Method for assessing reliability of main shaft of kilometer deep shaft hoist by considering multiple failure modes

A hoist and reliability technology, which is applied in the field of system reliability evaluation of mechanical products, can solve problems such as difficulty in obtaining failure data and reliability information, and achieve the goals of reducing the number of test designs, accurate and reasonable system reliability, and improving precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

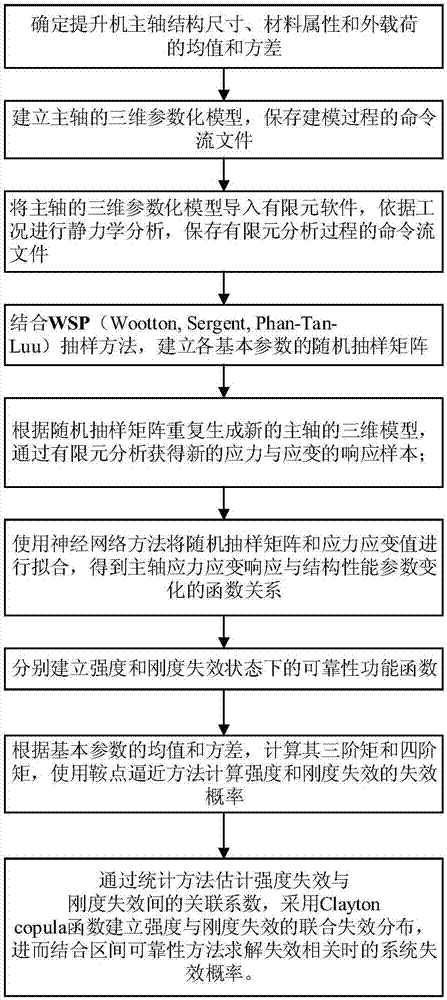

[0043] Such as figure 1 As shown, the system reliability assessment method considering multiple failure modes proposed by the present invention includes the following steps:

[0044] Step 1. Obtain the mean value and variance of dimensional parameters, material properties and working condition load through on-site surveying and mapping and the design drawings of the main shaft of the hoist, and determine the distribution type of each parameter;

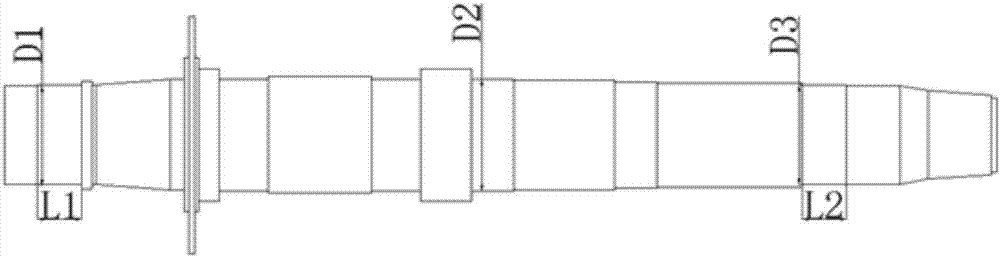

[0045] Step 2. According to the structural parameters of the main shaft of the hoist, a three-dimensional parametric model of the main shaft is established, and the three-dimensional parametric model of the main shaft is imported into the finite element software for static analysis.

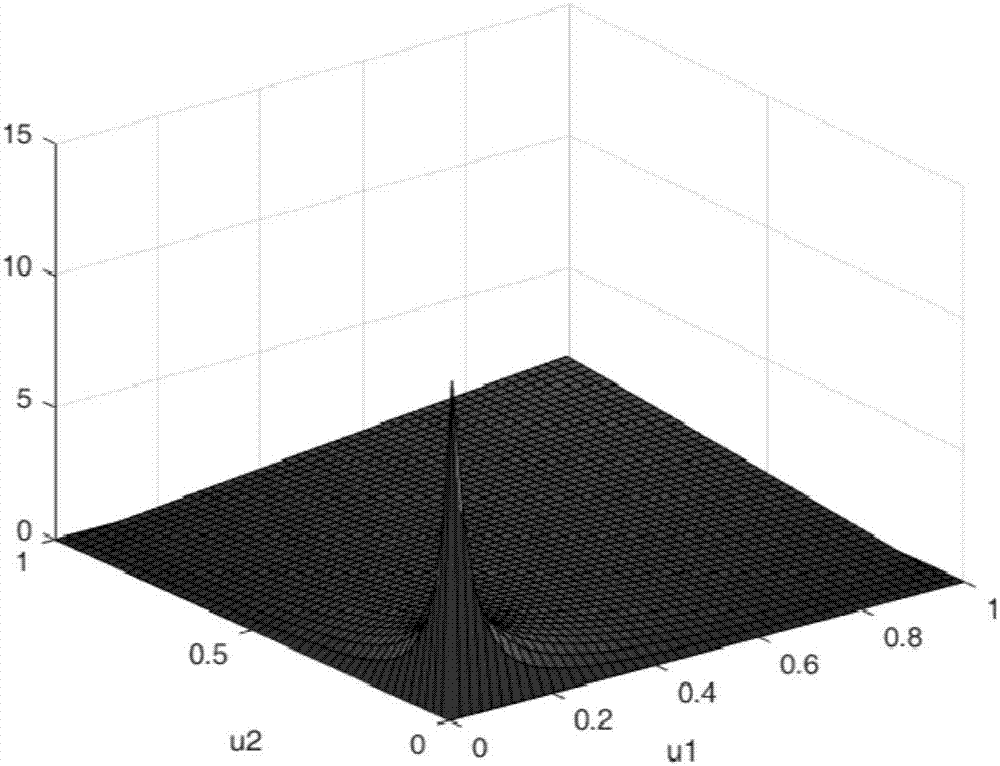

[0046] Step 3, according to the mean value and the variance of each basic parameter of the main axis determined in step 1, in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com