Dual-row reverse-vibration subsoiler

A subsoiler and reverse technology, which is applied in the direction of agricultural machinery, agricultural machinery and implements, plows, etc., can solve the problems of large fluctuation range of traction resistance, deterioration of the operator's working environment, and strong vibration of tractors, etc., to reduce traction resistance The fluctuating range, the overall structure is simple and compact, and the effect of optimizing the working conditions of the operator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment and accompanying drawing, the present invention will be described in further detail:

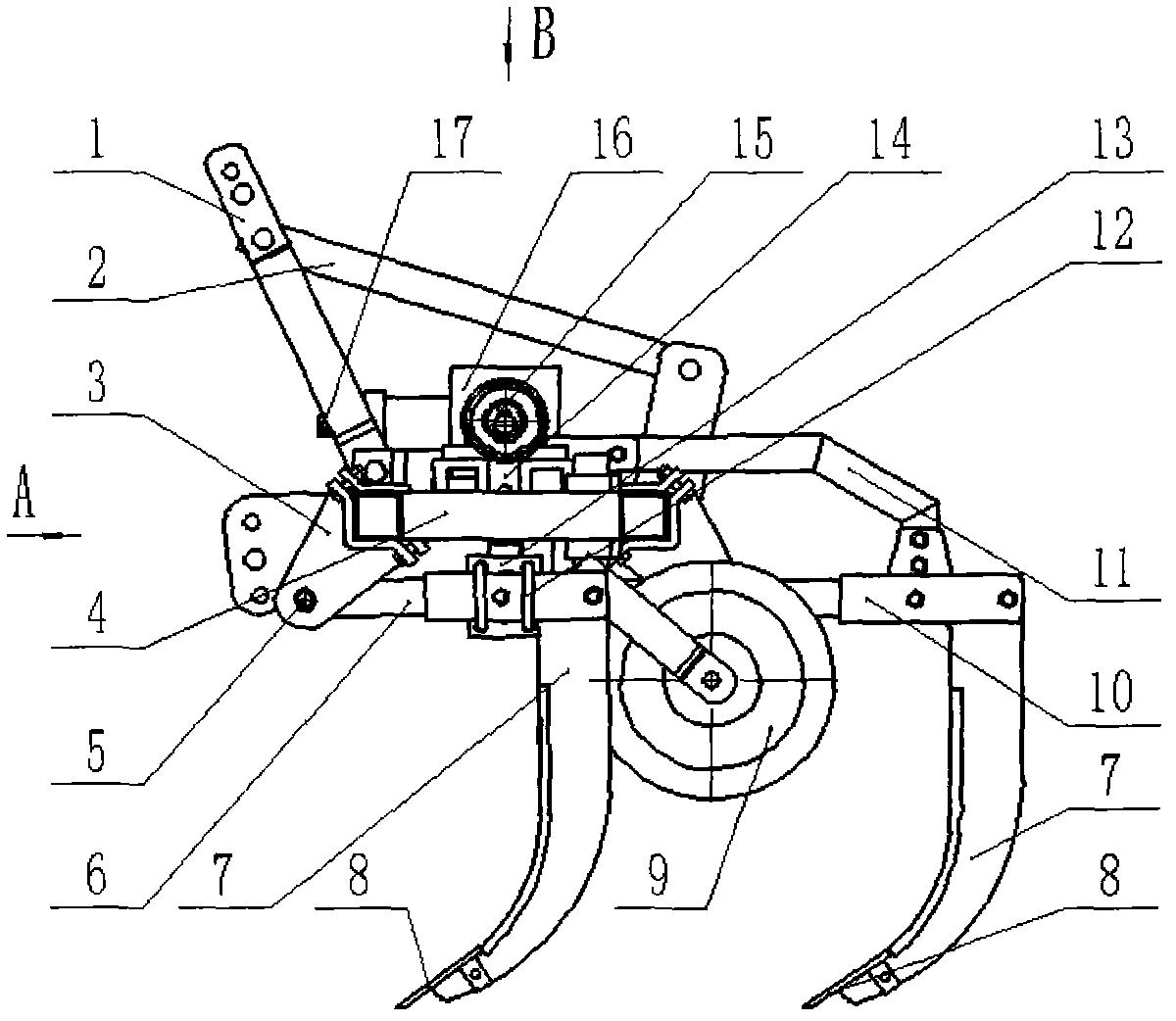

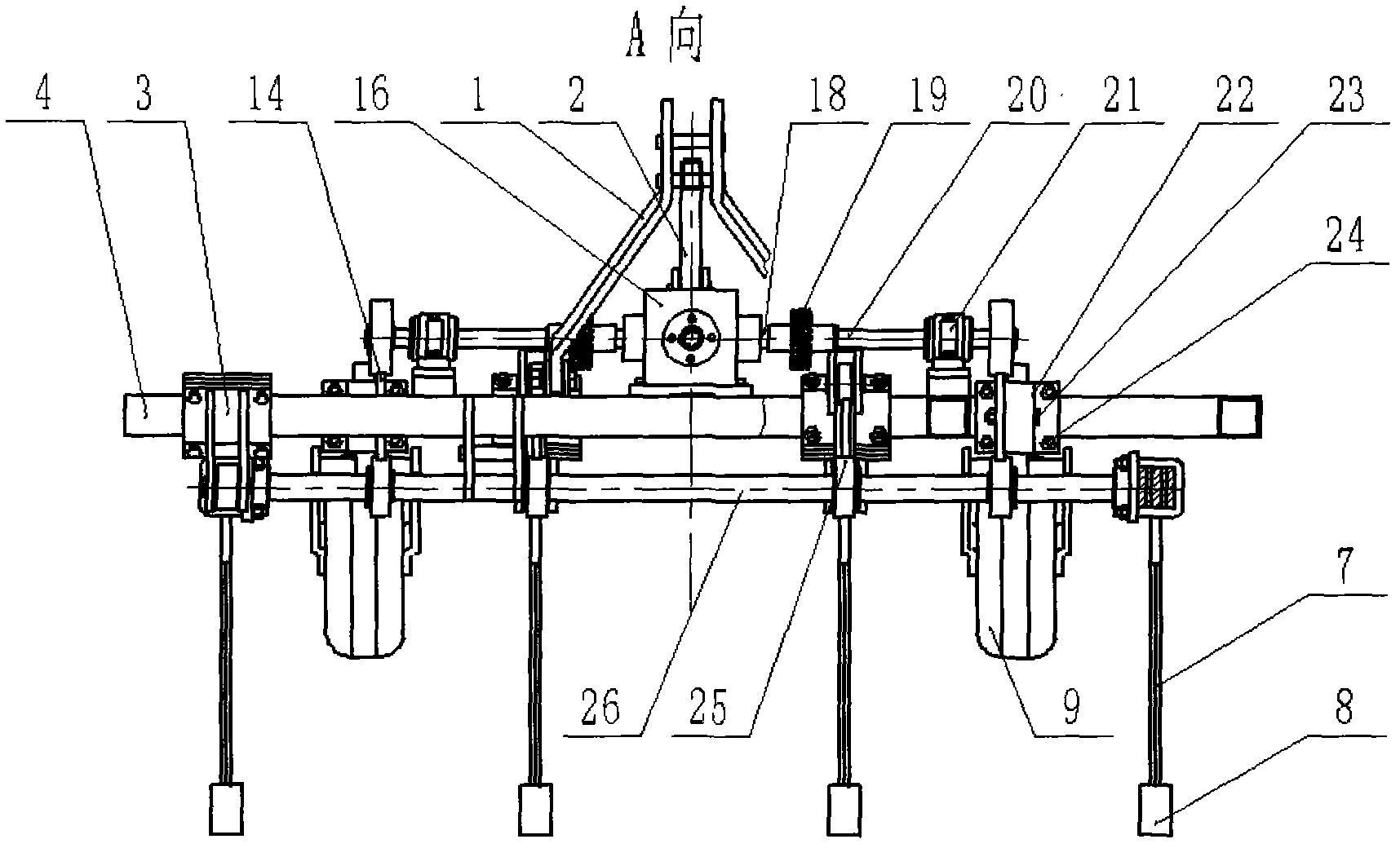

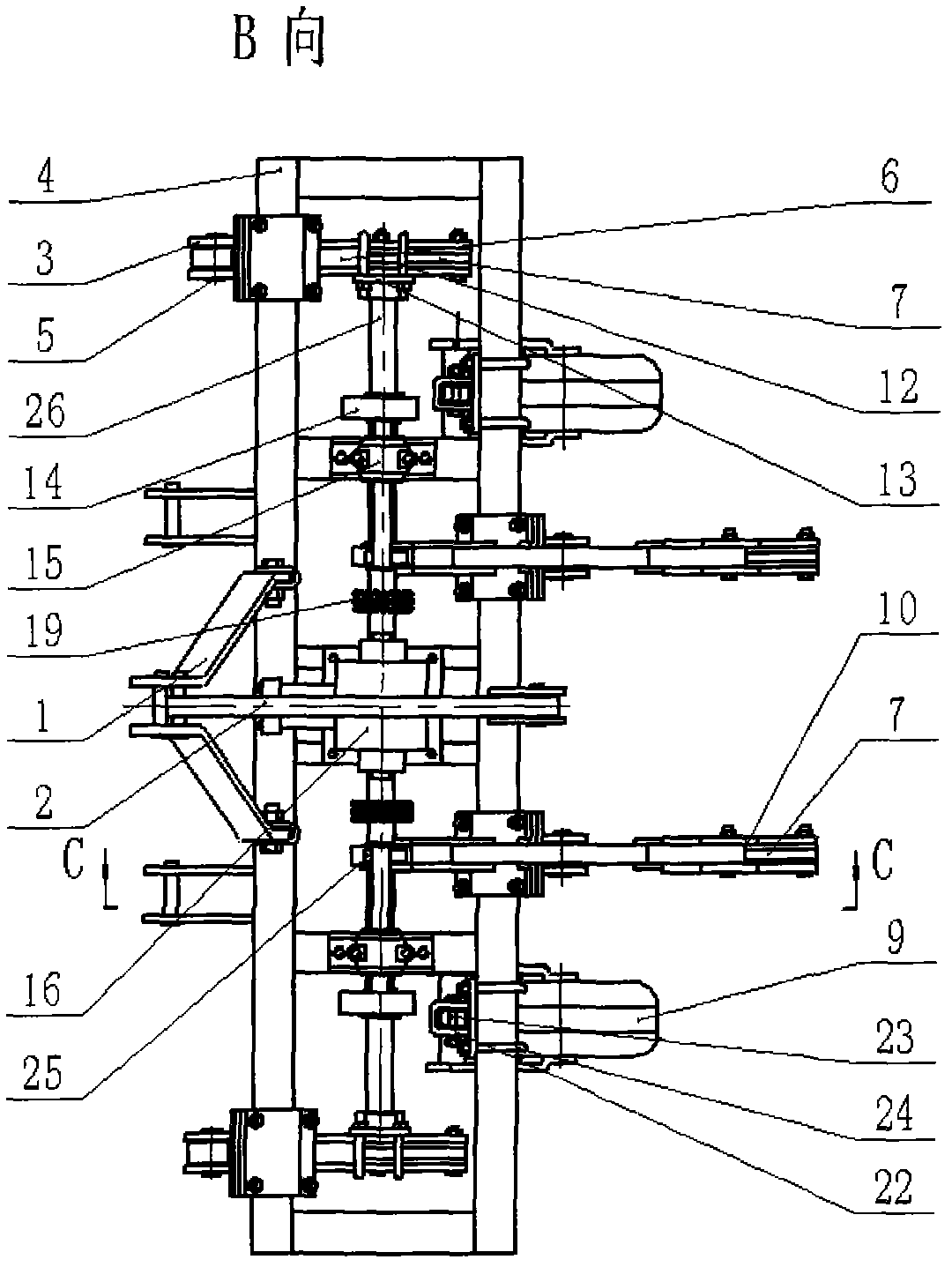

[0023] figure 1 It is the front view of the double-row reverse vibration subsoiler, figure 2 It is the left view of the double row reverse vibration subsoiler, image 3 It is the top view of the double-row reverse vibration subsoiler. The transmission system, vibrating subsoiling device, supporting depth-limiting device and suspension frame of the double-row reverse vibration subsoiler are all installed on the frame; The power is transmitted to the vibrating subsoiling device, the vibrating subsoiling device is placed under the frame, the supporting depth-limiting device is placed on both sides of the rear of the frame, and the suspension frame is placed at the front of the frame to connect with the tractor suspension device.

[0024] Such as image 3 , Figure 4 , Figure 5 In the transmission system shown, the T-shaped steering box 16 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com