Method for designing stiffness of helical spring of combined valve for shock absorbers

A coil spring and stiffness design technology, applied in the direction of shock absorbers, springs, shock absorbers, etc., can solve the problem that it is difficult to meet the requirements of shock absorber design and characteristic simulation modeling, there is no fast and accurate design method, and there is no established Reliable calculation methods and other issues to achieve the effect of avoiding repeated tests and modifications, reducing design and test costs, and accurate and reliable stiffness design values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail through an embodiment below.

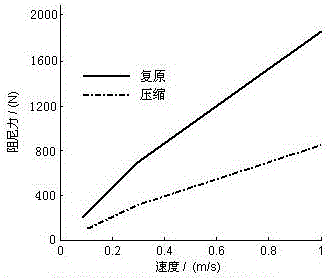

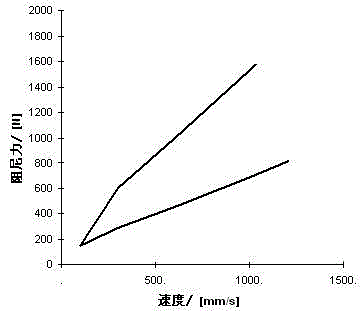

[0022] In order to meet the characteristic design requirements of the shock absorber, an automobile shock absorber adopts a compound throttle valve composed of a coil spring and a throttle valve plate. The inner circle radius of the throttle plate of the compound valve is =5.0mm; and valve port position radius =8.0mm; outer circle radius =8.5mm; Throttle valve thickness =0.15mm; the modulus of elasticity of the throttle plate material and Poisson's ratio , coil spring precompression =10.0mm; the pre-deformation of the valve plate required by the characteristics of the shock absorber =0.04mm.

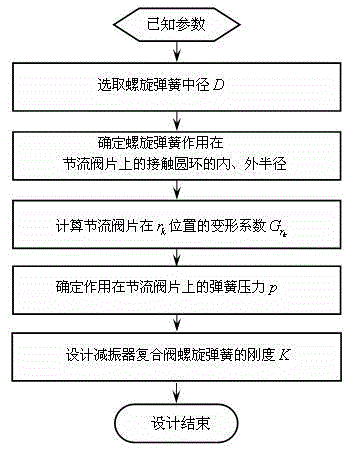

[0023] The specific steps of the method for calculating the deformation of the throttle plate of the cylindrical hydraulic shock absorber under the force of the spring provided by the embodiment of the present invention are as follows:

[0024] (1) According to the radius of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com