Attaching transport mechanism of touch screen ultraviolet (UV) laminating machine

A technology of handling mechanism and laminating machine, which is applied in layered products, lamination devices, lamination and other directions, can solve the problems of overflowing glue, poor controllability of turning angle, inability to accurately guarantee the lamination accuracy, etc. The effect of combining precision and thickness to improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

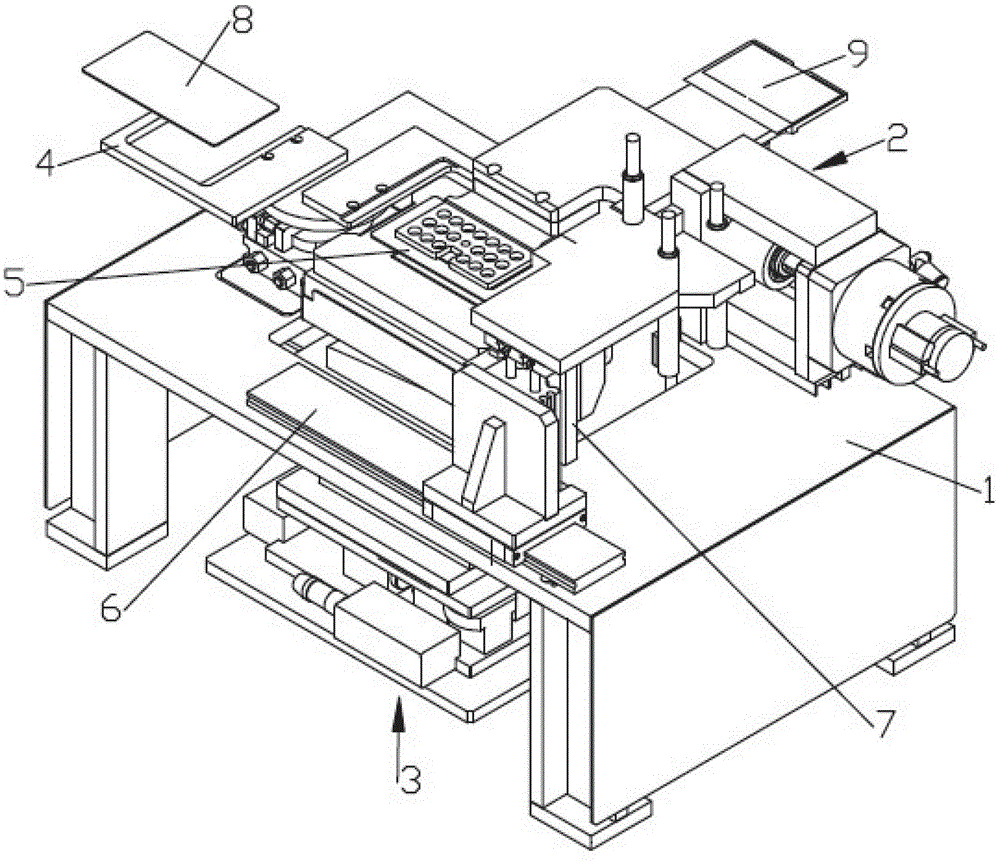

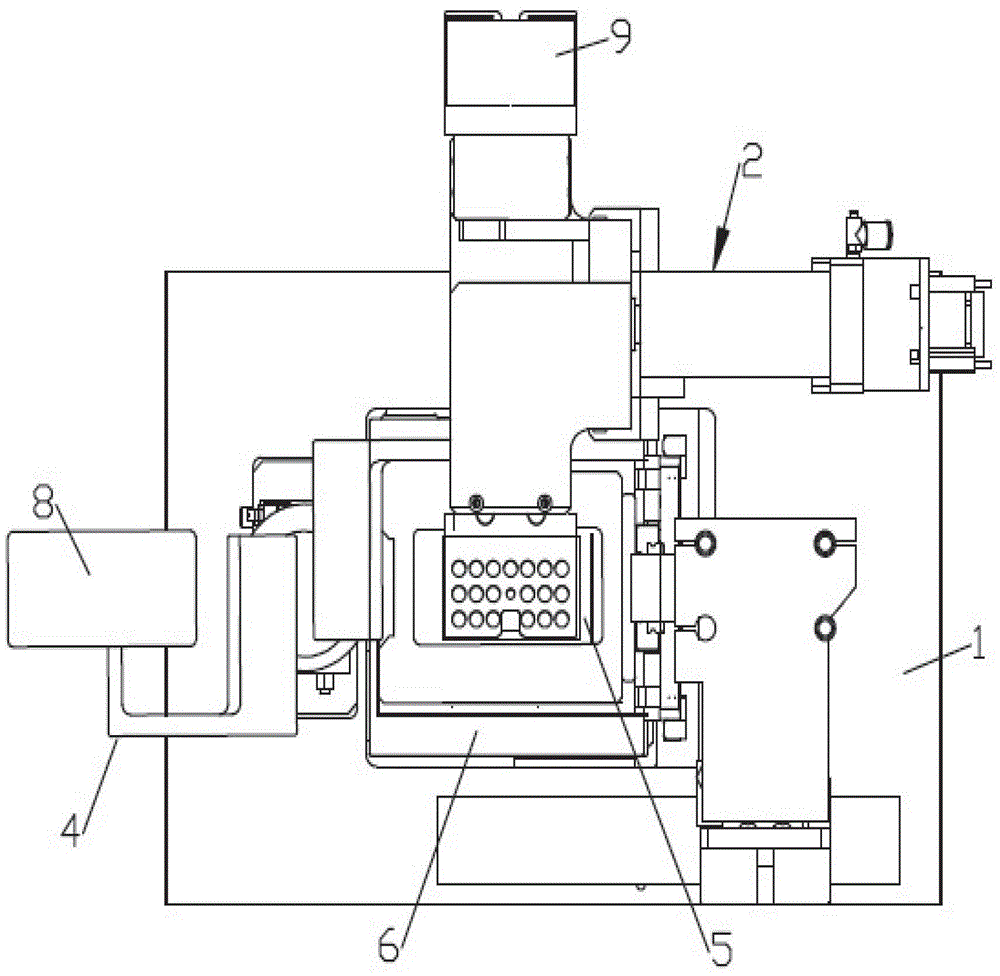

[0024] Such as figure 1 Shown, a kind of touch screen UV laminating machine laminating handling mechanism, including frame 1, cantilever type suction cup turning mechanism 2, four-axis fine-tuning laminating mechanism 3 and double station feeding mechanism 4; described cantilever type suction cup turning mechanism 2 is set Above the frame 1; the four-axis fine-tuning and fitting mechanism 3 is arranged below the frame, the double-station delivery mechanism 4 is located on the side of the four-axis fine-tuning and fitting mechanism 3, and the cantilever suction cup The turning mechanism 2 is located on the rear side of the four-axis fine-tuning fitting mechanism 3;

[0025] The four-axis fine-tuning fitting mechanism 3 includes a workpiece vacuum chuck 5, a servo motor, a linear guide rail 6, and a fitting cylinder 7 located on the top; The guide rail 6 is pressed downwards to ensure the parallelism of the fit; the servo motor is connected to the workpiece sucker 5 through a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com