A method for optimizing vibration damping structure design of full-face hard rock roadheader

A technology of a hard rock roadheader and a design method, which is applied in the directions of computer-aided design, design optimization/simulation, calculation, etc., to achieve the effect of improving construction efficiency, speeding up construction progress, and reducing the degree of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

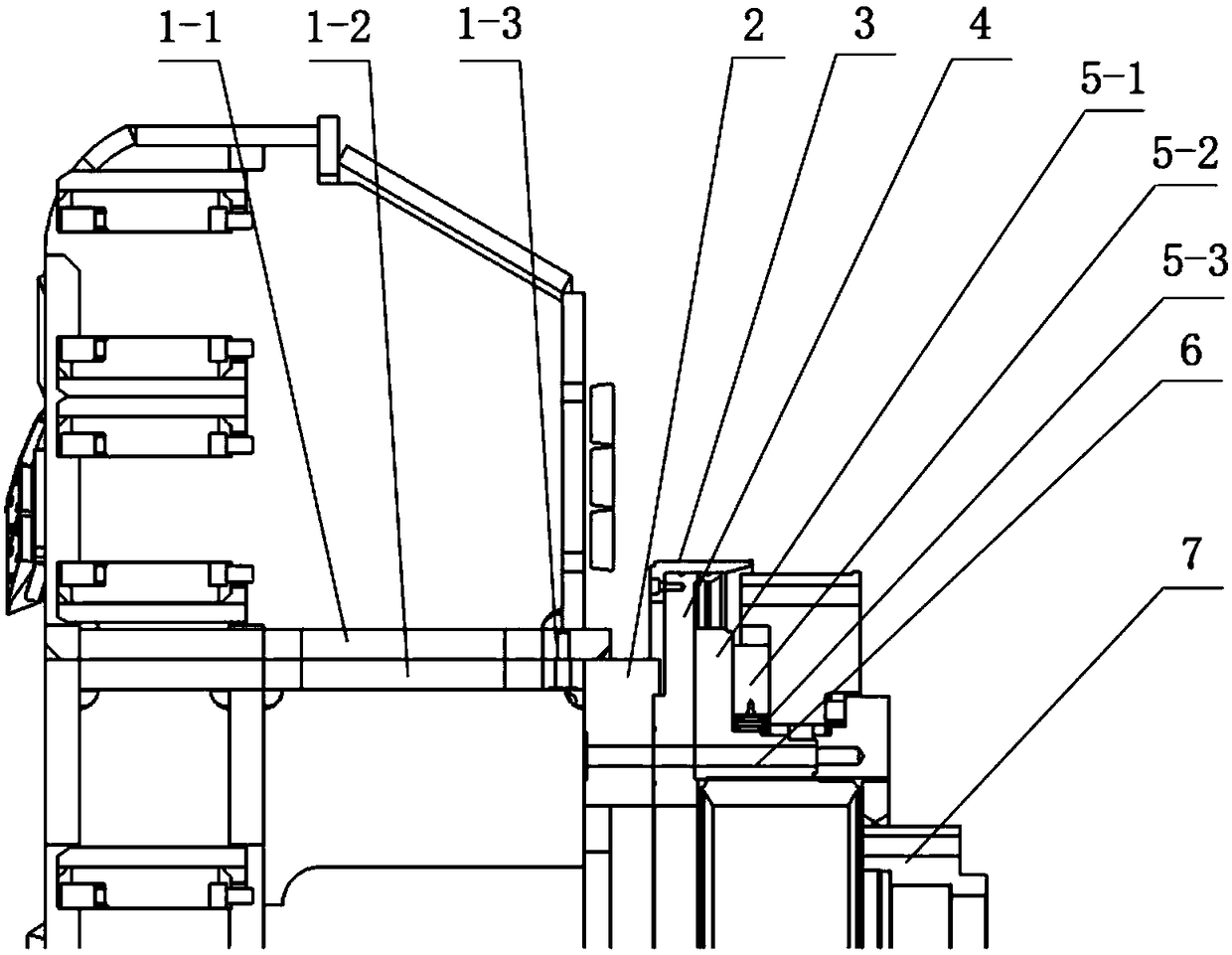

[0043] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0044] The present invention takes a tunnel project as an example, wherein: the main physical parameters of the rock are: the rock excavated by the full-face roadheader is mainly granite gneiss, and its rock density is 2750Kg m -3 , rock saturated compressive strength 95MPa, internal friction angle 33.4°, cohesion 0.9MPa, elastic modulus 20×10 3 MPa, Poisson's ratio 0.2, confining pressure 8-30MPa, buried depth 330-780m. The main parameters of the full-face roadheader are: cutter head radius R=5.015m, cutter head speed 8.5r / min, cutter head subsystem mass 155t, flange bolt connection subsystem mass 20t, support drive subsystem 300t.

[0045] In this example, the above-mentioned main parameters of the full-section roadheader and surrounding rock parameters are brought into a design method for vibration redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| cohesion | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com