Coupler for shaft suspending type installing direct drive motor and rigid design method thereof

A direct-drive motor and coupling technology, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problem that the connection structure on the motor side and the connection structure on the axle side cannot be centered and positioned, and the rubber blocks are difficult to install in place at the same time , Increase the failure risk of the motor system, etc., to improve the installation reliability and convenience, reduce the failure risk, and facilitate maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

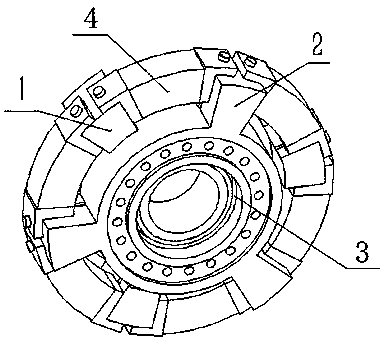

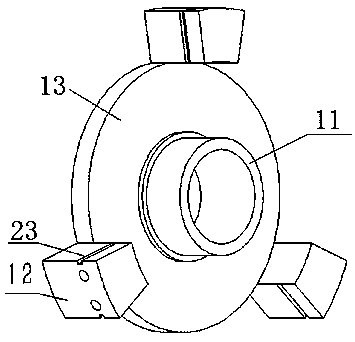

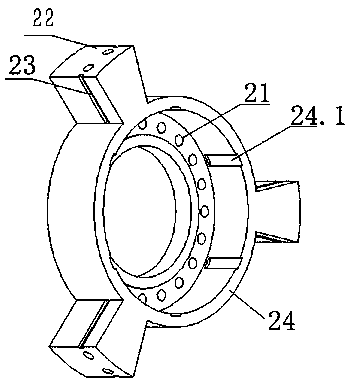

[0028] Combine below Figure 1 to Figure 7 Embodiments of the present invention are described in detail.

[0029] A shaft-suspended shaft coupling for a direct-drive motor, including a hub-side connection plate 1 coaxially fixed with the wheel shaft and a motor-side connection plate 2 coaxially fixed with the motor rotor shaft, characterized in that it also includes an elastically supported rotating assembly 3, The elastic support rotating assembly 3 is connected radially between the axle side connecting plate 1 and the motor side connecting plate 2, so that the wheel axle side connecting plate 1 and the motor side connecting plate 2 are coaxially rotatable connected, and the rotating assembly is supported by elastic support. 3 Carry the weight of the motor in the radial direction, and the connection plate 1 on the wheel shaft side and the connection plate 2 on the motor side are elastically connected in the circumferential direction.

[0030] In the present invention, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com