Patents

Literature

887 results about "Section plane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

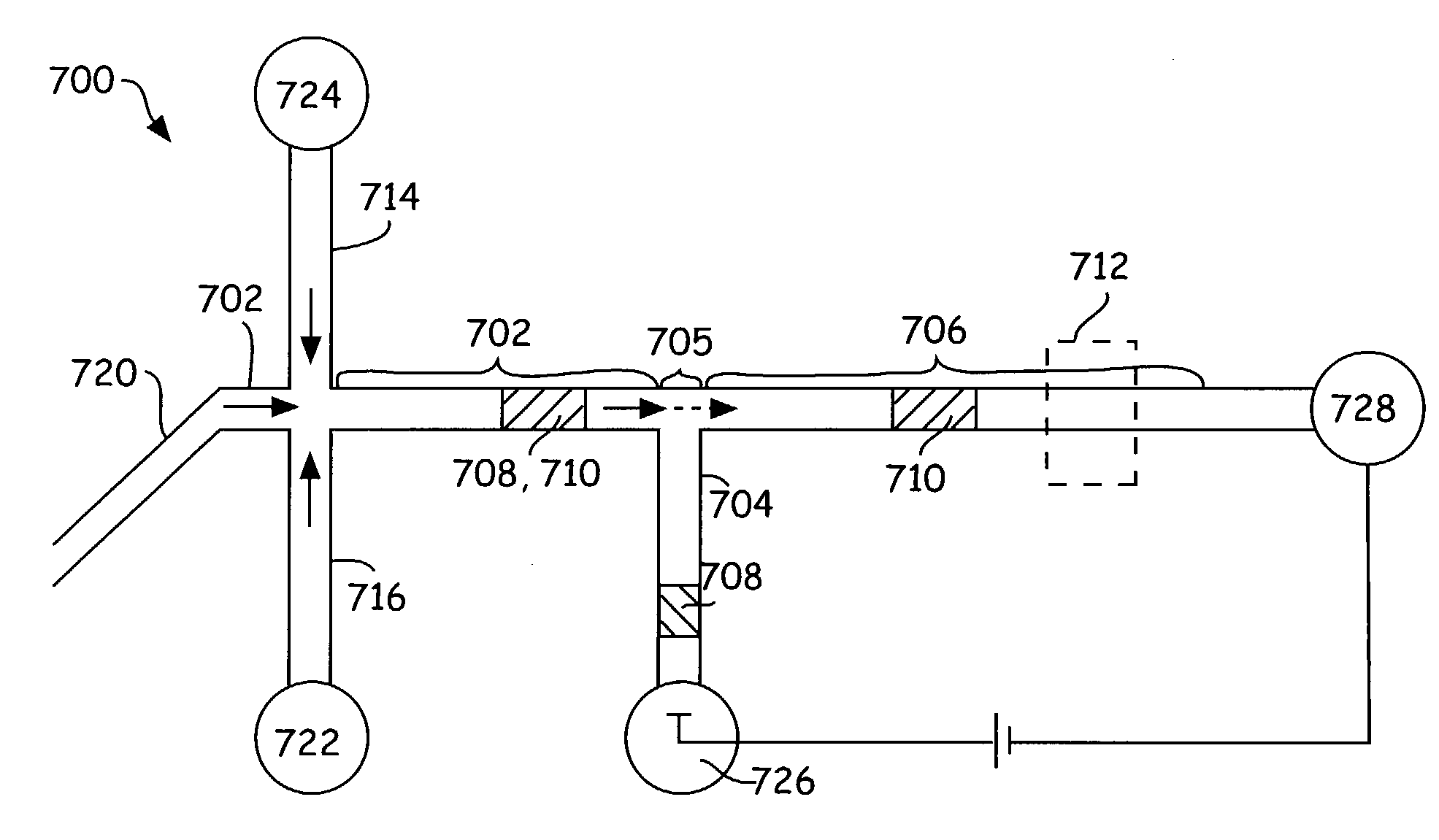

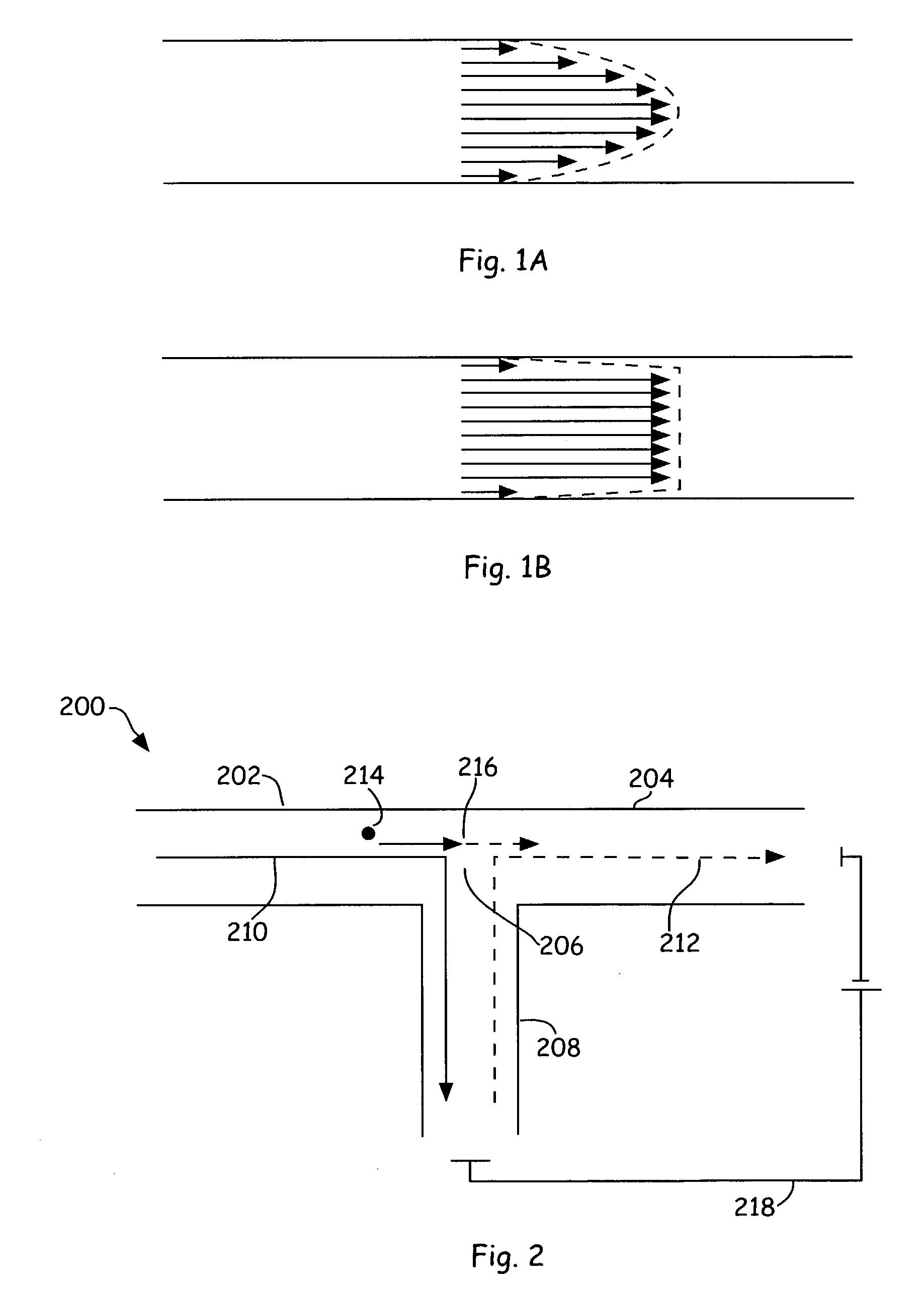

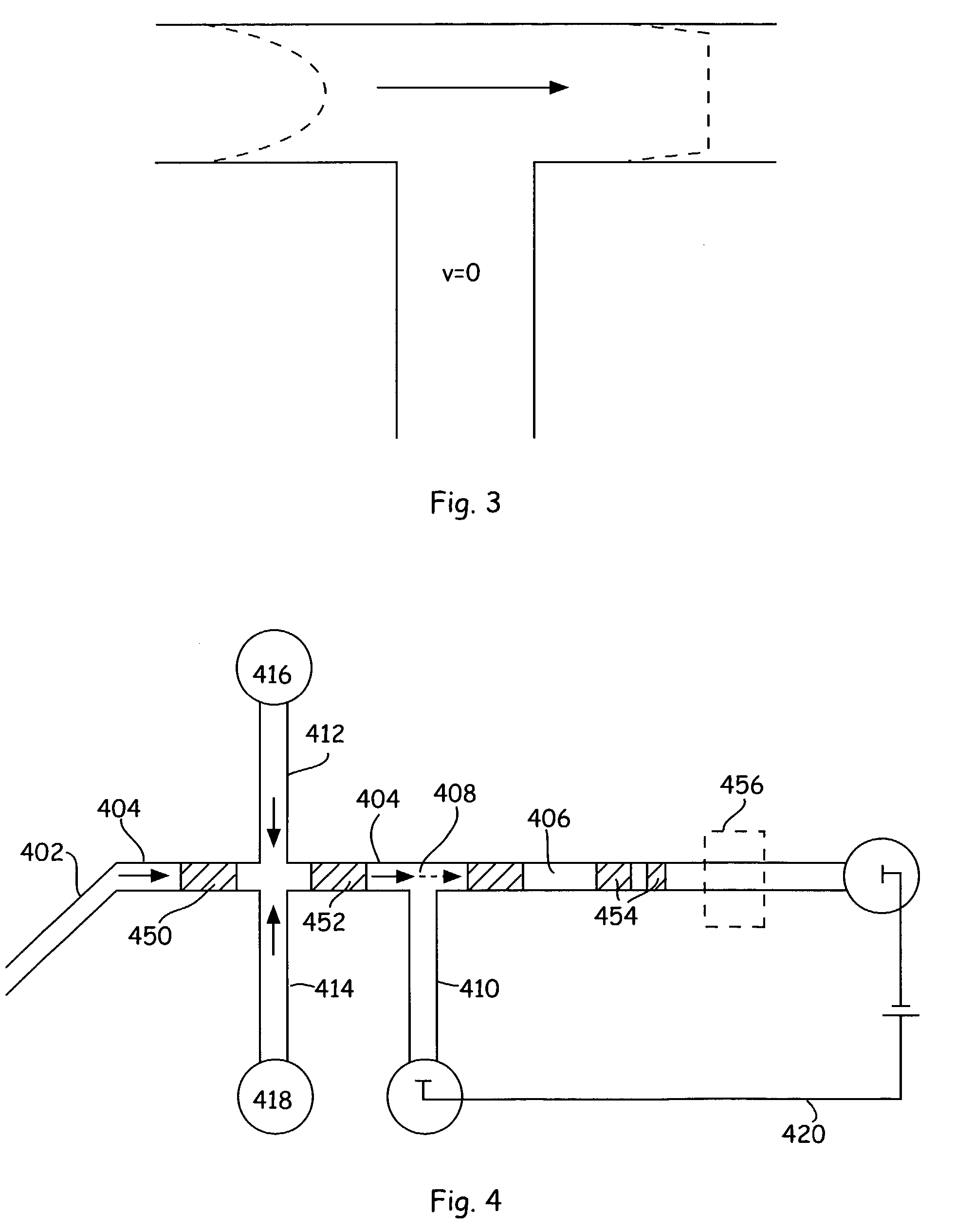

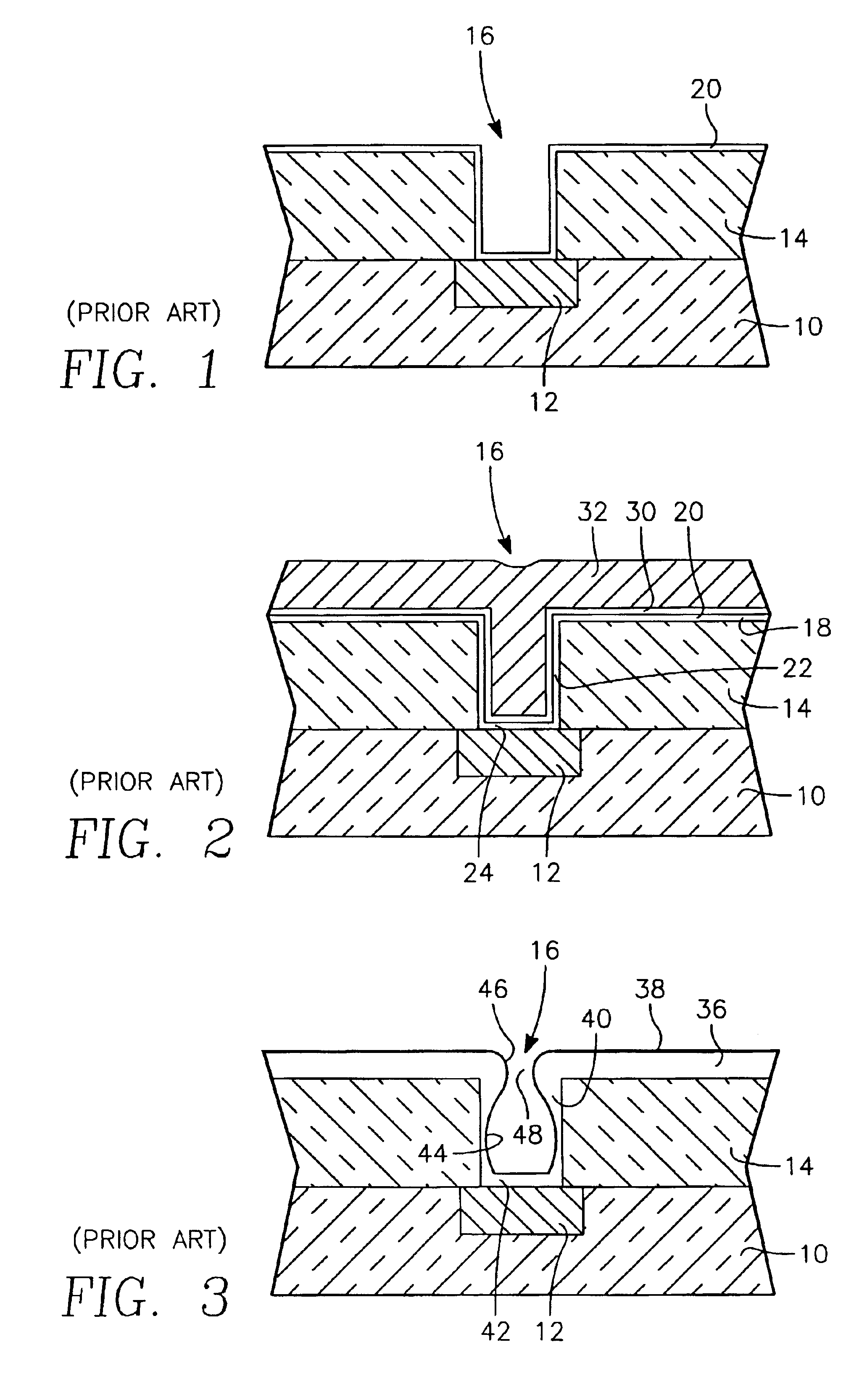

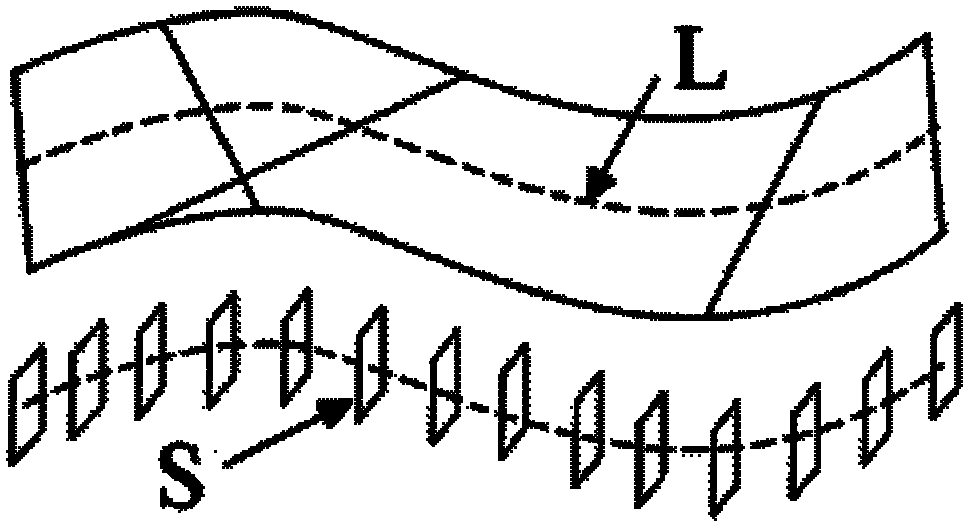

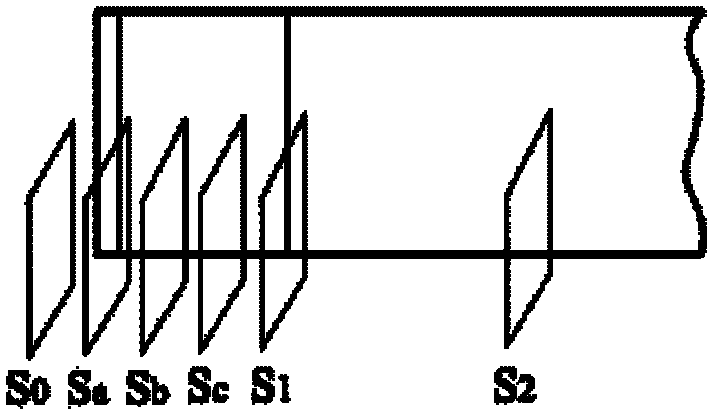

Mixed mode microfluidic systems

ActiveUS7160423B2Minimization requirementsReduce in quantitySludge treatmentElectrostatic separationSection planeChannel network

Methods and systems that employ hybrid fluid flow profiles for optimized movement of materials through channel networks. These systems employ hybrid pressure-based and electrokinetic based flow systems for moving materials through interconnected channel networks while maintaining interconnection among the various channel segments. In particular, the invention is generally directed to channel networks where flow in a first channel segment is driven by pressure flow with its consequent parabolic flow profile, while flow in an interconnected channel segment is dominated by electrokinetic flow with its consequent plug flow profile. The invention also provides channel networks wherein fluid flow in channel segments is driven by both pressure and electric field and the multiple species contained in a fluid plug are separated by altering the applied pressure and electric fields in the various channel segments of the channel networks.

Owner:CAPLIPER LIFE SCI INC

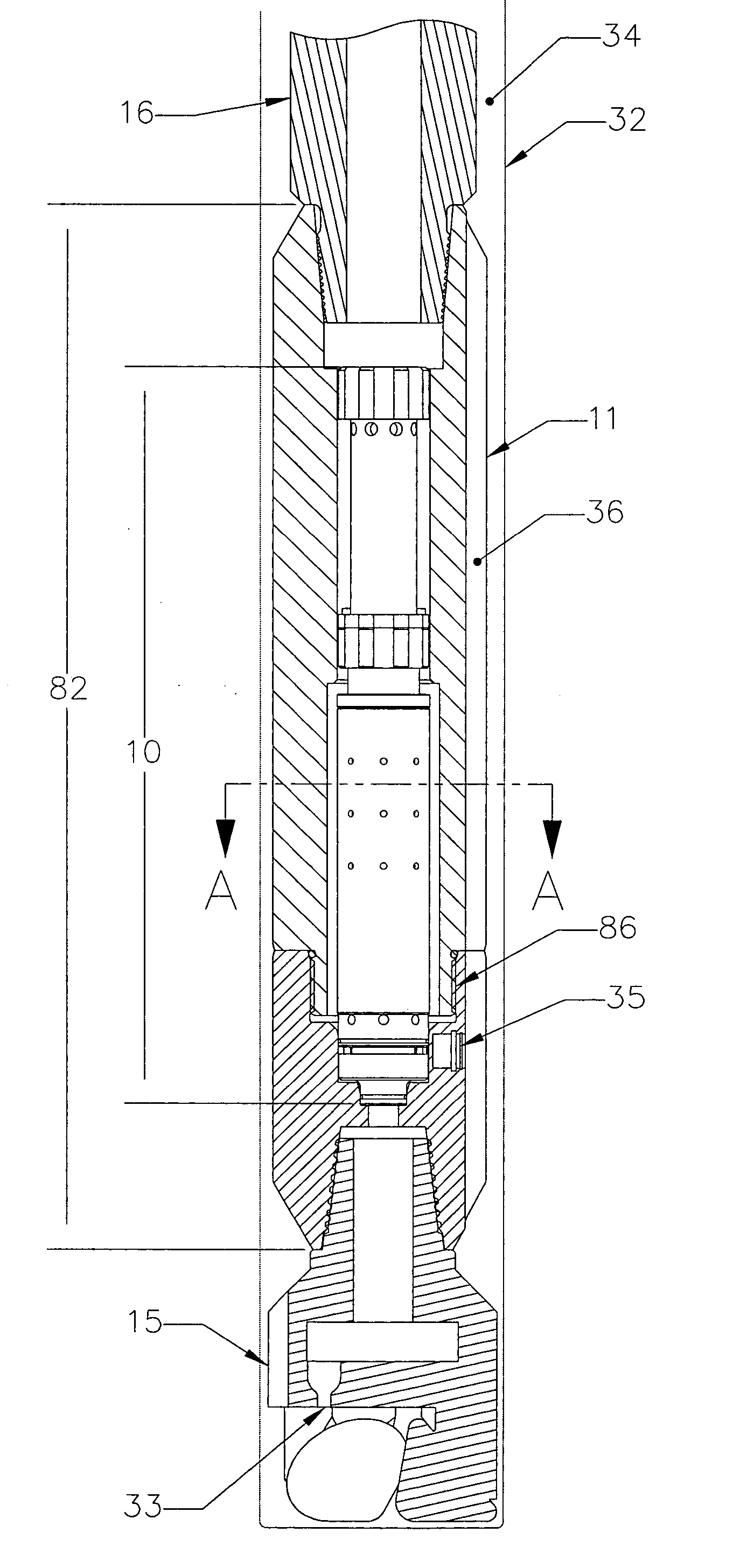

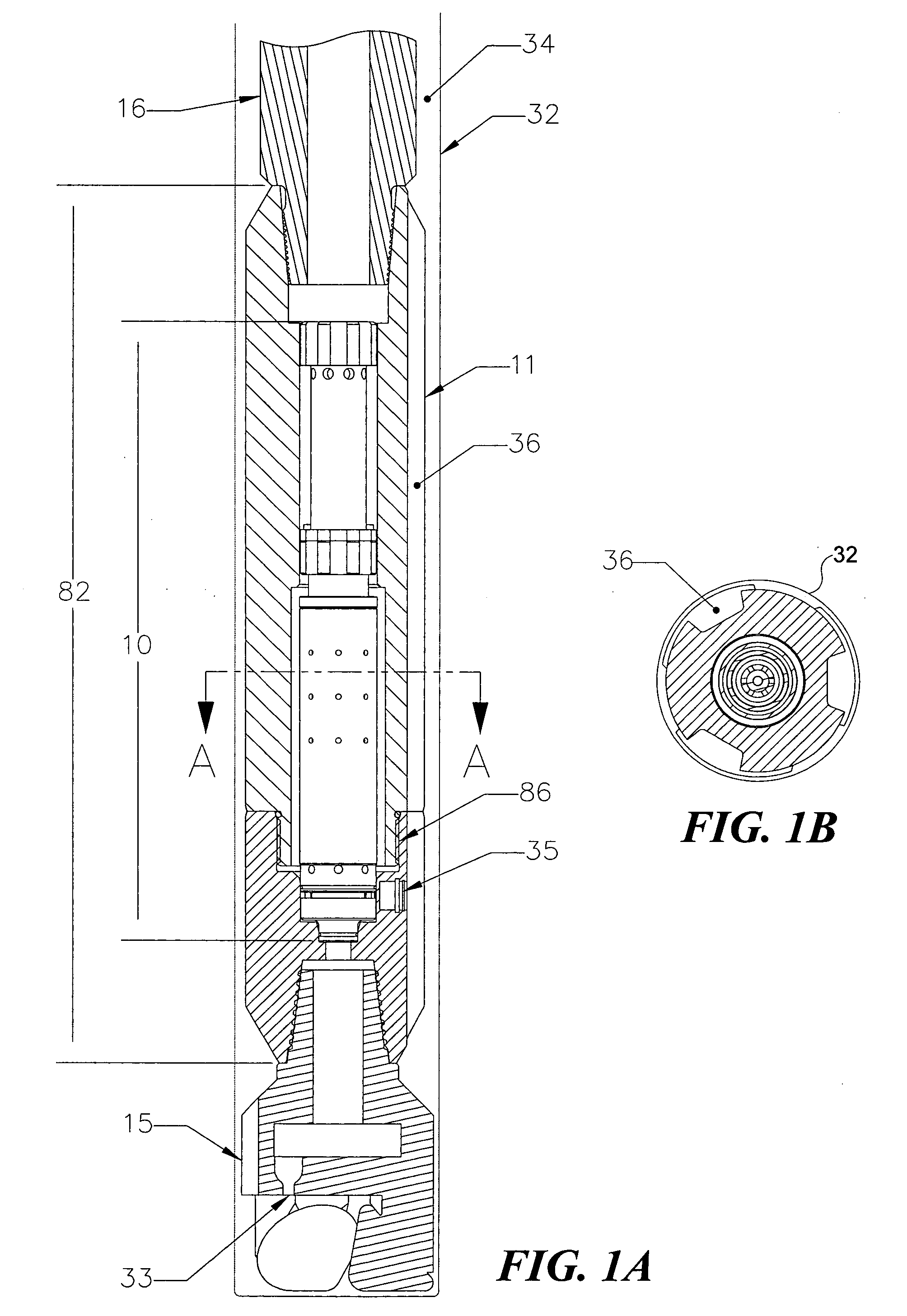

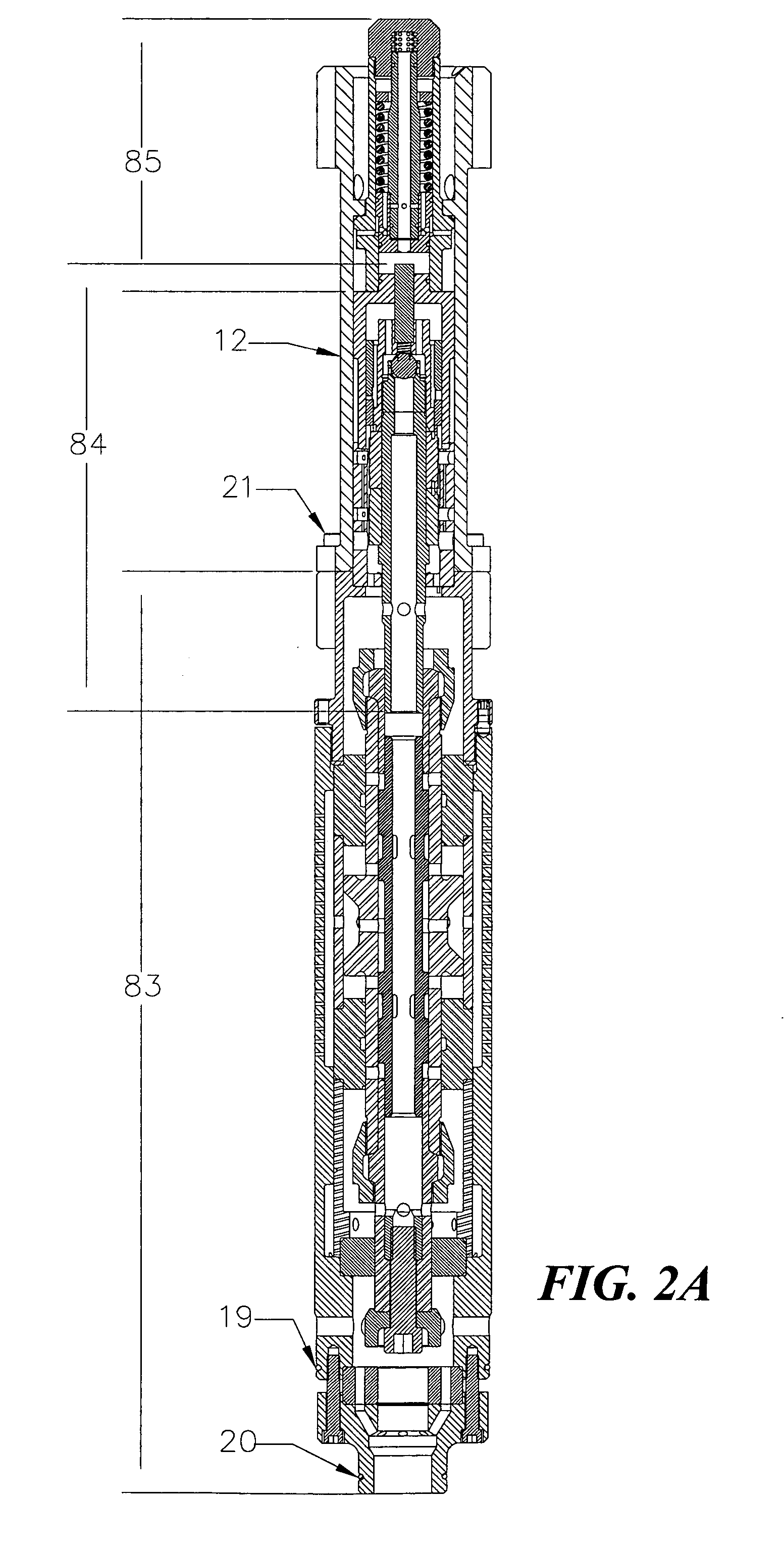

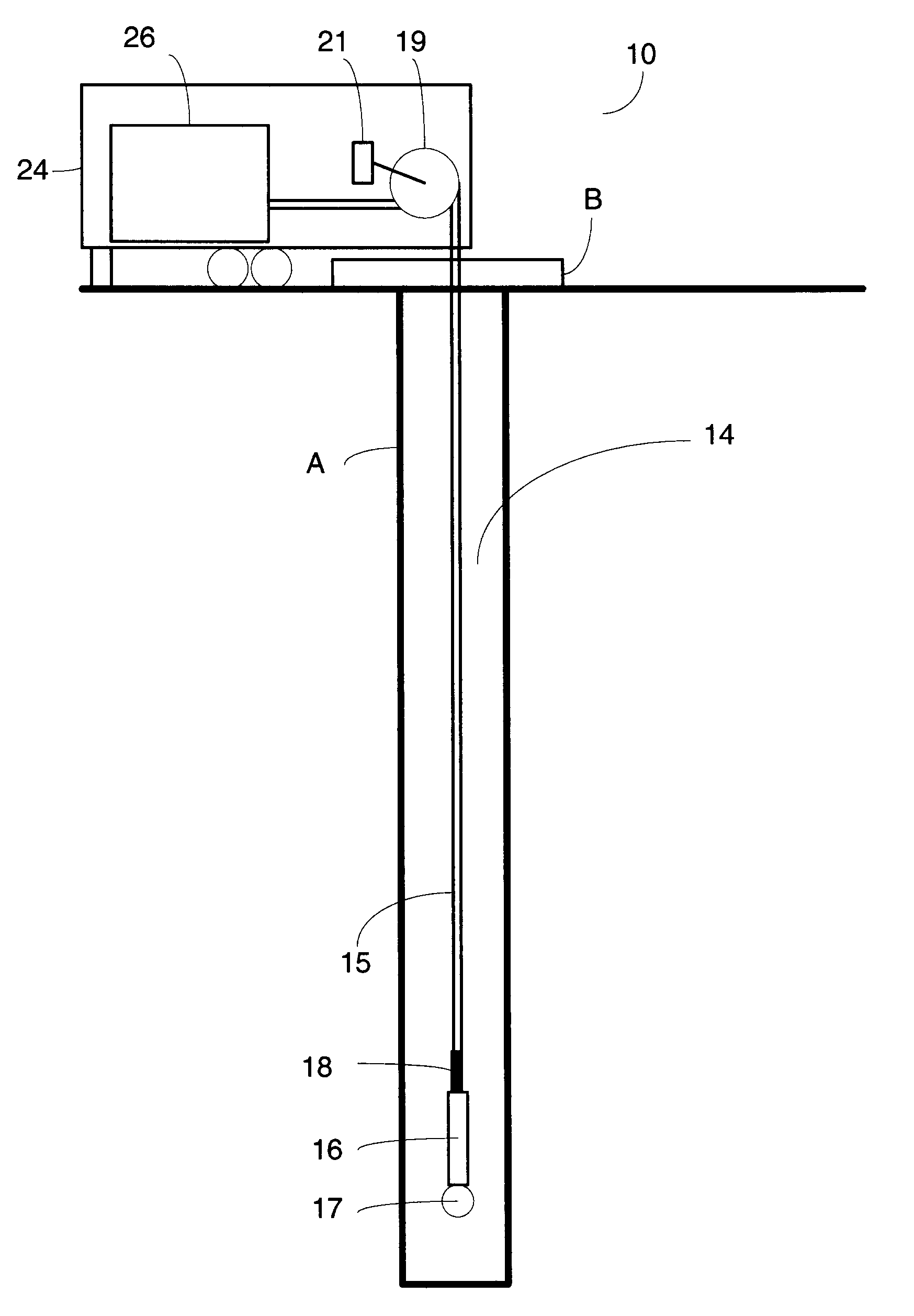

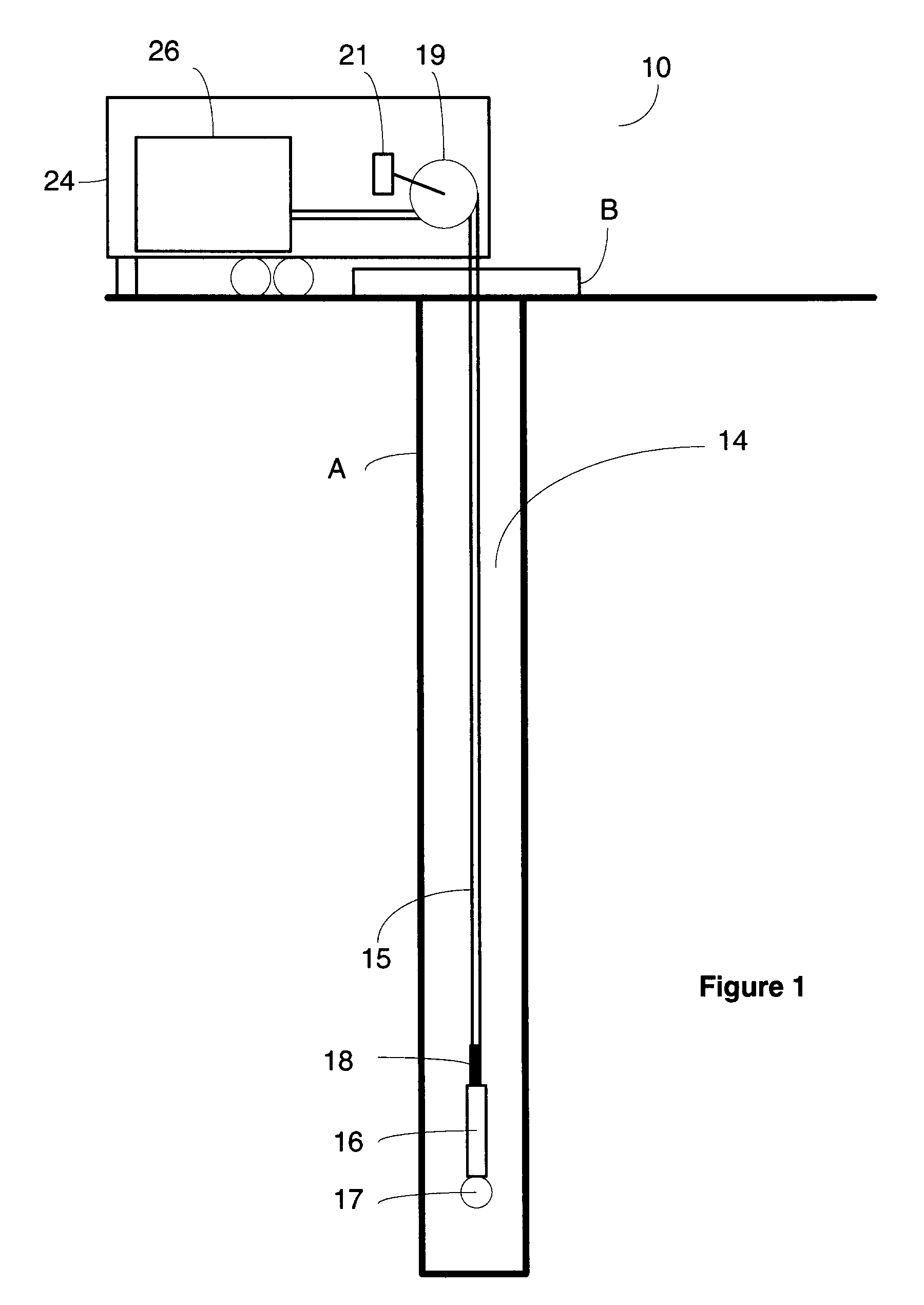

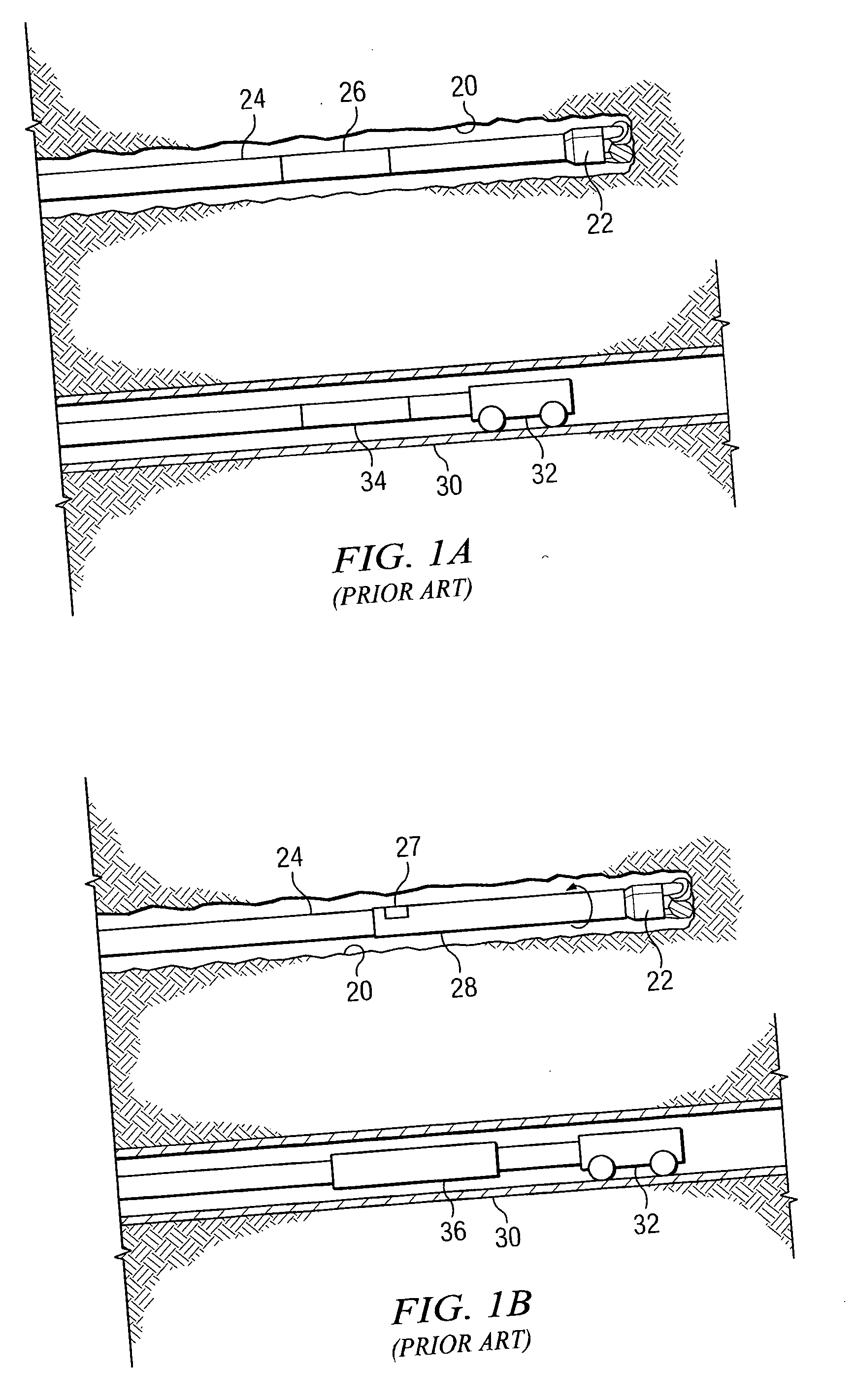

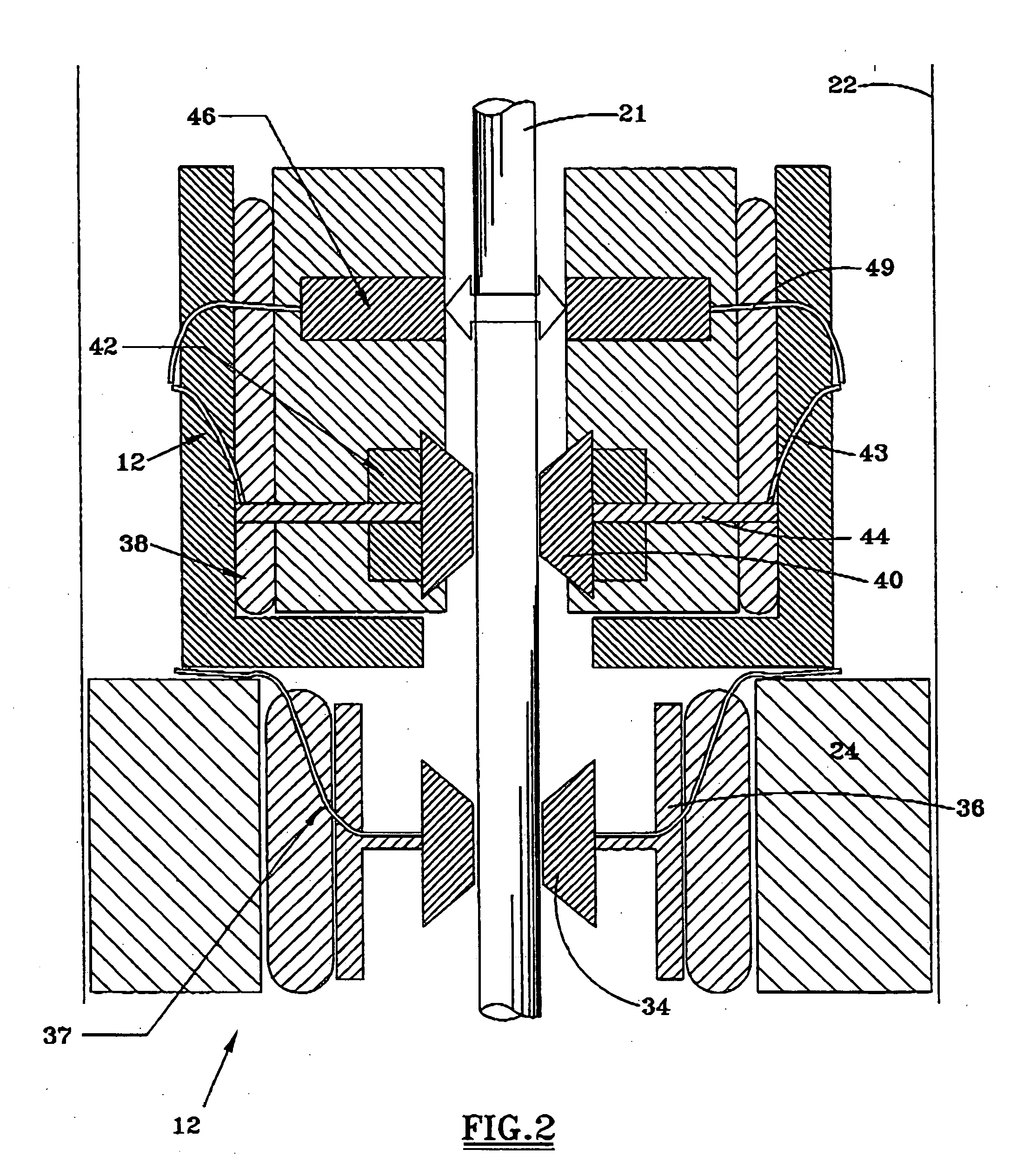

Hydraulic impulse generator and frequency sweep mechanism for borehole applications

ActiveUS20050178558A1Travel can be limitedEliminate water hammer effectSurveyOperating means/releasing devices for valvesGeophoneSeismic velocity

This invention discloses a valve that generates a hydraulic negative pressure pulse and a frequency modulator for the creation of a powerful, broadband swept impulse seismic signal at the drill bit during drilling operations. The signal can be received at monitoring points on the surface or underground locations using geophones. The time required for the seismic signal to travel from the source to the receiver directly and via reflections is used to calculate seismic velocity and other formation properties near the source and between the source and receiver. This information can be used for vertical seismic profiling of formations drilled, to check the location of the bit, or to detect the presence of abnormal pore pressure ahead of the bit. The hydraulic negative pressure pulse can also be used to enhance drilling and production of wells.

Owner:WELLS FARGO BANK NAT ASSOC +1

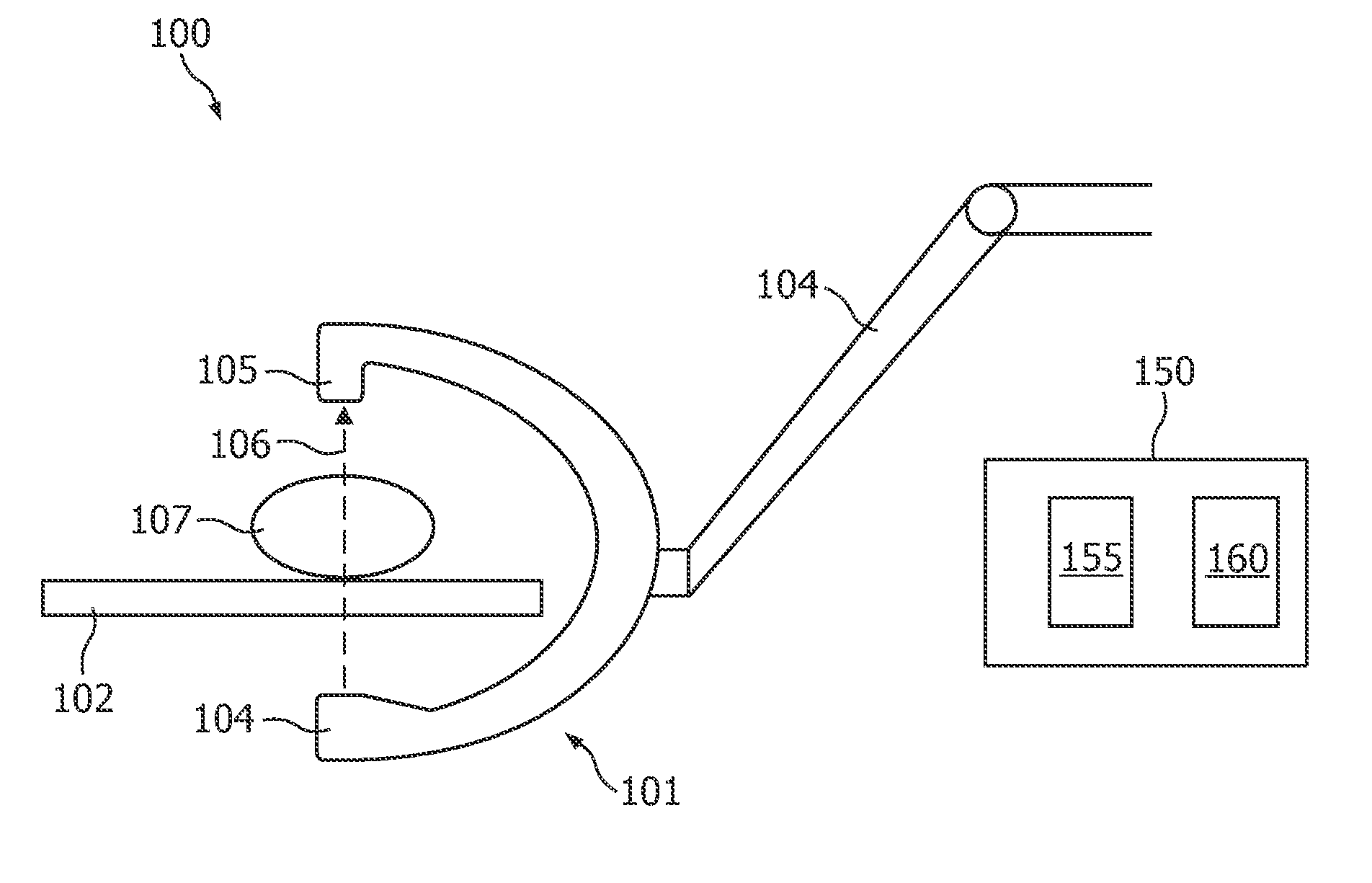

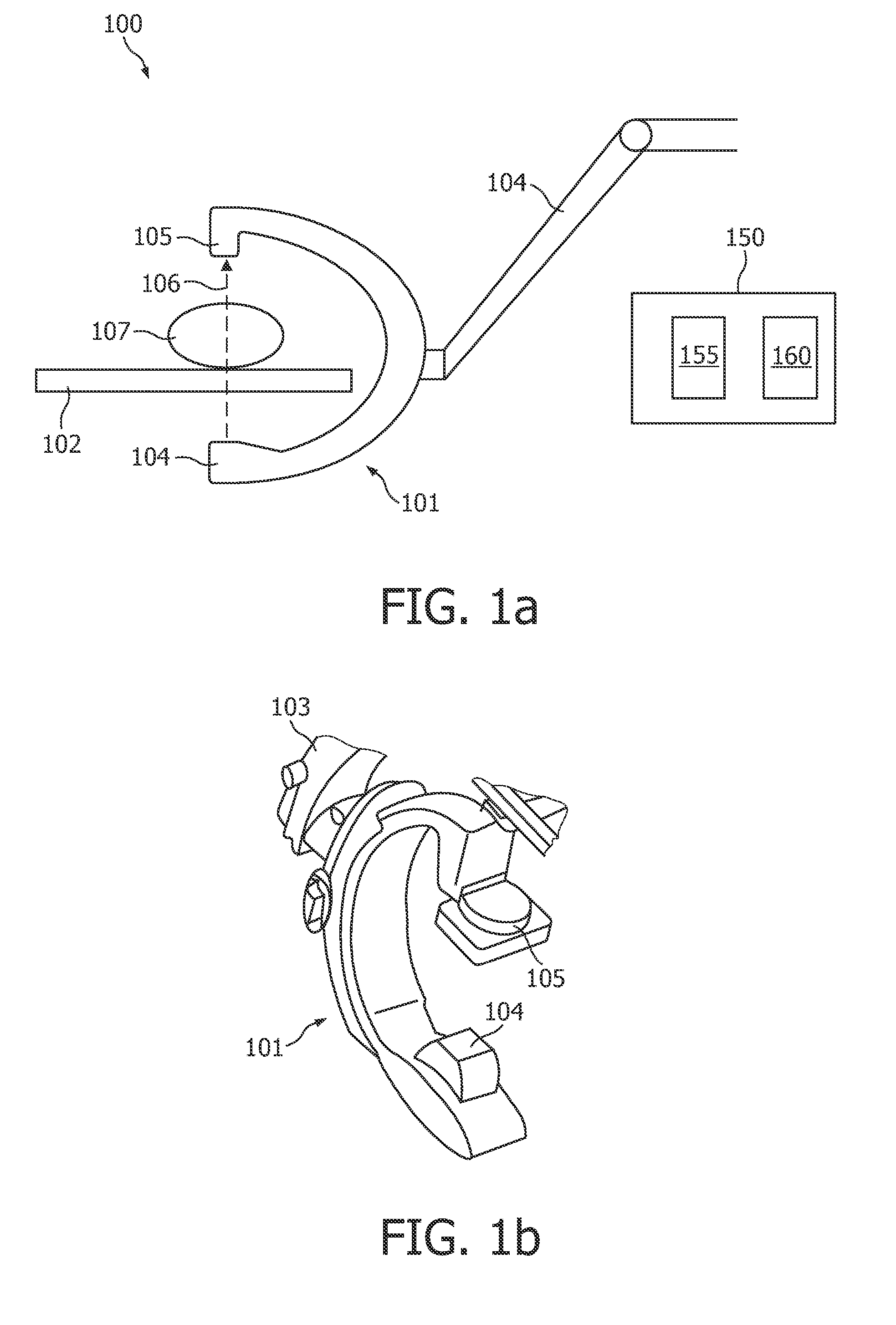

Method and apparatus for fluid migration profiling

ActiveUS20090326826A1Electric/magnetic detection for well-loggingConstructionsSection planeFluid migration

A method for obtaining a fluid migration profile for a wellbore, comprising the steps of obtaining a static profile for a logged region of the wellbore, obtaining a dynamic profile for the logged region of the wellbore, digitally filtering the dynamic profile to remove frequency elements represented in the static profile, to provide a fluid migration profile, and storing the fluid migration profile on a computer-readable memory.

Owner:HIFI ENG

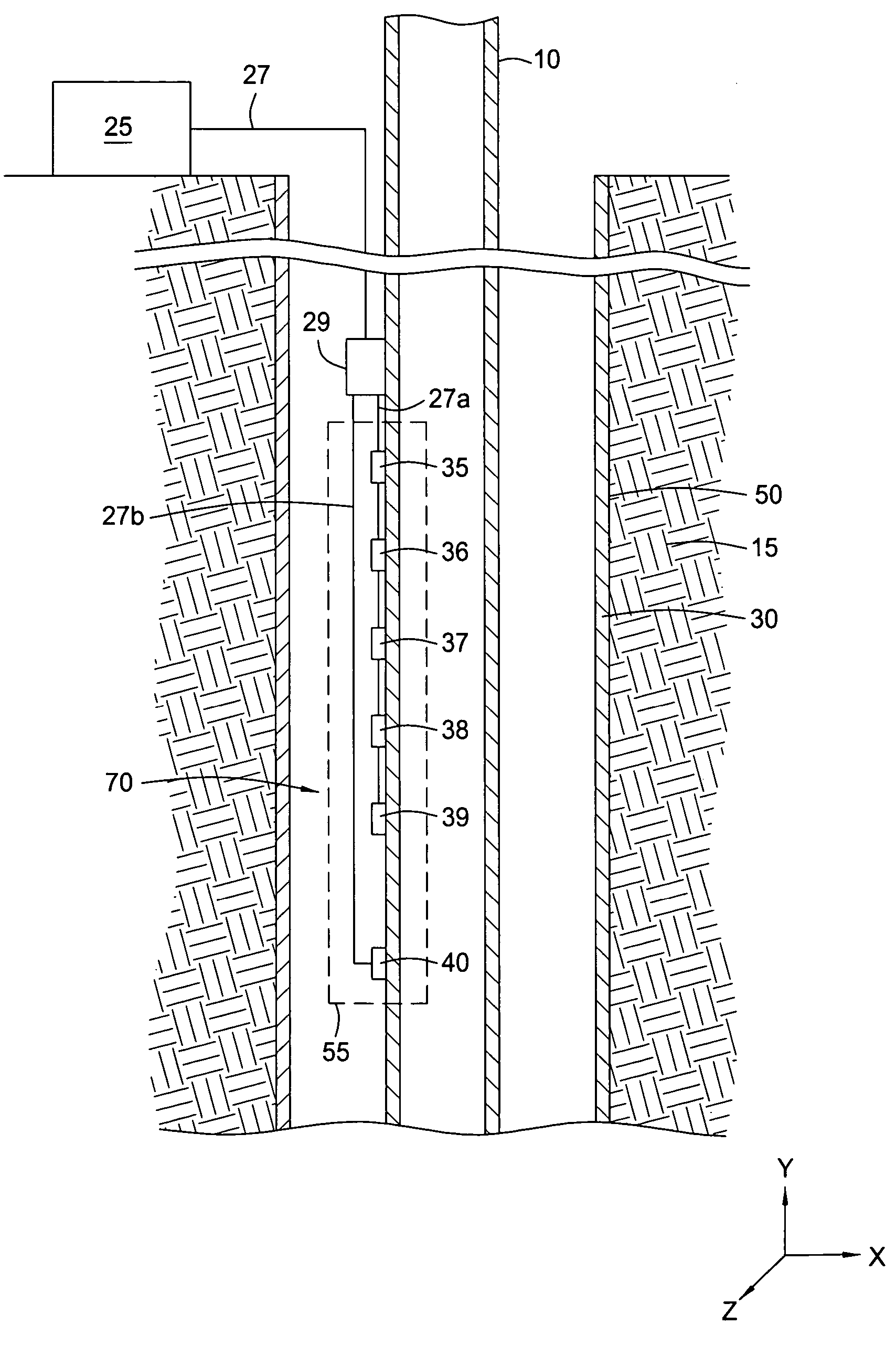

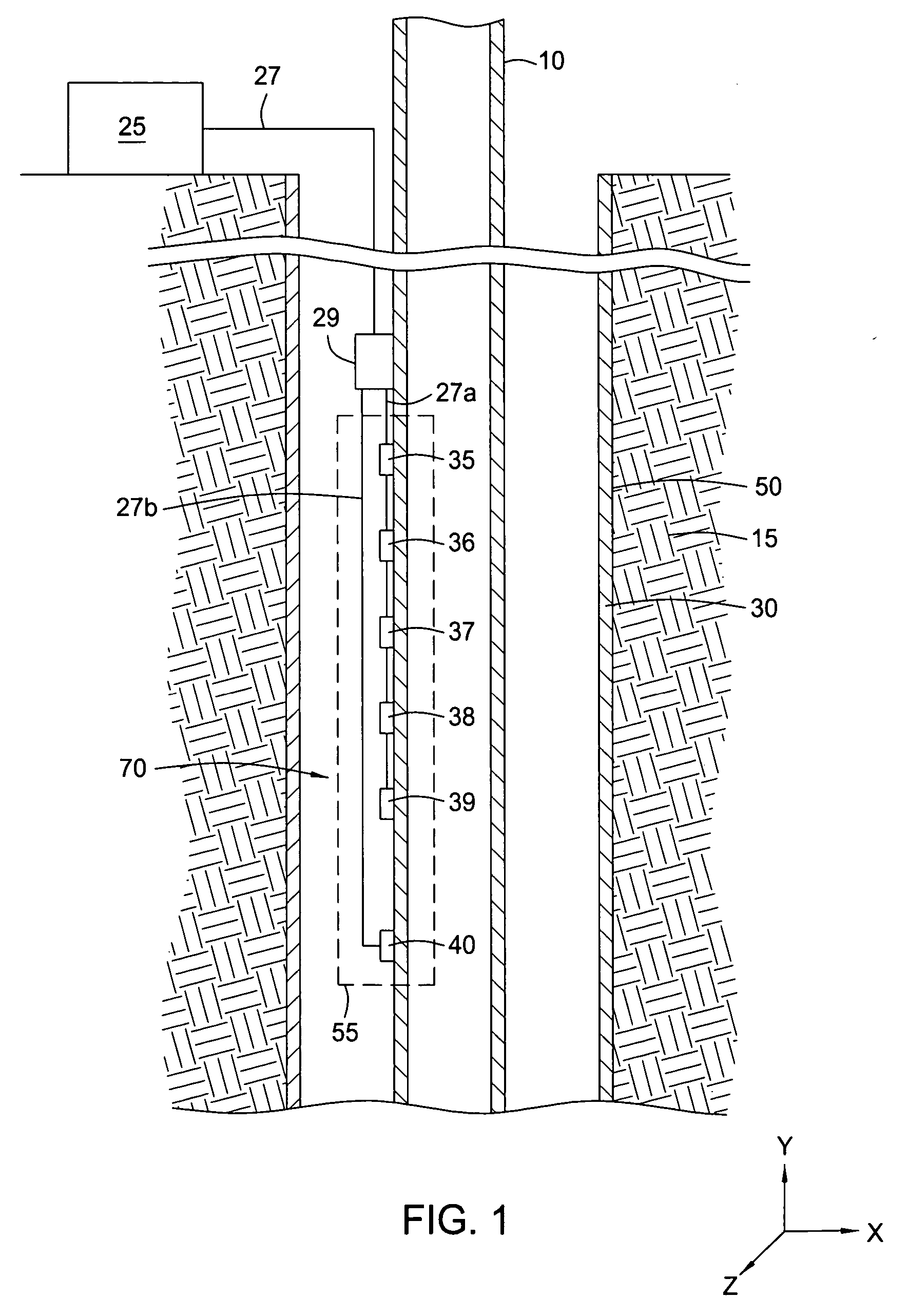

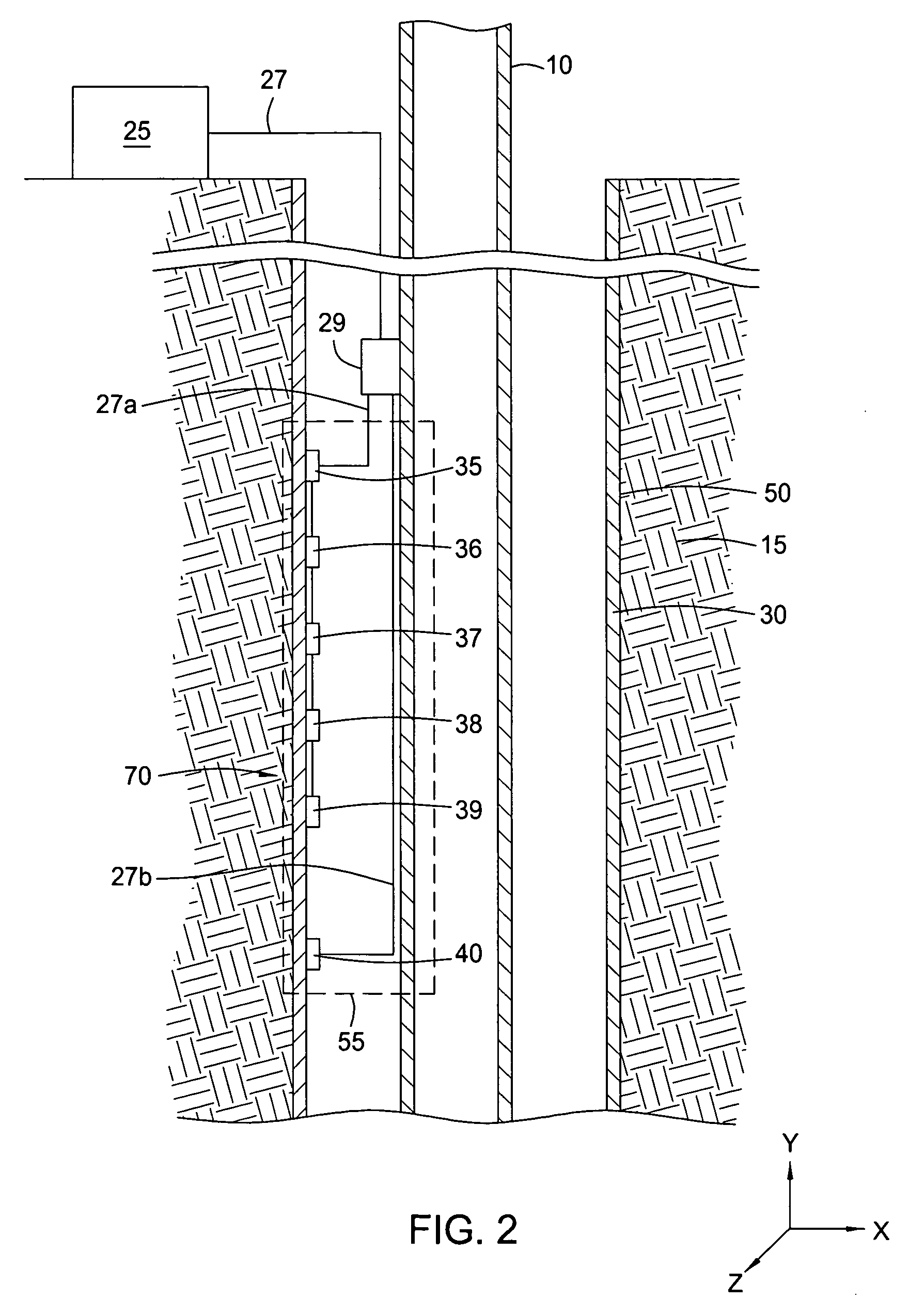

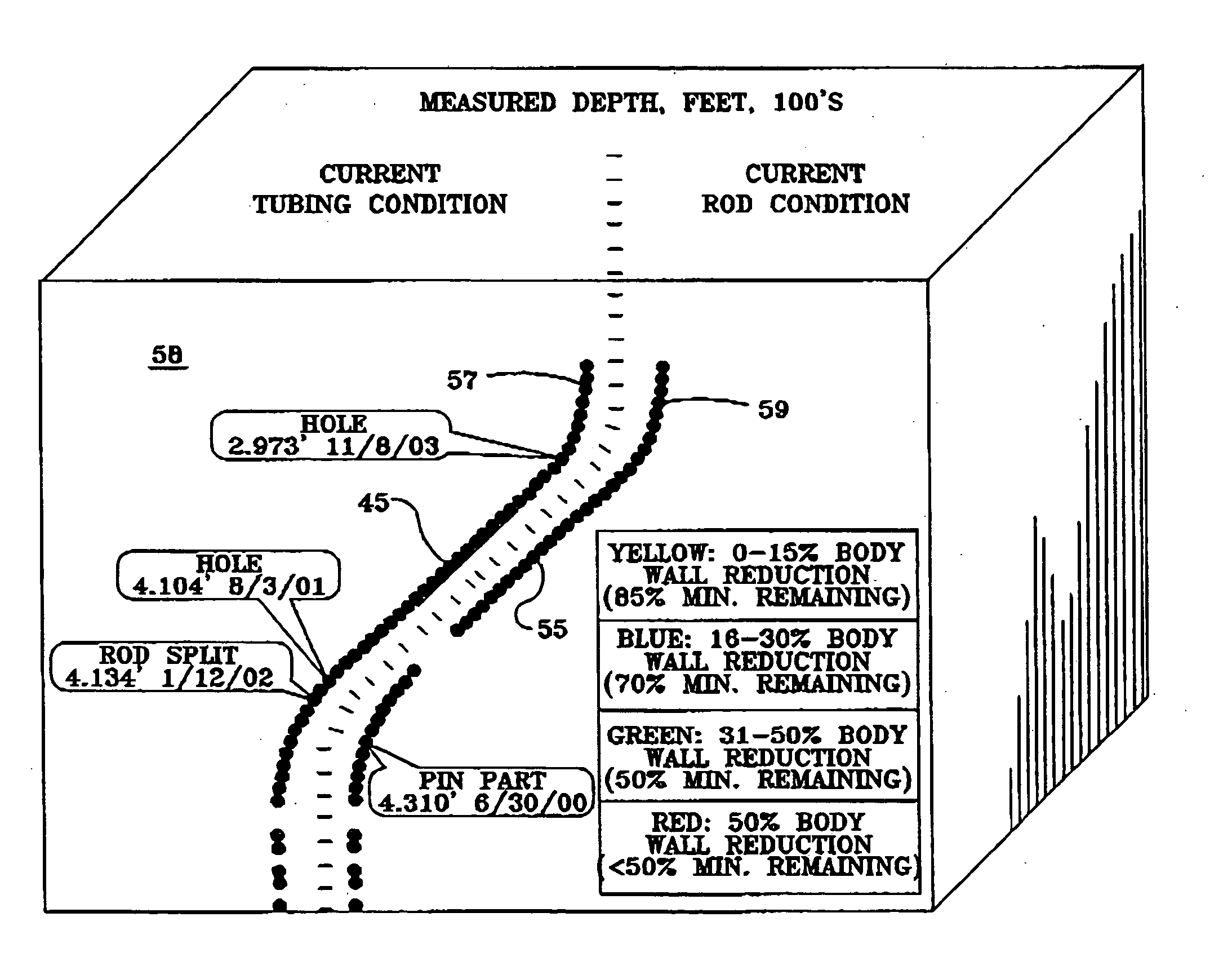

Wellbore evaluation system and method

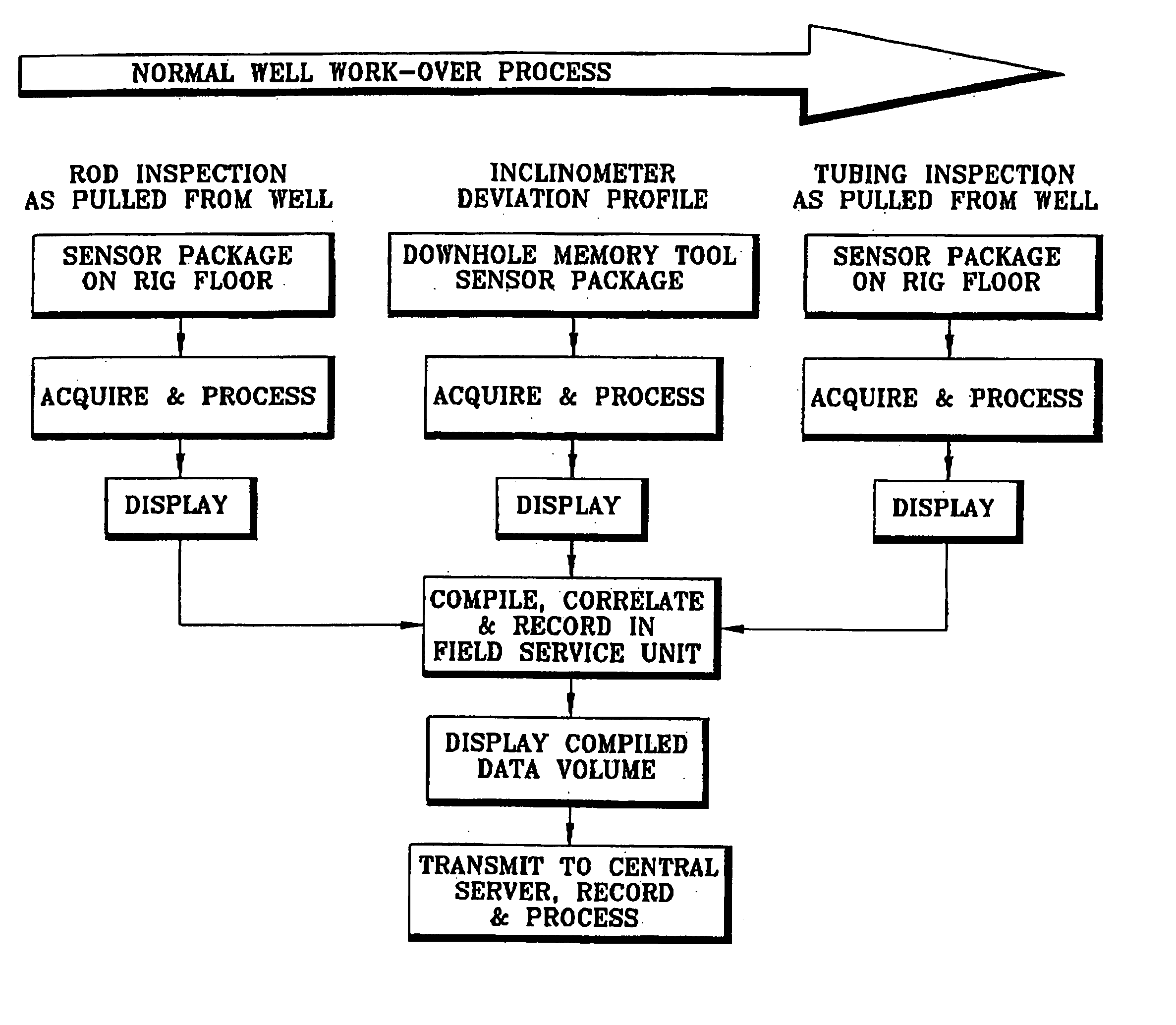

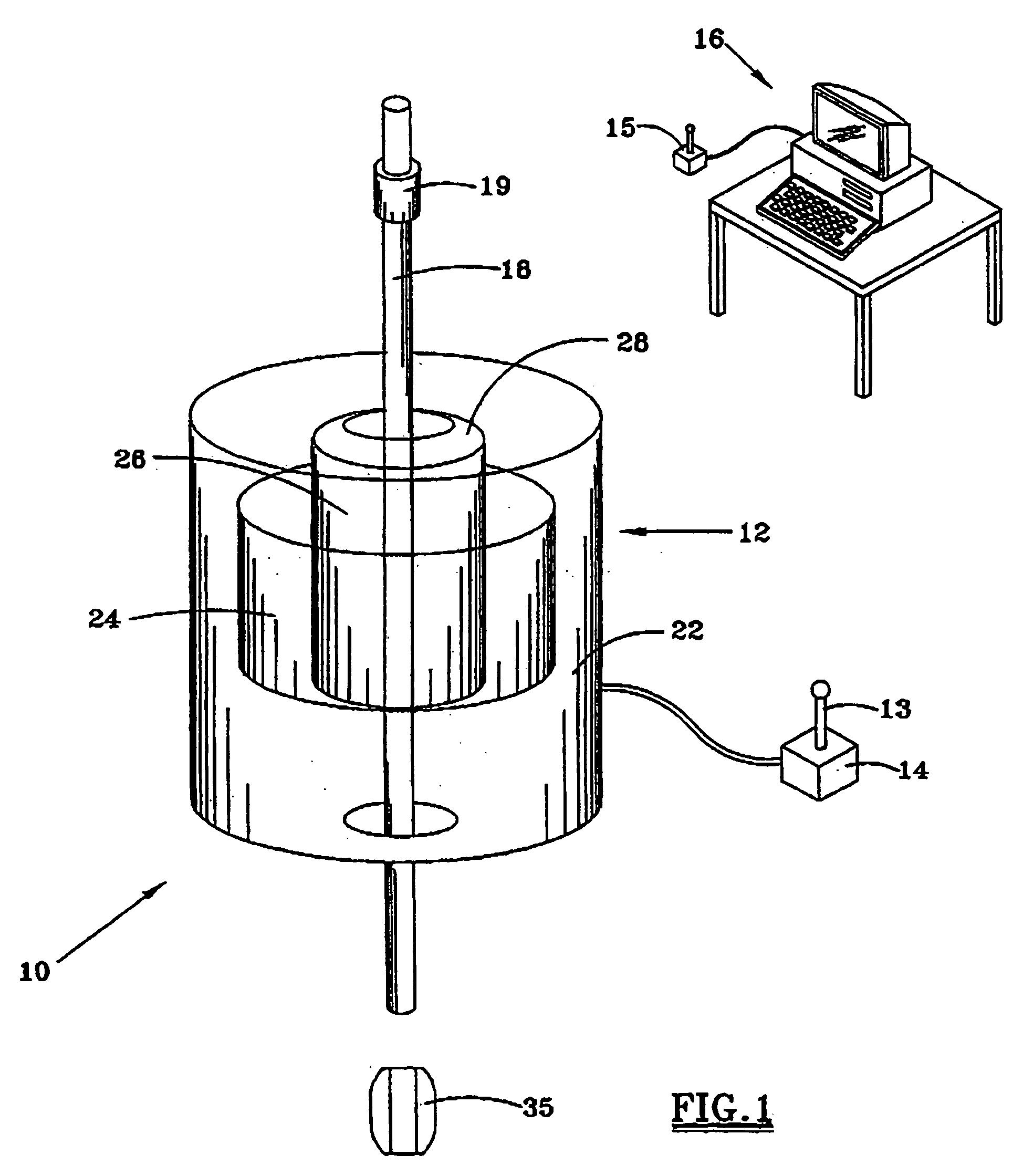

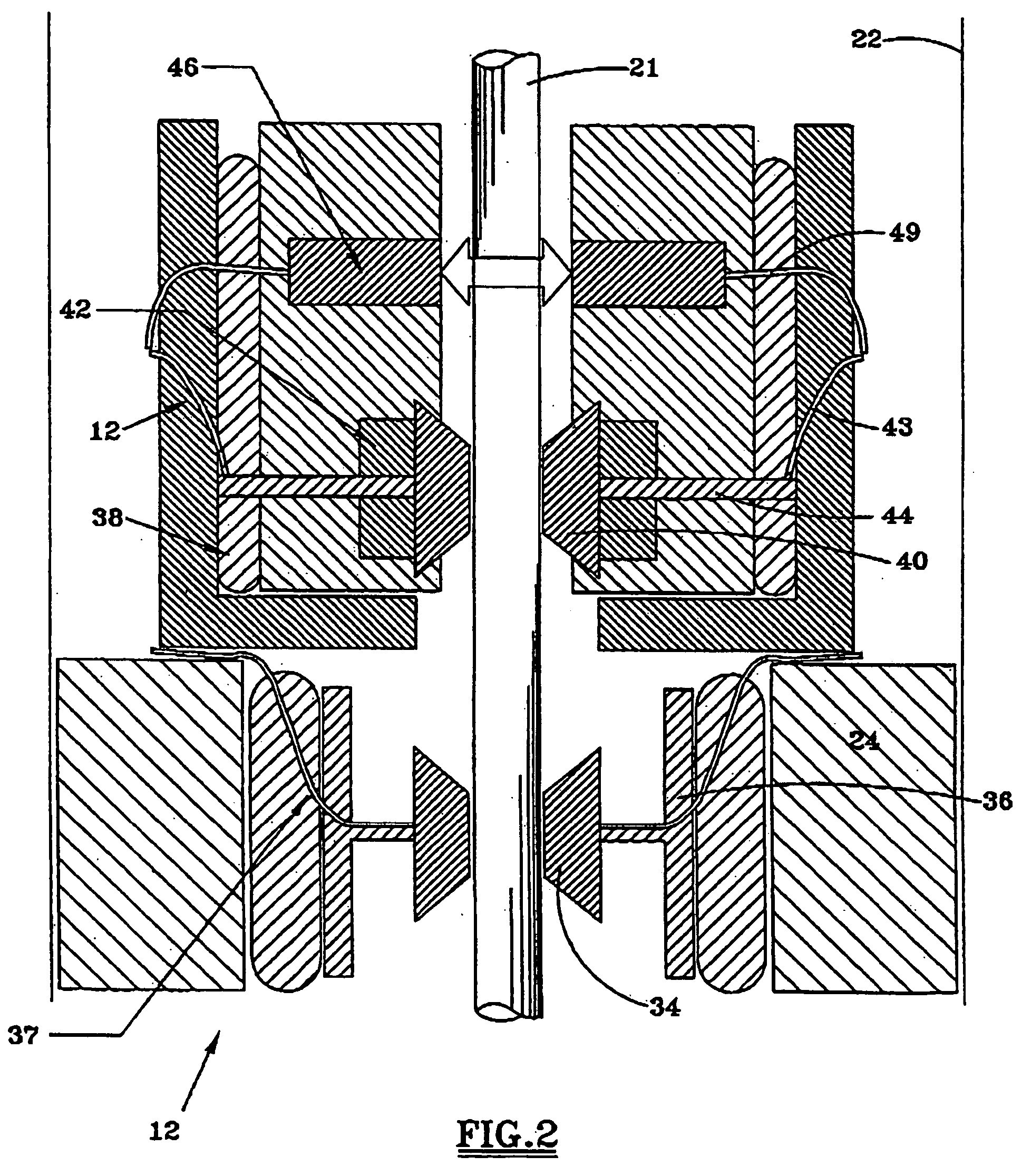

ActiveUS20060271299A1Electric/magnetic detection for well-loggingSurveySection planeData acquisition

A wellbore evaluation system evaluates mechanical wear and corrosion to components of a well system including a production tubing string positionable in a well and a sucker rod string movable within the production tubing string. A deviation sensor determines a deviation profile of the production tubing string in the well, and a rod sensor senses and measures wear and corrosion to the sucker rod string as it is removed from the well to determine a rod profile. A data acquisition computer is in communication with the sensors for computing and comparing the deviation profile and the rod profile as a function of depth in the well. A 3-dimensional image of wellbores, with isogram mapping, may be generated and examined over the internet.

Owner:ROBBINS & MYERS ENERGY SYST

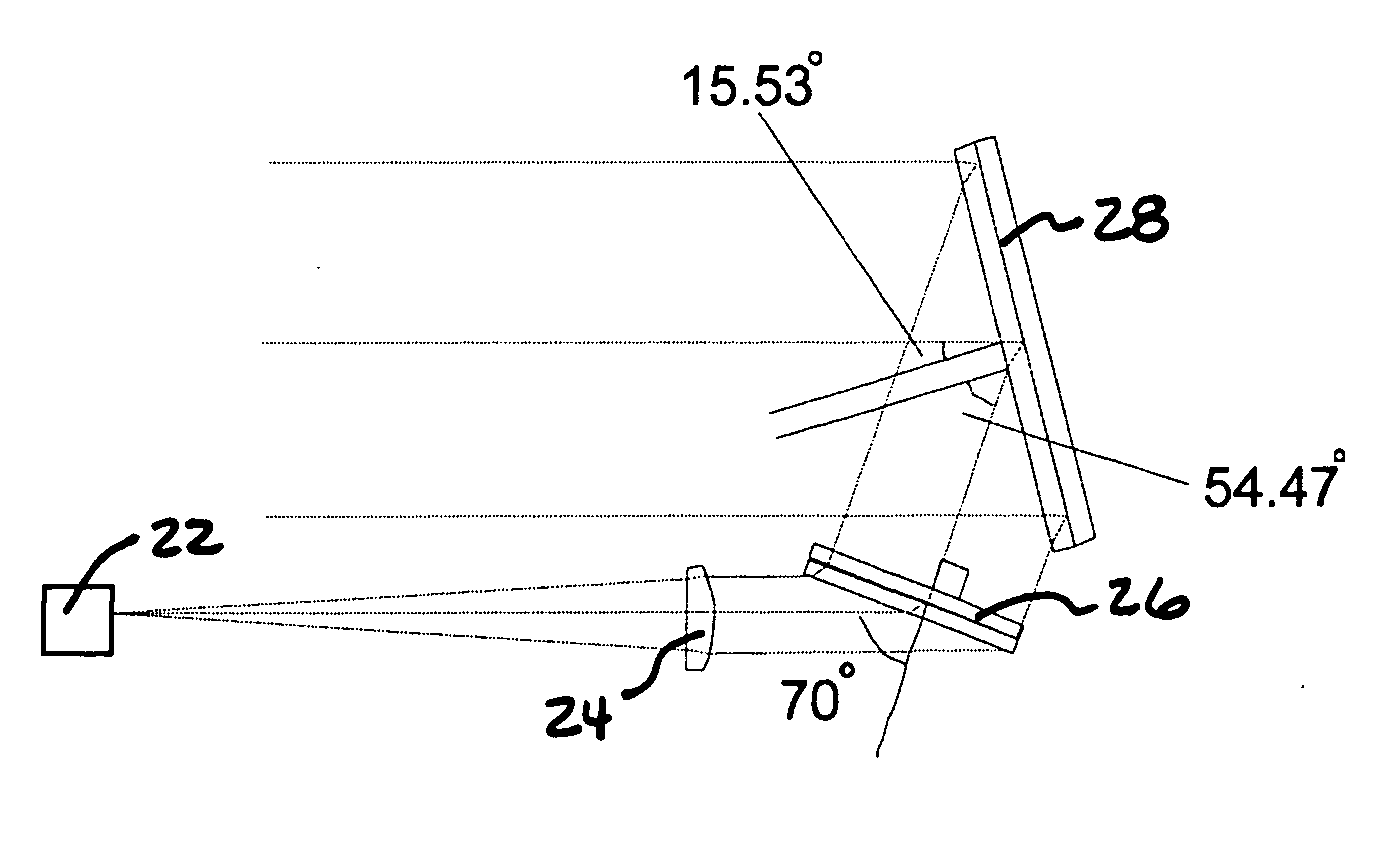

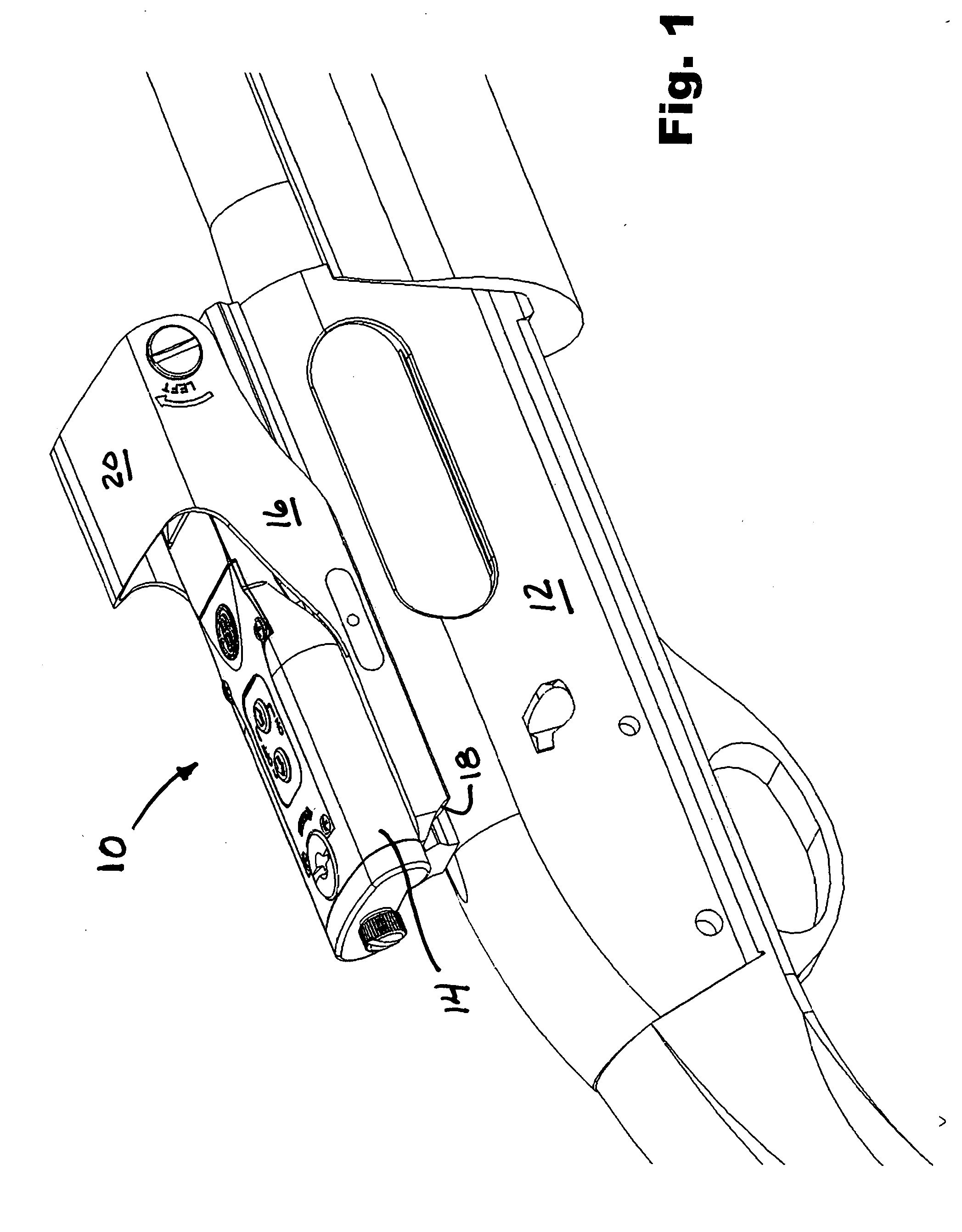

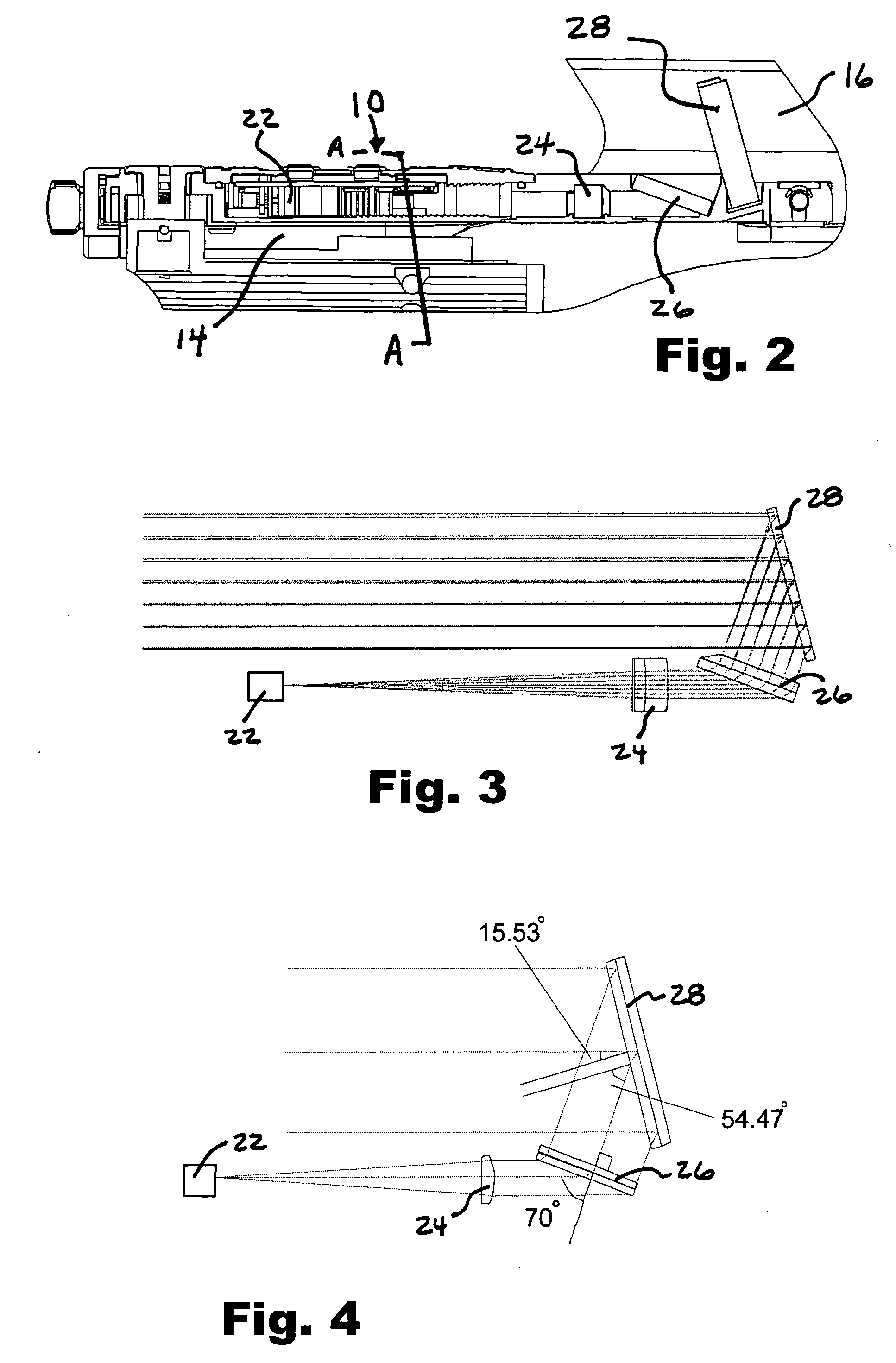

Low profile holographic sight and method of manufacturing same

A low profile holographic sight includes a base having a mounting mechanism and a body mounted on the base for housing a laser diode, an associated electronic control and power source, and optical elements including a collimator, a transmission image hologram of the reticle pattern, and a reflective diffraction grating, wherein the optical elements are arranged within the body to direct and fold the laser beam in a substantially generally horizontal path, and is insensitive to drift in laser wavelength. The optical elements superimpose an image of the reticle pattern over the direct view of the target scene in a generally parallel and close relationship with the barrel of a firearm, such as a shotgun or a rifle, upon which the sight is mounted.

Owner:EOTECH LLC

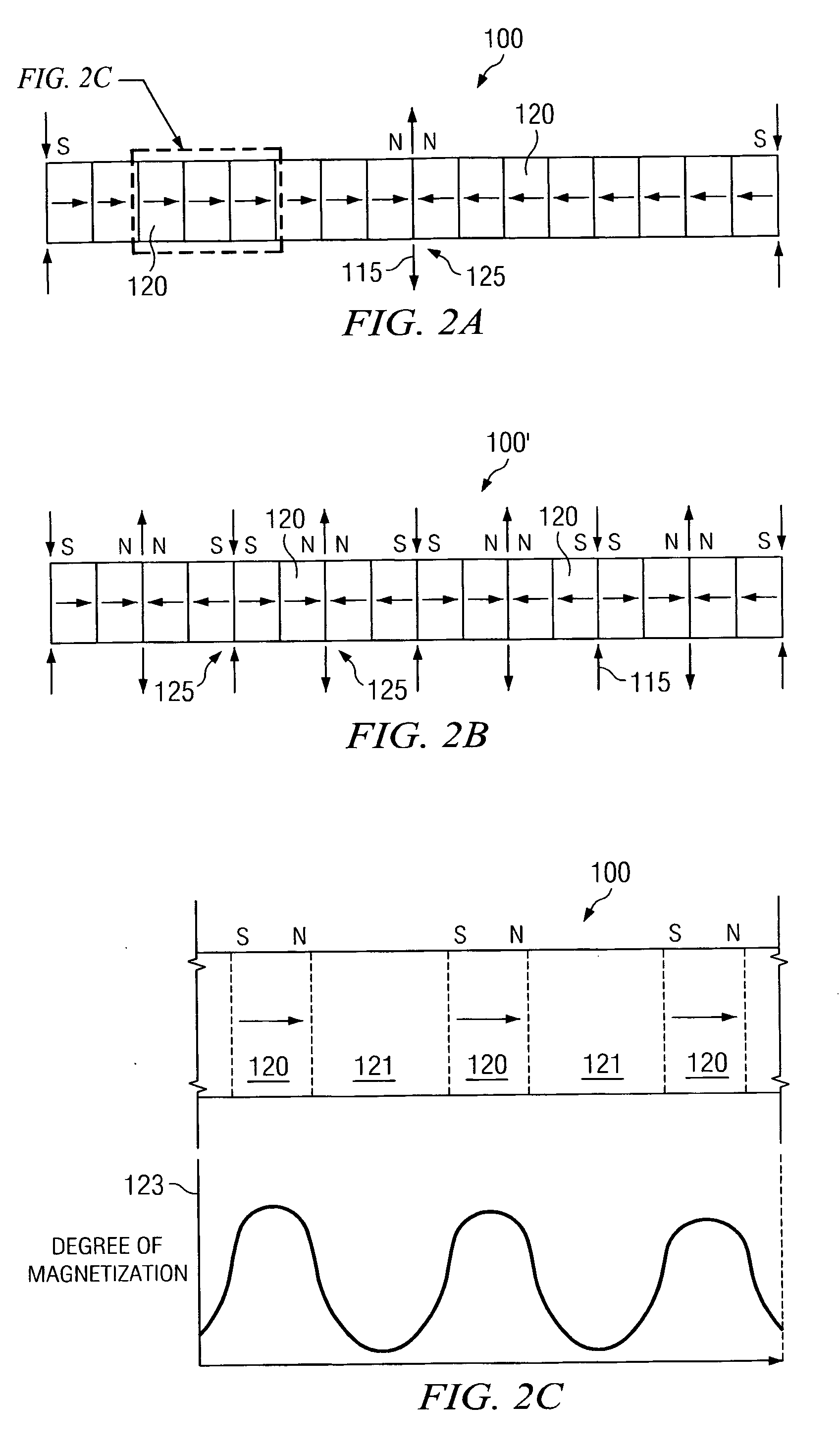

Magnetization of target well casing strings tubulars for enhanced passive ranging

InactiveUS20060131013A1Small diameterCost effectiveElectric/magnetic detection for well-loggingSurveySection planeMagnetic poles

A method for magnetizing a wellbore tubular is disclosed. The method includes magnetizing a wellbore tubular at three or more discrete locations on the tubular. In exemplary embodiments the magnetized wellbore tubular includes at least one pair of opposing magnetic poles located between longitudinally opposed ends of the tubular. Wellbore tubulars magnetized in accordance with this invention may be coupled to one another to provide a magnetic profile about a section of a casing string. Passive ranging measurements of the magnetic field about the casing string may be utilized to survey and guide drilling of a twin well. Such an approach advantageously obviates the need for simultaneous access to both wells.

Owner:SCHLUMBERGER TECH CORP

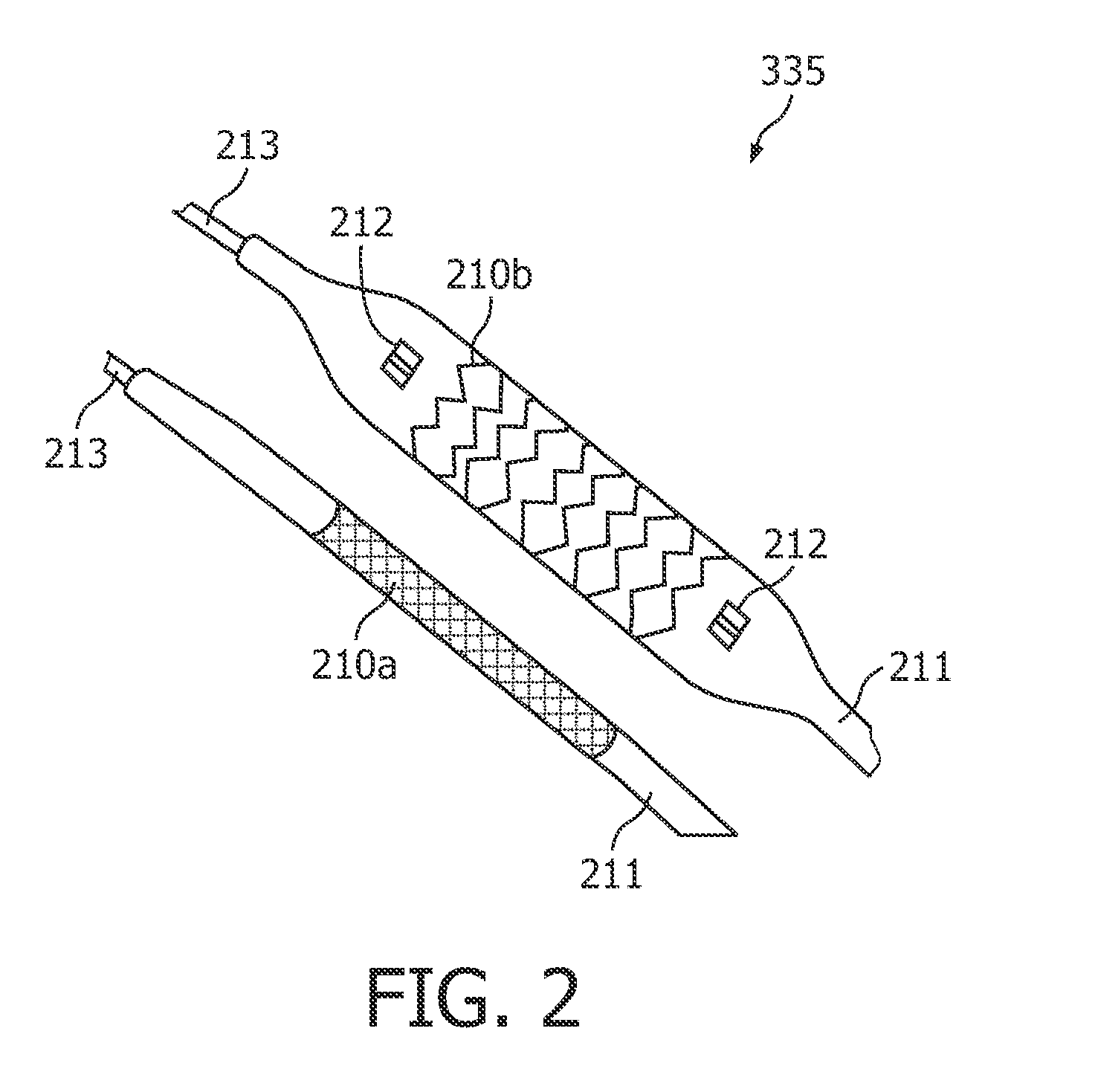

Spatial characterization of a structure located within an object by identifying 2d representations of the structure within section planes

InactiveUS20100099979A1Clear visualizationPrecise quantitative comparisonImage enhancementImage analysisSection planeSonification

It is described a virtual pullback as a visualization and quantification tool that allows an interventional cardiologist to easily assess stent expansion. The virtual pullback visualizes the stent and / or the vessel lumen similar to an Intravascular Ultrasound (IVUS) pullback. The virtual pullback is performed in volumetric data along a reference line. The volumetric data can be a reconstruction of rotational 2D X-ray attenuation data. Planes perpendicular to the reference line are visualized as the position along the reference line changes. This view is for interventional cardiologists a very familiar view as they resemble IVUS data and may show a section plane through a vessel lumen or a stent. In these perpendicular section planes automatic measurements, such as minimum and maximum diameter, and cross sectional area of the stent can be calculated and displayed. Combining these 2D measurements allows also volumetric measurements to be calculated and displayed.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

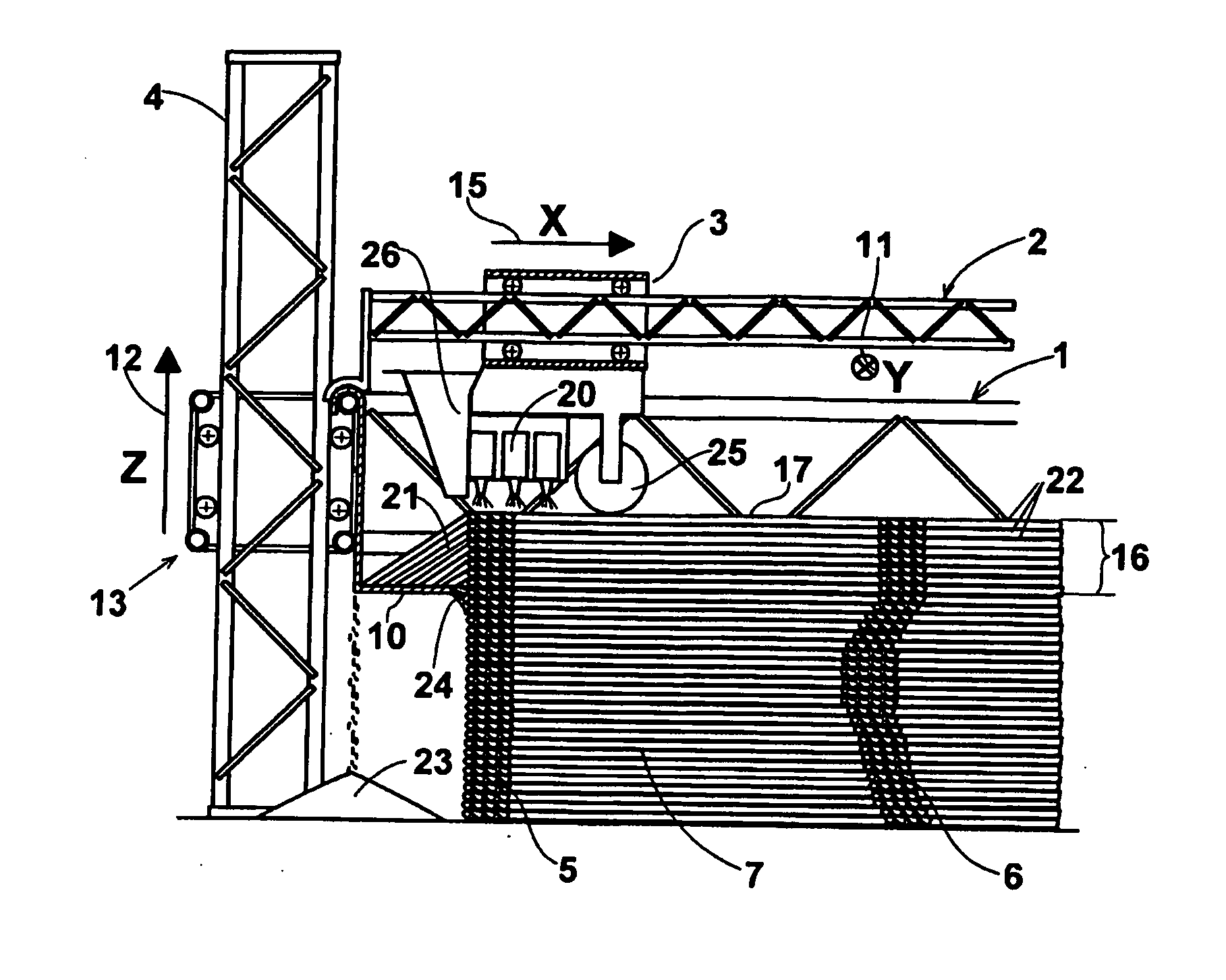

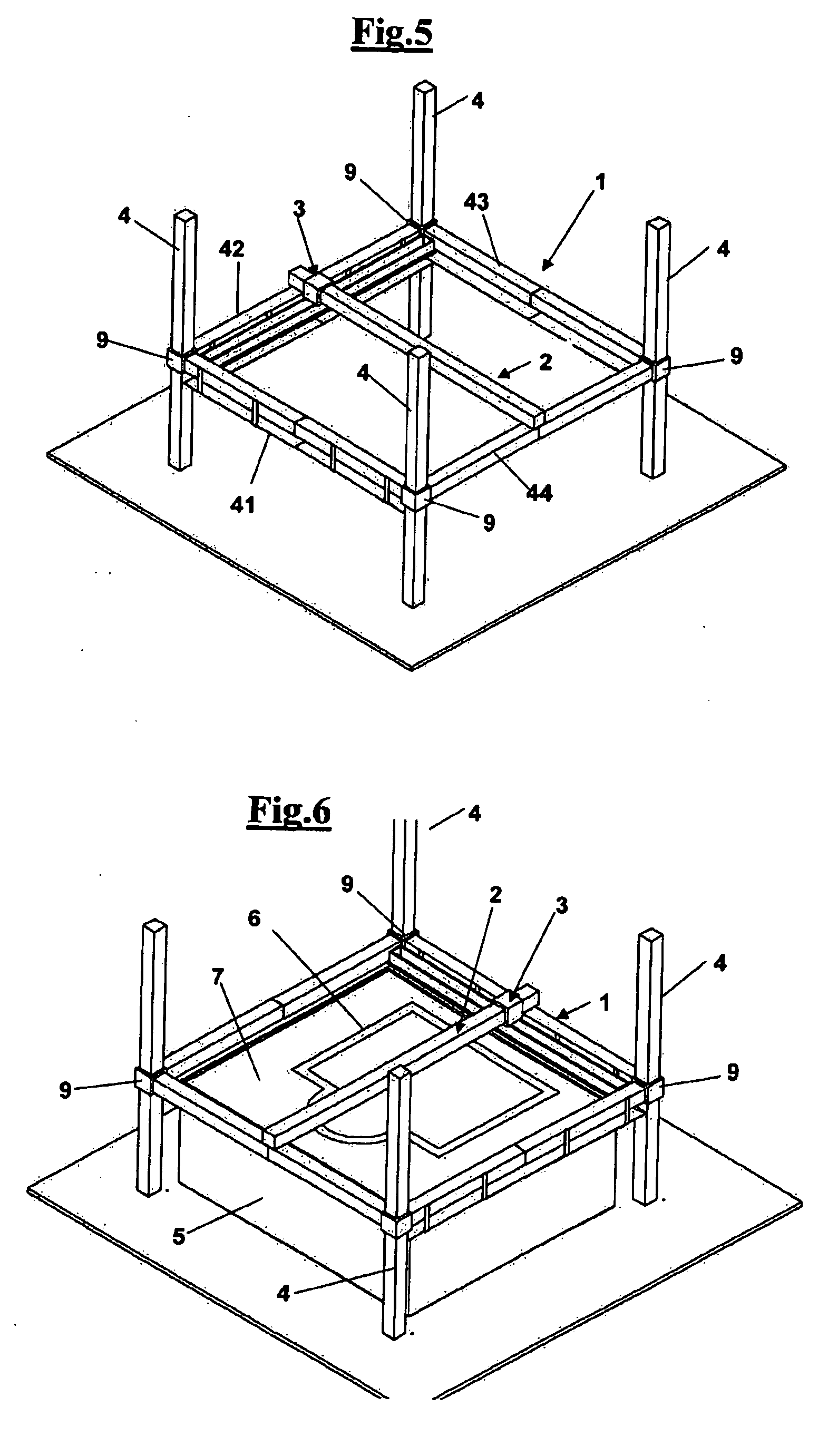

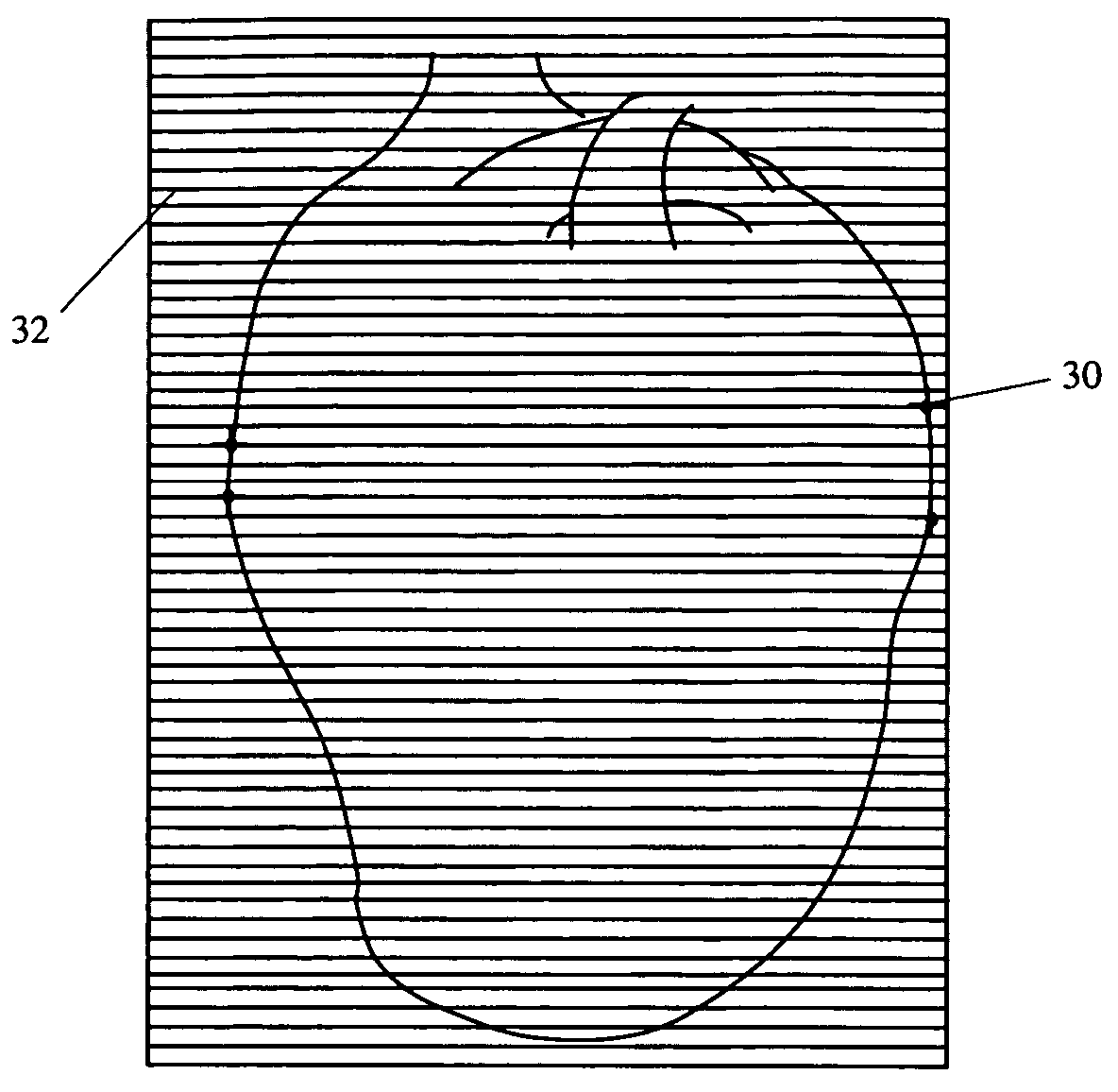

Method for automatically producing a conglomerate structure and apparatus therefor

InactiveUS20100207288A1Improve efficiencyReduce decreaseAdditive manufacturing apparatusMouldsSection planeEngineering

A method and an apparatus for automatically making conglomerated structures (6). The method comprises a) modelling a building structure and a containing shell about the structure by a computer using a CAD software thus obtaining a file; b) extracting sections of modelled structure and of modelled containing shell, by means of horizontal planes spaced apart of a predetermined pitch, such that a plurality of section planes is generated, said planes being sorted from below towards above with respect to the model of the structure and of the model of the shell; c) depositing by a moving unit (3) on a ground a bottom-to-top plurality of layers of granular material (22) alternate to a binding material liquid sprayed on the layers at filled areas corresponding to filled portions of the of the structure and of the containing shell, according to a predetermined path; d) vertically raising the moving unit (3) according to a pitch between a deposited layer and the following layer; e) repeating the step of depositing granulating material and repeating the step of spraying the binding material on a granulated material at filled areas of the structure and of the shell as many times as the planar cross sections into which said structure and the containing shell have been divided, each of said times for a different and consecutive section plane until the last layer (17) is complete; f) demolishing the containing shell (5) and removing unbound granular material (7) accumulated in the shell (5), thus releasing a conglomerate structure (6) that reproduces accurately said modelled structure. The apparatus comprises a horizontal frame (1), a bridge (2) sliding on guide on the horizontal frame (1), a moving unit (3) sliding along the bridge (2) or integral to the bridge (29) and have a spraying head (20). The horizontal frame (1) is moved along uprights (4) by a step actuator. The apparatus comprises a plurality of “skirts” (10) that surround the containing shell (5) and are integral to the horizontal frame (1). Such skirts scrape the outer surface of the containing shell (5) collecting the granular material (21) deposited out of the shell (5). Such skirts (10) can comprise an brush-like edge (20) suitable for externally sweeping the containing shell (5).

Owner:DINI ENRICO

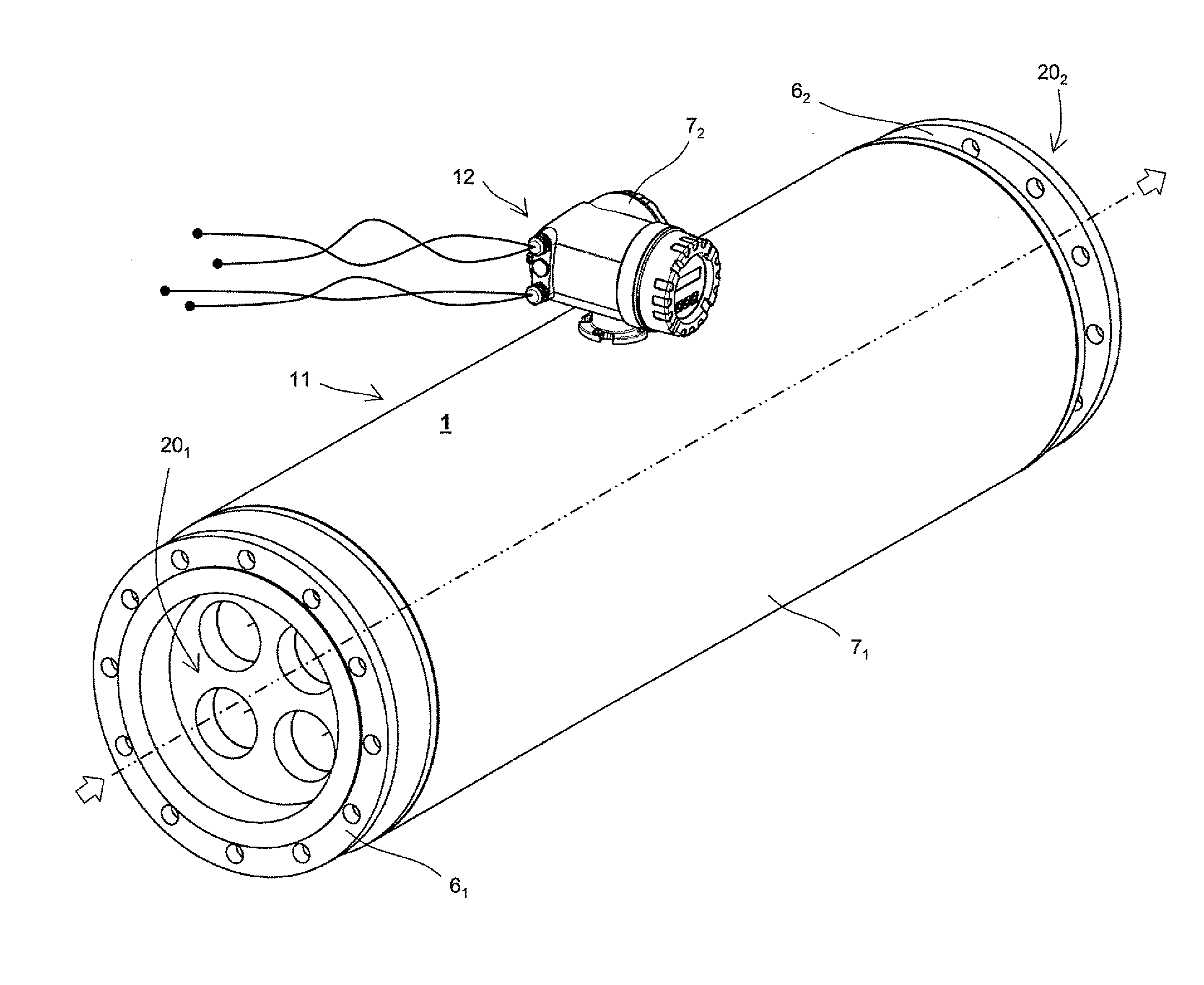

Permanently installed in-well fiber optic accelerometer-based seismic sensing apparatus and associated method

Embodiments of the present invention include a fiber optic seismic sensing system for permanent downhole installation. In one aspect, the present invention includes a multi-station, multi-component system for conducting seismic reservoir imaging and monitoring in a well. Permanent seismic surveys may be conducted with embodiments of the present invention, including time-lapse (4D) vertical seismic profiling (VSP) and extended micro-seismic monitoring. Embodiments of the present invention provide the ability to map fluid contacts in the reservoir using 4D VSP and to correlate micro-seismic events to gas injection and production activity.

Owner:WEATHERFORD TECH HLDG LLC

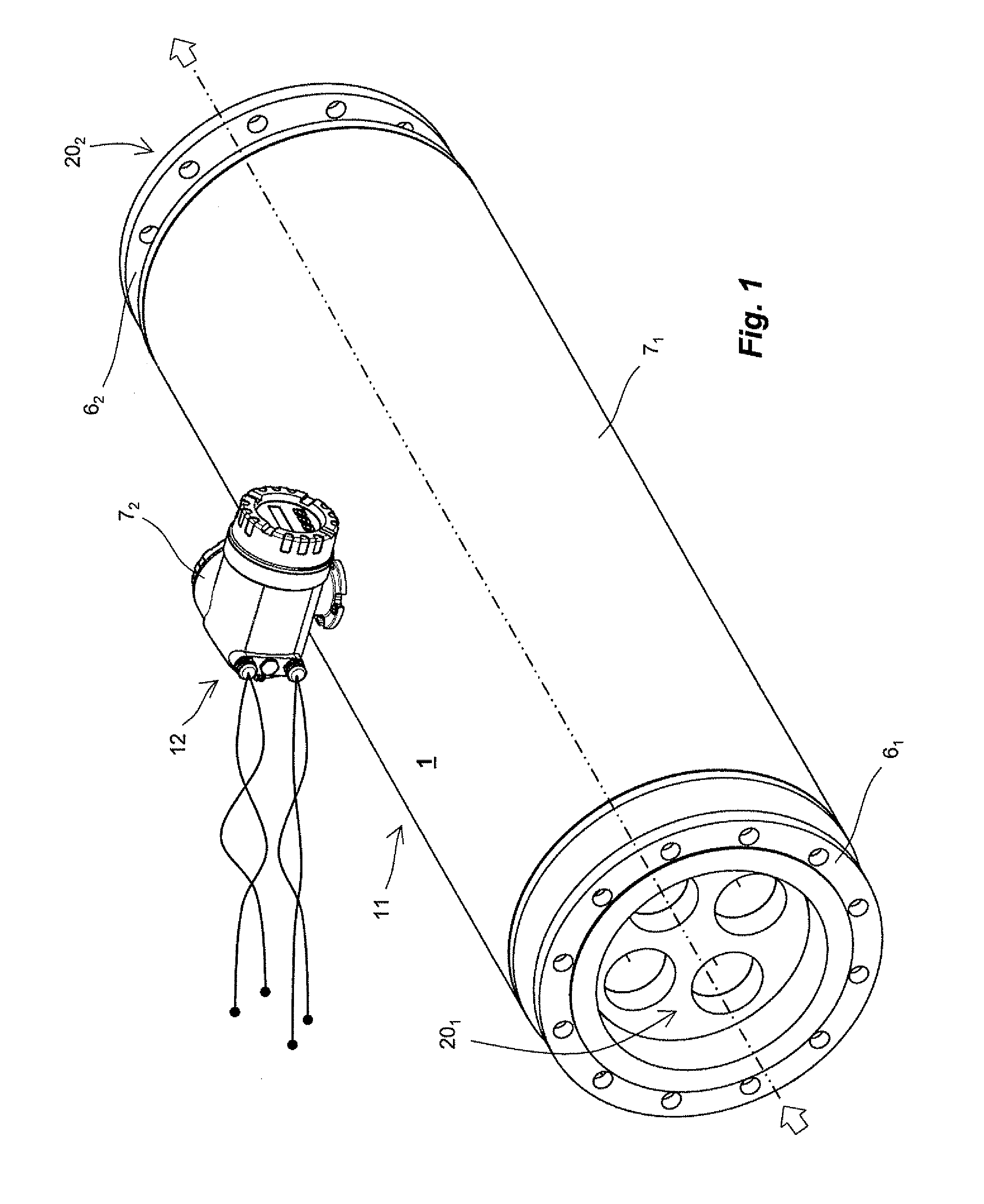

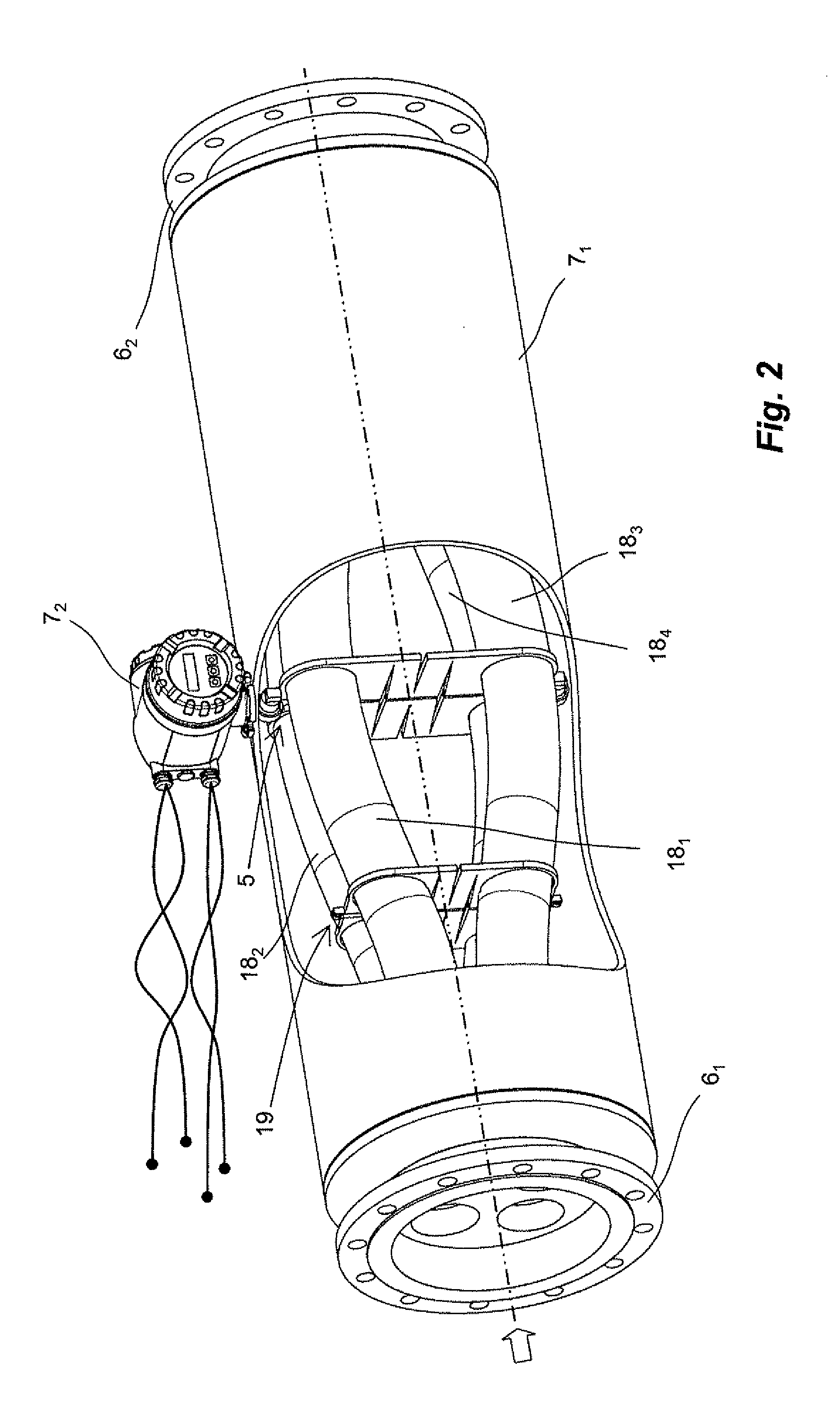

Measuring transducer of vibration-type

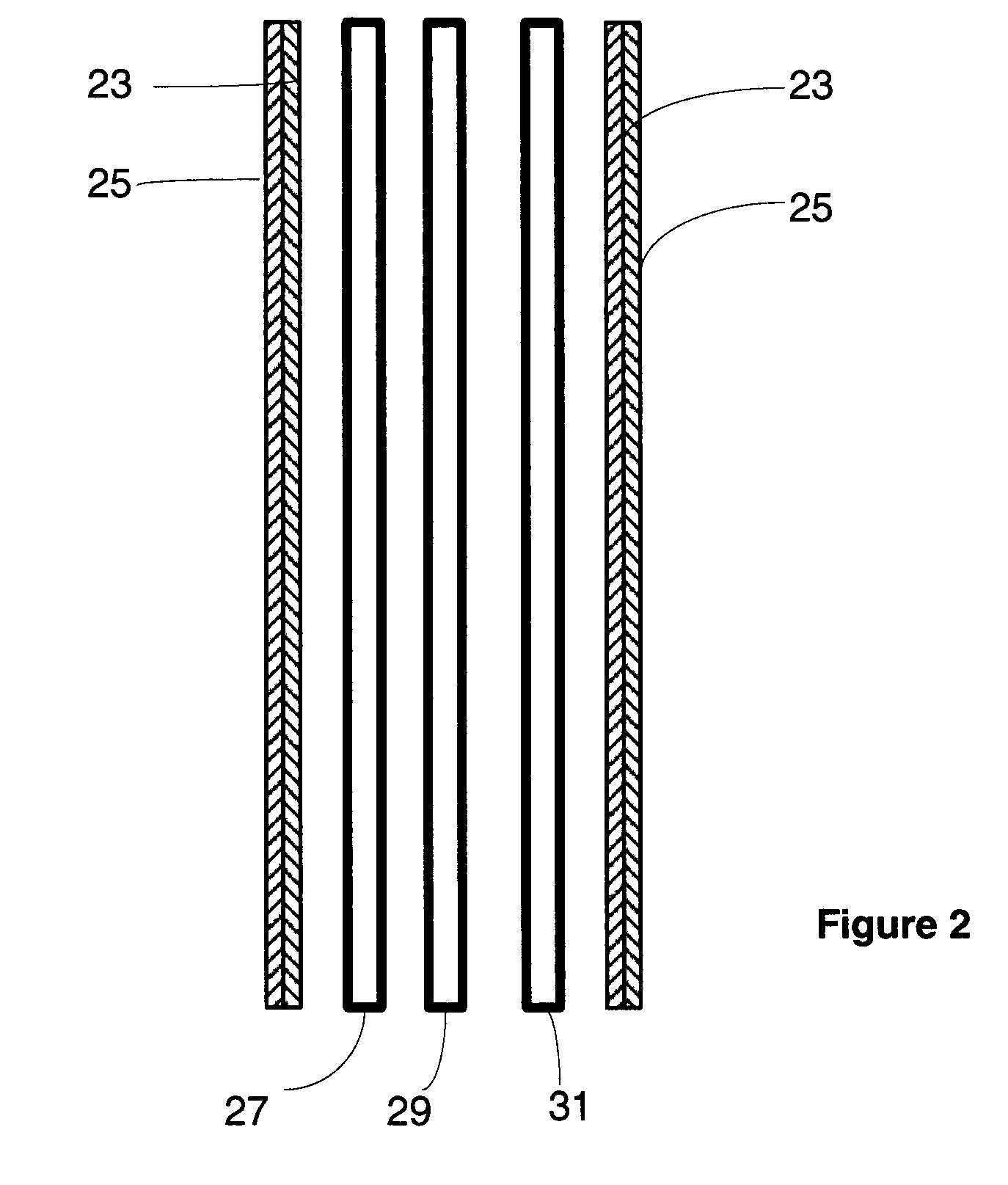

ActiveUS20110167907A1Impairs accuracy of measurementMeasurement accuracySpecific gravity using flow propertiesVolume variation compensation/correction apparatusSection planeTransducer

The measuring transducer comprises: a transducer housing, of which an inlet-side, housing end is formed by means of a flow divider including four flow openings spaced, and an outlet-side, formed by means of a flow divider including four flow openings spaced, from one another. A tube arrangement including four curved measuring tubes connected to the flow dividers for guiding flowing medium along flow paths connected in parallel. Each measuring tubes opens with an inlet-side, measuring tube end into one of the flow openings of the flow divider and with an outlet-side, measuring tube end into one the flow openings of the flow divider. The two flow dividers are embodied and arranged in the measuring transducer, so that the tube arrangement extends both between a first and a second of the measuring tubes and between a third and a fourth of the measuring tubes. An imaginary longitudinal-section plane, with respect to which the tube arrangement is mirror symmetric and perpendicular to the imaginary longitudinal-section plane, an imaginary longitudinal-section plane, with respect to which the tube arrangement likewise is mirror symmetric. An electromechanical exciter mechanism of the measuring transducer serves for producing and / or maintaining mechanical oscillations of the four measuring tubes.

Owner:ENDRESS HAUSER FLOWTEC AG

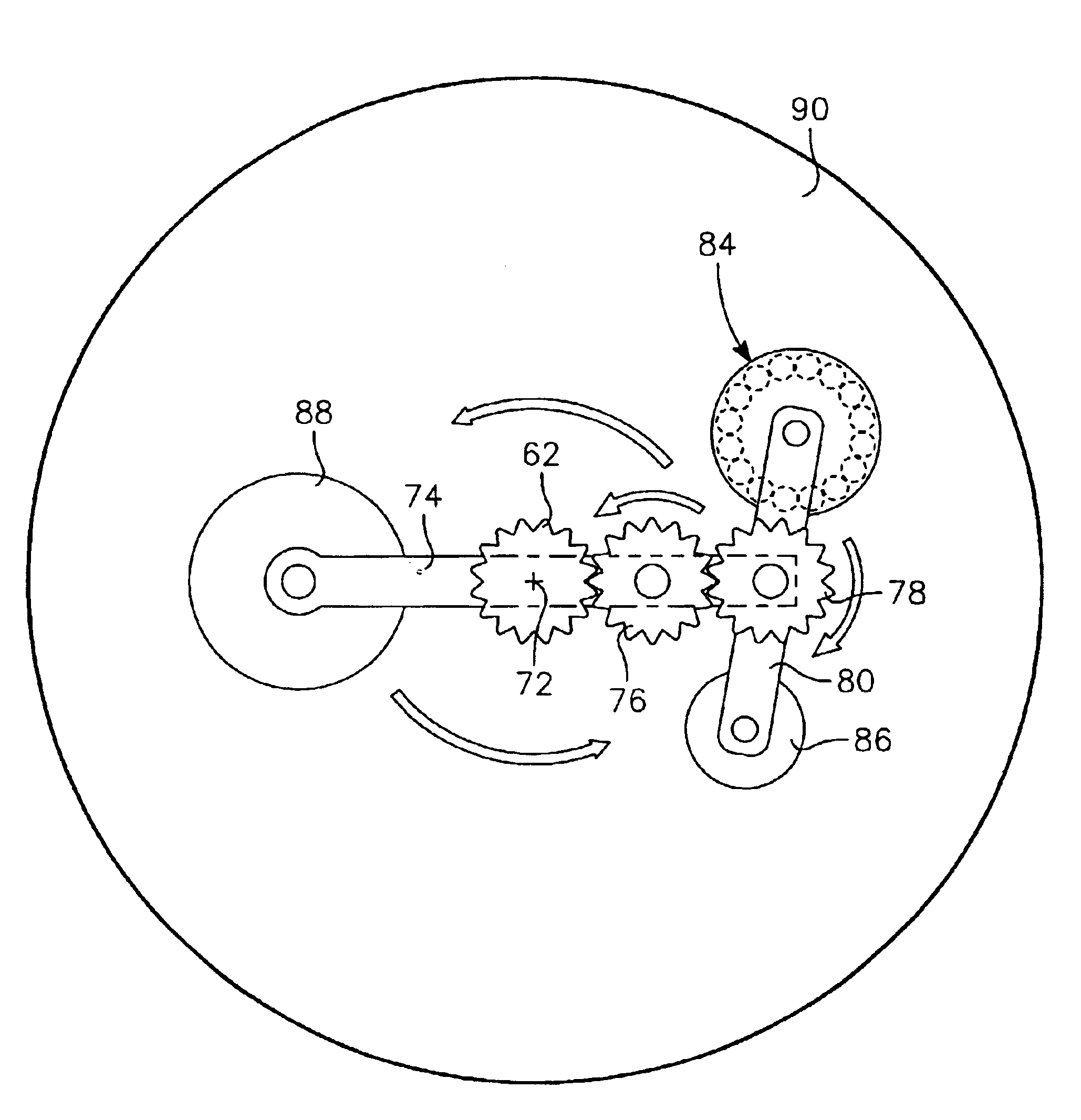

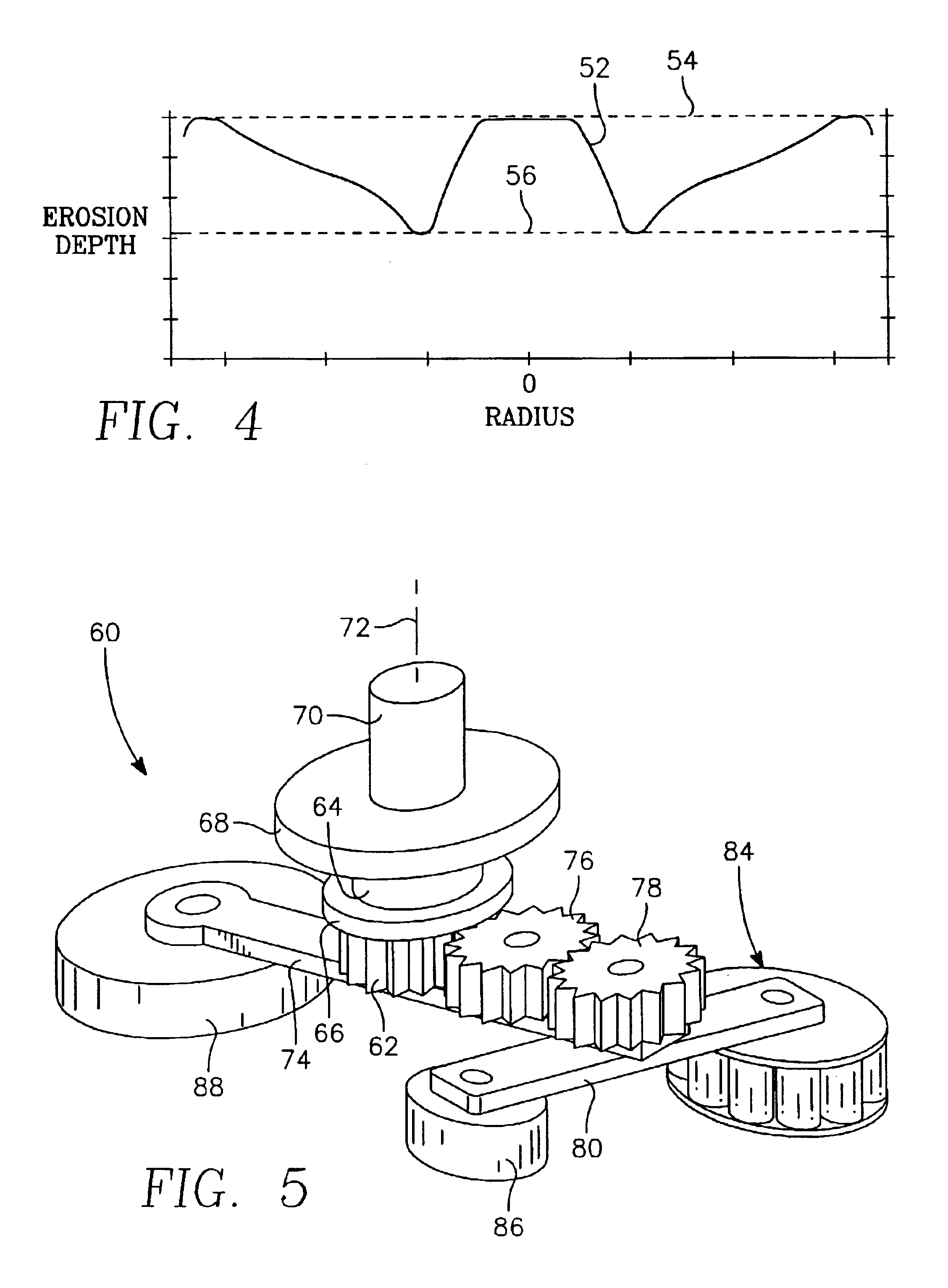

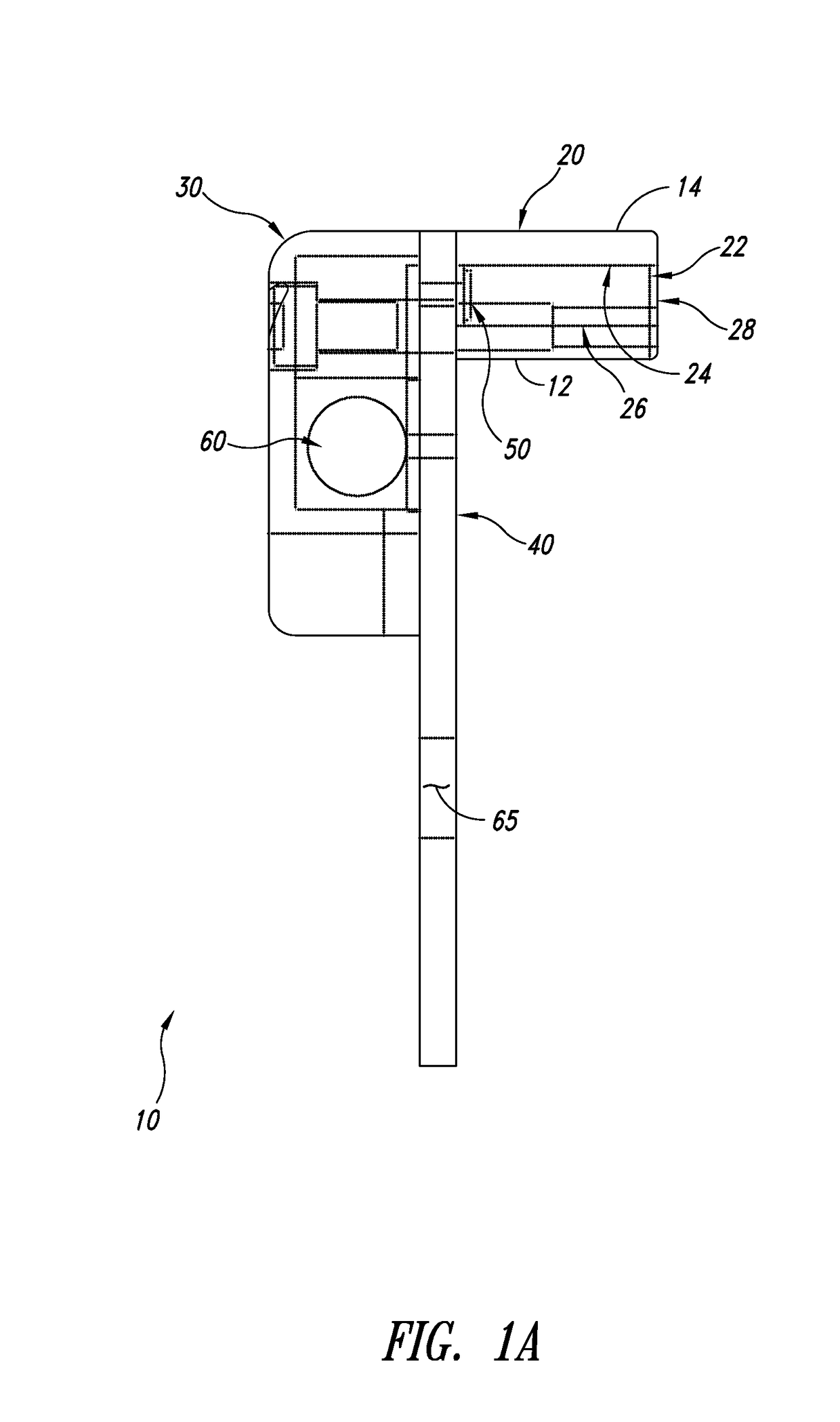

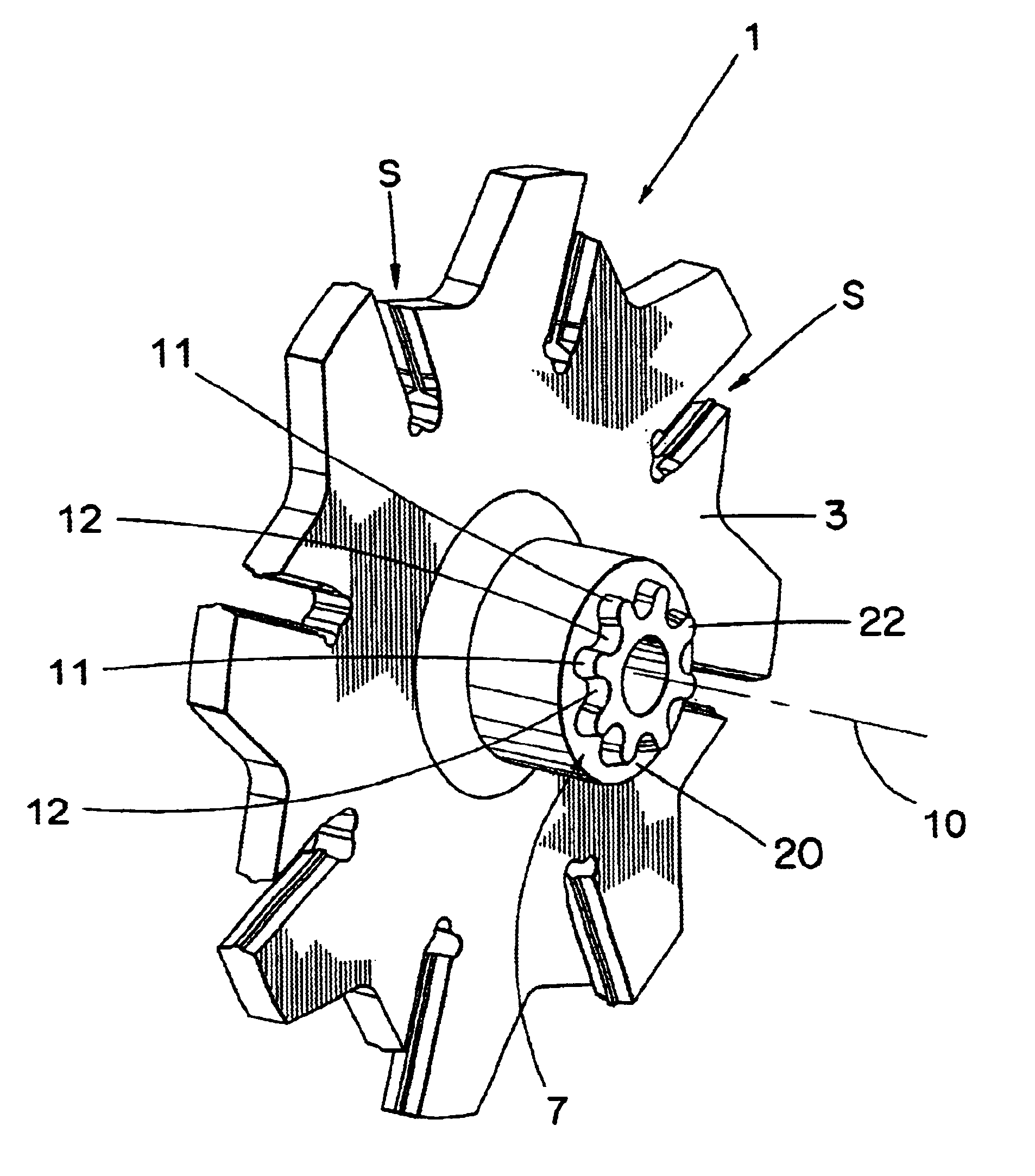

Small epicyclic magnetron with controlled radial sputtering profile

InactiveUS6852202B2Improve uniformityMore target utilizationCellsElectric discharge tubesSputteringSection plane

A small unbalanced magnet assembly is scanned in a retrograde planetary or epicyclic path about the back of a target being plasma sputtered including an orbital rotation about the center axis of the target and a planetary rotation about another axis rotating about the target center axis. The magnet assembly may pass through the target center, thus allowing full target coverage. A geared planetary mechanism may include a rotating drive plate, a fixed center gear, and an idler and a follower gear rotatably supported in the drive plate supporting a cantilevered magnet assembly on the side of the drive plate facing the target. The erosion profile may be controlled by varying the rotation rate through the rotation cycle or by modulating the target power. A second planetary stage may be added or non-circular gears be used. Auxiliary electromagnetic coils may create a focusing magnetic field.

Owner:APPLIED MATERIALS INC

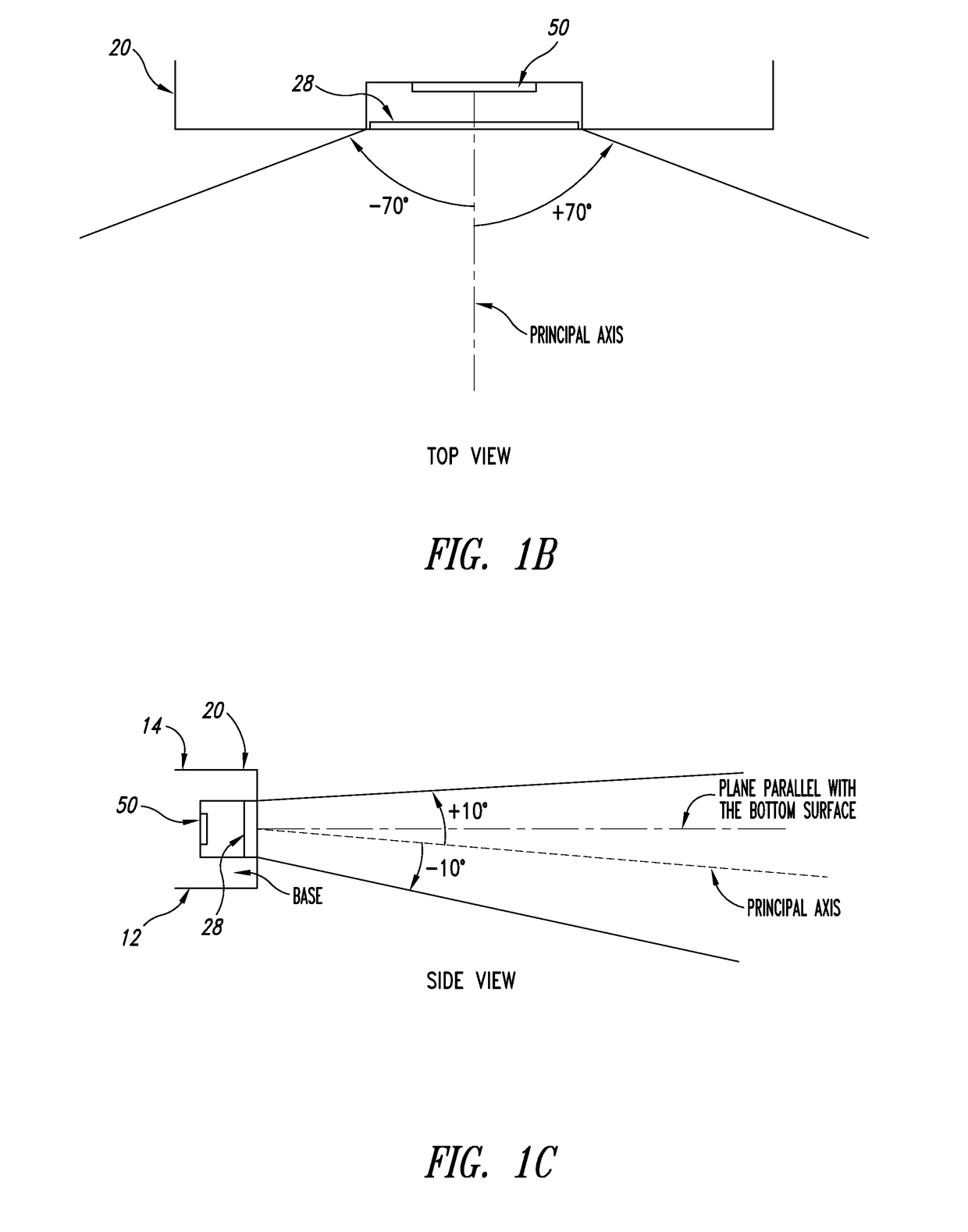

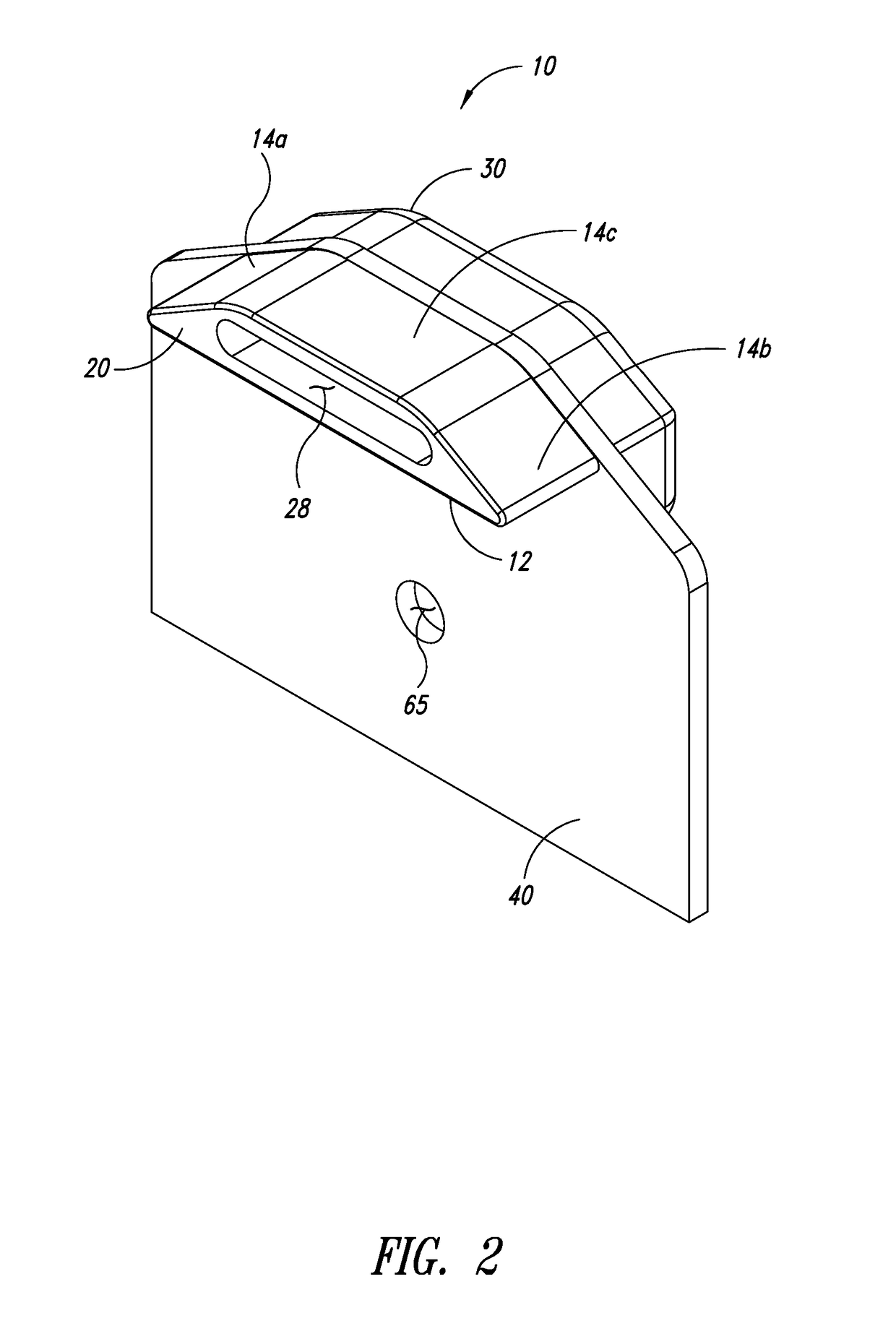

Low-profile pathway illumination system

A luminaire to illuminate surfaces comprises a housing, a mounting fixture and a light source. The housing includes a base having a bottom surface positionable on a surface to be illuminated, an interior, and at least one window providing access between the interior and an exterior of the housing. The mounting fixture extends at least approximately perpendicularly downward with respect to the bottom surface of the base to secure the housing into a peripheral portion of the surface to be illuminated. The light source has a principal axis of emission that is directed outwardly through the window of the housing at a downwardly oriented angle with respect to the bottom surface of the base such that, when in use with the luminaire mounted to the surface to be illuminated, the principal axis of emission of the light source is directed at a portion of the surface to be illuminated.

Owner:EXPRESS IMAGING SYST

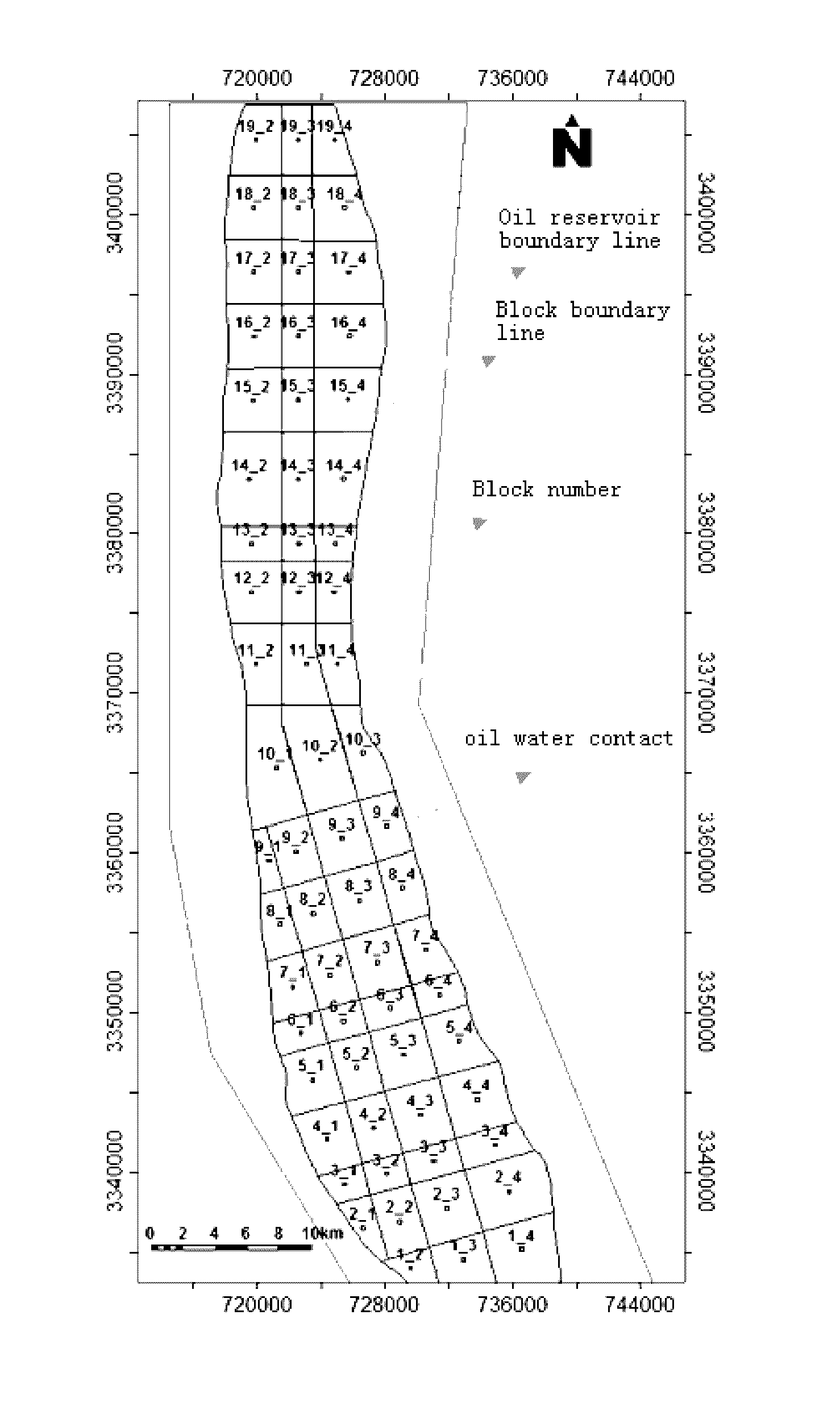

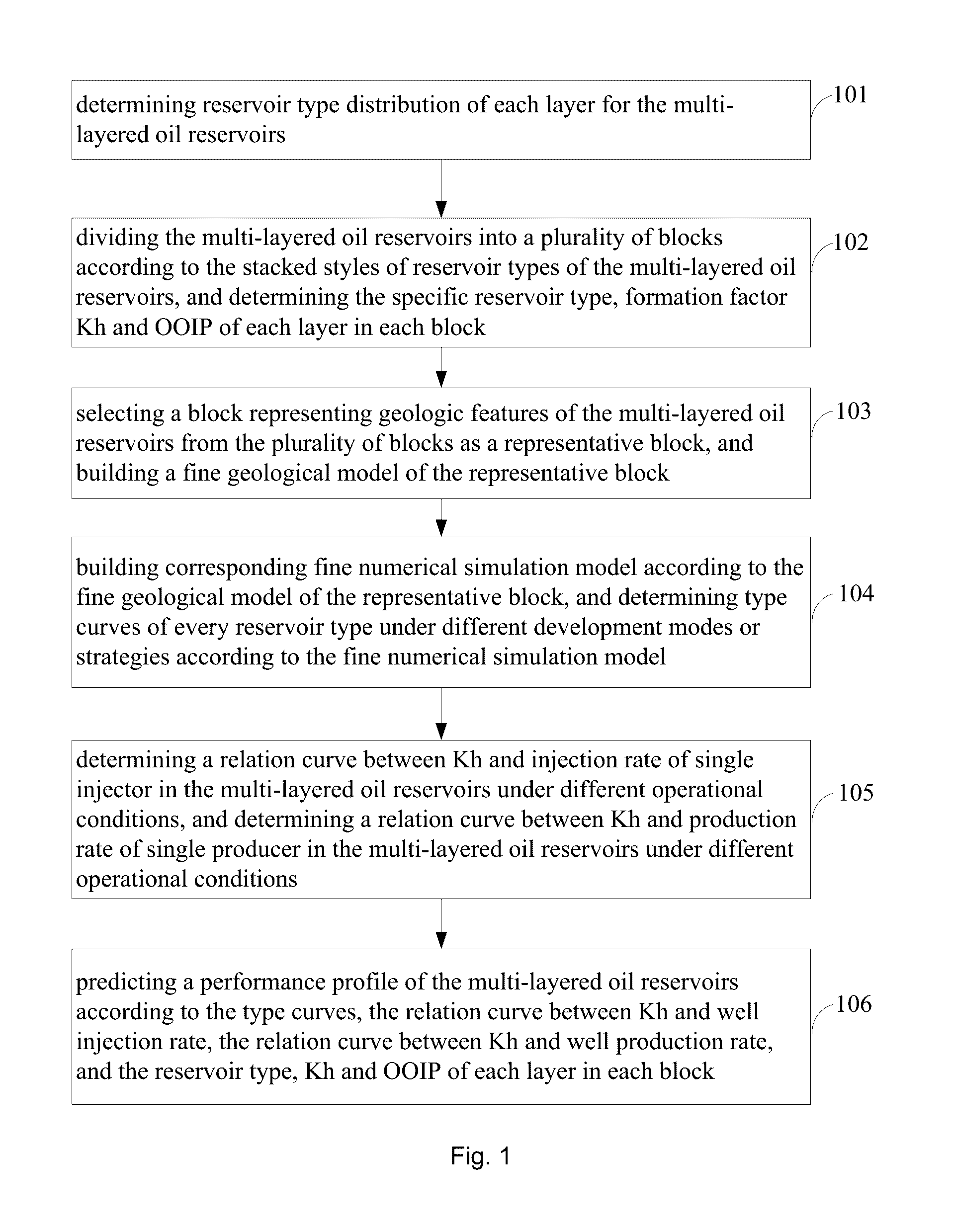

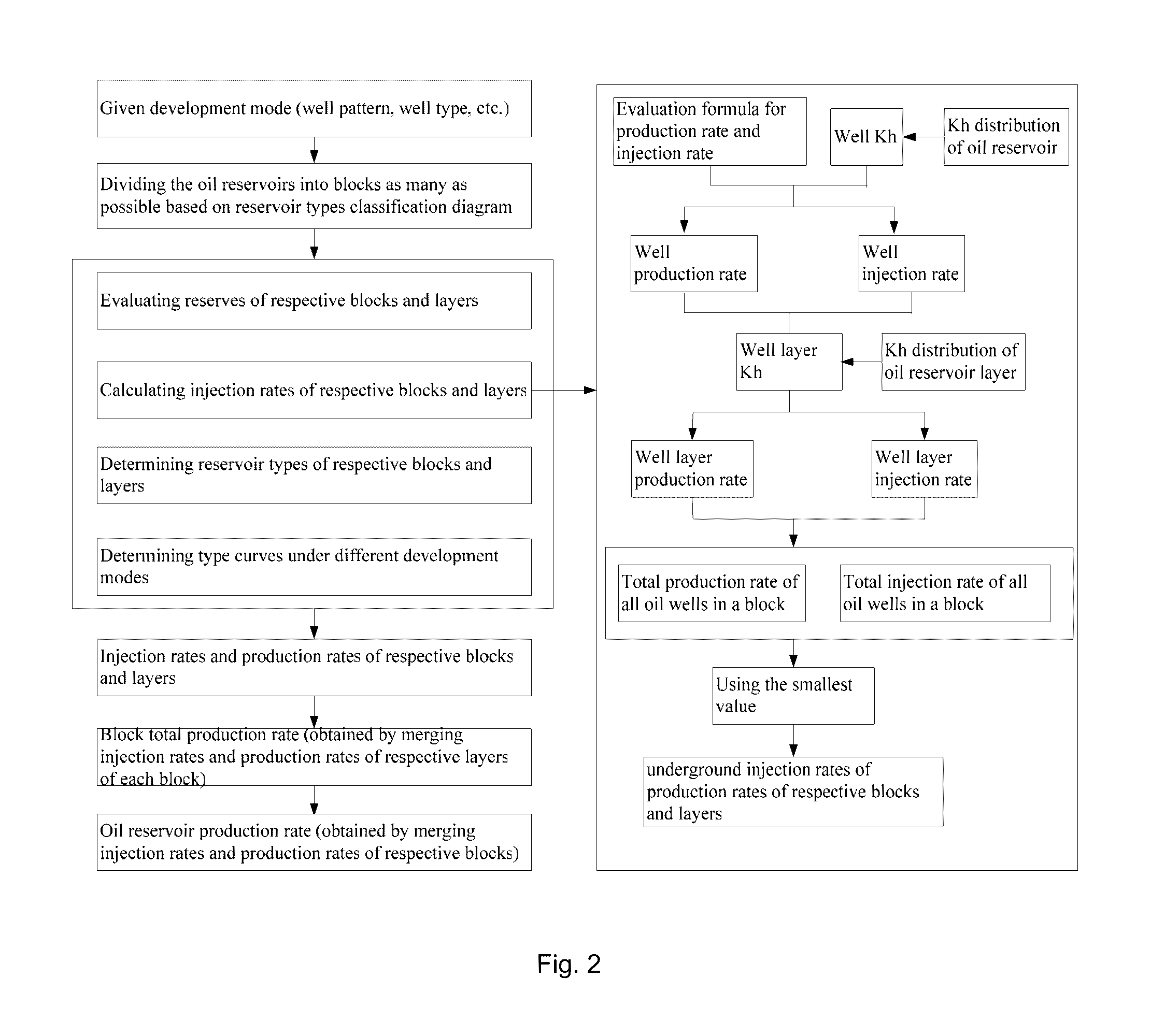

Method and Apparatus for Performance Prediction of Multi-Layered Oil Reservoirs

InactiveUS20160376885A1Decreasing man-powerConvenience to workElectric/magnetic detection for well-loggingConstructionsReservoir typeProduction rate

The present invention discloses a method and an apparatus for predicting performance profiles of multi-layered oil reservoirs, wherein the method comprises: dividing the multi-layered oil reservoirs into a plurality of blocks, and determining a reservoir type, formation factor Kh and an evaluated reserves of each layer in each block; selecting a block representing geologic features of the multi-layered oil reservoirs from the plurality of blocks as a representative block, to build a fine geological model of the representative block; building corresponding fine numerical simulation model according to the fine geological model of the representative block, and determining type curves of different reservoir types under different development strategies; determining a relation curve between Kh and well injection rate for injectors and a relation curve between Kh and well production rate for producers in the multi-layered oil reservoirs under different restrictive conditions; predicting performance of the multi-layered oil reservoirs according to the type curve, the relation curve between Kh and well injection rate, the relation curve between Kh and well production rate, and the reservoir type, formation factor Kh and evaluated reserves of each layer in each block.

Owner:PETROCHINA CO LTD

Wellbore evaluation system and method

ActiveUS20050267686A1Electric/magnetic detection for well-loggingSurveySection planeData acquisition

A wellbore evaluation system evaluates mechanical wear and corrosion to components of a well system including a production tubing string positionable in a well and a sucker rod string movable within the production tubing string. A deviation sensor determines a deviation profile of the well, a rod sensor senses and measures wear and corrosion to the sucker rod string as it is removed from the well to determine a rod profile, and a tubing sensor senses and measures wear and corrosion to the production tubing string as it is removed from the well to determine a tubing profile. A data acquisition computer is in communication with the sensors for computing and comparing two or more of the respective deviation profile, rod profile, and tubing profile as a function of depth in the well. A 3-dimensional image of wellbores, with isogram mapping, may be generated and examined over the internet.

Owner:ROBBINS & MYERS ENERGY SYST

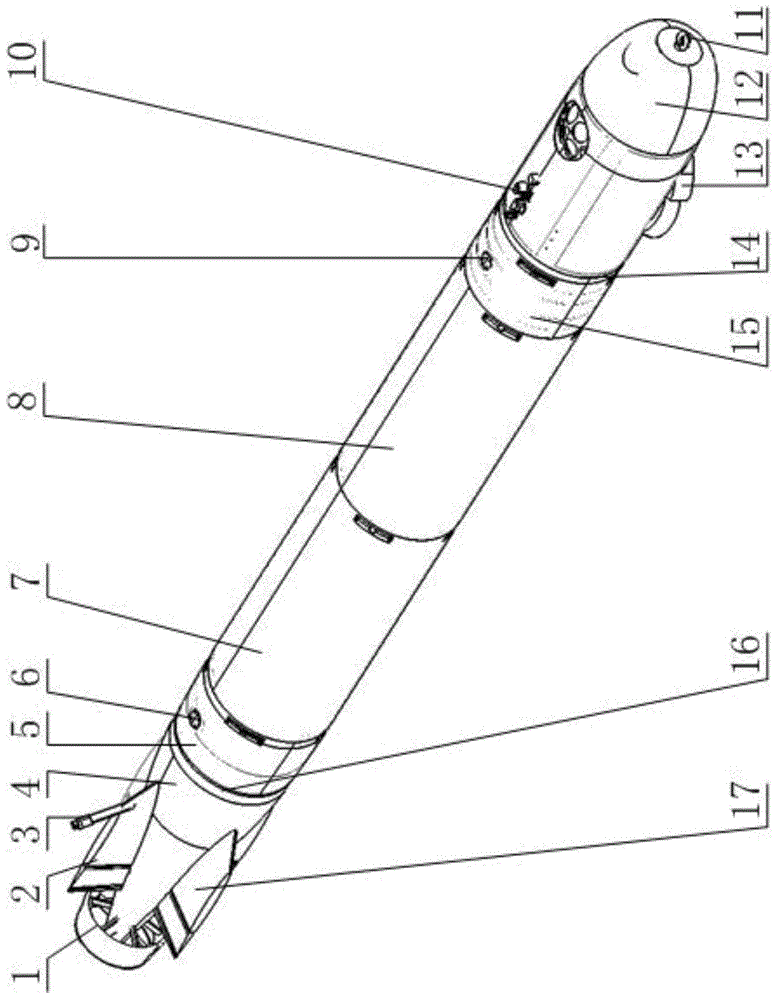

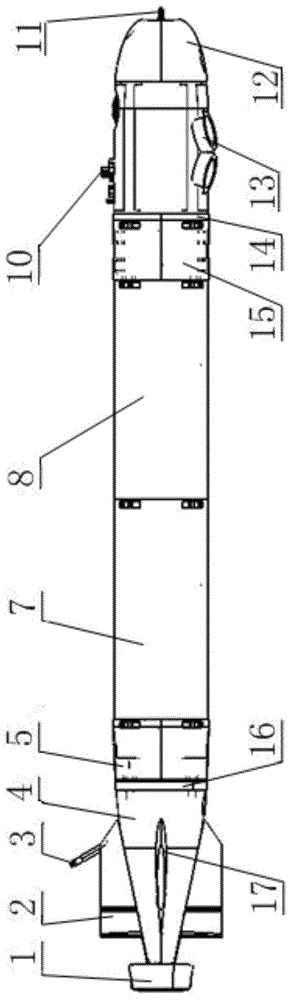

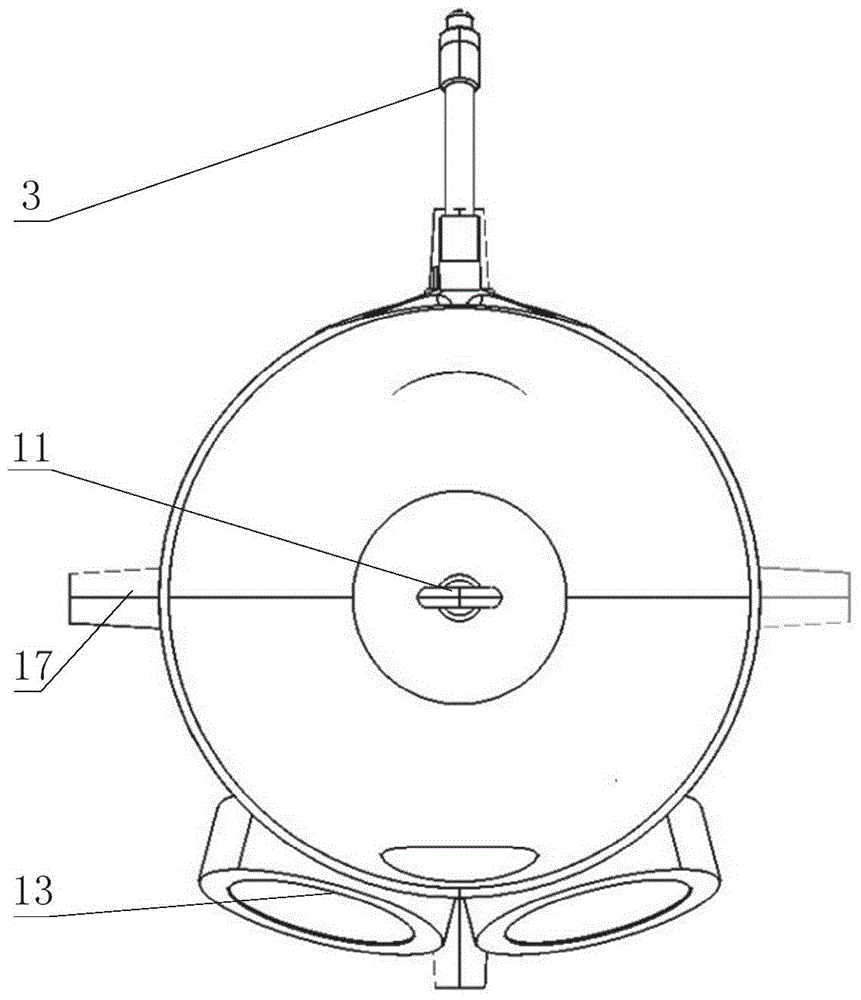

Long-term fixed-point vertical-section observation-type underwater robot

ActiveCN105644742AImprove abilitiesImprove the level ofUnderwater vesselsUnderwater equipmentSection planeMarine engineering

The invention belongs to the technical field of underwater robots, in particular to a long-term fixed-point vertical-section observation-type underwater robot. The long-term fixed-point vertical-section observation-type underwater robot comprises a propulsion section, a stern buoyancy adjusting section, a battery cabin section, an electronic cabin section, a bow buoyancy adjusting section and an observation load section, wherein the propulsion section and the observation load section use open frame structures; the observation load section carries an oceanographic hydrological data observation sensing equipment; the upper part of the propulsion section is provided with a satellite antenna; the stern buoyancy adjusting section, the battery cabin section, the electronic cabin section and the bow buoyancy adjusting section are arranged in a full-sealed pressure resistant cabin; and through double-way buoyancy adjusting of the stern buoyancy adjusting section and the bow buoyancy adjusting section, the motion posture of the underwater robot is adjusted and the underwater robot can hover at a fixed point. The underwater robot realizes a high-accuracy repeatable double-way buoyancy adjusting function and can realize autonomous balancing and fixed-point hovering.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Registration of three dimensional image data with X-ray imaging system

ActiveUS7657075B2Minimize cost functionSpeed up searchImage enhancementImage analysisData setSection plane

A method for determining a transformation of a three-dimensional pre-operative image data set to obtain a registration of the three-dimensional image data with an X-ray imaging system. In one aspect of the present invention, the method comprises the steps of the user identifying a center point and extreme contour points of the object from an X-ray image, obtaining a set of contour points for the image object in each of a plurality of section-planes, and selecting from a sampling of section-planes the points projecting nearest to the user-identified extreme points. The method then defines a grid having a predetermined number of intervals at a predetermined interval spacing with the grid center at the user-identified center of the pre-operative image, and performs a projection of the center point of the three-dimensional image data set onto each grid point for evaluation and selection of the grid point projecting nearest to the user-identified center. Registration of a three dimensional image data will allow, among other things, overlay of a visual representation of a pre-operative image object onto an X-ray image plane that can serve as a visual tool and a surgical navigation aid.

Owner:STEREOTAXIS

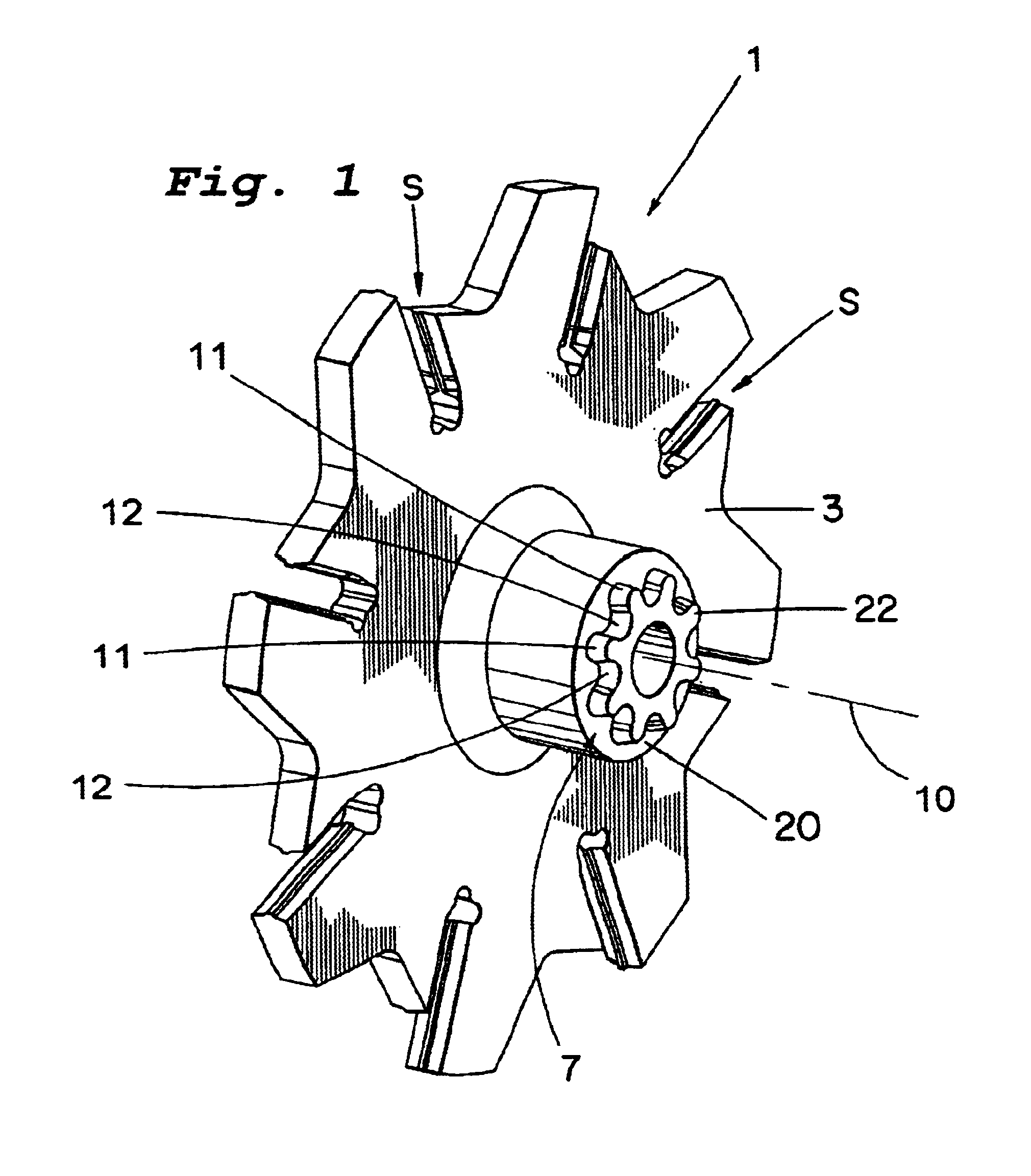

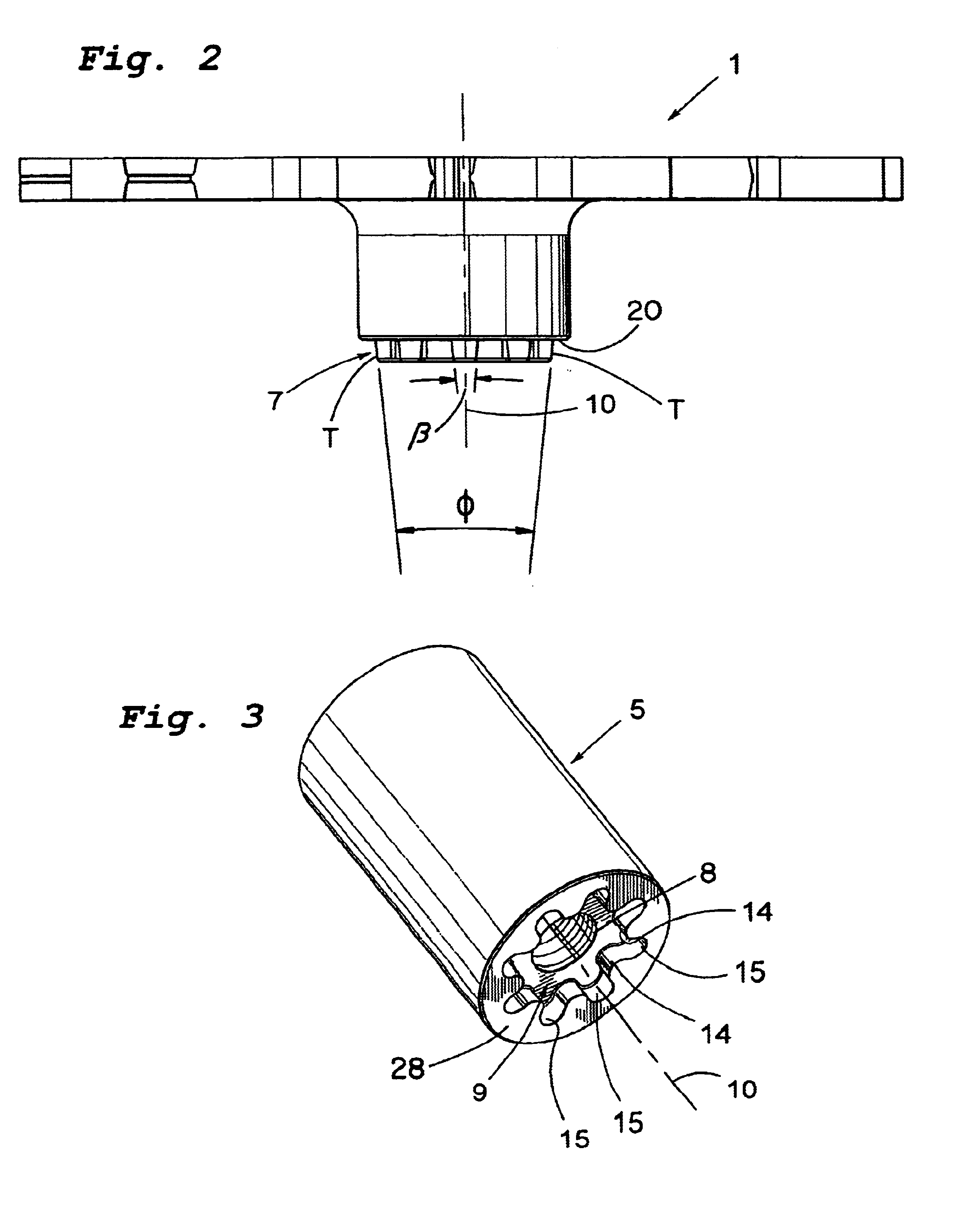

Toothed tool coupling for rotating a rotary tool

A driven tool includes a driven part which is rotatably driven by a drive part. The driven part and the drive part are coaxially arranged one inside of the other. The drive part and the driven part are conical as viewed in a longitudinal section plane containing the axis. The driven part includes driven teeth projecting generally radially with respect to the axis and received in respective radially-open recesses formed in the drive part. Each of the driven teeth makes contact with a wall of the respective recess at first and second contact places which are respectively situated on opposite sides of a generally radial line of symmetry of the driven tooth. The contact places are operable to transmit a drive force from the drive part to the driven part in respective directions of rotation. A driving angle in the range of -5° to +45° is formed at each contact place.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

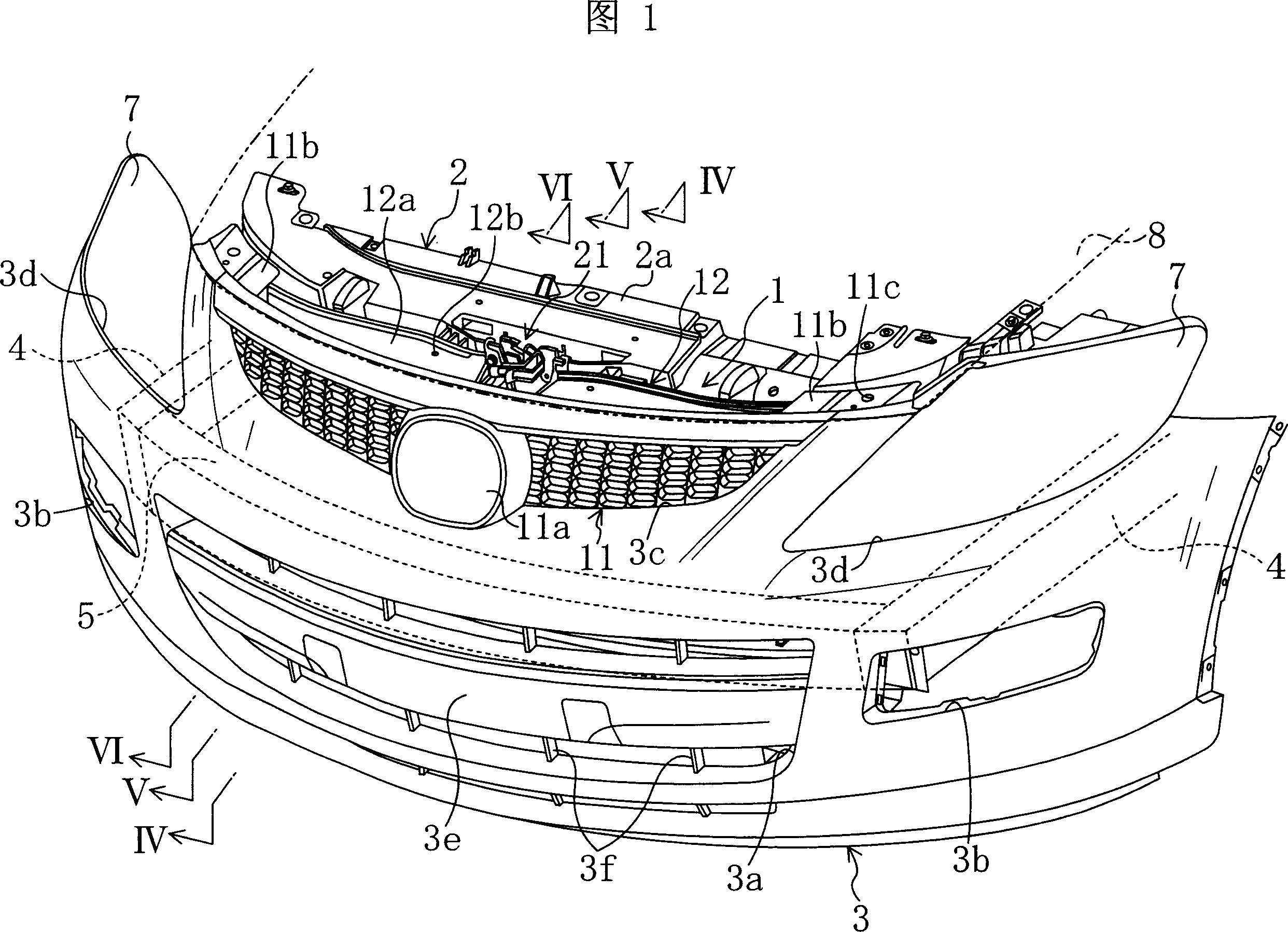

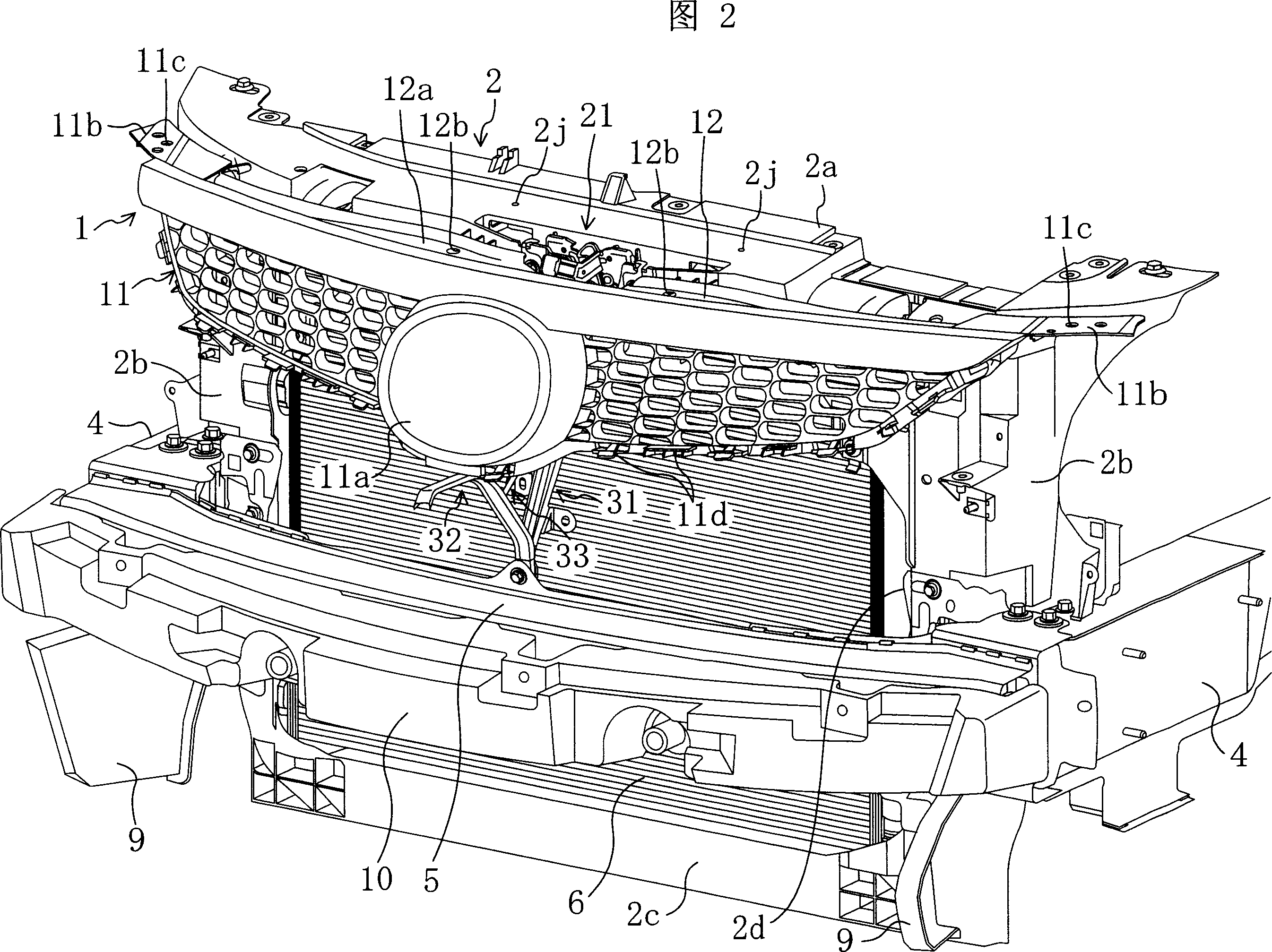

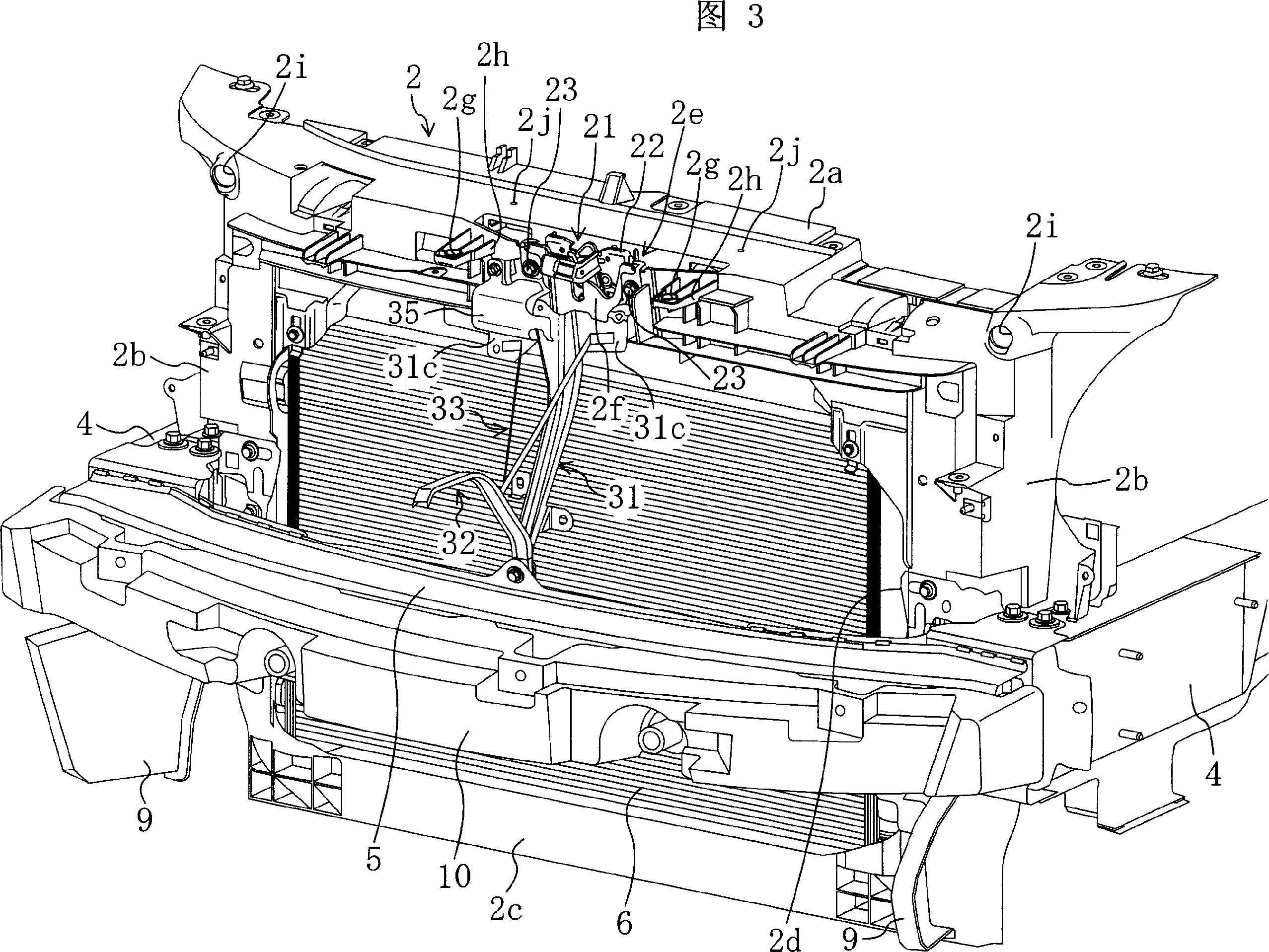

Vehicle front end structure

InactiveCN101020441APrevent saggingNo deterioration in assembly workabilityRadiatorsSection planeCoupling

The invention discloses a vehicle front part structure, and is to prevent a radiator grid from bending downwards due to the weight thereof in the vehicle front part structure with the large-scale radiator grid, which is tilted with the lower part ahead of the upper position and looks approximately cambered from above. A grid supporting component (32) is arranged on a central support (31) and integrated with the central support (31). The central support (31) bridging between the upper part (2a) of a radiator fixation frame and a bumper beam (5). The grid supporting component (32) is formed by folding a component, the section plane of which is rectangular with the left side open. The grid supporting component (32) consists of a coupling section (32a) coupled to the installation part (31b) of the central support (31) on the bumper beam; an elbow (32b) extending upwards and forwards from the coupling section (32a); a connecting part (32c) extending forwards from the front end of the elbow (32b) and supporting the radiator fixation frame(1) from below; and a guide part used to facilitate assembly of the radiator grid (1) onto the connecting part (32c).

Owner:MAZDA MOTOR CORP

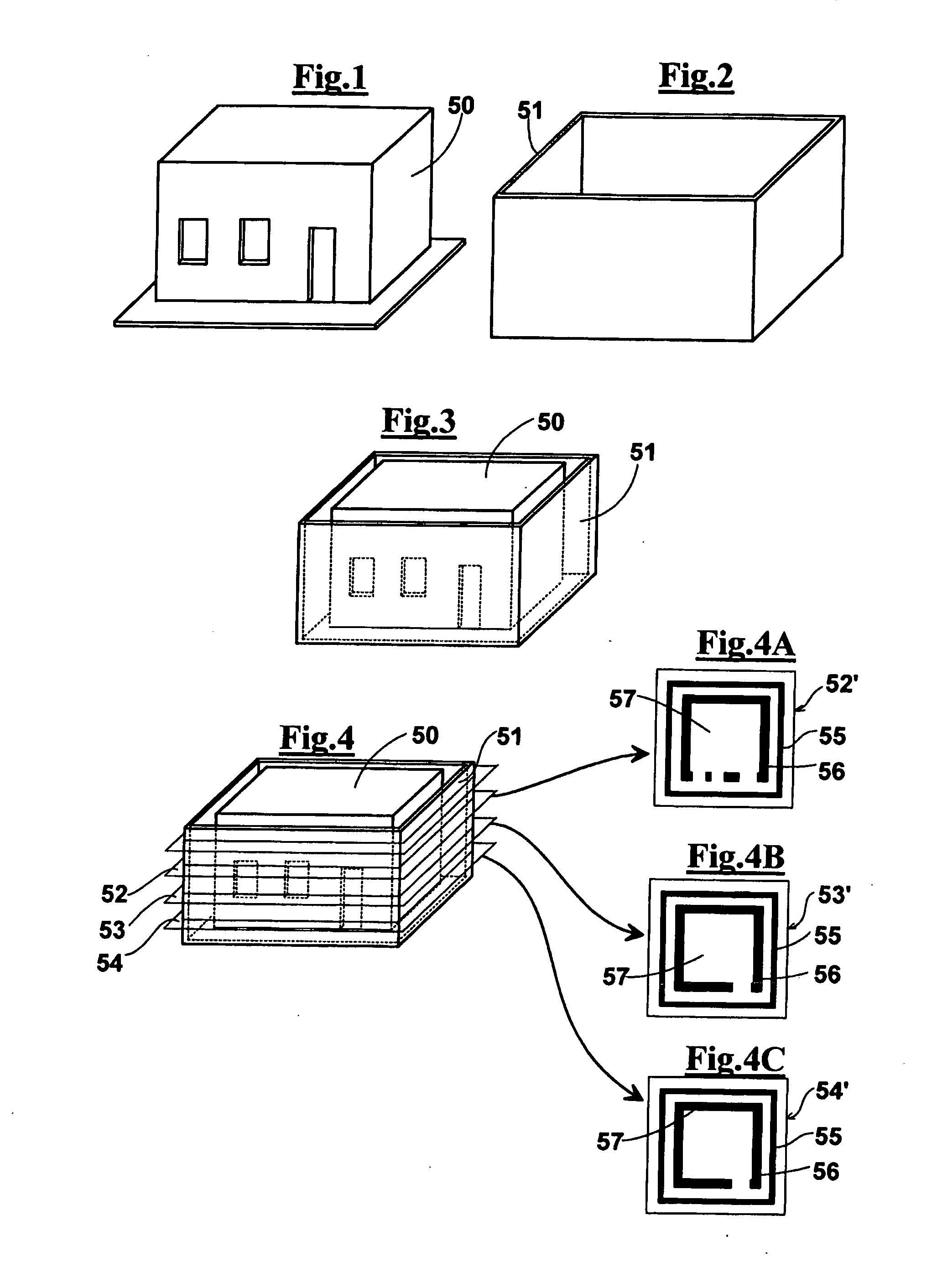

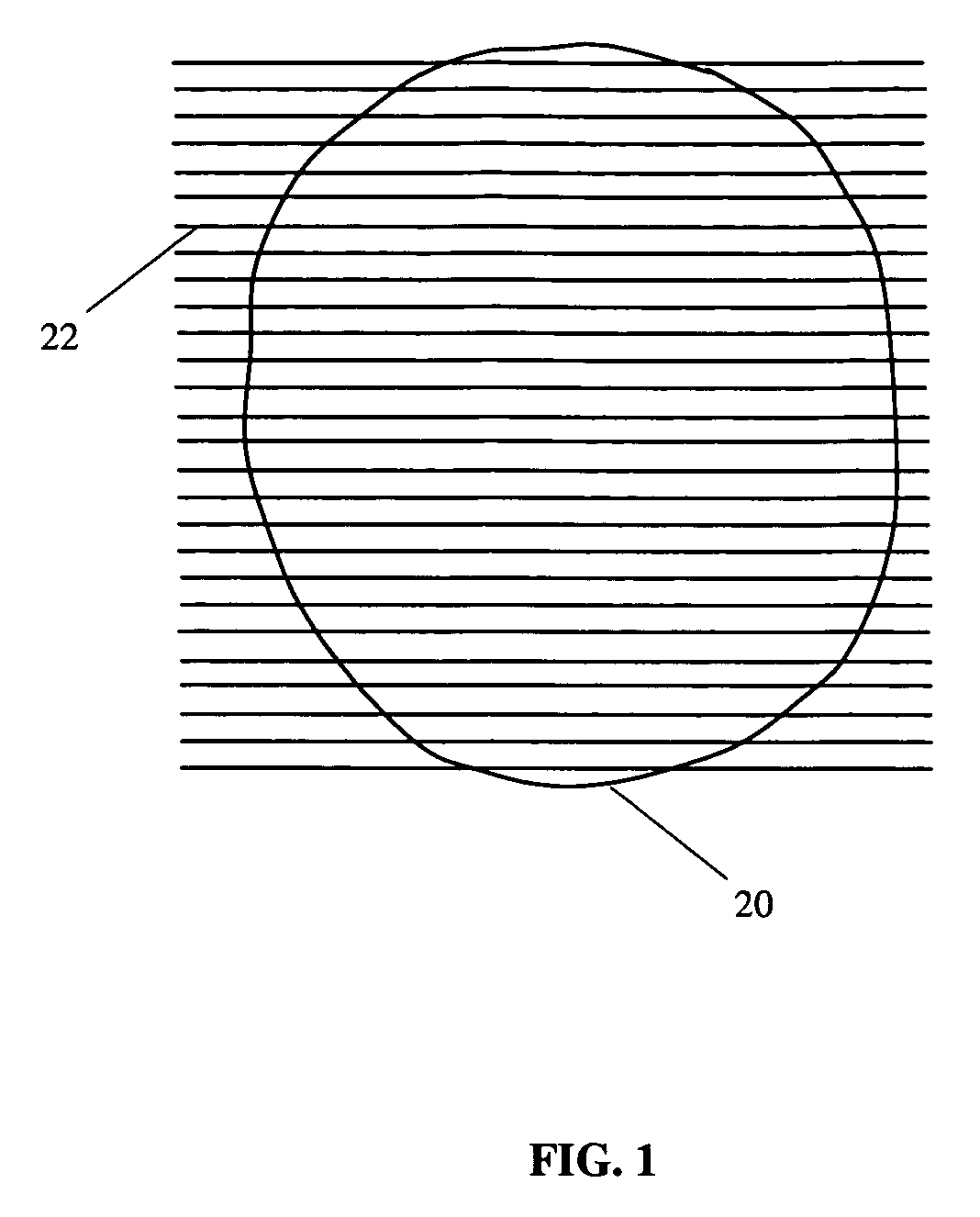

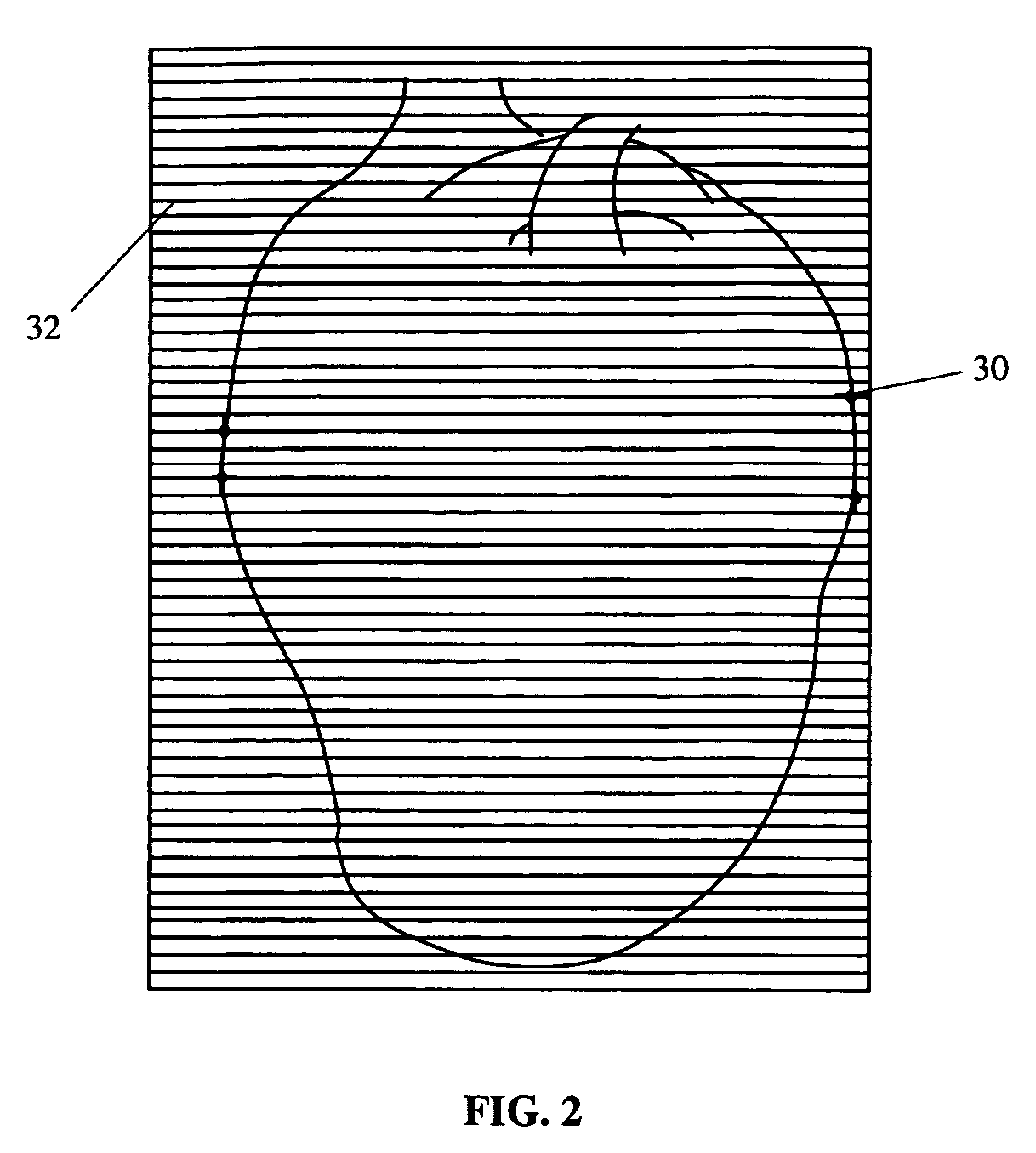

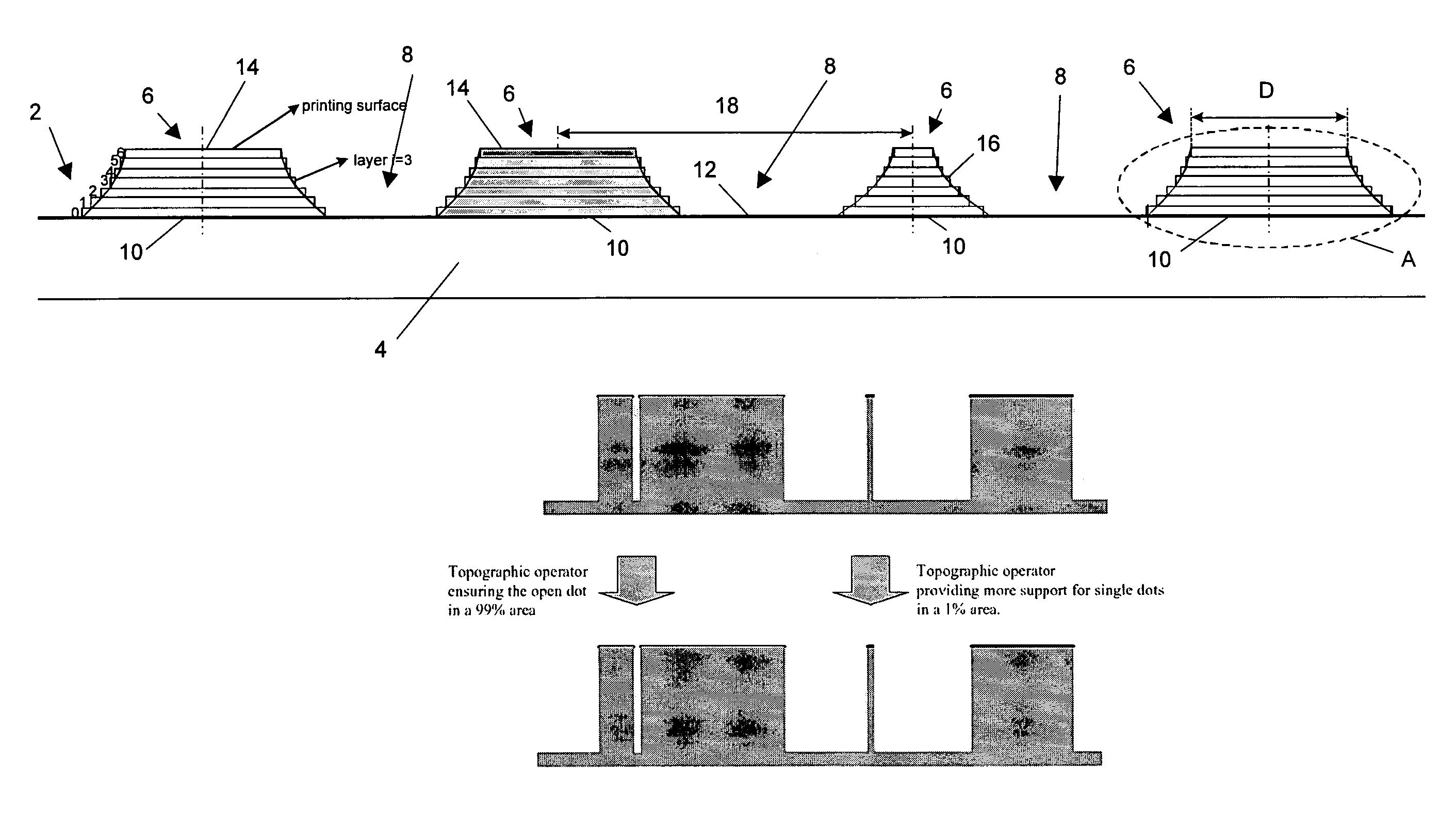

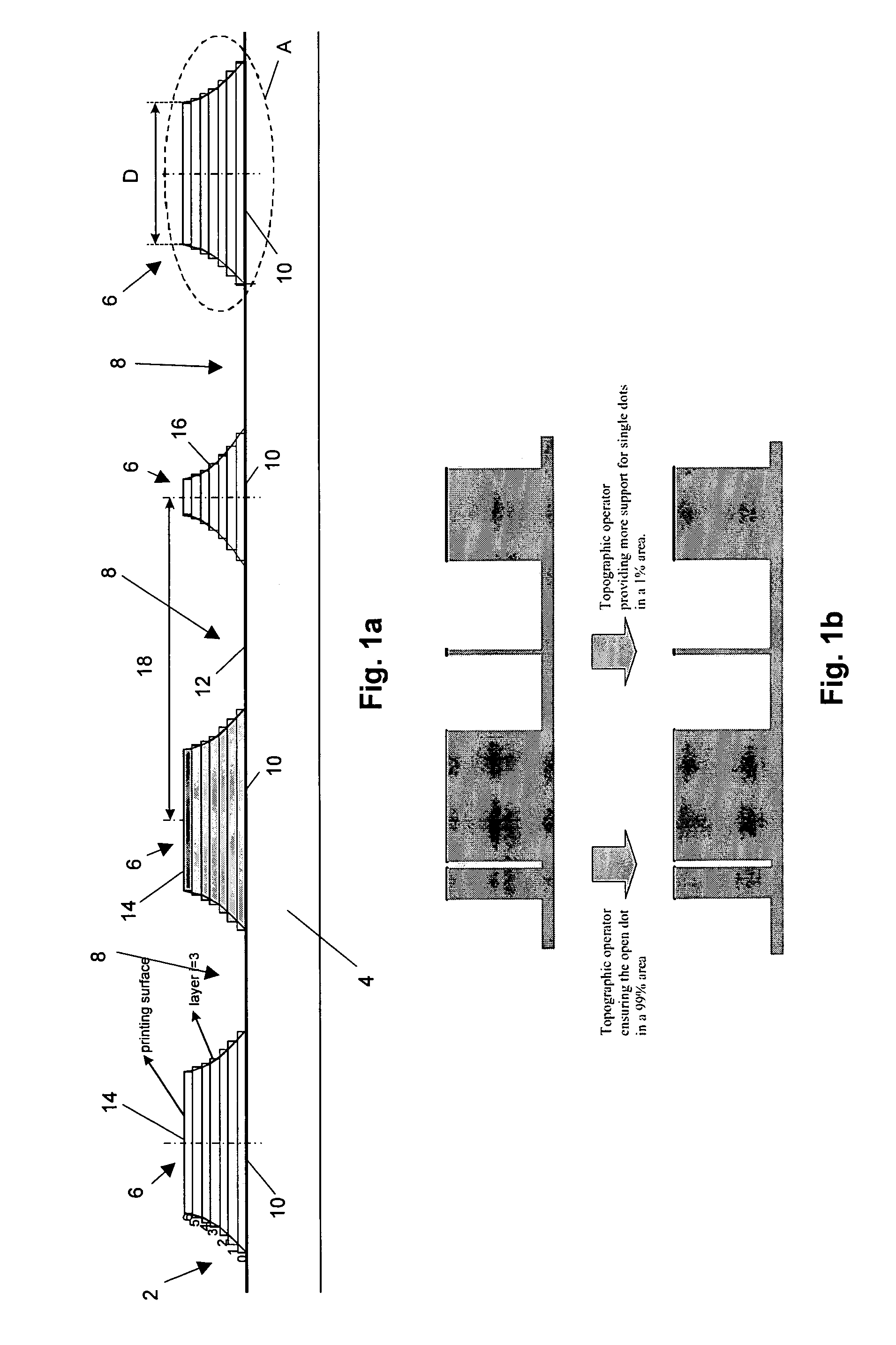

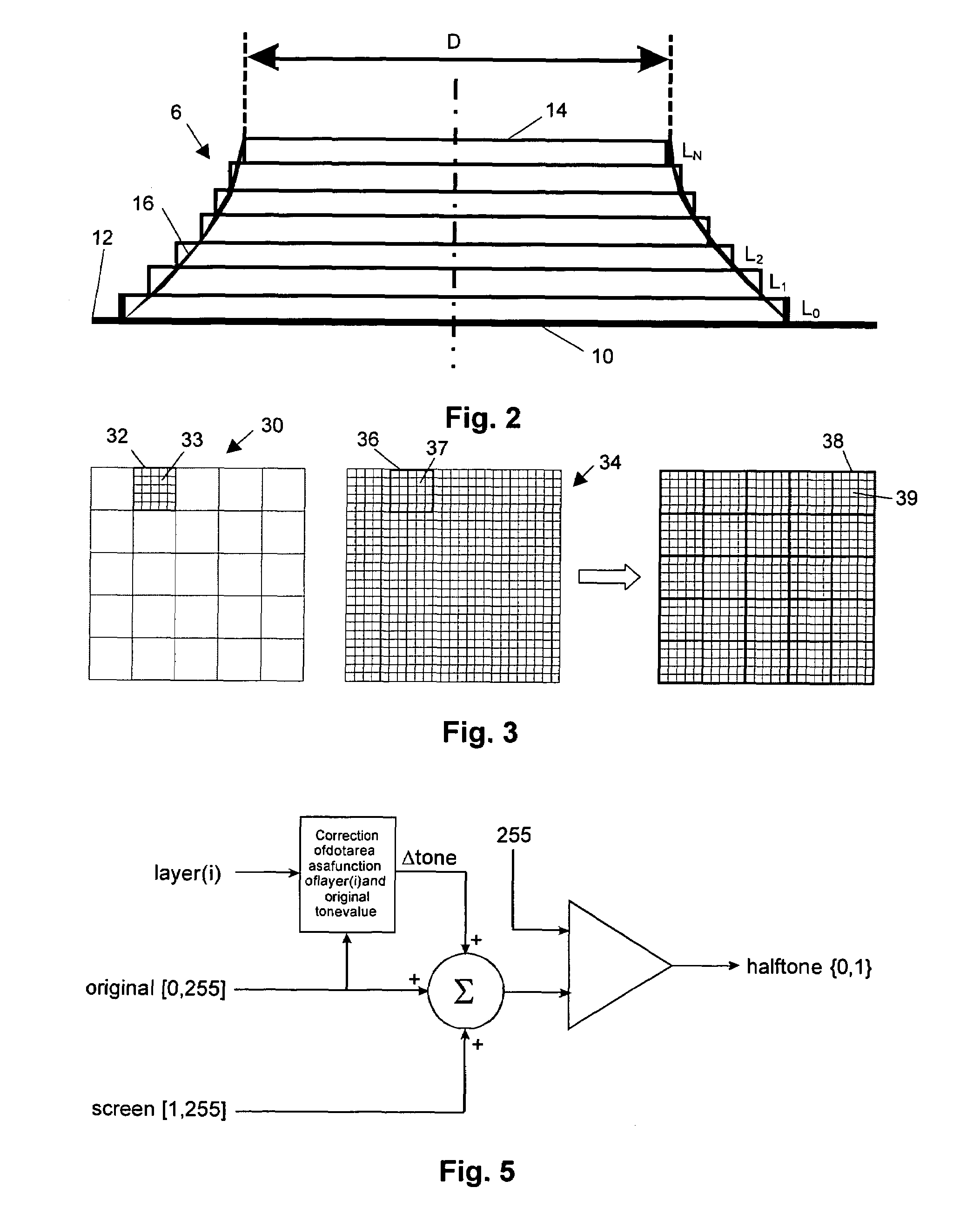

Method and apparatus for creating 3D-prints and a 3-D printing system

InactiveUS7589868B2Image enhancementDigitally marking record carriersSection planeComputer graphics (images)

A method and apparatus for creating a print file for printing a 3-D print using a 3-D printing system is described, the 3-D print comprising a plurality of 3-D structures printed on a substrate, each 3-D print structure having a height with respect to the substrate. A two-dimensional source image is input comprising a plurality of image pixel areas. A filtered image is obtained by applying a topographic operator to the source image to generate for every image pixel a representation of a pixel height profile, the pixel height profile corresponding to cross-sections through a 3-D print structure which is to be formed by 3-D printing. Thereby definitions of a plurality of image layers are generated from the filtered image for printing using the 3-D printing system. The print file is output based on the plurality of image layers.The topographic operator has the following property:any cross-section through a solid section of a 3-D structure at a second level in the 3-D print structure which is closer to the substrate than a first level has an area which is equal to or larger than the area of the cross-section of the 3-D structure at the first level.

Owner:AGFA NV

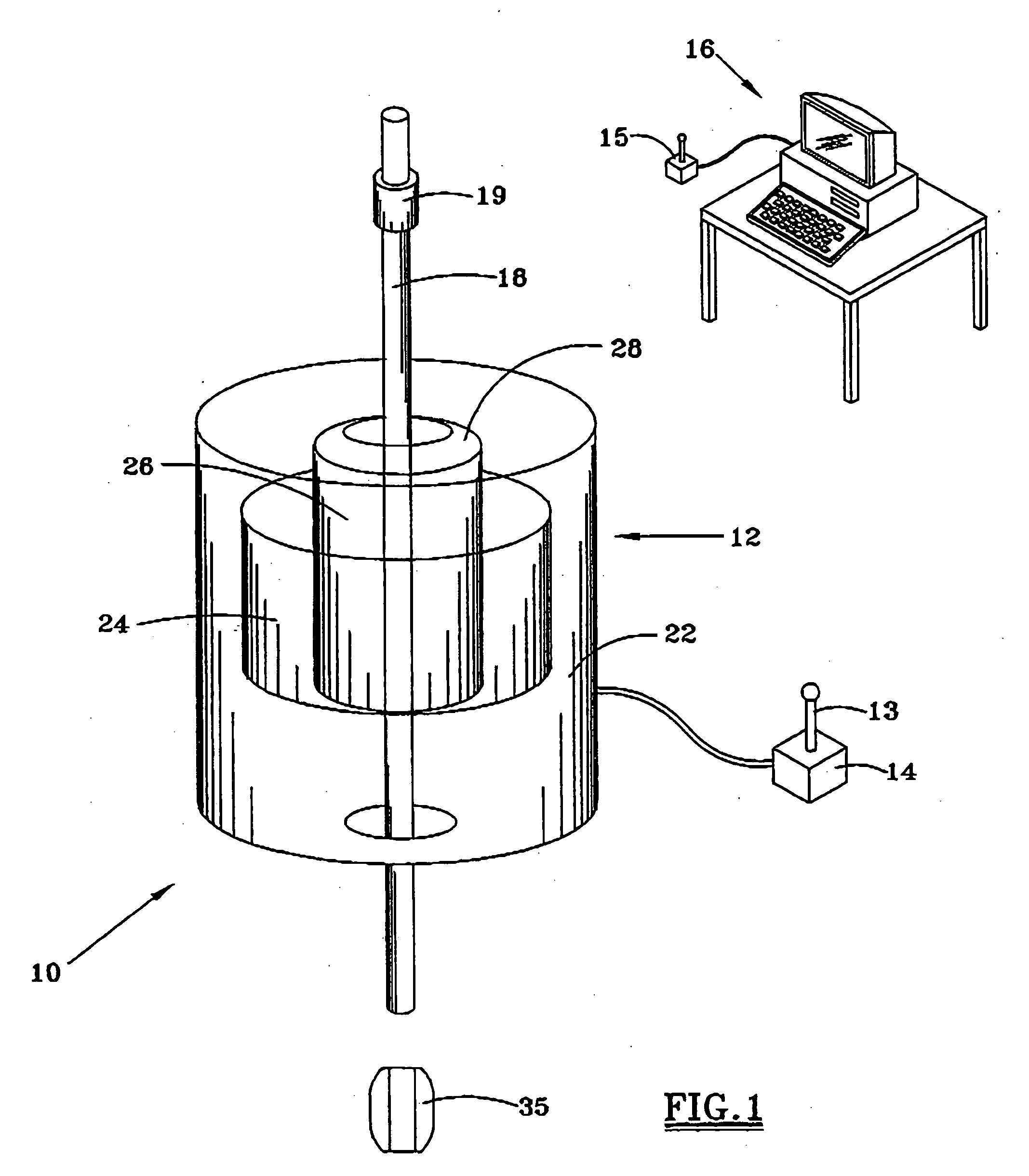

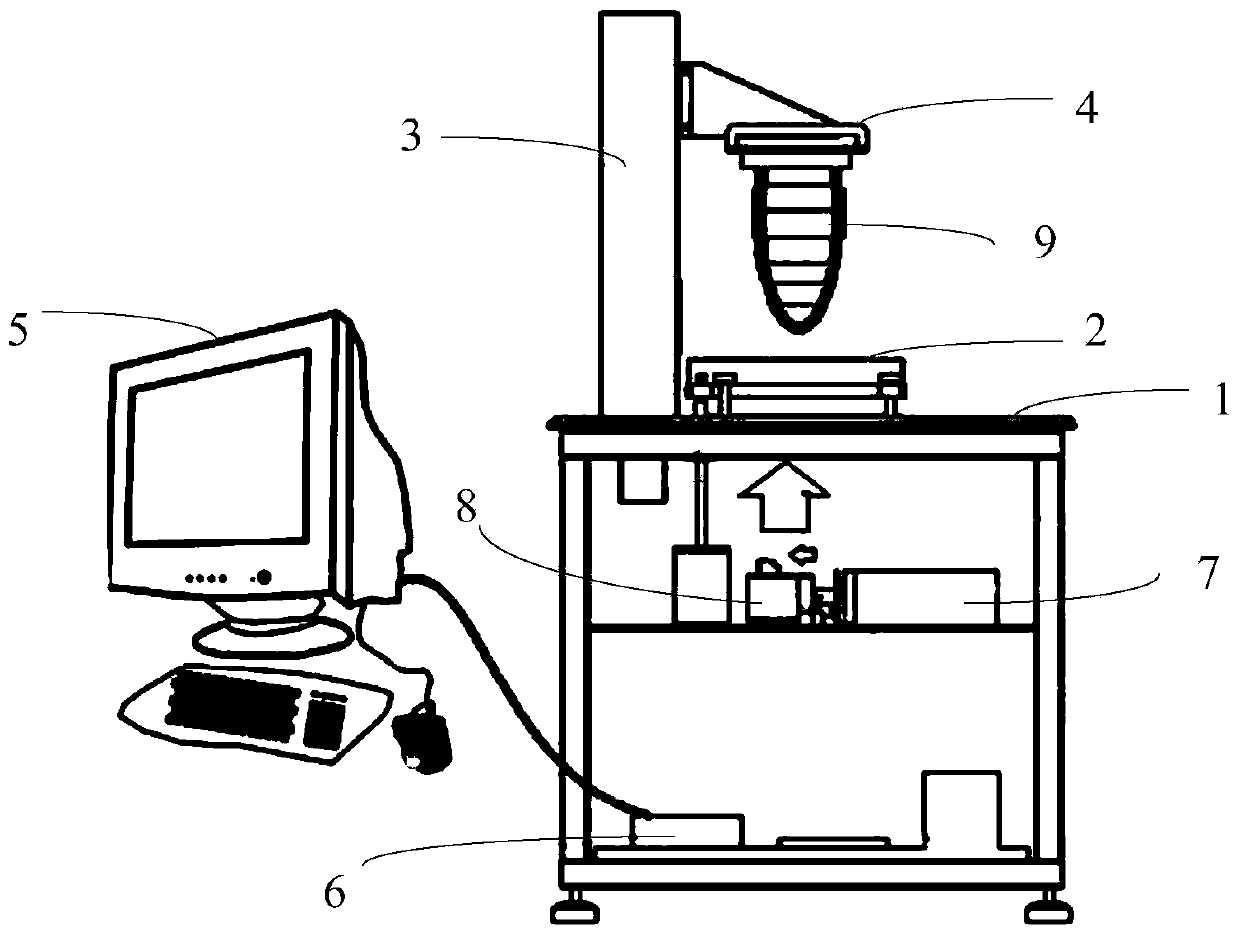

DLP principle based 3D printer

The invention discloses a DLP principle based 3D printer. The 3D printer includes: a resin tank, the bottom plate of which is light-transmitting; a vertical lifting mechanism, which is in fixed connection with a forming platform and is used for adjusting the distance between the resin tank and the forming platform; a computer, which is used for processing a three-dimensional model and segmenting the three-dimensional model into several profile graphs with certain thickness sequentially, and is connected to an electrical control device for controlling automatic lifting of the forming platform by the vertical lifting mechanism and controlling irradiation of a DLP projector on the liquid level of light-cured resin in the resin tank; and the DLP projector, which is arranged below the resin tank and is connected to the computer, and makes the graph light path of the profile graphs transmit the bottom plate of the resin tank so as to irradiate the light-cured liquid resin. According to the invention, the DLP projection technology is adopted and the light cured material forming technology is combined to form a set for system. The system has the characteristics of simple components and compact whole structure, the formed products have improved precision, the manufacturing cost is low, and the product forming speed is faster.

Owner:SHANGHAI KUNRONG IND

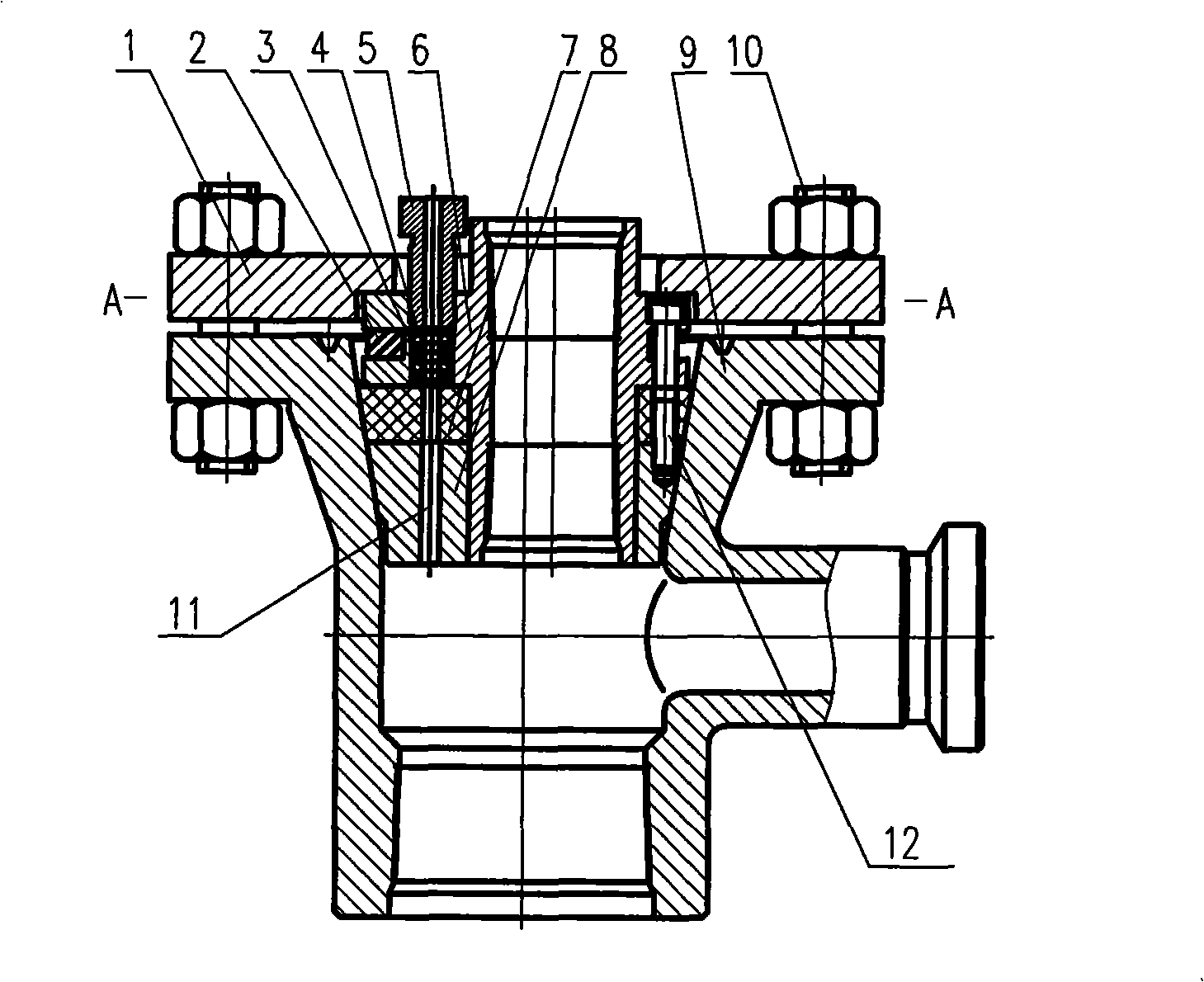

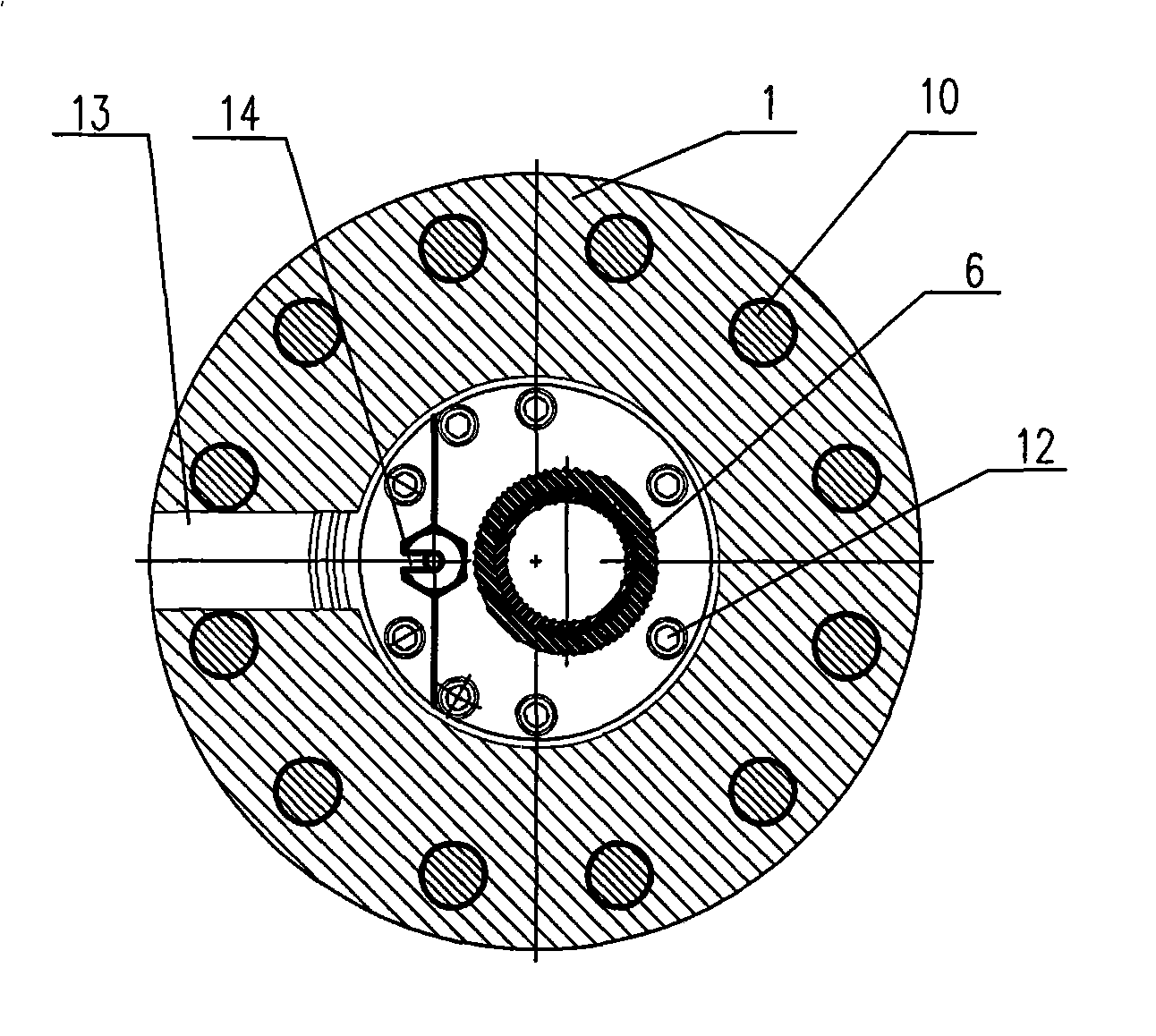

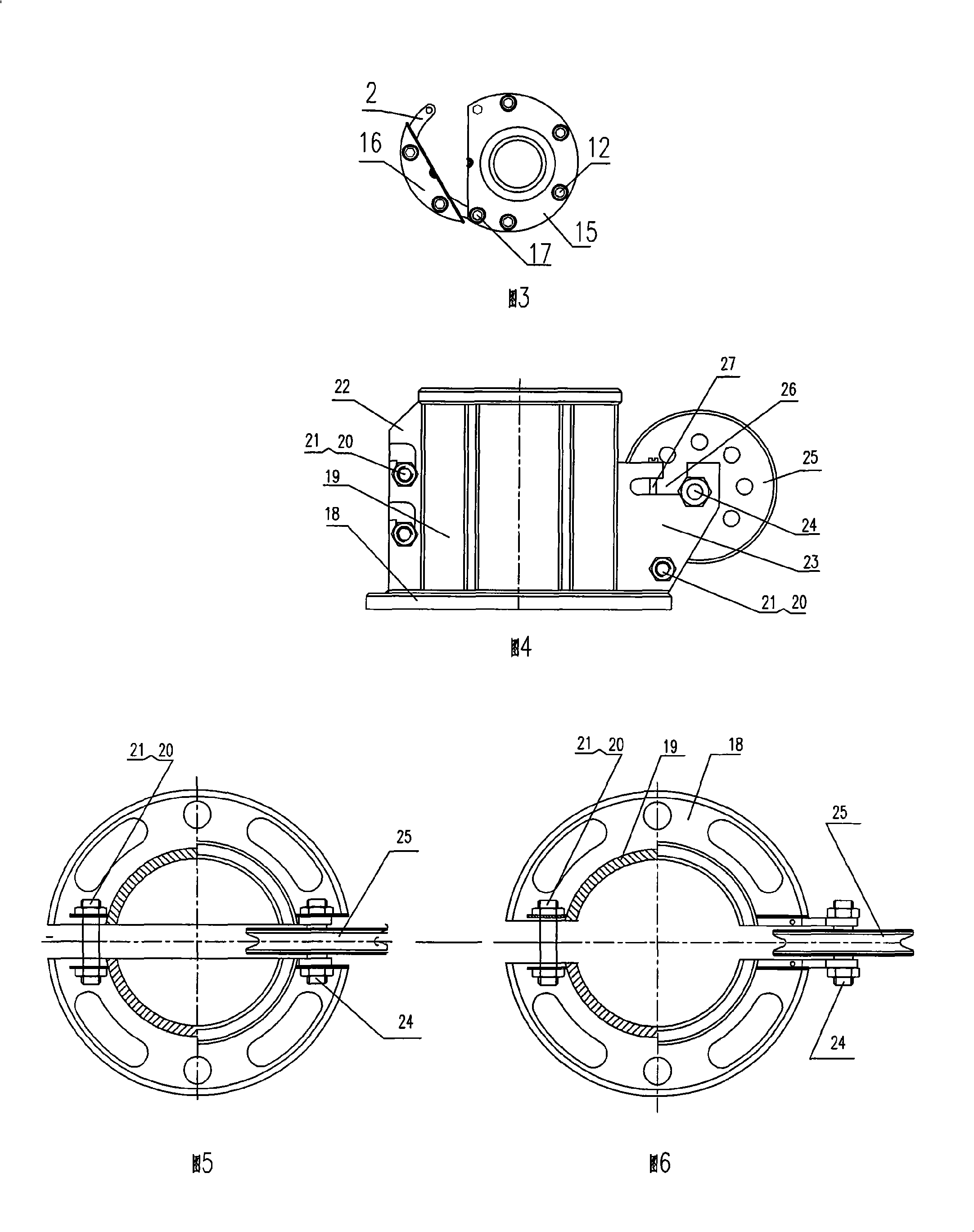

Preset production fluid section plane test method of mechanical mining horizontal well and special shaft mouth test apparatus

ActiveCN101403291AEasy to get up and downSo as not to damageSurveySealing/packingSection planeTubing hanger

The invention relates to a mechanical recovery horizontal well preset produced fluid profile testing method and a special wellhead testing device thereof, mainly aiming at solving the problem of the downhole testing of a mechanical recovery horizontal well. The invention is characterized in that: the special wellhead testing device comprises an eccentric type tubing hanger body connected with a tubing string, wherein, the side wall of the tubing hanger body is divided into a body and splits which are completely matched with each other, and the splits are fixed on a locking arm which is fixed on the body though bolts; and a corresponding matched cable penetrating a channel is arranged at the splitting seam of the body and the splits, the channel is internally provided with a cable gasket, a spacer and a pressing cap. By being matched with a special wellhead support, under the condition that a testing cable and a tester are pre-arranged in the horizontal well to test a target layer, an oil pipe does not touch the cable during the up and down process of the oil pipe. The method and the special wellhead testing device can realize the produced fluid profile testing of the mechanical recovery horizontal well, and ensure the accuracy of normal testing and data of the mechanical recovery horizontal well with simple and reliable operation method.

Owner:DAQING OILFIELD CO LTD +1

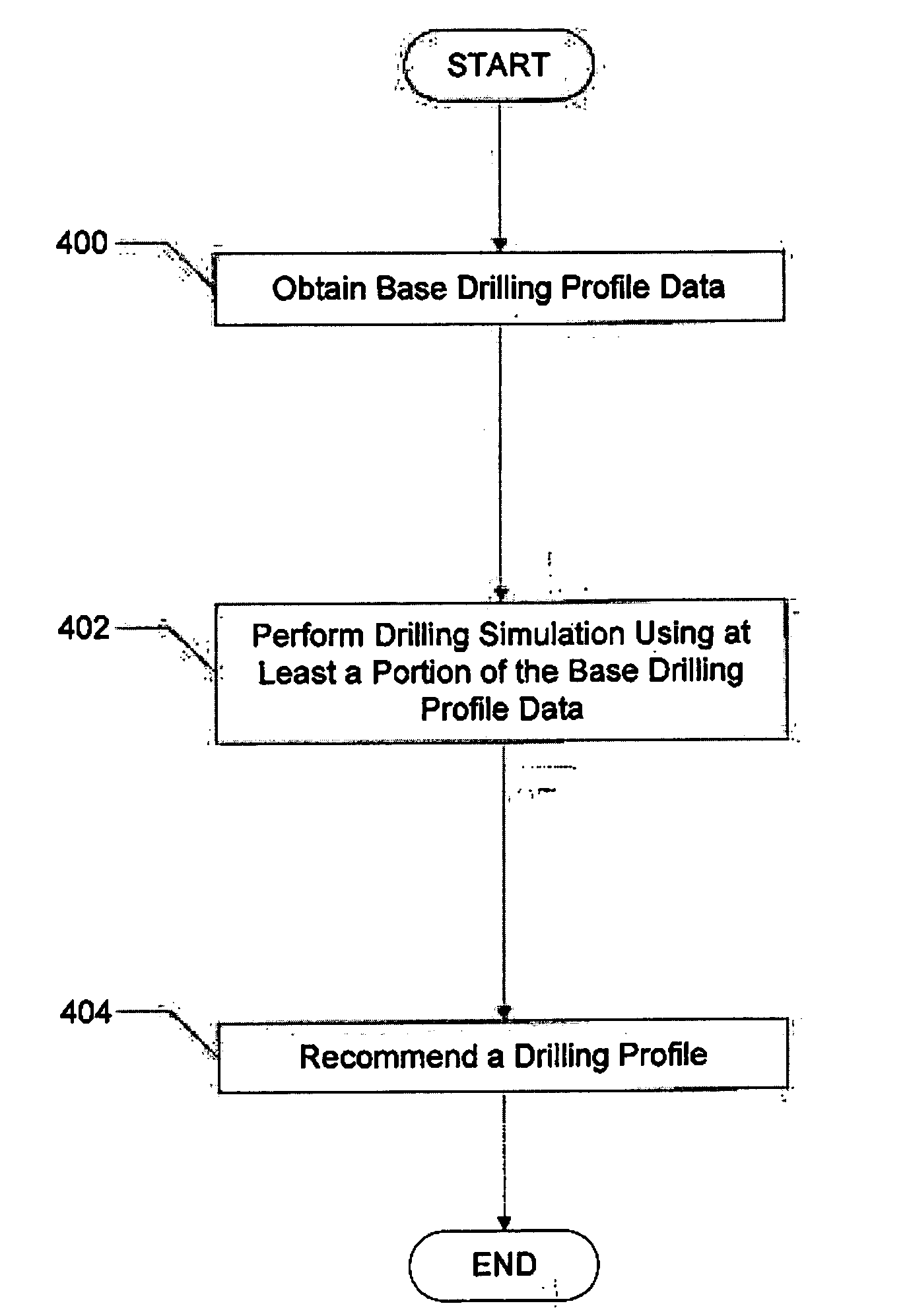

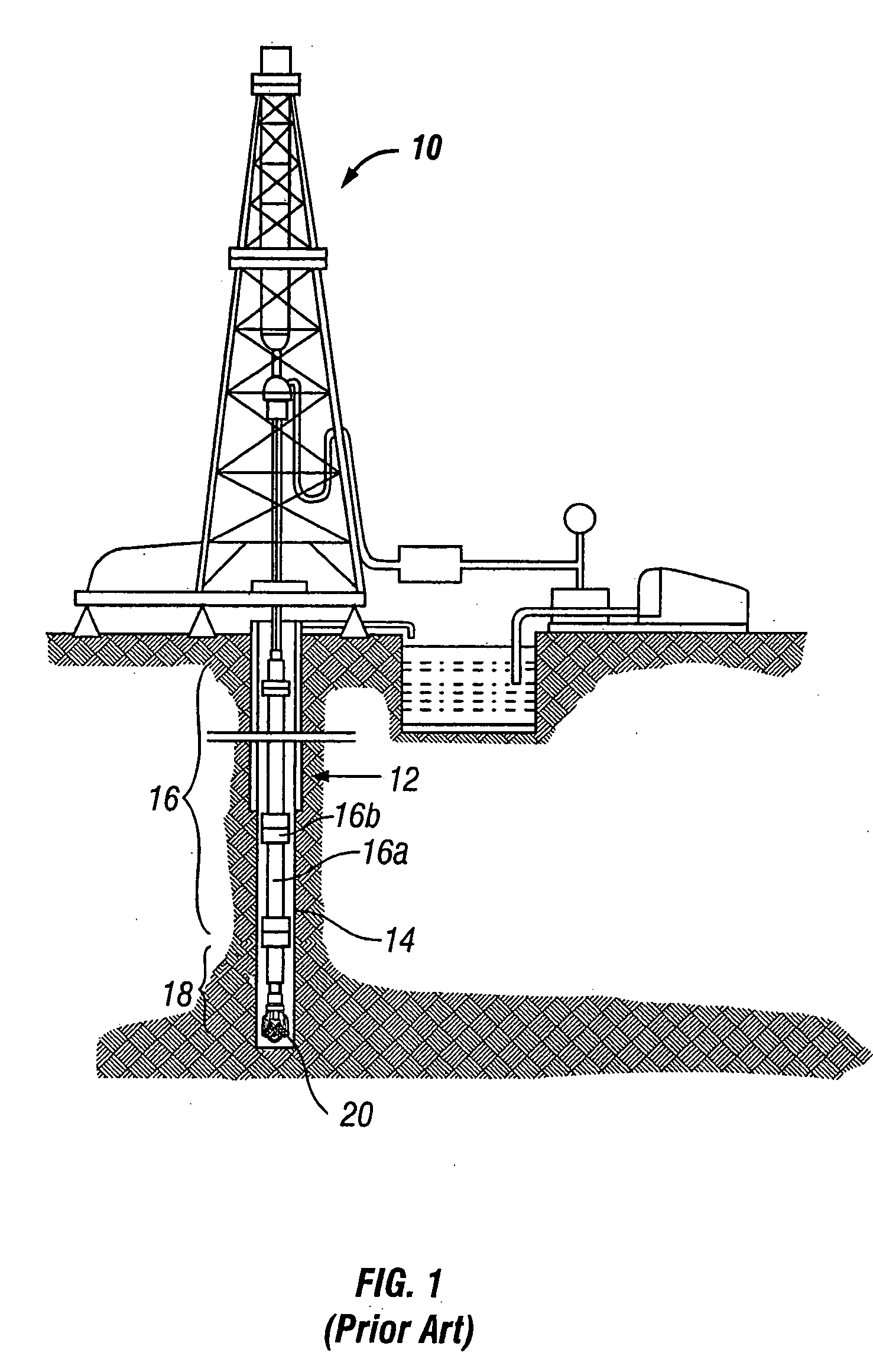

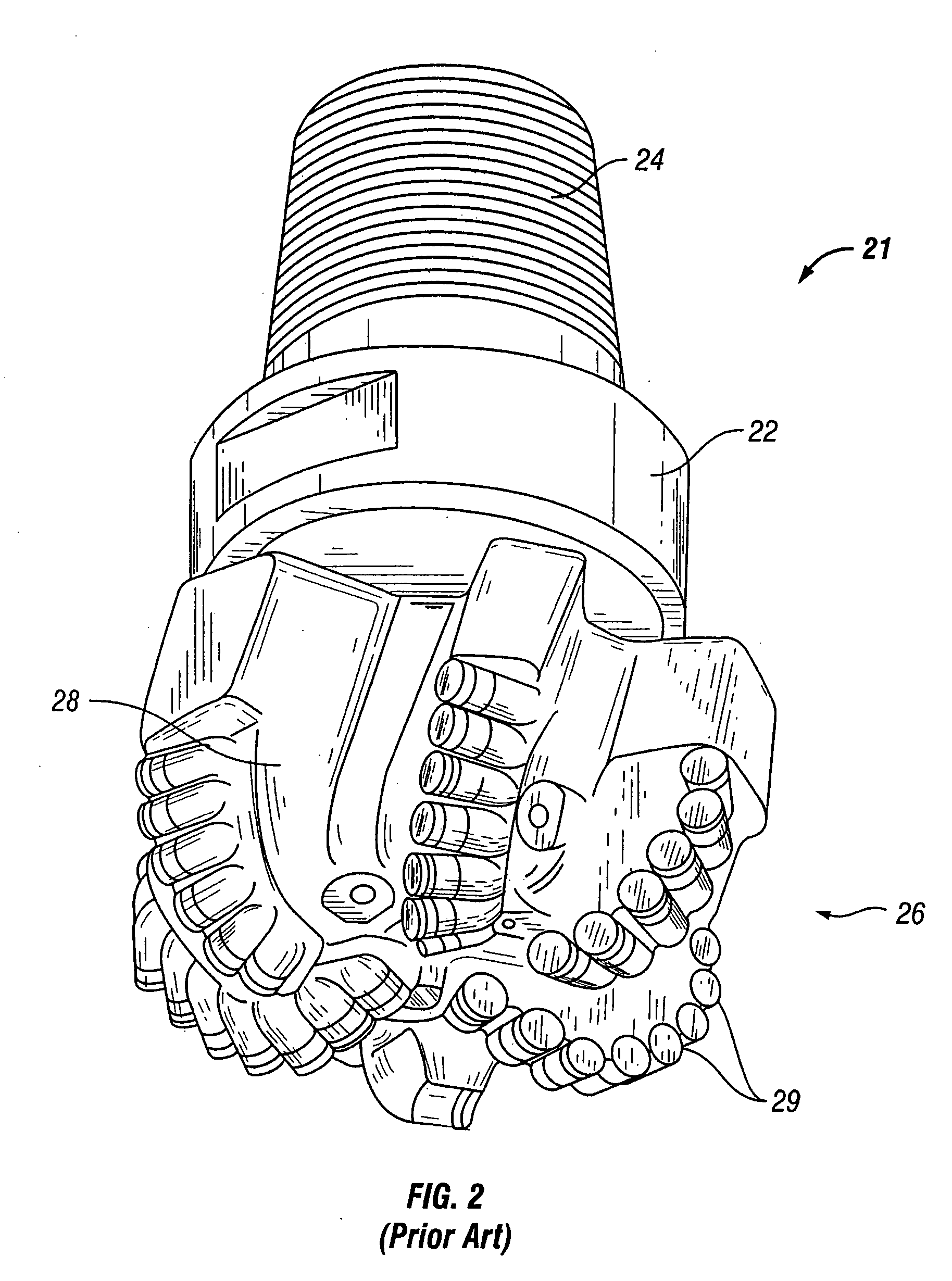

Methods for evaluating and improving drilling operations

InactiveUS20050273304A1Improve drilling performanceBorehole/well accessoriesAnalogue processes for specific applicationsSection planeWell drilling

Methods and computer systems for performing and using drilling simulations. The drilling simulations can be used to improve drilling performance or demonstrate drilling performance of a drilling profile. One method for creating a drilling profile includes obtaining drilling profile data and performing a drilling simulation using at least a portion of the drilling profile data. Modifications are then recommended for the drilling profile data.

Owner:SMITH INT INC

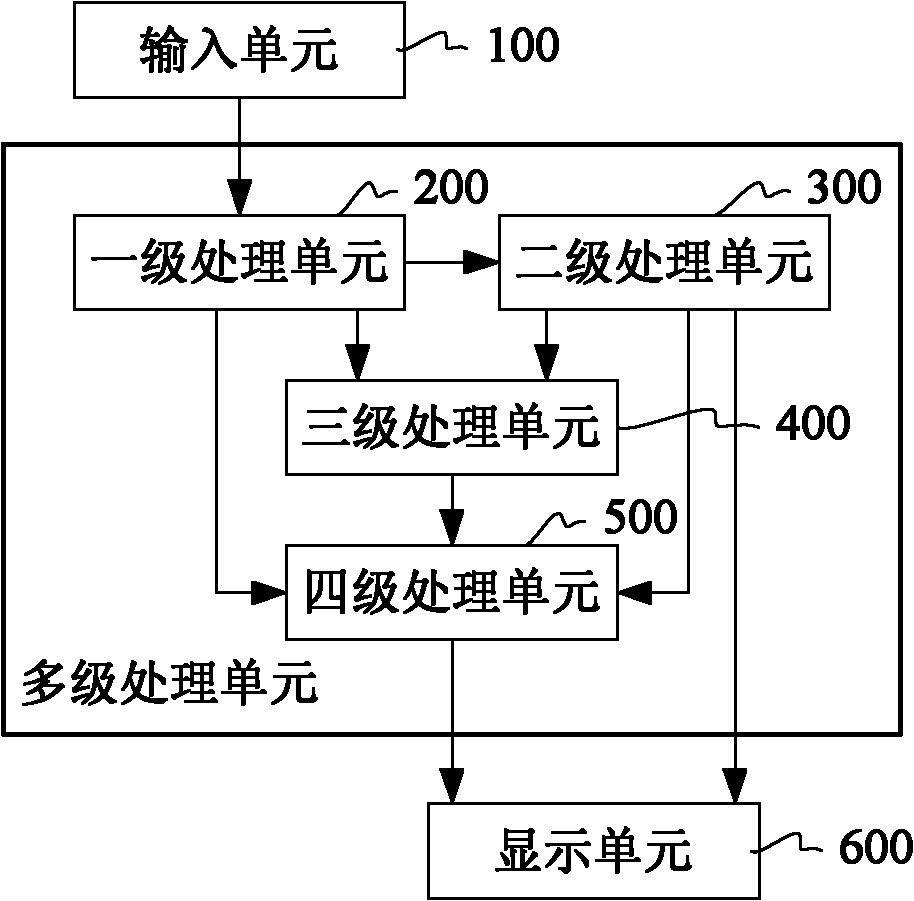

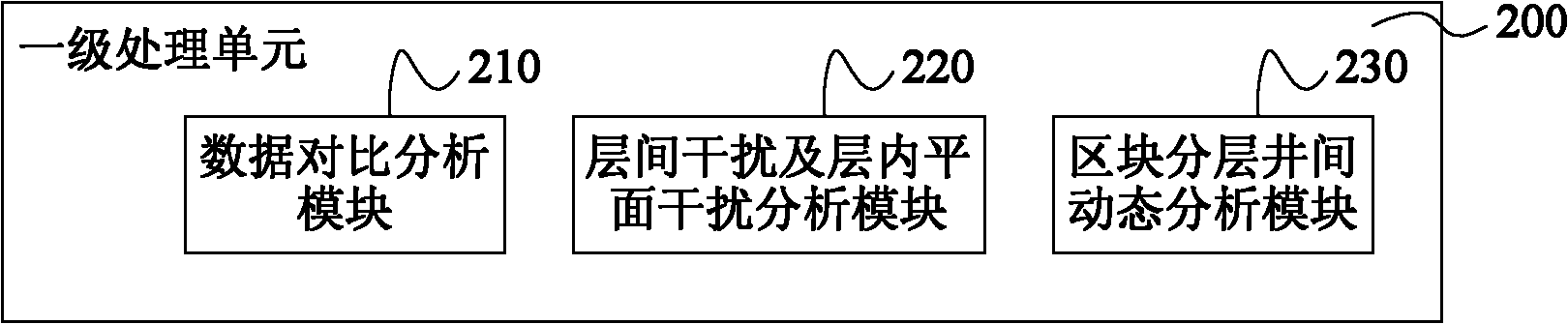

System for monitoring complicated oil deposit flooding conditions

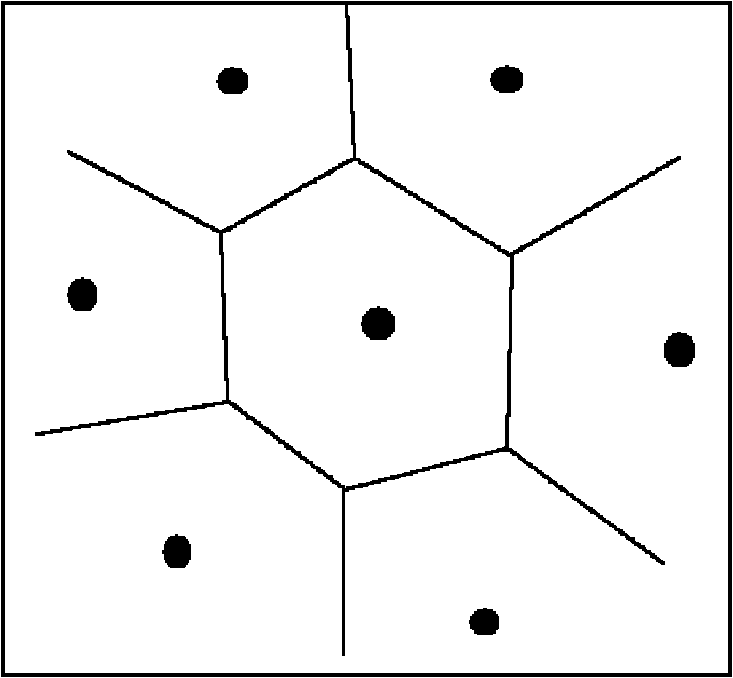

The invention discloses a system for monitoring complicated oil deposit flooding conditions, comprising an input unit, a multi-level processing unit and a display unit, wherein the input unit is used for inputting well point geologic parameters; the multi-level processing unit is used for building hidden geologic characteristic parameters according to the well point geologic parameters input by the input unit, finishing multi-layer, multi-well, multi-phase and multi-driving power energy balance analysis and calculation of a block, further building an injecting and extracting correspondence relationship among wells and carrying out comprehensive inversion treatment on the layered and partitioned flooding conditions by using improper functions to obtain distribution data of various sucking sections and layered flooding conditions of the block and a single well in different periods; and the display unit is used for displaying the injecting and extracting correspondence relationship amongwells, built by the multi-level processing unit, and the obtained diagram result data of the distribution of the various sucking sections and the layered flooding conditions of the block and the single well in different periods. The system can obtain accurate layered flooding condition data and different levels of section analyzed result data, improve the extracting precision, and save the manpower and material resources.

Owner:CHINA NAT OFFSHORE OIL CORP +1

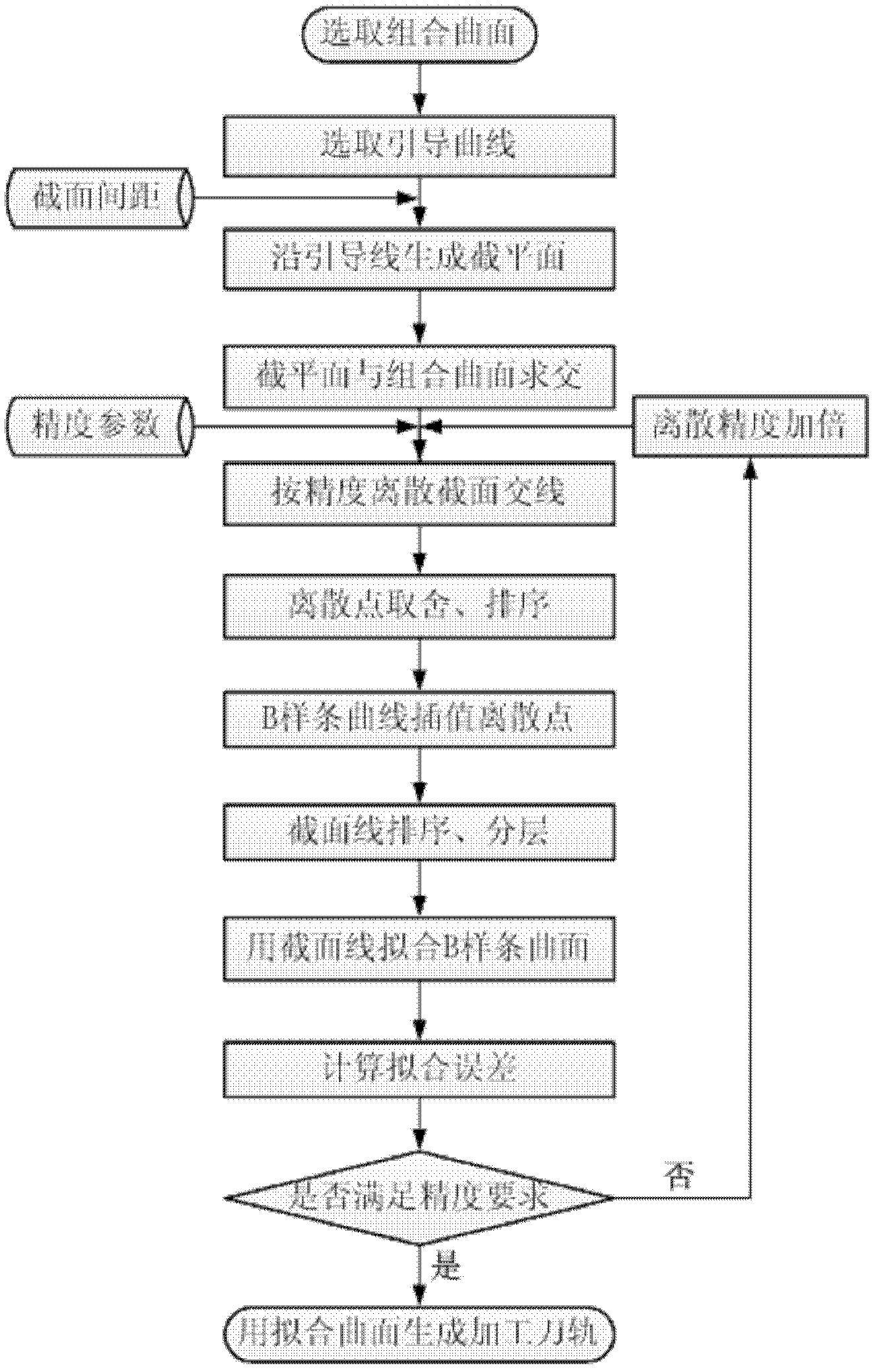

Method for generating numerical-control side milling machining tool path for complicated curved surfaces

ActiveCN102637216ASolve the problem of trajectory generationSolve build problemsSpecial data processing applicationsSection planeEngineering

The invention discloses a method for generating a five-axis numerical-control side milling machining tool path for a complicated combined curved surface. The method includes obtaining a section line by means of intersecting section planes and the combined curved surface, dispersing the section line into points according to a certain precision rule, then interpolating and fitting the disperse points on the various section planes by a spline curve B, and then fitting the section line into a spline surface B by the aid of skinning; and computing errors of the fit spline surface and the original combined curved surface, returning to the curve dispersion step if the precision requirement is not met, realizing dispersion with higher precision, fitting a spline curve, fitting a spline surface until the errors of obtained fitting curved surface meet the precision requirement, finally adopting a tool path generating algorithm combining integral arbor swing angle control with local fine adjustment and computing the machining tool path by the aid of the obtained fitting curved surface as a driving curved surface. The method is high in efficiency and precision, the side milling machining tool path for the combined curved surface is generated, an arbor swings stably and uniformly, and machining quality is high.

Owner:SUZHOU MACHINING PRECISION ELECTRONICS

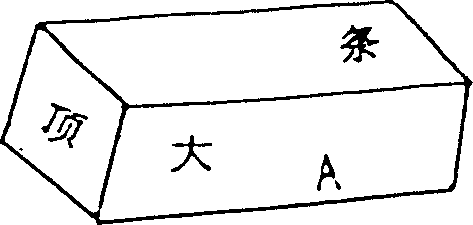

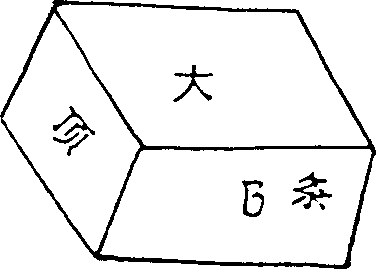

Composite wall with energy-saving and thermal insulating function and masonry method thereof

This invention relates to a composite wall with thermal insulating and heat-proof function, in addition to its masonry method. The character of the wall comprises: 1, it is combined by course of headers and stretcher course whose size and shape are totally different; 2, adding thermal insulating material between header course and stretcher course; 3, the header course and stretcher course are crisscross and vertical stack, which can avoid the straight-line joint from cross section or bisect; 4, the thermal conductivity factor of the composite wall is 0.48 / m2k, which can save energy 55% compared with the non-composite wall with the same thickness. (In accompanying diagram: A is stretcher course, B is header course, the margin part or shade part is thermal insulating material, unit is mm, ash steam is 10mm).

Owner:刘志伟

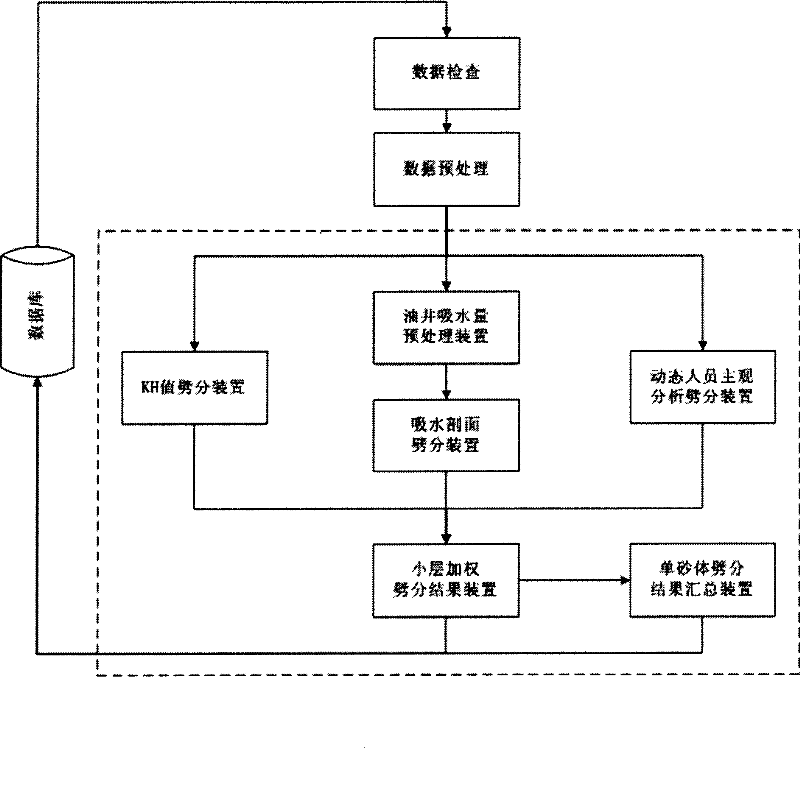

Complicated fault block fluvial facies reservoir oil water well using situation split system

It relates to the after potential exploration of an oil filed, with the ability of analyzing the oil distribution, left resource quantity, and so on. It comprises the data inspection device, data preprocessing device, KH value separation device, oil well water absorption preprocessing device, water absorption section separation device, dynamic personnel analysis separation device, small layer weighting separation device, single sand separation result accumulation device, data base, water filling effect, strata HK, and weighting of the oil reserve weighting by the dynamic personnel, determining the strata output through the water absorption section, water content of the strata through well fluid section, with the whole process being computerized and accurate.

Owner:PETROCHINA CO LTD

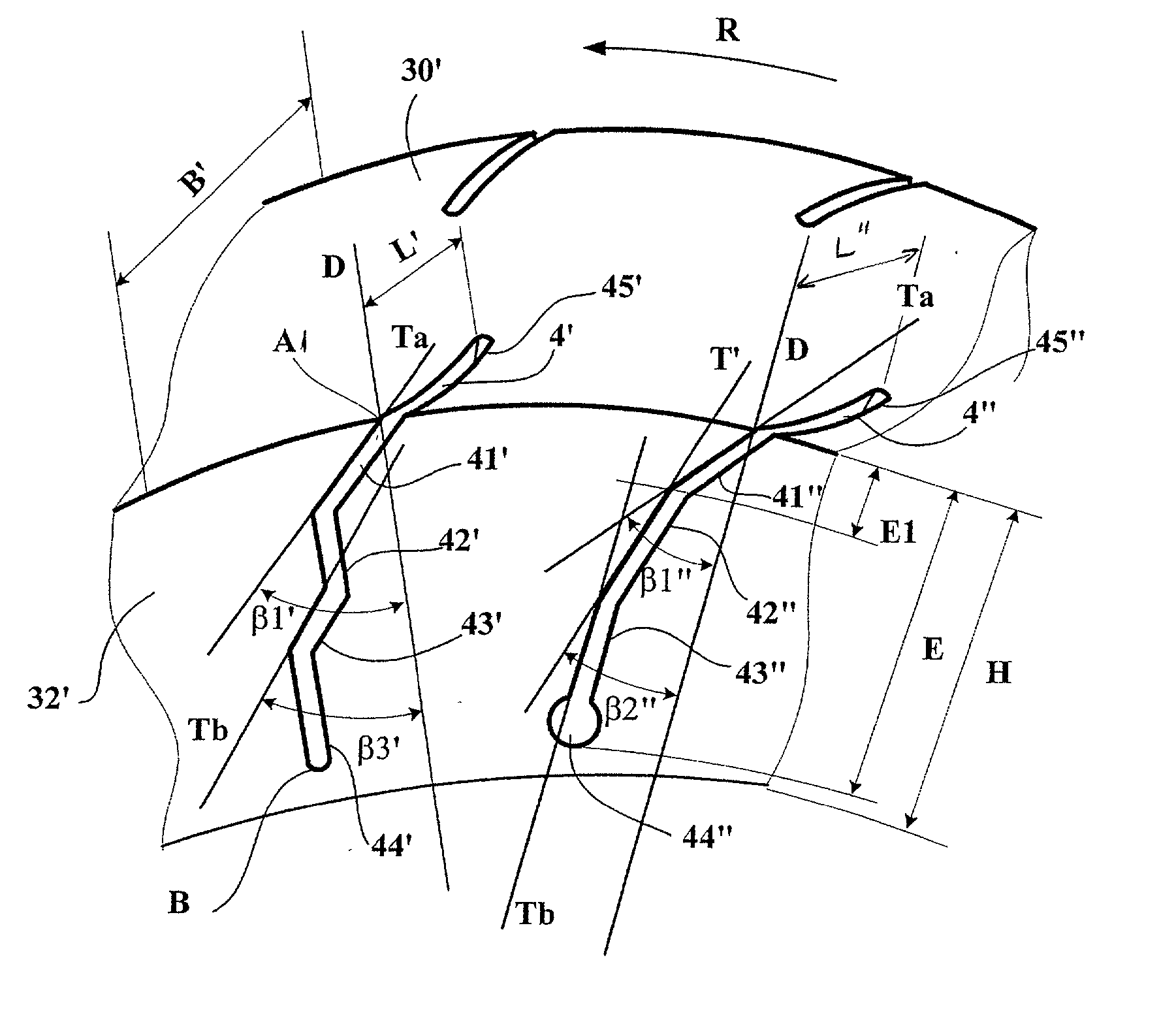

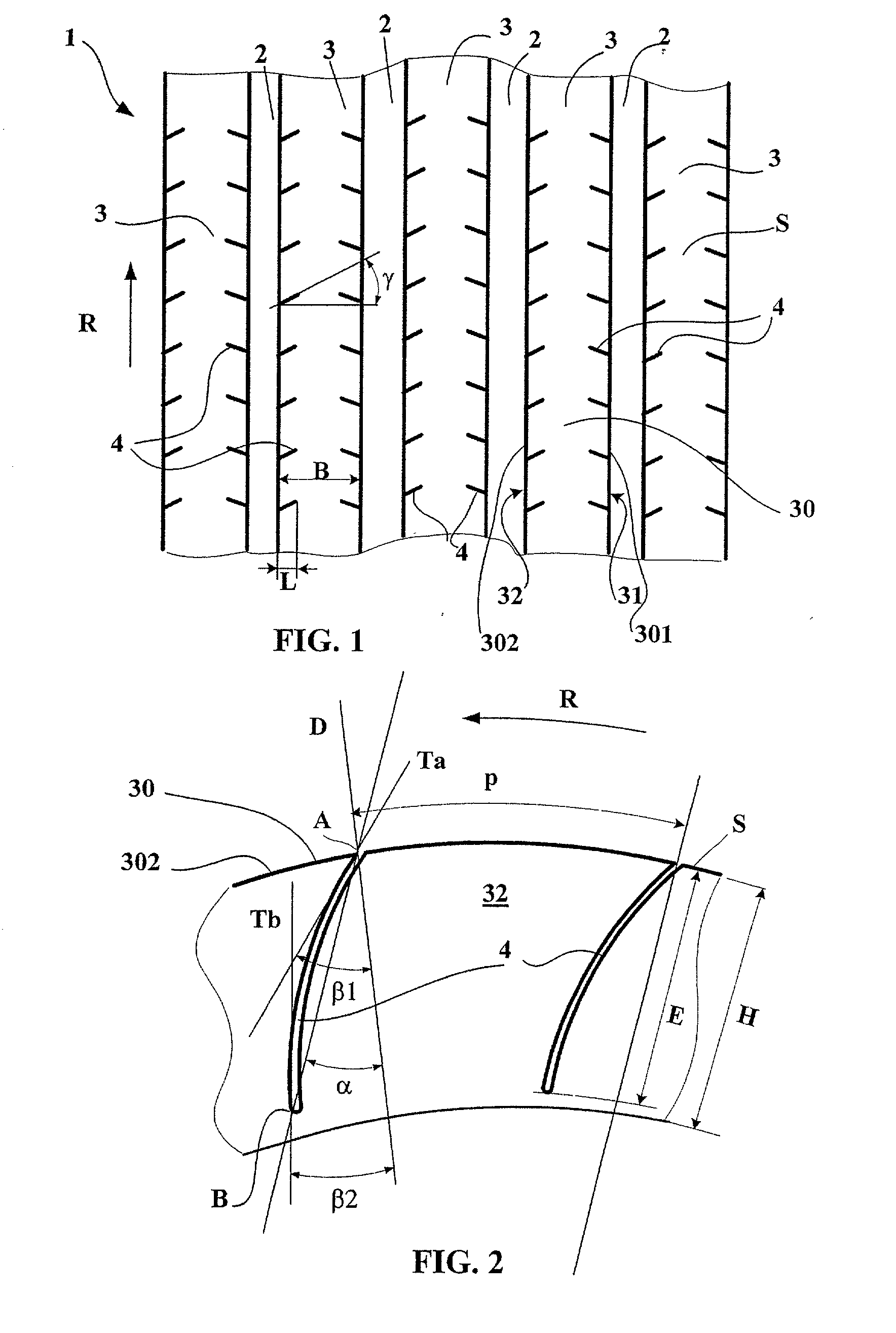

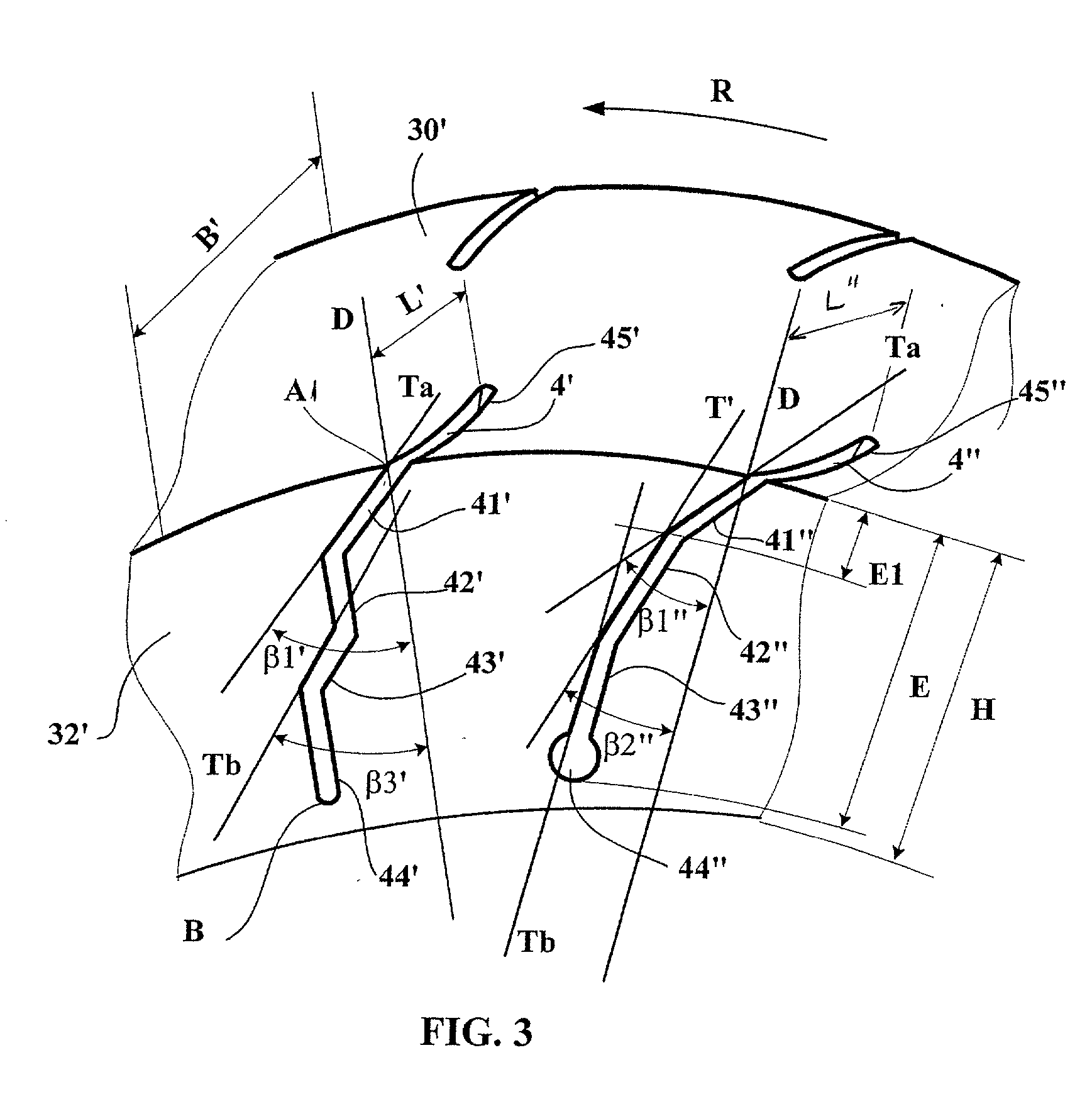

Tread comprising ribs provided with incisions of varying inclination

InactiveUS20020166613A1Restrict movementAppropriate stiffnessTyre tread bands/patternsNon-skid devicesRotational axisSection plane

A tread (1) for a tire with a preferred rolling direction, the tread having grooves (2) of substantially circumferential orientation which delimit ribs (30, 31, 32, 33, 35), at least one of which is provided close to each of its traverse edges with a plurality of incisions of width smaller than 1.5 mm. The incisions open onto the contact surface of the tread, are essentially parallel to one another, and having a mean inclination alpha different from zero relative to the direction perpendicular to the rolling surface (S) of the tread. The tread is characterized in that, when viewed in a section plane perpendicular to the rotational axis of the tire, each incision in a given rib, relative to a perpendicular to the contact surface of the rib at the point where the incision intersects the surface, has an inclination which varies through the thickness of the tread, each incision being inclined at an angle beta1 relative to said perpendicular at its point of intersection with the rolling surface when new, the angle beta1 being larger than the angle alpha, and at an angle beta2 at the point of the incision furthest inside the tread, the angle beta2 being smaller than the angle alpha. The point of the incision furthest inside the tread being located, relative to said perpendicular, such that it is ahead of the point of the incision located on the contact surface of the rib.

Owner:MICHELIN RECH & TECH SA

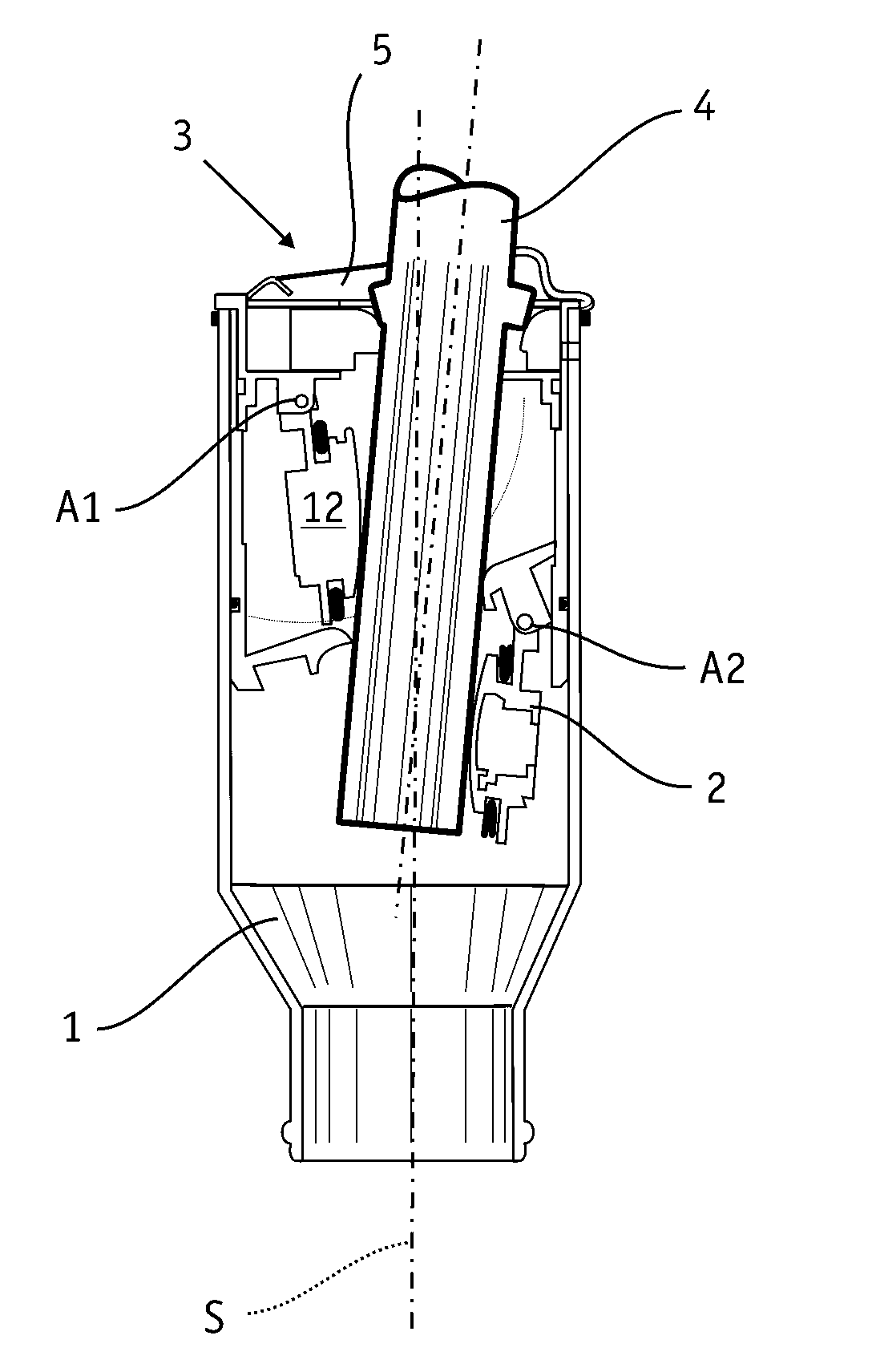

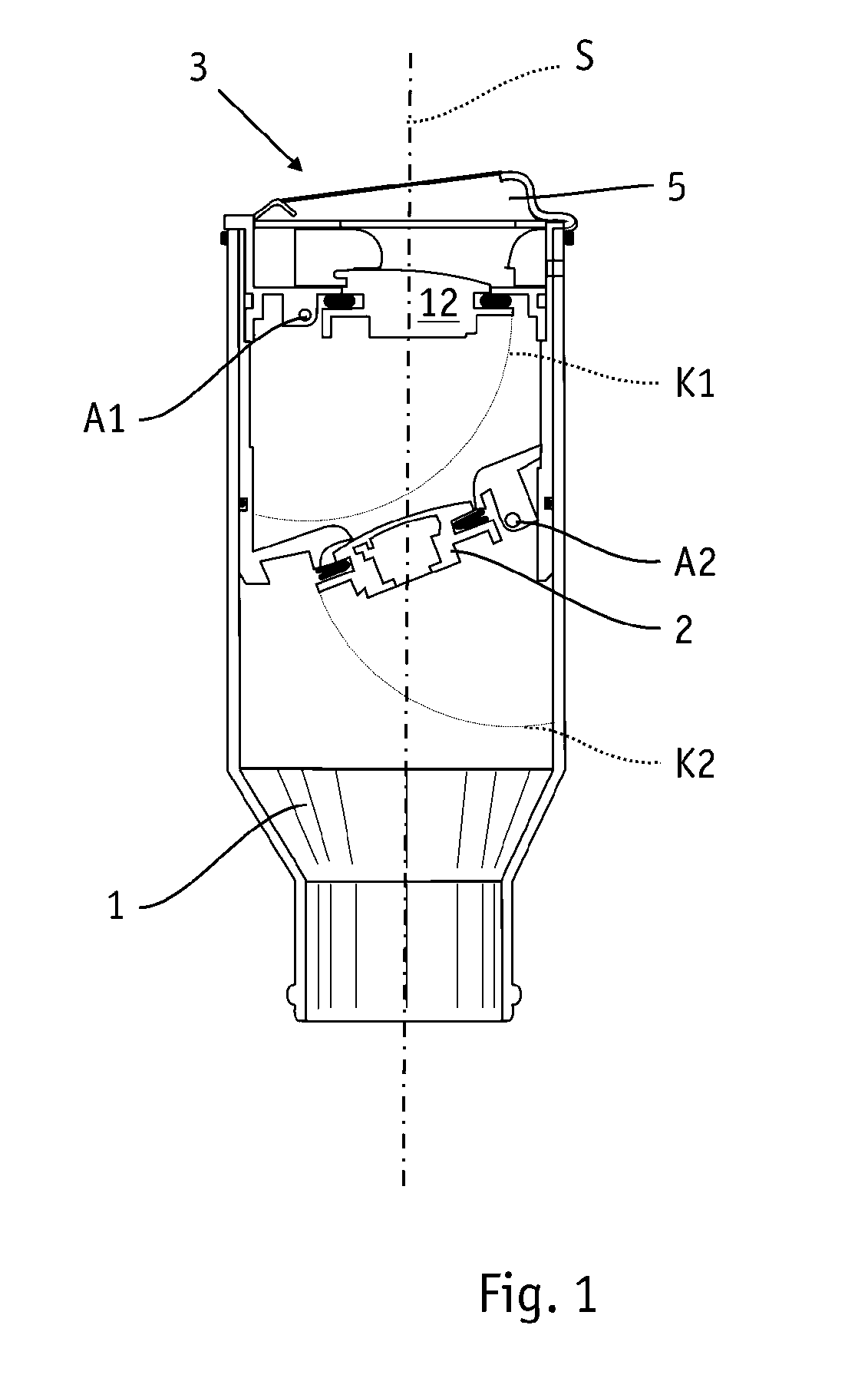

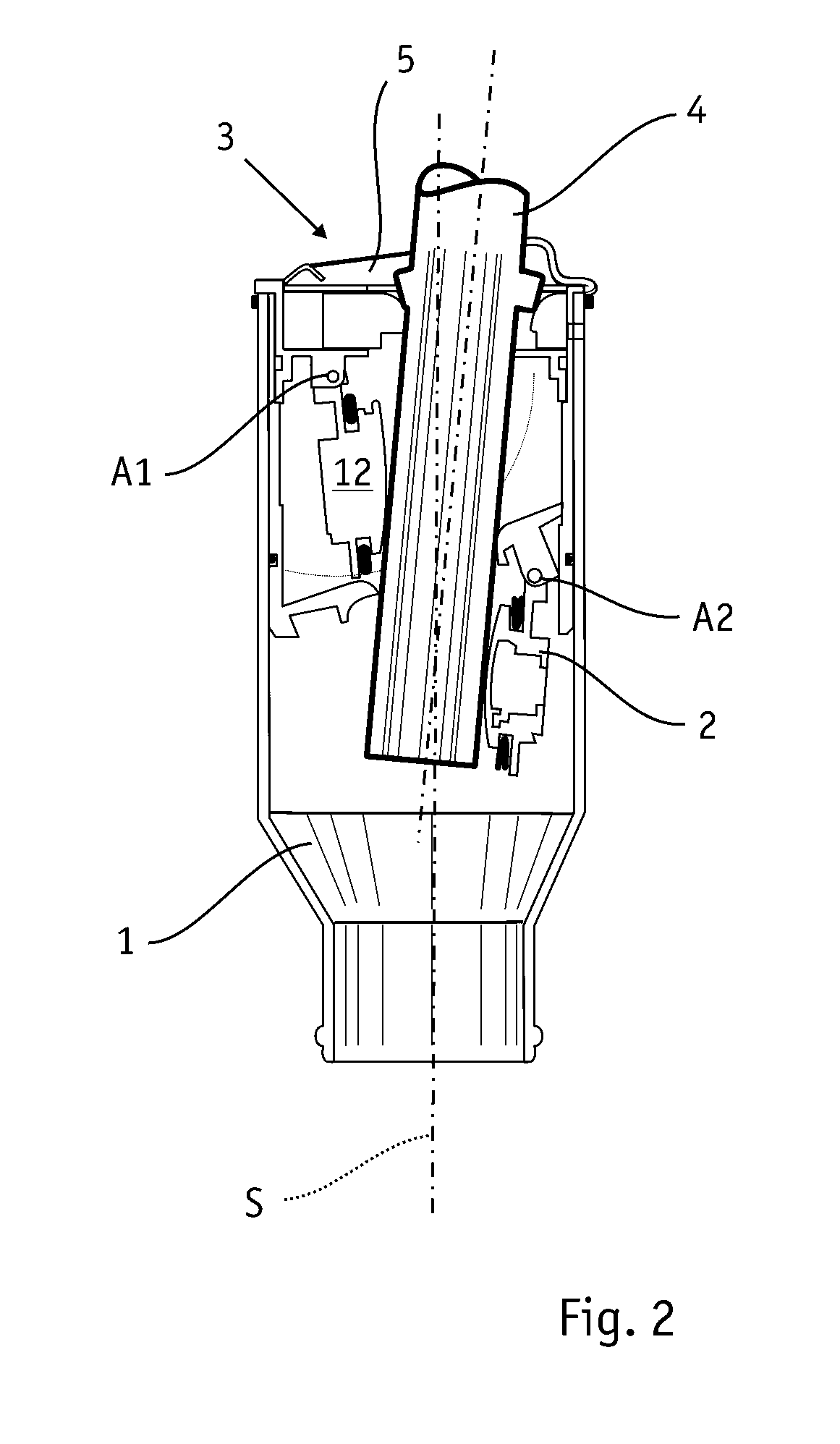

Neck end for a filler neck

ActiveUS20110108563A1Improve protectionReduced space required for installationLidsNon-removalbe lids/coversSection planeEngineering

The invention relates to an in particular capless neck end for a container, in particular a fuel container, with a double-flap closure which is formed by an upper pivoting flap (12) and a lower sealing flap (2). Neck ends of this type are known from WO 2006 / 084908. These known neck ends require too much installation space and are not optimally protected from the contents of the container being pumped out. This is improved by the invention in that the lower sealing flap is arranged in such a manner that it is arranged at an angle to the transverse section plane arranged at right angles to the neck axis (S) when in the closed state, and either the articulation point or, when in the closed state, the end opposite the articulation point of the lower sealing flap is arranged above the lower end of the first circular segment path. Furthermore, an anti-theft means (25) in the form of a mechanical barrier is provided below the double-flap closure.

Owner:GERDES

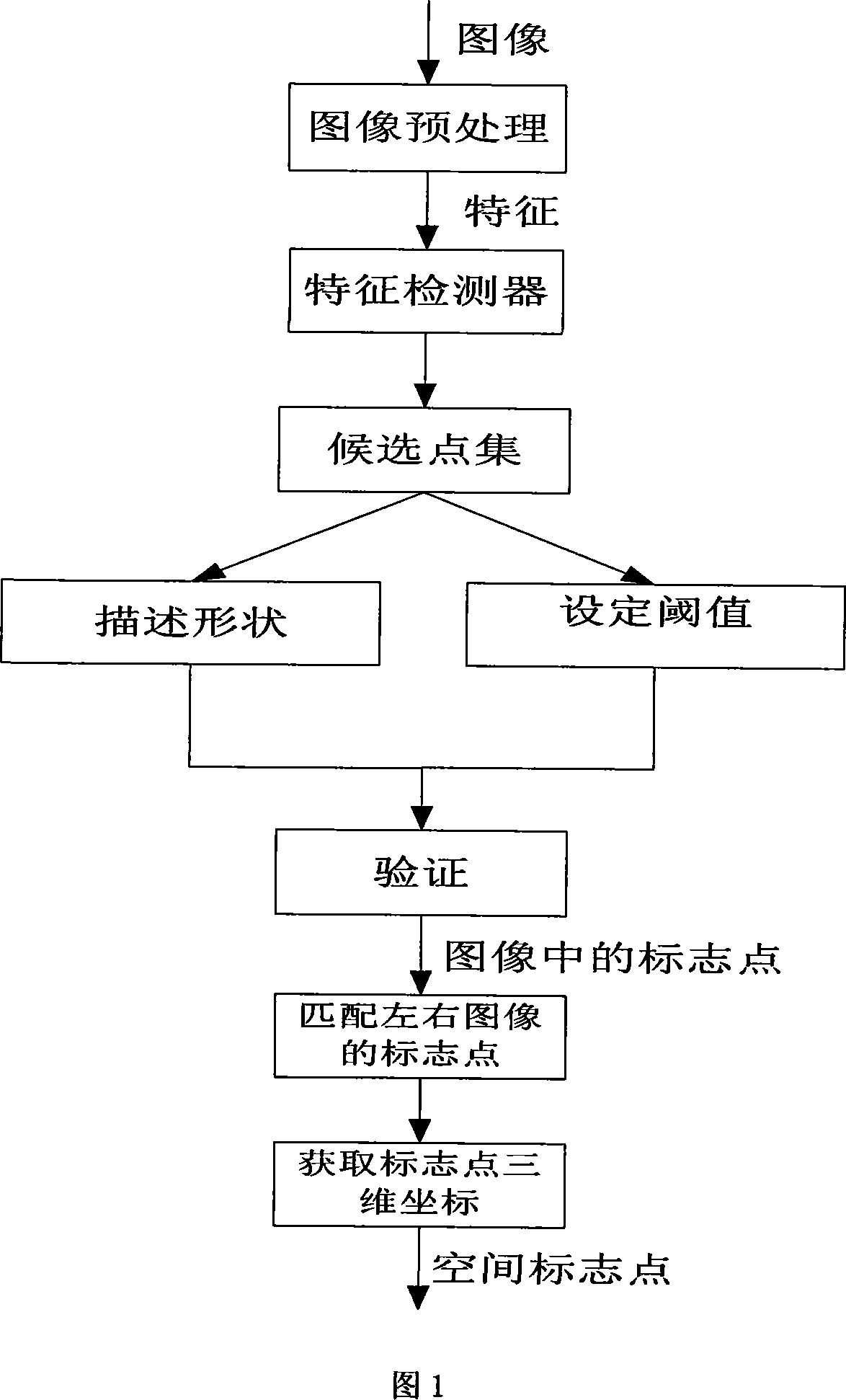

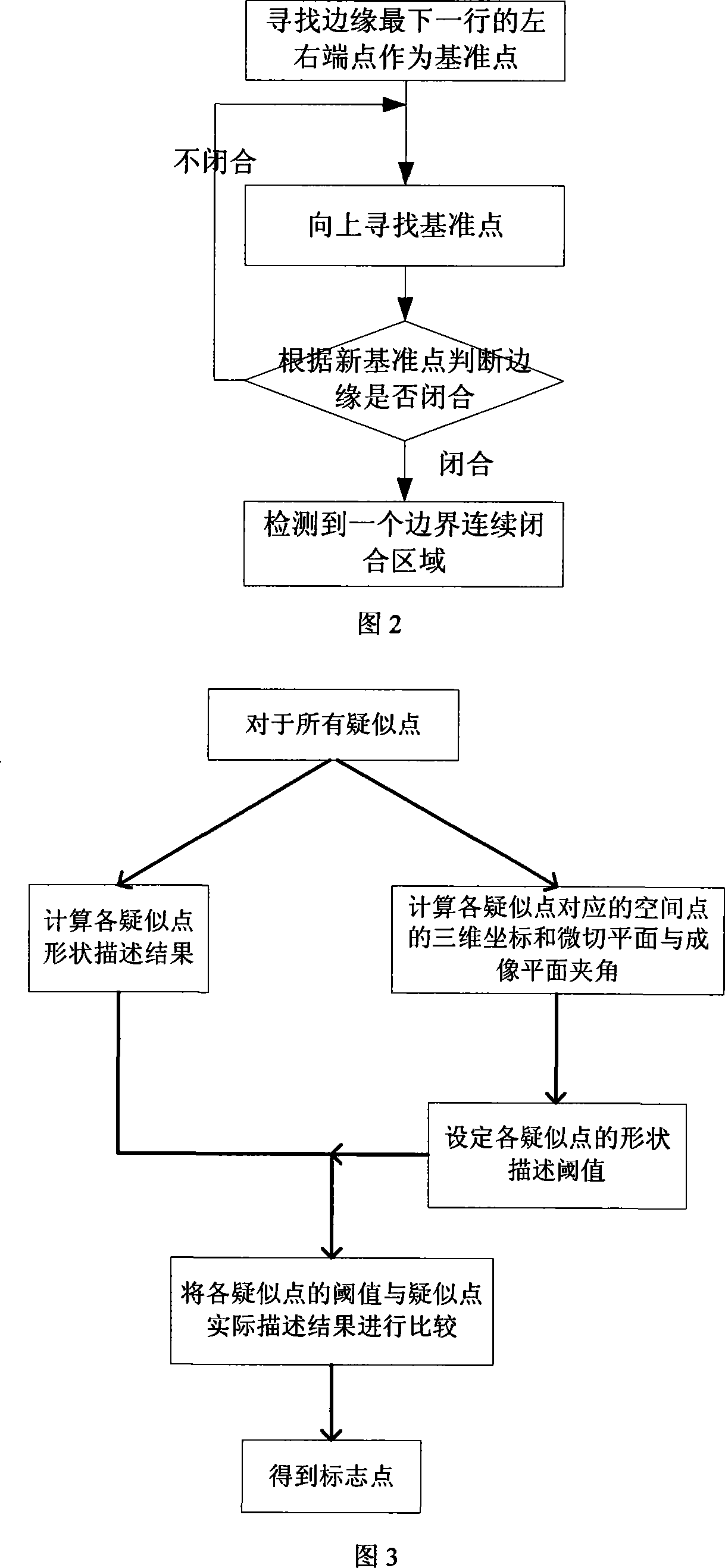

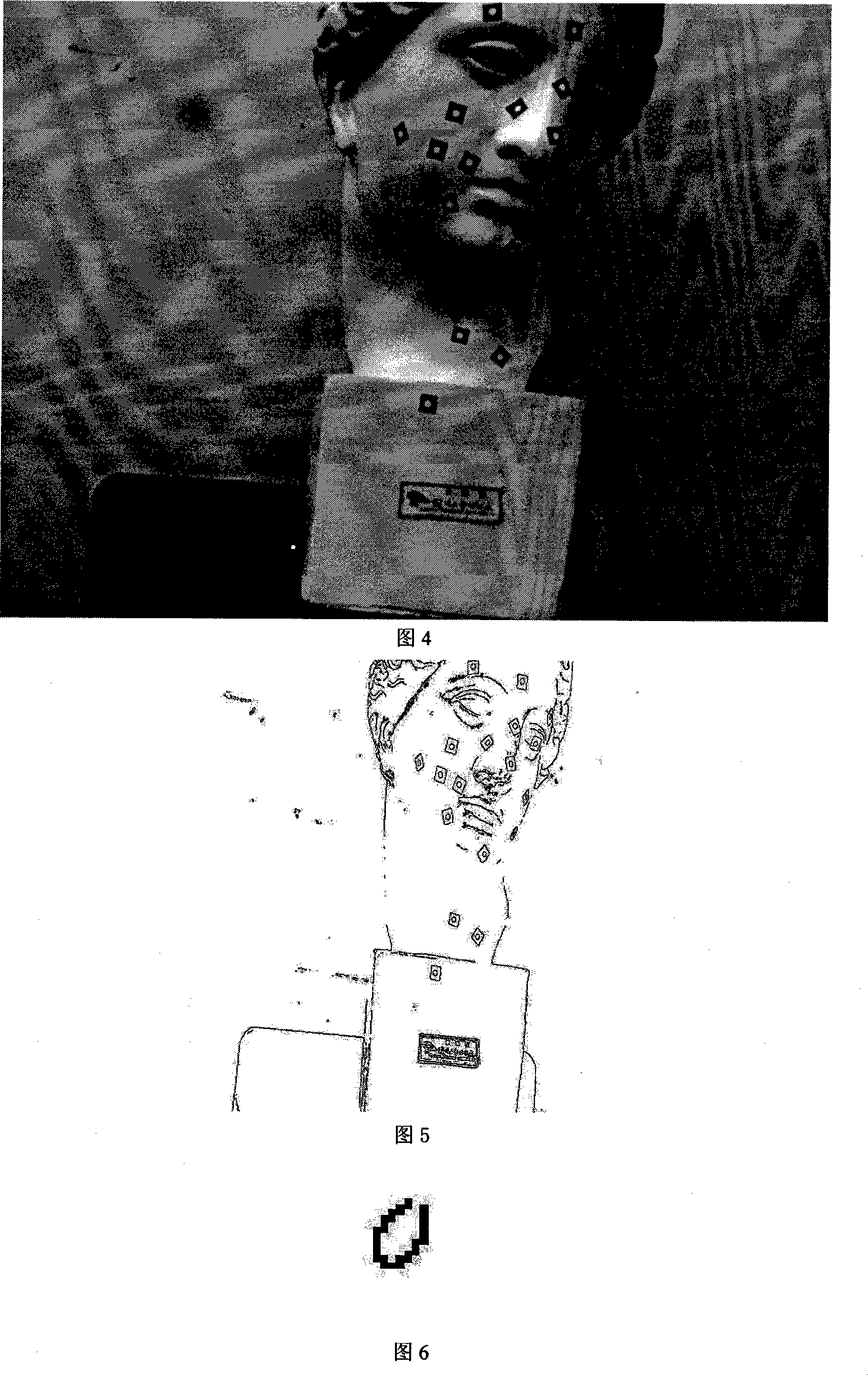

Three-dimensional scanning system circular index point detection method

InactiveCN101144708AAccurate detectionImprove robustnessImage analysisUsing optical meansPoint cloudSection plane

The invention relates to a round mark point detection method of a three-dimensional scanning system. The method firstly performs the pre-treatment to an image taken by a left and right video camera, the mark point is characterized in that a boundary in an outline map obtained after pre-treating is continuously closed, secondly, the boundary continuous closed area is taken as the characteristic of a mark mode, the corresponding characteristic detecting method is designed to detect the possible mark point in the image, the possible mark point is grouped into a suspected point set, and then the space corresponding point of each suspected point is utilized to set up the shape description a threshold in a self adapting way to the location in the point cloud and an angle between a micro-section plane and an imaging plane, and the threshold is utilized to perform the verification to the practical shape description result of the suspected point, to obtain the mark point in the image; at last, the matching is performed to the mark point in the image taken by the left and right video camera to obtain a mark point pair corresponded on the left and the right, and the space mark point corresponding to the matching mark point is obtained.

Owner:海安江理工技术转移中心有限公司 +1

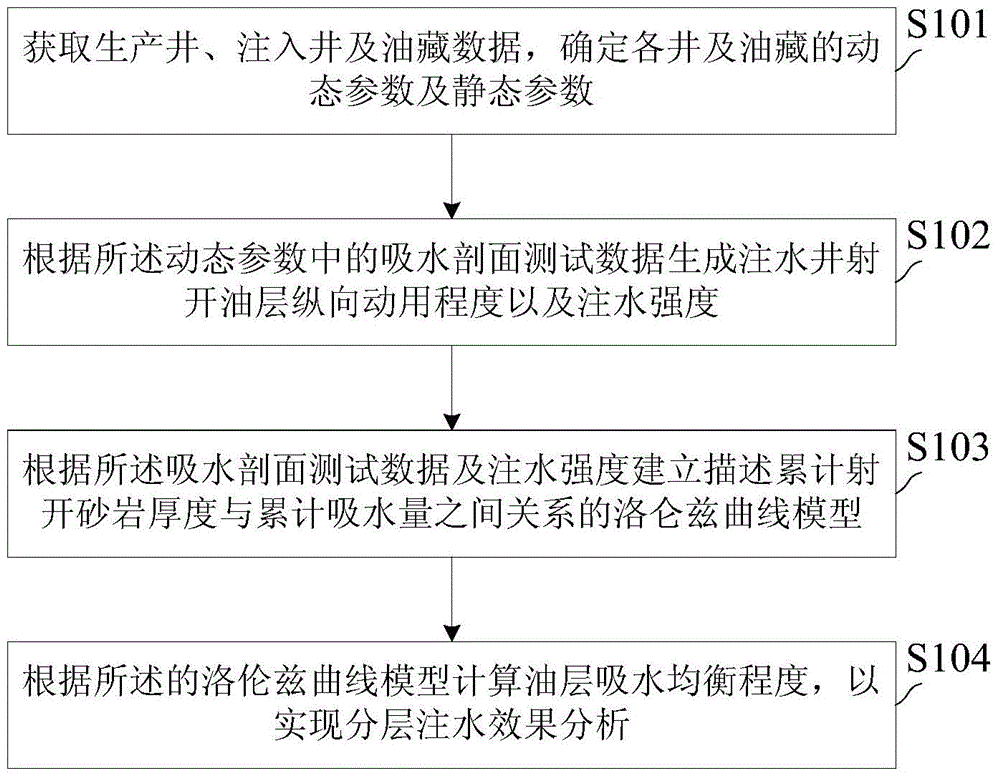

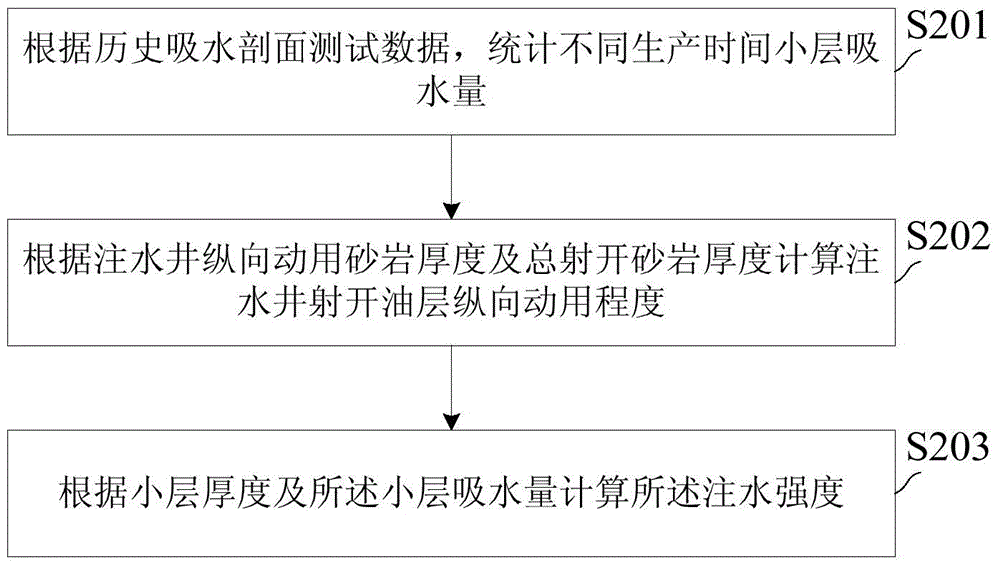

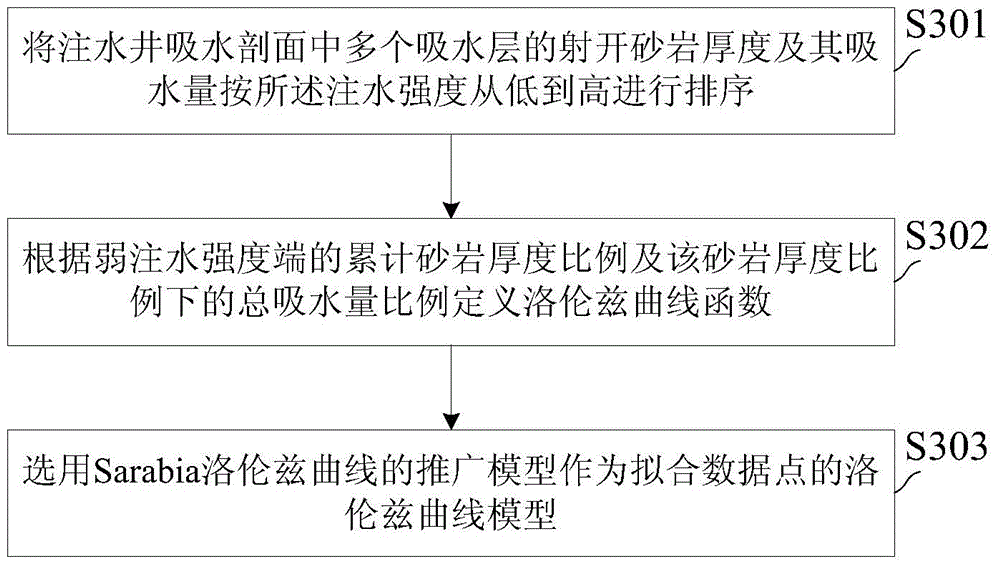

Layered water injection effect analysis method

ActiveCN104879103AEffect Prediction of Layered Water InjectionSurveyFluid removalSection planeUltimate tensile strength

The invention provides a layered water injection effect analysis method. The layered water injection effect analysis method includes the steps that data of a production well, an injection well and an oil deposit are obtained, and dynamic parameters and static parameters of the wells and the oil deposit are determined; the shooting oil layer longitudinal mobilization degree and the water injection strength of the water injection well are generated according to water absorption profile testing data in the dynamic parameters; a Lorentz curve model for describing the relationship between the accumulated shooting sandstone thickness and the accumulated water absorption amount is built according to the water absorption profile testing data and the water injection strength; the oil layer water absorption balance degree is calculated according to the Lorentz curve model so as to achieve layered water injection effect analysis. By means of the layered water injection effect analysis method, the proportion of the longitudinal mobilization sandstone thickness of the water injection well to the total shooting sandstone thickness and the water absorption balance condition of the shooting small-layer whole can be evaluated in a quantified mode; factors having influences on layered water injection are found in cooperation with the over-the-year actual measurement water injection profile, the stratum physical property, the sedimentary phase, the layered water injection tubular column structure and injection allocation data.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com