Method for generating numerical-control side milling machining tool path for complicated curved surfaces

A surface and tool path technology, which is applied in the field of tool path generation for five-axis CNC side milling machining of complex composite surfaces, can solve problems such as the lack of research on composite surface machining problems, and achieves the advantages of small machining interference, improved efficiency, and guaranteed fitting accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

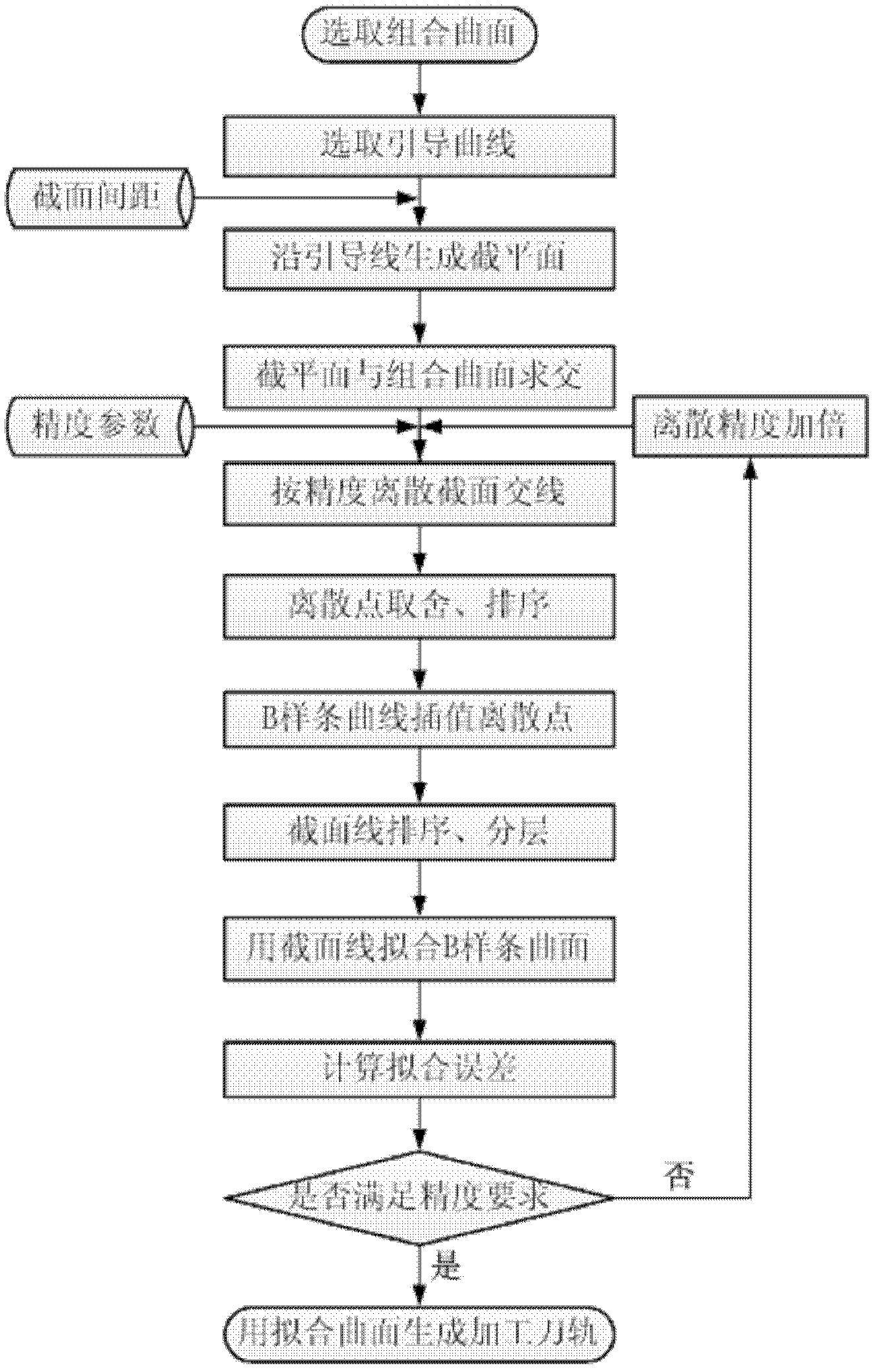

[0029] figure 1 It is a flow chart of the five-axis side milling processing method for complex combined curved surfaces of the present invention, as shown in the figure, including the following steps:

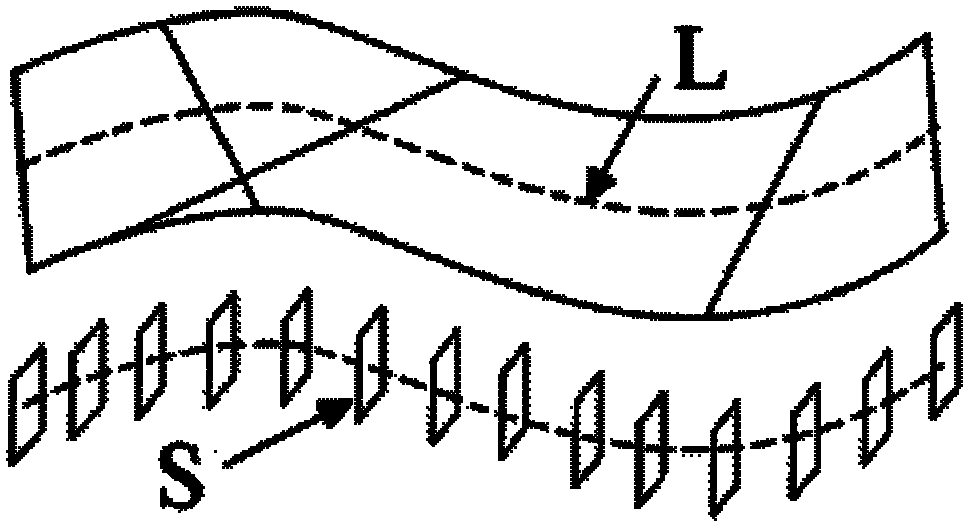

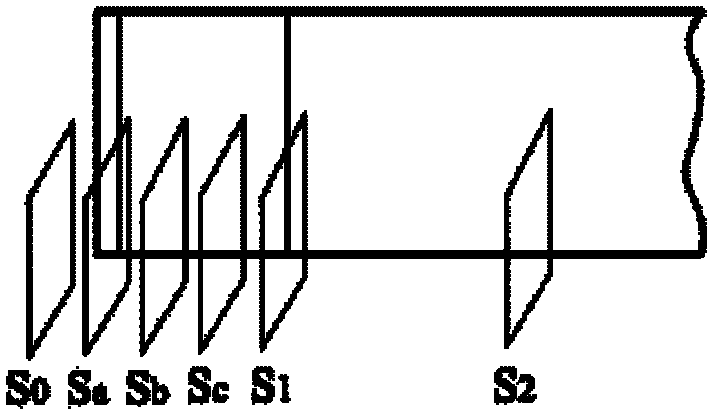

[0030] The first is to select various elements, including combined surfaces and guide lines, and set various parameters, including the distance between section planes, the maximum discrete step size, and the maximum chord height error. Such as figure 2 As shown, the selected combined surface is a group of surfaces that conform to a certain processing technology and can be processed as a whole; the selected guide line is a curve that runs through a certain parameter direction of the combined surface and is basically consistent with the direction of the surface, and can exceed the direction of the combined surface. outline. The distance between the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com