Novel high-speed heavy-duty high-speed rail bearing

A high-speed, high-speed rail technology, applied in the field of high-speed rail bearings, can solve problems such as raceway indentation, rollers are easy to skew, rolling element indentation or peeling, etc., and achieve high-speed stability and rigidity, reliable lubrication conditions, and good performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

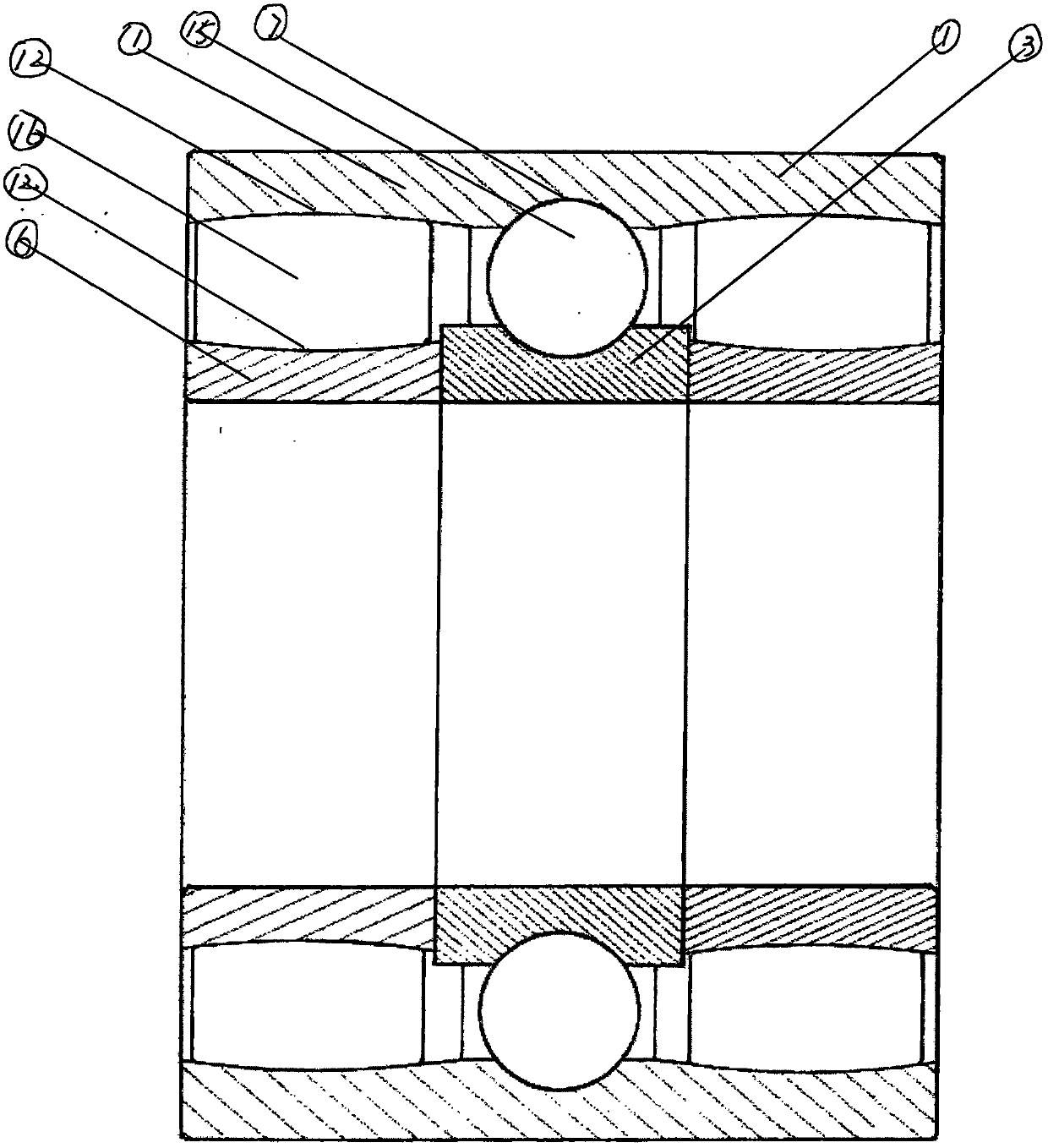

[0059] Such as figure 1 The "new high-speed heavy-duty high-speed rail bearing" shown includes: an outer ring 1, two double-half inner rings 6, a deep groove ball bearing inner ring 3, and three rows of rolling elements; the inner circumference of the outer ring 1 is axial Set a circle of deep groove spherical rolling body track 7 in the middle of the distance, set spherical rolling body 15 in the deep groove spherical rolling body track 7, and set a row of rings at the two ends of the deep groove spherical rolling body track 7 corresponding to the distance Roller track 12, ring roller 16 is arranged in the track,

[0060] The inner ring 3 of the deep groove ball bearing is arranged between the two double-half inner rings 6, and corresponds to a circle of deep groove ball rolling body tracks 7 set in the middle of the inner circumference of the outer ring 1, through the combination of spherical rolling bodies 15, Forming the center ball structure of the deep groove ball bear...

Embodiment 2

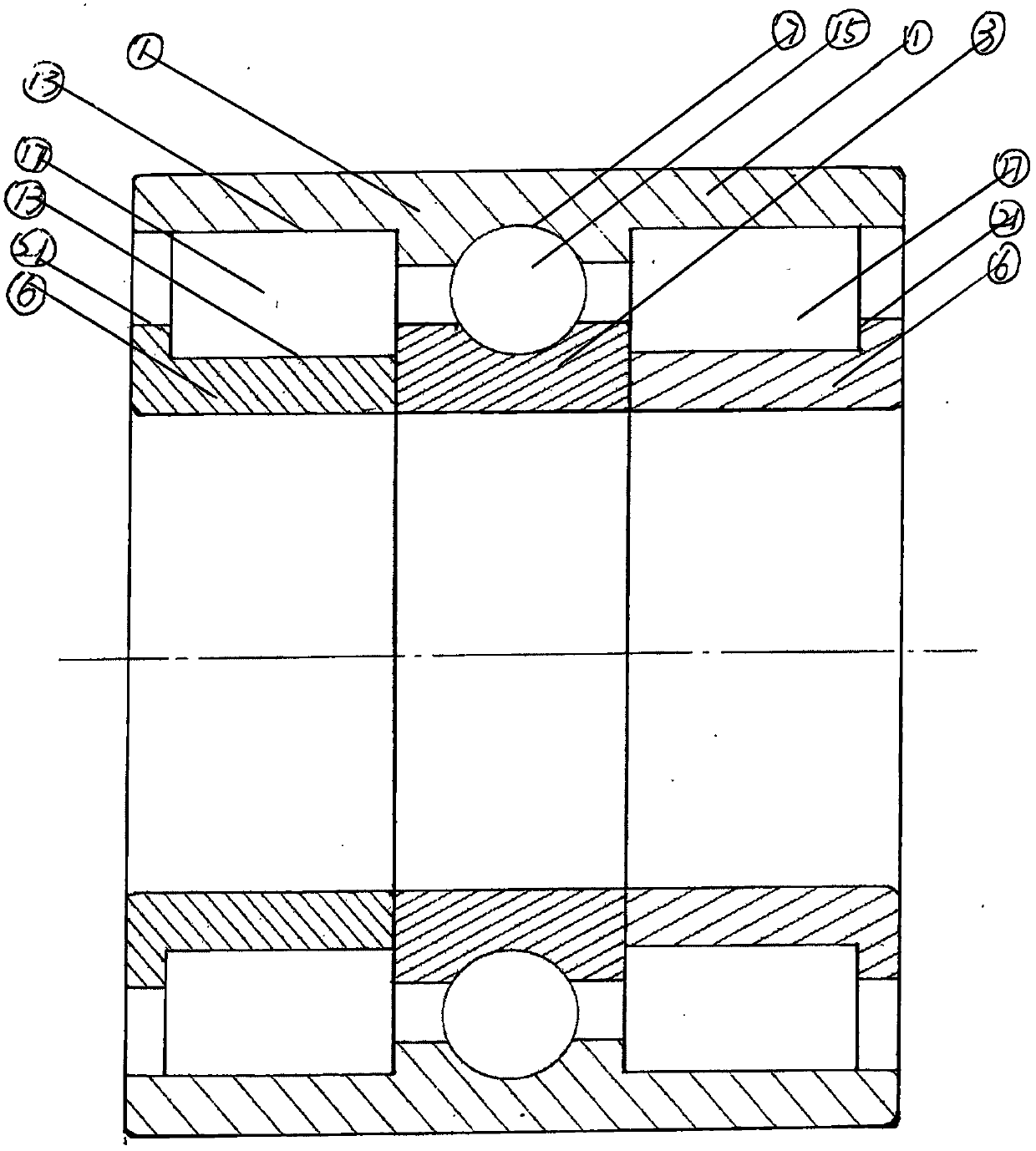

[0063] Such as figure 2 The "new high-speed heavy-duty high-speed rail bearing" shown includes: an outer ring 1, two double-half inner rings 6, a deep groove ball bearing inner ring 3, and three rows of rolling elements; it is characterized by: the outer ring 1 A circle of deep groove spherical rolling body track 7 is set in the middle of the axial distance of the inner circumference, and spherical rolling body 15 is arranged in the deep groove spherical rolling body track 7, and the distance between the two ends of the deep groove spherical rolling body track 7 corresponds to each There is a row of cylindrical roller tracks 13, and cylindrical rollers 17 are arranged in the cylindrical roller tracks 13,

[0064] The inner ring 3 of the deep groove ball bearing is arranged between the two double-half inner rings 6, and corresponds to a circle of deep groove ball rolling body tracks 7 set in the middle of the inner circumference of the outer ring 1, through the combination of ...

Embodiment 3

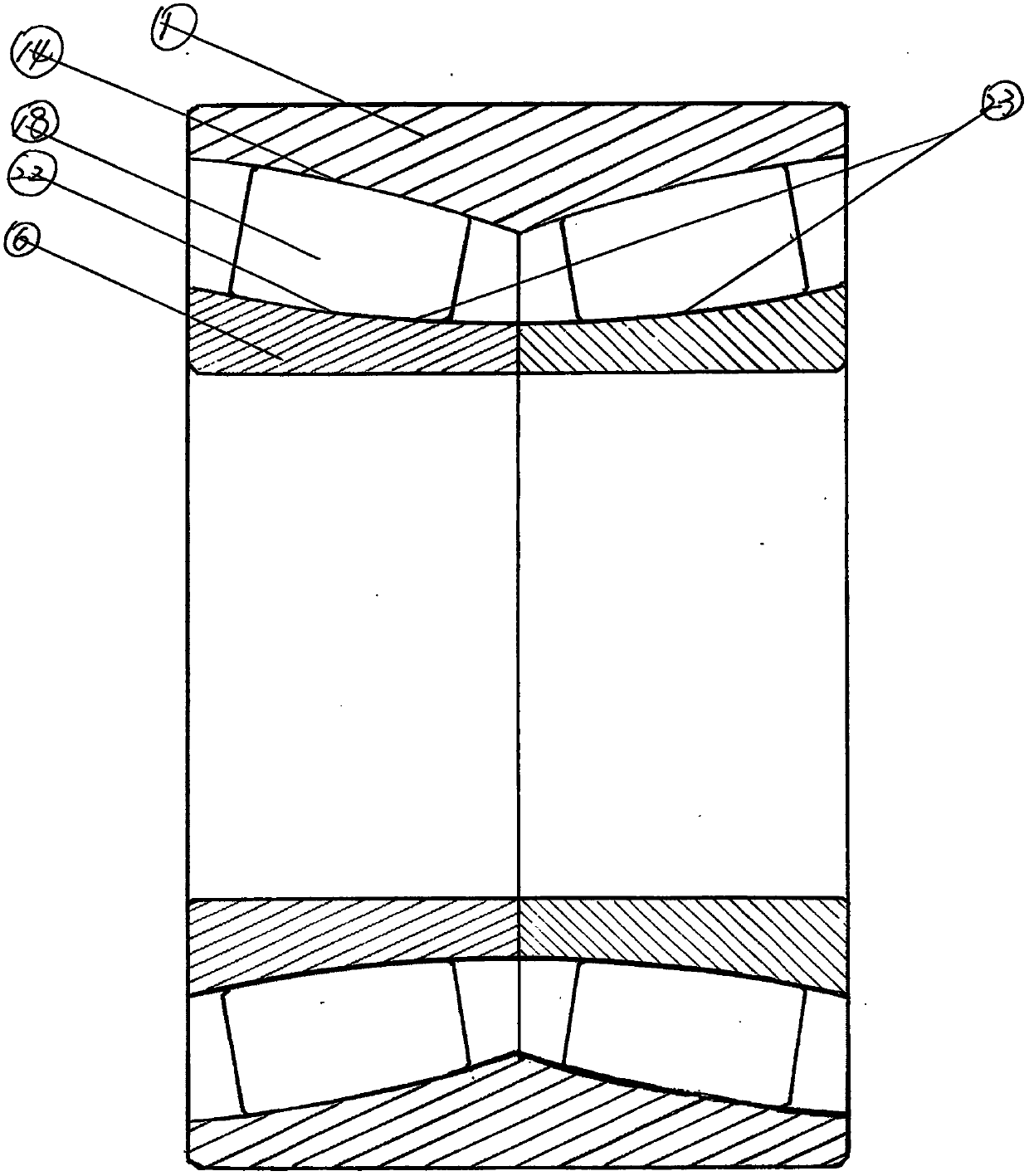

[0067] Such as image 3 The "new high-speed heavy-duty high-speed rail bearing" shown includes: an outer ring 1, two double-half inner rings 6, and two rows of spherical rollers 18; it is characterized in that: the outer ring 1 is axially A row of spherical roller tracks 14 are arranged corresponding to the distance on both sides of the distance, and spherical rollers 18 are respectively arranged in the spherical roller tracks 14,

[0068] The two double-half inner rings 6 are coaxially arranged on both sides of the inner circumference of the outer ring 1 where two rows of spherical roller tracks 14 are arranged, and the outer circumferences of the two double-half inner rings 6 are respectively provided with double inner rings. The reverse spherical roller track 22 of the ferrule has two double-half inner ferrules 6 coaxially combined into one body, and the reverse spherical surface of the double-half inner ferrule 6 respectively arranged on the outer circumference of the two d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com