Laminating device of substrate

A technology for laminating devices and substrates, which can be used in lamination devices, devices for applying liquid to surfaces, lamination, etc., and can solve problems such as limited use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

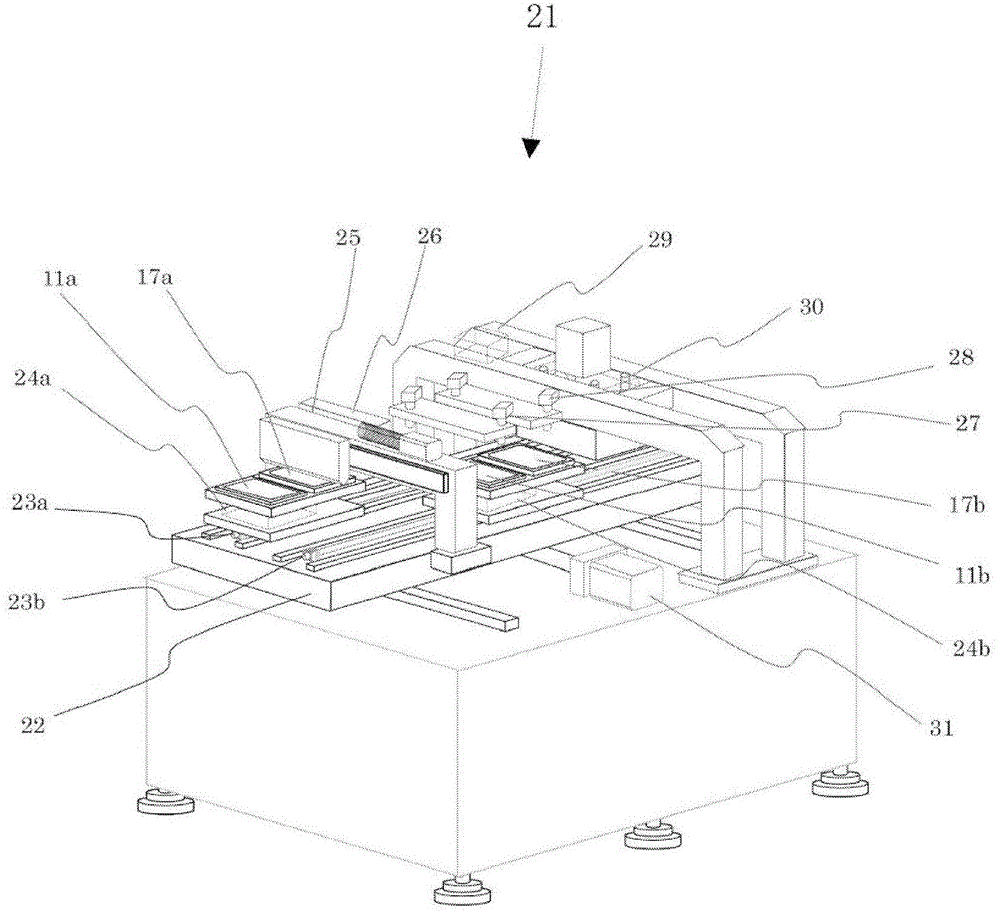

[0190] Next, for an embodiment of the bonding device of the substrate of the present invention, refer to image 3 and Figure 4 illustrate. image 3 It is an external view showing a schematic configuration of an embodiment of the substrate bonding apparatus of the present invention. again, Figure 4 It is an explanatory diagram showing a planar arrangement of each functional unit constituting the substrate bonding apparatus of the present invention. The outline of the device of the present invention will be described using these two figures.

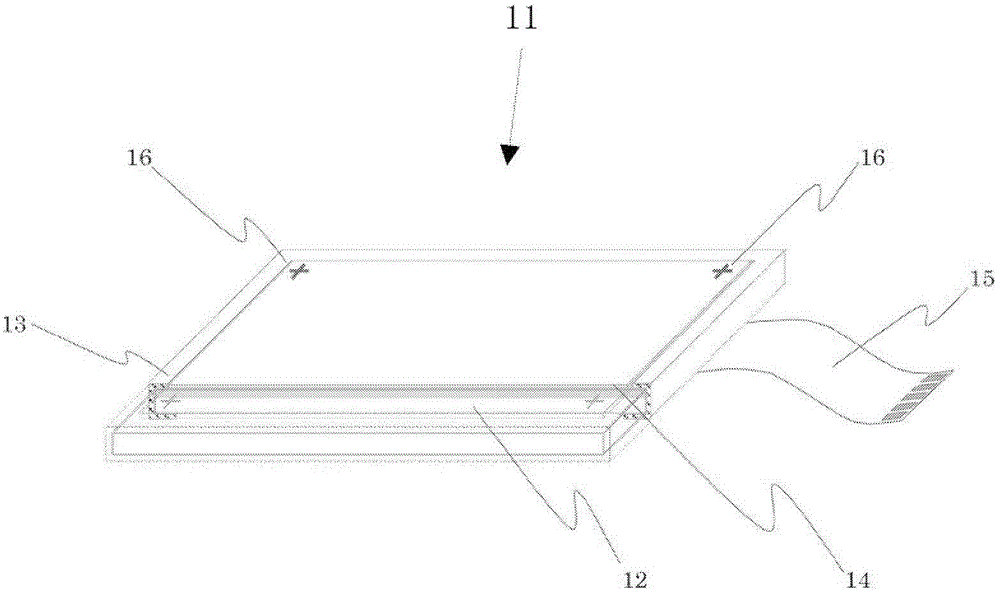

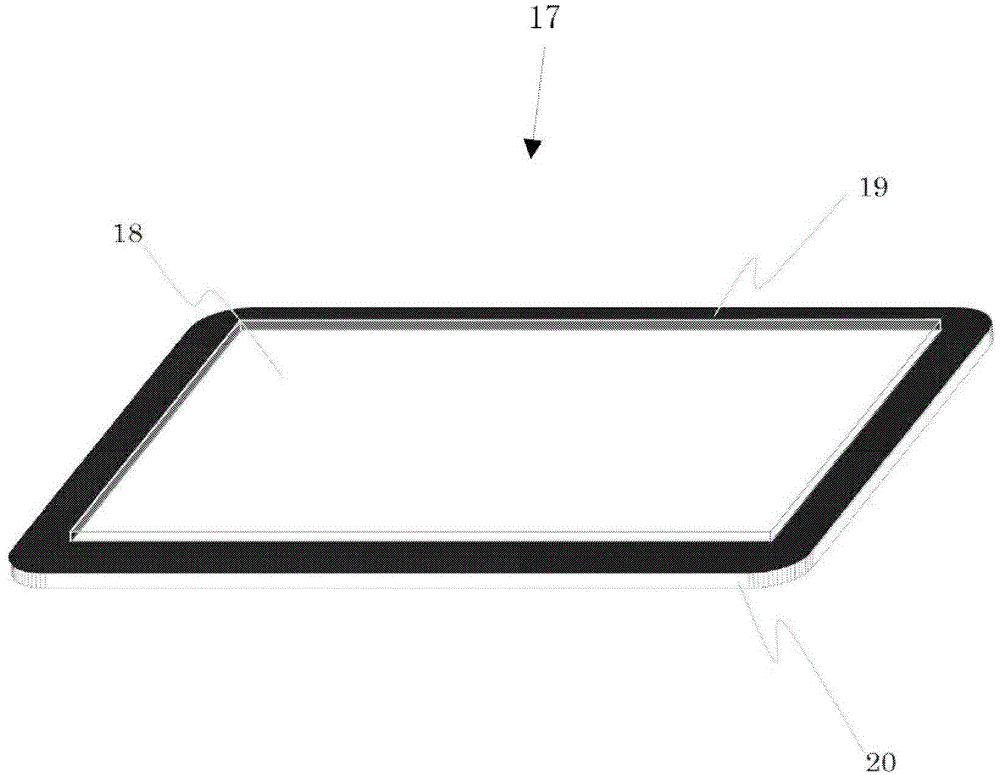

[0191] Such as image 3 It shows that the laminating device 21 of the substrate is equipped with a moving shaft 23a and a moving shaft 23b for laying two substrates that can be moved by a ball screw on a base 22 that can move back and forth, and is equipped with two moving shafts that can be positioned separately. The three-degree-of-freedom actuator on the moving shafts 23a and 23b is a substrate transfer system (each functional co...

Embodiment 2

[0235] As mentioned above, although the purpose of pre-curing is to prevent leakage or insufficient flow diffusion during bonding, once the viscosity-controlled bonding material is used in the bonding process, there is a possibility of omitting the pre-curing process. Especially when the viscosity of the material is about one digit higher than that of the current main materials (for example, around 50000cps), the flow can also be suppressed, and the experimental results that the coating shape can also be formed more stably can be obtained. Although the above high-viscosity bonding materials cannot be implemented with a slit-type coater that can stably and intermittently coat high-viscosity materials in a coating process that is more difficult than a bonding process, recently, a spiral quantitative material supply pump 37 The use of a coating head (slot-type coating head 34) that can withstand high pressure can be realized.

[0236] In the case where the pre-curing process can ...

Embodiment 3

[0239] also available from image 3 and Figure 4 It is known that the processes on the outer moving shaft 23a and the moving shaft 23a' are completely the same (coating function and pre-curing function). And, when these functions are performed differently from the outside of the left and right, it is natural that these functional components move and act alternately at the positions of the movement shaft 23a and the movement shaft 23a'. As long as the accuracy can be guaranteed, the slit-type coating head 34 and the ultraviolet irradiation head 38 can be formed into a single high-precision device, and the Figure 4 ( Figure 9 ) The process conditions and control calculations of state A and state B form a single, that is, it is possible to respond with a simplified control method.

[0240] In addition, the price can also be reduced from two units to one unit, which has the advantage of significantly reducing the price. Specific as Figure 11 It shows that the structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com