Tunnel supporting structure system rigidity design method and system

A technology of support structure and design method, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as strong subjectivity, poor scientificity, and reduced reliability and economy of engineering construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

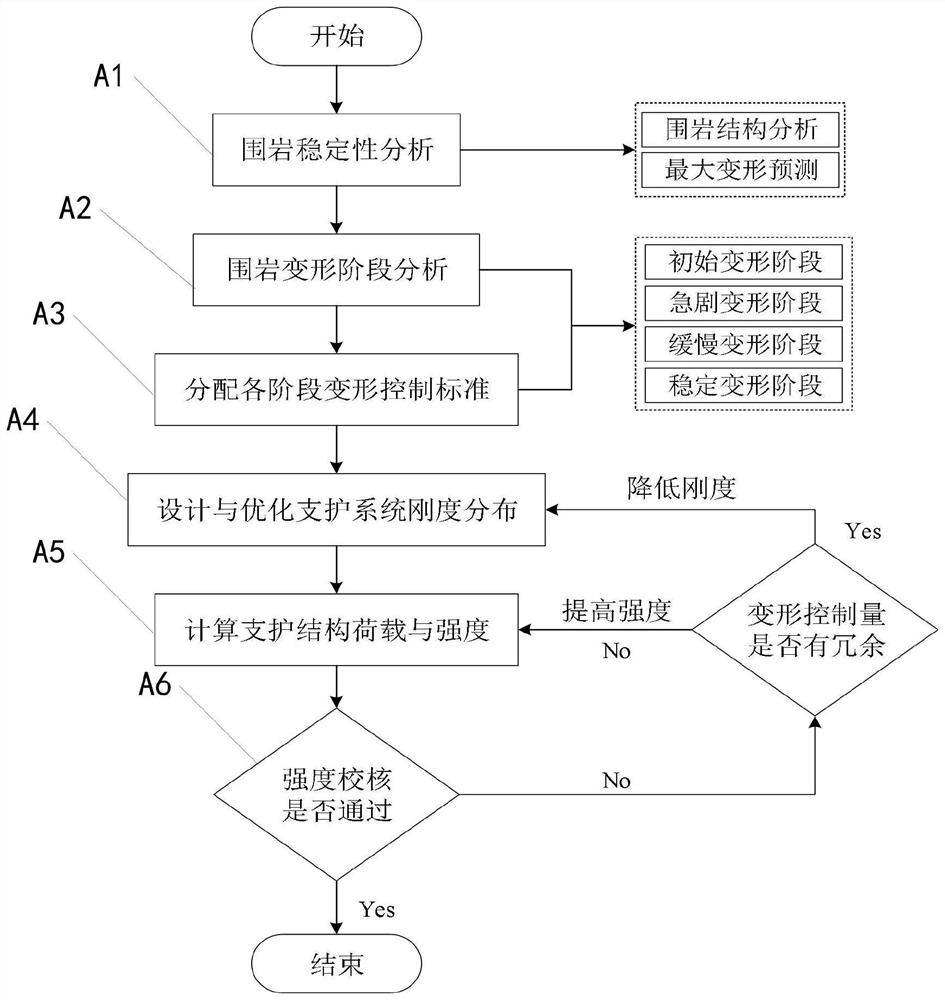

[0124] like figure 1 As shown, the embodiment of the present invention provides a method for designing the stiffness of a tunnel support structure system, and the specific implementation steps are as follows:

[0125] A1, Surrounding rock stability analysis

[0126] Firstly, the structure of surrounding rock and its possible maximum deformation are predicted by theoretical calculation or on-site monitoring data analysis. Then, the standard deformation of surrounding rock is determined according to the stability conditions of the deep surrounding rock structure layer. If the maximum deformation of the surrounding rock exceeds the standard deformation of the surrounding rock, it means that the surrounding rock cannot achieve a balanced state by adjusting its own stress. At this time, the stability of the surrounding rock itself does not meet the requirements, and it needs to be mobilized and assisted by providing support. Rock bearing.

[0127] The standard deformation of sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com