertilizing device comprises a fertilizer box, a fertilizer outlet of the fertilizer box is connected with an inlet of the fertilizer discharge pipe through a hose, the depth controller is depth-adjustable depth-limiting wheels arranged on two sides of the rack, and two sides of the rack behind the depth-limiting wheels are provided with pressing wheels arranged at the hindmost part by virtue of a pull rod respectively. The all-in-one machine disclosed by the invention can be matched with a large / middle-sized tractor for use, dry land vibration subsoiling operation can be carried out, the production efficiency is high, the subsoiling effect is good, and the operation cost is low.

Owner:ANHUI AGRICULTURAL UNIVERSITY

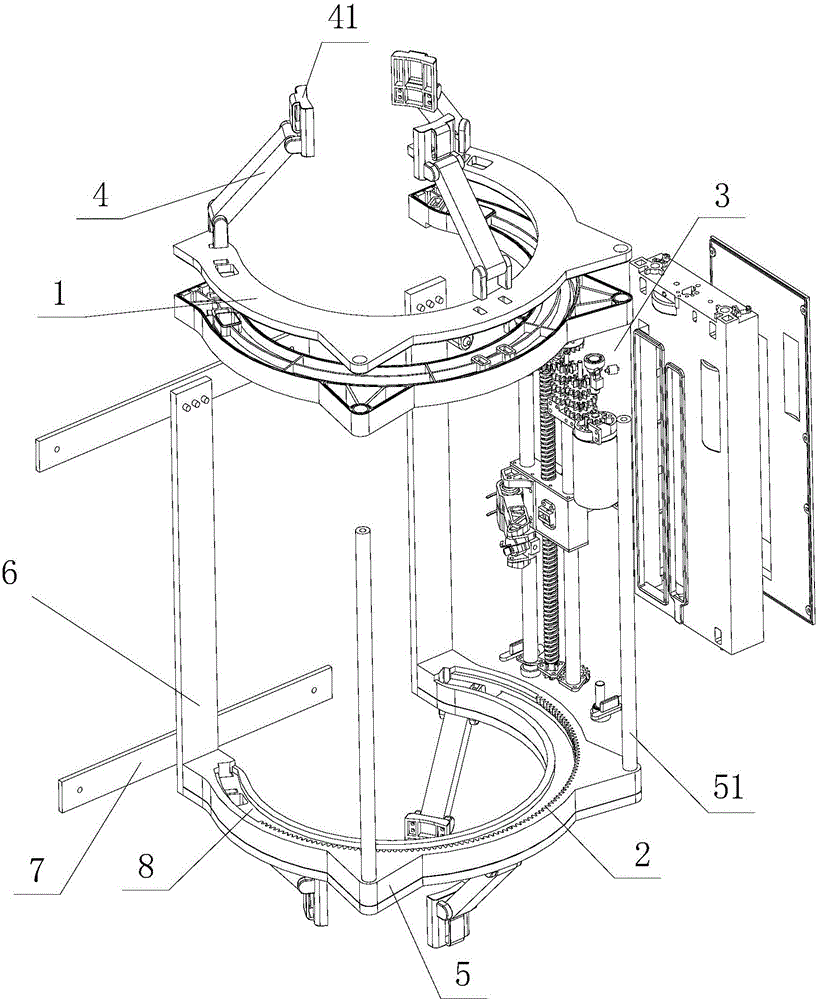

Dual-row reverse-vibration subsoiler

InactiveCN102626007AReduced drag drag peaksReduce vibration intensityAgricultural machinesPloughsTransmitted powerAgricultural engineering

The invention discloses a dual-row reverse-vibration subsoiler, belonging to the field of agricultural machinery. The dual-row reverse-vibration subsoiler comprises a transmission system, a vibration subsoiling device, a supporting and depth-limiting device, a suspension frame and a frame, wherein the transmission system is arranged at the upper front side of the frame and used for transmitting power to the vibration subsoiling device via a power output shaft of a tractor; the vibration subsoiling device is arranged below the frame; the supporting and depth-limiting device is arranged at two sides of the rear part of the frame; and the suspension frame is arranged in the front part of the frame and connected with a suspension device of the tractor. According to the vibration mechanism disclosed by the invention, a structure with eccentric wheels arranged symmetrically and a connecting rod is adopted, and subsoiling shovels in the front row and the rear row are driven by the same transverse shaft to realize reverse vibration; and the two rows of shovels alternatively act forward and backward to loosen soil. Compared with the vibrations of all subsoilers in the same direction, the dual-row reverse-vibration subsoiler can be used for reducing peak traction resistance and oil consumption of the tractor and reducing vibration transferred to the frame and the tractor, and is suitable for subsoiling, land preparation and medium cultivation of soil.

Owner:HENAN POLYTECHNIC UNIV

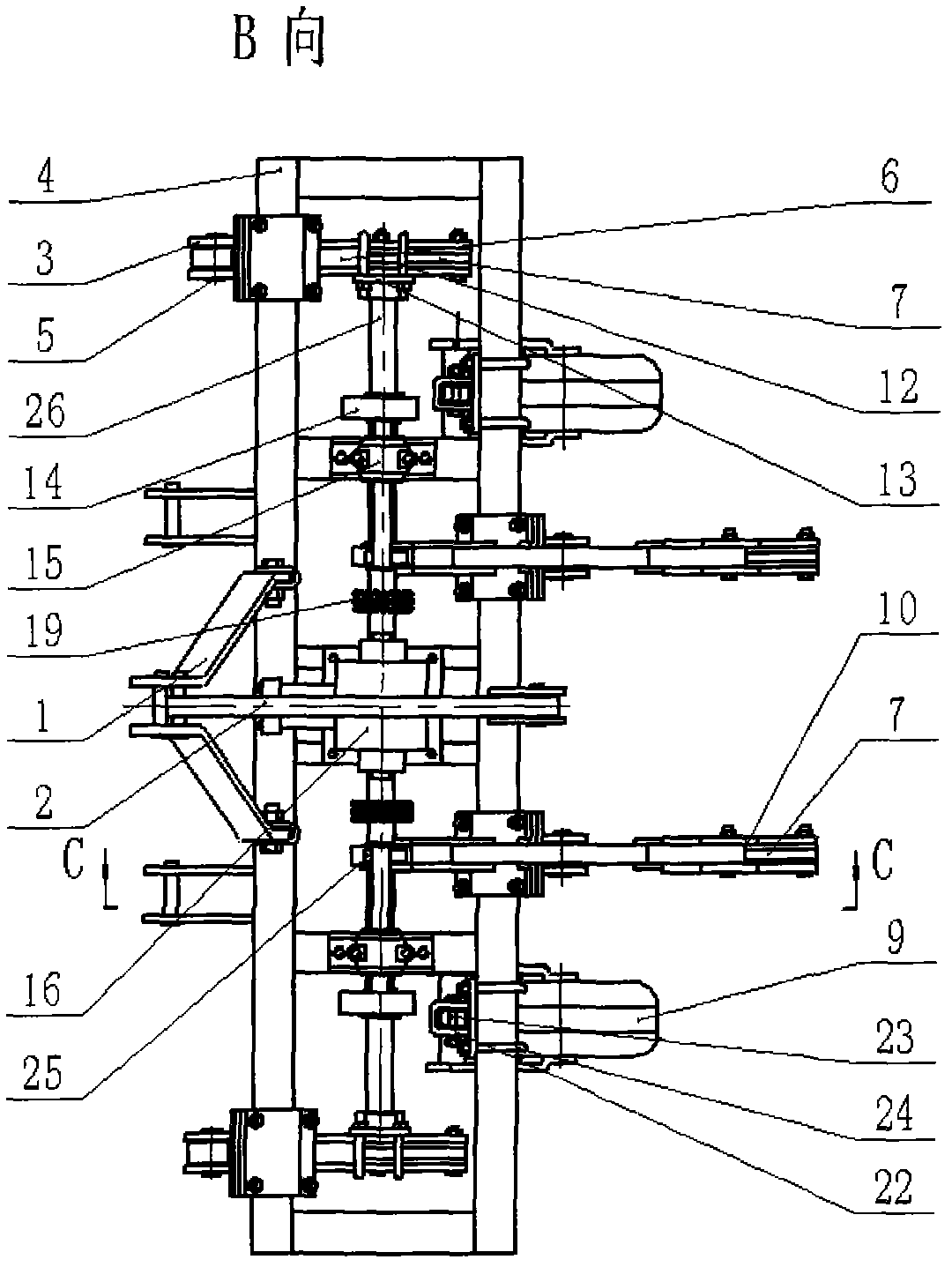

Endoluminal medical access device

An endoluminal medical access device (1) is disclosed that is devised for endoluminal delivery to an extravascular target site (5) at a vasculature site of a human or animal body vasculature, such as the microvasculature. The device (1) comprises a hollow body (112) arranged around a continuous channel (113) that ends in a distal end (100) and comprises a distal penetration portion (102) that is devised to extend across a tissue wall of said microvasculature said microvasculature site (4) at an extravascular target site in said body to provide communication with said extravascular target site through said channel (113) and devised for at least partly apposition to said tissue wall, and a proximal connection section (101), which proximally adjoins said penetration portion (102), and optionally comprises an intrusion depth limit unit (116, 118) and / or a hollow separation section (115) devised to provide a controllable separation of the penetration portion (102) from a connected proximal portion (110) of the hollow body.

Owner:SMARTWISE SWEDEN

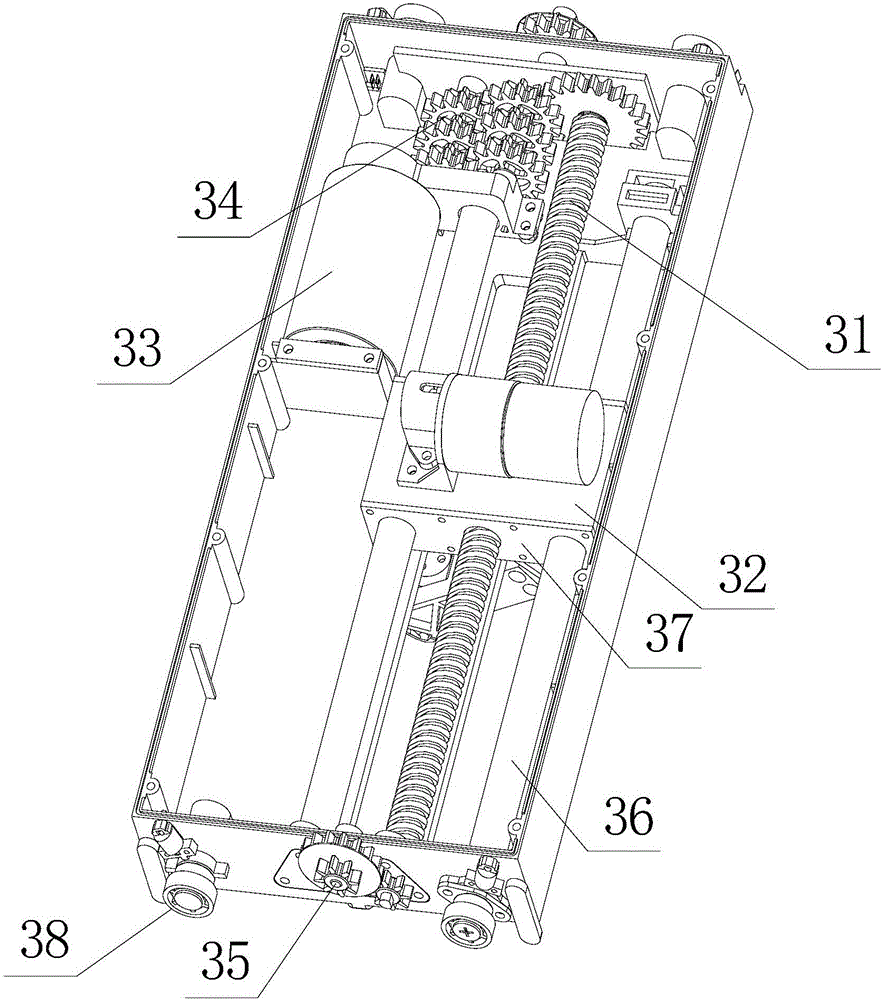

Intelligent air-suction seeder unit

PendingCN109451928AStable jobDoes not affect the depth of sowingPlantingFurrow making/coveringCircular discSeeder

The invention relates to an intelligent air-suction seeder unit, which belongs to the technical field of seeders. By adopting the intelligent air-suction seeder unit, the accurate control of a planting depth and a plant distance can be realized, the seeds can be precisely fed in place, the seeds can be saved, and the crop yield can be increased. A pressure control oil cylinder of a feeler mechanism is fixedly installed on a unit fixing frame and used for controlling a furrowing depth of a furrowing disc of a seeding mechanism, a depth limiting wheel pressure sensor of the feeler mechanism is installed on a tail end of an a depth limiting wheel adjusting handle of a depth limiting mechanism, and the depth limiting wheel pressure sensor is matched with the pressure control oil cylinder and used for transmitting a signal to the pressure control oil cylinder; and a seed metering device of the seeding mechanism is an electric control air-suction seed metering device. By adopting the hydraulic oil cylinder and the depth limiting wheel pressure sensor matched with each other, the hydraulic oil cylinder outputs stable setting pressure according to the signal and the depth limiting wheel pressure sensor, the change of seed quantity and unit weight of a seed box does not influence the seeding depth, the stable work of a furrowing device can be ensured, and the consistency of the furrowing depth and the seeding depth can be ensured.

Owner:黑龙江精播科技开发有限公司

Pneumatic-force-machinery combined type grape vine root part soil clearing device

The invention relates to a pneumatic-force-machinery combined type grape vine root part soil clearing device. The device comprises a rack part, a power transmission part, a root part soil brushing part, a pneumatic-force operating part and an obstacle avoiding part. The operating process of the device comprises the steps that the device is hanged at back of a tractor, a depth limiting wheel is adjusted according to the current situation of winter grape vine soil embedding, and the operating height of the rack is adjusted; the tractor is started to drive a hydraulic station and a fan to operateto drive the root part soil brushing part to start soil brushing, air blowing is started by the pneumatic force operating part, a telescopic oil cylinder moves after a rod touching sensor is in contact with a stone column, the stone column is avoided by the root part soil brushing part, and the root part soil brushing part extends out and continues to operate after the stone column is avoided. According to the device, a manner of soil sweeping plate brush and air blowing is adopted to thoroughly clear the soil on the vine root parts of grapes.

Owner:CHINA AGRI UNIV

Spiral inclined cross-ridge adjustable ridging machine

The invention discloses a spiral inclined cross-ridge adjustable ridging machine. The spiral inclined cross-ridge adjustable ridging machine comprises a machine frame. A hydraulic mechanism is arranged on the machine frame, and the lower portion of the machine frame is provided with a depth limiting mechanism, a soil loosening mechanism, a soil distributing mechanism and a spiral ridging mechanism from front to back in sequence. The spiral inclined cross-ridge adjustable ridging machine further comprises a ridging spacing adjusting mechanism arranged on the back of the machine frame. The ridging spacing can be adjusted according to the growing situation of crops in the intertillage ridging period and the soil situation through the ridging spacing mechanism, and the damage to the crops due to the over-wide or over-narrow ridging spacing is avoided. Ridge forms with different gradients can be formed through a ridge form adjusting mechanism according to the soil terrain situations, and the ridge form formed after ridging can be kept with a good original shape. The soil can be slantly milled and conveyed through the spiral ridging mechanism, the original mode that a ridging cutter blade pushes the loosened soil to the outer side of a packing auger, and the soil is thrown to the roots of the crops through the inertia is changed, the soil flow direction can be controlled, the mechanical damage to crops leaves can be reduced, and the soil ventilation performance is improved.

Owner:HENAN AGRICULTURAL UNIVERSITY

Garlic harvester

The garlic harvester is installed in the front of walking tractor and consists of frame as well as depth limiting wheel, vibrating digging spade, rod type conveying chain, speed variator, strip spreader and other units mounted on the frame successively from front to back. It can complete garlic digging, garlic separation from soil, strip spreading and other jobs. The engine of the walking tractor is shifted to below the handle. The present invention has the advantages of reasonable structure, high harvesting rate and low garlic damage rate.

Owner:徐州市农机技术推广站

Combined deep scarification and land preparation machine

InactiveCN105981496ALow traction resistanceGuaranteed profilingSpadesSaving energy measuresConventional tillageScarification

The invention relates to a combined deep scarification and land preparation machine which is characterized by comprising a rack, a full-direction deep scarification device and a turnover device, wherein the turnover device is arranged in front of the full-direction deep scarification device; the rack consists of a front beam, an upper suspended plate, lower suspended plates, transverse beams, fixed transverse beams, fixing plates, limiting plates, a rear beam and support beams; a partial deep scarification device is arranged on the rear beam; a soil crushing depth limiting device is arranged behind the support beams. According to the combined deep scarification and land preparation machine, a shallow layer and a conventional tillage mellow soil layer are loosened by using the turnover device, subsequently deep soil is cut by using the full-direction deep scarification device and is crushed by using the partial deep scarification device, furthermore the ploughed soil is crushed and flattened by using disc cutters in the soil crushing depth limiting device. In a word, by adopting the combined deep scarification and land preparation machine, combined soil preparation, shallow layer turnover operation, single full-direction deep scarification operation and partial deep scarification operation can be achieved according to agricultural requirements of different crops, the effect of one-machine multi-functions is achieved, the resistance can be reduced, the energy can be saved, and a good operation effect can be achieved.

Owner:SHIHEZI UNIVERSITY

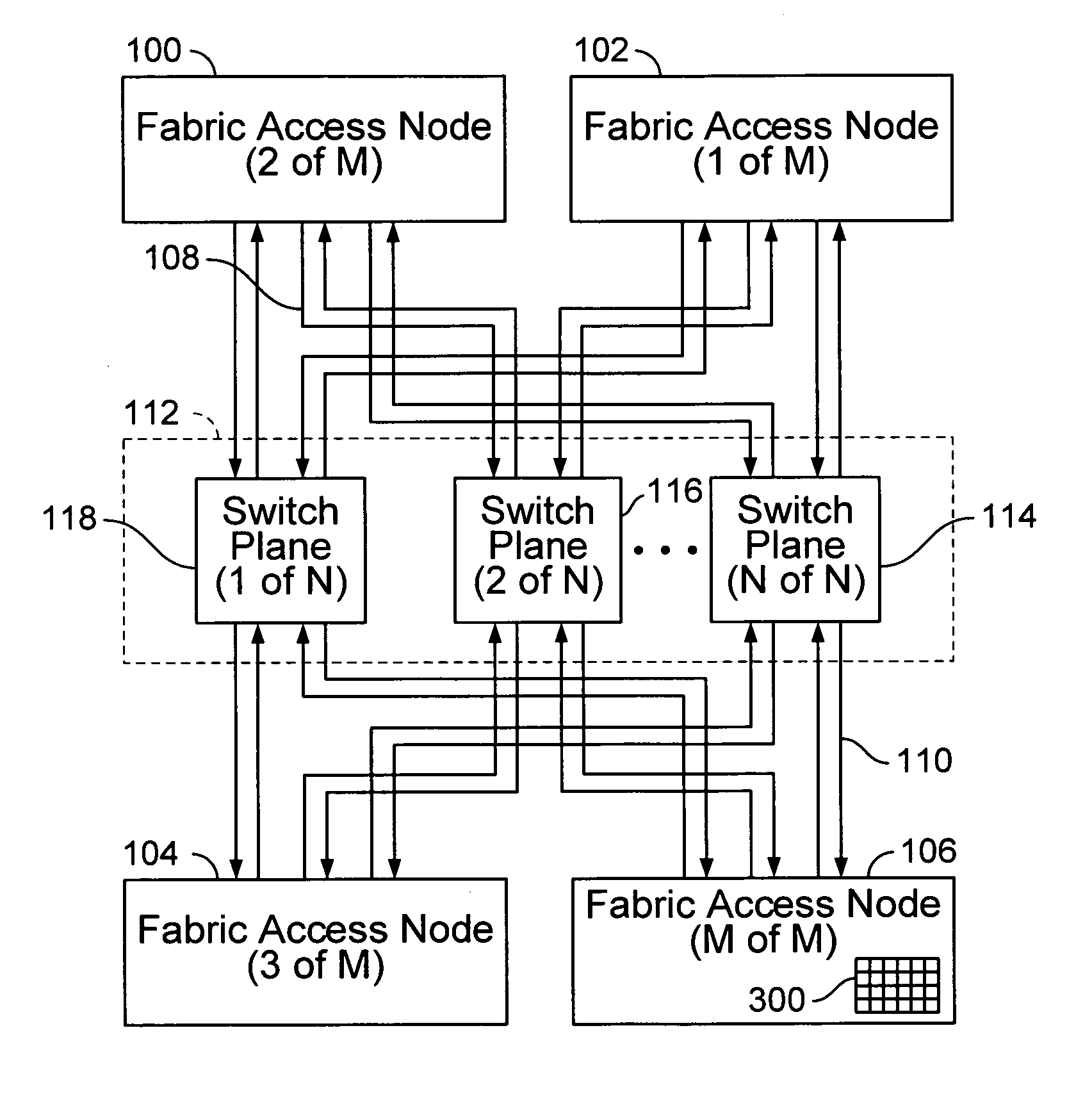

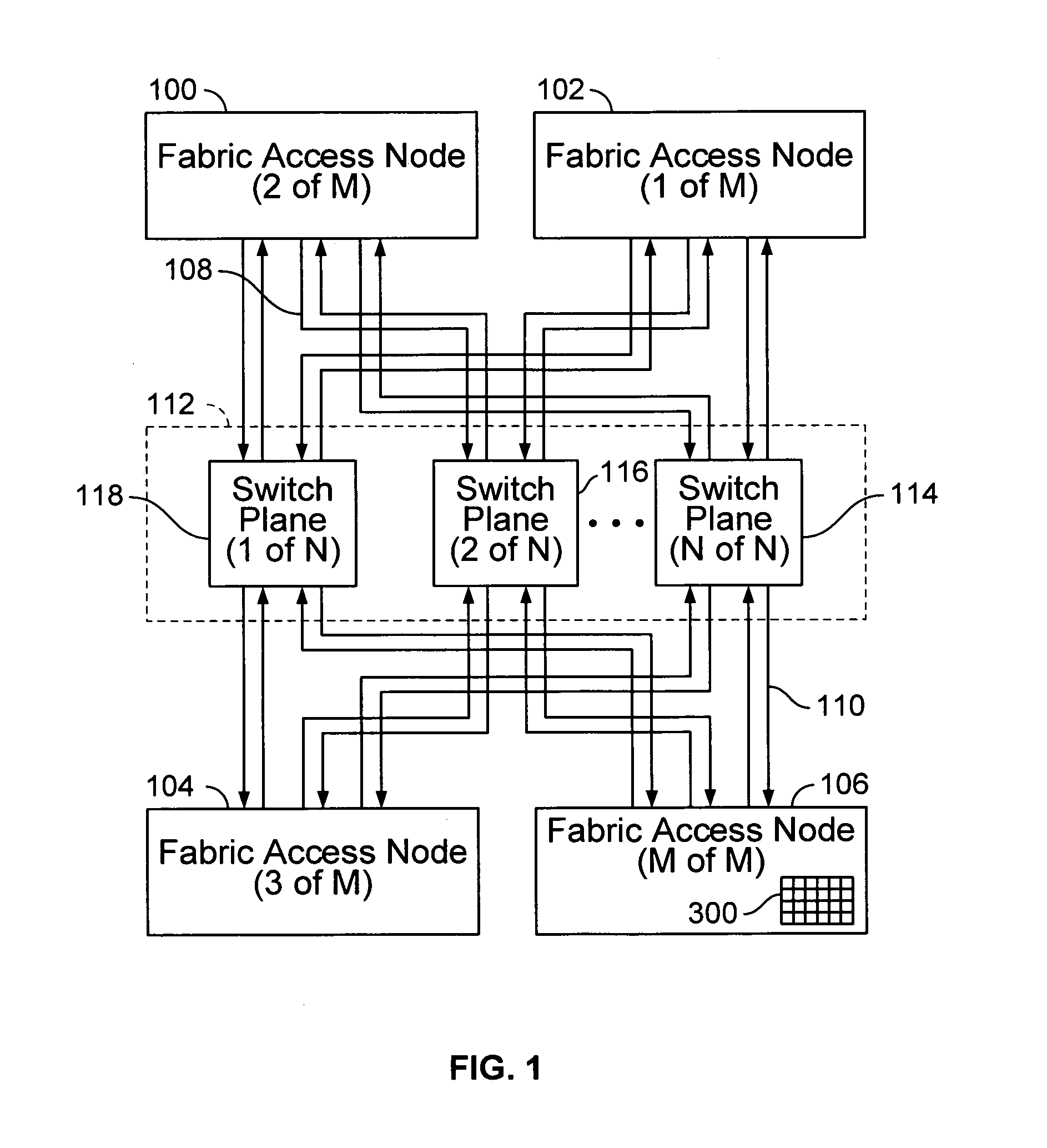

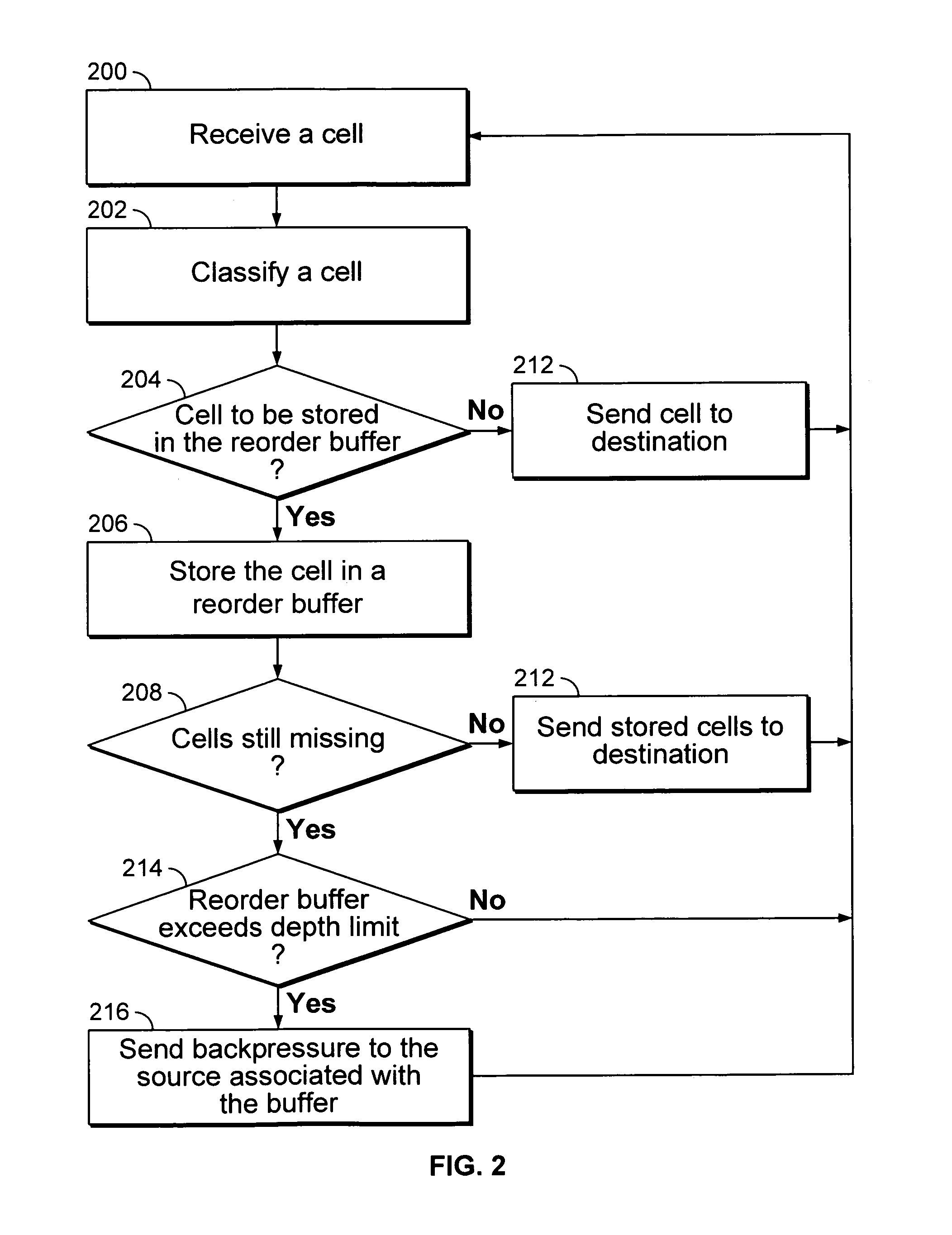

Fabric access integrated circuit configured to bound cell reorder depth

Bounding cell reorder depth is disclosed. It is determined whether a reorder buffer that is associated with a switch fabric exceeds a depth limit. In the event that the reorder buffer exceeds the depth limit, backpressure with respect to a source associated with the reorder buffer is sent. In such cases source based back pressure information is included in a reserved field in a cell that is being sent into the switch fabric. In the event that the reorder buffer does not exceed the depth limit, the cell is sent to the switch fabric. In such cases the reserved field is present in the cell but is unused.

Owner:WSOU INVESTMENTS LLC

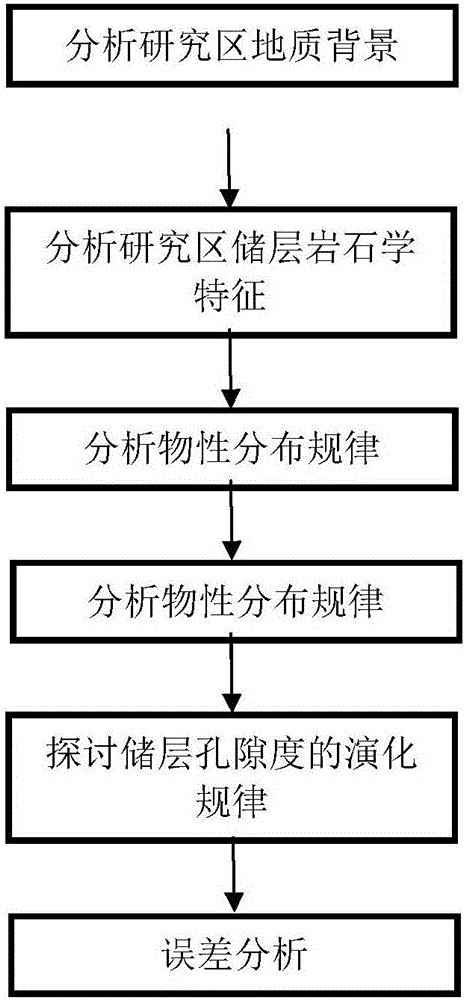

Method for quantitatively evaluating ultra-deep reservoir diagenesis and pore evolution

A method for quantitatively evaluating ultra-deep reservoir diagenesis and pore evolution comprises the steps of first, analyzing geological background of a research area; second, determining reservoir burial depth limit according to oil-gas reservoir burial depth, and analyzing lithological features of a research area reservoir; third, analyzing diagenesis, and dividing indexes according to multiple diagenetic sequences; fourth, analyzing physical distribution law, dividing physical development zones according to core physical analytical data, and studying controlled factors of reservoir physical distribution according to deposition and diagenetic evolution process experienced by the reservoir; fifth, investigating quantitative evolution law of reservoir porosity by studying the evolution of porosity parameters; sixth, analyzing errors, to be specific, investigating errors of porosity parameter calculation method by using porosity parameters obtained by using physical property analytical method as references, and analyzing main factors that influence the errors; in the method, a quantitative model for deep reservoir porosity evolution is acquired through experiments, and deviations due to excessively high original porosity of a reservoir are overcome.

Owner:XI'AN PETROLEUM UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com