Wear-resisting type paint for dry bulk carrier cargo hold

A technology for dry bulk cargo and cargo holds, applied in the field of wear-resistant coatings, can solve problems affecting the normal operation and service life of dry bulk cargo ships, and damage the coating on the surface of cargo holds, so as to achieve excellent mechanical properties, reduce operating costs, reduce The effect of interval time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

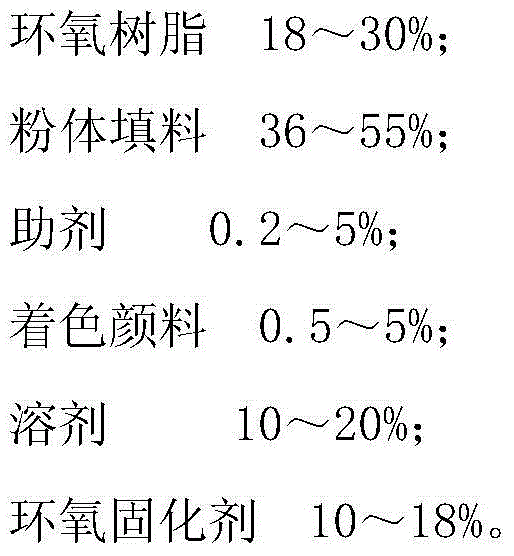

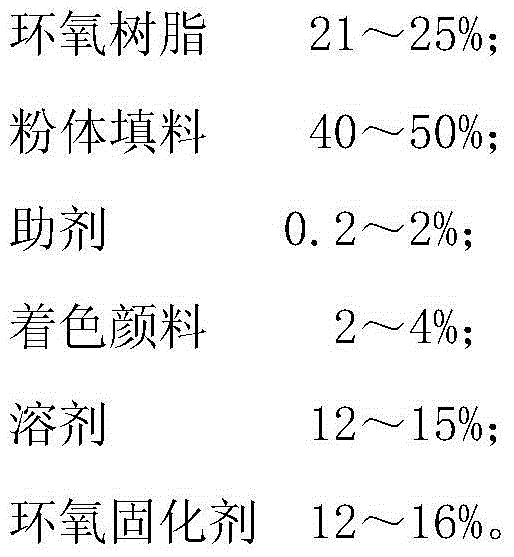

[0031] (1) A wear-resistant coating for the cargo hold of a dry bulk carrier, the weight percentage of each raw material in its component is:

[0032] Epoxy resin 30%, adopt the E-51 bisphenol A epoxy resin of the NPEL-128 model that South Asia Epoxy Resin (Kunshan) Co., Ltd. produces.

[0033] Talcum powder 26%, adopts the product of PDSJ-150 produced by Pingdu Shijie Chemical Stone Powder Co., Ltd.

[0034] Mica powder 10%, adopts 325 mesh mica powder produced by Fuyang Mica Products Factory.

[0035] Organic bentonite 0.5%, adopts organic bentonite produced by Zhejiang Fenghong New Material Co., Ltd., model HF-120.

[0036] Iron oxide red 3%, adopts the iron oxide red product of model S190 produced by Shanghai Yipin Pigment Co., Ltd.

[0037] n-Butanol 3.5% from a professional market supply.

[0038] Xylene 9%, using products available in the professional market.

[0039] Polyamide curing agent 18%, the product that adopts Air Products Company to produce, model is SUNMI...

Embodiment 2

[0050] (1) A wear-resistant coating for the cargo hold of a dry bulk carrier, the weight percentage of each raw material in its component is:

[0051] Epoxy resin 18% (the raw material that adopts is with embodiment 1).

[0052] Talcum powder 38% (the raw material that adopts is with embodiment 1).

[0053] Mica powder 16% (the raw material that adopts is the same as embodiment 1).

[0054] Organic bentonite 0.5% (the raw material that adopts is the same as embodiment 1).

[0055] Iron oxide red 3.5% (the raw material that adopts is the same as embodiment 1).

[0056] N-butanol 4% (the raw material that adopts is the same as embodiment 1).

[0057] Xylene 10% (the raw material that adopts is the same as embodiment 1).

[0058] Polyamide hardener 10% (the raw material that adopts is the same as embodiment 1).

[0059] (2) The preparation method of the wear-resistant coating for the cargo hold of a dry bulk carrier in Example 2 is the same as in Example 1.

[0060] (3) The...

Embodiment 3

[0062] (1) A wear-resistant coating for the cargo hold of a dry bulk carrier, the weight percentage of each raw material in its component is:

[0063] Epoxy resin 25% (the raw material that adopts is the same as embodiment 1).

[0064] Talcum powder 28% (the raw material that adopts is with embodiment 1).

[0065] Mica powder 12% (the raw material that adopts is the same as embodiment 1).

[0066] Organic bentonite 0.5% (the raw material that adopts is the same as embodiment 1).

[0067] Iron oxide red 3.5% (the raw material that adopts is the same as embodiment 1).

[0068] N-butanol 4.5% (the raw material that adopts is the same as embodiment 1).

[0069] Xylene 10.5% (the raw material that adopts is with embodiment 1).

[0070] Polyamide hardener 16% (the raw material that adopts is the same as embodiment 1).

[0071] (2) The preparation method of the wear-resistant coating for the cargo hold of a dry bulk carrier in Example 3 is the same as in Example 1.

[0072] (3) T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com