Composite wall with energy-saving and thermal insulating function and masonry method thereof

A thermal insulation and composite wall technology, which is applied in the field of building materials, can solve problems such as poor internal structure quality, unsatisfactory comprehensive benefits, and large land occupation by building walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

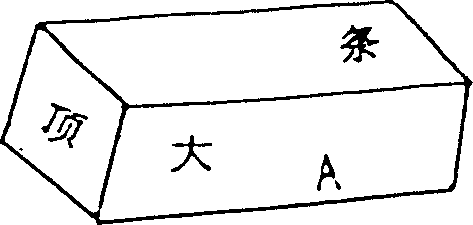

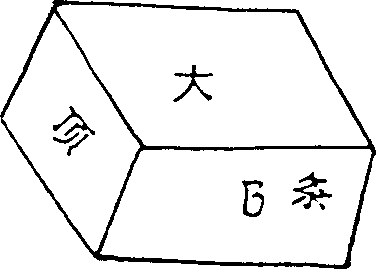

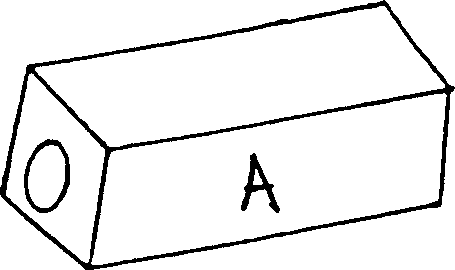

[0013] Now set the size of the length × height × width of the brick to be 240 × 90 × 73, the size relationship of length, width and height is length > height ≥ width, and the size of the length × width × height of the small brick is 156 × 115 × 90 , the dimensional relationship of its length, width and height is length > height ≥ width; the width of the thermal insulation material is 40, unit: millimeter (mm), and the gray joint is 10mm (see the attached diagram for details Figure 13 ). The specific implementation of masonry is as follows:

[0014] 1. Place the large side of the brick, that is, the 240×90 side outward or outward, leaving a space of 40mm, and then place the top surface of a small brick, that is, the 115×90 side outward or outward, and place it horizontally After putting, just formed empty bucket air composite wall, its implementation process is: 1 long+horizontal arrangement of the width+empty bucket air+1 small brick of brick=composite wall (Fig. 7, 8, 13) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com