Pipe pulling and supporting, cleaning and spraying integrated unit for horizontal centrifugal casting machine

A technology of centrifugal casting machine and combined device, which is applied in trusteeship, can solve the problems of large manpower, material resources, long production cycle and low work efficiency, and achieve the effect of shortening interval time, reducing production cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

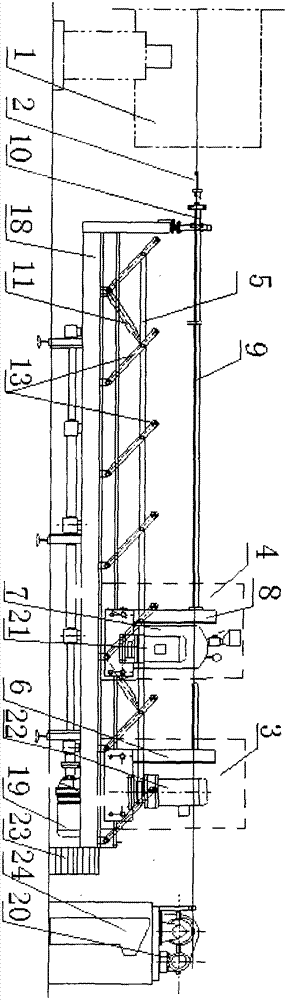

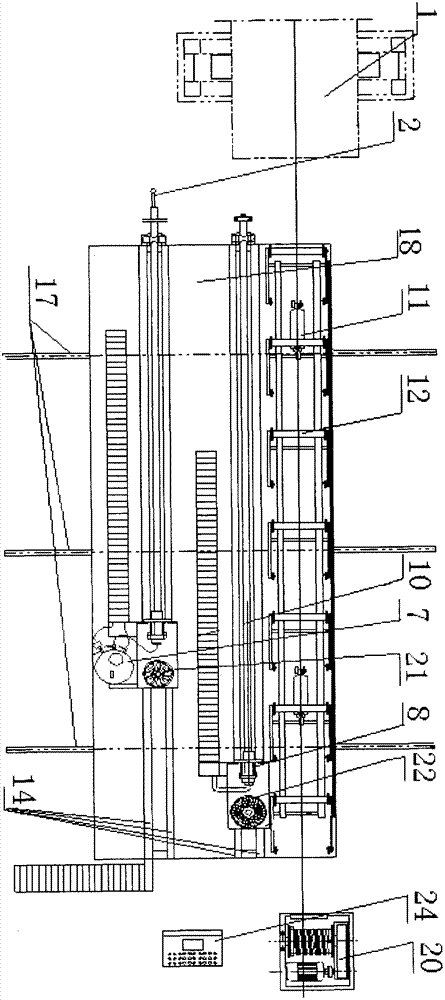

[0012] refer to figure 1 , figure 2 , the combined device for pulling out the custodian, cleaning, and spraying of the horizontal centrifugal casting machine of the present embodiment includes a cleaning device 3 and a spraying device 4, and it also includes a positioning cart 18, a console 24 and a device for pulling out a custodial roll, and the extraction of a custodial roll The device includes a custodial roller set and a hoist 20. A guide rail 17 is fixed on the ground at the tail end of the casting machine 1, and a positioning cart 18 is arranged on the guide rail 17. The custodian roller set, cleaning device 3 and spraying device 4 are installed side by side on the positioning large On the car 18, the hoist 20 is arranged at the right end of the positioning cart 18 and the axis of the centrifugal casting machine 1, and the console 24 is installed near the hoist 20. The upper side of the positioning cart 18 is provided with parallel guide rails 14, which are parallel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com