Patents

Literature

105results about How to "Guaranteed fitting accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

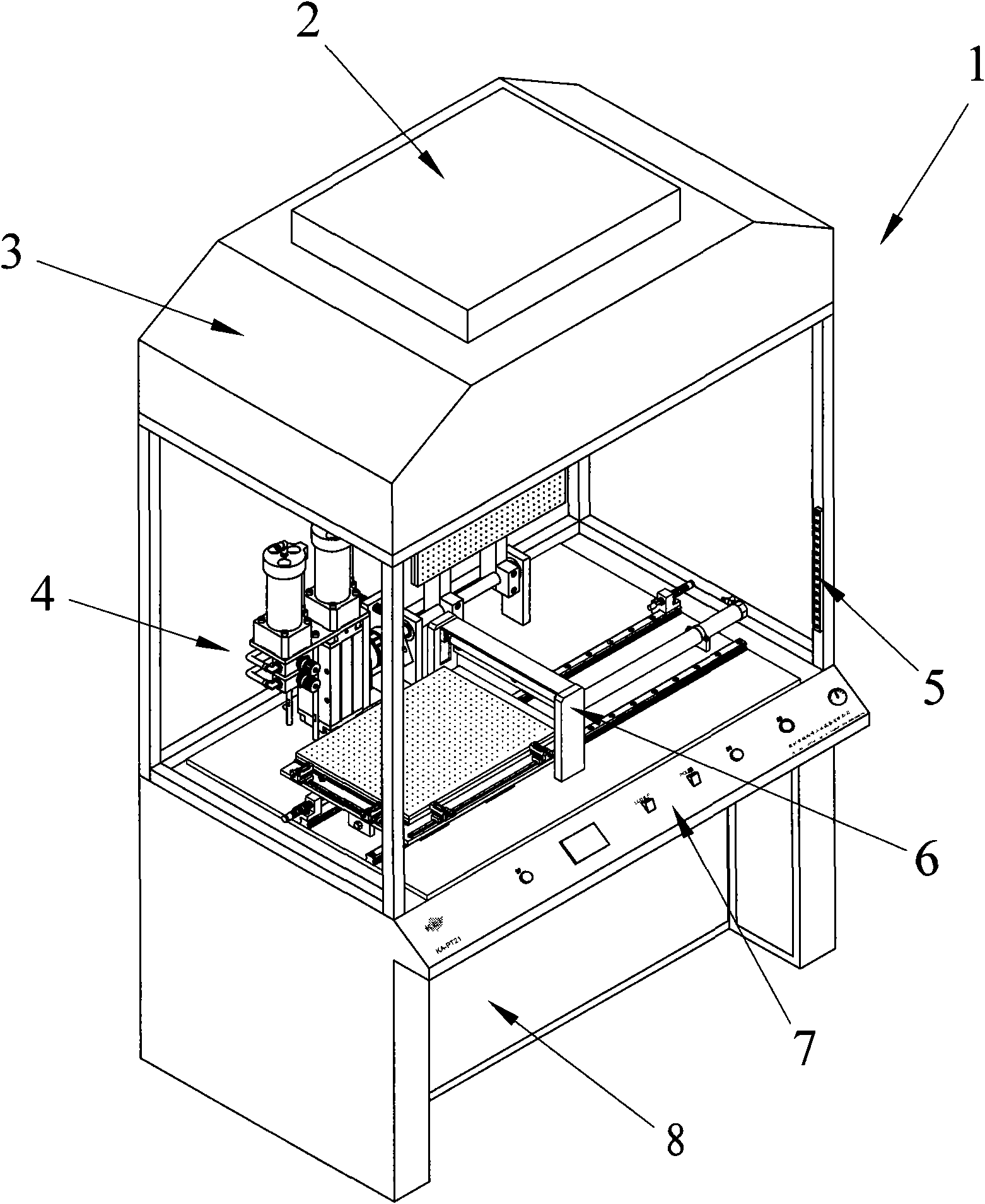

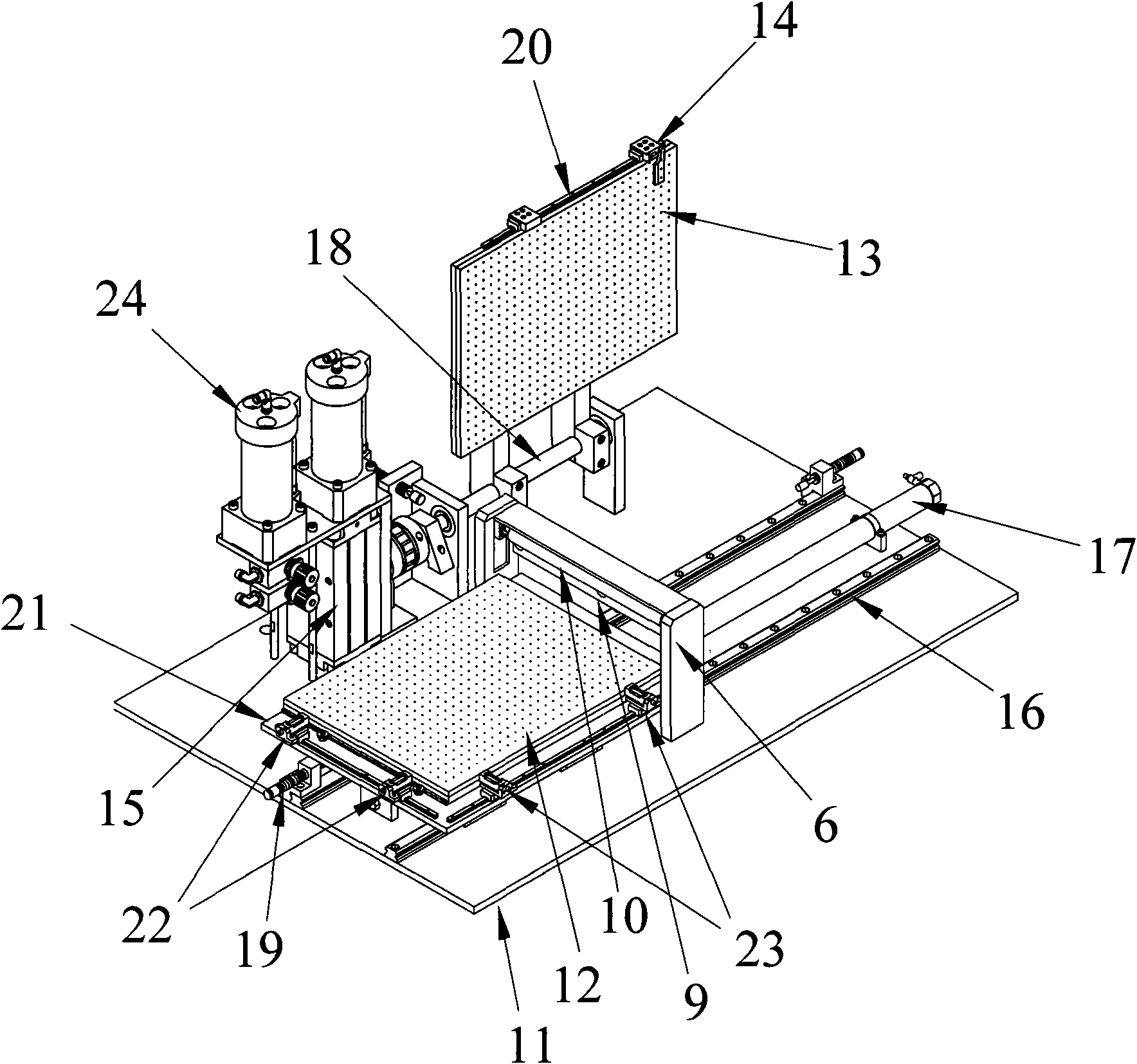

Semi-automatic laminating machine and laminating method thereof

InactiveCN101581850AGuaranteed cleanlinessEasy to operateLaminationLamination apparatusSemi automaticAtmospheric pressure

The invention discloses a semi-automatic laminating machine and a laminating method thereof. The semi-automatic laminating machine is provided with a stand, wherein an operating space for accommodating a laminating device is arranged in the middle part of the stand, an electric component box is placed in the stand and positioned below the laminating device, an air inlet opening is arranged at the top of the stand, an air purifier is placed at the top of the stand and an operating panel is installed on the stand and used for controlling the laminating machine. The material laminating is carried out by material placing, aligning, laminating by pressure roller, laminating completion and returning for standby. The semi-automatic laminating machine adopts various ways of vacuum adsorption, mechanical positioning and pneumatic motion to be provided with a precision fine adjustment device, a limitator, an oil-gas convertor, a linear slide rail and other precision components, thereby ensuring the laminating accuracy, reducing the dependence on the operators, overcoming the phenomenon of inaccurate positioning, low yield, air bubble, gauffer and defects existing in the laminating process of the diaphragm and the base material, reducing the running time due to the overlapped type motion and improving the production efficiency.

Owner:郑春晓

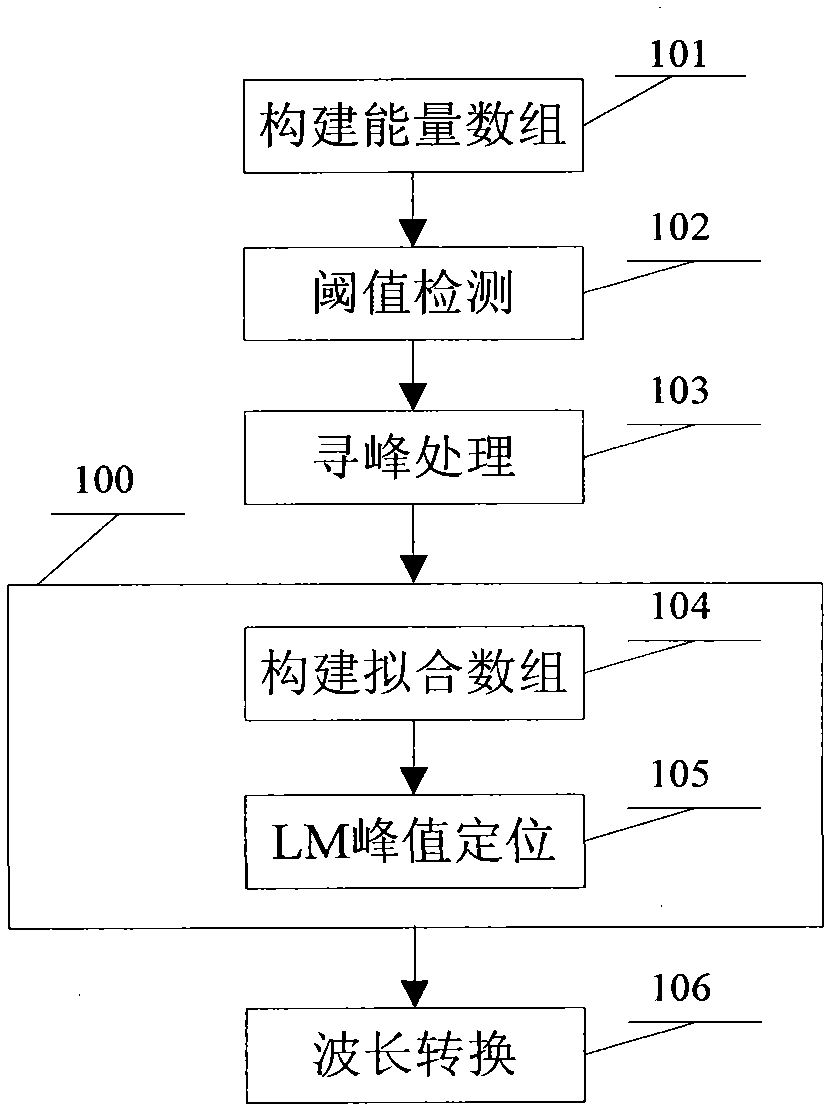

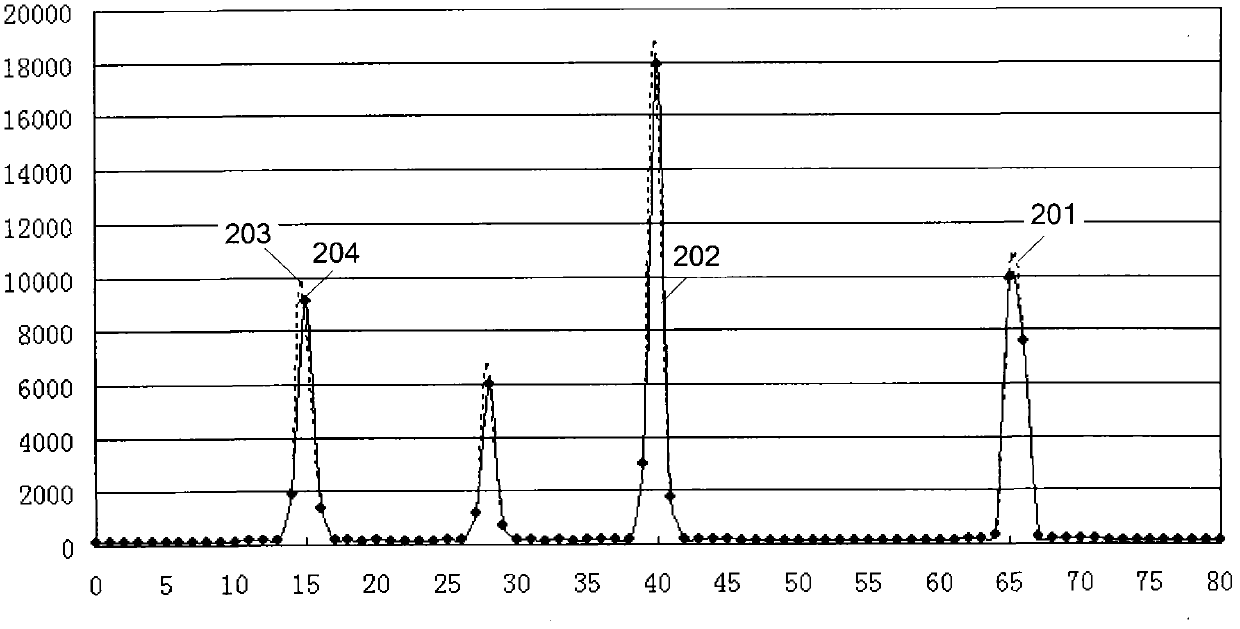

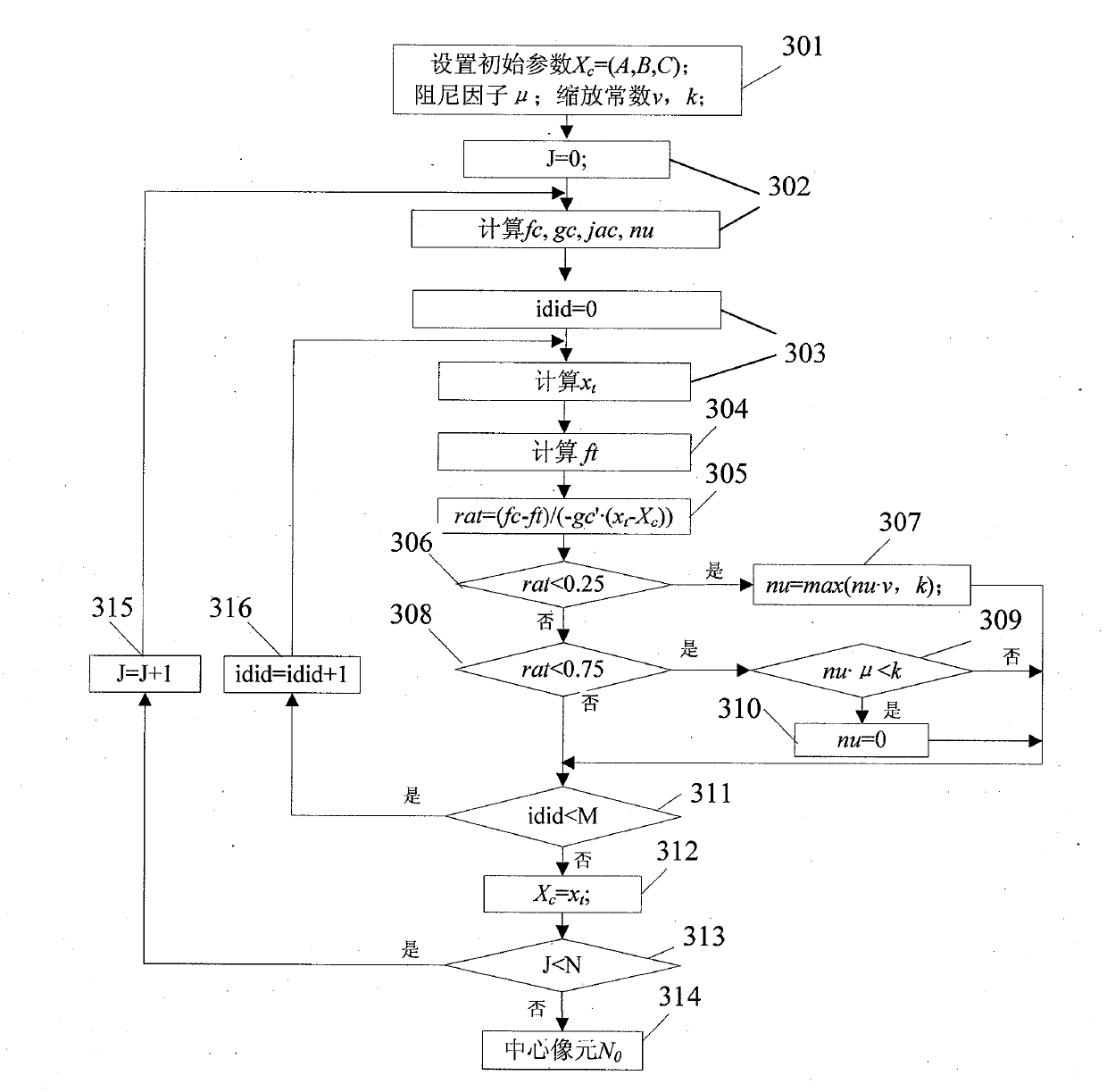

Optical fiber wavelength demodulating light spectrum peak value positioning method

ActiveCN102706372AHigh precisionFast convergenceConverting sensor output opticallyArray data structurePeak value

The invention relates to an optical fiber wavelength demodulating light spectrum peak value positioning method, belonging to the technical field of optical fiber sensing. The method comprises the following steps: firstly, carrying out maximum value detection on obtained diffraction light spectrum energy data; determining a suitable threshold value according to a maximum value and utilizing the threshold value to carry out peak searching treatment; constructing a fitting array by the processed data; and utilizing an LM peak value positioning algorithm to carry out accurate peak value positioning on the spectrum. Compared with the existing power weighted algorithm and Gaussian-polynomial fitting algorithm, the algorithm has the advantages of high-precision positioned light spectrum peak value; and the method is easy to realize on a digital television through a simplified data processing process.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

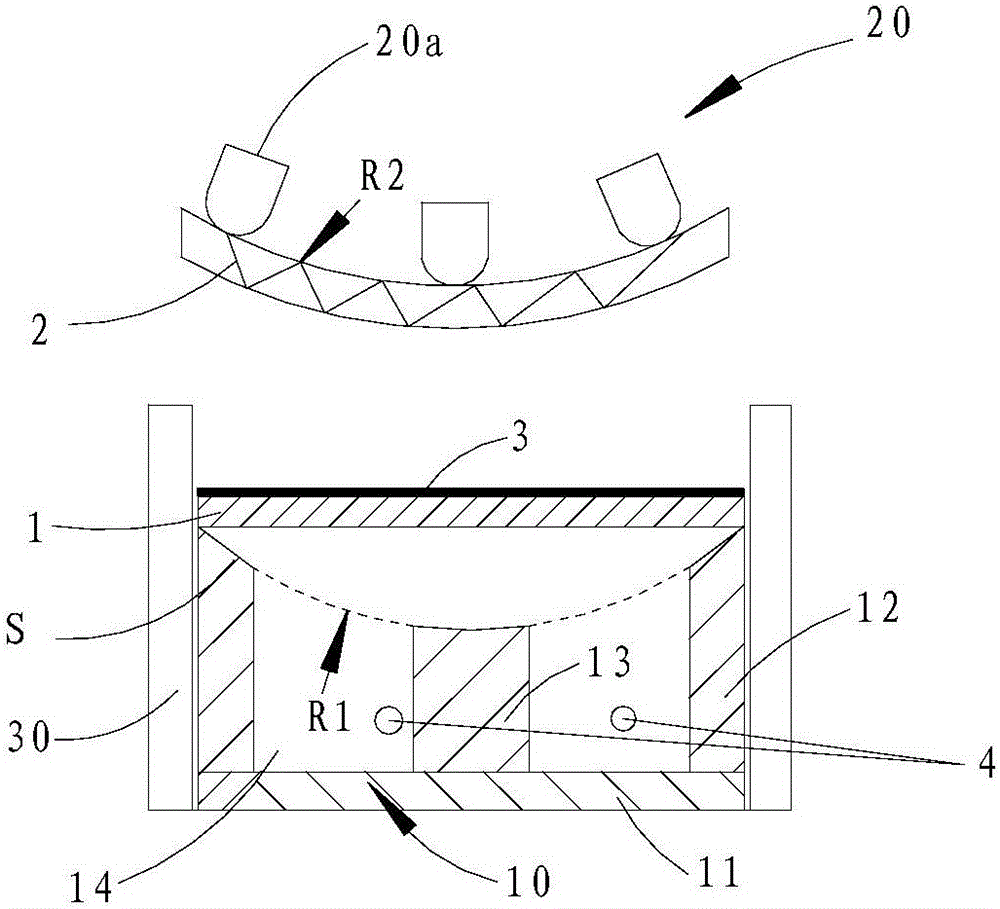

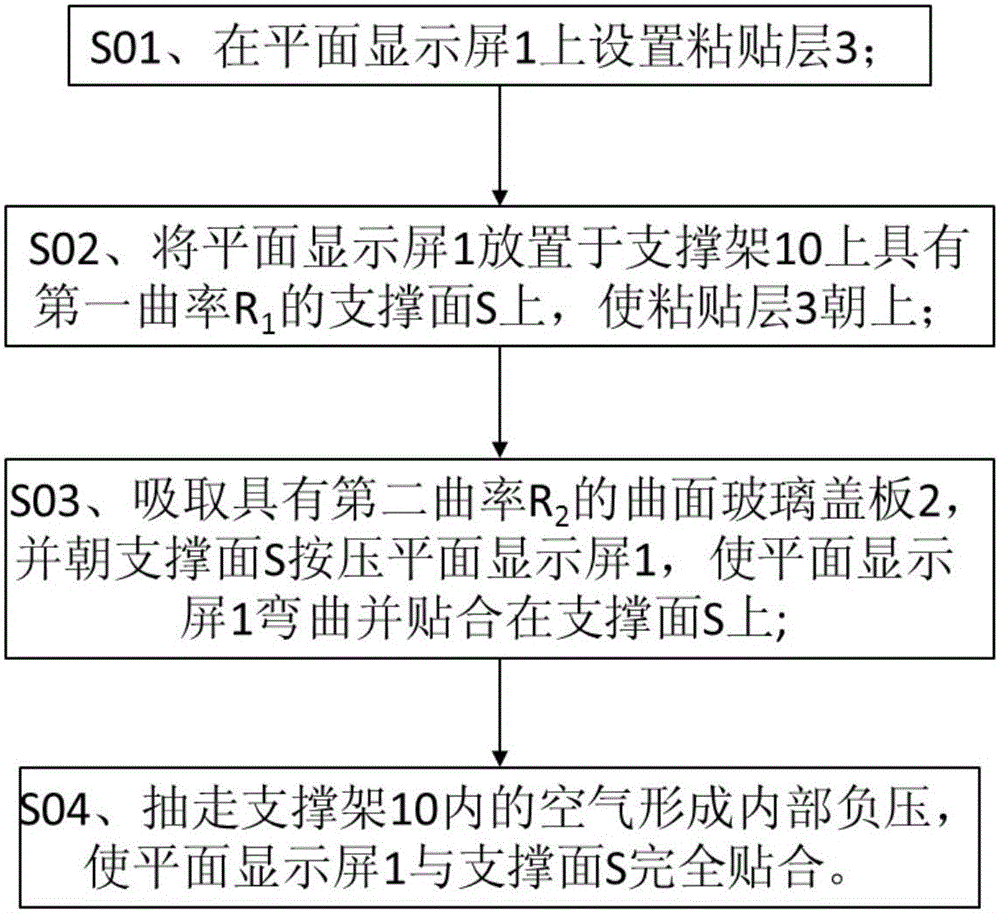

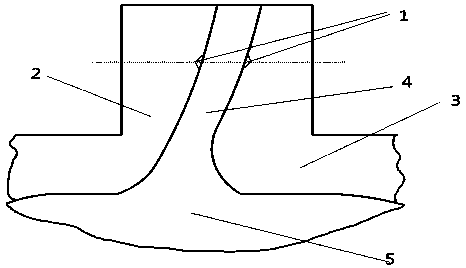

Laminating fixture between curved glass cover plate and flat display screen and laminating method

ActiveCN105128409AReliable paymentGuaranteed fitting accuracyLaminationLamination apparatusEngineeringGlass cover

The invention discloses a laminating fixture between a curved glass cover plate and a flat display screen. The laminating fixture includes: 1) a support bracket, on which the top is provided with a support surface having a first curvature and is used for supporting the flat display screen; and 2) a movable picking apparatus, which is used for picking the curved glass cover plate having a second curvature, and pressing the flat display screen arranged on the support surface through the curved glass cover plate towards the support surface, thereby bending the flat display screen and laminating the flat display screen with the curved glass cover plate. The invention also discloses a laminating method of a curved glass cover plate to the flat display screen. By means of design of the novel laminating fixture between, the flat display screen can be bent into a shape in a special curvature by pressing the flat display screen through the curved glass cover plate, and meanwhile, reliable lamination between the curved glass cover plate and the flat display screen is achieved, thereby ensuring laminating precision between the two parts and increasing laminating efficiency.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

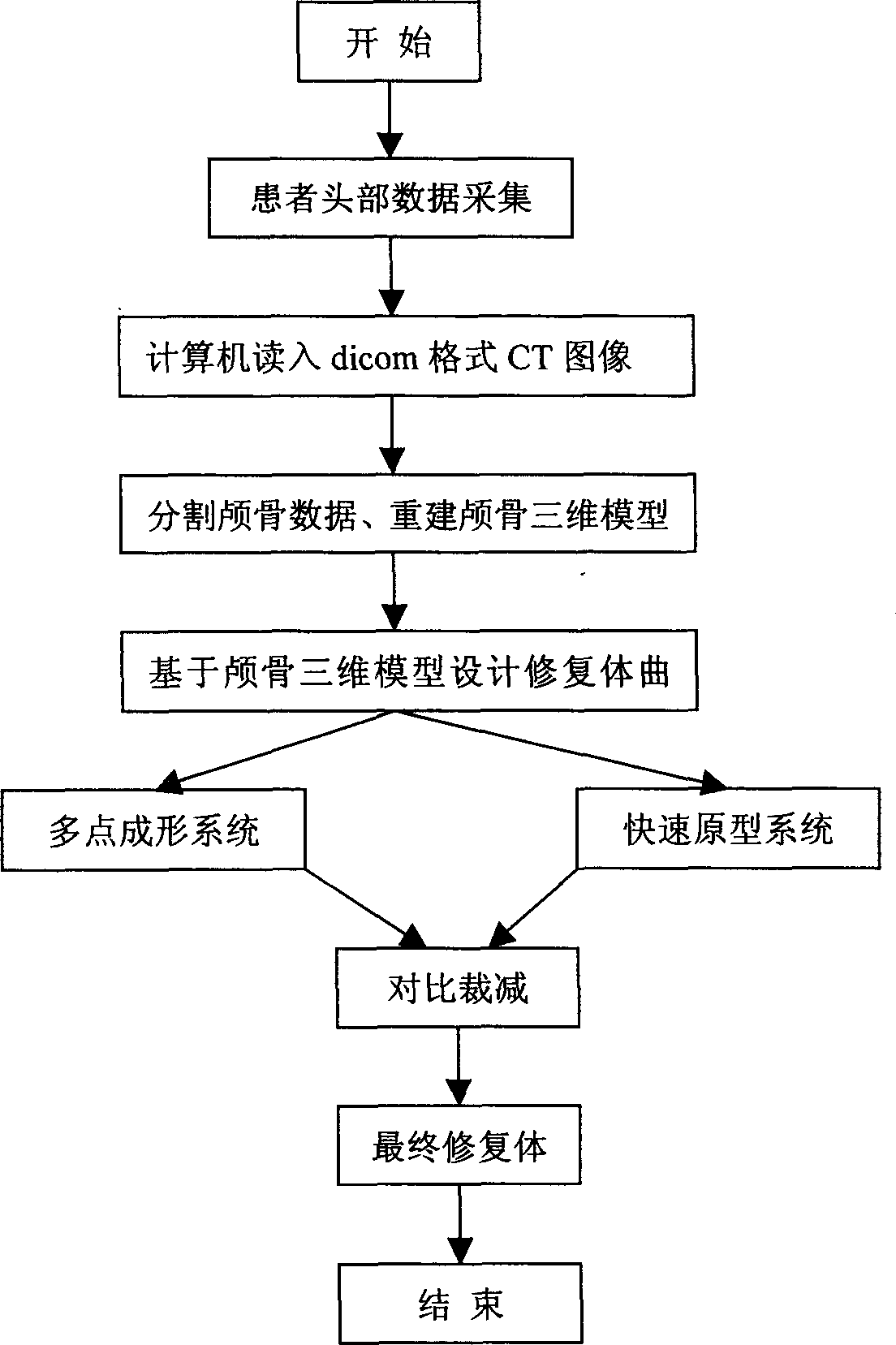

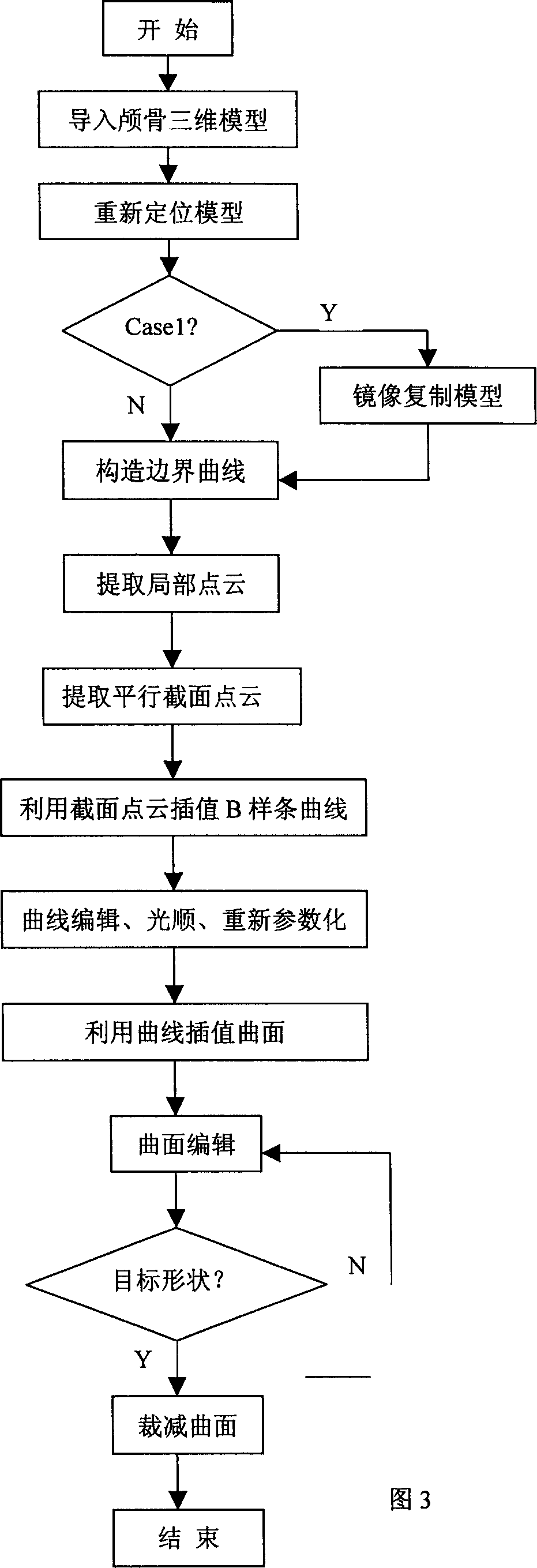

Method for preparing titanium alloy skull dummy

InactiveCN1523530AQuality improvementSolve the problem of rapid shapingSpecial data processing applications3D modellingCranial nervesDesign software

The invention is a manufacturing method for titanium alloy cranial bone dummy, applies to cranial nerves surgery cranial bone renovation field. The invention assembles the dummy based on the CT picture of patient; the character lies in: the computer with universal image processing software and back designing software reconstructs the three-dimension prototype of patient head after dividing the fracture image, designs the dummy of defect part according to the three-dimension prototype, and the designed dummy curved surface is guided into multi-point forming system and quick-prototype system to press titanium network board and produce dummy slice model, finally forms the terminal dummy through comparing and cutting the titanium network board; the invention uses multi-point forming technology to compress the dummy quickly, it can uses the softness character of mouldless multi-point to compress the dummy in order to solves the back springing problem. The cost is low, the speed is high.

Owner:BEIJING UNIV OF TECH

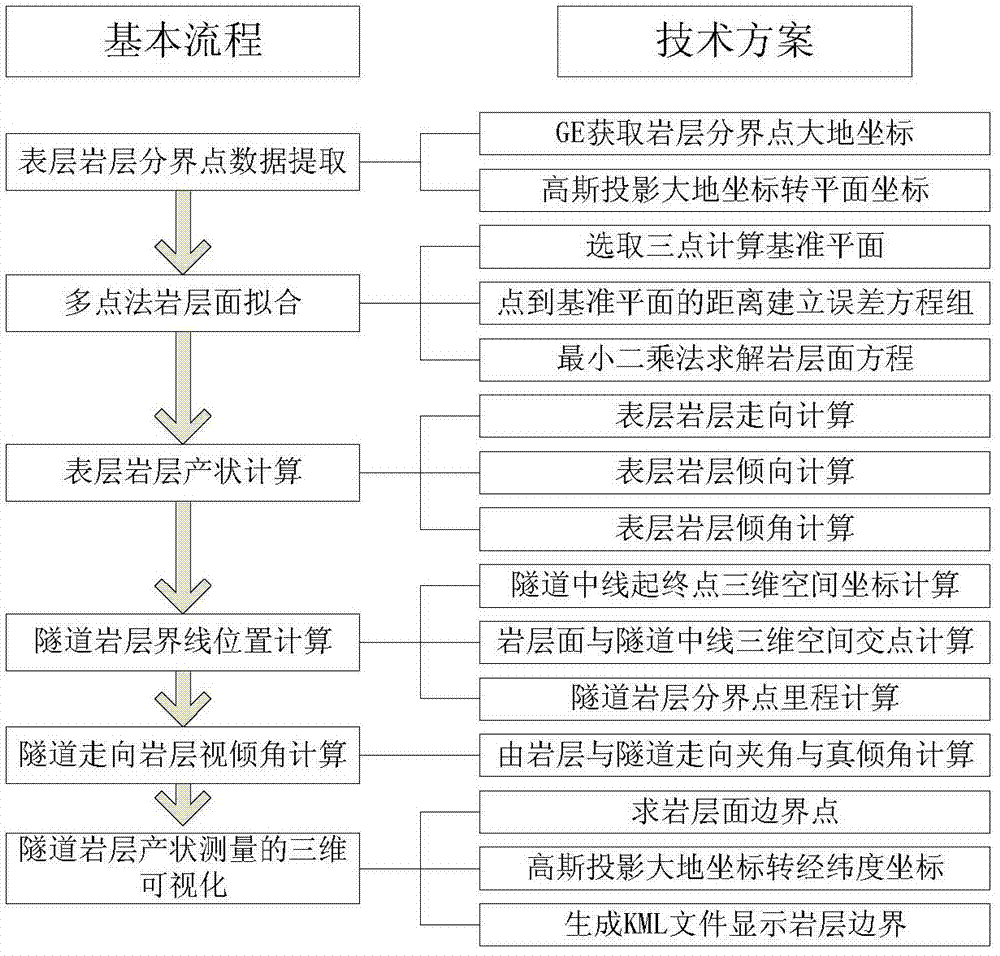

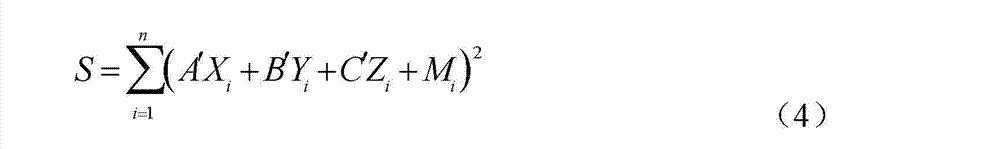

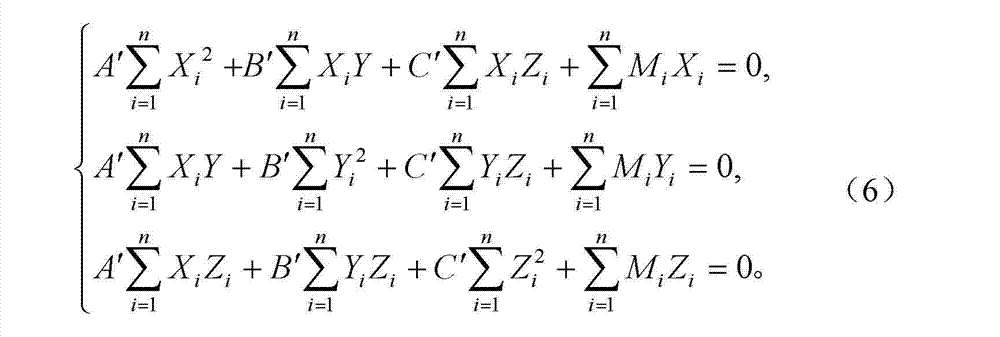

Three-dimensional measurement method for tunnel rock formation attitude

ActiveCN103207419AQuick batch fetchGuaranteed fitting accuracyGeological measurementsDemarcation pointComponent Object Model

The invention discloses a three-dimensional measurement method for a tunnel rock formation attitude. According to the method, a large amount of geographical information data such as digital elevation models (DEM) and images, which are provided by Google Earth, serve as a data source, a Google Earth component object model application program interface (COM API) is used for obtaining rock stratum demarcation point data from the Google Earth, rock stratum surface fitting is conducted, the rock formation attitude is calculated, and rock stratum surfaces and rock formation attitude elements are displayed visually through a marking language. Compared with field surveys conducted through geological compasses, the three-dimensional measurement method for the tunnel rock formation attitude based on a Google Earth platform has the advantages that time and effort can be saved, the survey range can be expanded, rock formation attitude elements of areas with harsh natural conditions and large rock stratum span ranges can be measured conveniently, and the method is a good supplement to traditional measurement methods.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

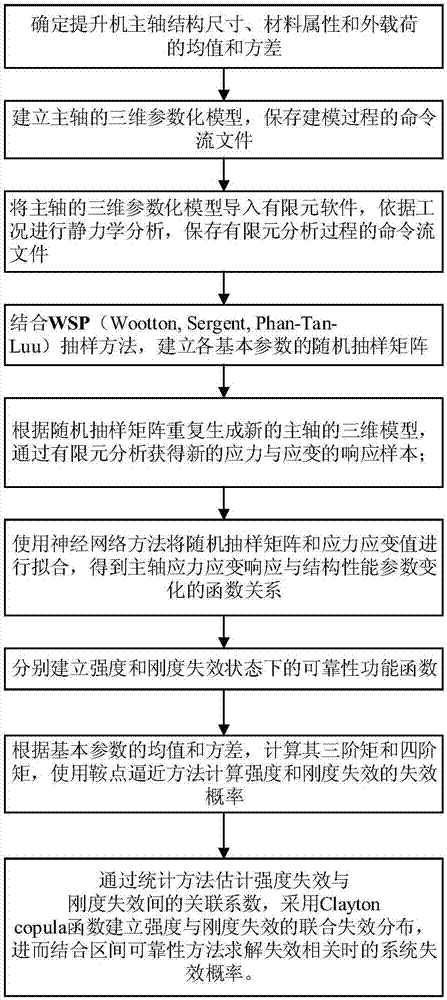

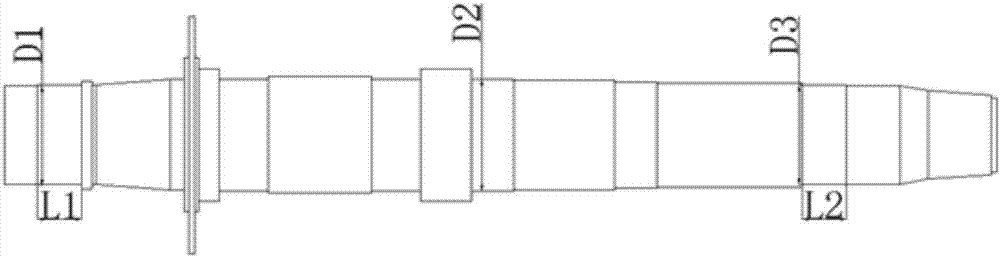

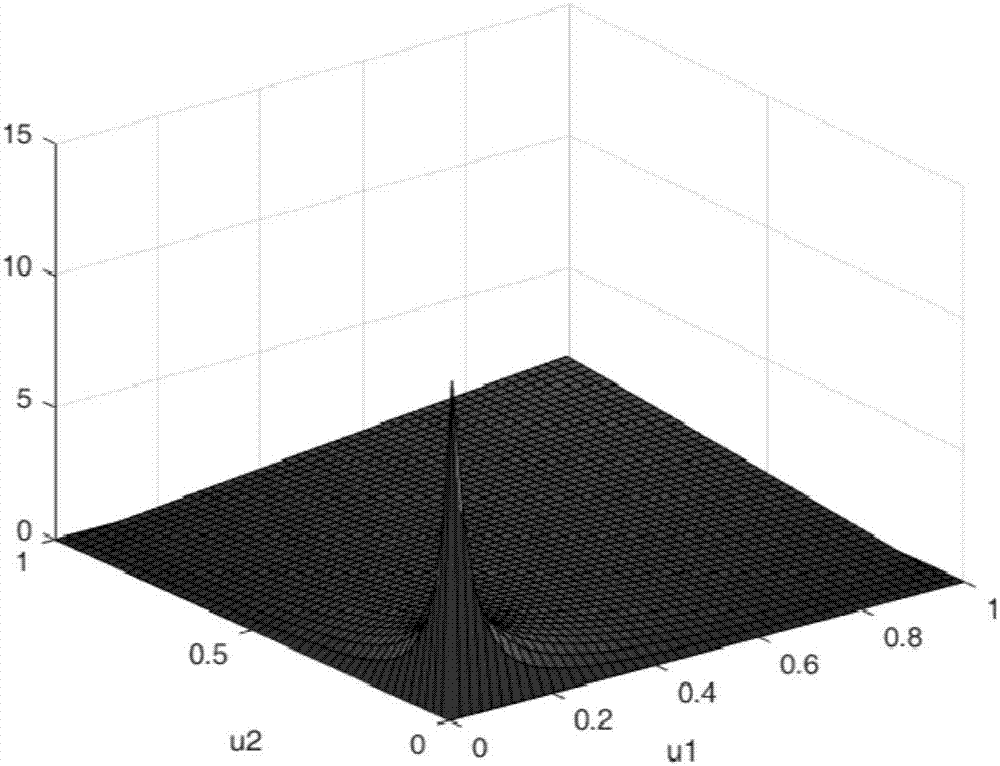

Method for assessing reliability of main shaft of kilometer deep shaft hoist by considering multiple failure modes

ActiveCN107291989AGuaranteed fitting accuracyReduce the number of experimental designsDesign optimisation/simulationFuzzy logic based systemsProbit modelFinite element method

The invention discloses a method for assessing the reliability of a main shaft of a kilometer deep shaft hoist by considering multiple failure modes. The method comprises the steps of firstly, building a parametric three-dimensional model of the main shaft according to the structure size of the main shaft; secondly, according to a probability attribute of a random variable of the main shaft, establishing a sampling matrix of the random variable, and solving strength and stiffness response of the main shaft under the sampling matrix by using a finite element method; thirdly, establishing an explicit function between the response and the random variable matrix by using a neutral network method, and according to strength and stiffness design criteria, establishing explicit functions in strength and stiffness failure modes; fourthly, calculating two failure probabilities by using a saddle point approximation method; and finally, building a joint failure probability model between the two failure modes through a Clayton copula function, and solving system reliability under joint failure by using an interval reliability method. According to the method, the probability correlation between strength failure and stiffness failure is considered, so that the system reliability of the main shaft of the hoist can be assessed more accurately and reasonably.

Owner:CHINA UNIV OF MINING & TECH

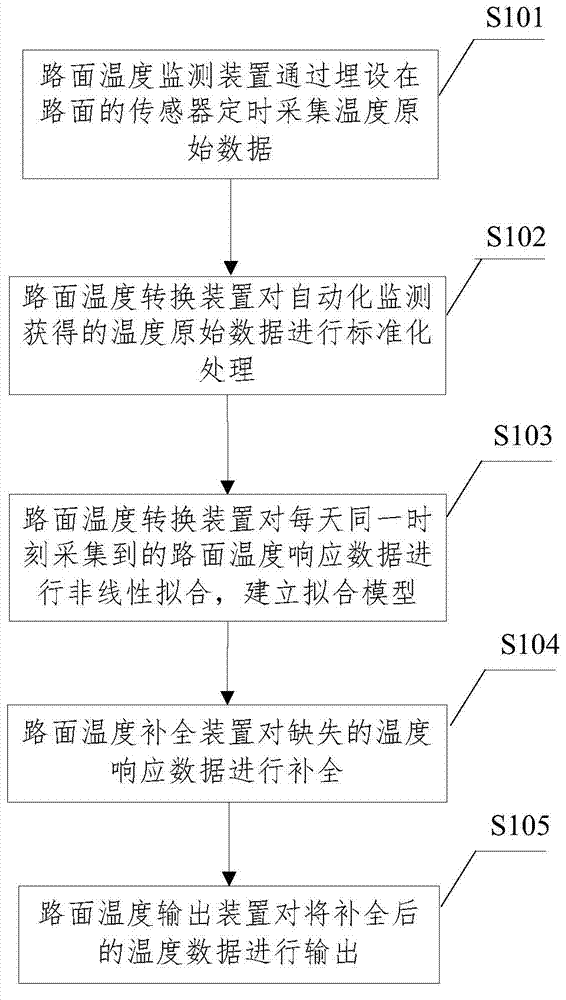

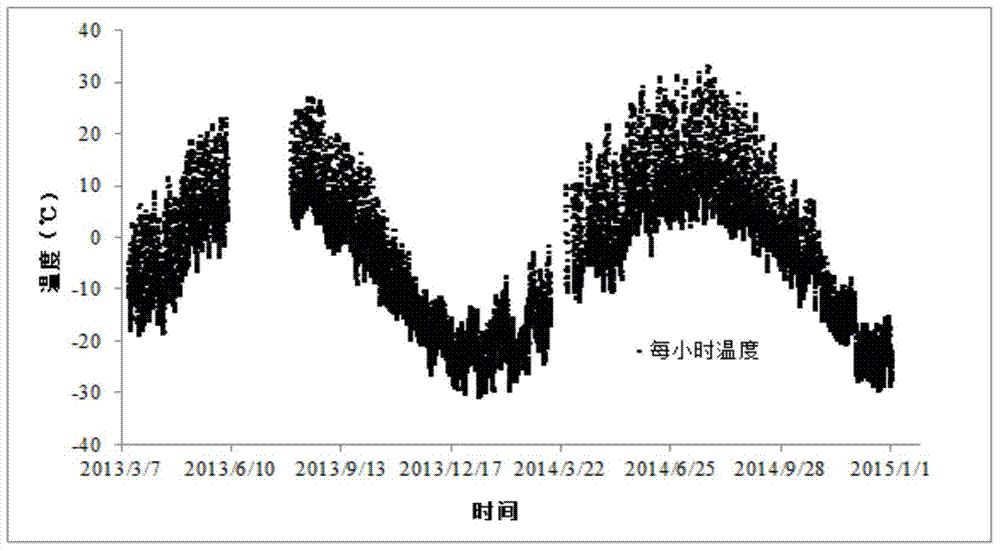

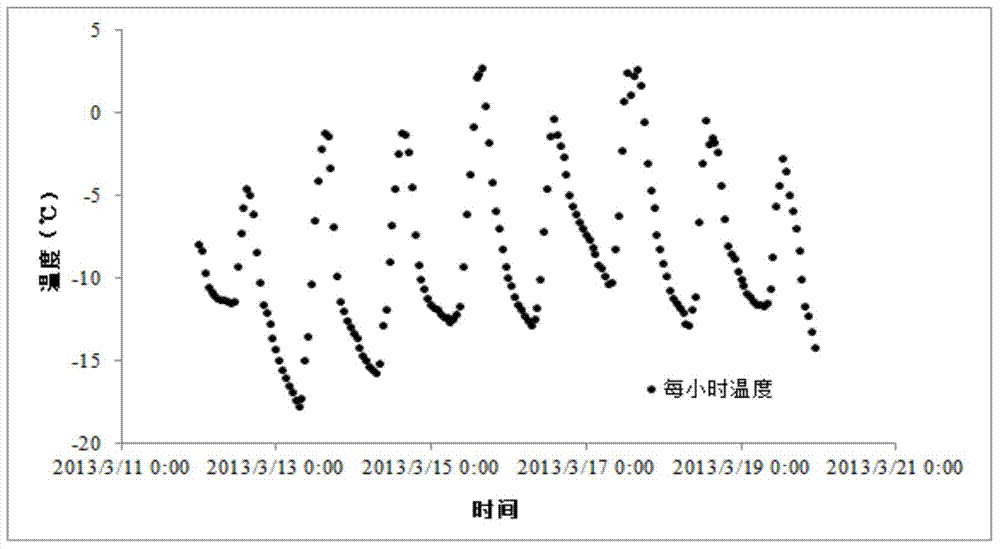

Completion method of pavement temperature response missing values

ActiveCN104776937AGuaranteed fitting accuracyThermometer applicationsTemperature responseAtmospheric temperature

The invention provides a completion method of pavement temperature response missing values and aims to solve the problems that traditional missing value completion methods are low in reliability, inconvenient to apply and the like. Under the conditions that pavement temperature monitoring is interrupted due to failures and temperature response has missing values, the missing values are completed. According to the method, the natural law that the atmosphere temperature fluctuates periodically and seasonally is used, an addition model adopting sine and cosine curves is adopted to simulate change features of pavement temperature response at the same moment every day, and corresponding mathematical models are established; on the basis of the randomness characteristic of pavement structure temperature response, a random number sequence related to the burying depth of a temperature sensor is put forward to correct the models, and the real situation of temperature response monitoring data can be better simulated. With the adoption of the method, the pavement temperature response missing values can be scientifically and effectively completed, and the continuity, stability and reliability of pavement temperature monitoring data can be well guaranteed.

Owner:CHINA ROAD & BRIDGE

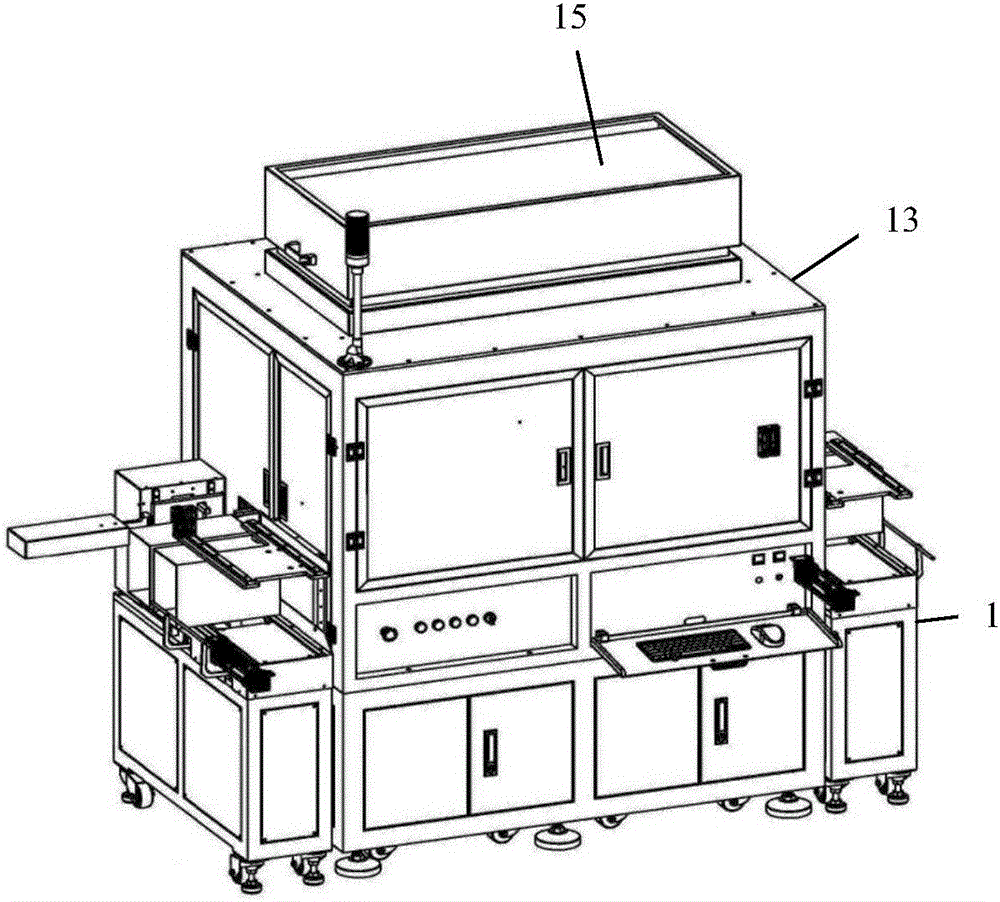

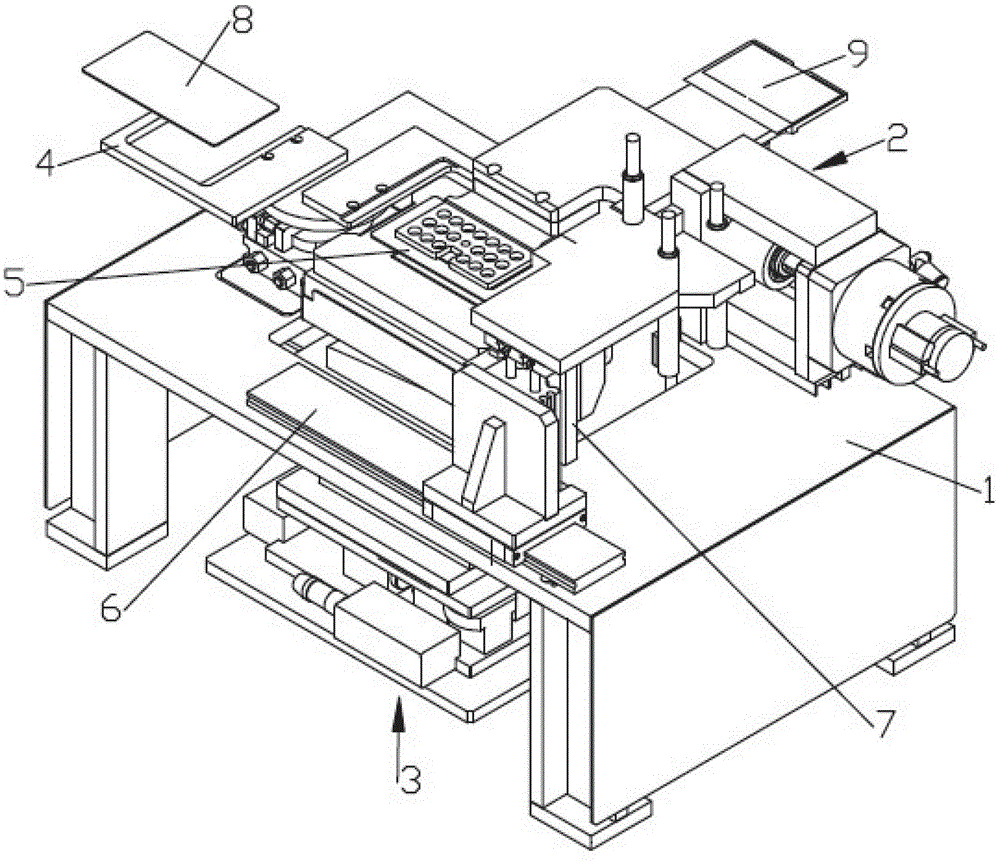

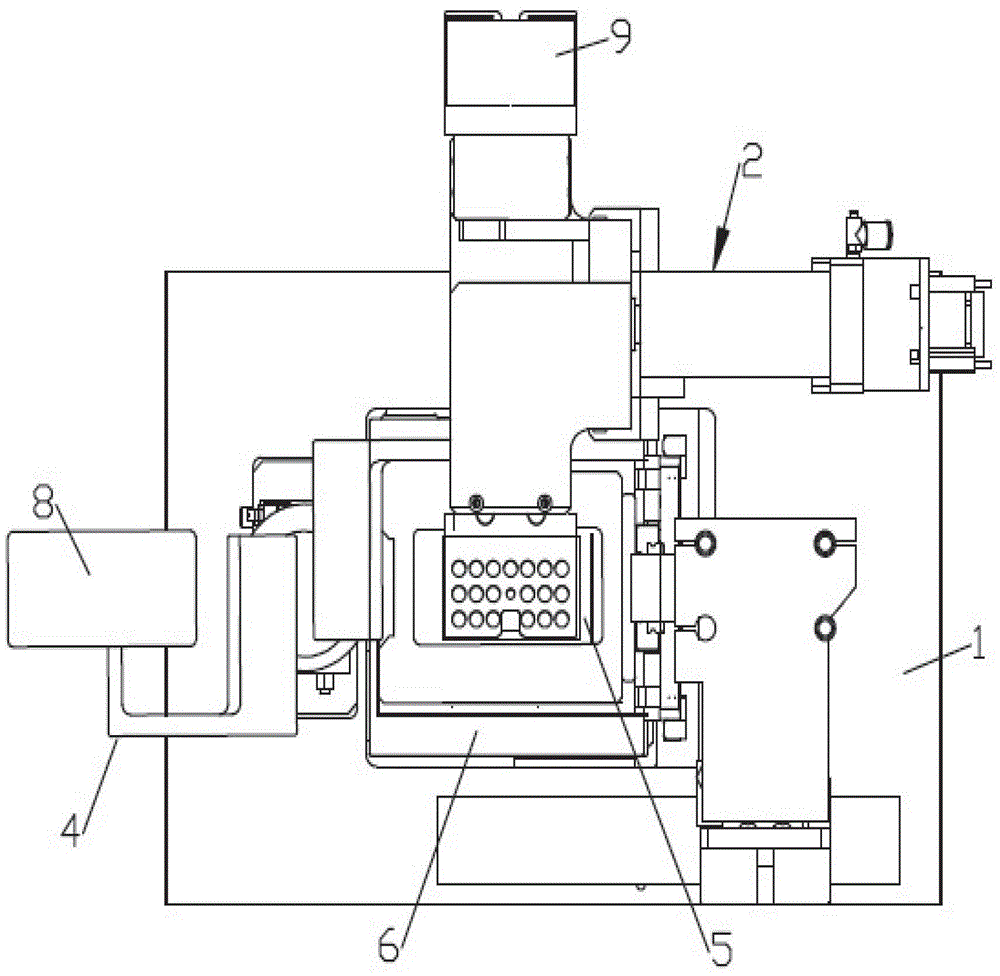

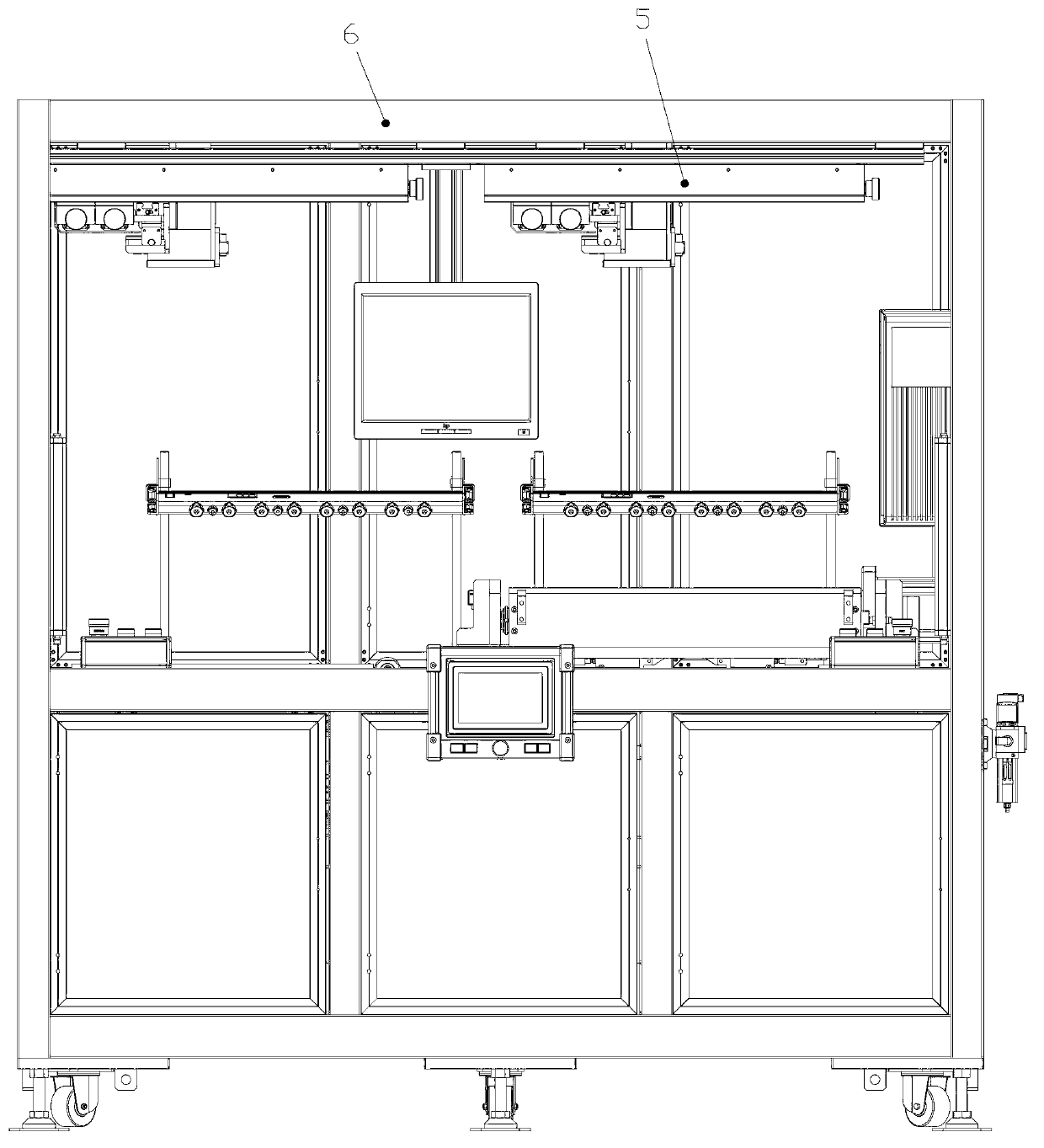

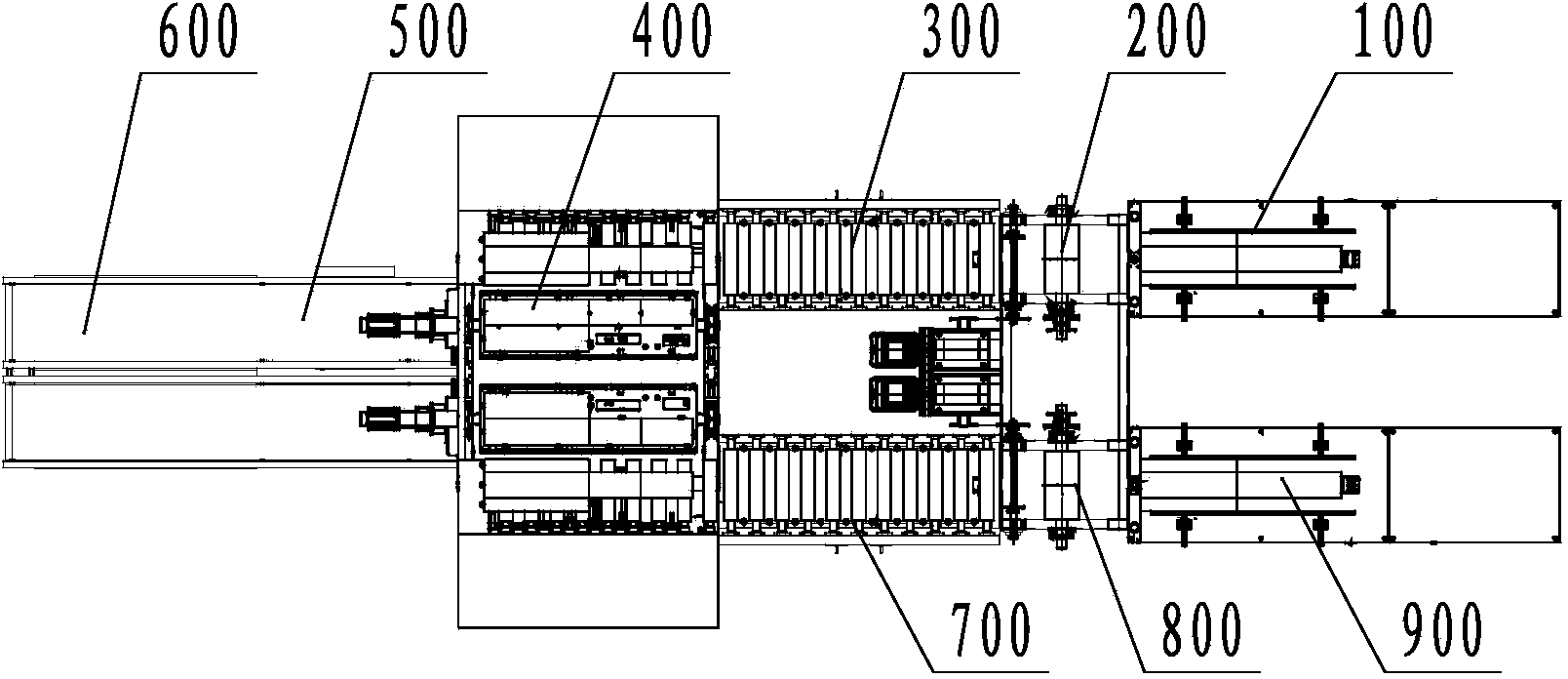

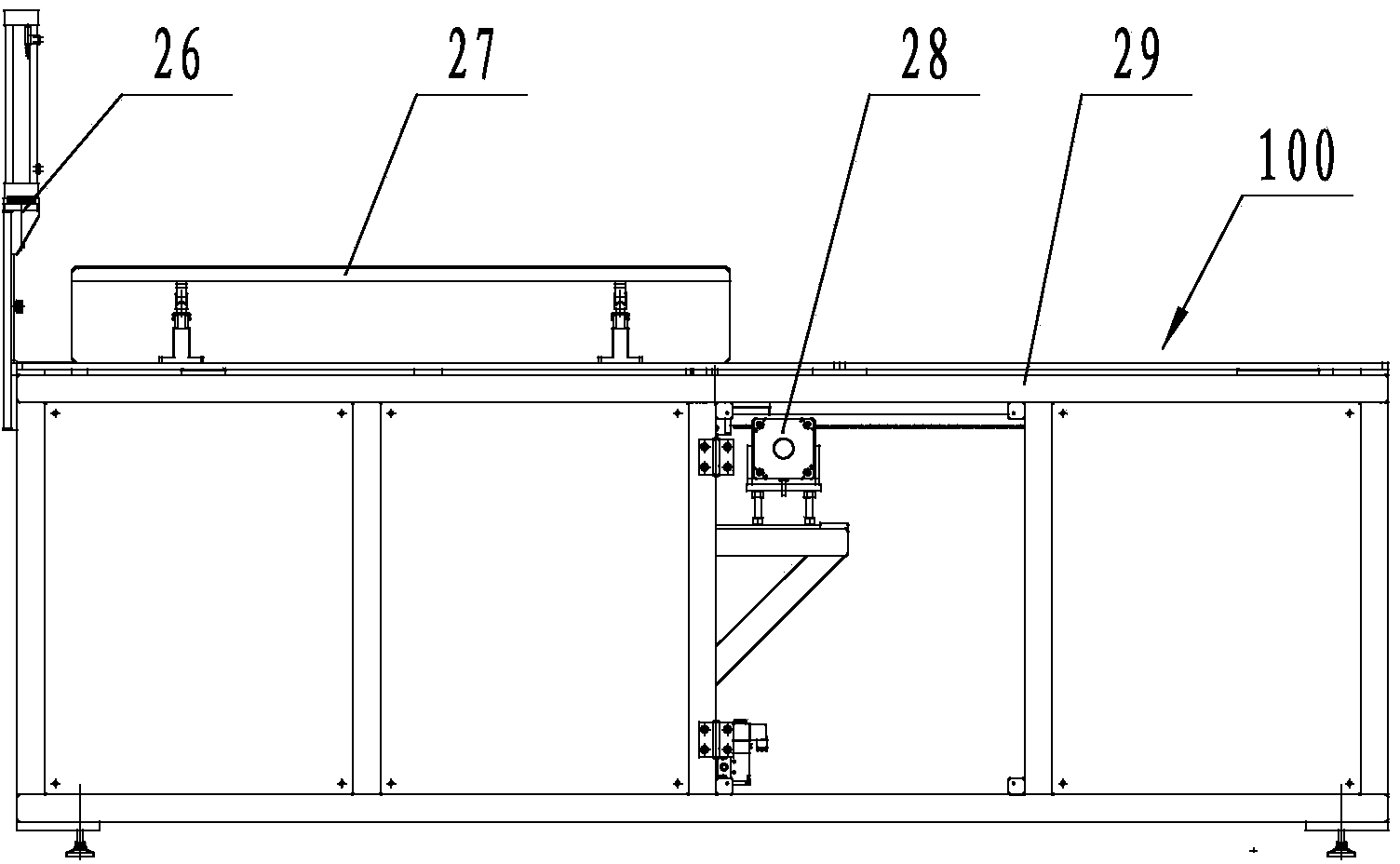

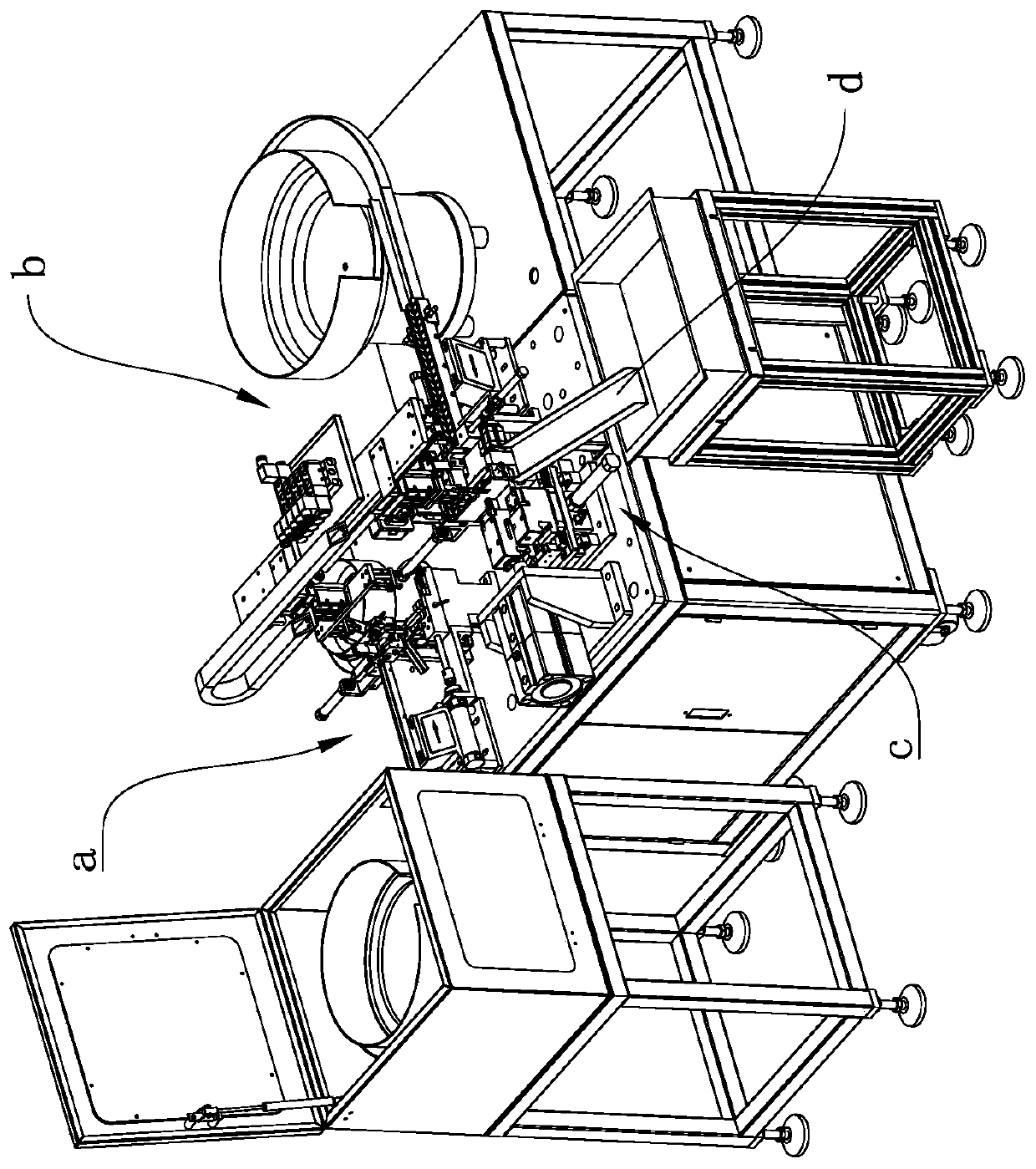

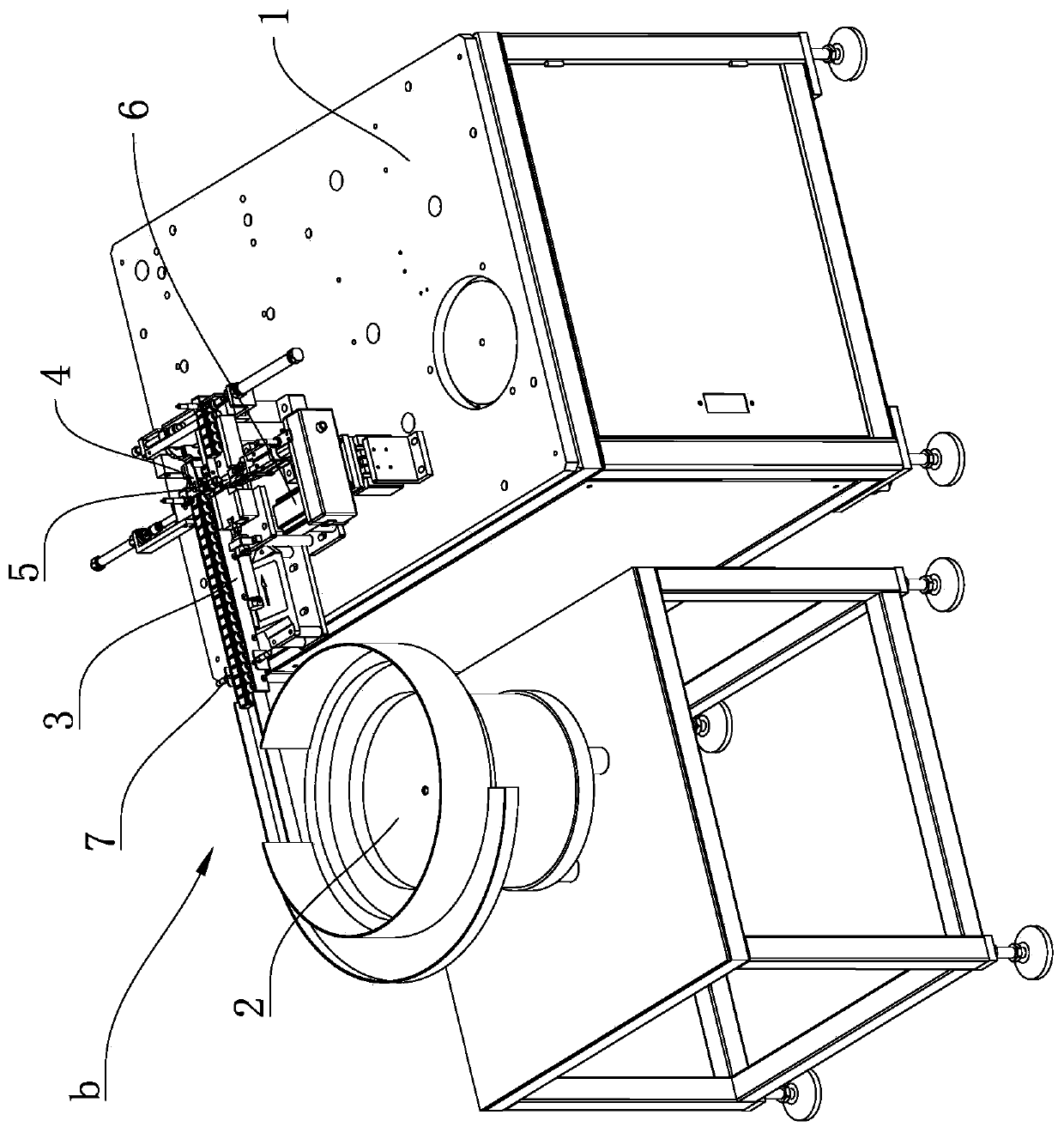

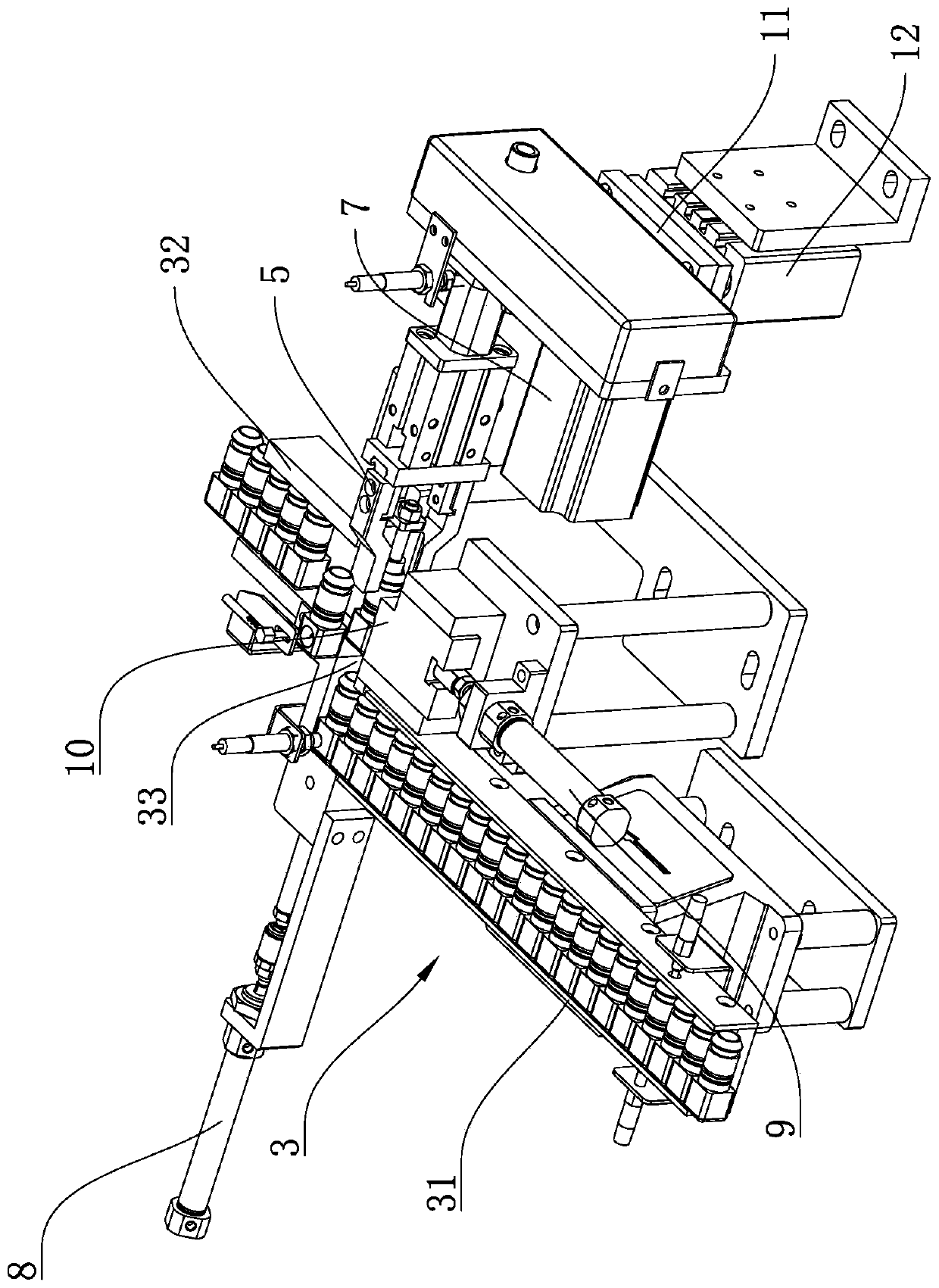

Adhesive dispensing and laminating machine for fingerprint recognition component

InactiveCN106824676AGuaranteed stabilityGuaranteed accuracyLiquid surface applicatorsCoatingsAdhesiveSilver colloid

The invention discloses an adhesive dispensing and laminating machine for a fingerprint recognition component. The adhesive dispensing and laminating machine comprises a rack, a material supplying and receiving mechanism, a transporting mechanism, an adhesive dispensing mechanism, a laminating mechanism and a locating mechanism; the material supplying and receiving mechanism comprises a first automatic clip material supplying machine, a first material receiving machine, a second automatic clip material supplying machine and a second material receiving machine; the transporting mechanism comprises a first transporting track and a second transporting track; the adhesive dispensing mechanism comprises a first silver colloid dispensing manipulator and a second silver colloid dispensing manipulator; the laminating mechanism comprises a base, a sliding rail, a four-axis laminating manipulator and a vacuum suction plate component; and the locating mechanism uses a CCD locating system. The adhesive dispensing and laminating machine for the fingerprint recognition component is mainly applied to adhesive dispensing and laminating processes of a fingerprint recognition cover plate and a metal ring to reach the requirements on laminating position and thickness accuracy, the operations of dispensing the adhesive and laminating are integrated, the automatic accurate adhesive dispensing and the high accuracy laminating are realized, the degree of automation and the controllability are strong, and the market prospect is wide.

Owner:KUNSHAN SAMON AUTOMATION TECH

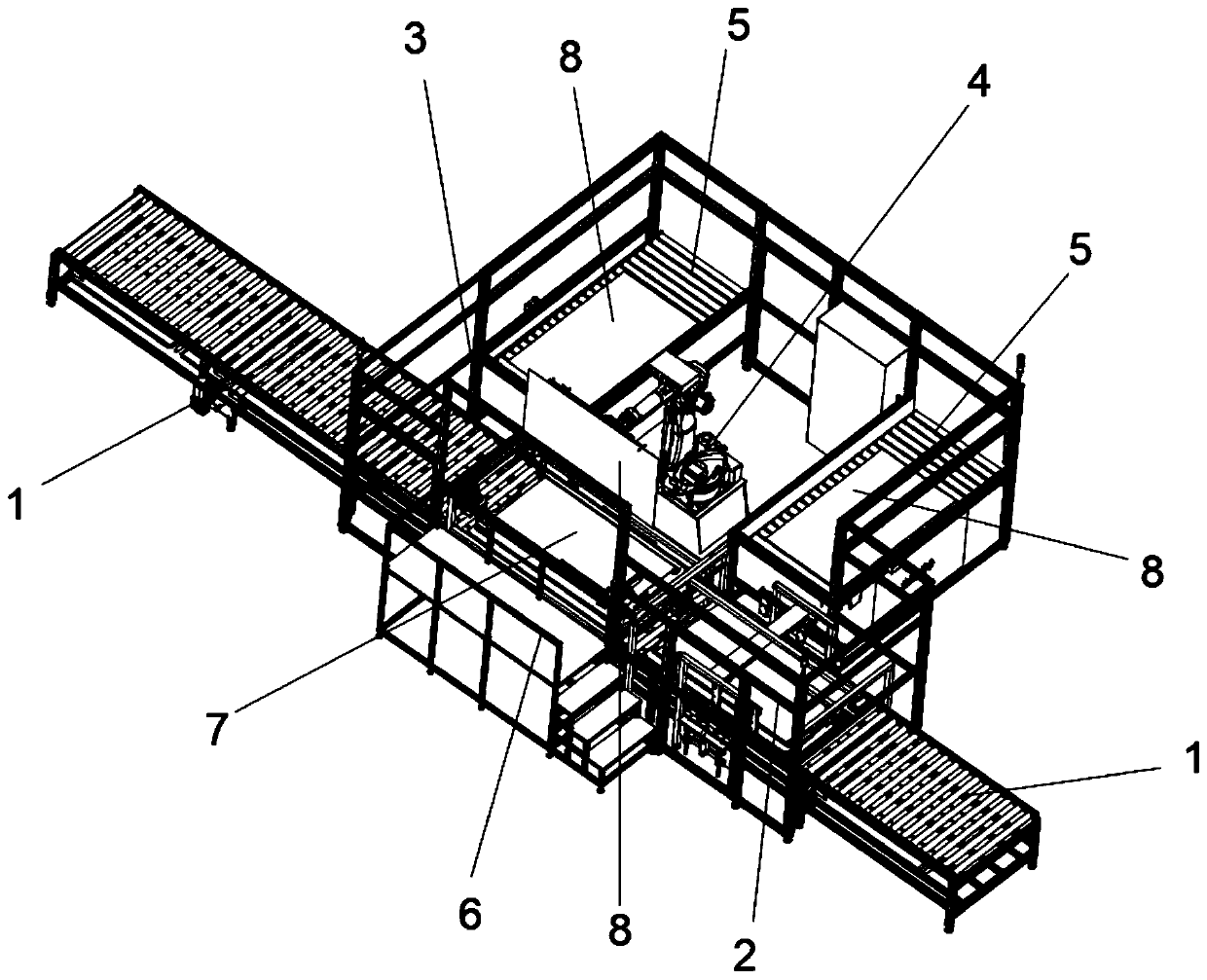

Screen laminating equipment and screen laminating method

ActiveCN110685983AAvoid destructionRealize the automation of bondingMaterial gluingNon-linear opticsComputer hardwareEngineering

The invention discloses screen laminating equipment and a screen laminating method, and used for laminating a display screen to a backlight module. The screen laminating equipment specifically comprises a laminating station and a manipulator fixture, the backlight module is positioned and then fixed by the laminating station, the manipulator fixture grabs and moves the display screen to the laminating station, a visual device located in the laminating station collects image of the backlight module and the display screen so as to calculate the position difference, the manipulator fixture movesthe display screen so that the position difference is within the range of the preset value, and the display screen is laminated on the backlight module. According to the screen laminating equipment, the display screen is grabbed and moved by the manipulator fixture, the problem that a display screen is prone to being damaged due to manual transporting of the display screen is solved, the manipulator fixture moves the display screen according to the position difference collected by the visual device, the display screen is laminated on the backlight module precisely and accordingly, automated laminating of the display screen and the backlight module is achieved, and the laminating accuracy of the display screen laminated on the backlight module is ensured.

Owner:SHENZHEN SKYWORTH PRECISION TECH

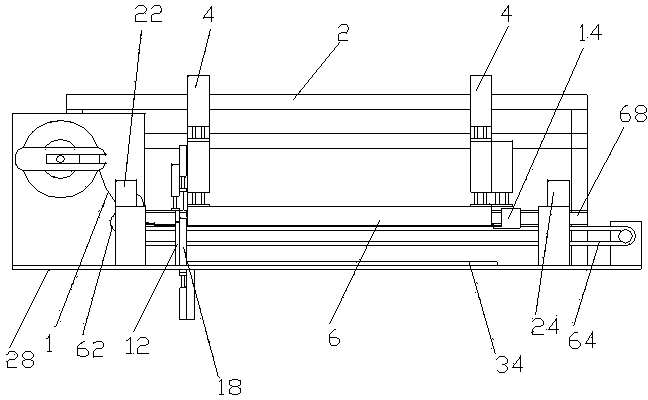

Device for attaching double-faced adhesive tape to cloth curtain

ActiveCN103625978AFitting position is accurateHigh precisionArticle deliveryVertical planeAdhesive belt

The invention relates to a device for attaching double-faced adhesive tape to a cloth curtain. The device comprises a rack and a press fit mechanism arranged on the rack. The press fit mechanism comprises a press fit cylinder which is perpendicularly arranged on the rack, and a cloth curtain pressing plate which is arranged at the bottom end of the press fit cylinder. The device is characterized in that a positioning mechanism is arranged on one side of the cloth curtain pressing plate, wherein the positioning mechanism comprises a supporting shaft which is longitudinally arranged on the rack, and a movable clamping piece which is arranged between the supporting shaft and the cloth curtain pressing plate; a feeding mechanism is arranged on the side, facing the press fit mechanism, of the positioning mechanism, wherein the feeding mechanism comprises a first clamping piece which can move transversely in the extension direction of the cloth curtain pressing plate. The device further comprises a cutting mechanism, wherein the cutting mechanism comprises a cutting piece which is arranged between the movable clamping piece and the cloth curtain pressing plate, and two second clamping pieces which are arranged on the two transverse sides of the cloth curtain pressing plate respectively, and the cutting piece comprises a cutter which can move in a vertical plane to cut the adhesive tape; the movable clamping piece, the first clamping piece and the second clamping pieces can clamp and release the adhesive tape respectively. The device is good in adhesive tape attaching quality and high in adhesive tape attaching efficiency.

Owner:KUSN HUANGTIAN AUTO PARTS INDAL

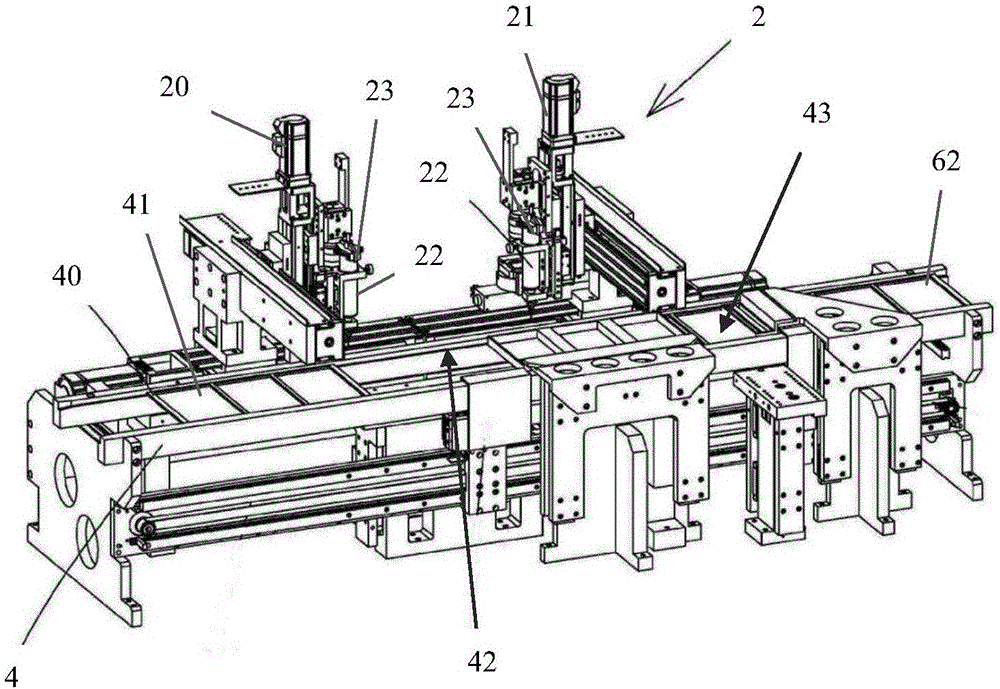

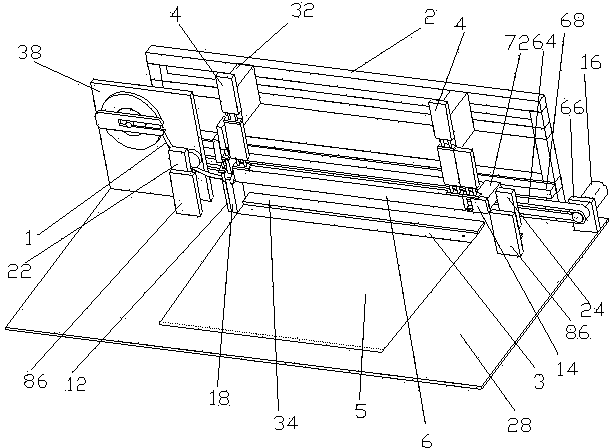

Attaching transport mechanism of touch screen ultraviolet (UV) laminating machine

ActiveCN102975467AHigh precisionImprove product qualityLaminationLamination apparatusAutomatic controlUltraviolet

An attaching transport mechanism of a touch screen ultraviolet (UV) laminating machine comprises a rack, a cantilever type sucker turnover mechanism, a four-axis fine turning attaching mechanism and a double-position feeding mechanism. The cantilever type sucker turnover mechanism is arranged above the rack, the four-axis fine turning attaching mechanism is arranged below the rack, the double-position feeding mechanism is arranged on the side of the four-axis fine turning attaching mechanism, the cantilever type sucker turnover mechanism is arranged on the rear side of the four-axis fine turning attaching mechanism. The four-axis fine turning attaching mechanism is composed of a workpiece vacuum sucker which is arranged on the top, a servo motor, a linear guide rail and an attaching cylinder. The attaching cylinder and the cantilever type sucker turnover mechanism are connected, and a controller presses downwards along the linear guide rail to ensure attaching parallel accuracy. The servo motor is connected with the workpiece sucker by the rotary shaft and controls turnover to ensure accuracy of an angle of a turnover mechanism. A product after attached does not spill over glue, attaching accuracy and thickness can be ensured, high-accuracy and automatic control operation procedures are achieved, and transport attaching motion is effectively completed.

Owner:SUZHOU LING AUTOMATION EQUIP

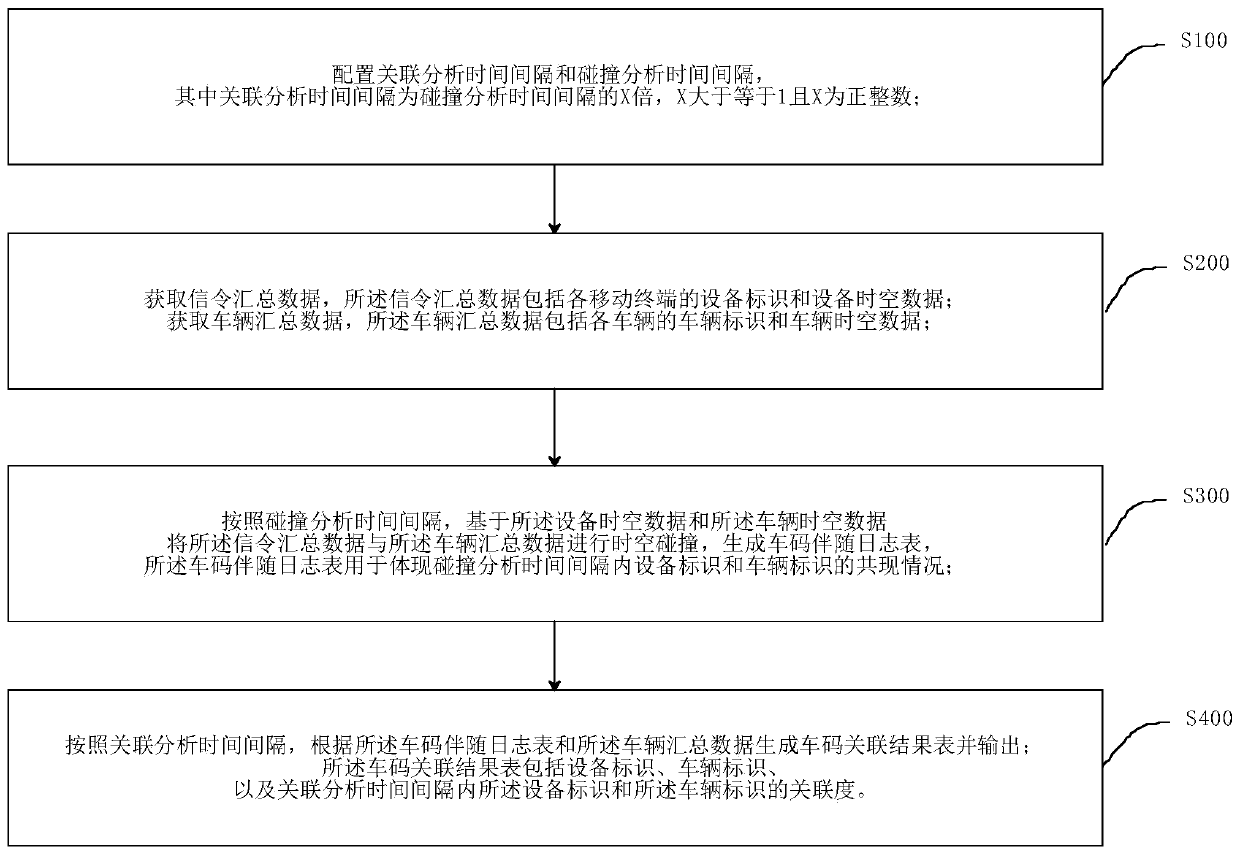

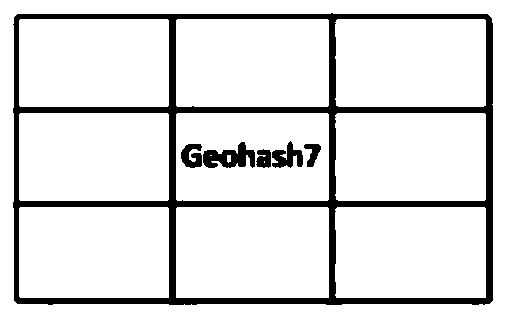

Geohash matching-based vehicle code fitting method and system

ActiveCN110888884AEasy to trackSmall amount of calculationRelational databasesSpecial data processing applicationsMobile Telephone NumberCollision analysis

The invention discloses a geohash matching-based vehicle code fitting method and system. The geohash matching-based vehicle code fitting method comprises the following steps of configuring an association analysis time interval and a collision analysis time interval; acquiring signaling summary data, wherein the signaling summary data comprises equipment identifiers and equipment spatio-temporal data of the mobile terminals; acquiring checkpoint summary data, wherein the checkpoint summary data comprises vehicle identifiers and vehicle spatio-temporal data of vehicles; according to a collisionanalysis time interval, performing space-time collision on the signaling summary data and the gate summary data based on the equipment space-time data and the vehicle space-time data to generate a vehicle code accompanying log table; and according to the association analysis time interval, generating a vehicle code association result table according to the vehicle code accompanying log table and the bayonet summary data, and outputting the vehicle code association result table. According to the method, the license plate number and the mobile phone number can be fitted, the fitting accuracy ishigh, and the requirement for associated positioning of the vehicle and the mobile phone number at present is met.

Owner:HANGZHOU SANHUI DIGITAL INFORMATION TECH

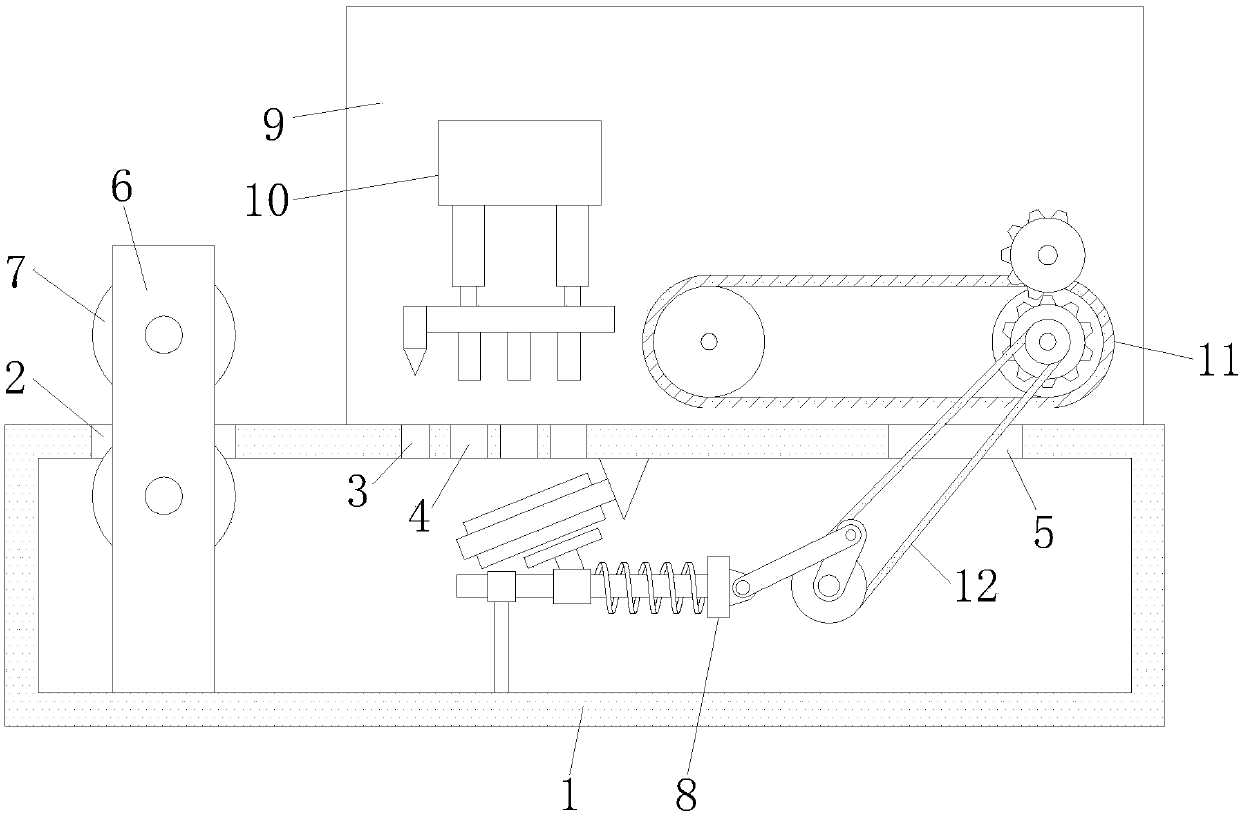

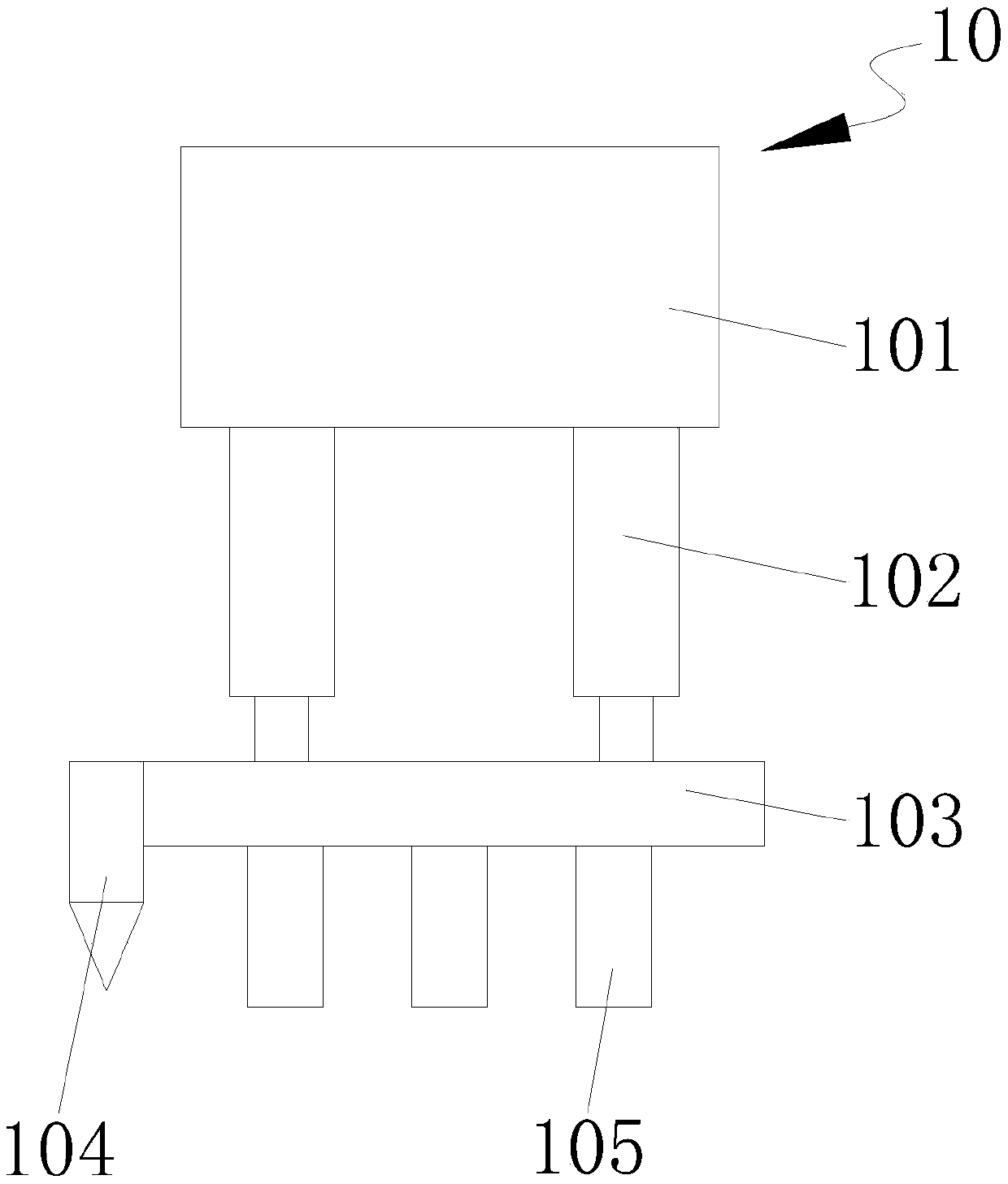

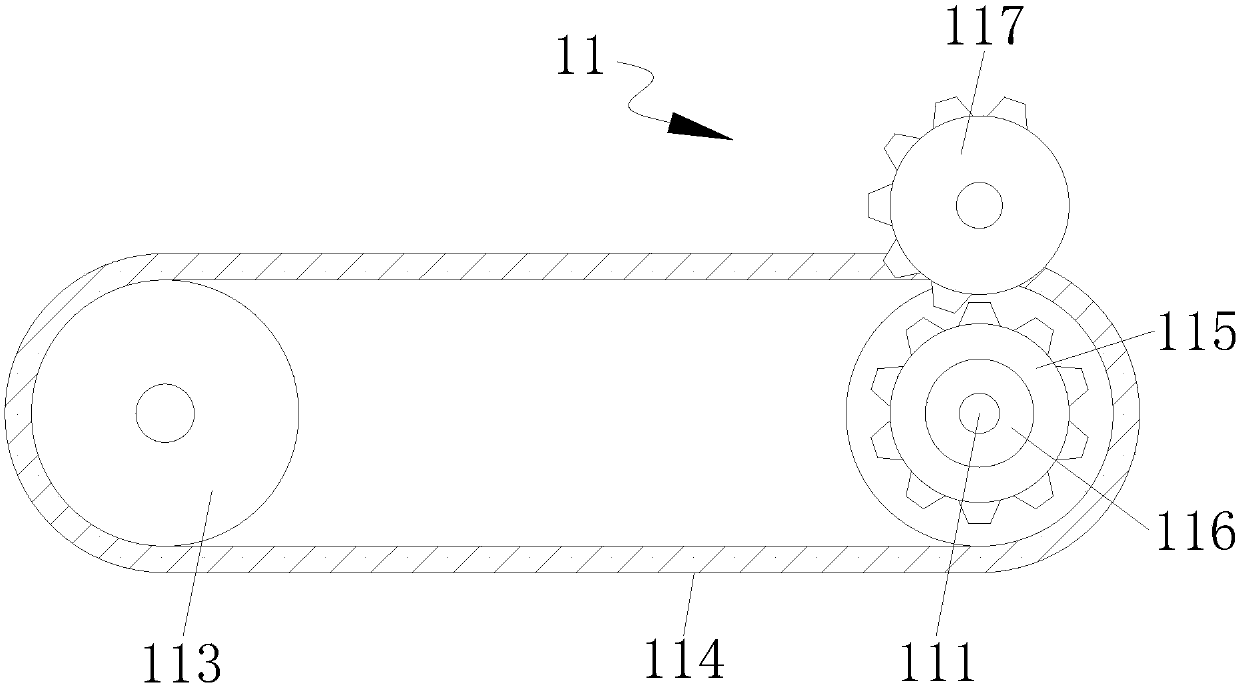

Cable bridge connecting piece punching device

ActiveCN109570334AImprove efficiencyLabor savingMetal-working feeding devicesStripping-off devicesPunchingEngineering

The invention relates to the technical field of cutting and punching machining of cable bridge connecting pieces, and discloses a cable bridge connecting piece punching device. The cable bridge connecting piece punching device comprises a device bottom box, wherein a first opening, a cutting groove, three material returning grooves and a second opening are formed in the top of the device bottom box from left to right in sequence, a fixing frame is fixedly arranged on the inner bottom wall of the device bottom box, the upper end of the fixing frame penetrates through the first opening and is fixedly provided with a transmission roller fixedly installed on the fixing frame, a discharging mechanism is arranged on the inner wall of the device bottom box, the top of the bottom box of the deviceis fixedly provided with a fixing plate, and a punching and cutting mechanism and a conveying mechanism are arranged on the fixing plate. The device solves the problems that an existing punching device is poor in material returning effect, waste materials can be clamped on a die at times, next punching machining is affected, the quality of the processing is not high, the cutting and punching of aconnecting piece are separately processed, the investment cost is increased, and the working efficiency is low.

Owner:皖缆集团股份有限公司

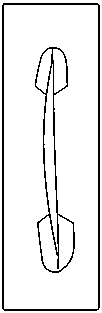

Blisk linear friction welding repairing method

ActiveCN108372386AQuality improvementGuaranteed fitting accuracyNon-electric welding apparatusFriction weldingEngineering

The invention relates to a blisk linear friction welding repairing method. According to the blisk linear friction welding repairing method, clamping blocks attached to blade profiles are adopted to beclamped on the circumferences of residual blade roots, cavities are reserved in the positions, corresponding to the stopping positions where linear friction welding is completed, of the clamping blocks; high-temperature plastic metal is guided to be gathered at the cavities to enable all the welding defects possibly occurring to exist in the outer side of a blade profile area, and the interior quality of repaired blades is ensured; and by combining and adopting a high-frequency and low-amplitude welding method, it is ensured that the interior quality of the repaired blades is reliable, the defects caused by complex change of plastic metal flowing are reduced, and the stability of a welding technology is improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

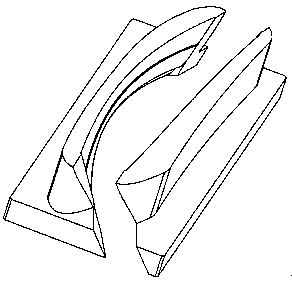

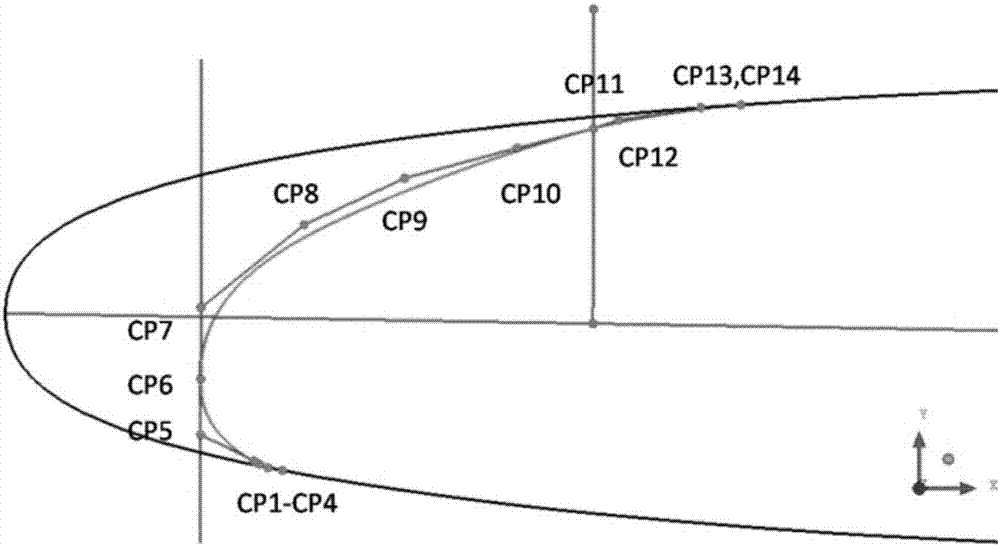

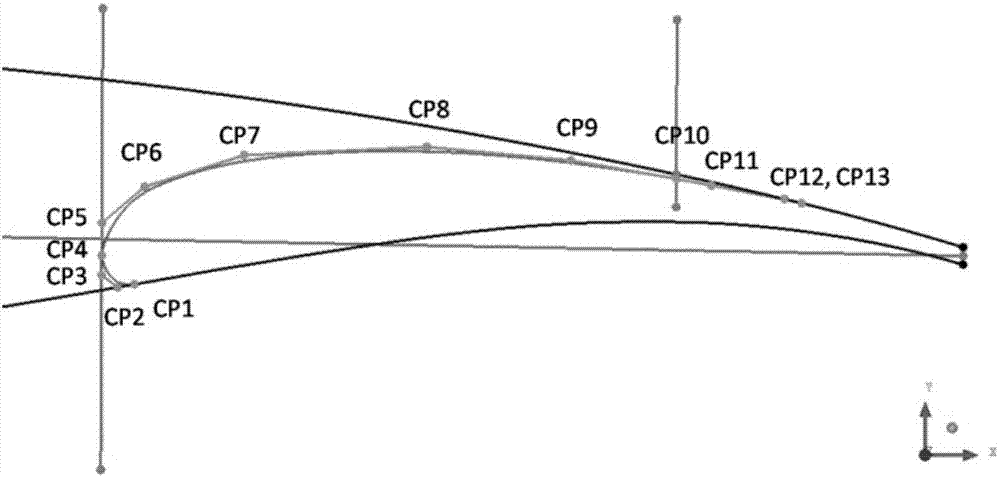

Two-dimensional high lift device parametrization design method based on NURBS curve and meeting engineering constraints

InactiveCN107220415AGuaranteed fitting accuracyThe geometric consistency constraints are satisfiedGeometric CADSustainable transportationGeometric consistencyEngineering

The invention provides a two-dimensional high lift device parametrization design method based on an NURBS curve and meeting engineering constraints. Firstly, the positions of slat and main wing interfaces and flap and main wing interfaces are determined on a two-dimensional airfoil profile, and control nodes are arranged, deflection angles of slats and flaps and rotary shaft positions are determined according to aerodynamic design requirements; secondly, the control nodes are respectively fitted to obtain geometric profiles of the slat and main wing interfaces and the flap and main wing interfaces; thirdly, intersection points of the interfaces and the two-dimensional airfoil profile are found again and are utilized to split the two-dimensional airfoil profile, the geometric profiles of the interfaces are spliced with the split two-dimensional airfoil profile to form slat profiles, flap profiles and main wing profiles; finally, according to the deflection angles of the slats and flaps and rotary shaft positions, fixed-shaft rotation is conducted on the slats and flaps to obtain a high lift device profile. The method adopts a non-uniform rational B-spline method to parametrize a two-dimensional high lift device, a complicated geometric profile is fit at higher precision, and the problem that the engineering constraints and geometrical consistency constraints are difficult to meet is solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

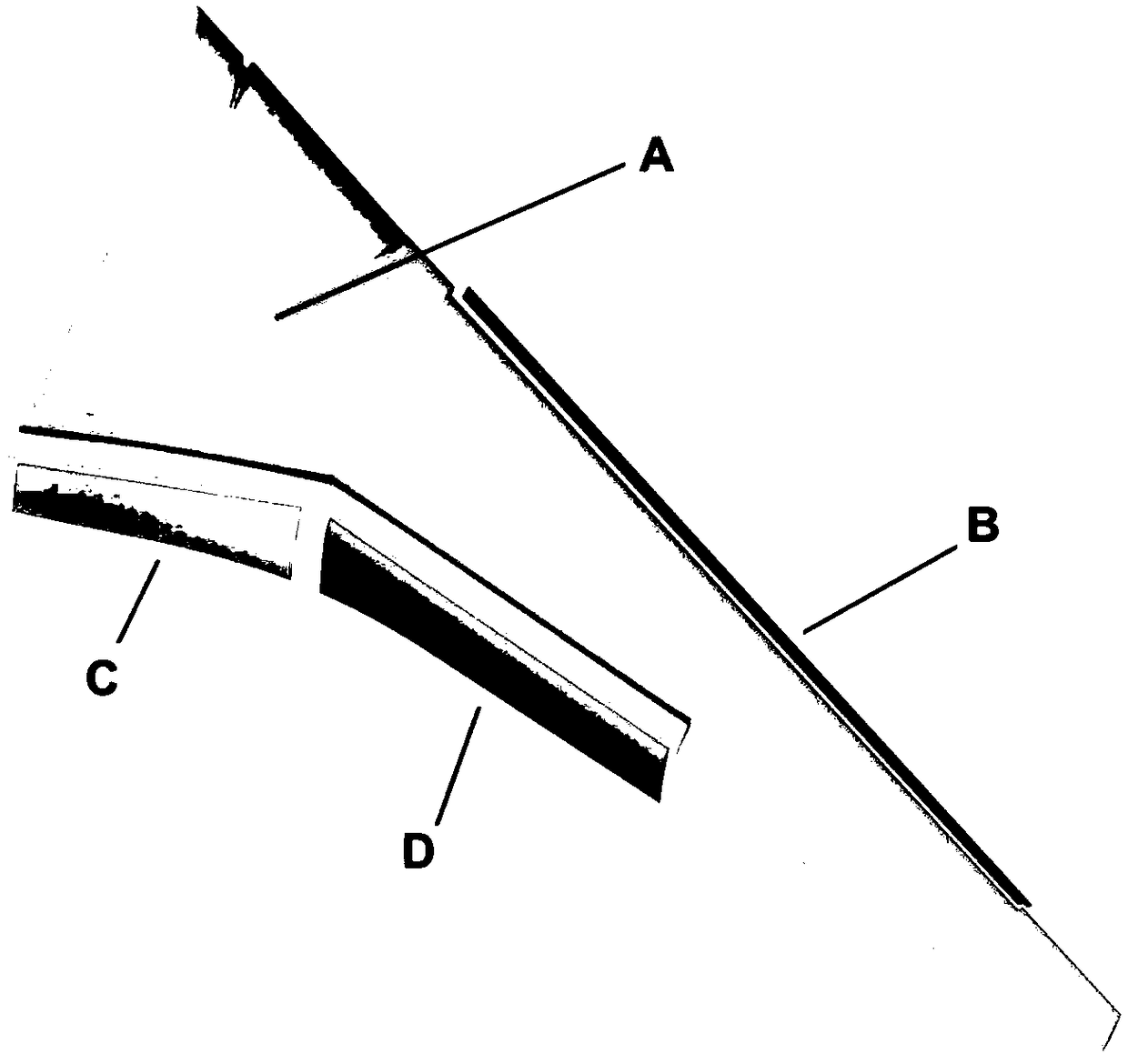

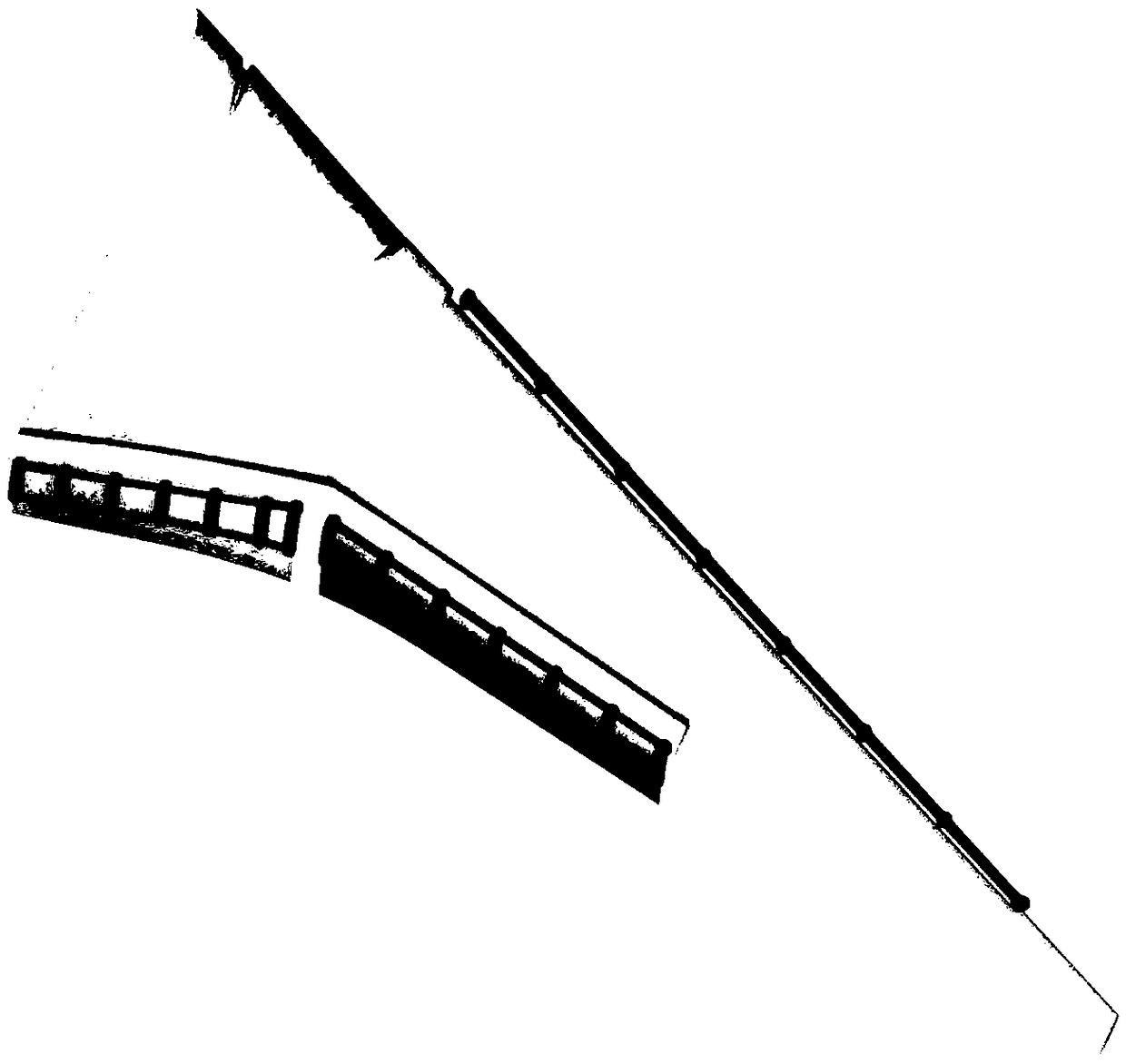

A three-dimensional lifting device parameterization method meeting engineering constraints based on an FFD method

InactiveCN109408987AGuaranteed fitting accuracySolve constraint problemsGeometric CADSpecial data processing applicationsGeometric consistencyCoordinate vector

The invention provides a three-dimensional augmentation device parameterization method meeting engineering constraints based on an FFD method, and the method comprises the steps: firstly, measuring the position parameters of a three-dimensional augmentation device, arranging a control frame on a slat and a flap of an initial configuration, carrying out parameterization disturbance on the object surface in the control frame, and changing the geometric shapes of the slat and the flap in the control frame; Reversing a control frame arranged on the initial configuration slat and the flap to the main wing according to the position parameters to obtain local coordinates of corresponding object plane grid points on the main wing in the corresponding control frame; and reversing the deformed control frame on the slat and the flap to the main wing according to the position parameters to obtain a global coordinate vector after the corresponding object plane grid point on the main wing is deformed. According to the method, the FFD method is used for guaranteeing the fitting precision of the geometric shape of the lifting device, the intersection interface part of the main wing in the method is processed, the geometric consistency constraint is met, finally, the generated three-section wing shape is subjected to fixed-axis rotation and translation operation, and the engineering constraintproblem is solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

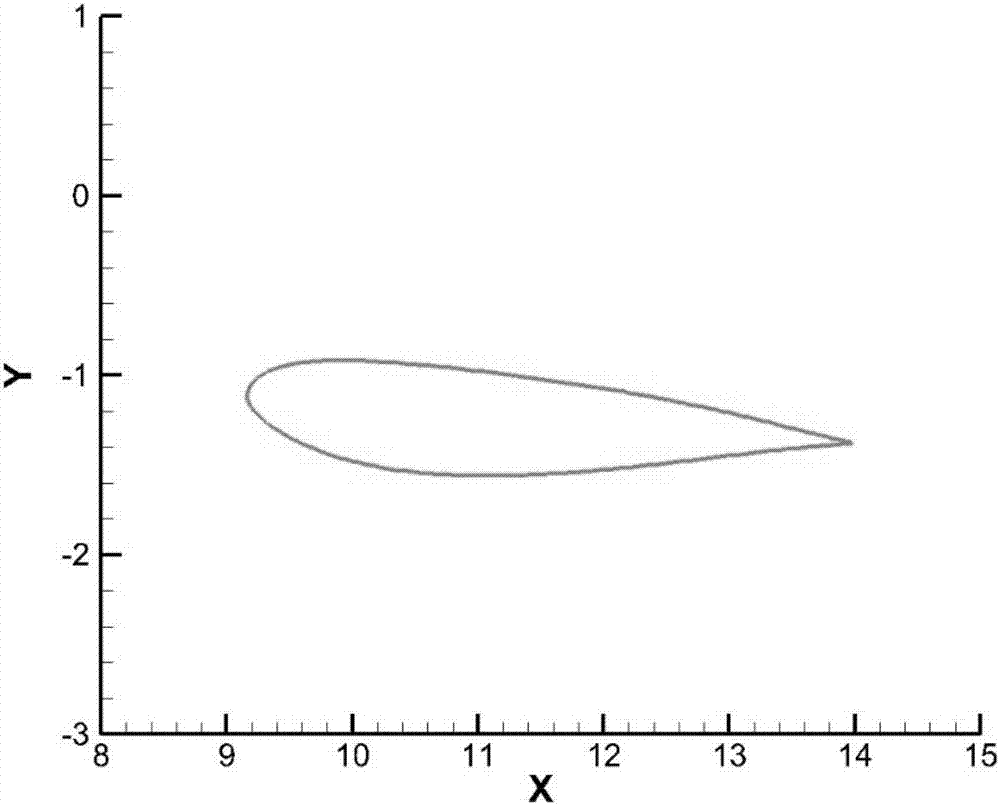

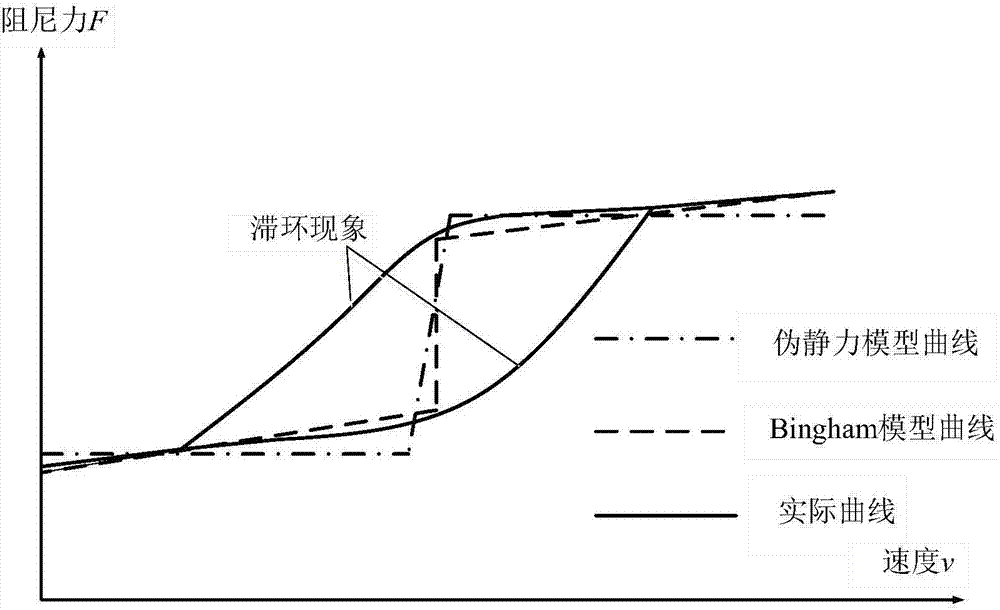

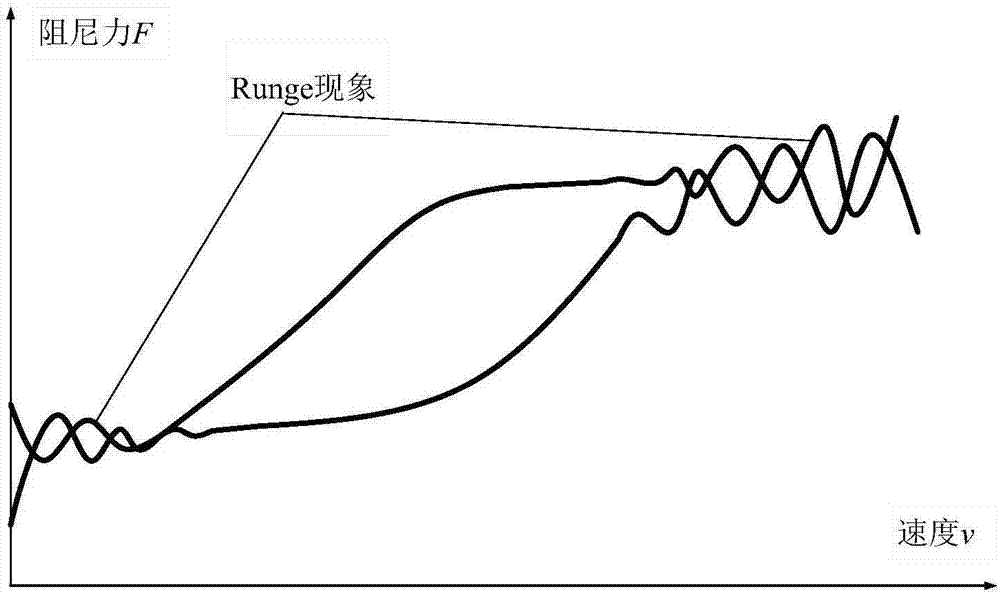

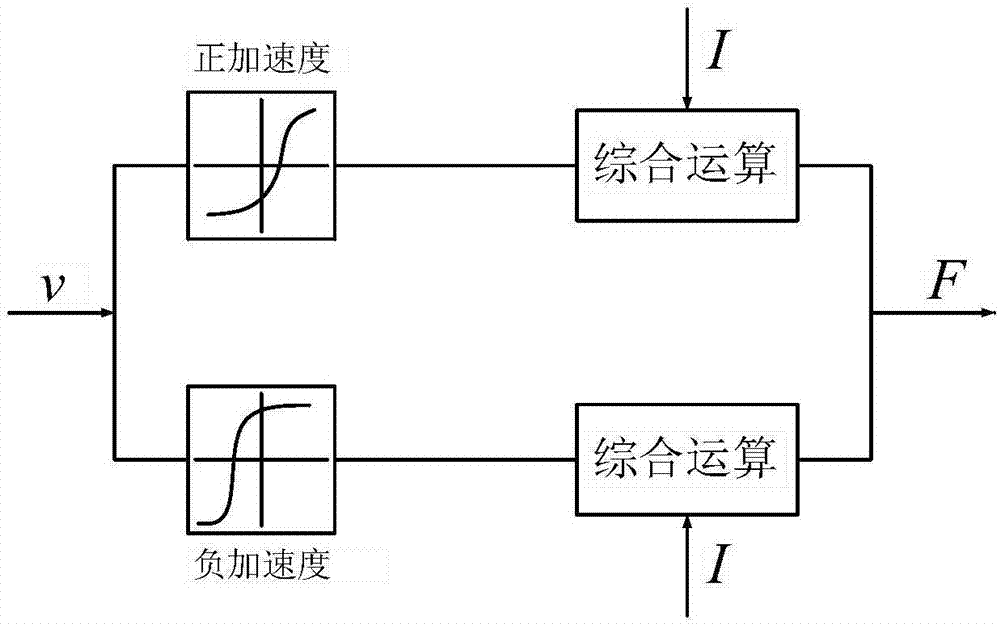

Non-parametric dynamics computation method for damping force of magnetorheological fluid damper

ActiveCN106870620AGuaranteed fitting accuracyFit closelyGeometric CADSpringsHysteresisMechanical models

The invention discloses a non-parametric dynamics computation method for damping force of a magnetorheological fluid damper. According to the damping force-velocity curve obtained through experiments or engineering, the polynomial model degree is adjusted for the complexity of the hysteresis character of the damping force-velocity curve, an actual curve is divided into two parts including positive acceleration (an ascending section) and negative acceleration (a descending section), the two parts of curves are subjected to fitting, and the fitting accuracy of a model on the damping force-velocity curve is guaranteed; according to two end areas where the Runge phenomenon happens to the higher-degree polynomial, the Bingham mechanical model is adopted for fitting, and the model degree is lowered on the basis that precision is guaranteed; in combination of usage of the polynomial model and the Bingham mechanical model, the traditional situation that only the polynomial model and the Bingham mechanical model are used is improved, the model fitting precision is guaranteed, meanwhile, generation of the higher-degree polynomial Runge phenomenon is avoided, and the purpose of better fitting of the damping force-velocity characteristic curve is achieved.

Owner:YANSHAN UNIV

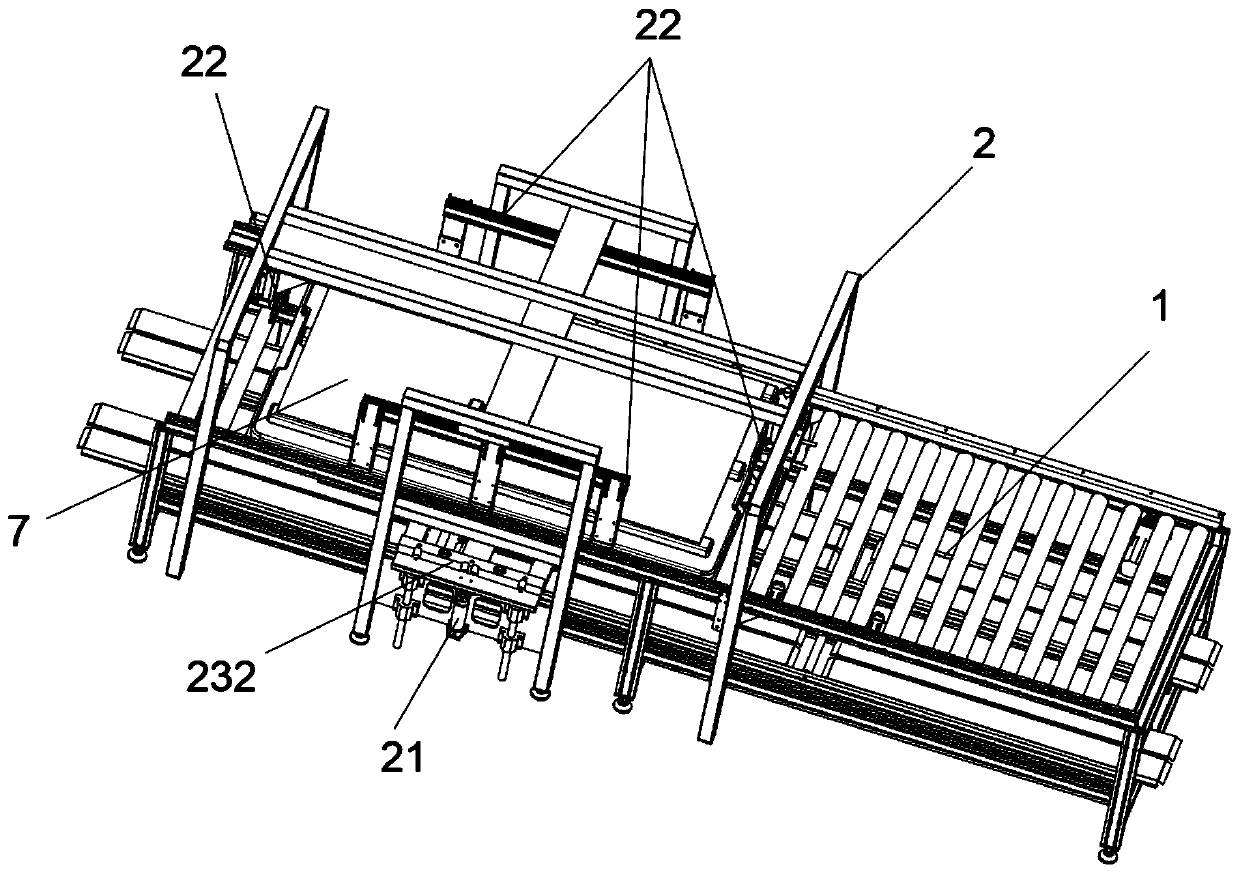

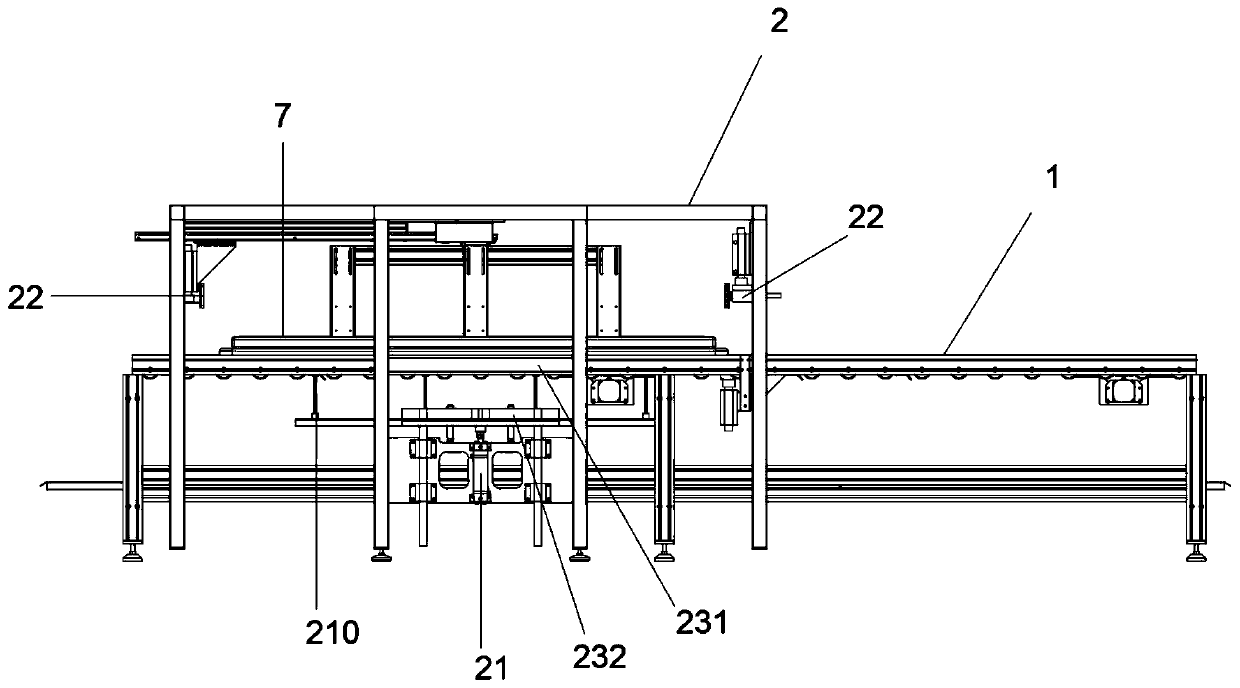

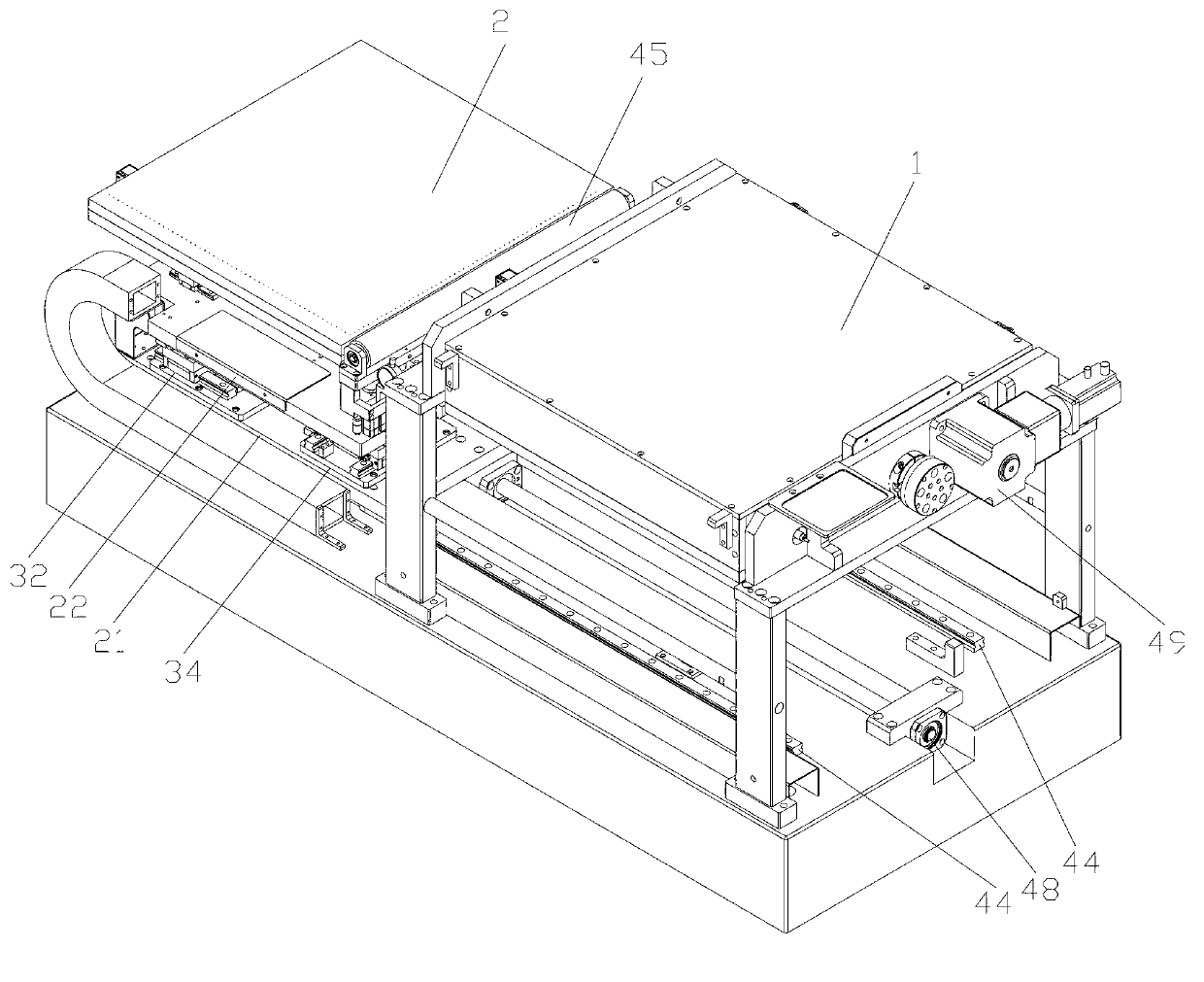

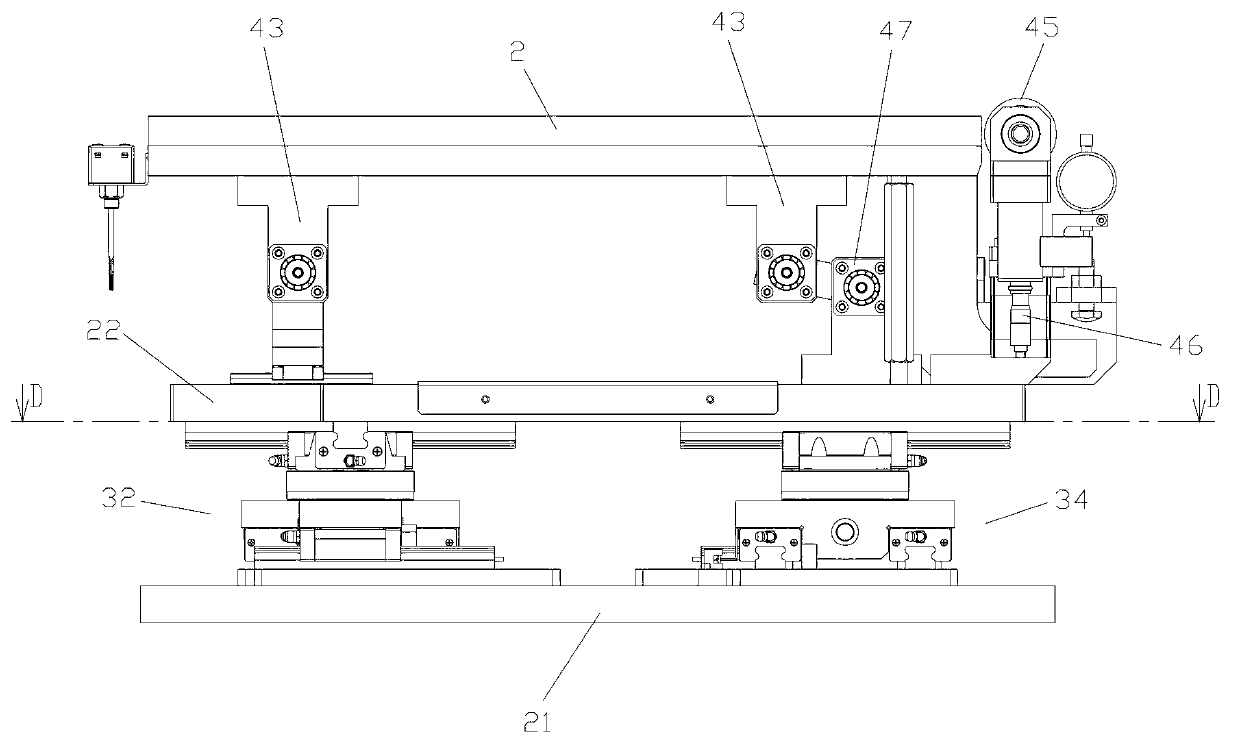

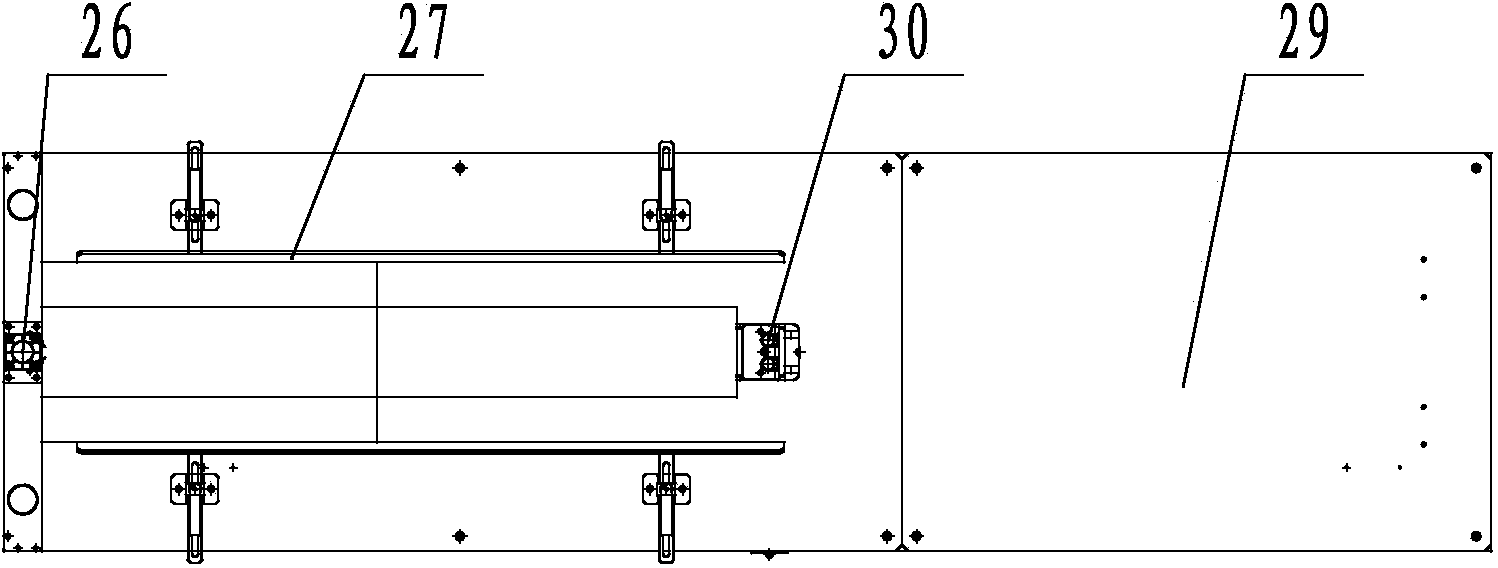

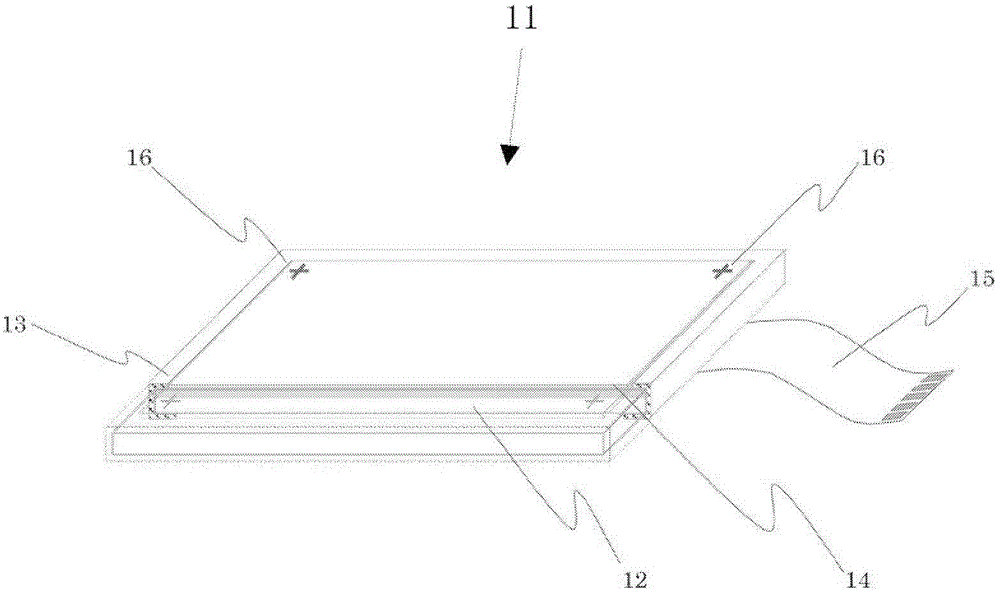

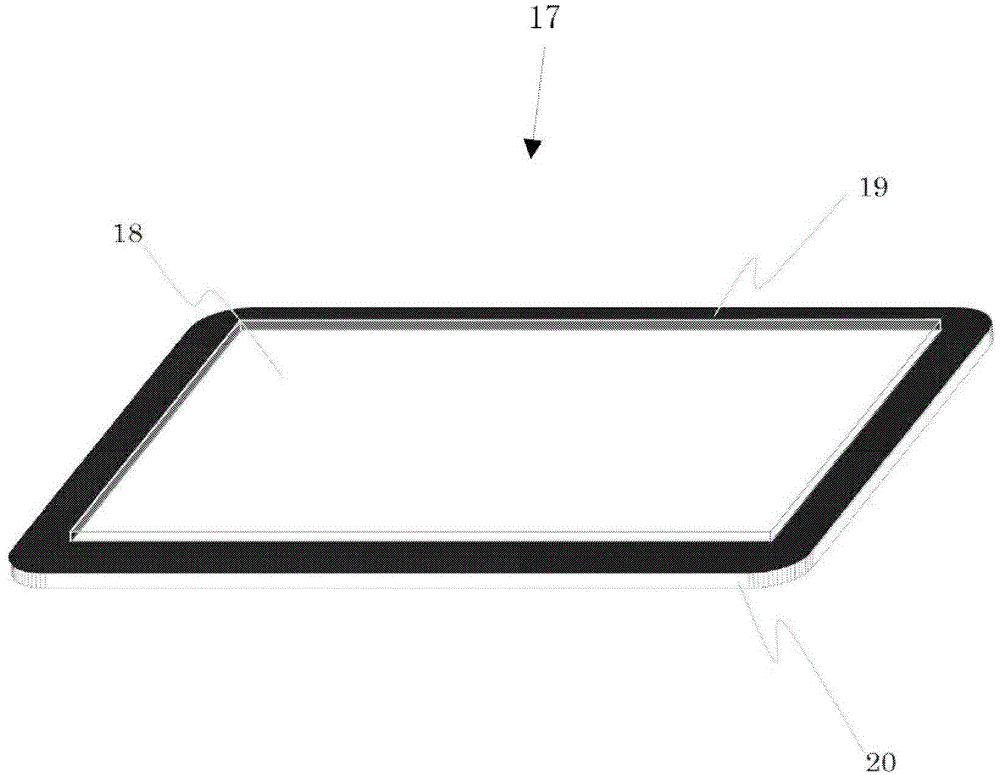

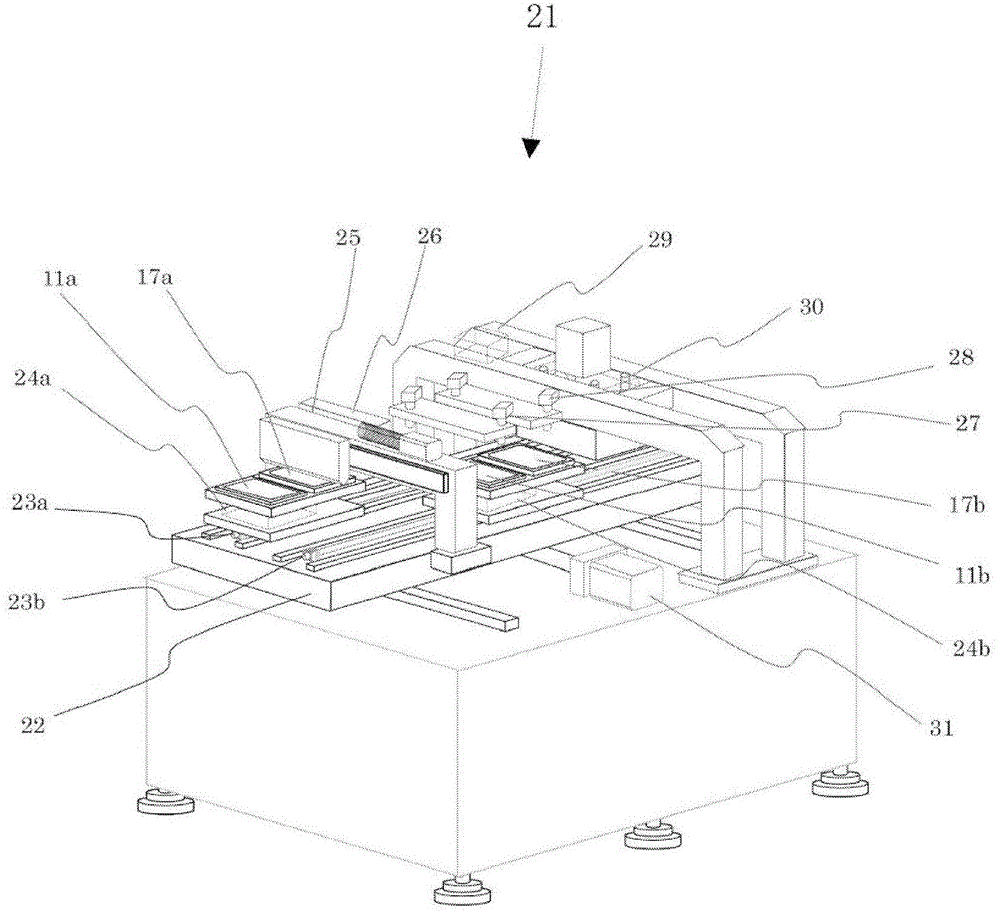

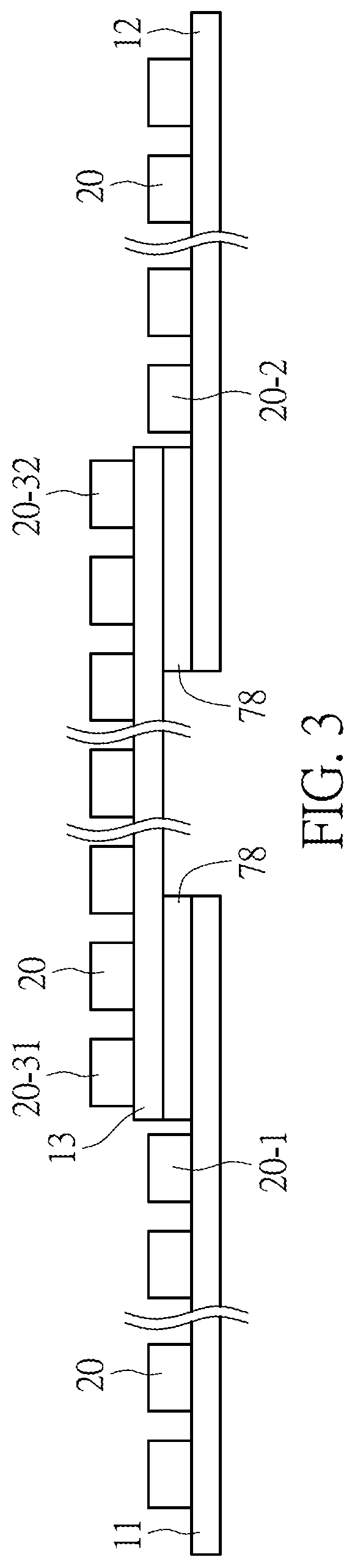

Laminating machine

InactiveCN102909926AGuaranteed fitting accuracyLaminationLamination apparatusDeflection angleMechanical engineering

The invention is applicable to the field of electromechanical technology and provides a laminating machine. The laminating machine comprises an upper bench for holding an upper workpiece, a lower bench for holding a lower workpiece, and a rolling laminating device for pressing the two workpieces together. An adjusting device used for adjusting the position of the lower bench to align the lower workpiece and the upper workpiece during laminating is disposed below the lower bench. The adjusting device comprises an adjusting table, a base and a plurality of angular displacement adjustments arranged between the adjusting table and the base. The lower bench is disposed on the base. Deflection angle and position of the lower bench are adjusted through the angular displacement adjustments, so that the lower workpiece and the upper workpiece are aligned during laminating and laminating precision of the laminating machine is guaranteed.

Owner:SHENZHEN SHENLAN PRECISION MACHINERY

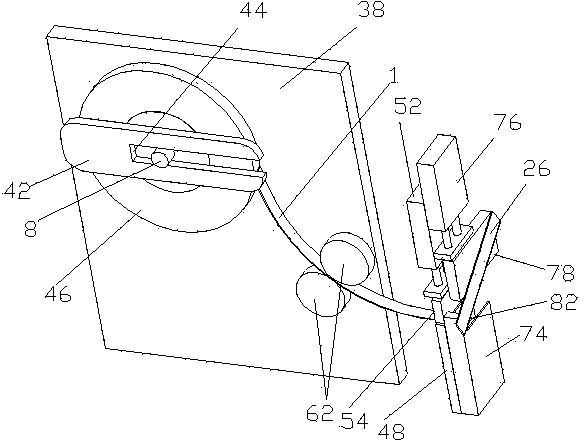

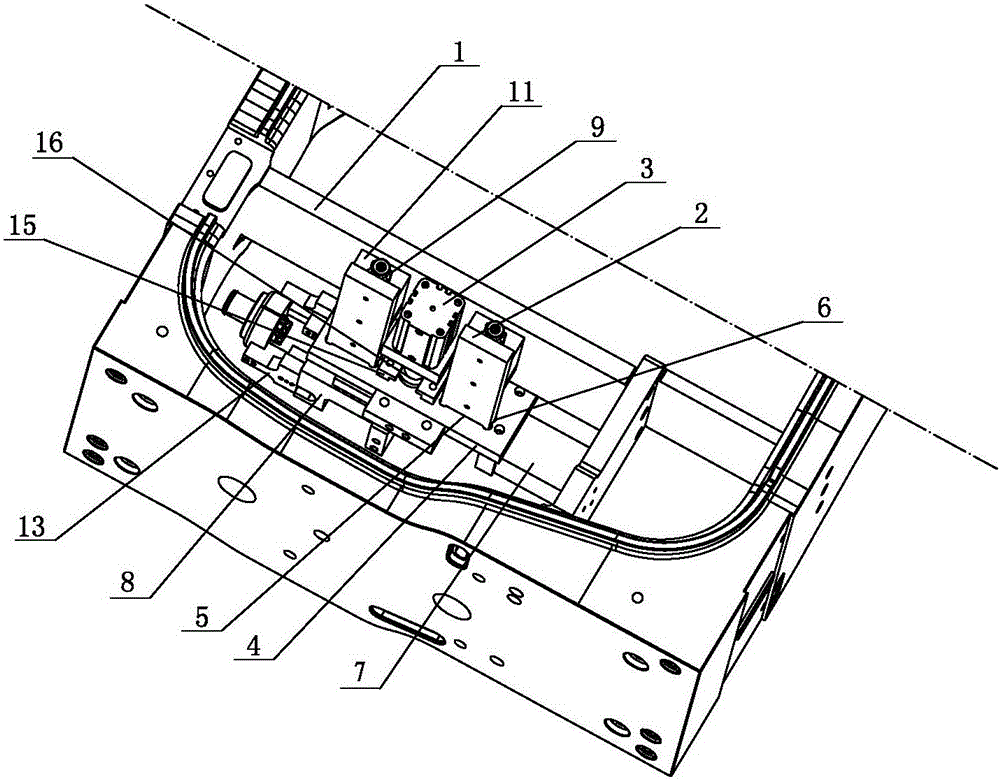

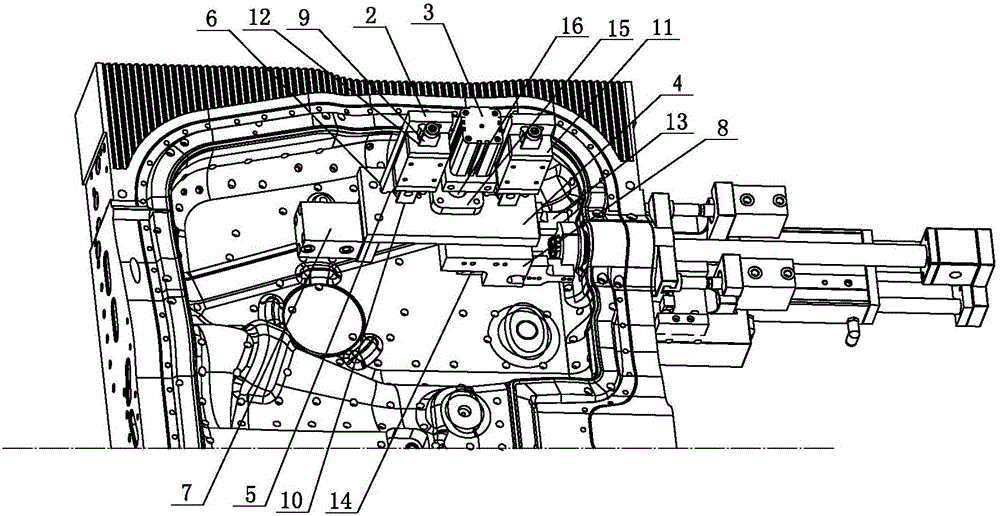

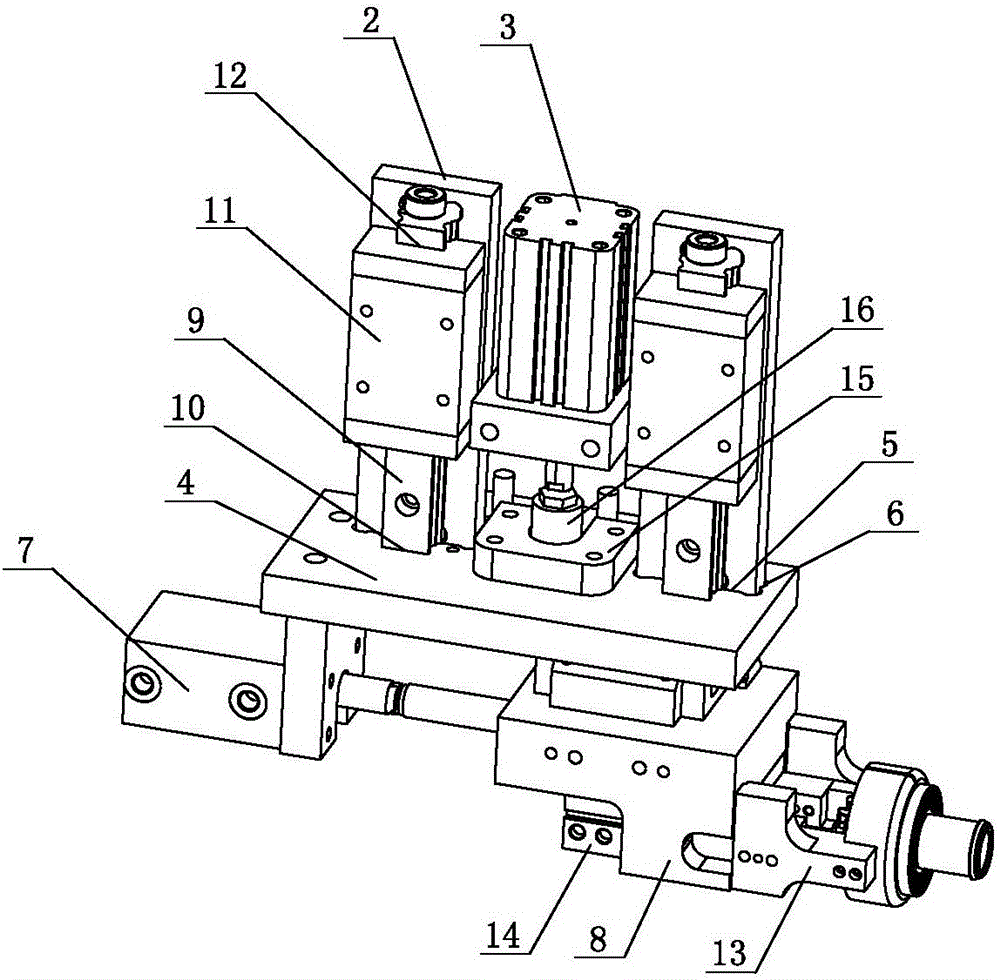

Oil filling opening insert mounting mechanism of oil tank mould

An oil filling opening insert mounting mechanism of an oil tank mould comprises a support fixedly arranged in an oil tank mould cavity, and a fixed plate (2) and a first air cylinder (3) are arranged on the support (1); a platform (4) is in sliding connection to the fixed plate (2), and a through hole (5) allowing the fixed plate (2) to penetrate is formed in the platform (4); the end face, close to the first air cylinder (3), of the platform (4) is connected with a piston rod of the first air cylinder (3), and a second air cylinder (7) and a sliding block (8) are arranged on the end face, away from the first air cylinder (3), of the platform (4); the sliding block (8) is in sliding connection to the platform (4), and is connected with a piston rod of the second air cylinder (7); and an oil filling opening insert clamping component is arranged on the sliding block (8). Compared with the prior art, the oil filling opening insert mounting mechanism has the advantages that the product precision and tightness are good, the yield can be greatly improved, the product production cost can be greatly reduced, and the use stability of a product can be improved.

Owner:NINGBO FANGZHENG TOOL

PVC (polyvinyl chloride) floor fitting device

ActiveCN103722863AGuaranteed fitting accuracyShorten the timeLamination ancillary operationsLaminationPolyvinyl chlorideEngineering

The invention relates to a PVC (polyvinyl chloride) floor fitting device which comprises a high-speed fitting machine, wherein a surface material loading gluing device and a base material loading gluing device are arranged at the feeding end of the high-speed fitting machine, and a belt conveying line and a pressure applying and maintaining machine are arranged at the discharging end of the high-speed fitting machine; the surface material loading gluing device and the base material loading gluing device are respectively provided with a feeding device, a gluing machine and a conveying device; the high-speed fitting machine comprises a surface material fitting roller and a base material fitting roller which are arranged in parallel and are rotatably mounted on a surface material fitting roller moving mechanism and a base material fitting roller moving mechanism respectively; a surface material conveying roller and a surface material loading mechanism are respectively arranged on the outer side of the surface material fitting roller; a base material conveying roller and a base material loading mechanism are arranged on the outer side of the base material conveying roller. According to the PVC floor fitting device, the product fitting operation is finished by adopting the high-speed fitting machine with the two opposite rotatable fitting rollers, the loading and unloading operations can be performed at the same time, and the fitting efficiency is improved.

Owner:WUXI WOGE SOFTWARE

Laminating device of substrate

InactiveCN104859264AShorten the intervalAvoid it happening againLaminationPretreated surfacesEngineeringMechanical engineering

The present invention aims to provide a laminating device which consists of four functional elements respectively for coating, precuring, aligning and laminating and achieves improvement of productbility, shortening of processing time, and great reduction of set area of a device on the premise of ensuring quality in the laminating process of laminating a plurality of devices such as smart phones or flat terminals through optical resin. The laminating device of substrate is characterized in that two independent left and right shafts arranged in a direction perpendicular to the moving direction of a base are respectively carried on the base capable of moving back and forth, through two substrate loading platforms capable of moving along the left and right shafts and capable of positioning, the base moves back and forth, thereby ensuring three independent moving shaft positions, on the three independent moving shaft positions, the functional elements respectively for coating, precuring, aligning and laminating are provided for performing laminating of two substrates with carrying of the substrates.

Owner:TELECOMM SA

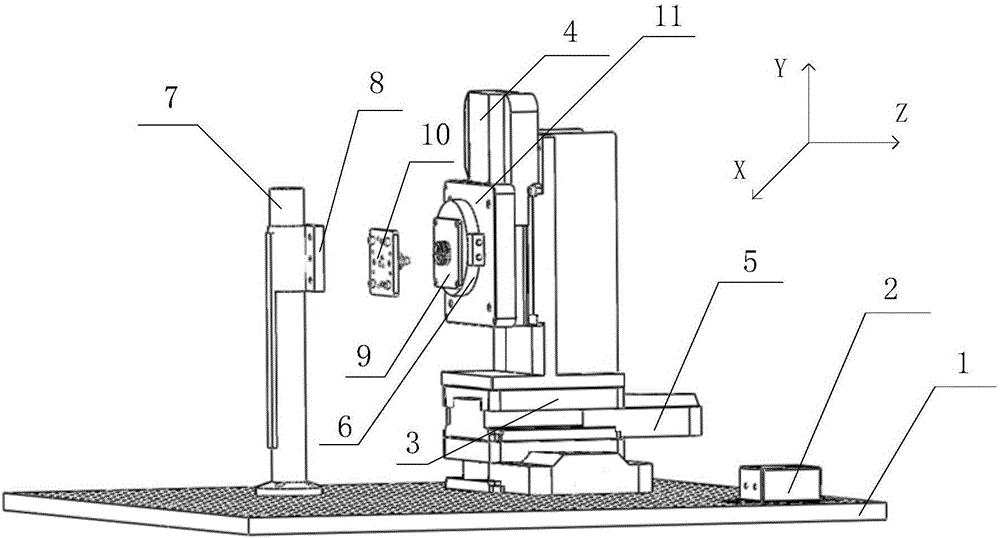

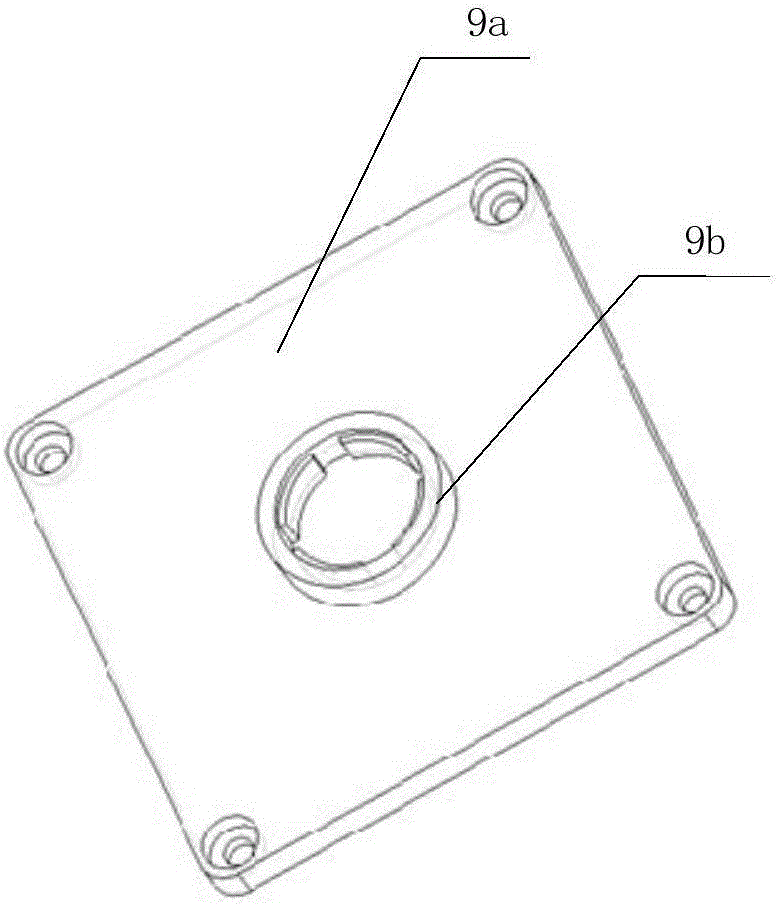

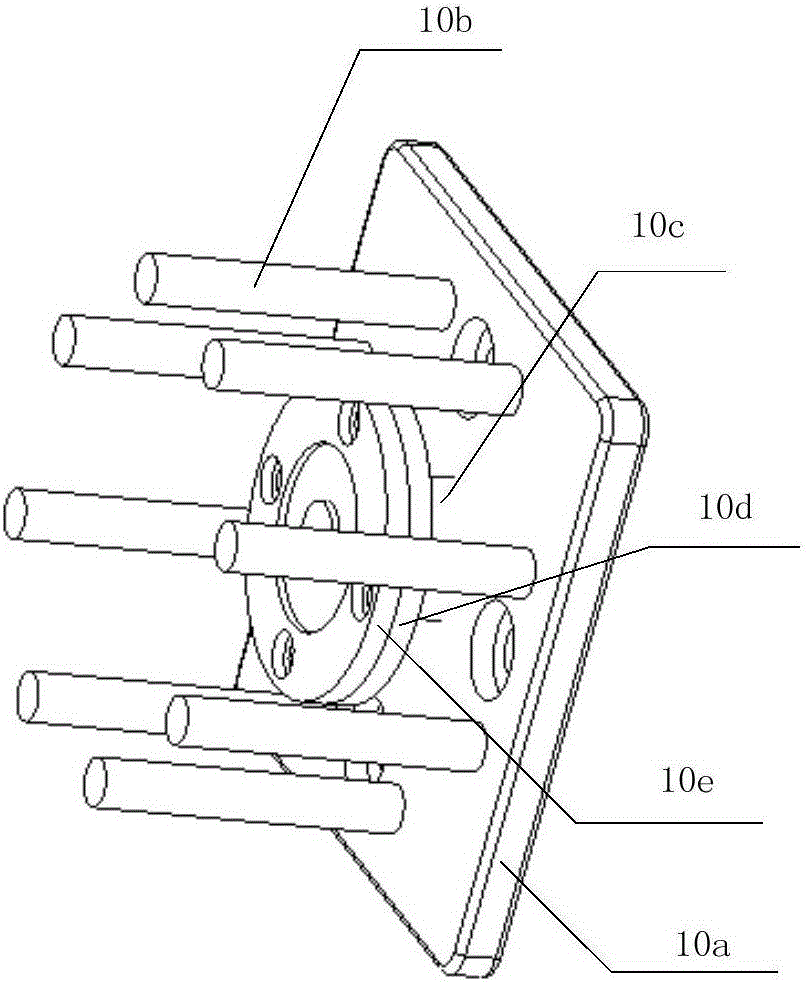

Magnetic suspension sensor rigidity testing system and method

The invention discloses a magnetic suspension sensor rigidity testing system and method, and the system comprises a precise electrical control displacement platform, a controller, a force sensor, and a tool. The force sensor is connected between a rotor pasting tool and a vertical column tool through a force sensor connecting tool, precisely obtains the size of force on a rotor and determines a mechanical zero point, a balance point and a test initial position of the precise electrical control displacement platform through the controller, reads the values of the force sensor for many times at preset intervals, obtains the relation between the size of the force on the stator part of a to-be-tested magnetic suspension sensor and the displacement, and obtains the rigidity of the magnetic suspension sensor after displacement derivation. The system is suitable for the testing of the rigidity of the magnetic suspension sensor, and the testing method is accurate and simple.

Owner:BEIJING PULIMEN ELECTRO MECHANICAL HIGH TECHN CO

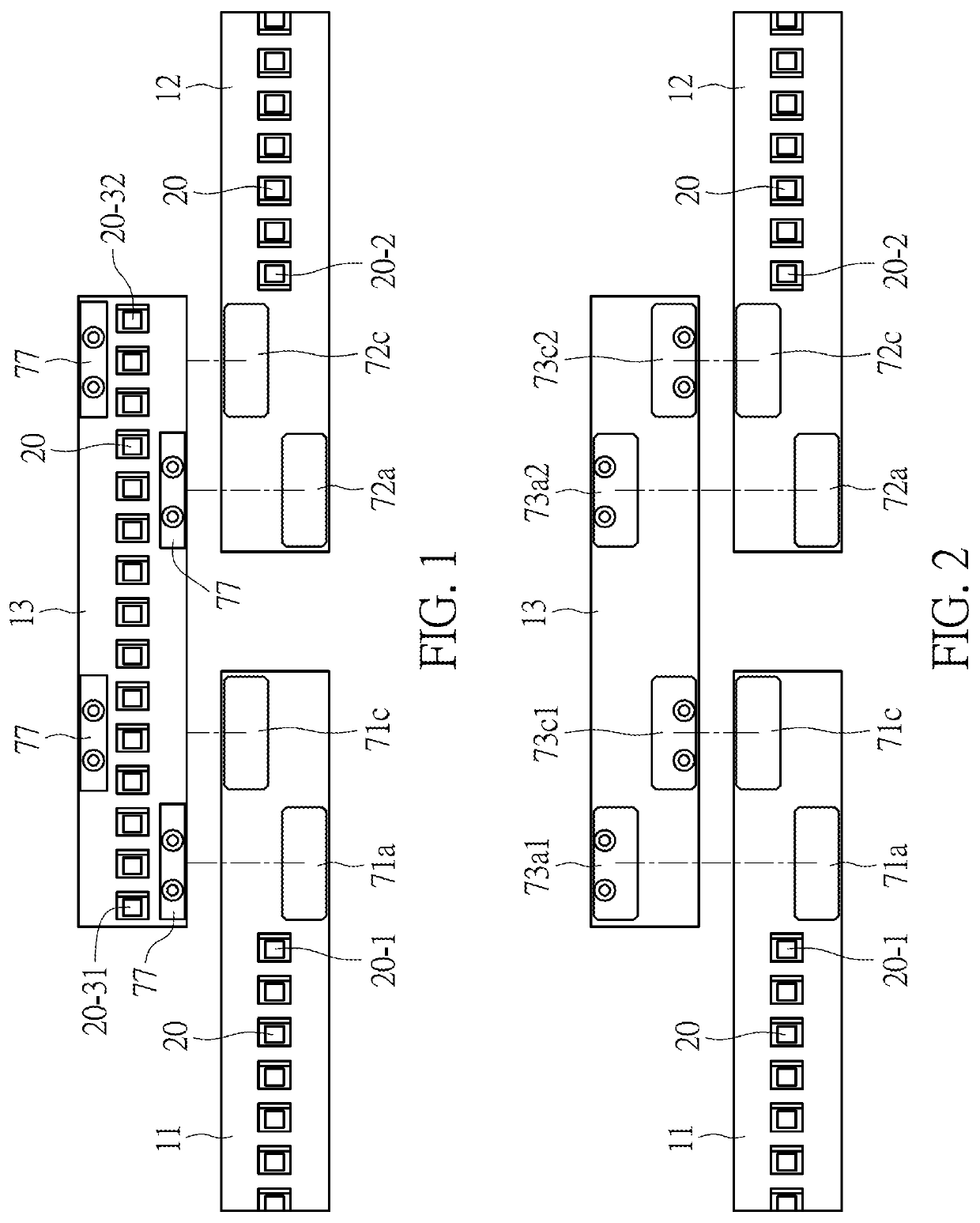

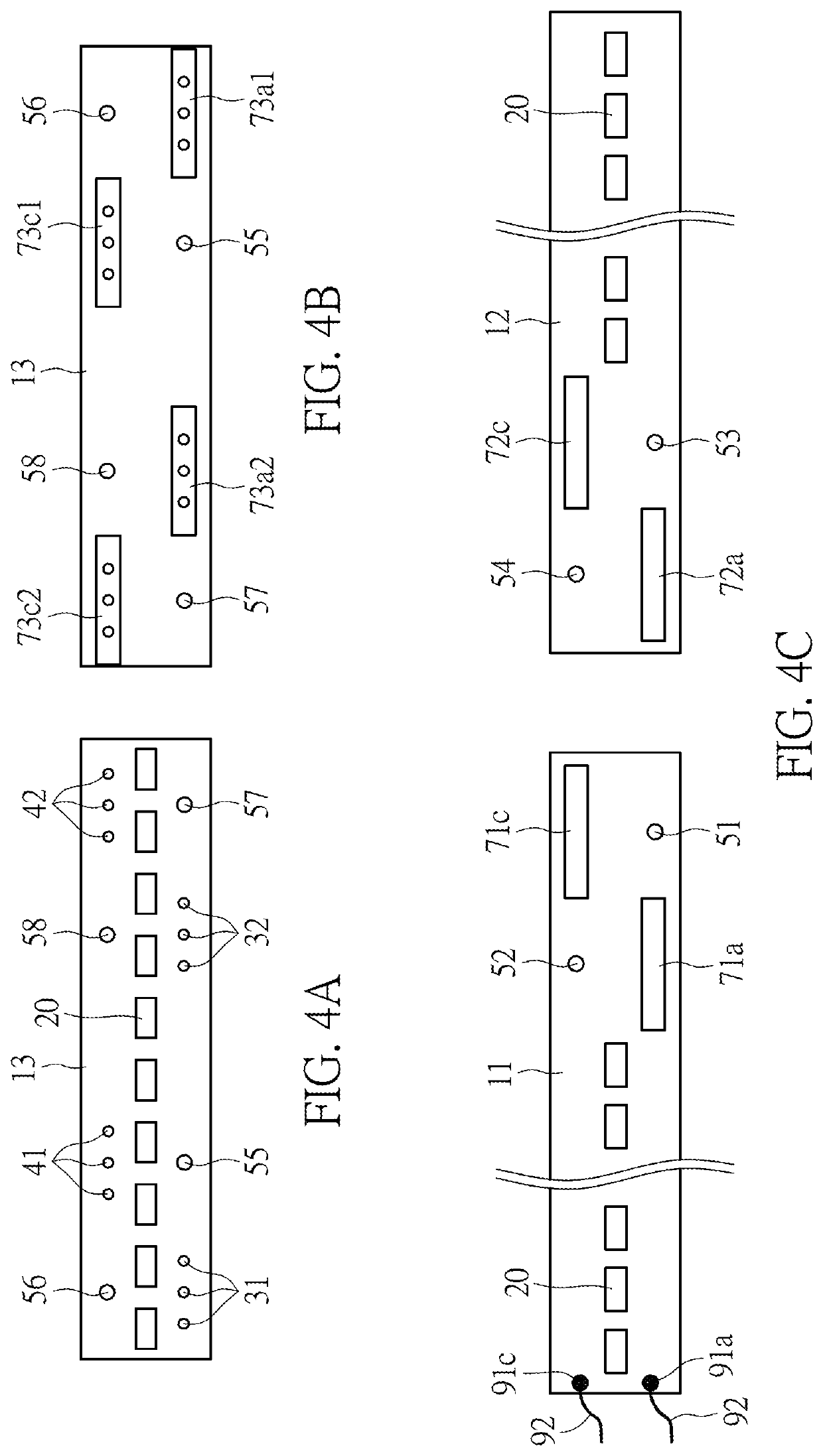

Uniformly emitting linear LED light source assembly and method

ActiveUS10582616B1Good illumination uniformityIncrease profitLighting support devicesElongate light sourcesEngineeringMaterials science

Disclosed are a uniformly emitting linear LED light source assembly and a method thereof. The linear LED light source assembly comprises a first light strip, at least one second light strip and at least one connecting board which are all provided with a plurality of LEDs closely arranged at equal intervals, wherein the equal interval is less than 3.5 mm to realize uniform illumination. The connecting board connects the first light strip and the second light strip. The LED closest to the first light strip on the connecting board and the LED closest to the connecting board on the first light strip are formed at the same pitch as the equal interval. In addition, the LED closest to the second light bar on the connecting board and the LED closest to the connecting board on the second light bar are formed at the same pitch as the equal interval.

Owner:EXCELLENCE OPTO INC

Assembling machine for right-angle male connectors

ActiveCN111185741AHigh degree of automationIncrease productivityMetal working apparatusMachine buildingElectric machinery

The invention belongs to the technical field of machine manufacturing, and particularly relates to an assembling machine for right-angle male connectors. The assembling machine comprises a rack; a soldering lug and bamboo joint assembling mechanism for embedding soldering lugs and bamboo joints and a male connector direction detecting and adjusting mechanism for adjusting the directions of the male connectors are arranged on the rack; the assembling machine further comprises an assembling mechanism which is arranged on the rack and used for assembling the bamboo joints into the male connectors; and the assembling mechanism communicates with a guiding trough. According to the assembling machine, whole-process automatic operation can be realized from feeding, detection, assembling to discharging, the automation degree is relatively high, the production efficiency is improved, and the production cost is reduced; and besides, according to the assembling machine, the surfaces, provided withside holes, of the male connectors are detected by the aid of a first detecting mechanism, then an adjusting clamping jaw is driven by an adjusting motor to rotate the male connectors, the side holesof the male connectors are rotated to the proper direction, and thus automatic inserting assembling of the right-angle male connectors is realized.

Owner:绍兴简效自动化科技有限公司

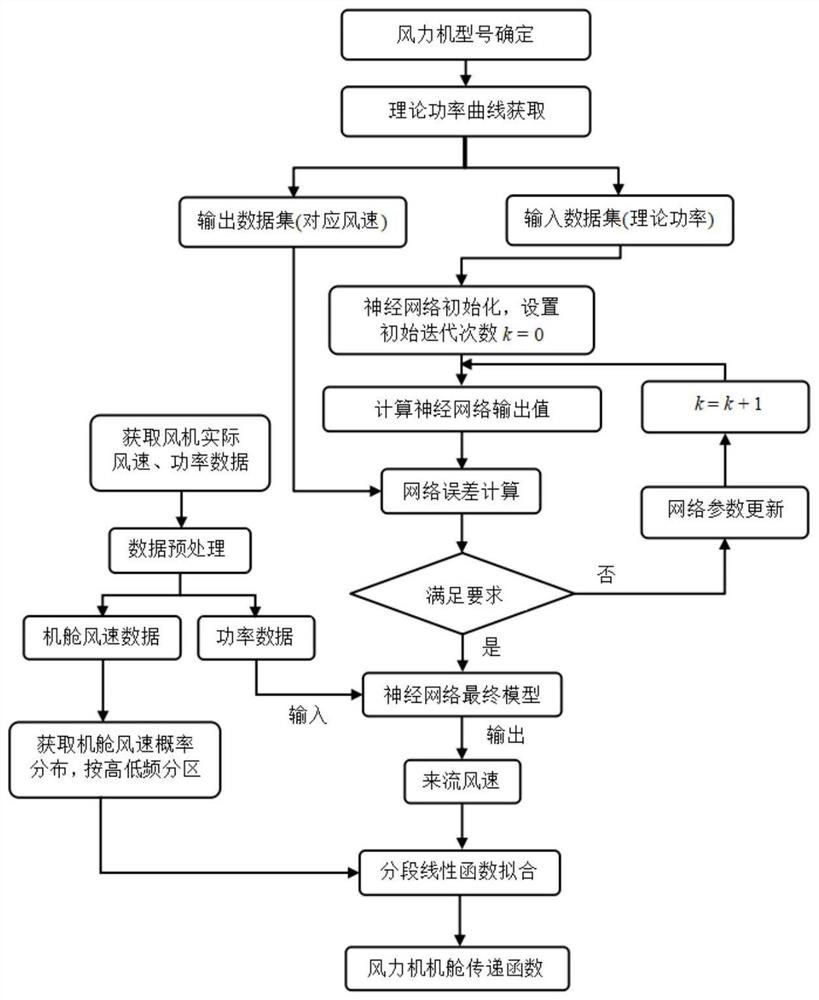

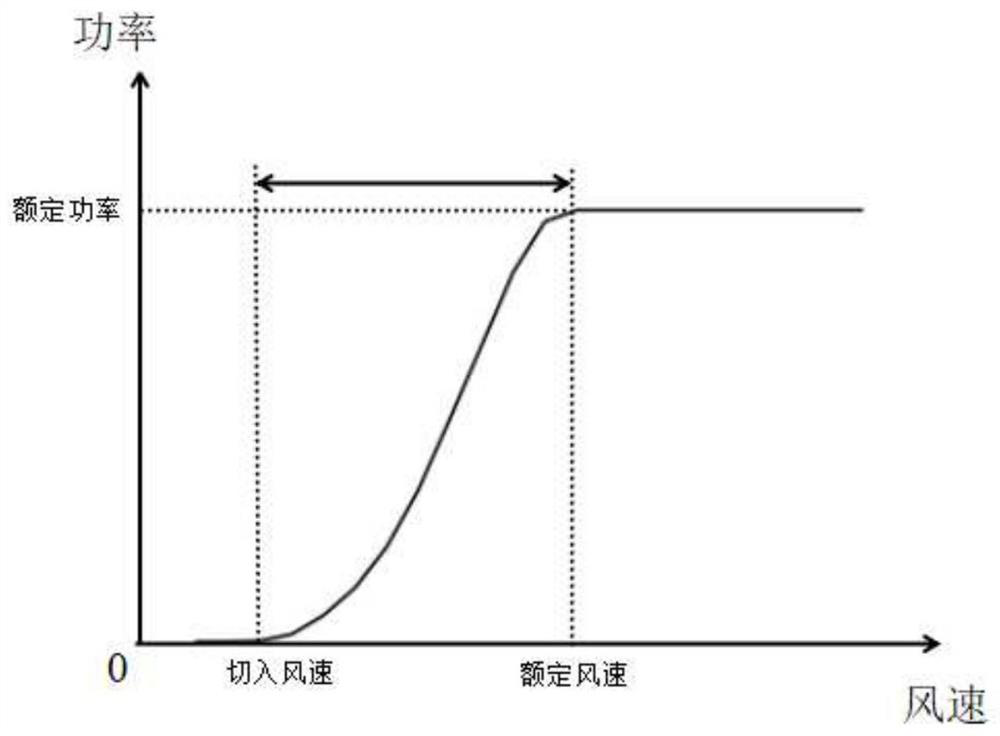

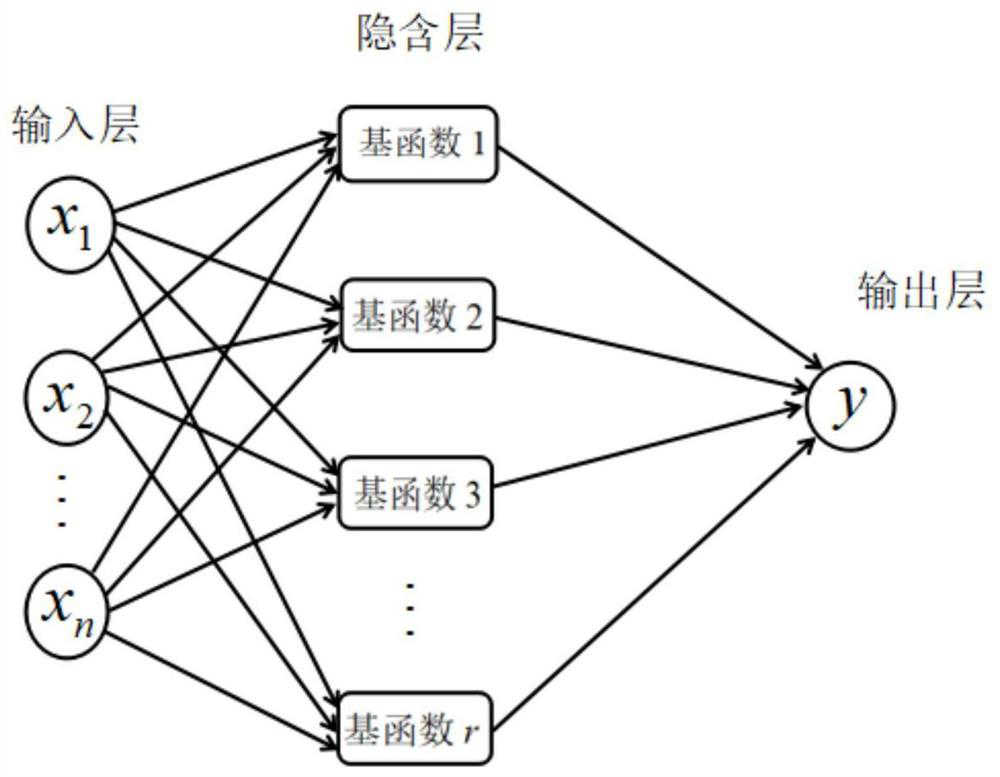

Method for calculating transfer function of cabin of wind turbine

ActiveCN112861429APowerful nonlinear function approximation capabilityPossess self-learning self-adaptive abilityDesign optimisation/simulationWind energy generationNacelleAtmospheric sciences

A method for calculating a cabin transfer function of a wind turbine comprises the following steps: acquiring a theoretical power curve of a single fan, and selecting an area between cut-in wind speed and rated wind speed; adopting the neural network to carry out backward deduction on the area, and inputting wind power data from an actual operation wind power plant into the trained neural network to obtain a corresponding incoming flow wind speed value; acquiring cabin wind speed data in one-to-one correspondence with the wind power data, and dividing the cabin wind speed data into a high-frequency region and a low-frequency region; and performing partition processing on the high-frequency region and the low-frequency region respectively; in each interval, carrying out linear function fitting on the cabin wind speed and the corresponding incoming flow wind speed, and forming a cabin transfer function of the fan according to the linear function fitting. The wind turbine cabin transfer function calculation method has the advantages of being high in fitting precision and small in calculation amount, and is suitable for wind turbine incoming flow wind speed calculation and wake flow evaluation.

Owner:CHINA THREE GORGES CORPORATION

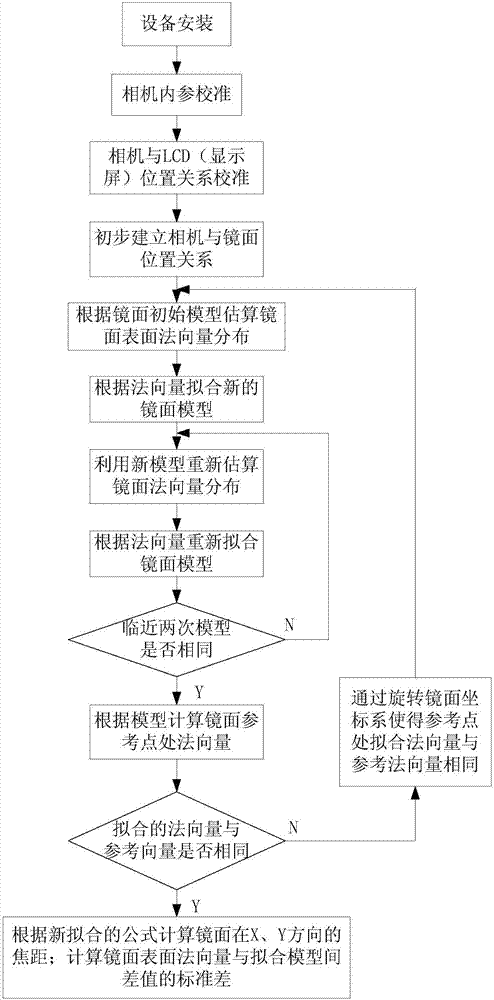

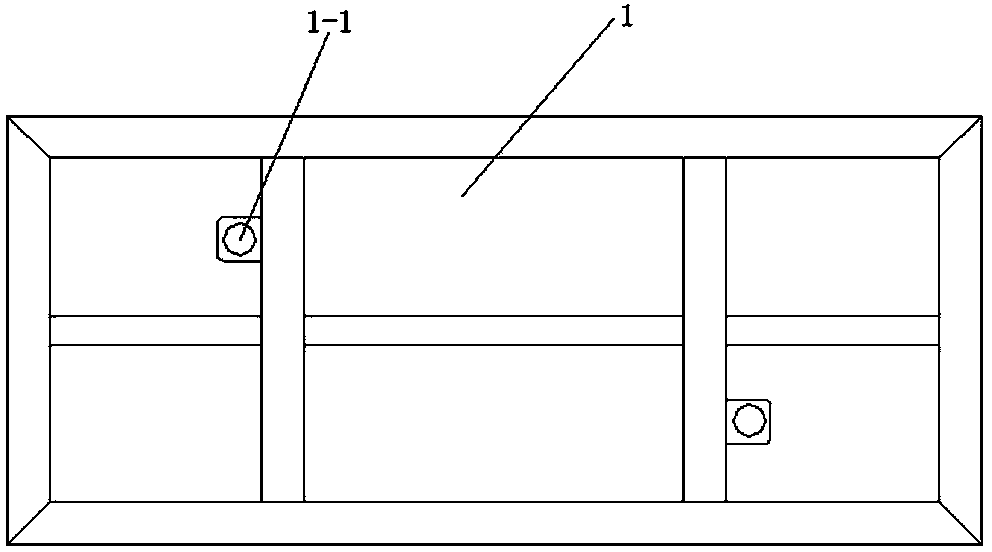

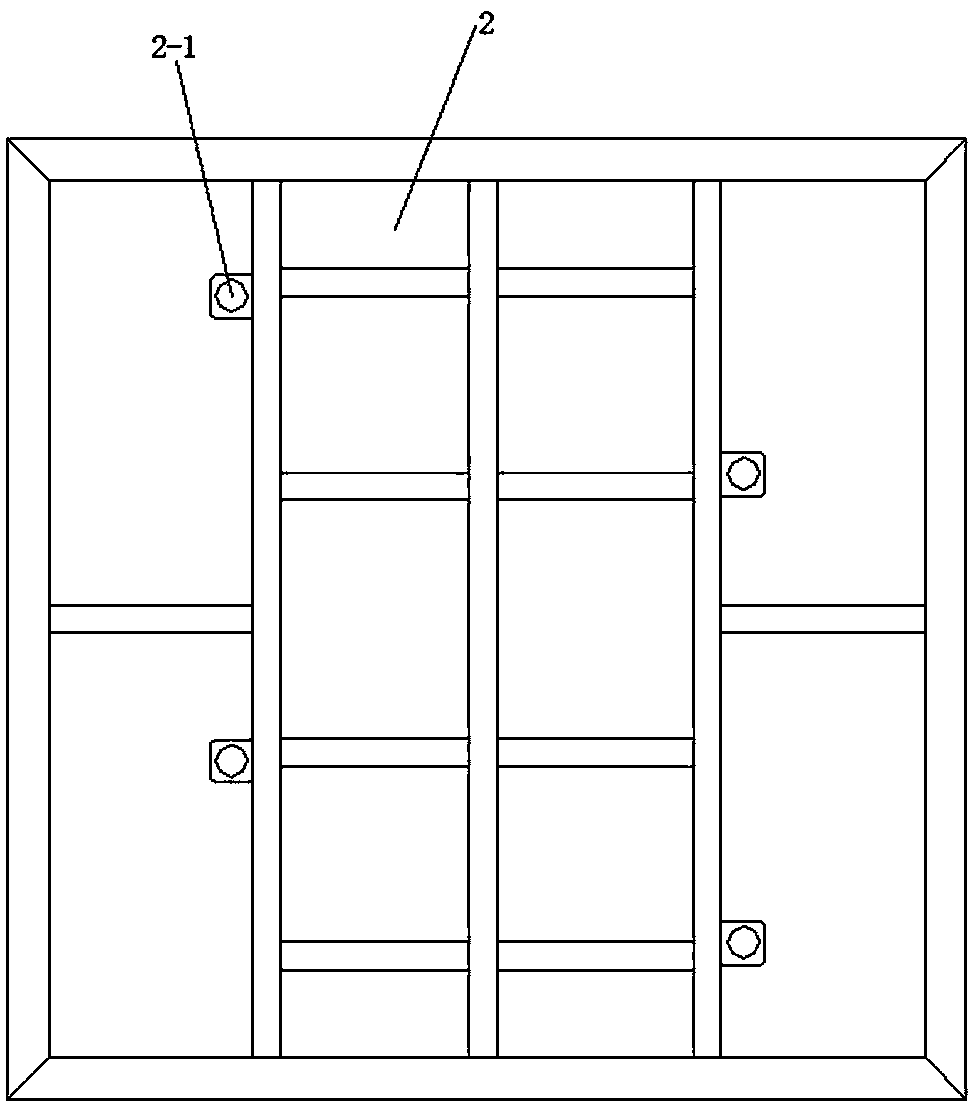

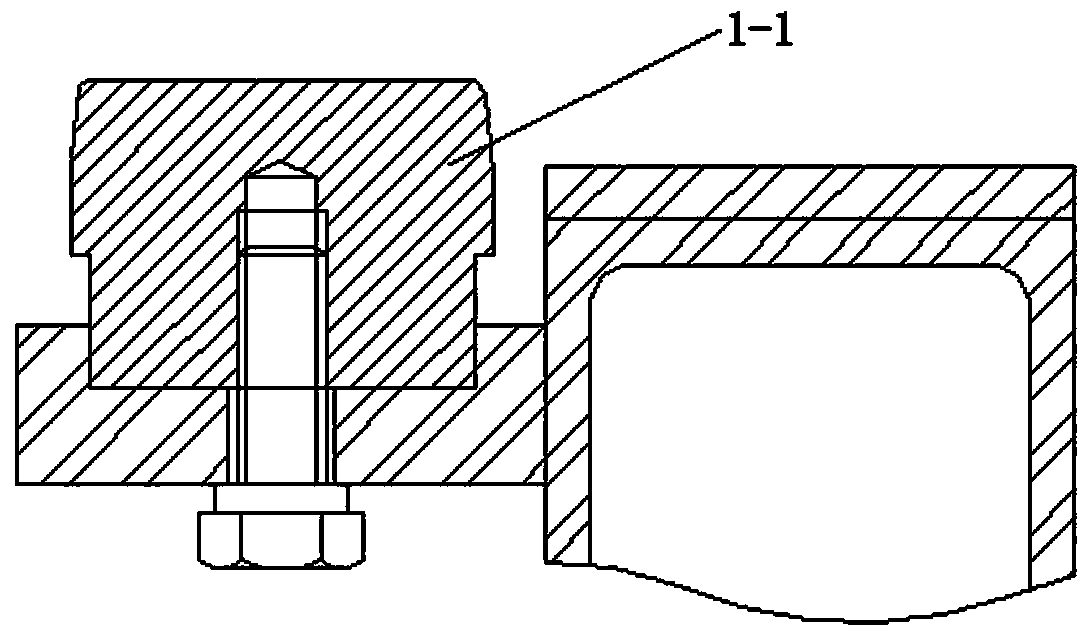

Dish Stirling solar energy light-concentrating mirror surface quality detection method

The invention discloses a dish Stirling solar energy light-concentrating mirror surface quality detection method. The method includes the following steps: 1. Installing a device; 2. calibrating internal parameters of a camera; 3. calibrating the position relation of the camera and a LCD display; 4. initially establishing the position relationship between the camera and a mirror surface; 5. on the basis of a mirror surface initial model, estimating the distribution of normal factors on the surface of the mirror surface; 6. on the basis of the normal factor, knitting a new mirror model; 7. re-computing the distribution of the normal factors on the surface of the mirror surface, again knitting a mirror surface model; 9. comparing the parameters of the two adjacent knitted models until the models are converged; 10. on the basis of the converged mirror surface model, computing the normal vector at a mirror surface reference point of the mirror surface model; 11. superpose the normal vector which is knitted at the reference point and an engineered normal factor which are different by rotating around the reference point by a mirror surface coordinate system; and 12. computing the standard differences between the normal vector on the surface of the mirror surface and an ideal difference so as to represent the smoothness of the mirror surface. According to the invention, the method has high detection efficiency and high detection precision.

Owner:ZHEJIANG UNIV OF TECH

Accurate positioning device for engine cylinder block sand core

ActiveCN103978165AReduce manufacturing costSimple structureFoundry mouldsMoulding machine componentsEngineeringCylinder block

The invention relates to the technical field of positioning devices, and in particular relates to an accurate positioning device for an engine cylinder block sand core. The accurate positioning device comprises a primary positioning support plate, a secondary positioning support plate and a positioning climbing mechanism. Firstly the primary positioning support plate is adopted for primary positioning for a cylinder cover top cover core and a cylinder cover bottom cover core, then the secondary positioning support plate is adopted for secondary positioning for the cylinder cover top cover core and the cylinder cover bottom cover core, and finally the positioning climbing mechanism is adopted for accurate positioning during mould assembling. The positioning climbing mechanism can be lifted automatically according to set production takt, two positioning elongated conical pins at the top of the positioning climbing mechanism can penetrate through a neutral gear of the secondary positioning support plate when being lifted along with a climbing machine, and primary positioning for other two technical holes (deeper) of a cylinder cover sand core is realized. In the positioning device, since the position of the climbing mechanism is unchanged all the time, the position of the sand core climbed every time is unique, and the grabbing precision and mould assembling precision of a robot can be fully met.

Owner:上柴动力海安有限公司

Secret image camouflage recovery method by combining secret key and random orthogonal tensor basis

ActiveCN108717683AGuaranteed to be strictly orthogonalGuaranteed fitting accuracyGeometric image transformationRecovery methodAlgorithm

The invention discloses a secret image camouflage recovery method by combining a secret key and random orthogonal tensor basis. The method comprises the following steps: firstly dividing a secret image and a public image into equal number of small matrix blocks, and constructing random orthogonal tensor basis by using a unit orthogonal matrix generated by the secret key; secondly, performing sufficient and effective linear expression on small secret image blocks by solving the projections on the random orthogonal tensor basis on the small secret image blocks, selecting the front k projection coefficients with large amplitude and energy from the projection and recording an index location to construct a line sequence and a row sequence; and secondly embedding the selected projection coefficient, the line sequence and the row sequence into the corresponding public small image blocks through a secret-writing method for performing tiny adjusting and large-capacity embedding on the public image, thereby forming a channel public transmission image; and finally reconstructing the secret image through a conversion parameter extracted from the channel public transmission image and by combining the secret key.

Owner:SHAANXI NORMAL UNIV

Audio frequency camouflage and recovery method that combines secret key with random unit orthogonal basis

ActiveCN108877818AGuaranteed fitting accuracyExpress fully and effectivelyKey distribution for secure communicationGeometric image transformationRecovery methodOrthogonal basis

The invention discloses an audio frequency camouflage and recovery method that combines a secret key with random unit orthogonal basis; the method comprises the following steps: firstly dividing a secret audio frequency and a public audio frequency into small segment sequences of the same quantity, and using the secret key to build the random unit orthogonal basis; secondarily, solving the projection of the secret audio frequency small segment sequence on the random unit orthogonal basis so as to fully, effectively and linearly express the secret audio frequency small segment sequence, selecting first k projection factors with large amplitude and energy and recording index positions, and thus forming an index sequence; finely adjusting the public audio frequency and using a high capacity built-in secret writing method to embed the selected projection factors and a line sequence into the corresponding public audio frequency small segment sequence, thus forming a channel public transmission audio frequency; using transform parameters extracted from the channel public transmission audio frequency, and combining with the secret key so as to reconstruct the secret audio frequency. Compared with the prior art, the method can reconstruct the secret audio frequency with different precisions, and strictly depends on the user secret key, thus providing a higher safety.

Owner:SHAANXI NORMAL UNIV

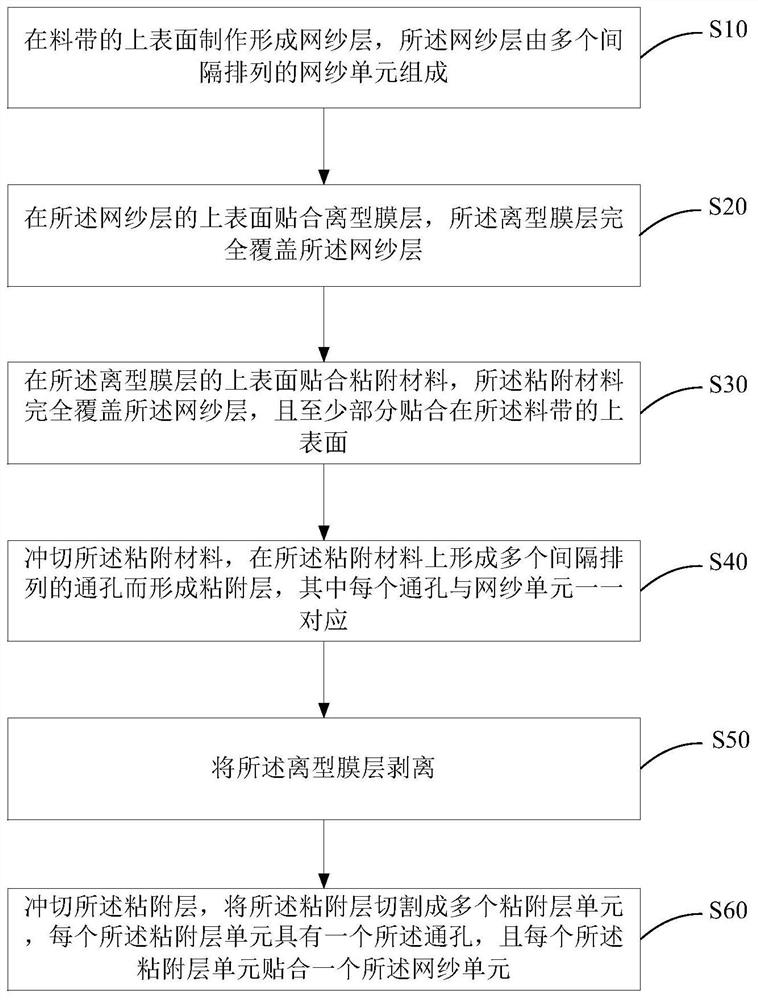

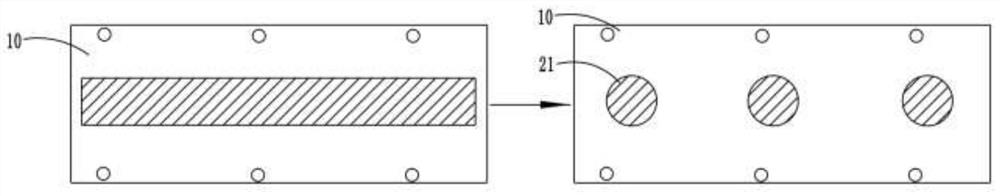

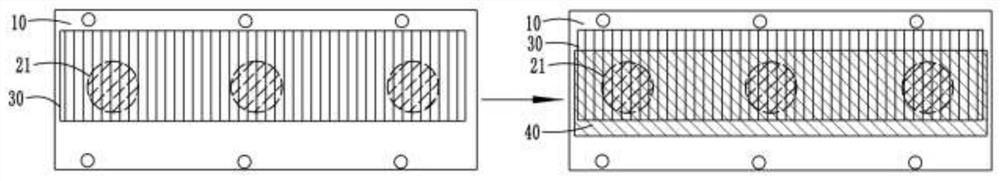

Die cutting method of gauze film layer

The invention discloses a die cutting method of a gauze film layer. The die cutting method comprises the steps that a gauze layer is manufactured and formed on the upper surface of a material belt, wherein the gauze layer is composed of a plurality of gauze units arranged at intervals; a release film layer is attached to the upper surface of the gauze layer, wherein the release film layer completely covers the gauze layer; an adhesive material is attached to the upper surface of the release film layer, wherein the adhesive material completely covers the gauze layer, and is at least partially attached to the upper surface of the material belt; and the adhesive material is punched, a plurality of through holes which are arranged at intervals are formed in the adhesive material to form an adhesive layer, each through hole is in one-to-one correspondence with the gauze unit. The release film layer is attached to the gauze layer, so that the gauze layer is prevented from being damaged whenthe adhesive material is punched, meanwhile, a punching material of the adhesive layer can be discharged easily, a finished product is directly subjected to die cutting, the attaching precision is guaranteed, manual assembling operation is omitted, and the productivity is greatly improved. Finally, the release film layer is stripped in the side direction so as to realize lamination of the adhesivelayer and the gauze units.

Owner:苏州佰瑞兴实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com