Patents

Literature

88 results about "Stiffness design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

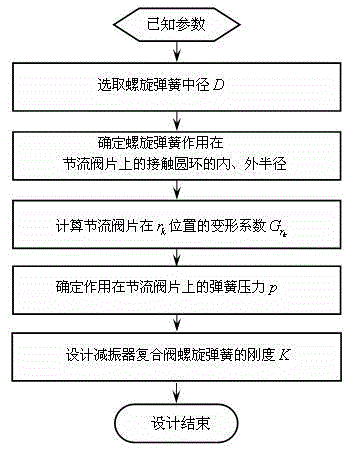

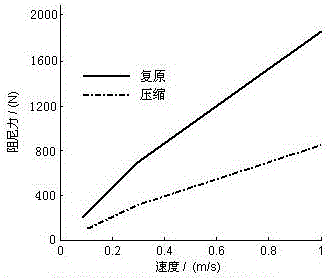

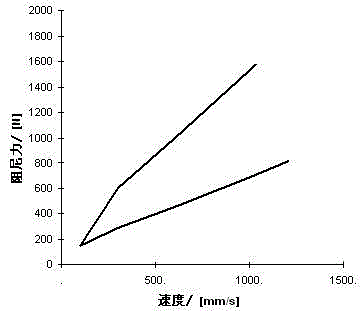

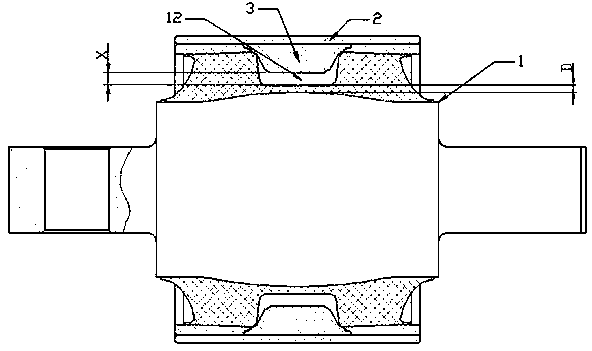

Method for designing stiffness of helical spring of combined valve for shock absorbers

The invention relates to a method for designing the stiffness of a helical spring of a combined valve for shock absorbers, which belongs to the field of shock absorbers. The method is characterized by comprising the following steps: (1) according to the radius of the inner circle of a throttling valve sheet of the combined valve for shock absorbers and the radius at the position of a valve port, selecting an intermediate diameter of the helical spring; (2) determining the inside and outside radii of a contact circular ring (acted on the throttling valve sheet) of the helical spring; (3) calculating the deformation coefficient of the throttling valve sheet at the position of the valve port; (4) determining the spring pressure acted on the throttling valve sheet; and (5) determining the stiffness of the helical spring of the combined valve for shock absorbers. According to the invention, as an analytical design method is adopted, the stiffness design value is more accurate and reliable, thereby avoiding the operations of repeated testing and modifying, lowering the design cost of a shock absorber, and improving the development cycle of the shock absorber; and by using the analytical design method, the fast and accurate design requirements of helical springs of combined valves for shock absorbers for automobiles can be satisfied.

Owner:SHANDONG UNIV OF TECH

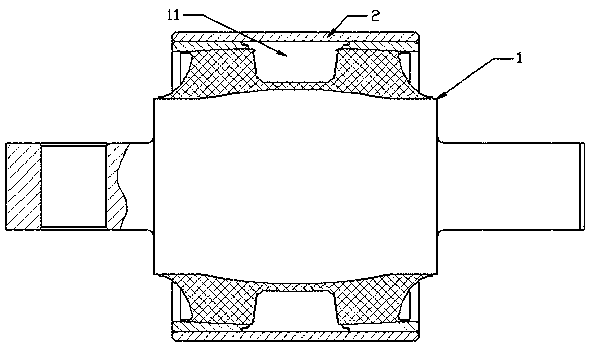

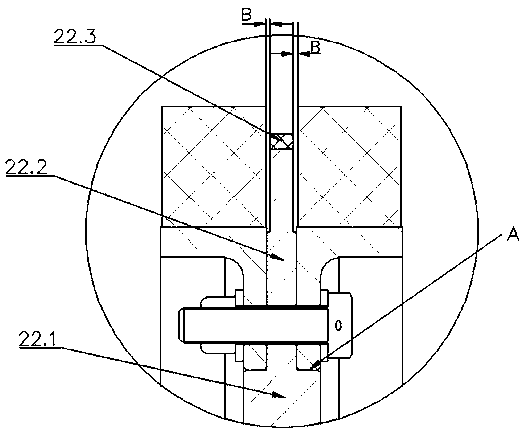

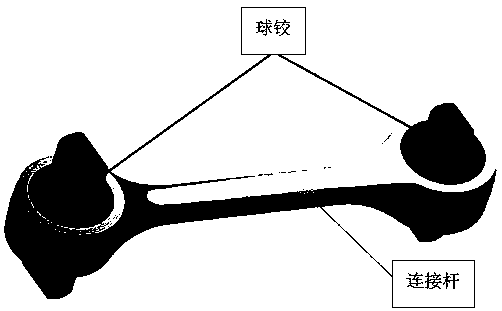

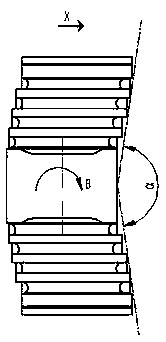

Variable-rigidity spherical hinge and variable-rigidity design method

ActiveCN108999884AIncrease free spaceAvoid enteringGeometric CADSprings/dampers functional characteristicsHinge angleStiffness design

The invention discloses a variable-rigidity spherical hinge and a design method. The variable-rigidity spherical hinge comprises a spherical hinge body and an outer sleeve, wherein the outer sleeve sleeves the spherical hinge body; the variable-rigidity spherical hinge and the design method are characterized in that an annular sealing space in the circumferential direction is formed between the spherical hinge body and the outer sleeve, the annular sealing space penetrates into a rubber layer of the spherical hinge body, an annular stopping block is arranged in the annular sealing space, and the annular sealing space is not completely filled with the annular stopping block; and an annular gap which is arranged in the axial direction is formed between the spherical hinge body and the annular stopping block, the minimum radial width of the annular gap is X, and X is larger than 0.5mm and less than 10 mm. According to the variable-rigidity spherical hinge and the design method, the requirements that the required rigidity is small of the spherical hinge under a small load, the required rigidity is obviously increased of the spherical hinge under a large load and the bearing requirements of the time limit can be met; and external dust, soils and even sand particles can be effectively prevented from entering the interior of the spherical hinge, the release space of the rubber is increased, the rubber is effectively prevented from being bent and deformed, the increase of the pre-compression amount of the product is facilitated, the generation of rubber cracks is prevented, and thefatigue life is prolonged.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

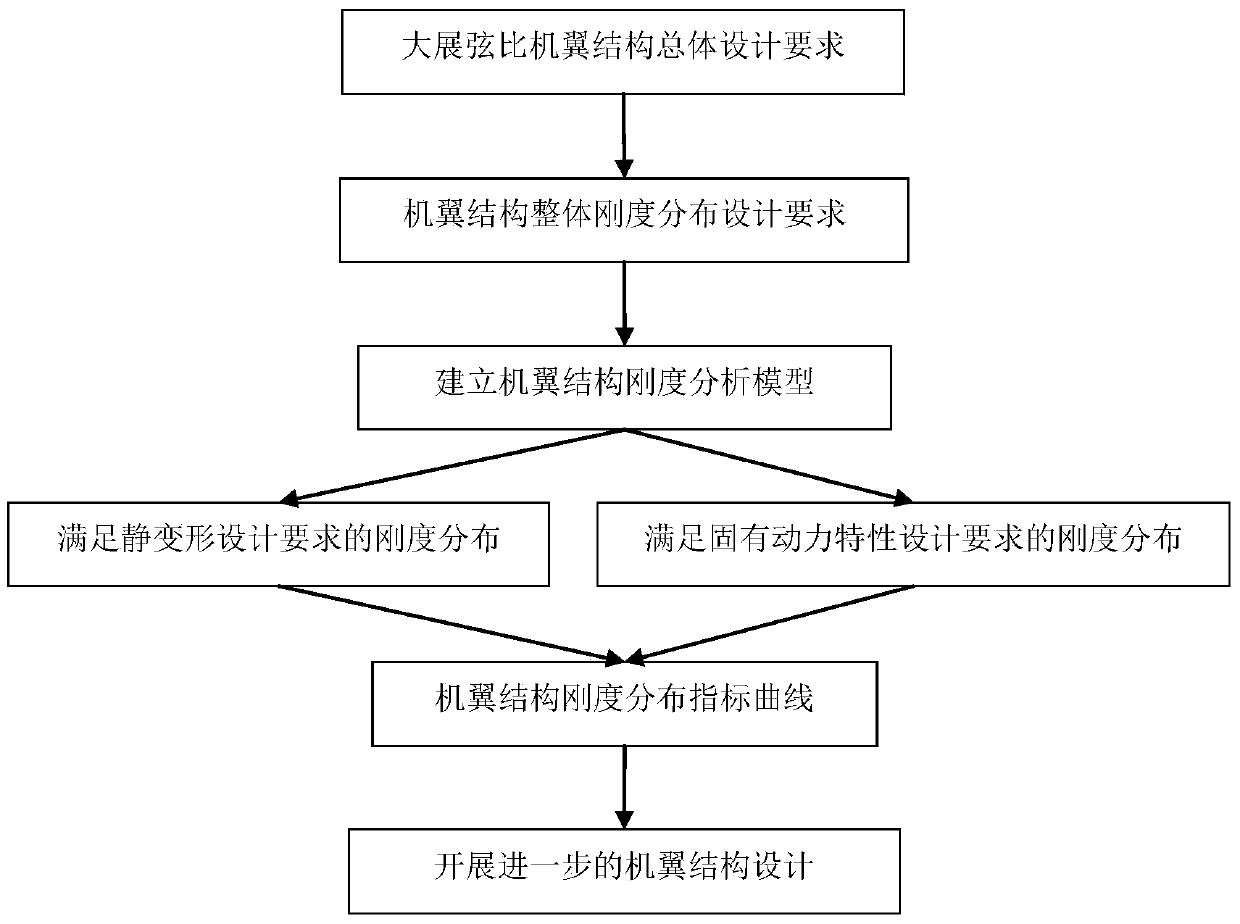

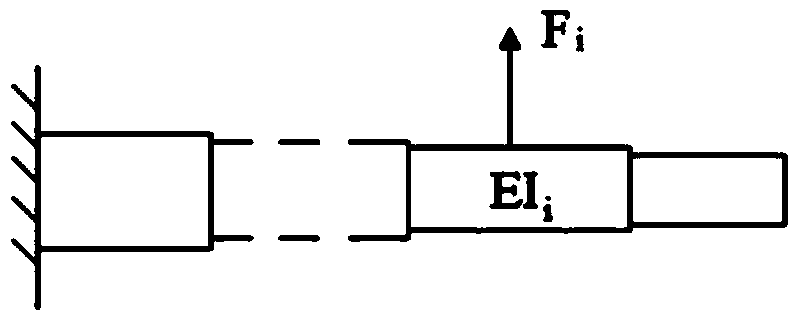

Determining method for structural stiffness index of high-aspect-ratio wing

InactiveCN103745066AAvoid passivityImprove design qualitySpecial data processing applicationsAviationStiffness index

The invention discloses a determining method for a structural stiffness index of a high-aspect-ratio wing, and belongs to the technical field of aerospace engineering. The determining method mainly includes the following steps: step 1, analyzing and determining structural stiffness design requirements of the wing; step 2, creating a structural stiffness analysis model of the wing; step 3, analyzing structural stiffness distribution, meeting the design requirements, of the wing; step 4, calculating a structural stiffness distribution index curve of the wing by a stiffness simulation analysis platform. According to conventional wing structural design methods, the stiffness design requirements are regarded as starting points, preliminary structural design is firstly performed according to design experiences, stiffness check is then performed, and the structural design is modified repeatedly according to check results to meet the stiffness design requirements. According to the determining method, for passivity and defects of the conventional wing structural design processes, the stiffness distribution index curve is provided before starting of the structural design to guide the wing structural design, so that iteration modification processes are reduced, and scientificity and design efficiency of the wing structural design are improved.

Owner:BEIHANG UNIV

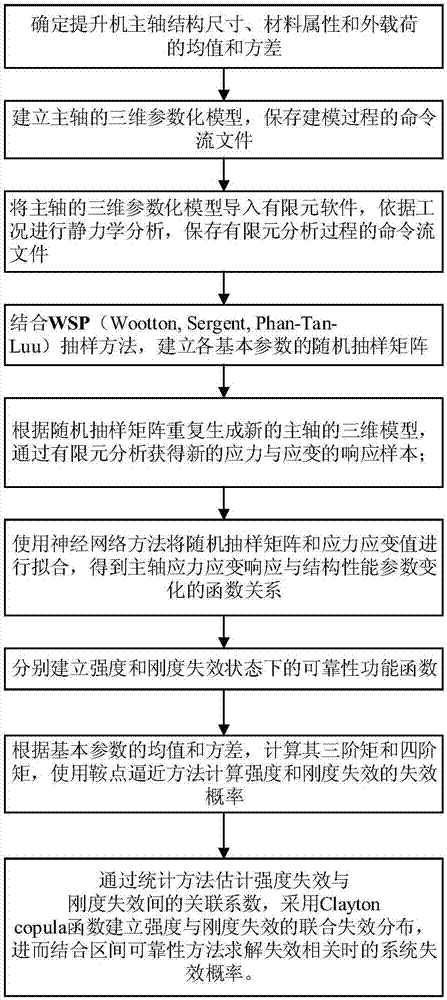

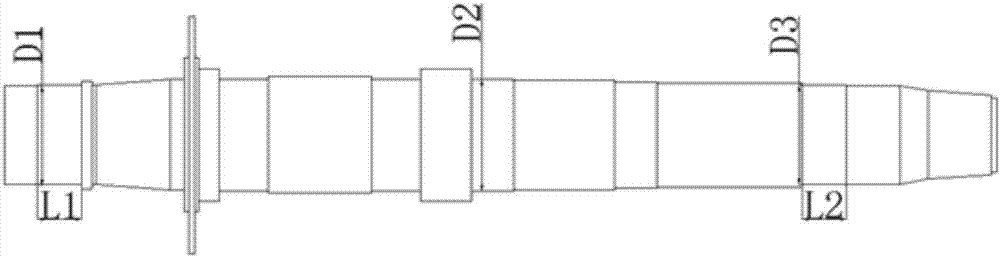

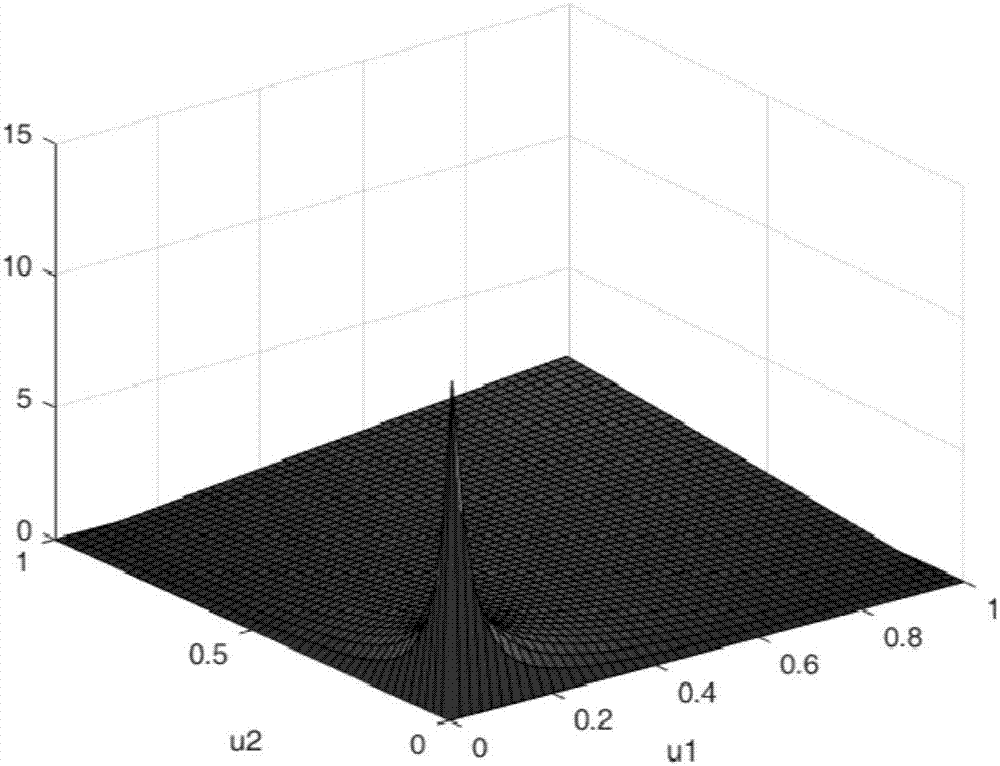

Method for assessing reliability of main shaft of kilometer deep shaft hoist by considering multiple failure modes

ActiveCN107291989AGuaranteed fitting accuracyReduce the number of experimental designsDesign optimisation/simulationFuzzy logic based systemsProbit modelFinite element method

The invention discloses a method for assessing the reliability of a main shaft of a kilometer deep shaft hoist by considering multiple failure modes. The method comprises the steps of firstly, building a parametric three-dimensional model of the main shaft according to the structure size of the main shaft; secondly, according to a probability attribute of a random variable of the main shaft, establishing a sampling matrix of the random variable, and solving strength and stiffness response of the main shaft under the sampling matrix by using a finite element method; thirdly, establishing an explicit function between the response and the random variable matrix by using a neutral network method, and according to strength and stiffness design criteria, establishing explicit functions in strength and stiffness failure modes; fourthly, calculating two failure probabilities by using a saddle point approximation method; and finally, building a joint failure probability model between the two failure modes through a Clayton copula function, and solving system reliability under joint failure by using an interval reliability method. According to the method, the probability correlation between strength failure and stiffness failure is considered, so that the system reliability of the main shaft of the hoist can be assessed more accurately and reasonably.

Owner:CHINA UNIV OF MINING & TECH

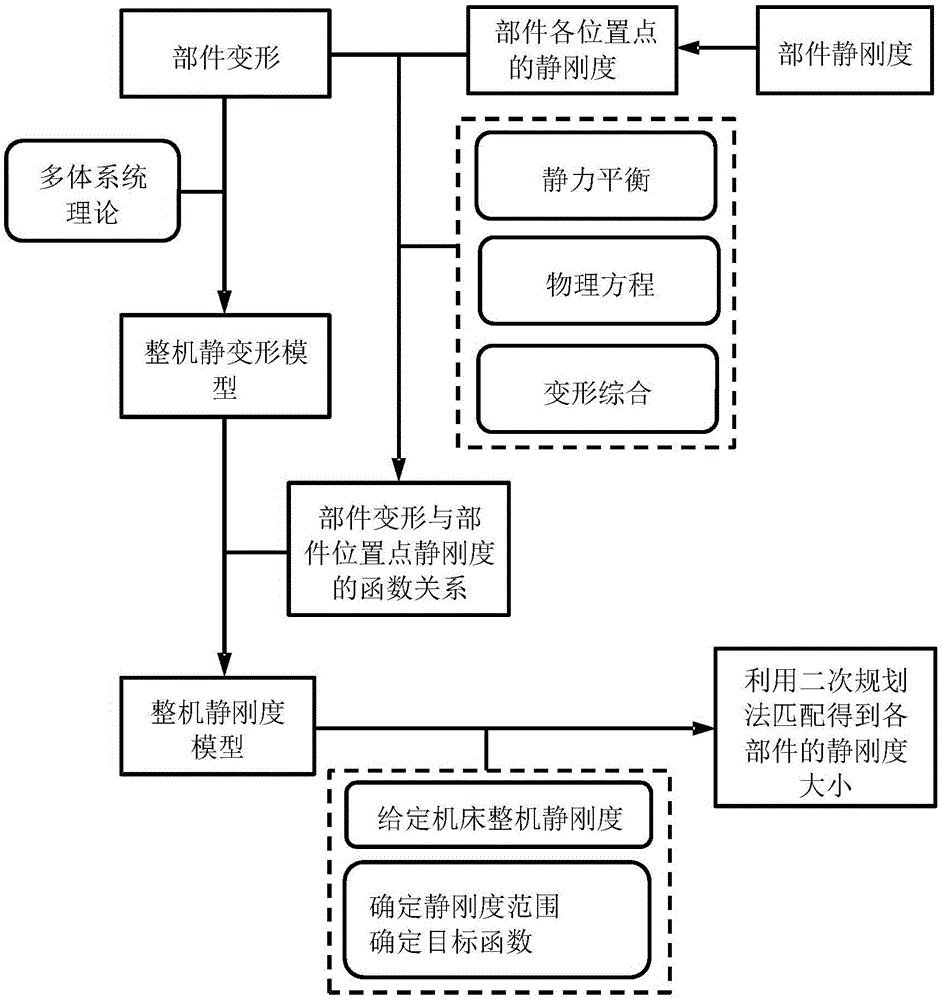

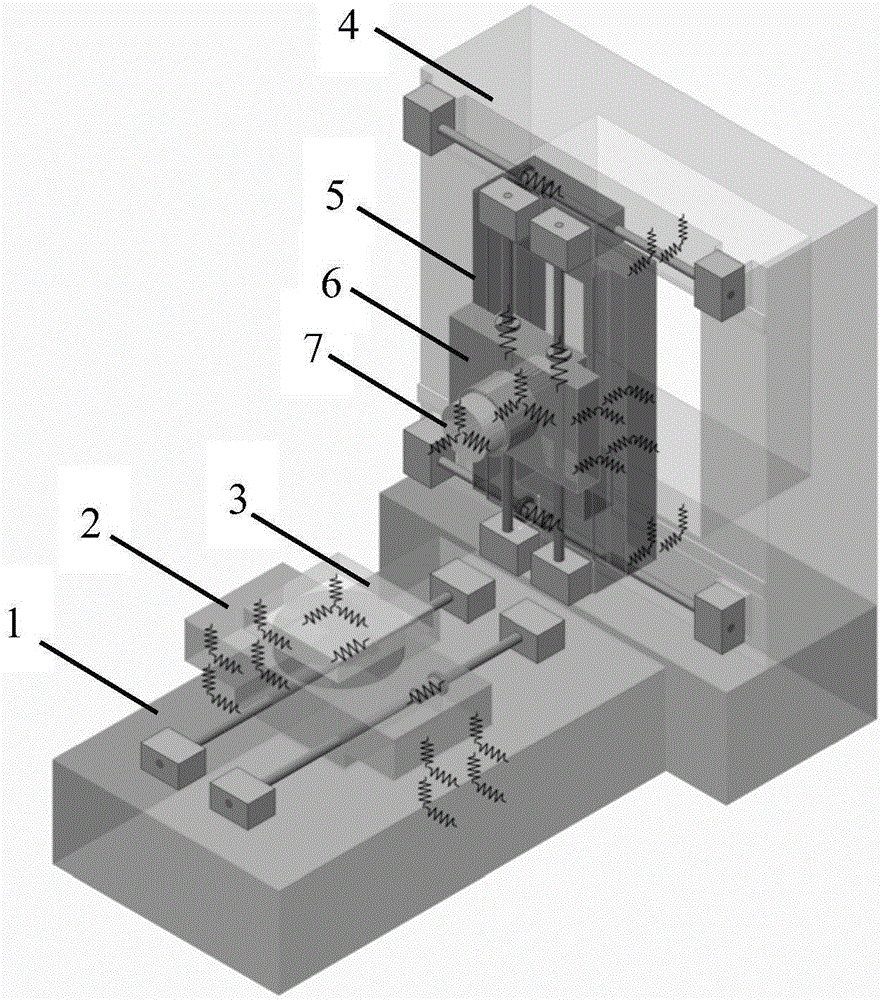

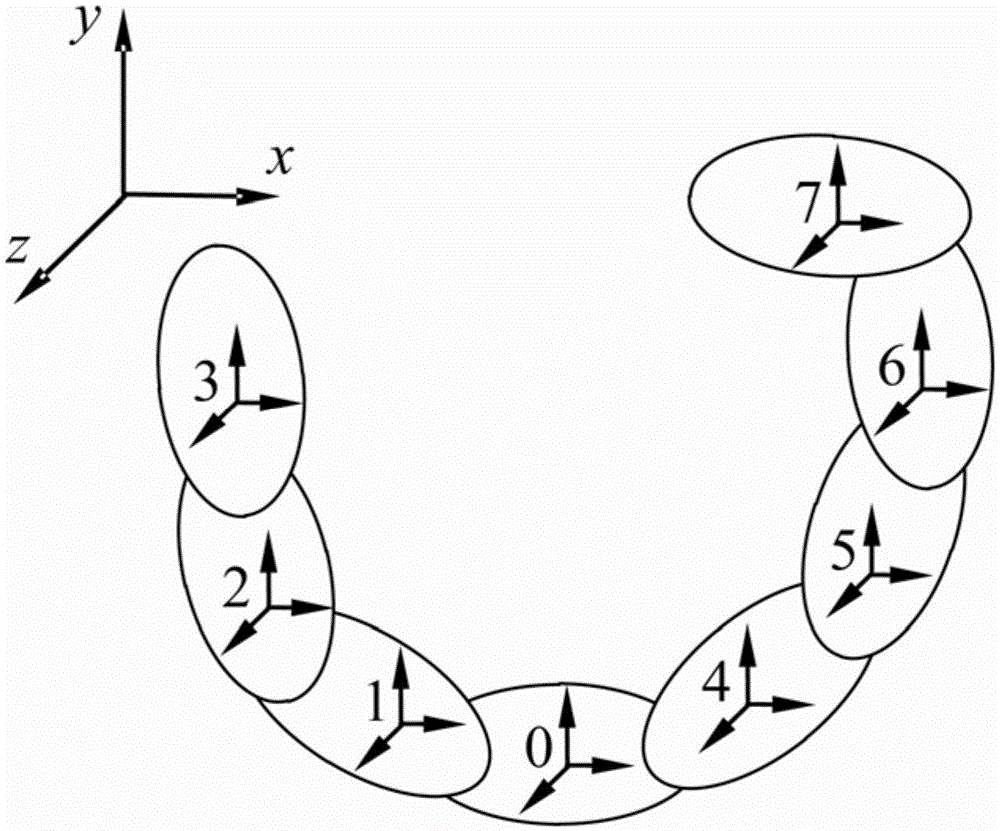

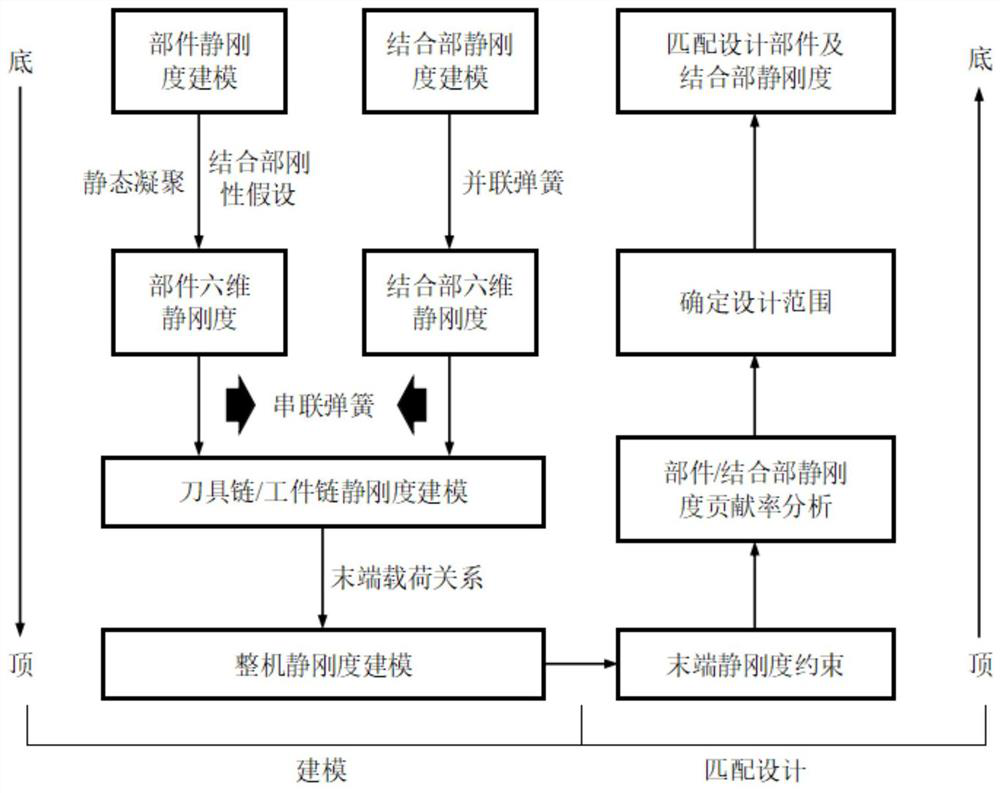

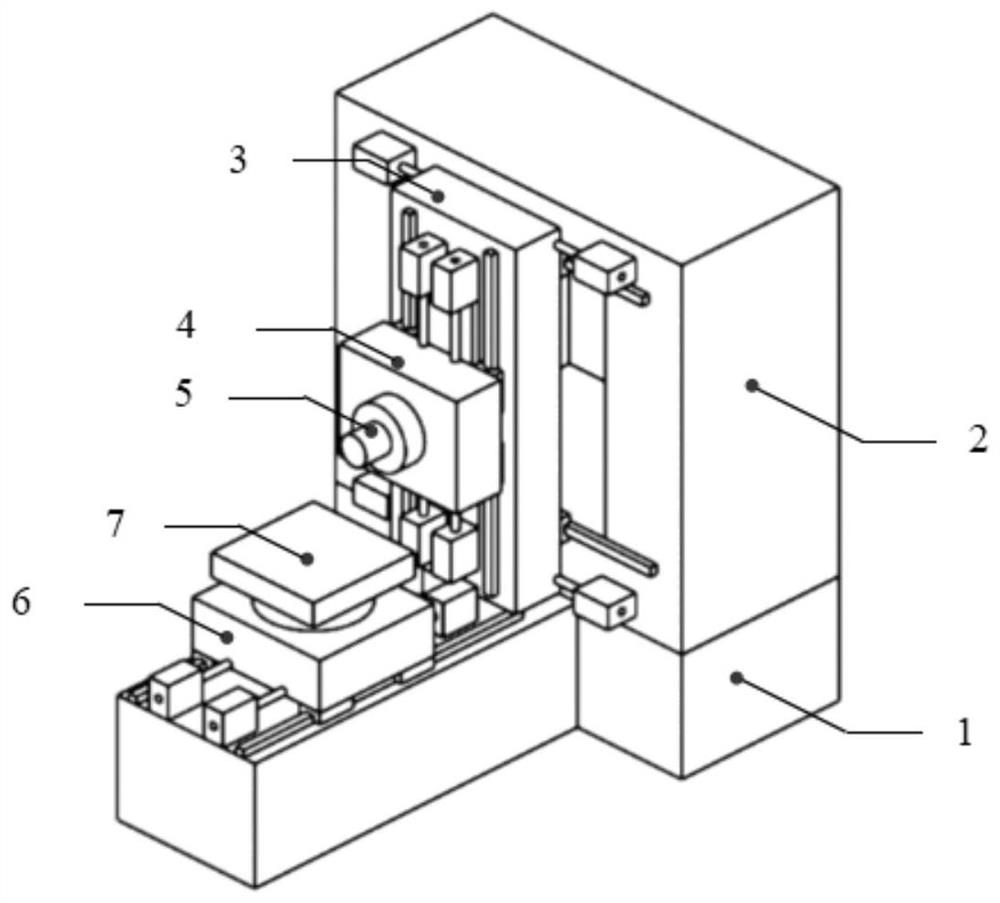

Whole machine static stiffness matching and designing method in view of machine tool top-down design

InactiveCN105005673AStatic Stiffness Estimation and ControlImprove machining accuracySpecial data processing applicationsTangential forceForce analysis

The invention discloses a whole machine static stiffness matching and designing method in view of machine tool top-down design. The method comprises steps: static stiffness of each part of the machine tool in a difference place is defined; a static stiffness model for the whole machine is built; force analysis is carried out on each part of the machine tool, a force condition of each part is obtained, and normal forces and tangential forces of the machine tool body, a vertical column and a slide carriage are obtained through analysis; a function relation between deformation of each part of the machine tool and static stiffness of each part of the machine tool is built; the static stiffness model for the whole machine is built; and on the basis of the static stiffness model for the whole machine, static stiffness matching and designing are carried out. In the machine tool concept design stage, the whole machine static stiffness given by a user serves as a target, machine tool static stiffness design is carried out in a top-down mode, and in the condition in which static stiffness in three directions at the tail end of the whole machine tool is given, reasonable static stiffness for each part is obtained through matching and designing. The static stiffness of the machine tool can be estimated and controlled at the beginning of the design, the efficiency and the accuracy of design are improved, the processing precision of the machine tool is improved, product performance estimation can also be carried out, and the production cost and the manufacturing cost are reduced.

Owner:TIANJIN UNIV

Collocated metal frame PZT micro-actuator with a lower stiffness suspension design

Owner:SAE MAGNETICS (HK) LTD

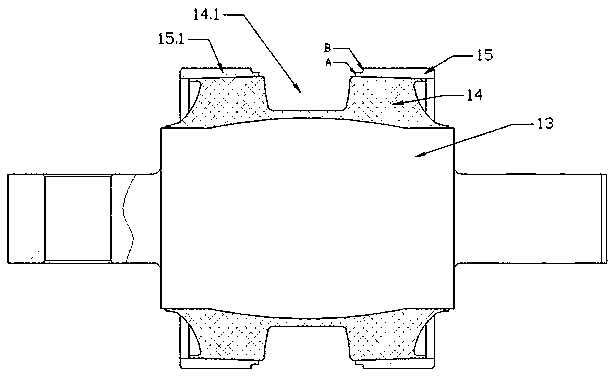

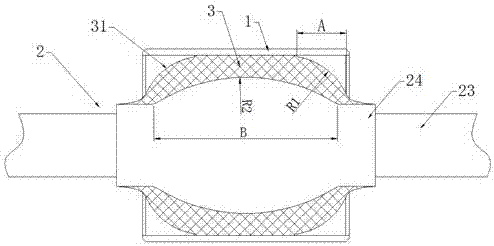

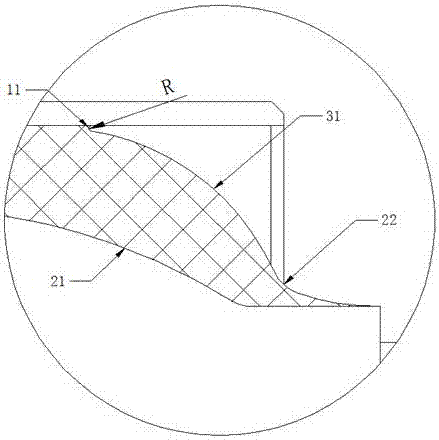

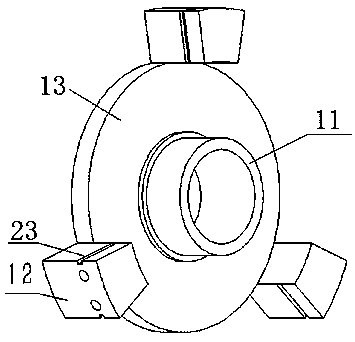

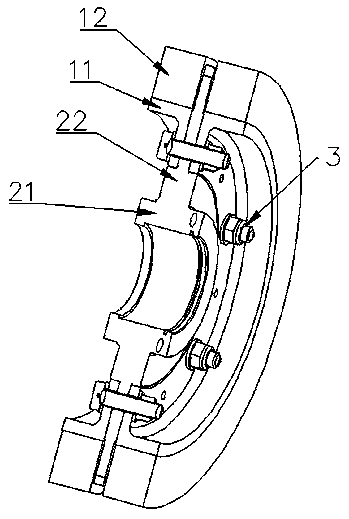

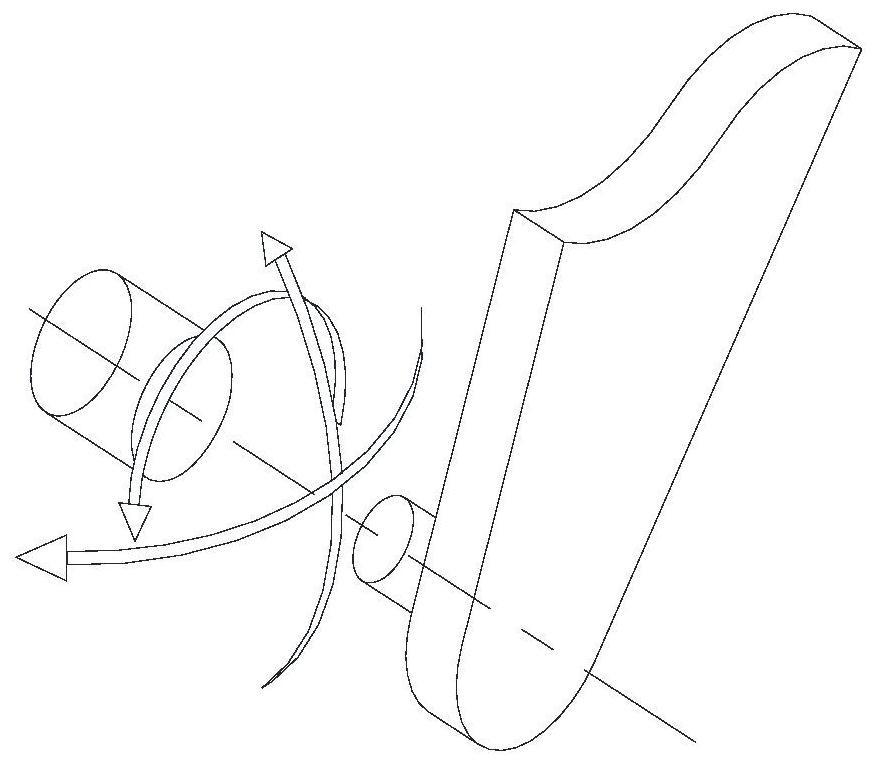

Traction spherical hinge for rail vehicles and rigidity design method of traction spherical hinge

ActiveCN107161169AAdjustable axial deformationSatisfy the load requirementSpringsBogie-underframe connectionsVulcanizationClassical mechanics

A traction spherical hinge for rail vehicles comprises a case, a mandrel and a rubber layer bonded between the case and the mandrel through vulcanization. The traction spherical hinge is characterized in that the middle section of a bonding part for the mandrel and the rubber layer is an arc surface bulge bulging outwards in the radial direction, the center line of the arc surface bulge coincides with that of the mandrel, the deformation profile of the rubber layer is a convex arc surface gradually getting close to the inner wall of the case from outside to inside in the axial direction, the arc radius of the deformation profile is R1, the arc radius of the arc surface bulge is R2, and R1 is smaller than R2. Rigidity adjustment can be performed on the axis, diameter, deviation and torque of the spherical hinge can be realized, and the non-linear rigidity characteristics and fatigue resistance of the spherical hinge in the bearing process can be improved. The invention further provides a rigidity design method of the traction spherical hinge for the rail vehicles.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

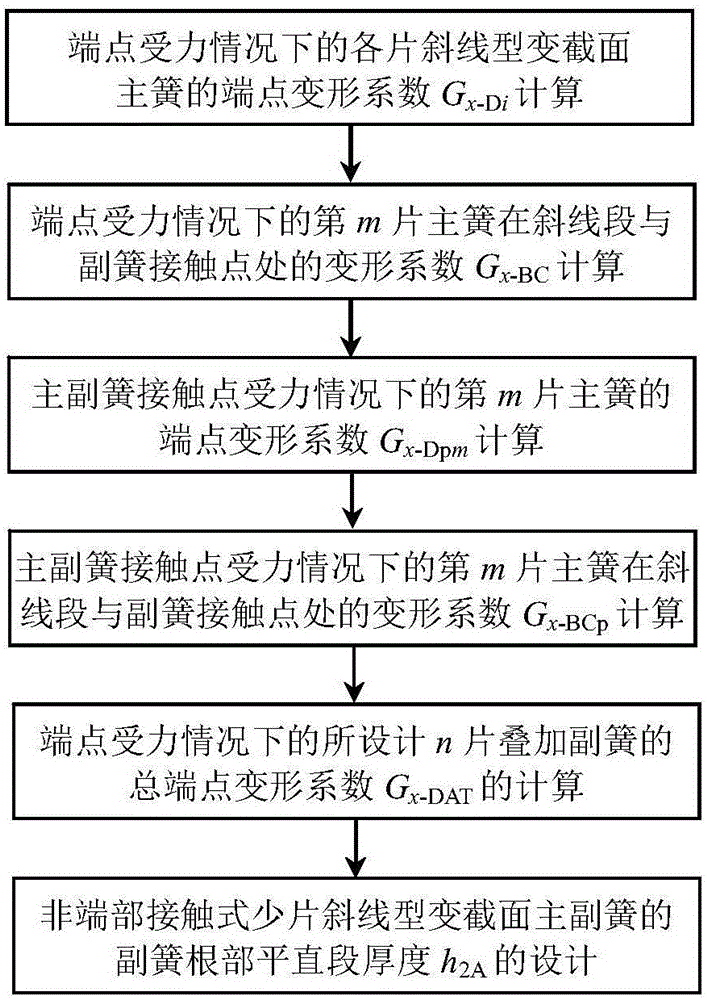

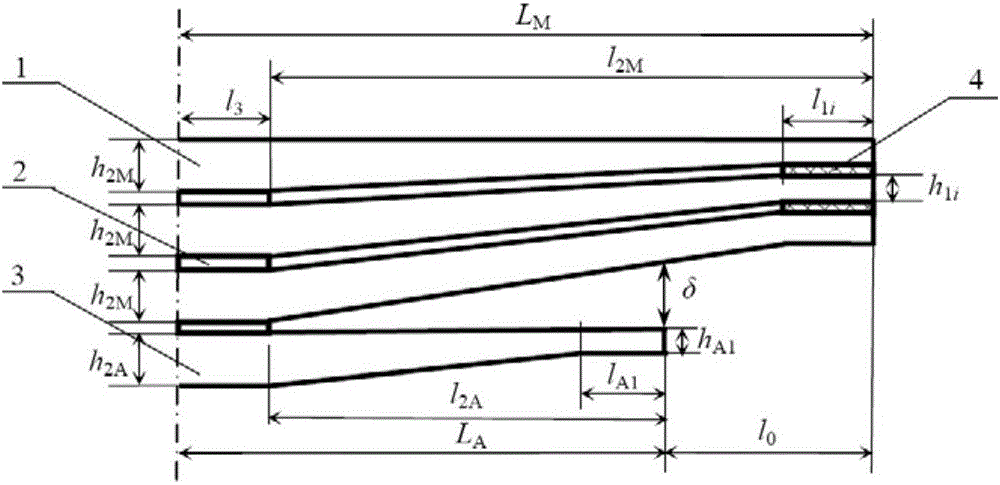

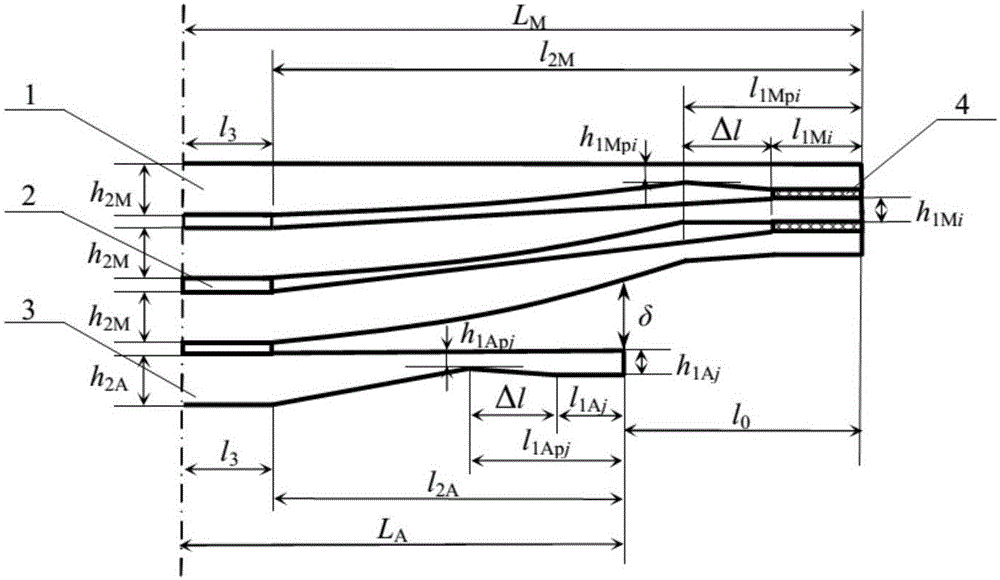

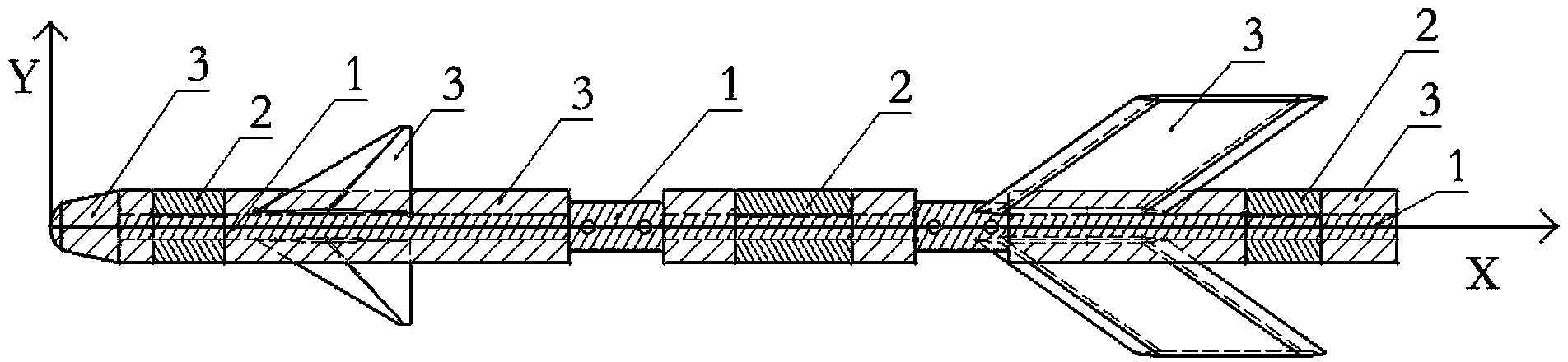

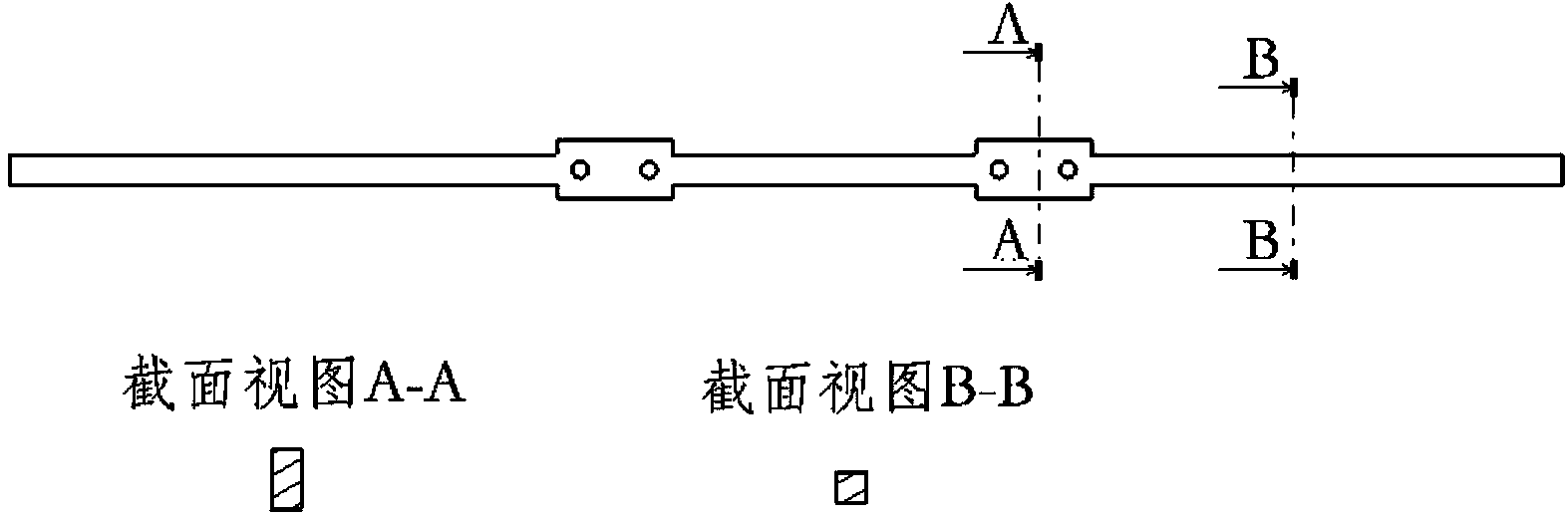

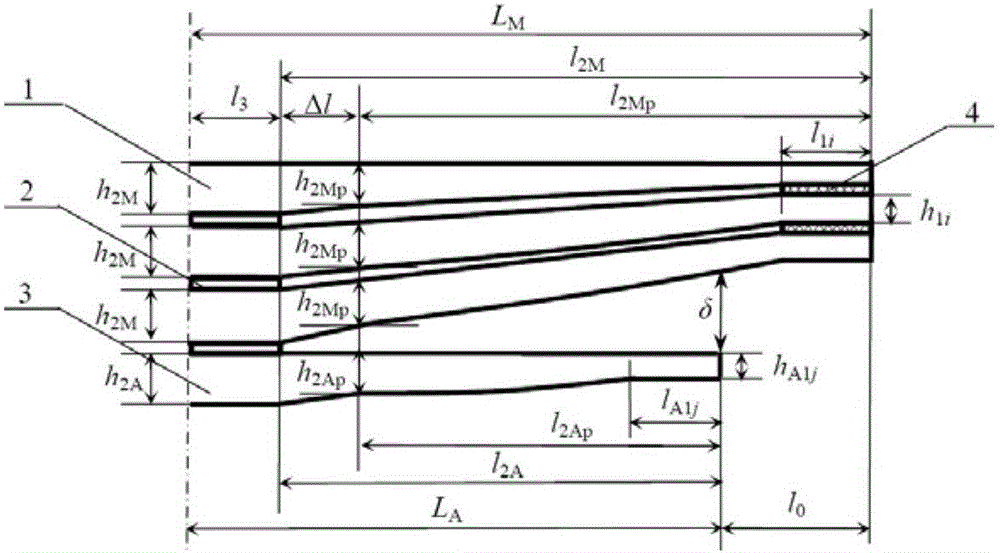

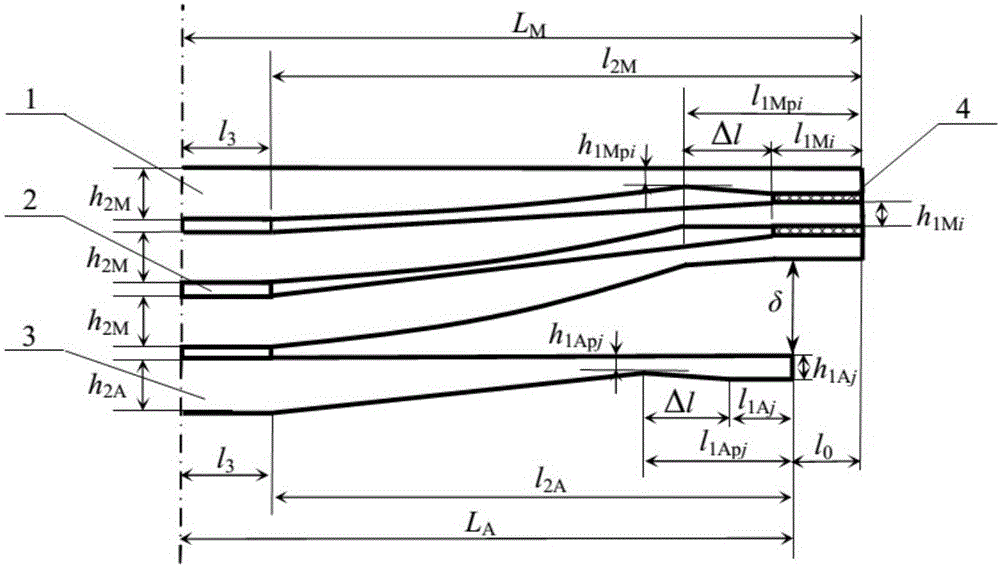

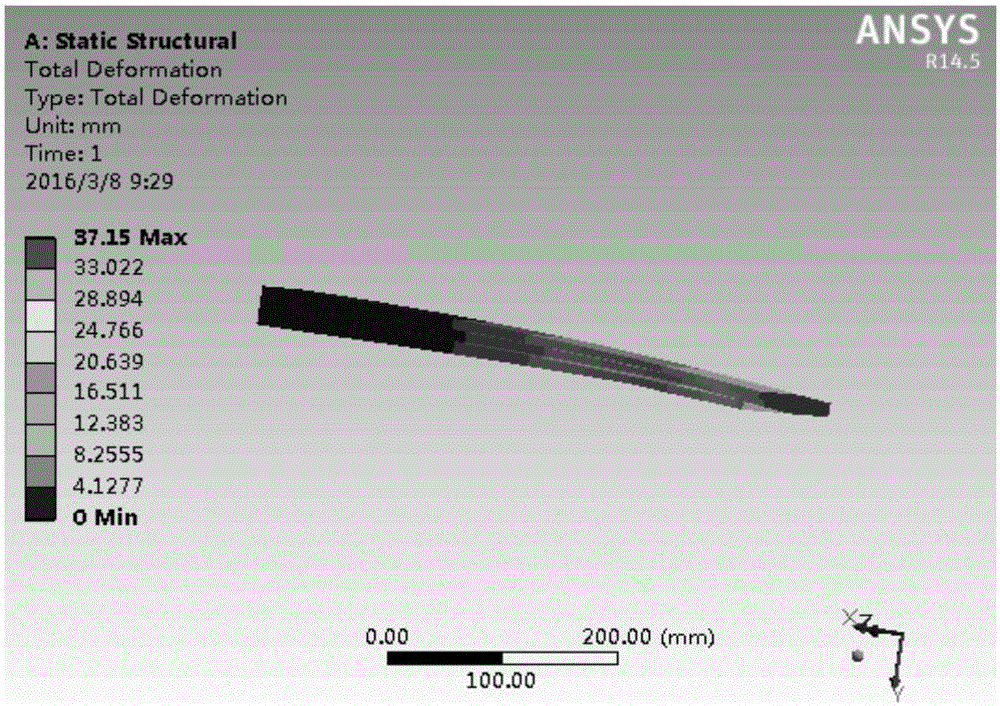

Design method for root thickness of non-end-contact few-leaf oblique-line type auxiliary spring

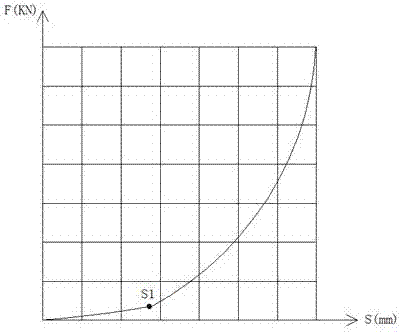

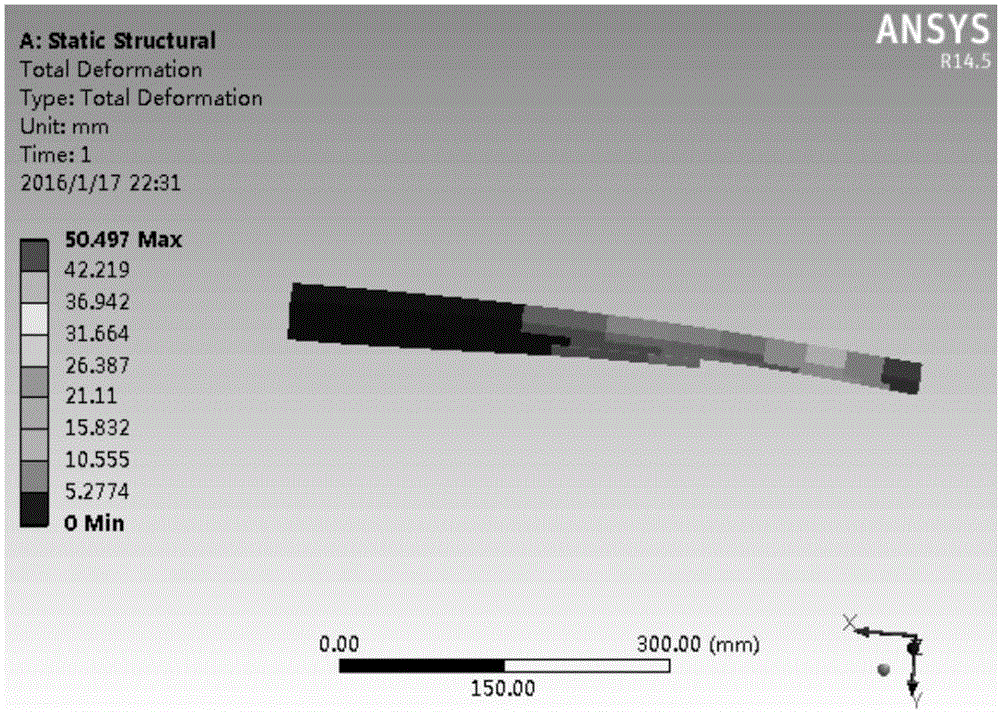

ActiveCN105864335AAccurate and reliable design valueImprove the design levelGeometric CADLeaf springsEngineeringOblique line

The invention relates to a design method for a root thickness of a non-end-contact few-leaf oblique-line type auxiliary spring, and belongs to the technical field of suspension steel plate springs. The design method disclosed by the invention is capable of designing a thickness of a straight section of a root of the non-end-contact few-leaf oblique-line type variable-section auxiliary spring according to the structural parameters and elasticity modulus of each main spring of a non-end-contact few-leaf oblique-line type variable-section main-auxiliary spring, the length of the auxiliary spring, the thickness ratio of the oblique-line segments of the auxiliary spring, and a composite stiffness design requirement value KMAT of the main-auxiliary spring. Through examples and simulation verification, the design method for the root thickness of the non-end-contact few-leaf oblique-line type variable-section auxiliary spring, which is provided by the invention, is correct, an accurate and reliable design value of the root thickness of the auxiliary spring can be obtained, a reliable design method is provided for the root thickness of the auxiliary spring, and the design level, product quality and performance, and vehicle running smoothness of the non-end-contact few-leaf oblique-line type variable-section main-auxiliary spring are improved by virtue of the method; and meanwhile, design and test expenses can also be reduced, and the development speed of products can be accelerated.

Owner:山东恒日悬架弹簧股份有限公司

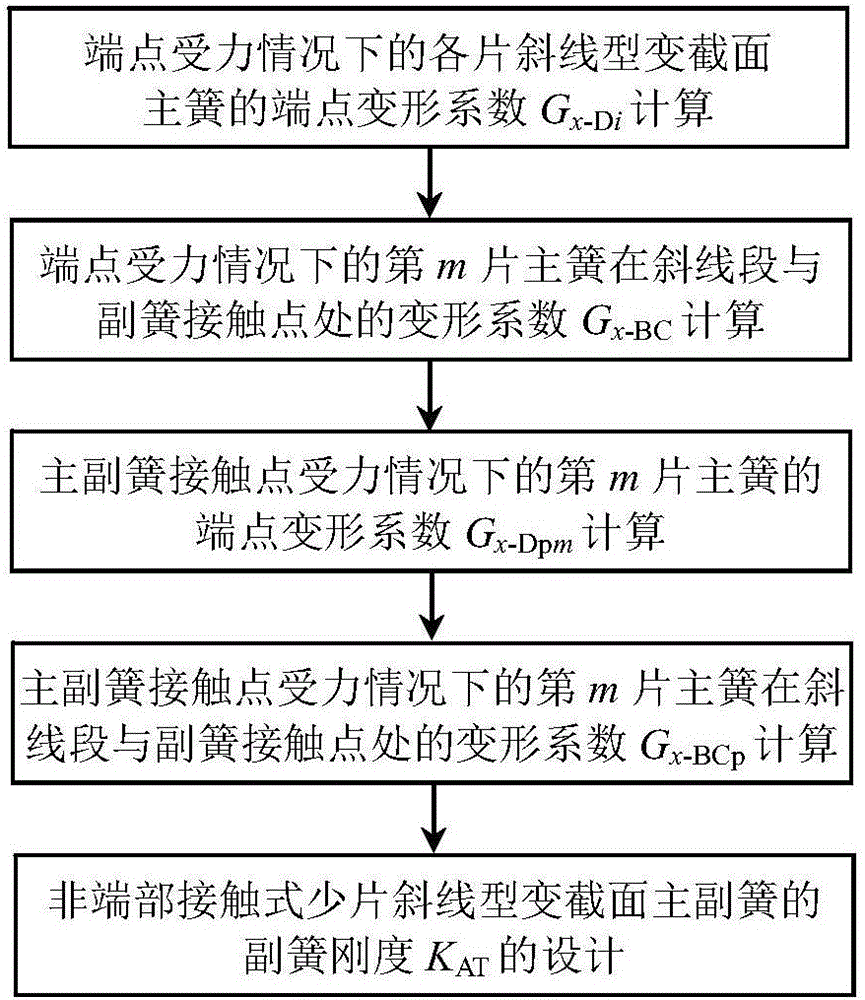

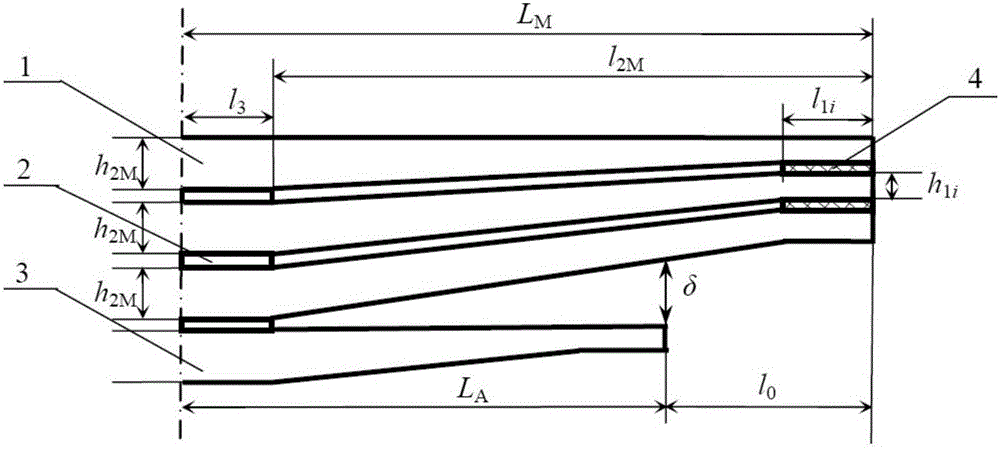

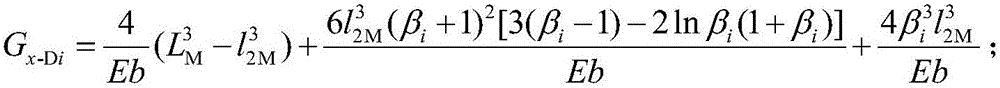

Design method for stiffness of auxiliary spring of non-end-contact few-leaf oblique-line type main-auxiliary spring

ActiveCN105864336AImprove the design levelQuality improvementGeometric CADLeaf springsStiffness designOblique line

The invention relates to a design method for a stiffness of an auxiliary spring of a non-end-contact few-leaf oblique-line type main-auxiliary spring, and belongs to the technical field of suspension steel plate springs. The design method disclosed by the invention is capable of designing the stiffness of the auxiliary spring of the non-end-contact few-leaf oblique-line type main-auxiliary spring according to the structural parameters and elasticity modulus of each main spring of the non-end-contact few-leaf oblique-line type variable-section main-auxiliary spring, the length of the auxiliary spring, and a composite stiffness design requirement value of the main-auxiliary spring. Through examples and experimental test, the design method for the stiffness of the auxiliary spring of the non-end-contact few-leaf oblique-line type variable-section main-auxiliary spring, which is provided by the invention, is correct, an accurate and reliable design value of the stiffness of the auxiliary spring can be obtained, a reliable technical foundation is laid for a design for the auxiliary spring of the non-end-contact few-leaf oblique-line type variable-section main-auxiliary spring, and the design level, product quality and performance, and vehicle running smoothness of the non-end-contact few-leaf oblique-line type variable-section main-auxiliary spring are improved by virtue of the method; and meanwhile, design and test expenses can also be reduced, and the development speed of products can be accelerated.

Owner:山东恒日悬架弹簧股份有限公司

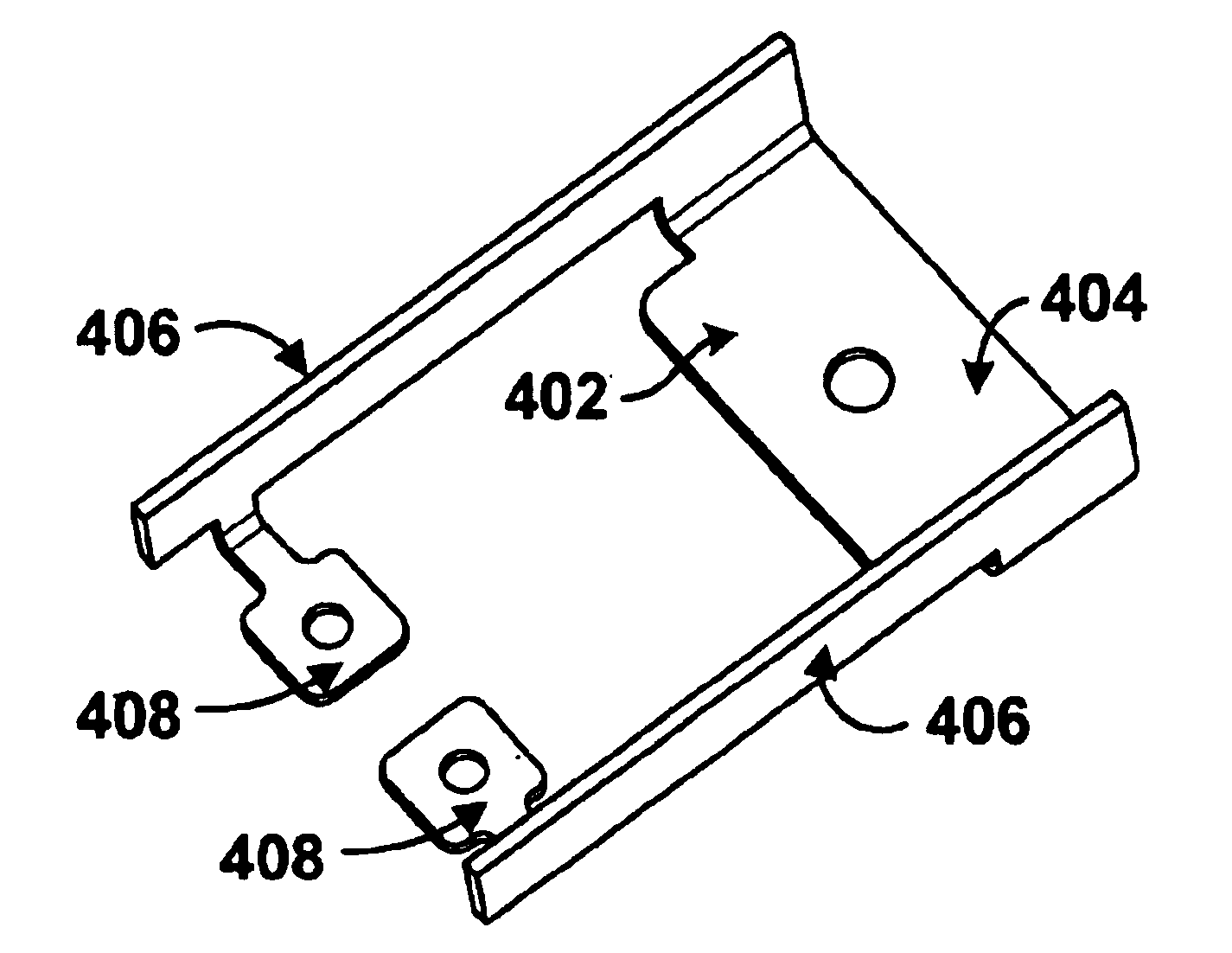

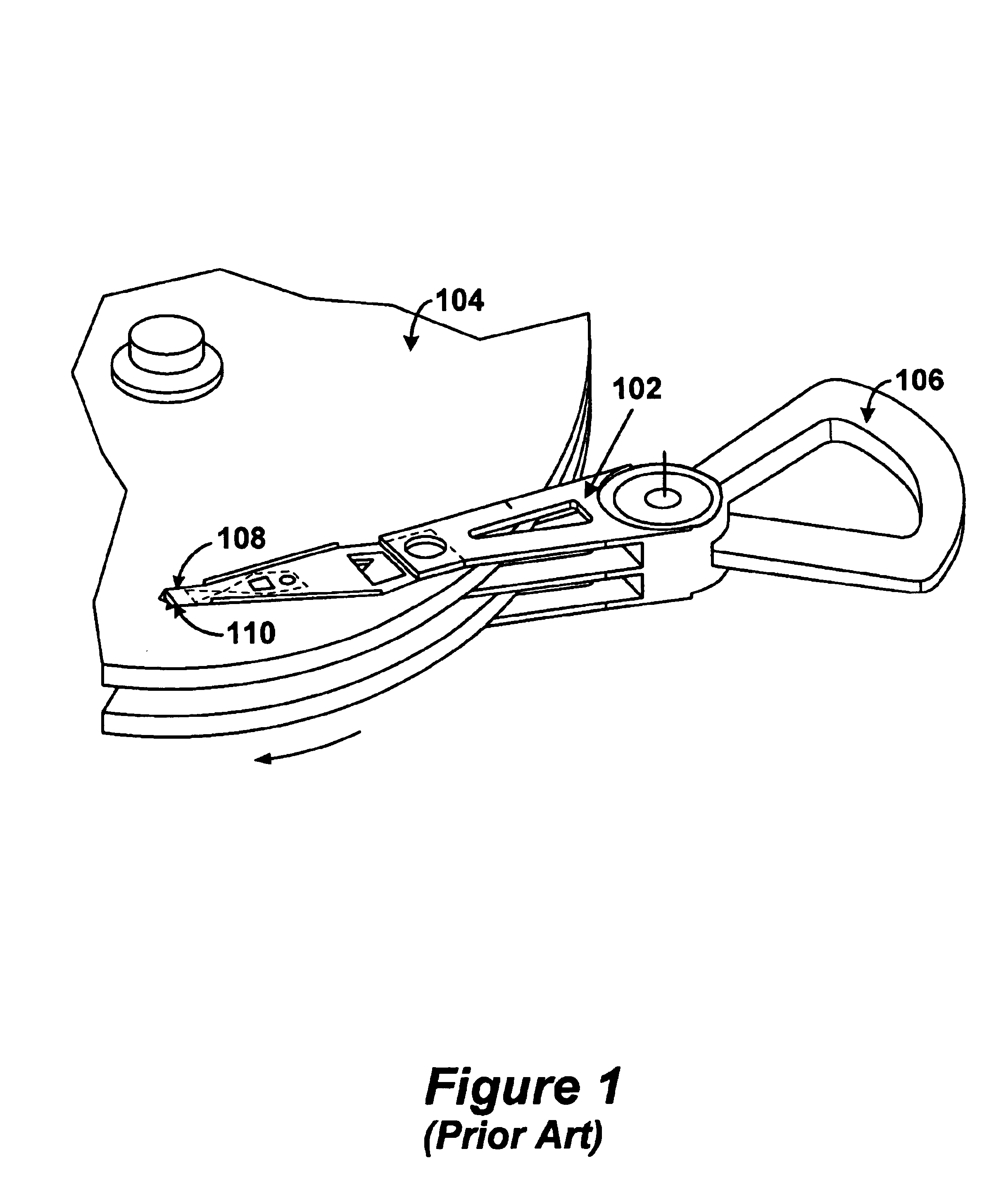

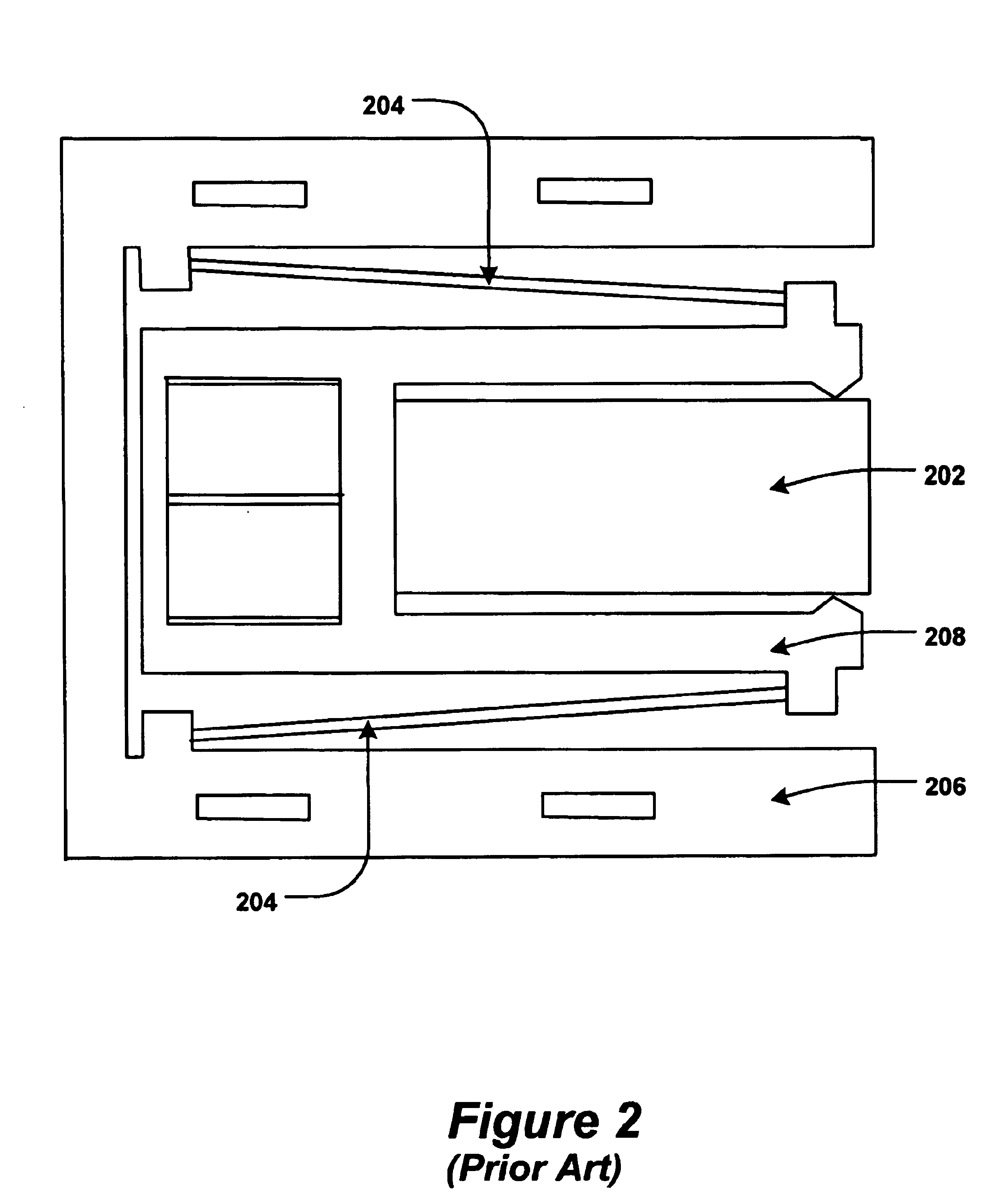

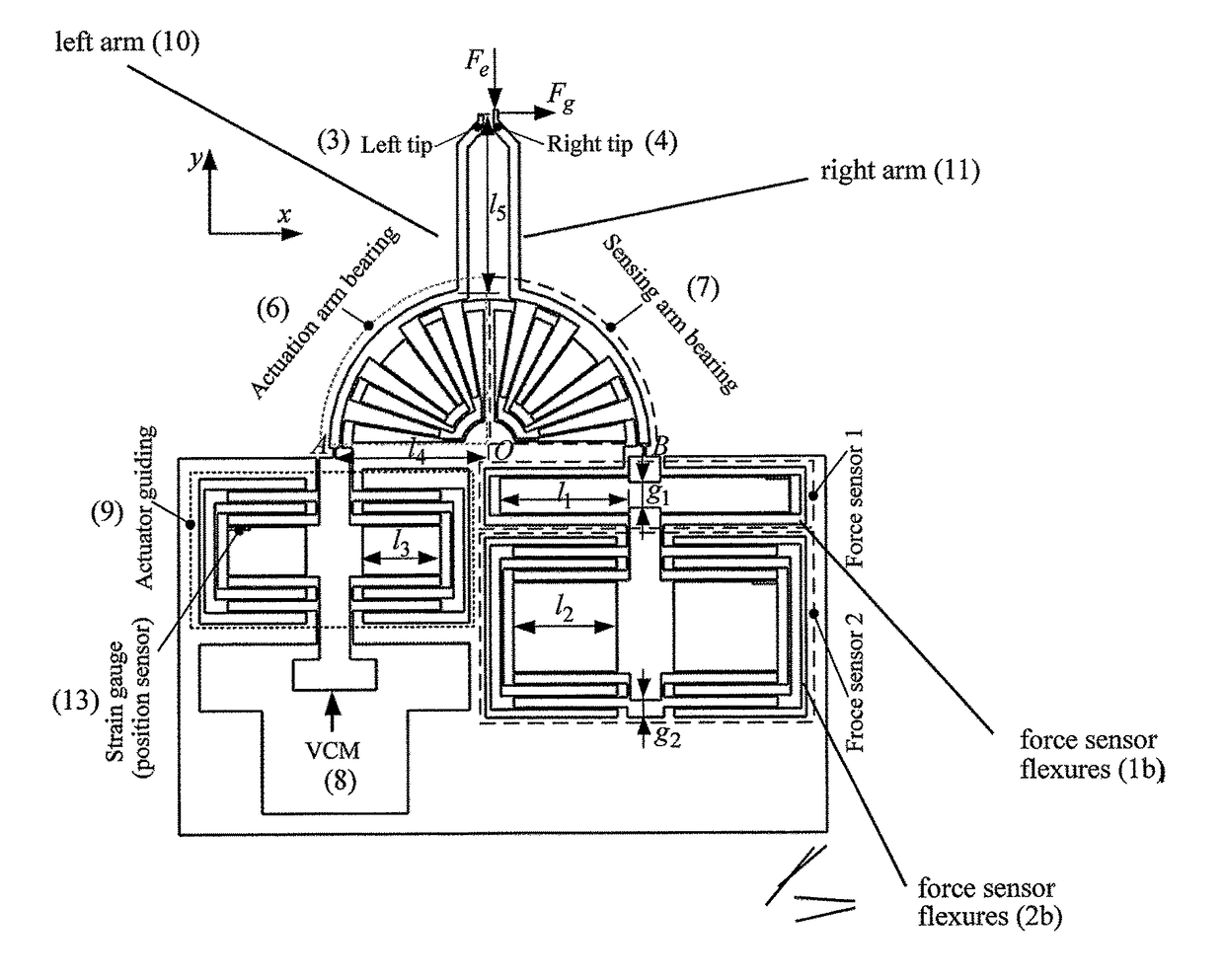

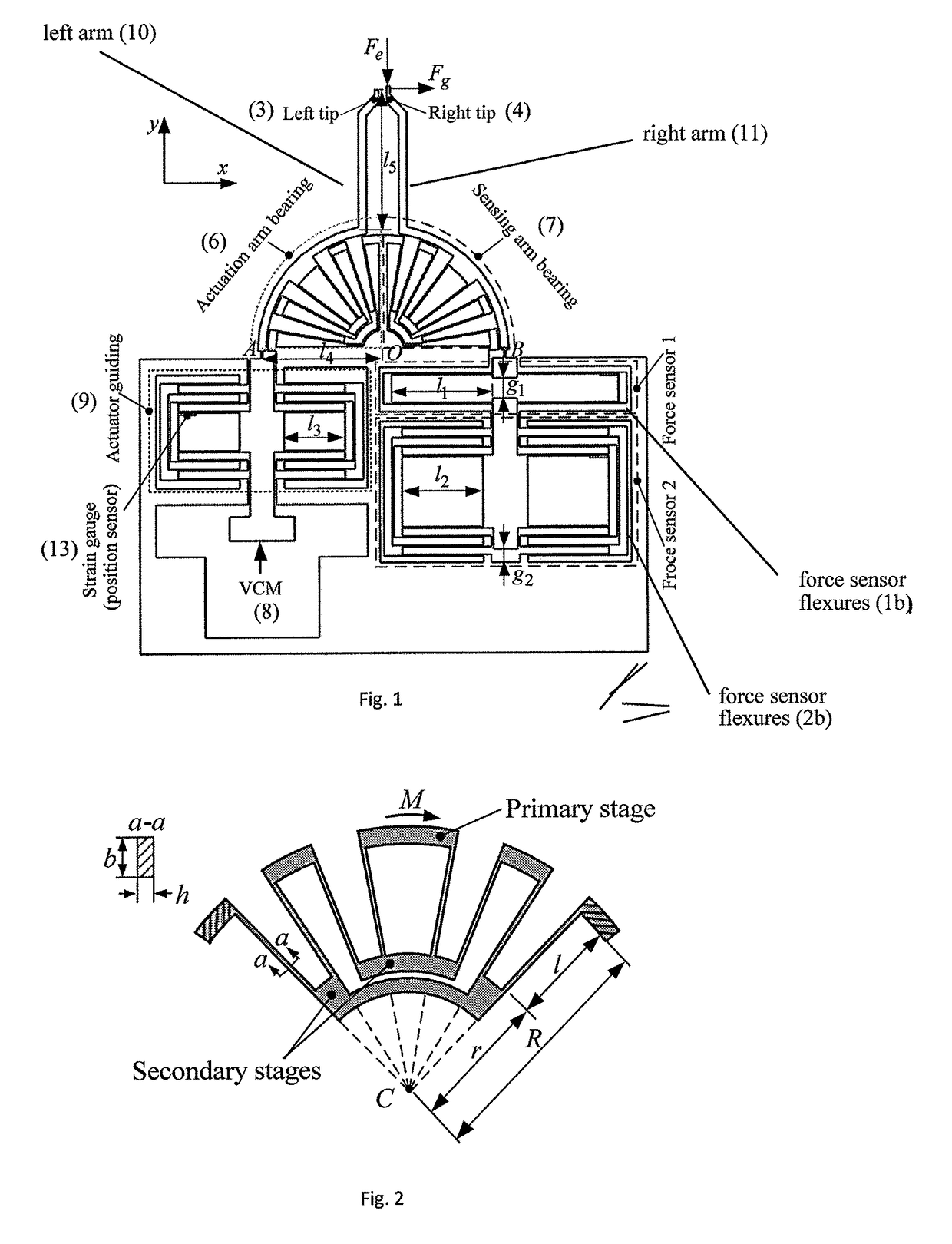

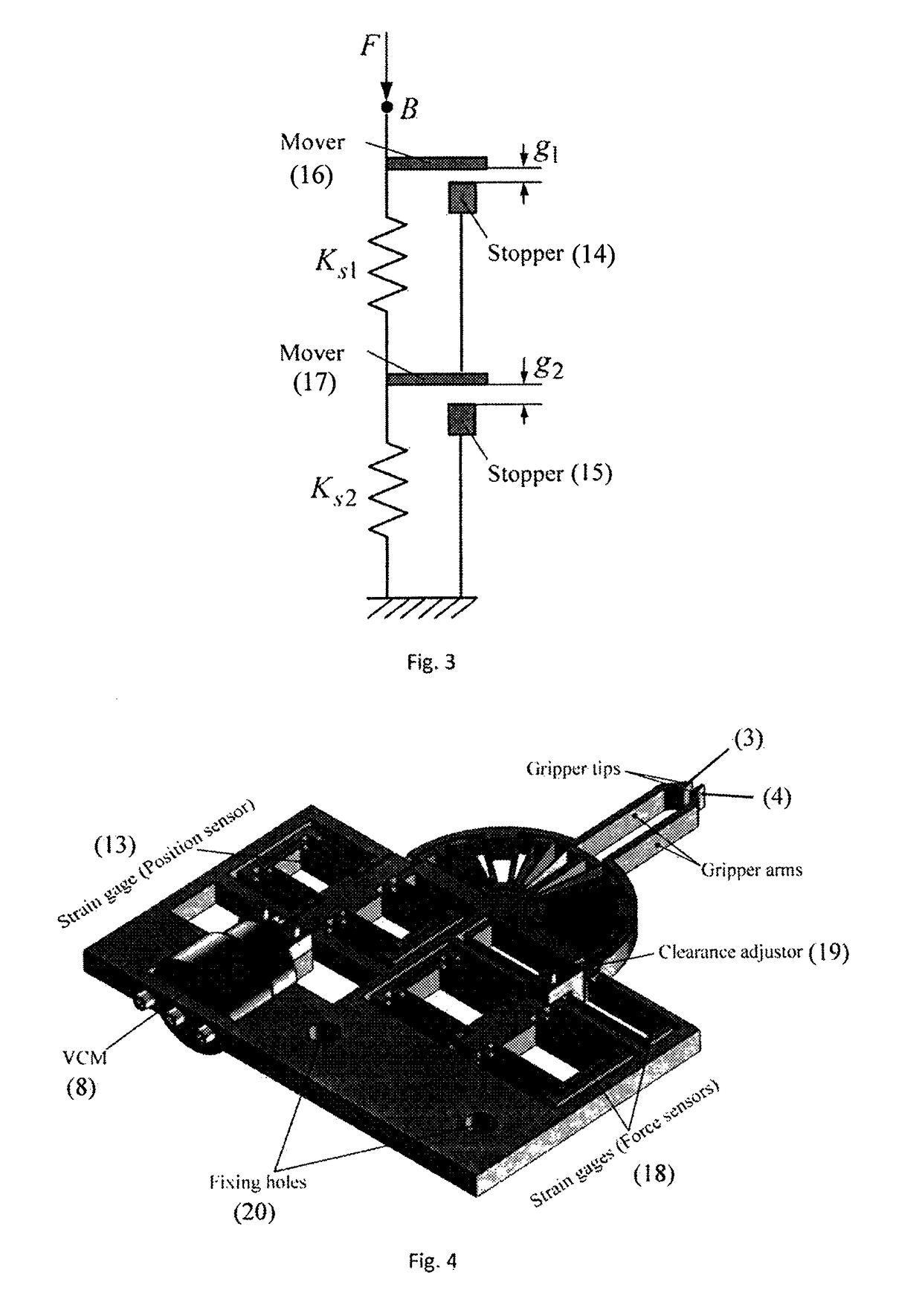

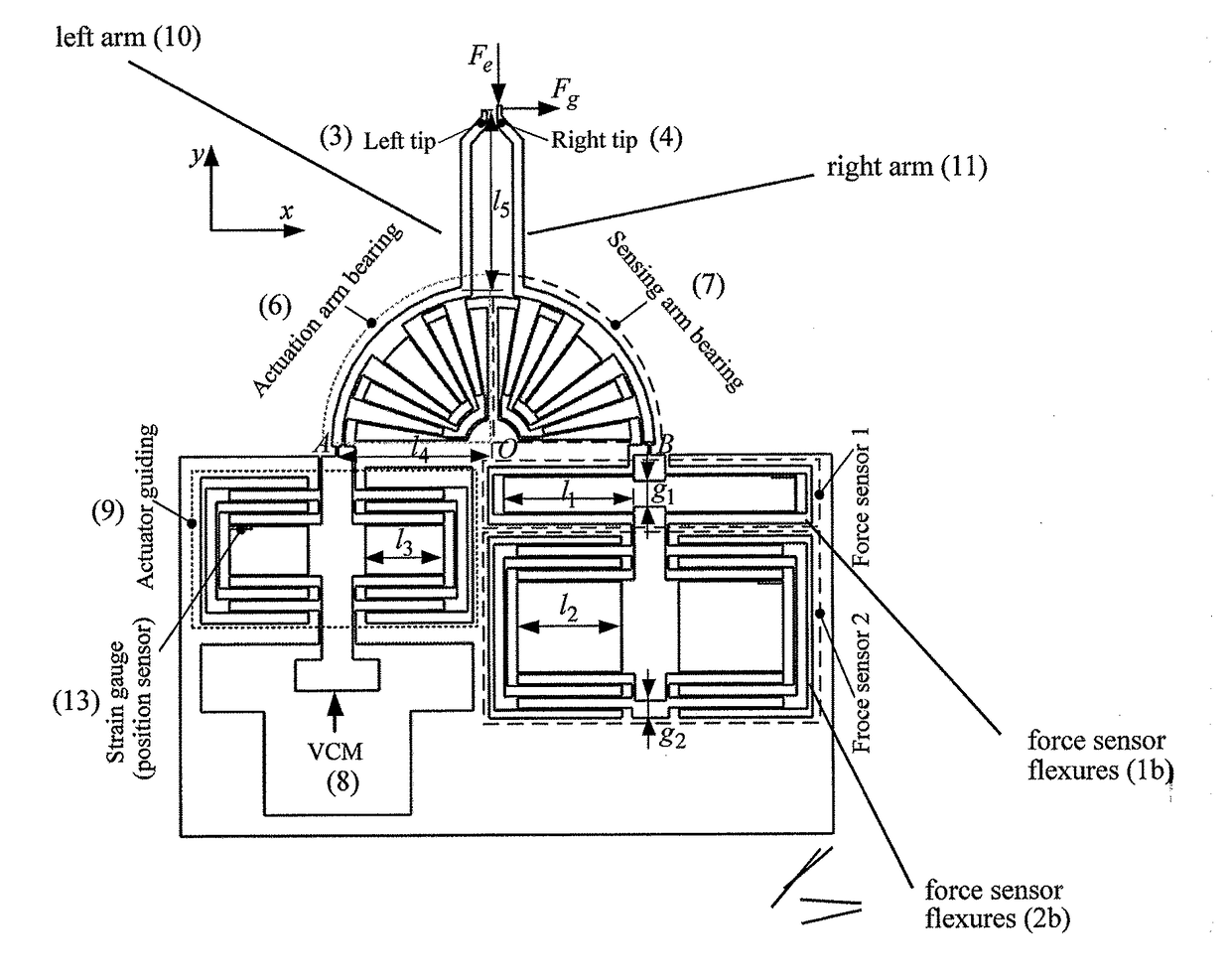

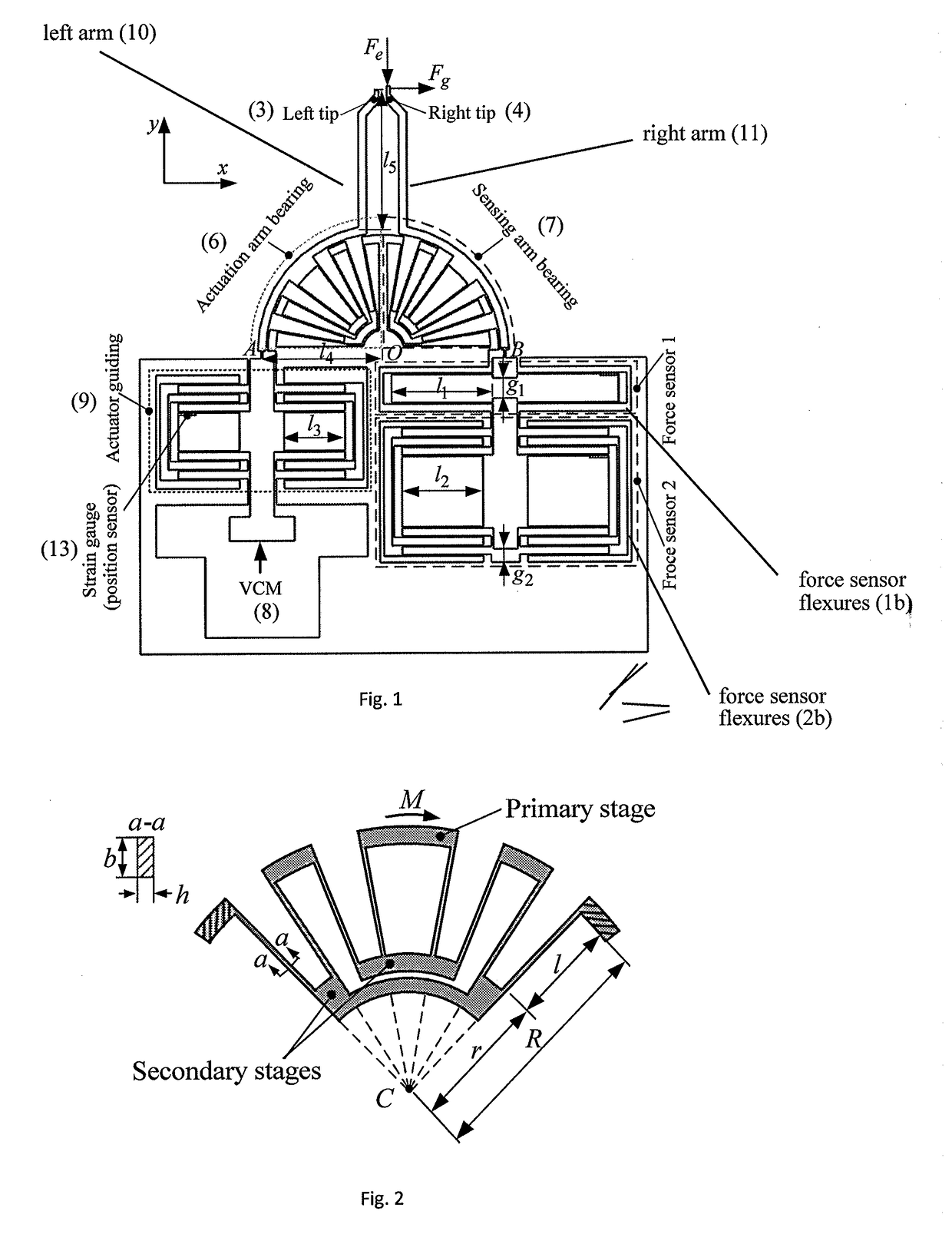

Compliant gripper with integrated position and grasping/interaction force sensing for microassembly

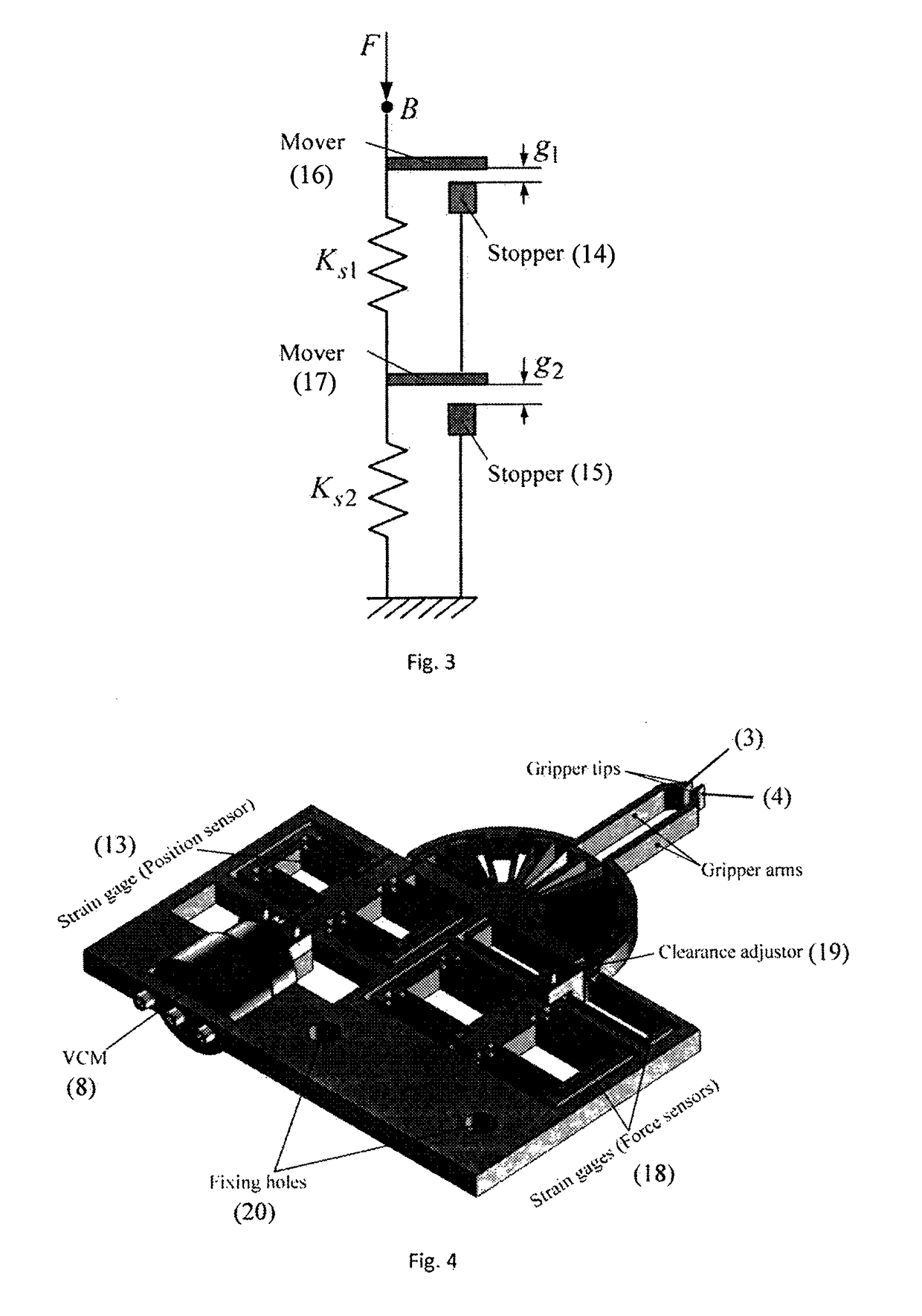

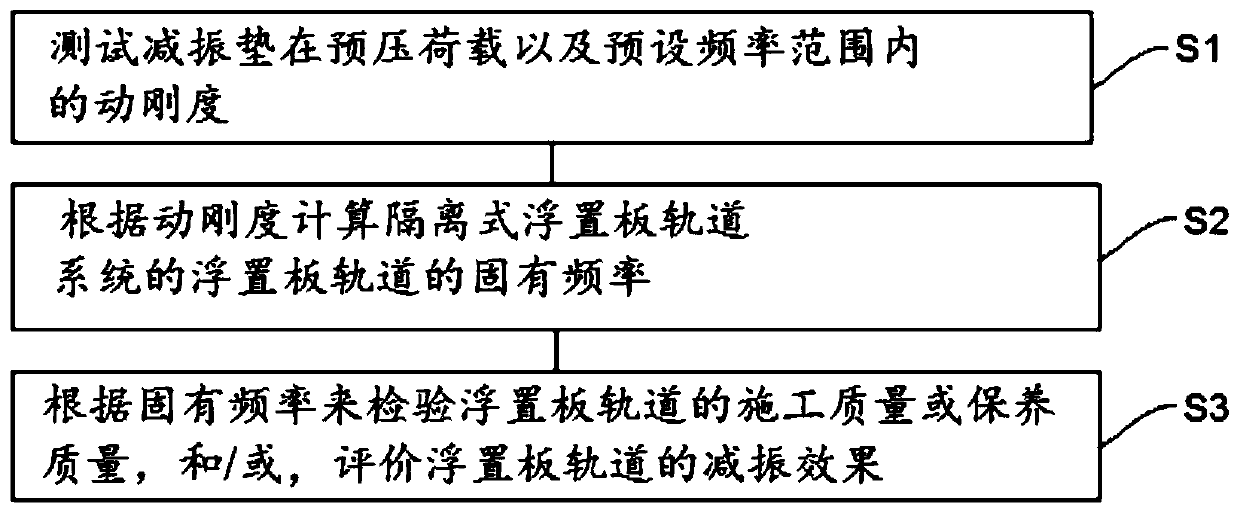

ActiveUS9708135B2Overcome deficienciesLarge grabbing rangeProgramme-controlled manipulatorMicromanipulatorCompliant mechanismElement analysis

A compliant gripper with integrated position and force sensors dedicated to automated micro-assembly tasks. The gripper possesses a larger gripping range with a bidirectional drive, and is capable of detecting grasping force and environmental interaction forces in horizontal and vertical axes. The gripper has a compliant rotary flexure bearing. The gripper further has a compliant mechanism with two-stage stiffness designed to provide force sensing with dual sensitivities in two measuring ranges to accommodate the grasping of objects with different sizes. The dual-sensitivity, dual-range force sensor provides finer and coarser force sensing in a small and large ranges, respectively. Analytical models are derived to predict the grasping range, force sensing sensitivities, and force measuring ranges. These models are verified by conducting finite-element analysis simulations.

Owner:UNIVERSITY OF MACAU

Compliant gripper with integrated position and grasping/interaction force sensing for microassembly

ActiveUS20170096305A1Reduce sensitivityOvercome deficienciesProgramme-controlled manipulatorMicromanipulatorCompliant mechanismElement analysis

A compliant gripper with integrated position and force sensors dedicated to automated micro-assembly tasks. The gripper possesses a larger gripping range with a bidirectional drive, and is capable of detecting grasping force and environmental interaction forces in horizontal and vertical axes. The gripper has a compliant rotary flexure bearing. The gripper further has a compliant mechanism with two-stage stiffness designed to provide force sensing with dual sensitivities in two measuring ranges to accommodate the grasping of objects with different sizes. The dual-sensitivity, dual-range force sensor provides finer and coarser force sensing in a small and large ranges, respectively. Analytical models are derived to predict the grasping range, force sensing sensitivities, and force measuring ranges. These models are verified by conducting finite-element analysis simulations.

Owner:UNIVERSITY OF MACAU

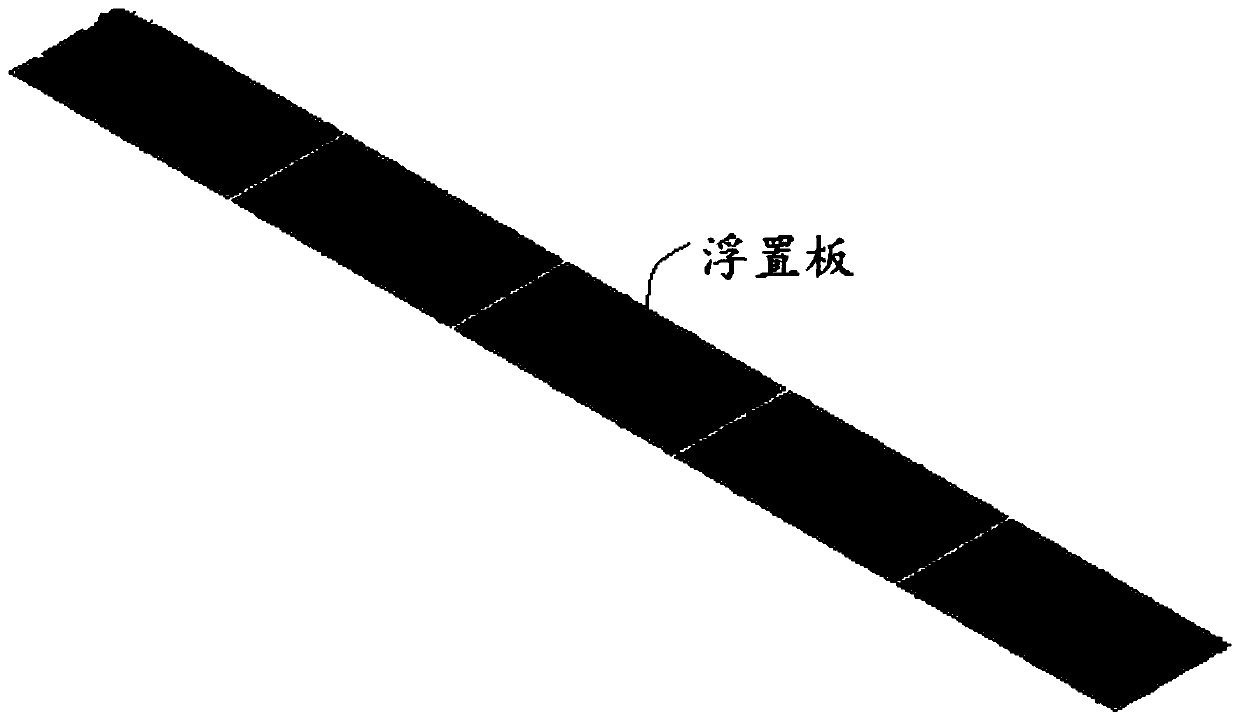

Dynamic stiffness design method

ActiveCN110055834AVibration damping effect avoidImprove versatilityRailway tracksDesign technologyStiffness design

The invention provides a dynamic stiffness design method, and relates to the technical field of rail transit vibration damping rail design. The dynamic stiffness design method is suitable for design of the dynamic stiffness of a vibration damping pad of an isolated floating plate rail system. The design method includes the steps that the dynamic stiffness of the vibration damping pad within the preloading load and preset frequency range is tested, according to the dynamic stiffness, the inherent frequency of a floating plate rail of the isolated floating plate rail system is calculated, the construction quality or maintenance quality of the floating plate rail is inspected according to the inherent frequency, and / or the vibration damping effect of the floating plate rail is evaluated. According to the dynamic stiffness design method, quick inspection and scientific evaluation of the construction quality or maintenance quality of the floating plate rail can be achieved, and meanwhile, the real vibration damping effect of the floating plate rail can also be evaluated.

Owner:SOUTHWEST JIAOTONG UNIV +2

Coupler for shaft suspending type installing direct drive motor and rigid design method thereof

ActiveCN110671436AImprove radial load capacityThe direction of rotation does not affectYielding couplingRolling contact bearingsCouplingElectric machinery

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

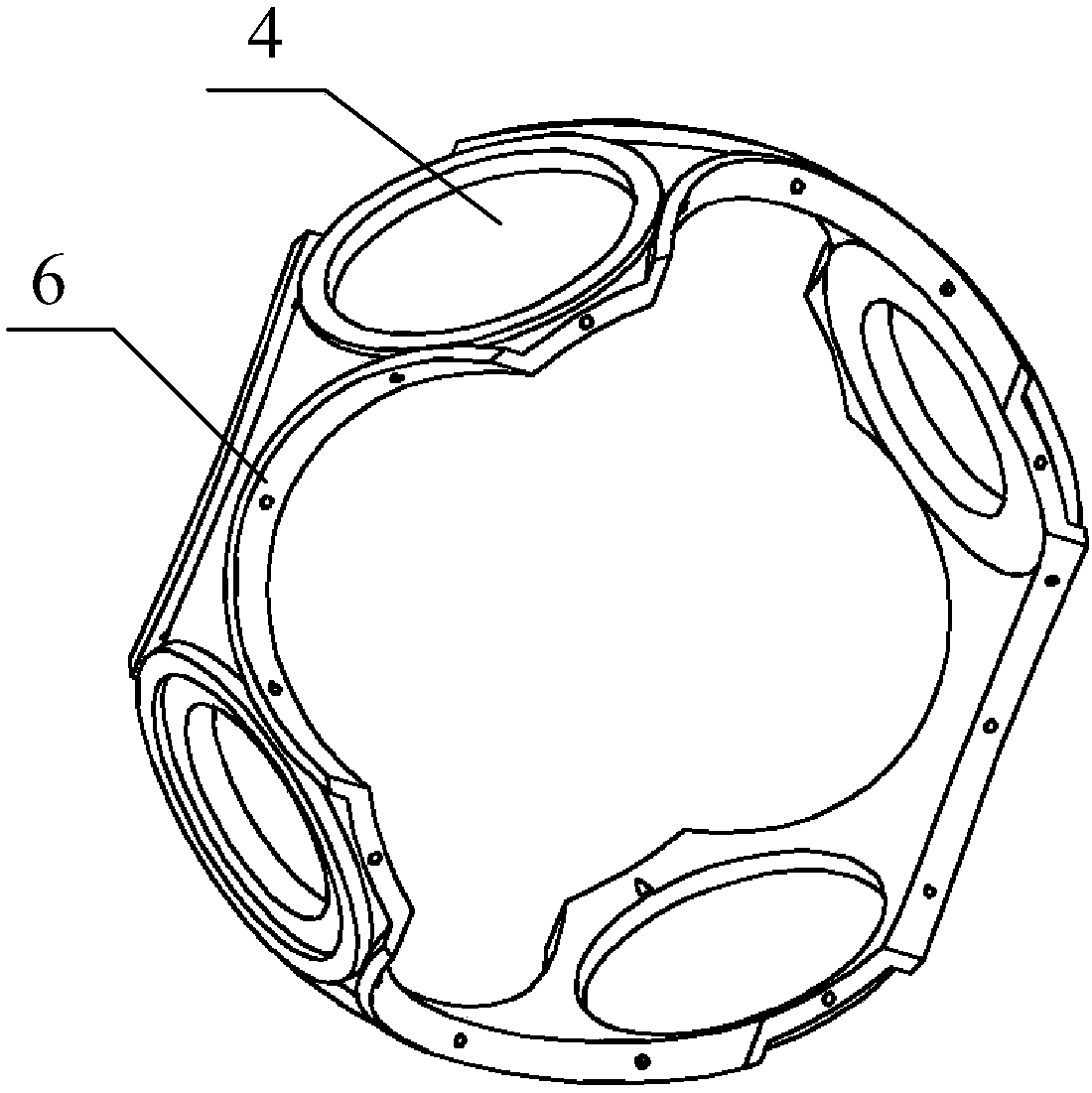

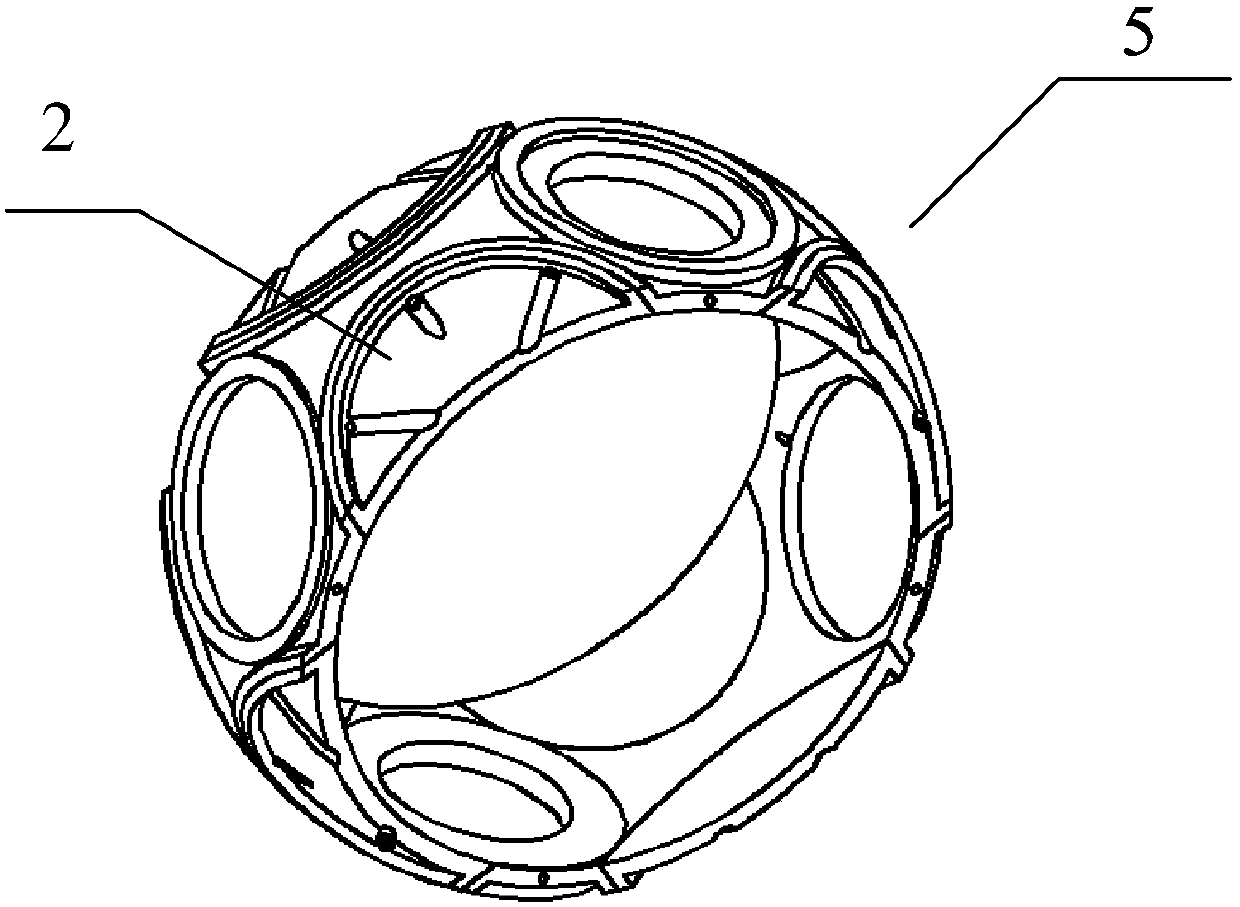

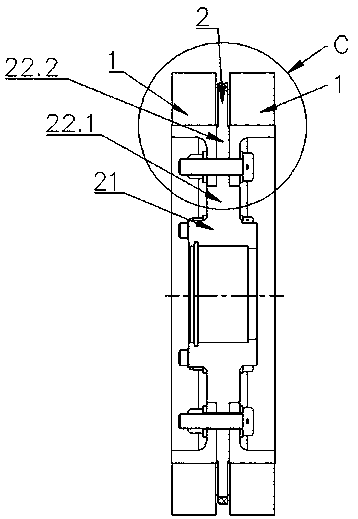

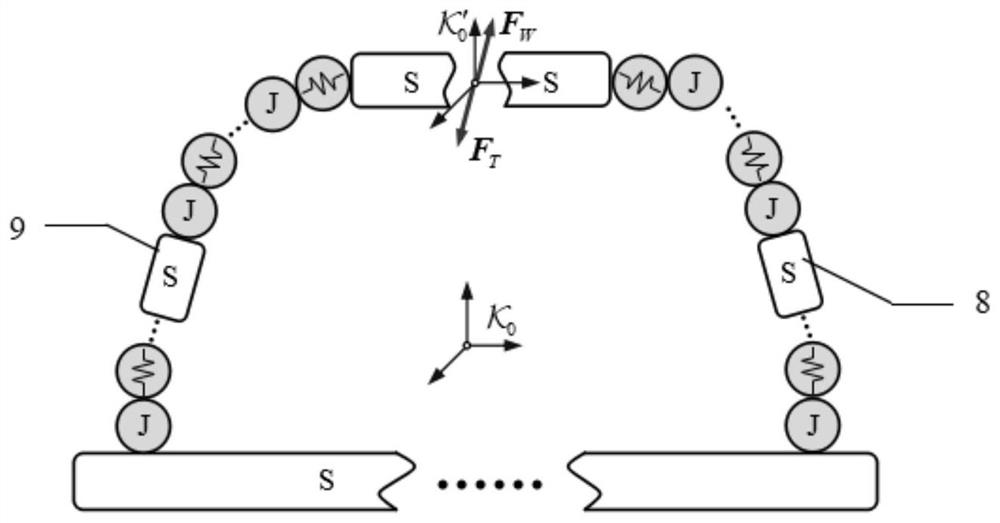

Combined type spherical frame for inertial stabilization platform

ActiveCN107131880AImprove stabilityConducive to lightweightNavigation by speed/acceleration measurementsMiniaturizationEngineering

The invention relates to a combined type spherical frame for an inertial stabilization platform, which is composed of an integrated body structure, 2N cambered structures and two spherical structures, wherein a shaft end assembly is mounted on the integrated body structure, and no splicing on the mounting surface of the shaft end assembly is ensured by adopting the integrated structure type, thereby being favorable for ensuring the mounting accuracy of the shaft end assembly and reducing the form and position error; the 2N cambered structures can be disassembled relative to the body structure so as to facilitate mounting or disassembly of effective loads in the spherical frame, thereby realizing the miniaturization of the inertial stabilization platform structure; and the two spherical structures realize the equal stiffness design of the spherical frame, thereby reducing the second-order disturbance torque caused by the non-equal stiffness design. The spherical frame provided by the invention can ensure the mounting accuracy of the shaft end assembly to the maximum limit and reduce the dynamic error, thereby increasing the torque disturbance resisting capability of the frame, effectively reducing the rotary volume occupied by the frame, and realizing high accuracy, high stability and miniaturization of the inertial stabilization platform.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

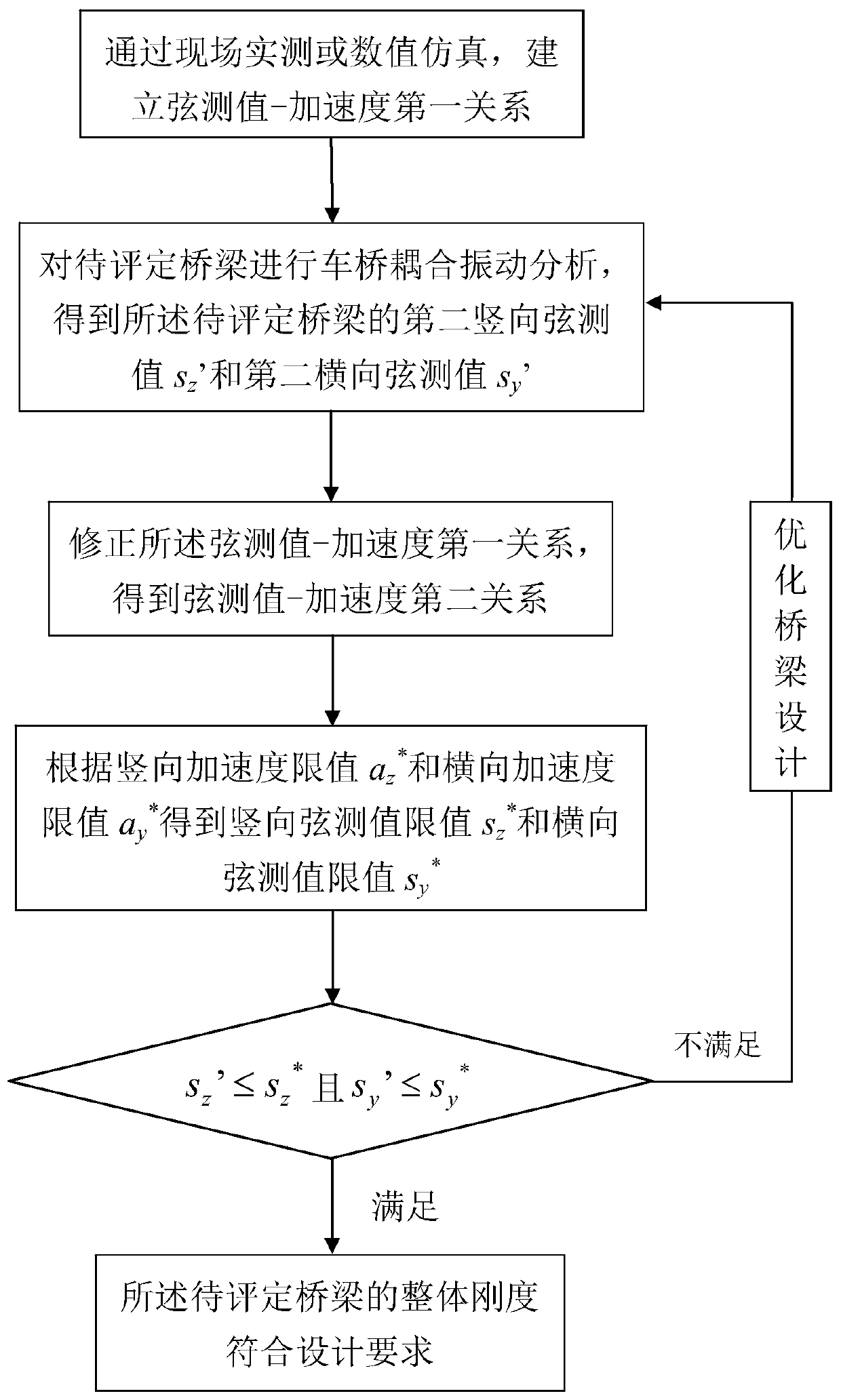

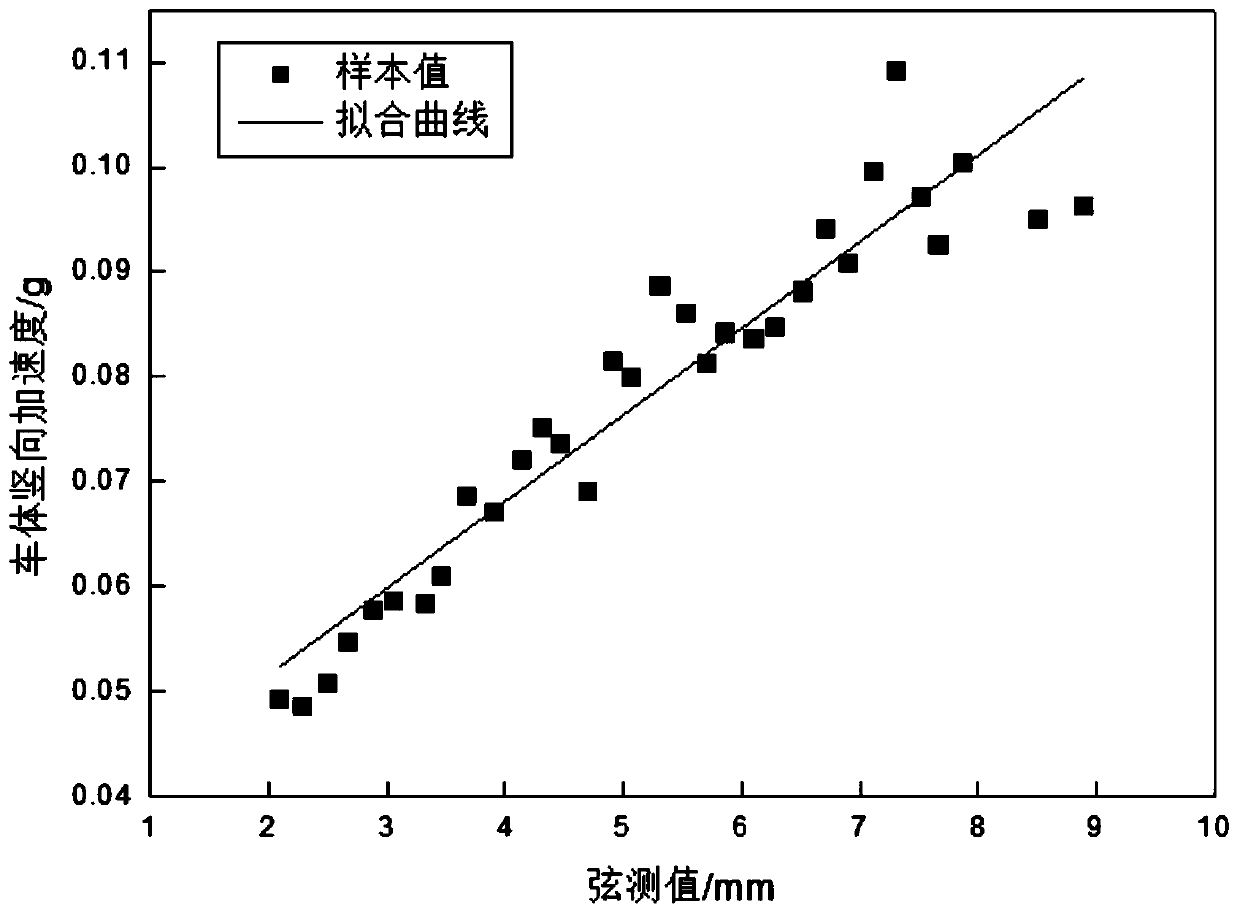

Method for judging overall rigidity of railroad bridge

ActiveCN111324925AAvoid normal workLow costGeometric CADDesign optimisation/simulationBridge typeTrackway

The invention relates to the technical field of bridge rigidity design, and particularly discloses a method for judging the overall rigidity of a railroad bridge. According to the method, the overallrigidity of the bridge is judged through the chord measurement value, the calculation is convenient, rapid review is faciliated, the established sample library can be widely applied to rigidity evaluation of each bridge design stage; differences of influences of various loads on rail deformation under different spans, bridge types and geological conditions do not need to be considered; the methodis simple in operation, saves design time and cost, is particularly suitable for overall rigidity evaluation of large-span bridges which are not involved in existing specifications, effectively avoidsa large amount of dynamic analysis and check calculation work during large-span bridge design and the problems of construction cost rising, later maintenance difficulty and operation safety caused byunreasonable design rigidity, and has an excellent application prospect.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

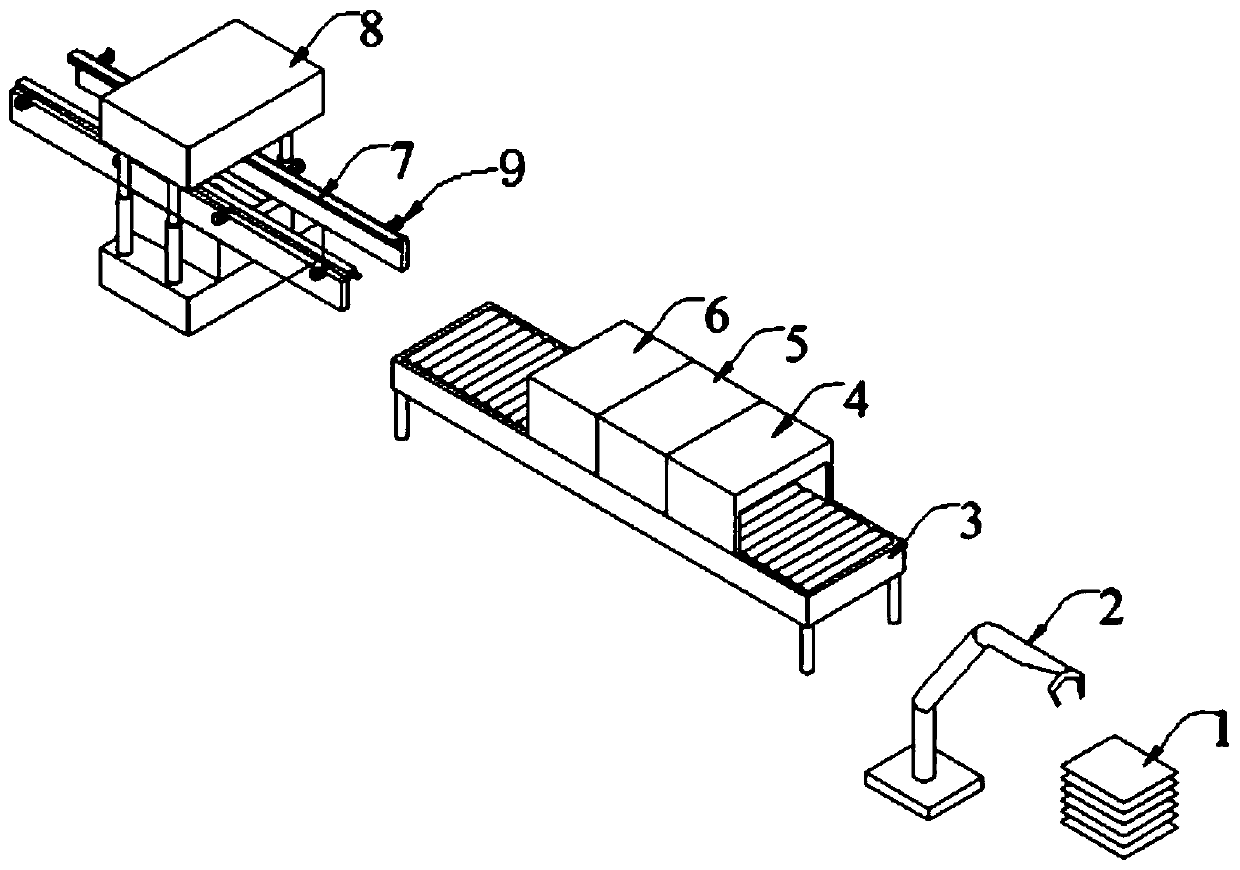

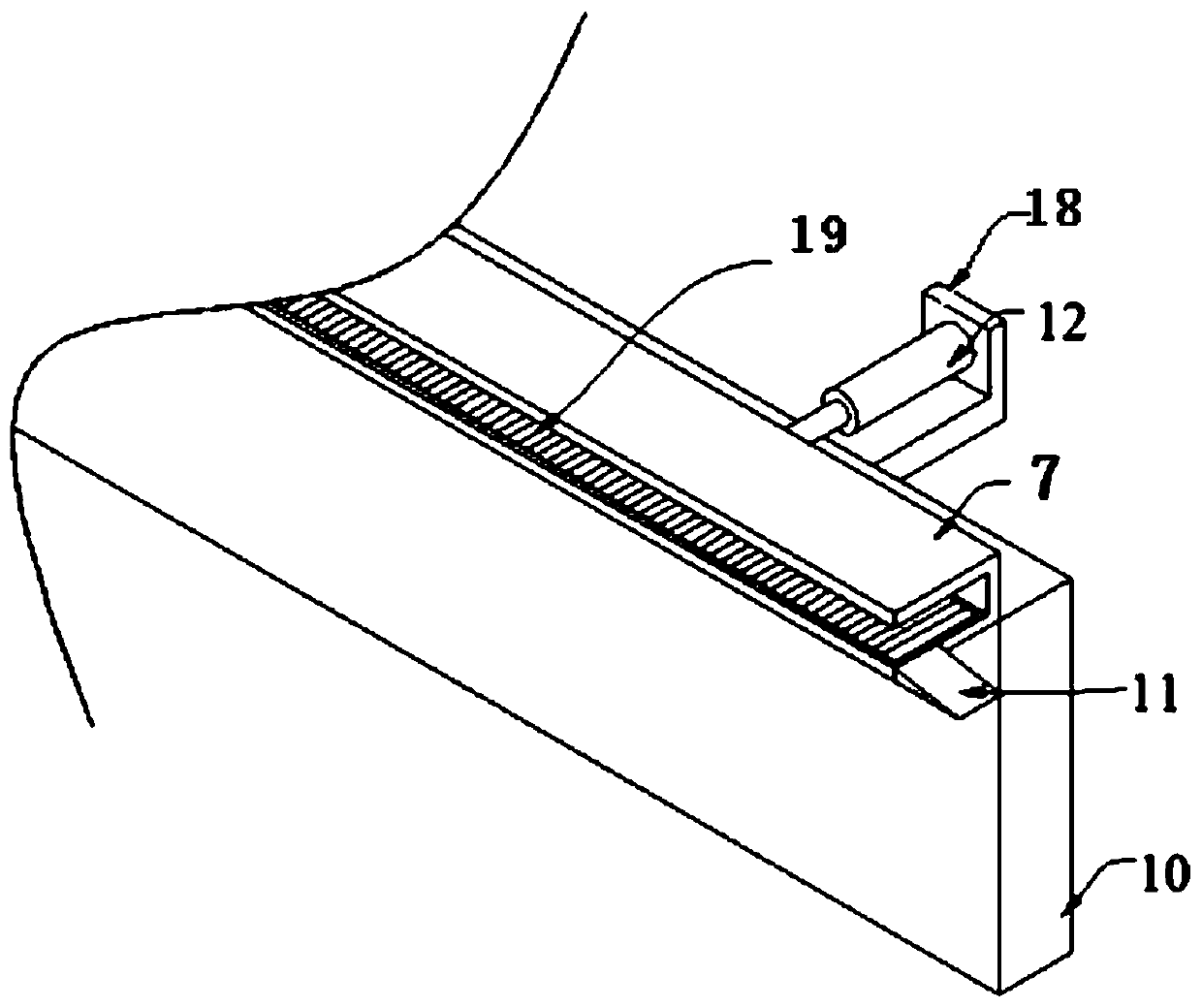

Control device and method for morphic gradient of ultrahigh-strength steel

PendingCN111069331AReduce transfer timeReduce surface oxidationShaping toolsMetal-working feeding devicesHot stampingSynchronous control

The invention discloses a control device for morphic gradient of ultrahigh-strength steel. The device comprises a conveying frame, a first heating furnace, a rolling device and a second heating furnace are sequentially mounted on the conveying frame from input end to output end, the output end of the conveying frame is connected with a stamping device, the stamping device comprises an upper male die and a lower female die which are matched, a telescopic device is mounted on the side faces, facing to each other, of the lower female die, the output end of the telescopic device is connected witha side roller rail, multiple cooling water ways are evenly mounted in the upper male die and the lower female die, each cooling water way is independently controlled, and temperature of each cooling water way is monitored by a thermocouple. The invention further discloses a control method for the morphic gradient of the ultrahigh-strength steel. The method comprises following steps of preheating,variable-thickness online rolling, austenitizing and synchronous setting stress removal, hot stamping, and partition quenching. According to the device and method, synchronous control over rigidity, strength and toughness gradient of ultra-high strength steel plates can be effectively achieved, the morphic gradient of the steel plates can be achieved, and light weight is achieved while the rigidity design needs are ensured.

Owner:NANJING INST OF TECH +1

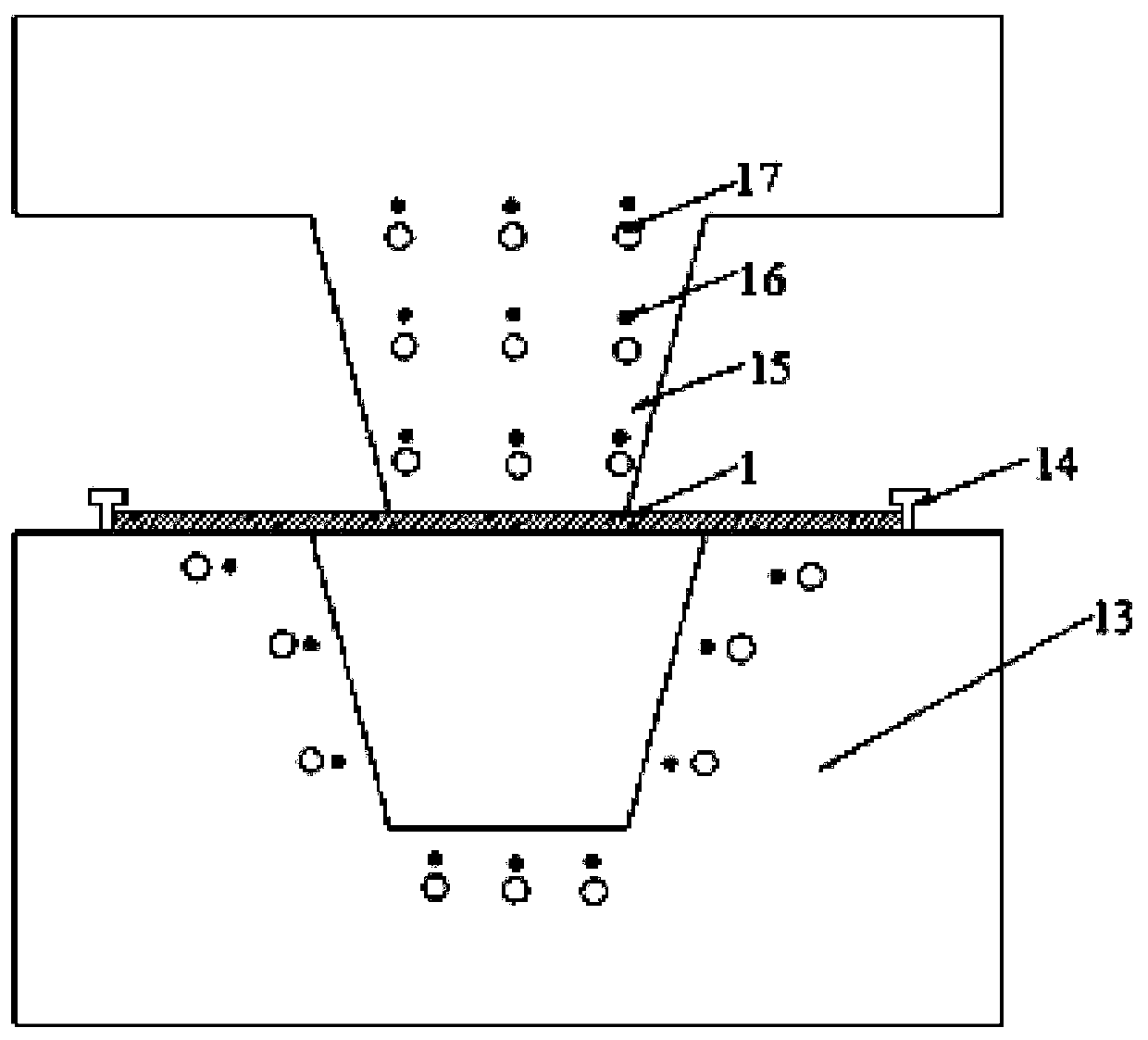

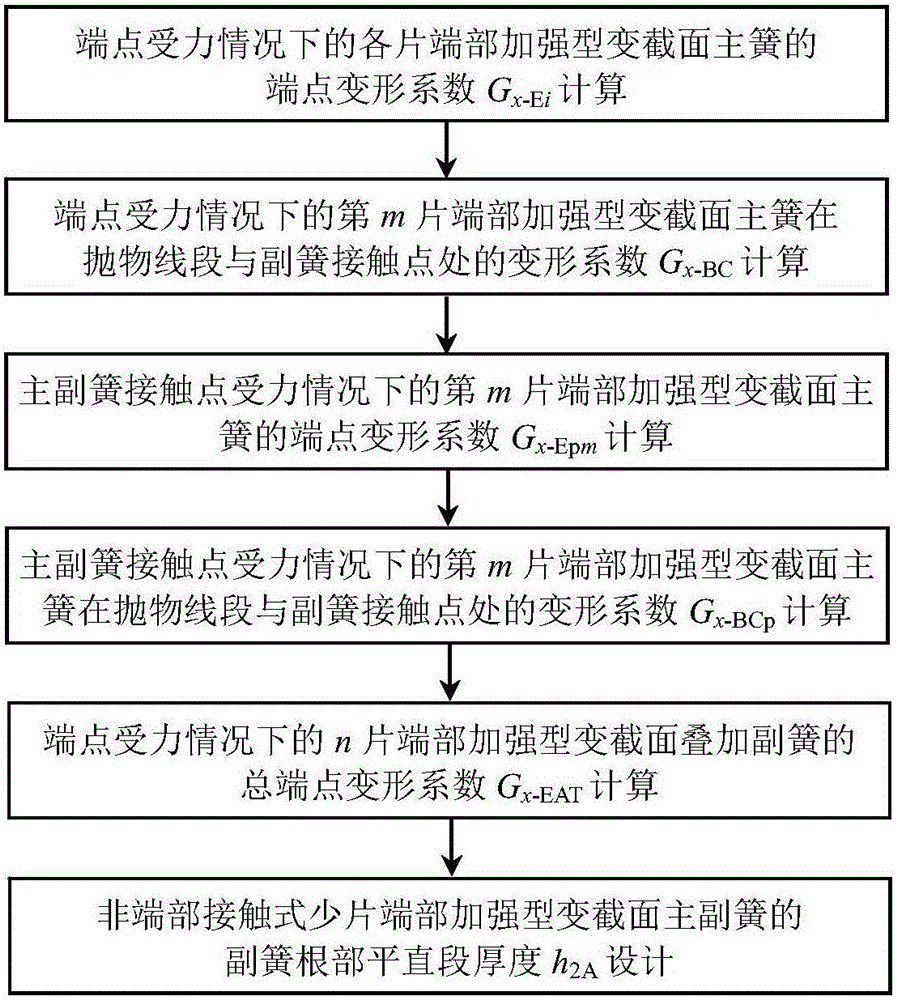

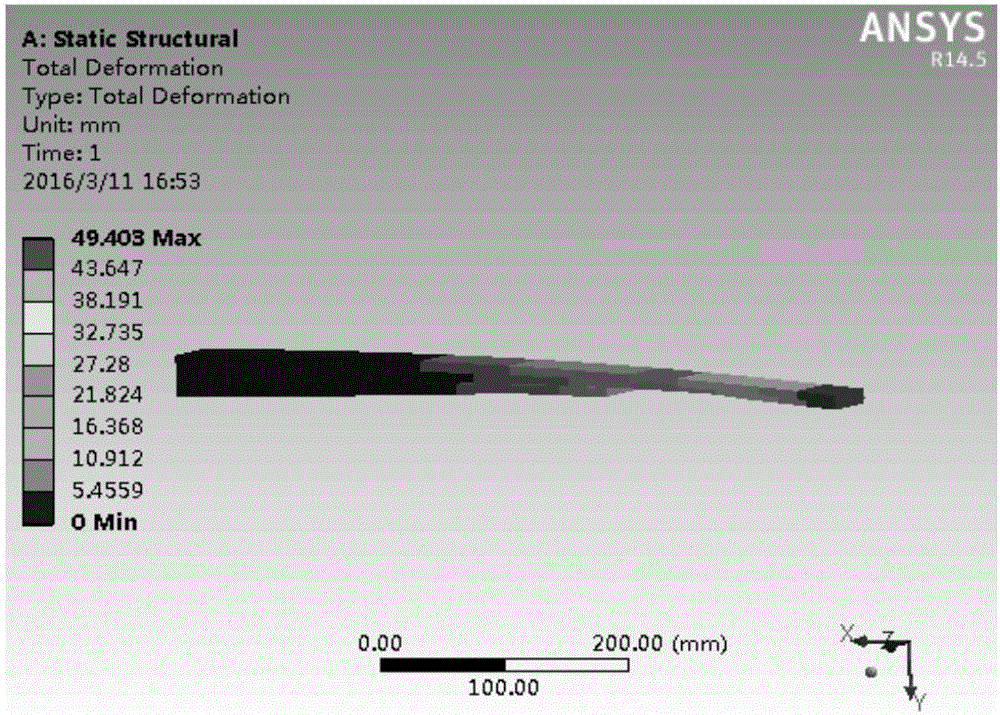

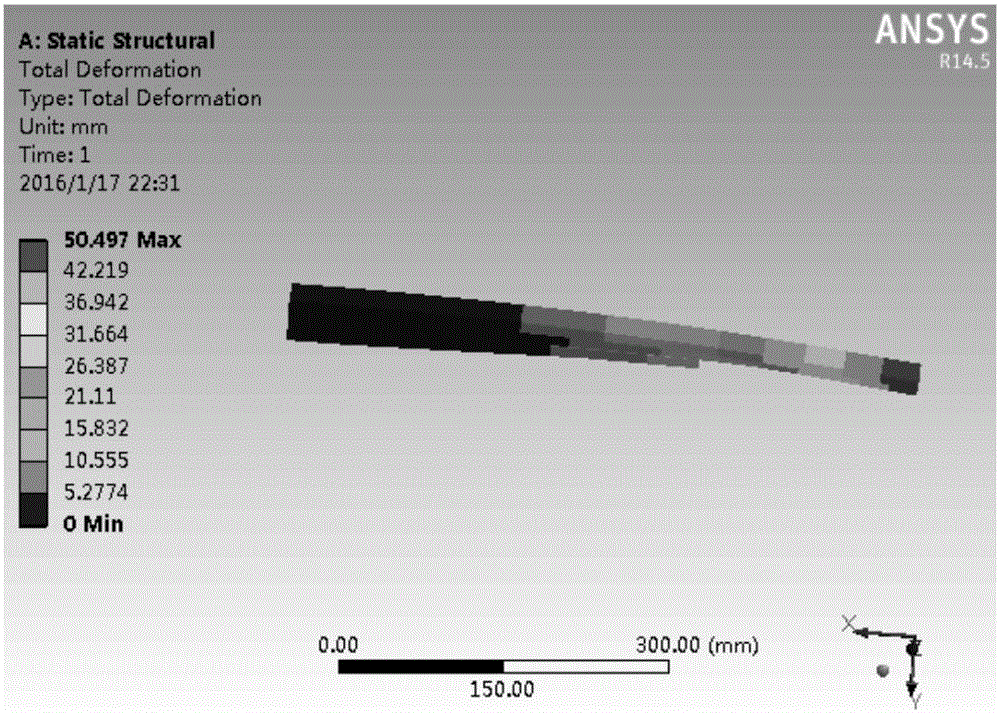

Method for designing root thickness of non-end-contact type taper-leaf end reinforced auxiliary spring

InactiveCN105956311AQuality improvementImprove performanceGeometric CADSpecial data processing applicationsEngineeringSoftware development

The invention discloses a method for designing the root thickness of a non-end-contact type taper-leaf end reinforced auxiliary spring, and belongs to the technical field of suspension steel plate springs. According to the structural parameters of each main spring, the lengthes and the number of pieces of the auxiliary springs, the thickness ratios of parabolic and oblique segments of the auxiliary springs, the elastic modulus and the design requirement values of composite rigidities of the main-and-auxiliary springs, the invention can design the thickness of the root of the non-end-contact type taper-leaf end reinforced auxiliary spring with the variable cross-section. Through examples and ANSYS simulation verifications, it can be seen that the method can obtain accurate and reliable design values of the thicknesses of root parts of the auxiliary springs, which provides a reliable design method for the thickness of the root of the auxiliary spring of the main-and-auxiliary spring type, and establishes a reliable technical foundation for CAD software development. The method can improve the design level of the vehicle suspension taper-leaf main-and-auxiliary springs with variable cross sections, improve the product quality, improve the vehicle ride comfort, reduce the weights and cosst of the suspension springs, reduce design and test costs and accelerate the speed of product development, simultaneously.

Owner:SHANDONG UNIV OF TECH

Design method of cylindrical object flutter model free of independent counter weight space

ActiveCN104143014AQuality improvementIncrease the mass of the counterweightSpecial data processing applicationsQuality by DesignMoment of inertia

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

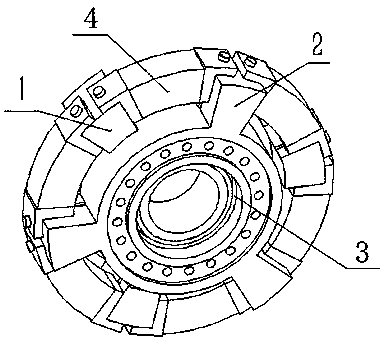

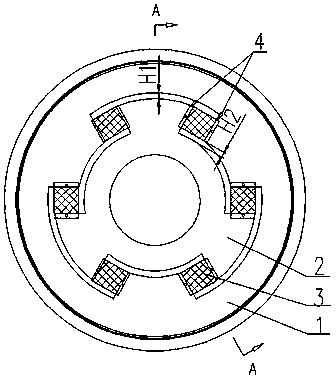

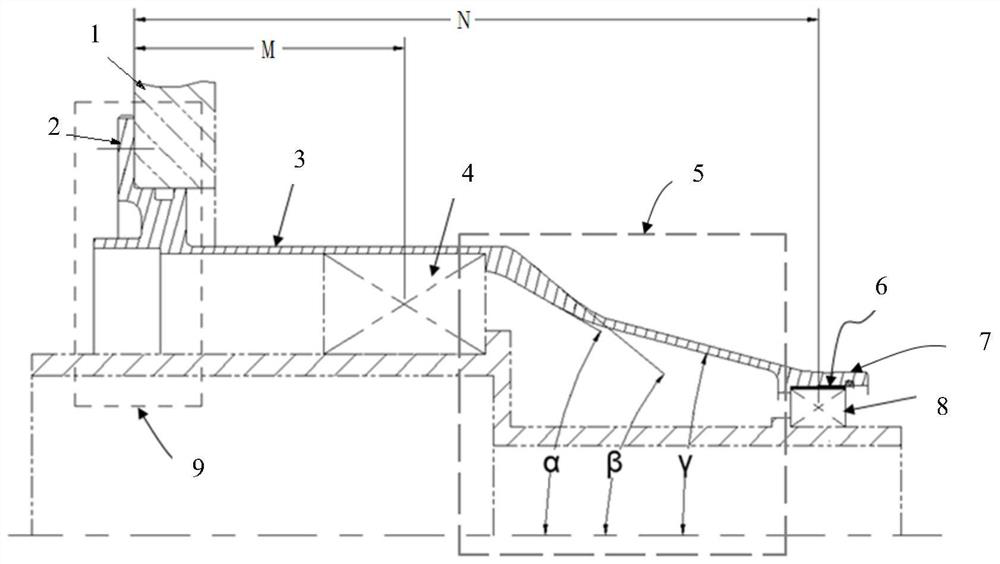

Combined solid wheel for rail transit vehicle and stiffness design method thereof

ActiveCN109109560AAchieving nonlinear radial stiffnessImprove ride comfortRail-engaging wheelsRail transitStiffness design

Provided is a combined solid wheel for rail vehicles, which is characterized by comprising a wheel vulcanizate vulcanized from an inner metal layer and an outer rubber layer and a flange connecting disk which can be fitted with an axle. The number of the wheel vulcanizates is two and is coaxially aligned, the flange connecting disk is sandwiched between the two wheel vulcanizates and detachably connected with the wheel vulcanizates, the outer diameter of the flange connecting disk is smaller than the outer diameter of the wheel vulcanizates, and the flange connecting disk extends between the rubber layers of the two wheel vulcanizates. As that combine structure provided by the invention is simple and reliable, and is easy to assemble and replace, the non-linear radial stiffness of the wheel in the load-bearing proces can be realized, the ride comfort of the vehicle can be improved, and the stopper limit function can be provided, the radial deformation limit of the wheel can be realized, and the safety and reliability of the vehicle operation can be improved. The invention also provides a stiffness design method of a combined solid wheel for a rail transit vehicle.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

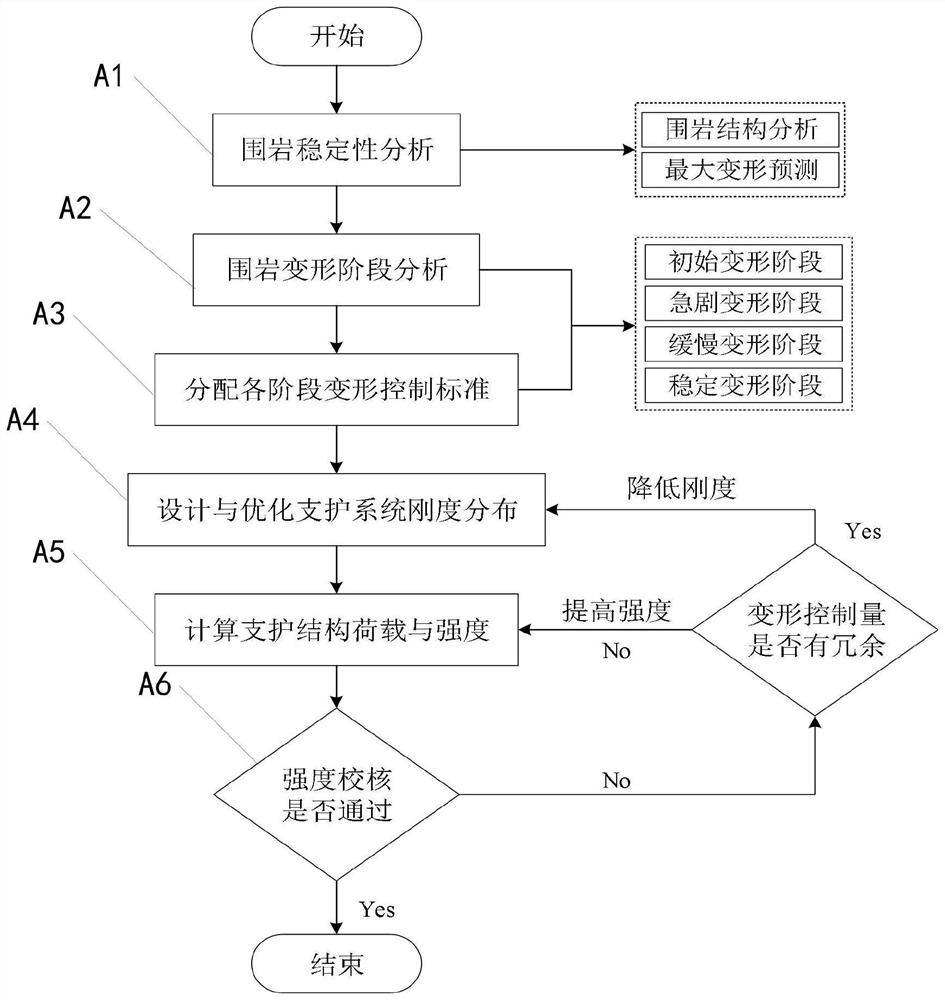

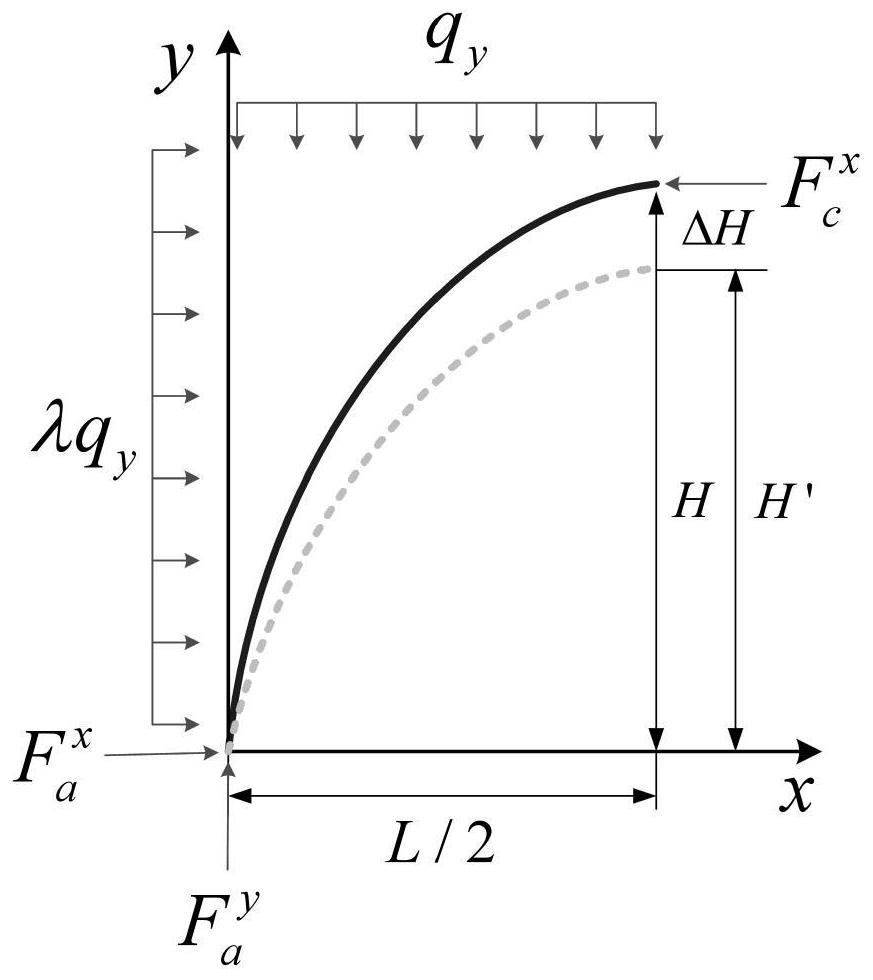

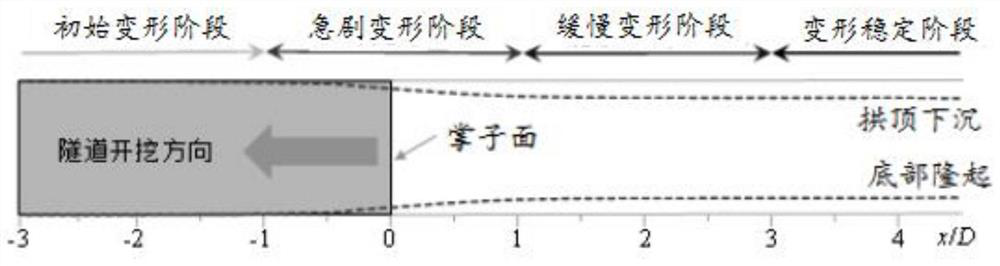

Tunnel supporting structure system rigidity design method and system

PendingCN112507429ARealize quantitative designImprove scienceGeometric CADDesign optimisation/simulationSupporting systemMechanical models

The invention relates to a tunnel supporting structure system rigidity design method and system, and the method comprises the steps of dividing surrounding rock deformation into four stages accordingto the relation between a deformation position and a tunnel excavation direction and the relation between the deformation position and a tunnel face, and then respectively calculating the surroundingrock standard deformation quantities of the four stages; preliminarily designing the support structure system rigidity value of each stage according to the surrounding rock standard deformation quantity of the four stages, and finally adjusting the rigidity value of the support structure. The quantitative design of the tunnel supporting structure system is realized by establishing the tunnel mechanical model, formulating the surrounding rock deformation quantitative control standard and establishing the quantitative relationship between the tunnel surrounding rock deformation and the supporting rigidity, and the optimal distribution of the supporting system rigidity is further performed to obtain the most economical rigidity design scheme, so that the supporting design is more scientific and reasonable.

Owner:BEIJING JIAOTONG UNIV

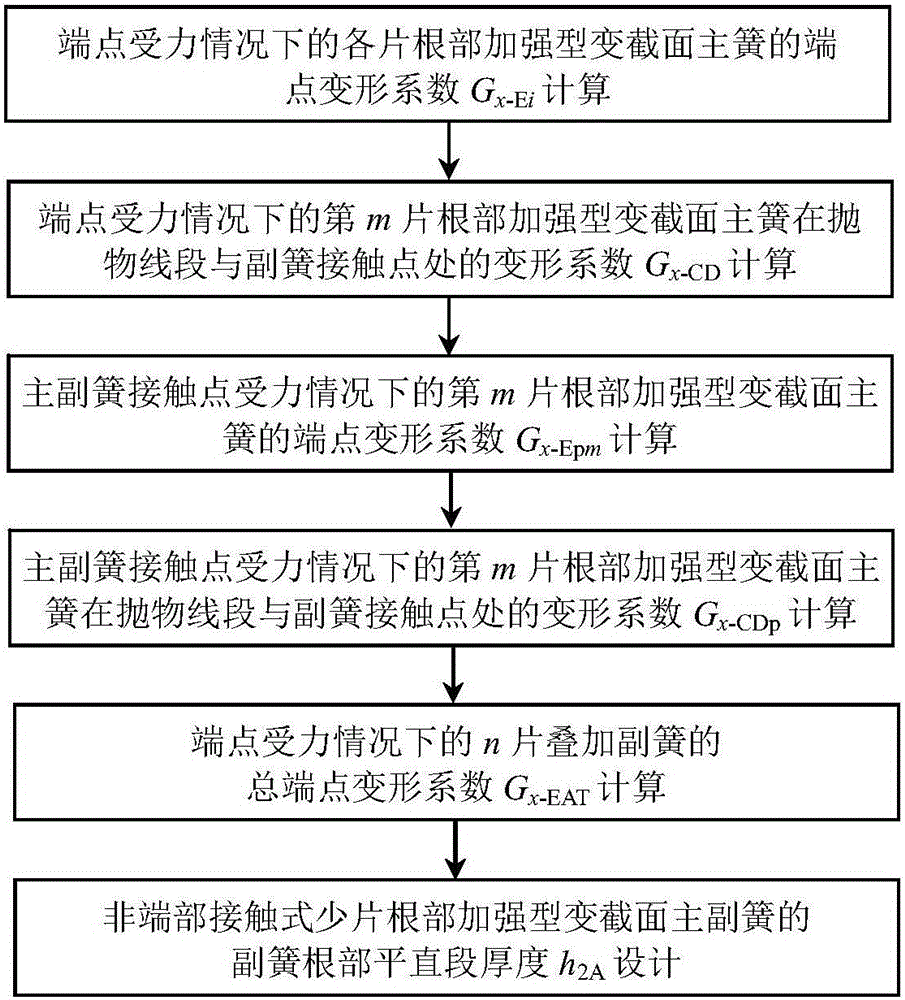

Design method for root thickness of end-contactless few-leaf root-enhanced sub-spring

InactiveCN105930596AMeet the design requirements for composite stiffnessImprove the design levelGeometric CADSpecial data processing applicationsEngineeringVehicle driving

The present invention relates to a design method for a root thickness of an end-contactless few-leaf root-enhanced sub-spring, and belongs to the technical field of suspension leaf springs. According to the method, the thickness of a flat straight section of a sub-spring root of end-contactless few-leaf root-enhanced main and sub springs with a variable cross section can be designed according to a structure parameter of each leaf of main spring, a length and a leaf number of a sub-spring, a thickness ratio of an inclined line segment of the sub-spring and a thickness ratio of a parabolic line segment, an elastic modulus, and a main and sub spring composite stiffness design requirement value. It can be known by instances and simulation verification that the design method for the root thickness of the end-contactless few-leaf root-enhanced sub-spring, which is provided by the present invention, is correct, and an accurate and reliable sub-spring root thickness design value can be obtained, and a reliable design method is provided for design of the end-contactless few-leaf root-enhanced main and sub springs, and by using the method, the design level, product quality and performance of the few-leaf main and sub springs with the variable cross section as well as vehicle driving smoothness can be improved. Moreover, design and experiment costs can be lowered, and product development can be sped up.

Owner:SHANDONG UNIV OF TECH

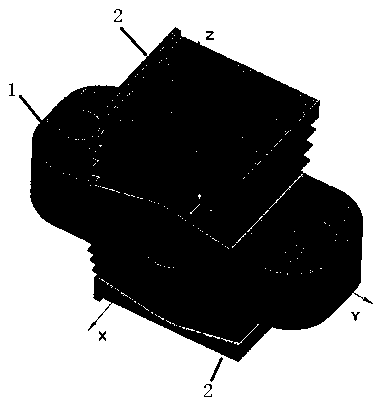

Machine tool complete machine static rigidity design method

ActiveCN112417736AImprove design efficiencyImprove accuracyGeometric CADDesign optimisation/simulationStructural engineeringMachine

The invention discloses a machine tool complete machine static rigidity design method, which comprises the steps of by adopting a static condensation method and joint part rigidity assumption, establishing a component six-degree-of-freedom static rigidity model; establishing a six-degree-of-freedom contact rigidity model of the joint part according to the principle of equal deformation and load superposition of parallel springs; establishing a complete machine tail end relative static rigidity model; taking the relative static rigidity of the tail end of the complete machine as a constraint condition, calculating the contribution rate of the static rigidity of each component and the joint part in the complete machine structure to the rigidity of the tail end according to the established model, and determining the design range; and adopting a design process from the relative static rigidity of the tail end of the complete machine to the static rigidity of each component and the joint part to perform quick matching design on the static rigidity of each component and the joint part. According to the method, the tail end static component distribution of the whole machine tool in the global working space can be rapidly calculated in the stages of initial design, optimization analysis and structure modification, the component and joint part model meeting the tail end static rigidityconstraint is designed, the design efficiency and accuracy are improved, and the production and manufacturing cost is reduced.

Owner:TIANJIN UNIV

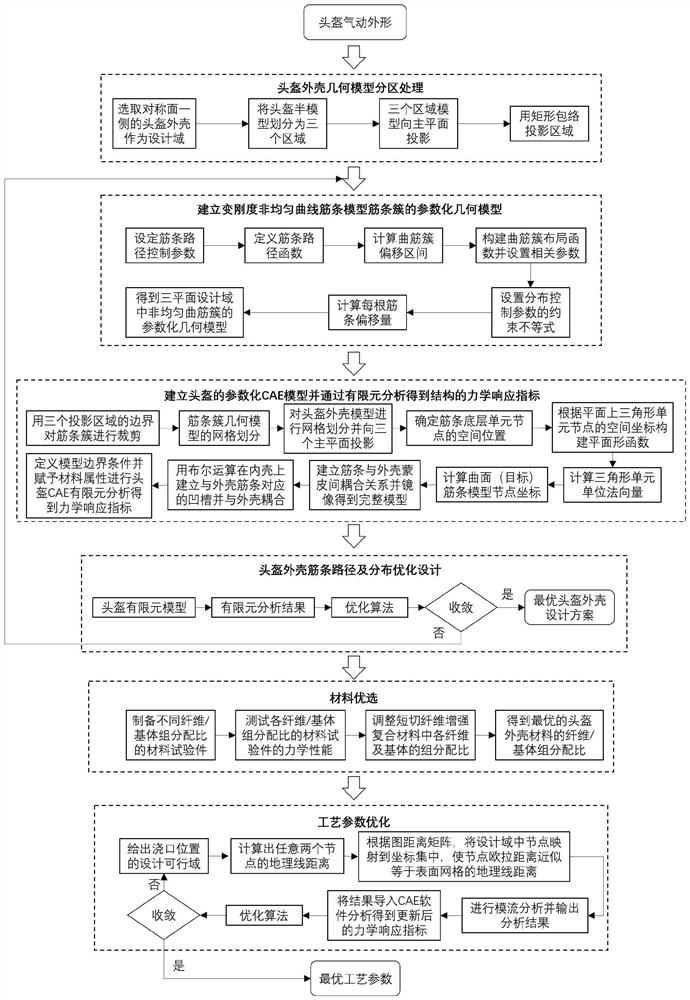

Intellectualized design method facing machine tool strut member ribbed slab layout with high specific stiffness

InactiveCN103106337AAchieve high specific stiffnessImprove structural rigiditySpecial data processing applicationsBearing surfaceMachine tool

The invention discloses an intellectualized design method facing machine tool strut member ribbed slab layout with high specific stiffness. The intellectualized design method facing the machine tool strut member ribbed slab layout with the high specific stiffness specificly comprises preprocessing, self-adaptation generating and postprocessing, wherein the preprocessing comprises the following step: constructing virtual three-dimensional generating space model of a machine tool strut member; the self-adaptation generating comprises the following step; obtaining optimal layout of projecting of a machine tool strut member inner ribbed slab layout on a bearing surface; the postprocessing comprises the following steps: conducting stretch processing on projection configuration of the machine tool strut member bearing surface along an assigned direction; and then obtaining layout designing scheme of the machine tool strut member inner ribbed slab layout. By constructing a self-adaptation generating criterion of the bearing configuration, intellectualized design method facing the machine tool strut member ribbed slab layout with the high specific stiffness can achieve high specific stiffness design of the machine tool strut member, meet requirements of low carbon and saving materials, and can be widely used in optimal design of heavy type and extra-heavy type manufacturing equipment bearing configuration.

Owner:XI AN JIAOTONG UNIV

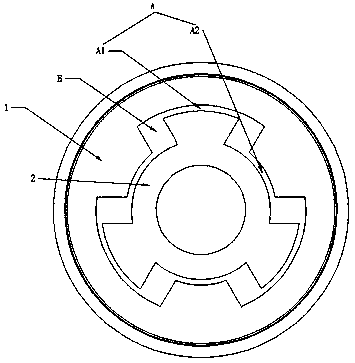

V-shaped rubber stack component, stiffness design method and application

ActiveCN109910938ALow rotational stiffnessImproved vibration protectionAxle-boxes mountingLateral stiffnessEngineering

The invention discloses a V-shaped rubber stack component. The component comprises a horizontally arranged mounting plate, and two rubber stacks bonded on the mounting plate in a vulcanized manner, wherein each rubber stack comprises a rubber layer, a baffle laminated with the rubber layer, and an outer layer plate arranged in the outmost layer; the rubber layer, the baffle and the outer layer plate are bonded into a whole in a vulcanized manner; the two rubber stacks are symmetrically arranged on the upper and lower layers of the rubber plate and bonded to the middle of the mounting plate; the rubber stack is inclined to the longitudinal direction of a product; the two rubber stacks form V shape distribution with an included angle being alpha; and the angle alpha is greater than 120 degrees and smaller than 180 degrees. The V-shaped rubber stack component is high in vertical and lateral stiffness, low in lateral and longitudinal rotational stiffness, and suitable for the stiffness requirements during suspension and bearing processes, improves the vibration reducing to suspended pieces, is high in vibration reducing reliability, meets the requirements on vibration reducing and moving adaptability of gear cases, motors and engines, saves mounting space, is convenient for mounting and maintenance, and low in cost. The invention further provides a stiffness design method and the application of the V-shaped rubber stack component.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

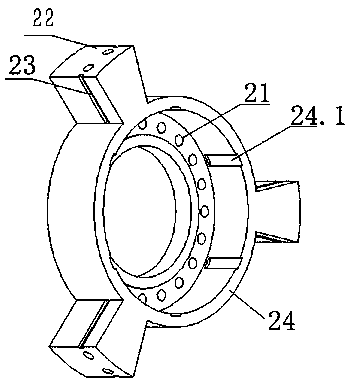

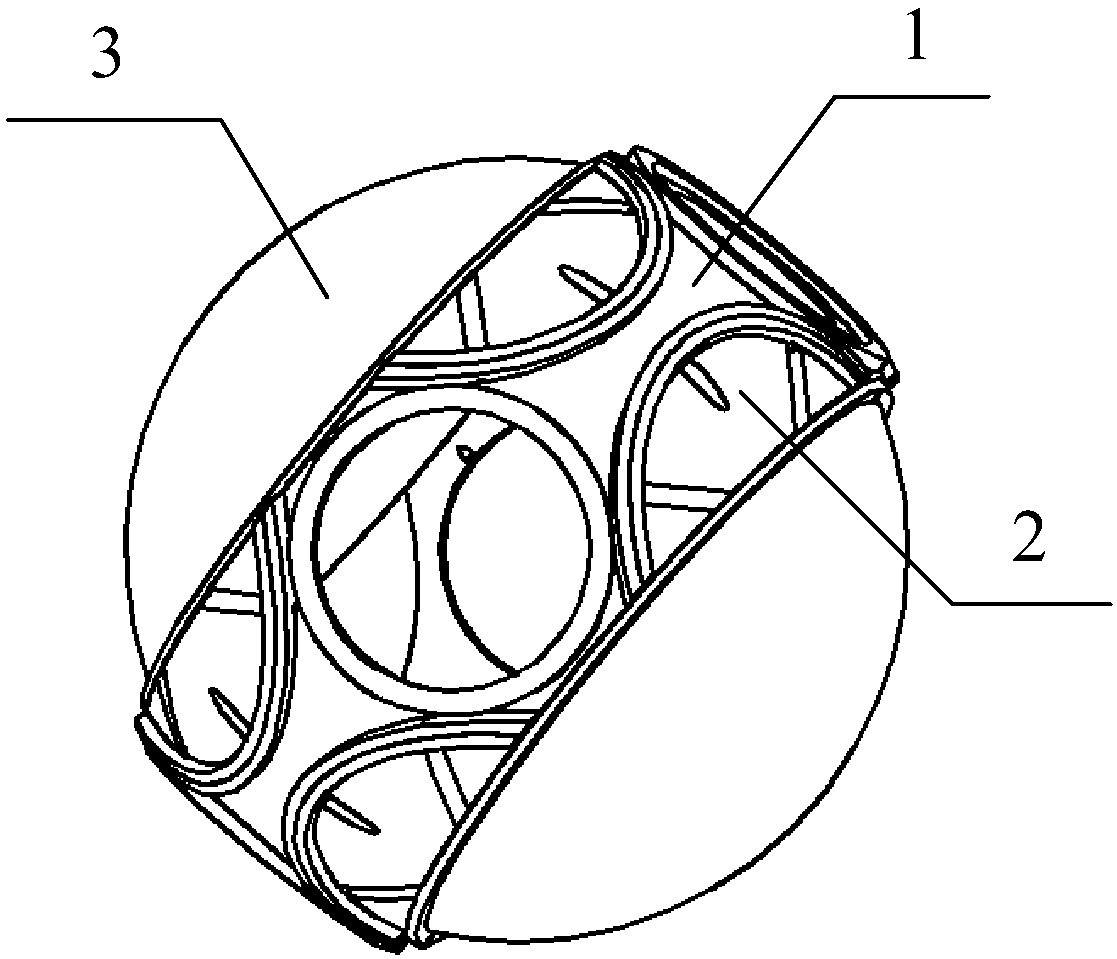

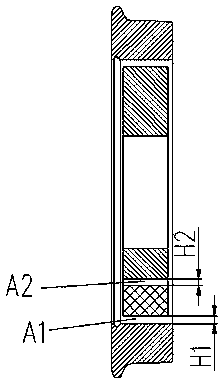

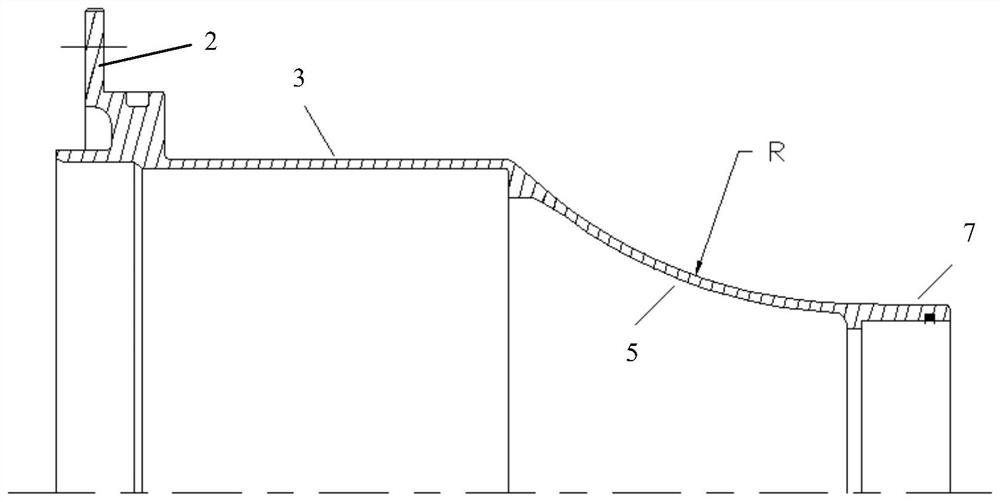

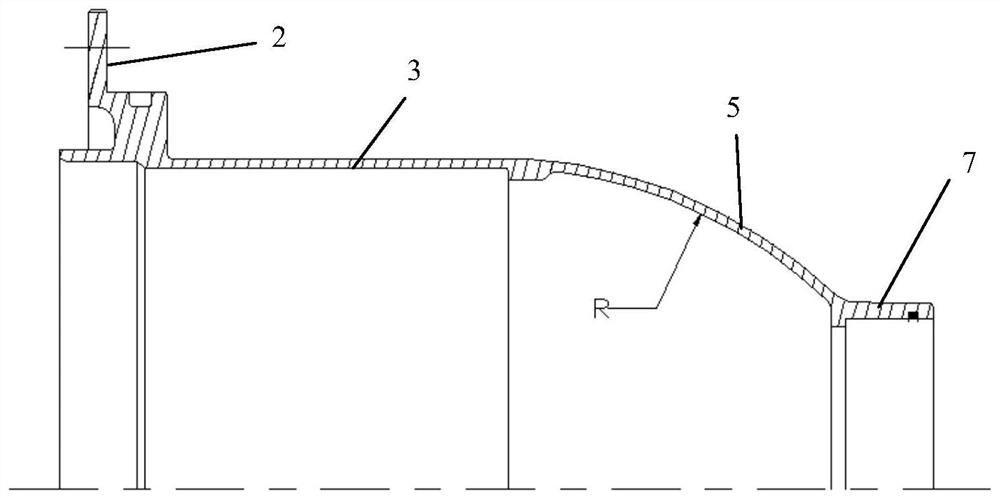

Elastic wheel for rail traffic vehicle and assembling method and rigidity design method thereof

ActiveCN110154640AReduce radial stiffnessDecrease the diameter-to-axis stiffness ratioRail-engaging wheelsElastomerStructural stability

An elastic wheel for a rail traffic vehicle comprises a tire, a wheel core and elastic bodies, wherein the tire and the wheel core are radially separated to form radial clearances and are circumferentially separated to form circumferential clearances; N*2 circumferential clearances are circumferentially uniformly distributed, and N is not less than 3; each elastic body is compressed into the corresponding circumferential clearance; the elastic bodies are radially separated from the tire and the wheel core without contact; and the circumferential clearances are arranged parallel to two sides towhich the elastic bodies are clung. With the adoption of the elastic wheel for the rail traffic vehicle, the radial rigidity of the elastic wheel can be effectively reduced; the radial axis rigidityratio of the elastic wheel is reduced; the vibration condition of a lower part of a vehicle spring is reduced; the structure stability and reliability of the elastic wheel is improved; the rigidity demand of the lower part of the vehicle spring in a low-floor vehicle under different route conditions can be met; the use safety of the elastic wheel is improved; the production cost and the maintenance cost of the elastic wheel are low; and the practicability of the elastic wheel is improved. The invention also supplies an assembling method and a rigidity design method of the elastic wheel for therail traffic vehicle.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

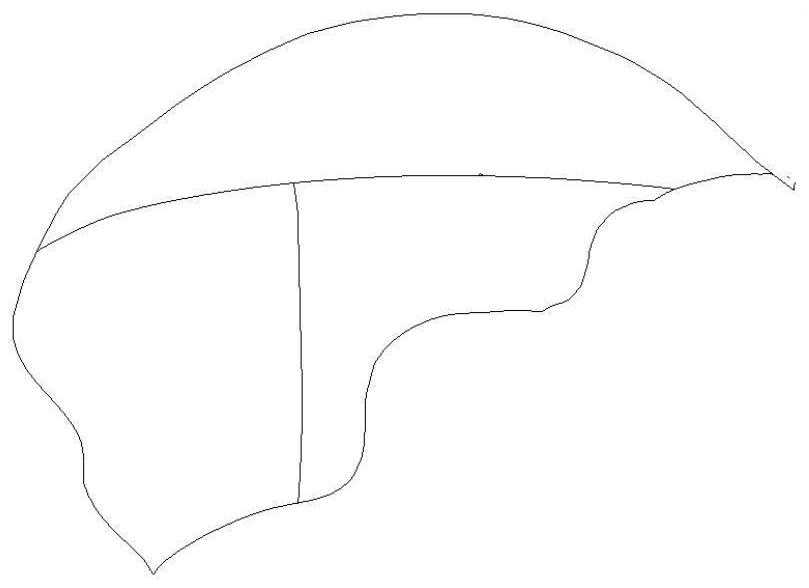

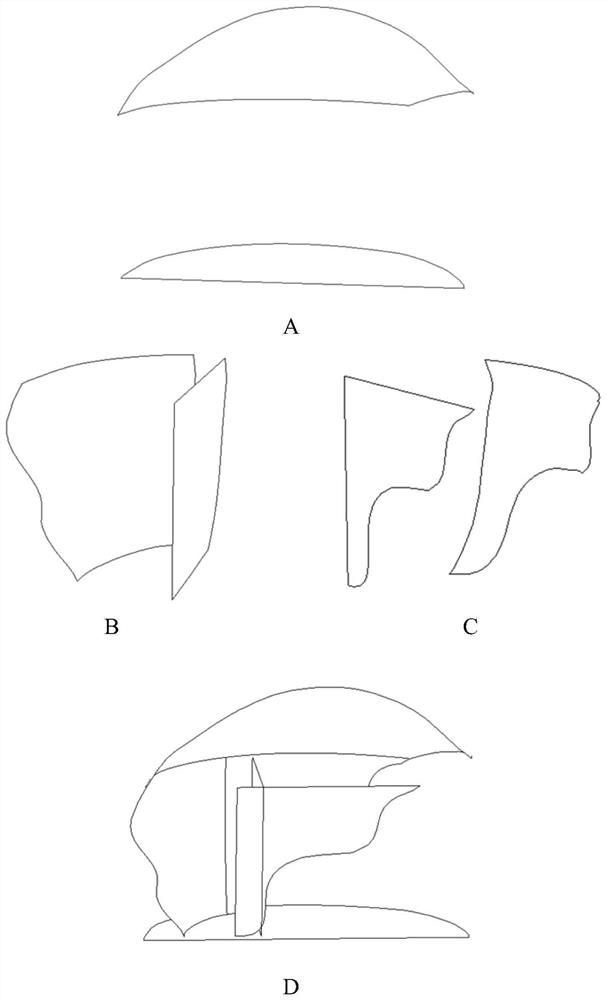

High-protective-property variable-rigidity skiing helmet and design and preparation method thereof

PendingCN114417676AIncrease stiffnessHigh strengthGeometric CADDesign optimisation/simulationExperimental testingGeometric modeling

Owner:DALIAN UNIV OF TECH

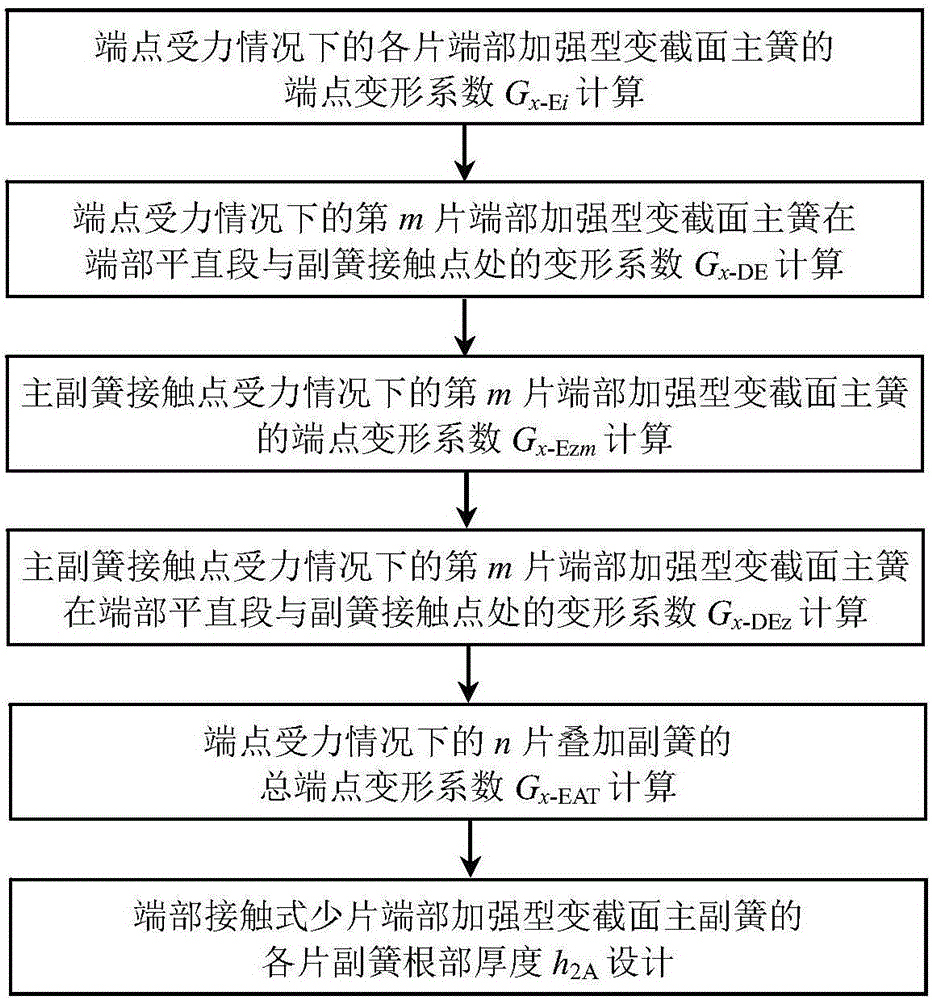

Design method for root thickness of end contact type few leaf end enhanced auxiliary springs

InactiveCN105889378ARobust Design MethodPrecise design methodGeometric CADLeaf springsEngineeringContact type

A design method for root thickness of end contact type few leaf end enhanced auxiliary springs relates to the field of suspension leaf spring technology. In the invention, root straight section thickness of auxiliary springs of end contact type few leaf end enhanced main and auxiliary springs can be designed according to structure parameter of each main spring, length and leaf number of the auxiliary springs, elastic modulus and required value of complex stiffness design of the main and auxiliary springs. Instances and the ANSYS simulation verification show that the design method for the root thickness of the end contact type few leaf end enhanced auxiliary springs is correct, the root design value of the auxiliary springs can be obtained accurately and reliably, and a reliable technology foundation can be laid for the development of the CAD software of the end contact type few leaf end enhanced main and auxiliary springs. By using the method, the product design level, the product property and the vehicle running smoothness can be improved, meanwhile the cost of the product design and the cost of tests can be reduced, and the product development can be sped.

Owner:SHANDONG UNIV OF TECH

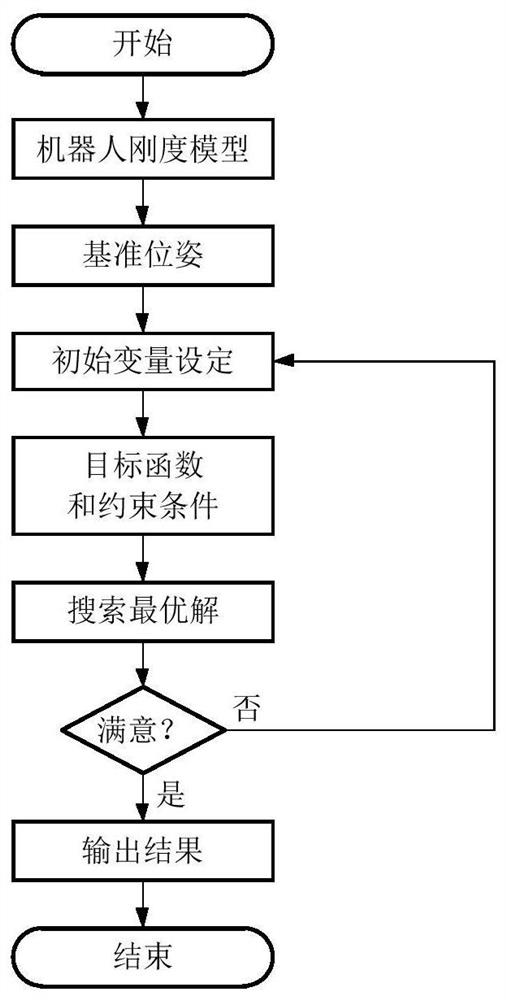

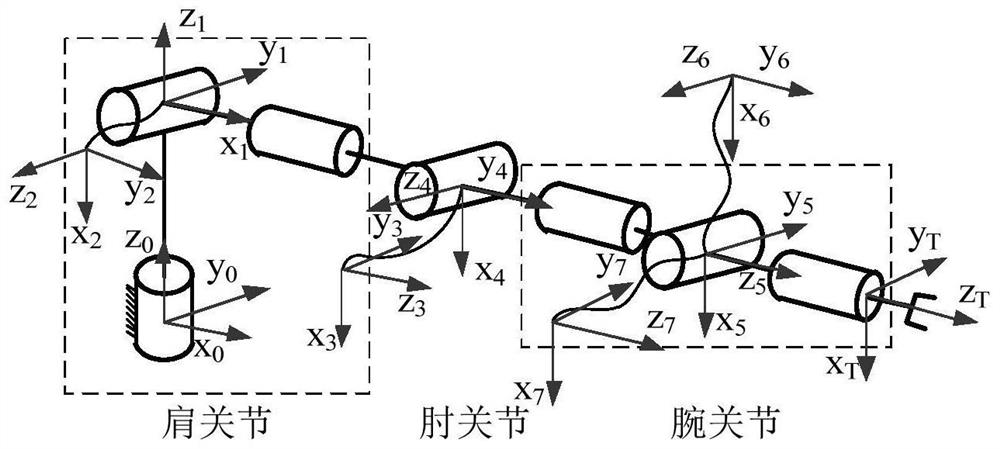

A robot stiffness design method and terminal based on stiffness model

ActiveCN112571452BPerfect Stiffness Modeling TheoryReasonable stiffnessManipulatorSimulationControl theory

The invention discloses a stiffness model-based robot stiffness design method and a terminal. The method includes the following steps: establishing a robot stiffness model according to the robot structure and stiffness design parameters; selecting a reference pose for robot stiffness design; constructing a stiffness comprehensive evaluation The stiffness optimization comprehensive model of functions, constraints and initial values; the optimal solution of the stiffness design variables is obtained by solving the stiffness optimization comprehensive model. The invention can find the optimal allocation scheme of the robot stiffness parameters under the constraint of the robot end stiffness, makes the robot stiffness and structural design more reasonable, and has great significance for reducing the manufacturing cost of the robot.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP +1

Elastic buffer casing and rigidity coefficient design method thereof

ActiveCN113027548ADecreased stiffness coefficientPlay the role of flexible protectionGeometric CADHydro energy generationStiffness coefficientAviation

The invention discloses an elastic buffer casing and a rigidity design method of the elastic buffer casing. The elastic buffer casing sequentially comprises a flange part section, a first bearing seat section, a transition section and a second bearing seat section in the axial direction, wherein the flange part section is provided with a flange edge, and the flange edge is fixedly connected with an outer casing through bolts, so that one end of the elastic buffer casing is fixed on the outer casing; an inner hole of the first bearing seat section is matched with an outer circle of a first bearing mounted on a power output shaft assembly; an inner hole of the second bearing seat section is matched with an outer circle of a second bearing mounted on the power output shaft assembly; and the diameter of the transition section is gradually transited from the diameter of the first bearing seat section to the diameter of the second bearing seat section in the axial direction. The action time of impact force is prolonged by reducing the rigidity coefficient of the elastic buffer casing, so that the effect of preventing a power turbine rotor system and the casing from being damaged by vibration impact is achieved, and safe and stable work of a whole aircraft engine is ensured.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

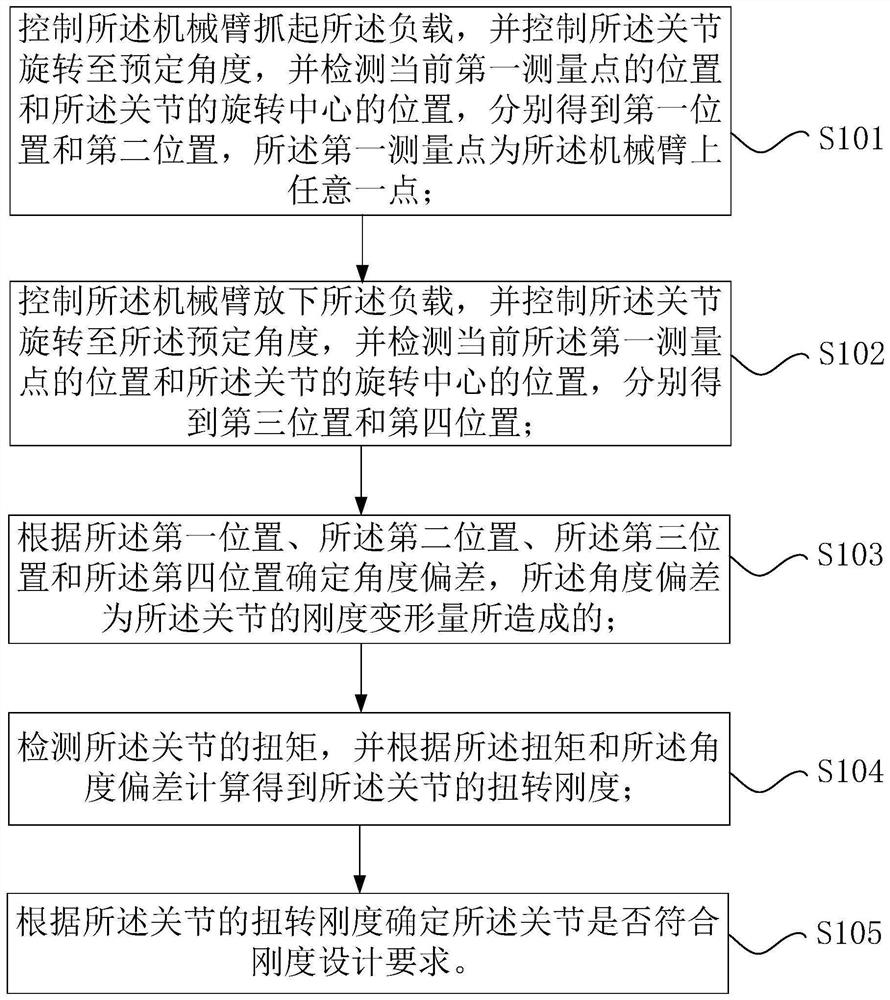

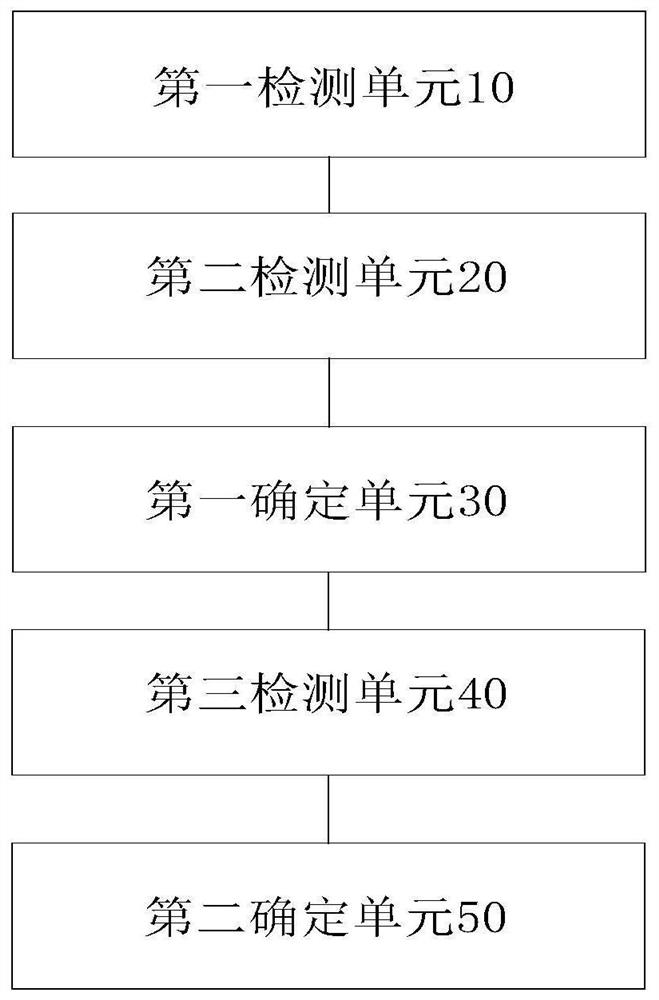

Method and device for detecting joint rigidity of robot and robot

The invention provides a method and device for detecting the joint rigidity of a robot and the robot. The method comprises the steps: controlling a mechanical arm to grab a load, controlling a joint to rotate to a preset angle, detecting the position of a current first measuring point and the position of the rotation center of the joint, and obtaining a first position and a second position respectively, wherein the first measuring point is any point on the mechanical arm; controlling the mechanical arm to put down the load, controlling the joint to rotate to a preset angle, and detecting the current position of the first measuring point and the position of the rotation center of the joint to obtain a third position and a fourth position respectively; determining an angular deviation according to the first position, the second position, the third position and the fourth position; detecting the torque of the joint, and calculating the torsional rigidity of the joint according to the torque and the angular deviation; and determining whether the joint meets the rigidity design requirement or not according to the torsional rigidity of the joint. The problem that whether the joint rigidity of the robot meets the design requirement or not is difficult to determine in the prior art is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com