Dish Stirling solar energy light-concentrating mirror surface quality detection method

A quality inspection method and solar concentrating technology, applied in the field of dish solar energy, can solve the problem of inability to take into account efficiency and accuracy, and achieve the effects of improving efficiency, simple equipment and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

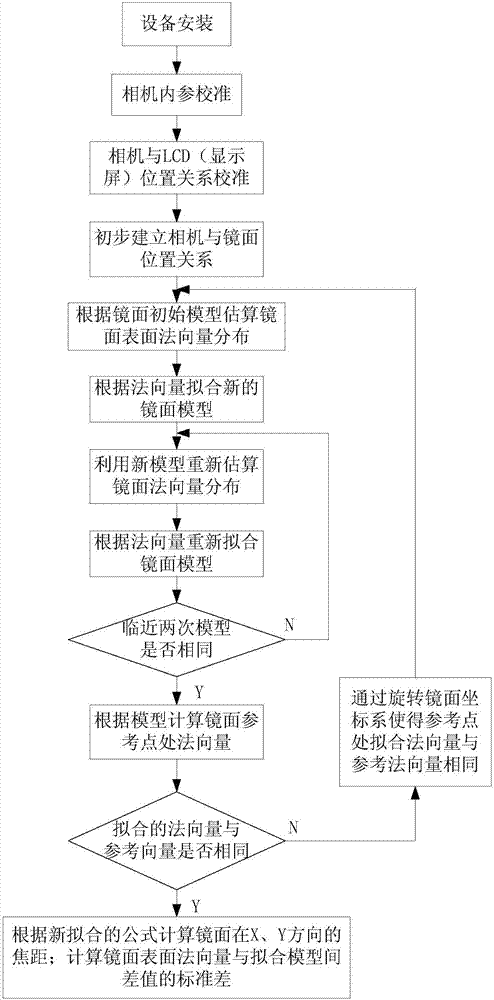

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

[0034] refer to figure 1 , a dish type Stirling solar concentrating mirror surface quality detection method, comprises the following steps:

[0035] 1) Install the device. The measuring equipment of the present invention is an industrial camera and an LCD display. Fix the two devices together and place them at a distance of about 2 times the focal length from the mirror. Adjust the camera angle so that the specular area it sees is all on the LCD screen.

[0036] 2) Camera internal parameter calibration. Use the checkerboard calibration board to calibrate the internal parameters of the camera, including the calibration of focal length, image center, and lens distortion.

[0037] 3) Calibrate the positional relationship between the camera and the LCD display. Place the rectangular flat mirror in front of the camera and the screen, display a standard checkerboard on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com