Whole machine static stiffness matching and designing method in view of machine tool top-down design

A design method and static stiffness technology, applied in the field of static stiffness matching design of the whole machine, can solve problems such as no estimation means, inability to control the static stiffness of the whole machine, and failure to meet the user's requirements for the static stiffness of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A design method for static stiffness matching design of the whole machine tool for forward design of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

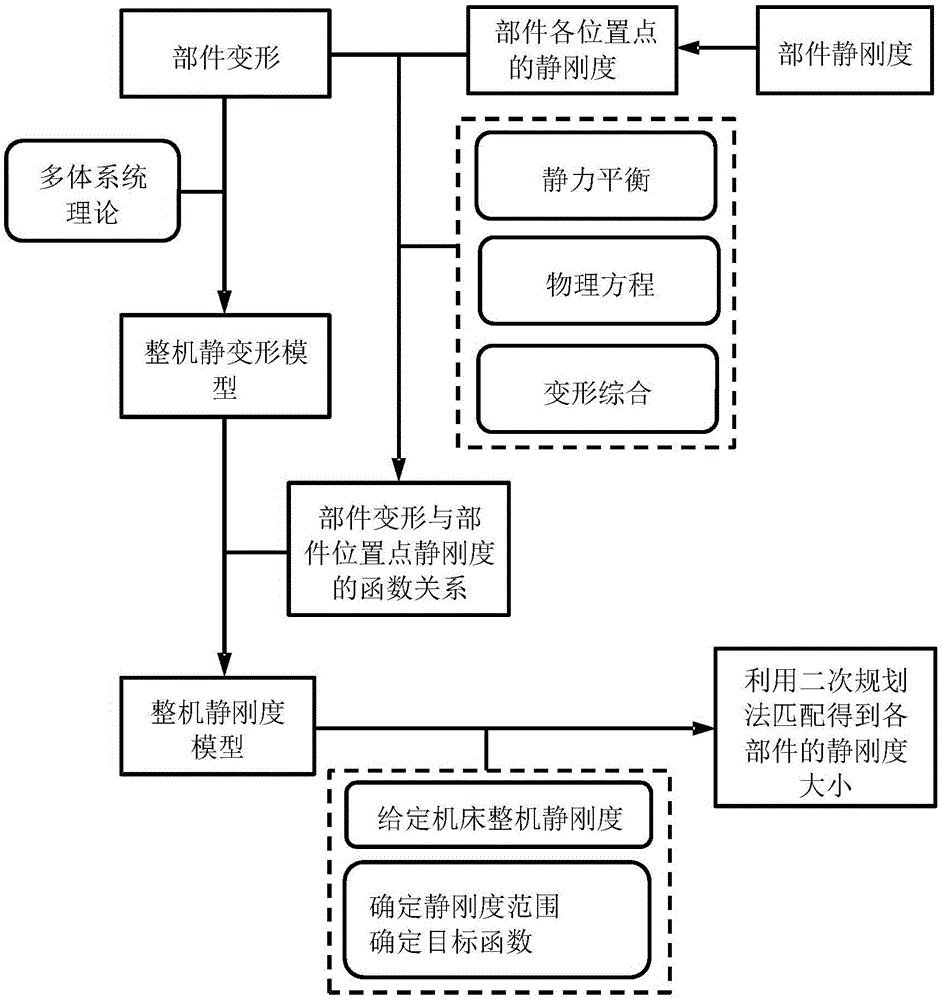

[0047] Such as figure 1 As shown, a kind of whole machine static stiffness matching design method oriented to machine tool forward design of the present invention comprises the following steps:

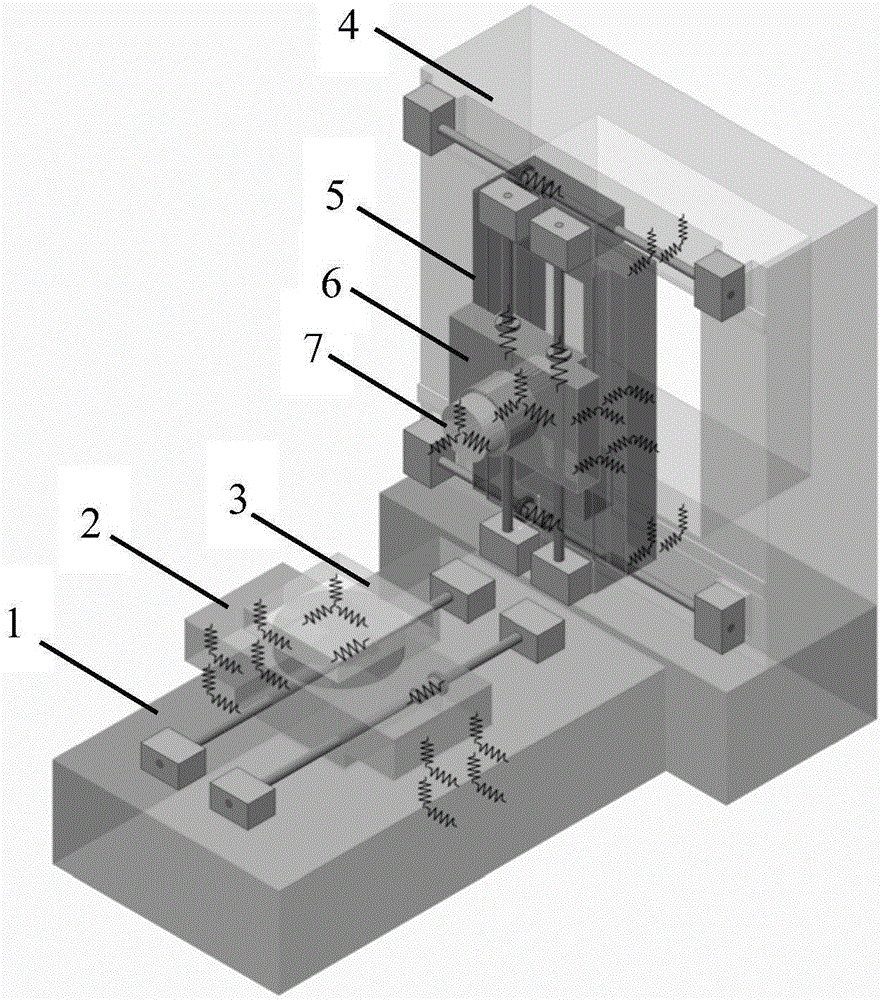

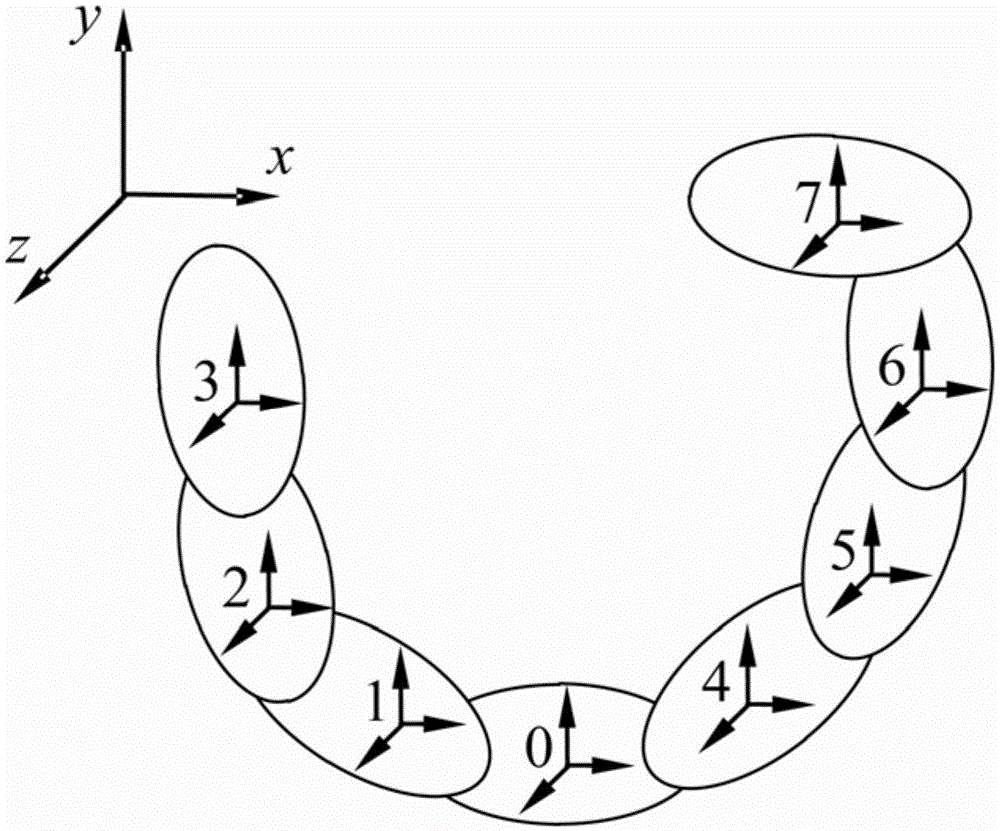

[0048] 1) Define the static stiffness of each component of the machine tool at different points; the forward design of the machine tool starts at the conceptual design stage, at this time there is only the overall layout plan, and each component has only the basic structural size. In this case, to carry out the forward design of the static stiffness of the whole machine, the static stiffness model of the whole machine must be established first. In order to describe the stiffness of the component and facilitate the establishment of the static stiffness mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com