Two-dimensional high lift device parametrization design method based on NURBS curve and meeting engineering constraints

A technology of increasing lift device and curve, which is applied in the field of parametric design of two-dimensional increasing device to achieve the effect of ensuring the fitting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below, and the examples of the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

[0025] This embodiment is based on the free-form surface curve deformation theory, using the parameterization method of NURBS curves, and proposes a parametric design method of a two-dimensional high-lift device based on NURBS curves that satisfies engineering constraints, specifically including the following steps:

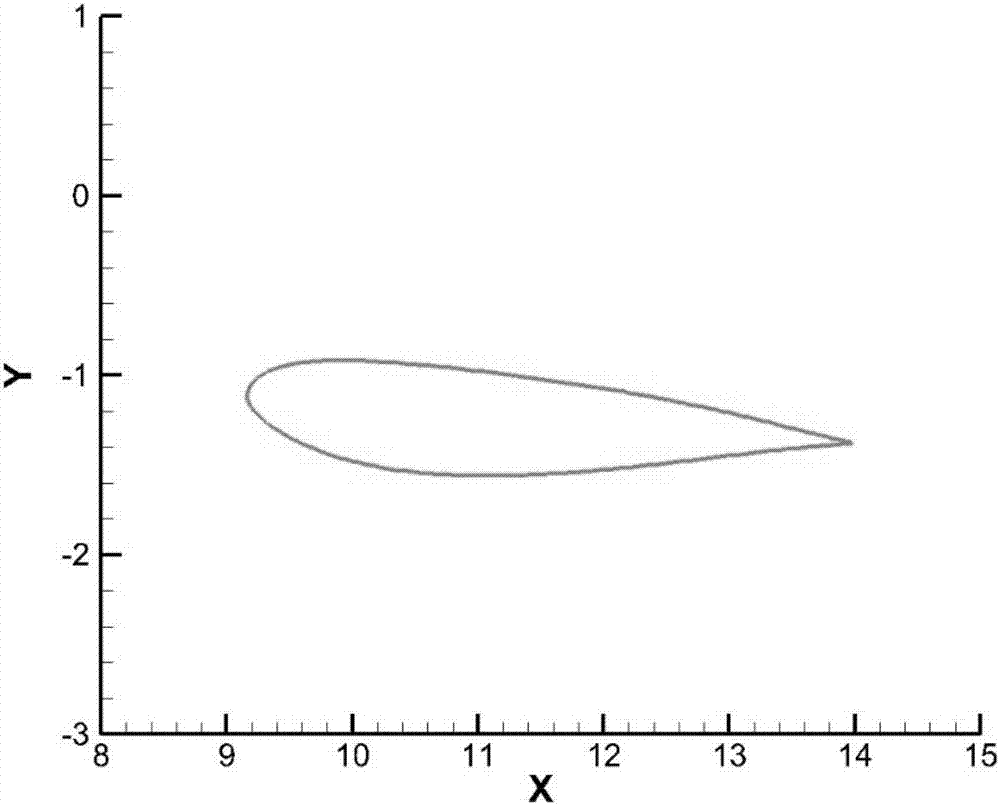

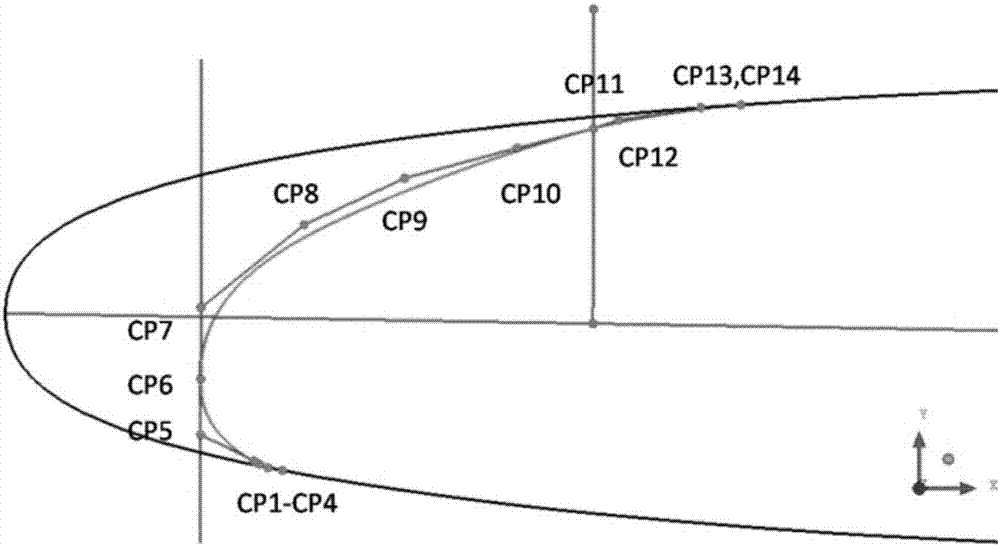

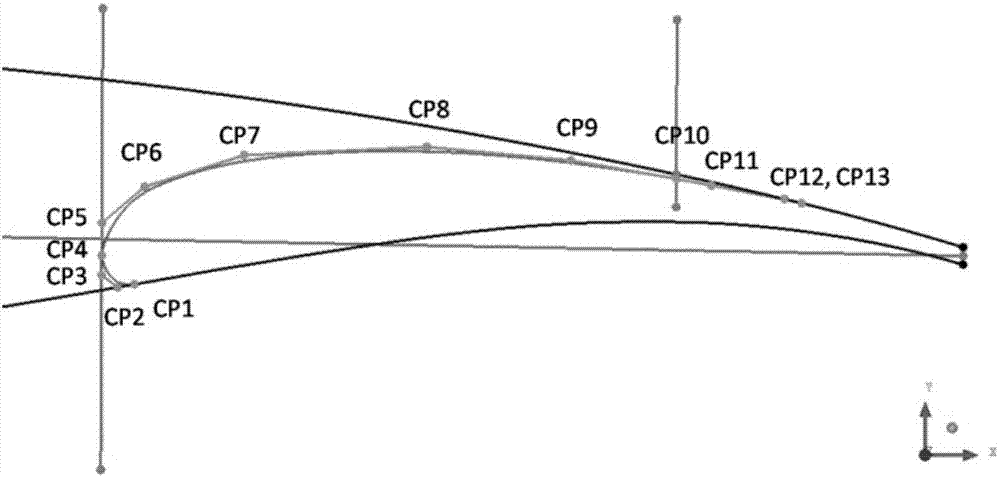

[0026] Step 1: Based on figure 1 The two-dimensional cruising airfoil of the design shown in Fig. The control nodes are arranged on the interface of the main wing, and the slat control points and flap control points are arranged as follows: figure 2 , image 3 shown; and determine the slat deflection angle, slat rotation axis position, flap deflection angle and flap rotation axis position according to the aerodynamic de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com