Composite janus microspheres based oil-water micro-emulsion separation method

A separation method and microemulsion technology, applied in separation methods, liquid separation, microsphere preparation, etc., can solve the problems of limited number of recycling times, difficult oil removal, secondary pollution, etc., and achieve rapid separation and rapid oil-water separation , the effect of efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for separating oil-water microemulsion based on composite Janus microspheres, comprising the steps of:

[0040] 1) Disperse crescent-shaped polyacrylic acid-polystyrene-polydivinylbenzene Janus microspheres with a particle size of 2.4 μm in ethanol to obtain a Janus microsphere dispersion with a concentration of 10 mg / mL;

[0041] 2) Disperse the magnetic iron ferric oxide nanoparticles in ethanol to obtain a magnetic nanoparticle dispersion with a concentration of 5 mg / mL;

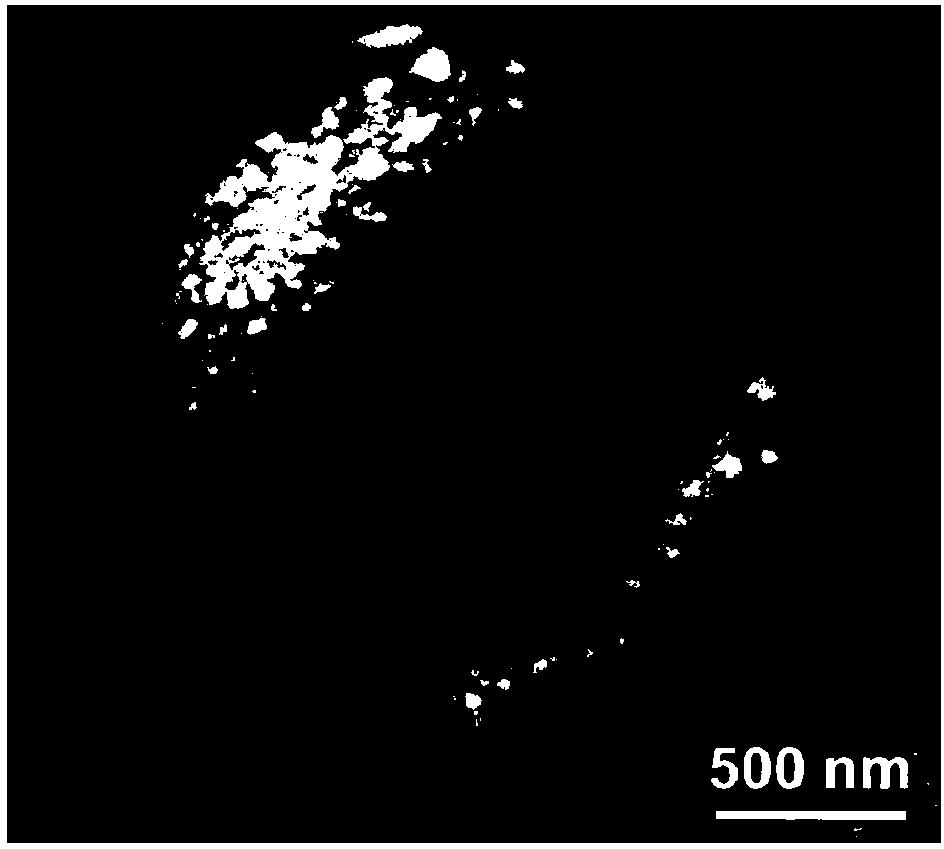

[0042] 3) Mix and stir 20mL of the Janus microsphere dispersion and 10mL of the magnetic nanoparticle dispersion for 12h to obtain a suspension; place the suspension in a centrifuge for separation to obtain a solid precipitate; use the solid precipitate to Washed twice with absolute ethanol, collected by centrifugation, and then dried in vacuum at 50°C to obtain composite Janus microspheres;

[0043] 4) dispersing the composite Janus microspheres in water to obtain a composite Janus micro...

Embodiment 2

[0048] A method for separating oil-water microemulsion based on composite Janus microspheres, comprising the steps of:

[0049] 1) Disperse crescent-shaped polyacrylic acid-polystyrene-polydivinylbenzene Janus microspheres with a particle size of 1 μm in ethanol to obtain a Janus microsphere dispersion with a concentration of 1 mg / mL;

[0050] 2) Dispersing magnetic cobalt oxide nanoparticles in ethanol to obtain a magnetic nanoparticle dispersion with a concentration of 0.5 mg / mL;

[0051]3) 10 mL of the Janus microsphere dispersion and 5 mL of the magnetic nanoparticle dispersion were mixed and stirred for 10 h to obtain a suspension; the suspension was placed in a centrifuge for separation to obtain a solid precipitate; the solid precipitate was used Washed twice with absolute ethanol, collected by centrifugation, and then dried in vacuum at 40°C to obtain composite Janus microspheres;

[0052] 4) dispersing the composite Janus microspheres in water to obtain a composite J...

Embodiment 3

[0057] A method for separating oil-water microemulsion based on composite Janus microspheres, comprising the steps of:

[0058] 1) Disperse hemispherical polyitaconic acid-polystyrene-polydivinylbenzene Janus microspheres with a particle size of 5 μm in ethanol to obtain a Janus microsphere dispersion with a concentration of 5 mg / mL;

[0059] 2) Disperse the magnetic nickel oxide nanoparticles in ethanol to obtain a magnetic nanoparticle dispersion with a concentration of 5 mg / mL;

[0060] 3) Mix and stir 20mL of the Janus microsphere dispersion and 10mL of the magnetic nanoparticle dispersion for 12h to obtain a suspension; place the suspension in a centrifuge for separation to obtain a solid precipitate; use the solid precipitate to Washed twice with absolute ethanol, collected by centrifugation, and then dried in vacuum at 50°C to obtain composite Janus microspheres;

[0061] 4) dispersing the composite Janus microspheres in water to obtain a composite Janus microsphere di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com