Patents

Literature

47results about How to "Achieve demulsification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite janus microspheres based oil-water micro-emulsion separation method

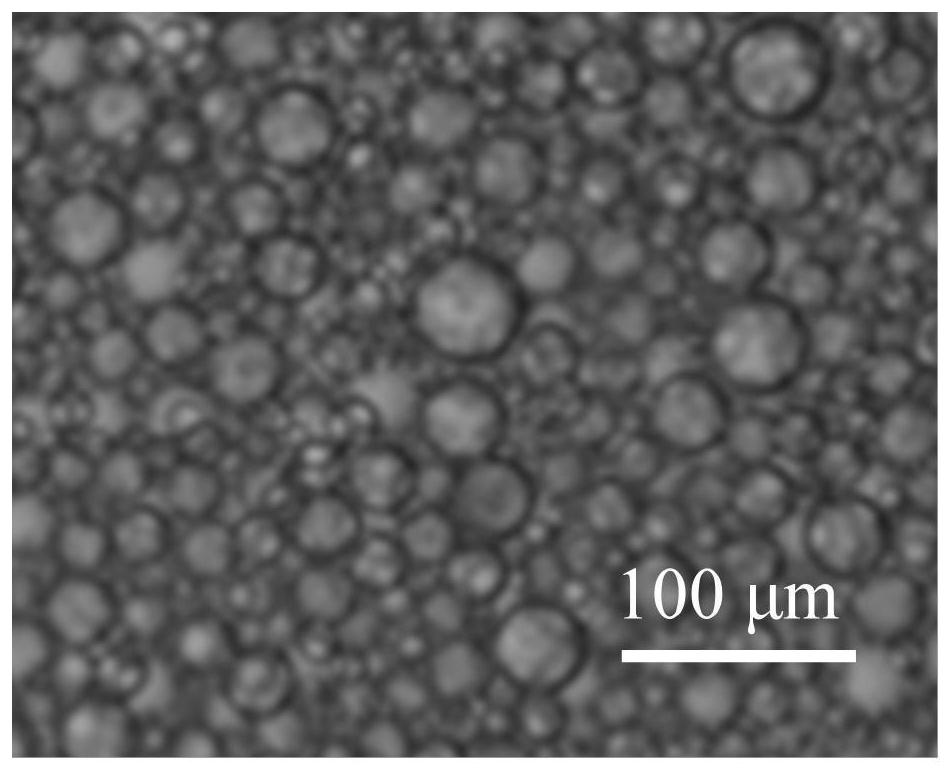

ActiveCN108311067AEfficient separationEasy to separateFatty/oily/floating substances removal devicesWater treatment compoundsChemical compositionMicrosphere

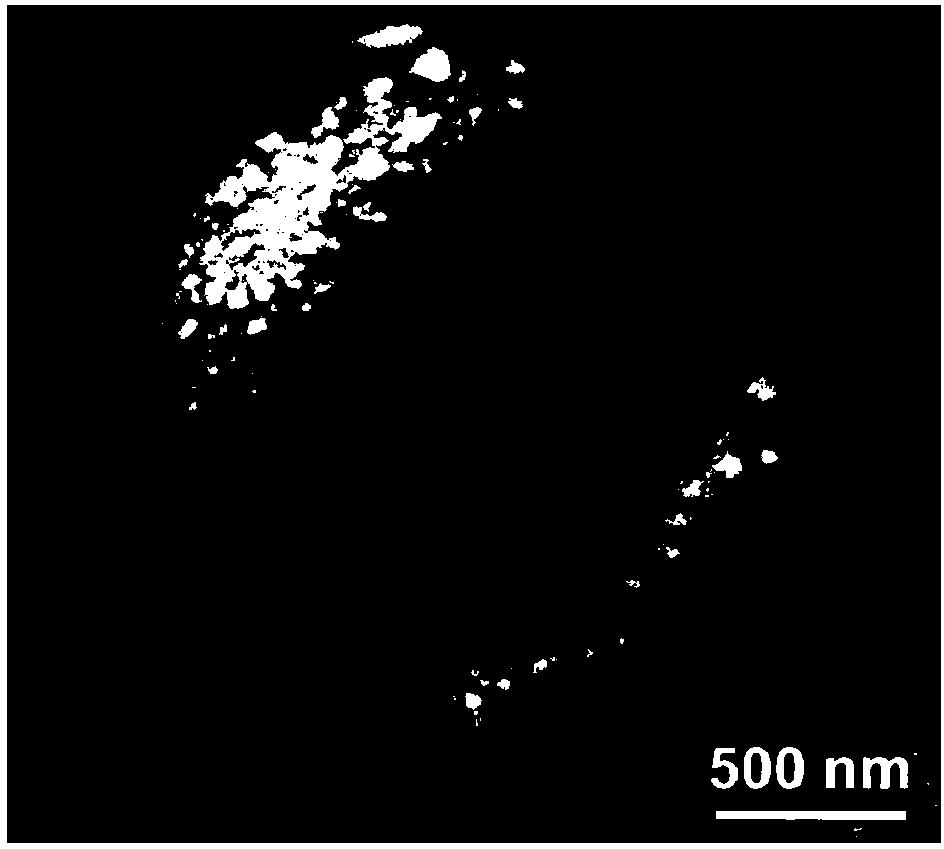

The invention discloses a composite janus microspheres based oil-water micro-emulsion separation method. With the polymers Janus microspheres with different structures and different chemical compositions as a base material, the method comprises the following steps: adsorbing magnetic nano particles on the surfaces of the microspheres through electrostatic interaction, to obtain composite Janus microspheres with magnetic responsiveness; mixing and stirring the composite Janus microspheres and an oil-water emulsion; realizing demulsification and layering of the oil-water emulsion; after the layering, applying a magnetic field to realize efficient and quick oil-water separation. According to the method disclosed by the invention, the composite Janus microspheres serve as a particle surfactanton the oil-water interface to realize the demulsification and layering of the oil-water emulsion; by applying the magnetic field, efficient and quick separation of oil and water can be realized. Theoil-water micro-emulsion separation method disclosed by the invention has the advantages of simplicity, quick process and easiness in condition control, and is applicable to efficient separation of oil water formed by different types of large-area oil.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

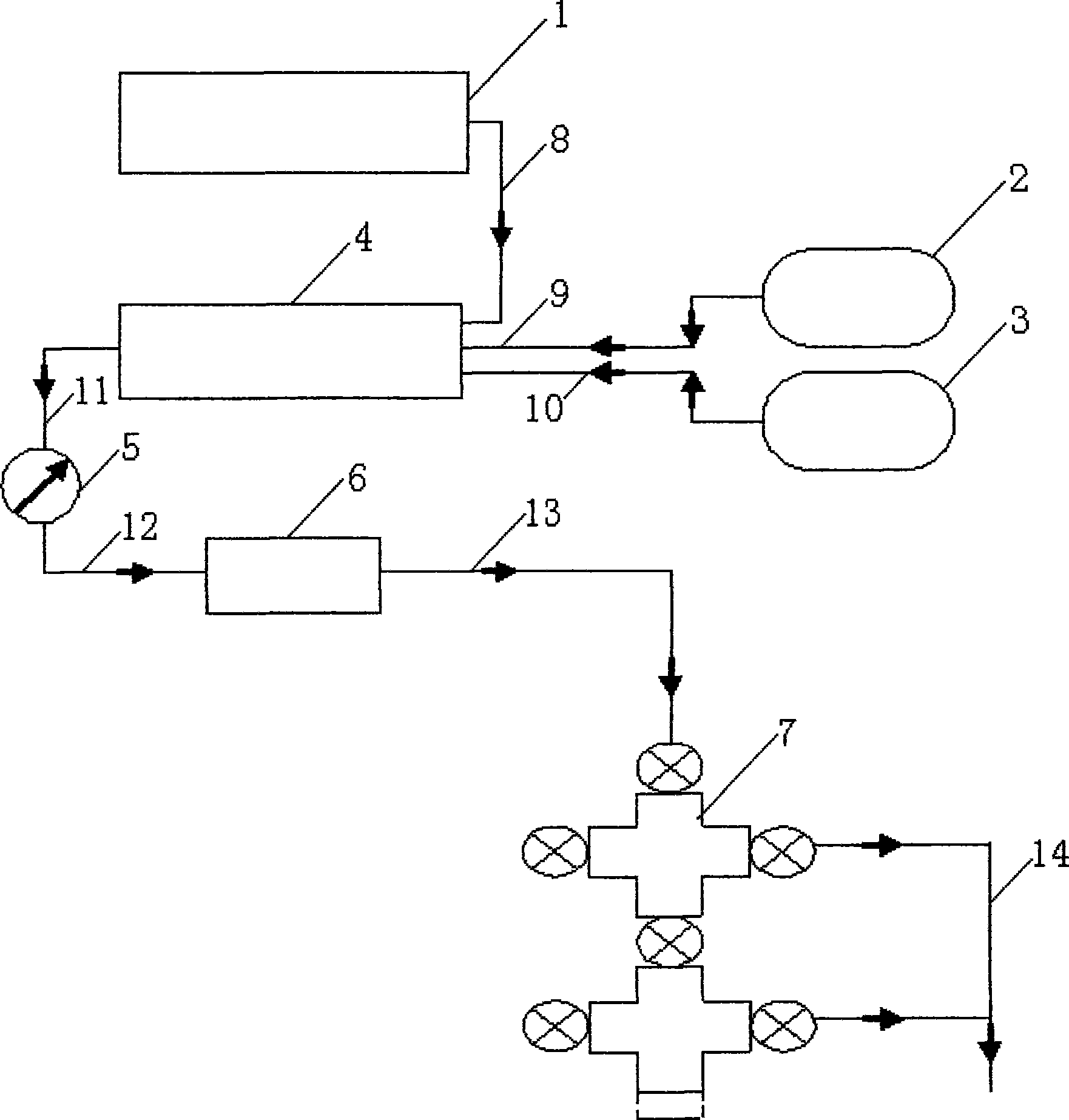

Ultra-deep ultra-thick oil thermal steam-gas (CO2 and N2) well bore viscosity reduction and oil production technology

The invention relates to a technology for producing ultra-deep and ultra-heavy oil. An ultra-deep and ultra-heavy oil hot steam-gas (CO2 and N2) shaft body viscosity reduction oil production technology is the oil production technology for replacing 'less thin oil' or 'no thin oil'. The principle is to inject steam, CO2 and N2 which are prepared together by a steam-gas generator into a shaft body simultaneously with a continuous and disconnected process. The steam, the CO2 and the N2 are circulated in the shaft body to achieve the processes of injection, viscosity reduction, circulation, lifting and production at the same time. The technology has a normalized injecting flow of the steam, the CO2 and the N2 without building a ground flow, has wide adaptability to the production of the ultra-deep and ultra-heavy oil, and provides a novel technical support and technical reserve for the large scale development and production of the ultra-deep and ultra-heavy oil in China. With the technology to produce the ultra-deep and ultra-heavy oil, the cost can be greatly reduced and the benefit can be greatly improved.

Owner:李志明

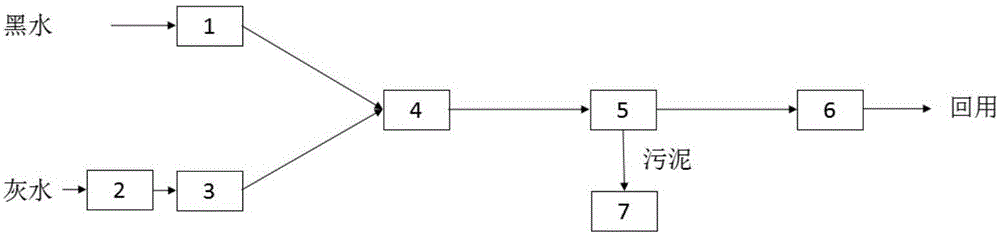

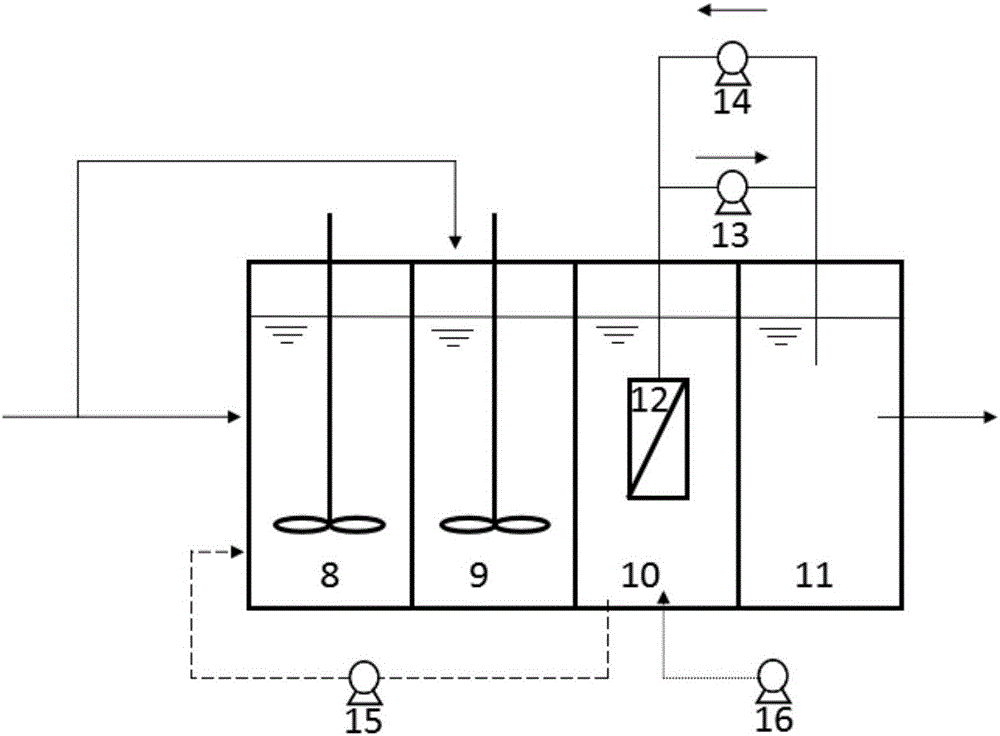

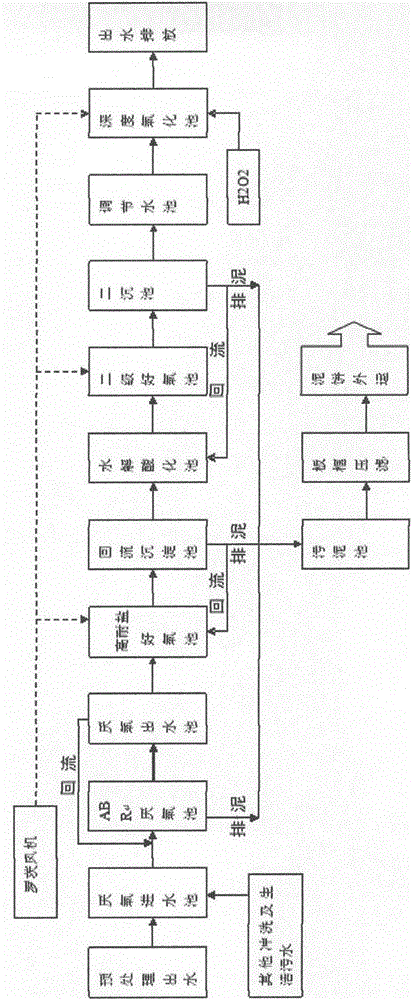

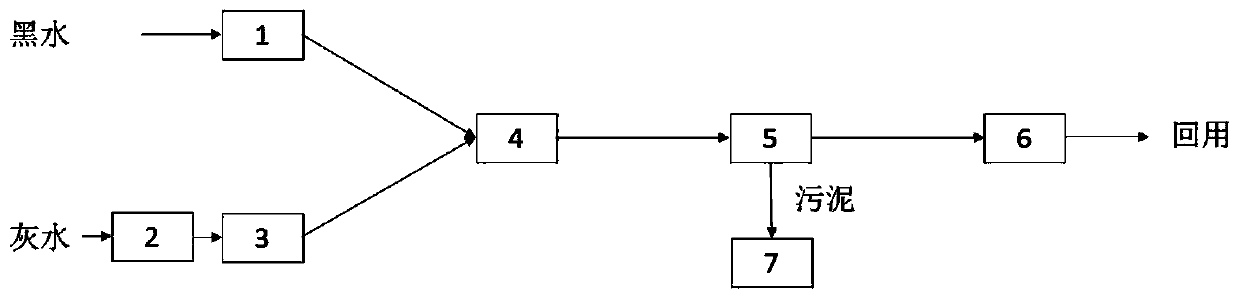

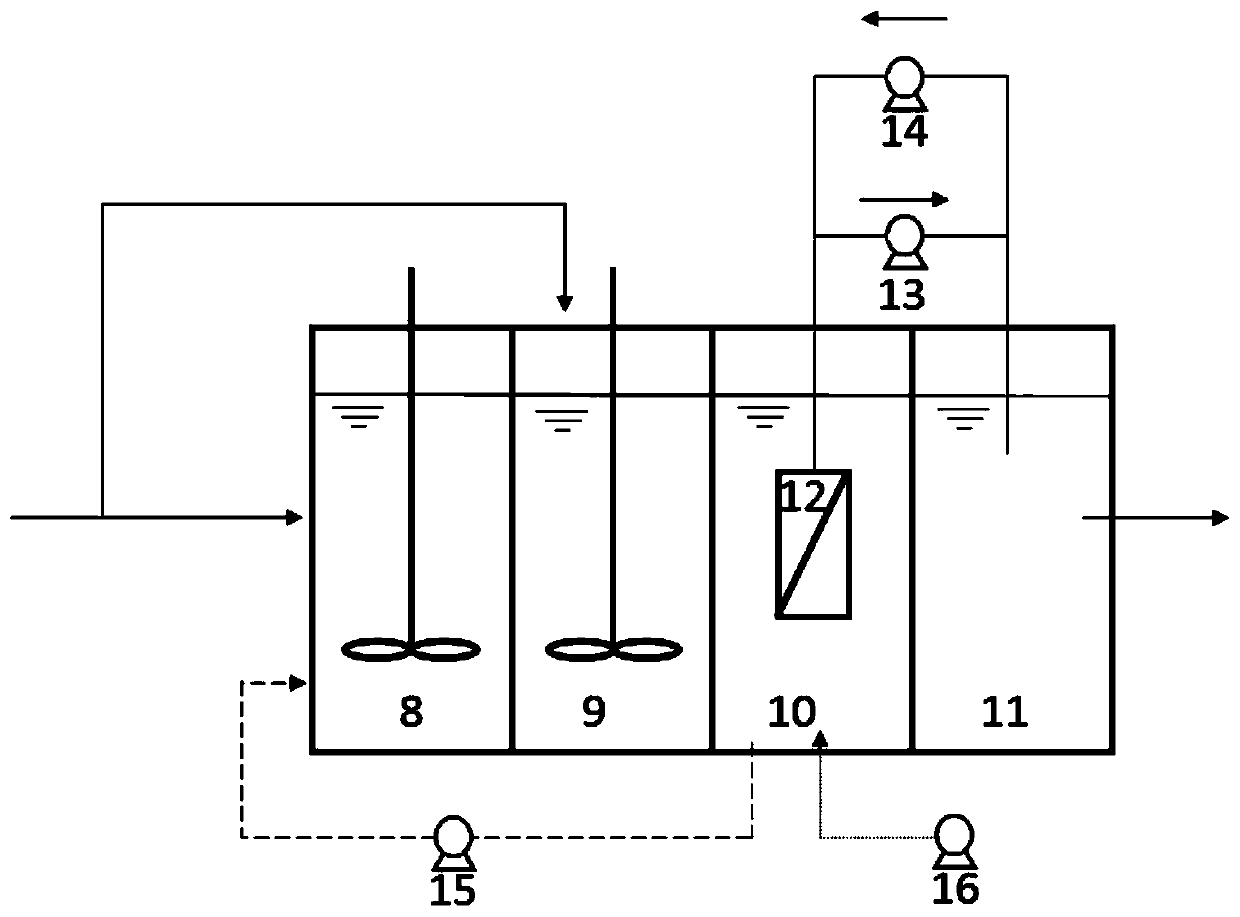

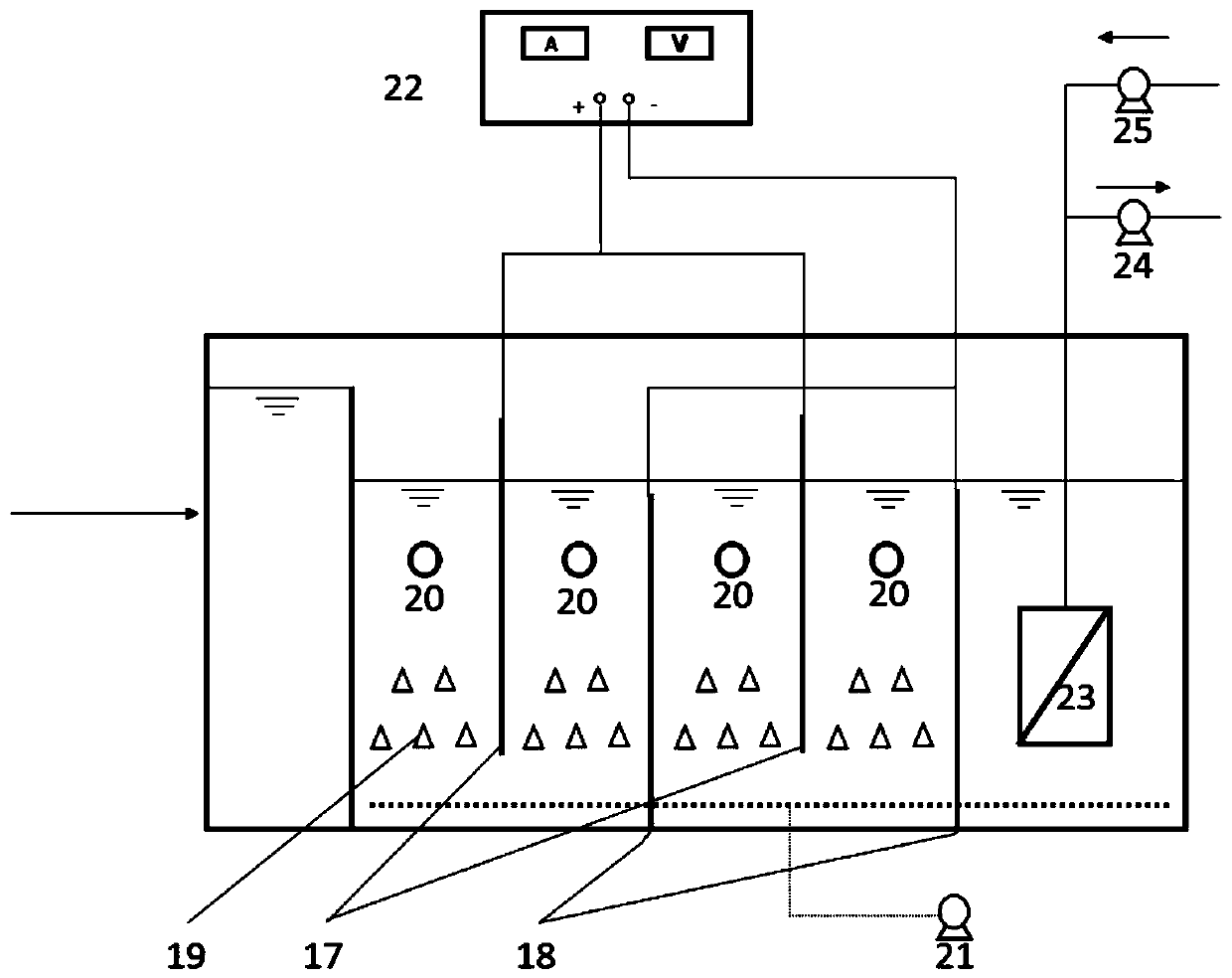

Ship black water and ash water treatment device and method

ActiveCN106430821AAchieve demulsificationRelieve pressureTreatment with aerobic and anaerobic processesSustainable biological treatmentSludgeWater quality

The invention provides a ship black water and ash water treatment device and method. The device comprises a pretreatment unit, a biological treatment unit, a photoelectrocatalytic reaction unit and a sludge treatment unit, wherein ash water is mixed together with simply treated black water after being subjected to ultrasonic enhanced coagulation and efficient gravity type solid-liquid separation treatment, and the mixture enters the biological treatment unit; sewage in the biological treatment unit is treated by an anaerobic pond, an anoxic pond and an MBR pond and enters a clear water tank, BOD and nitrogen and phosphorus pollutants in the water are removed in the biological treatment unit, and effluent of the clear water pond enters the photoelectrocatalytic reaction unit; organic pollutants difficult to degrade in the sewage and bacteria in water are degraded and removed under the synergistic action of photocatalysis and electrocatalysis, the sewage is filtered finally by a membrane assembly and discharged, and the quality of the discharged water meets the recycling standard; the sludge treatment unit simply dewaters sludge discharged from the biological treatment unit. The device and the method are simple and convenient to operate and efficiently treat ship black water and ash water, so that the black water and the ash water meet the recycling standard.

Owner:HARBIN ENG UNIV

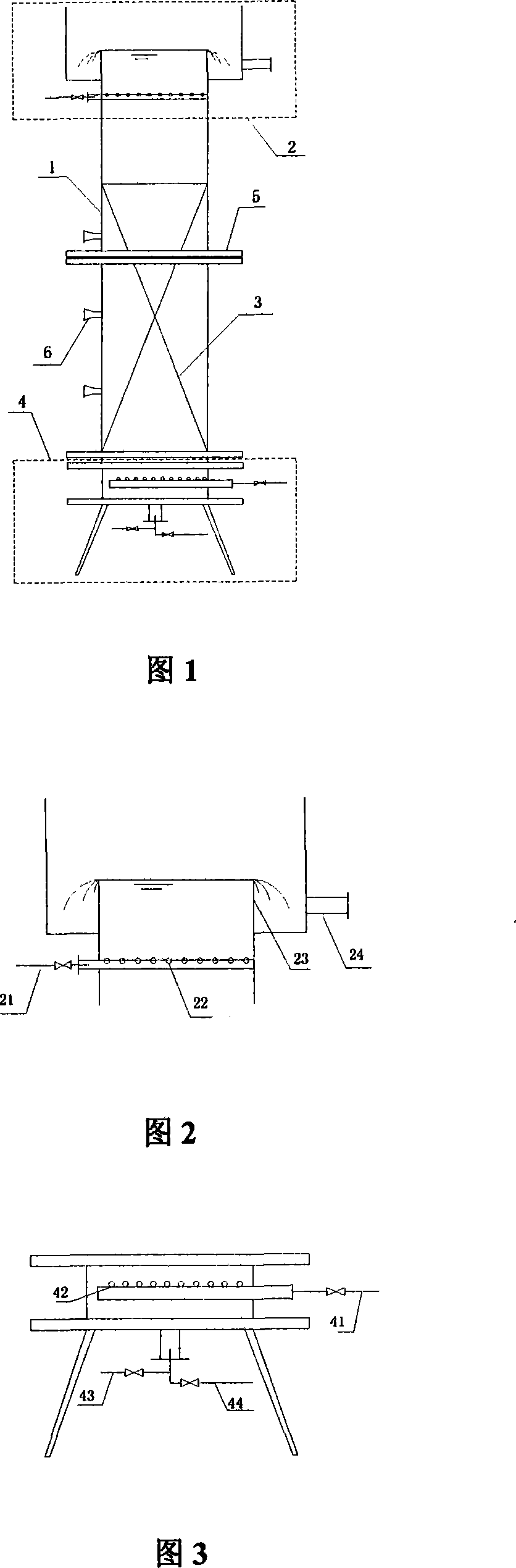

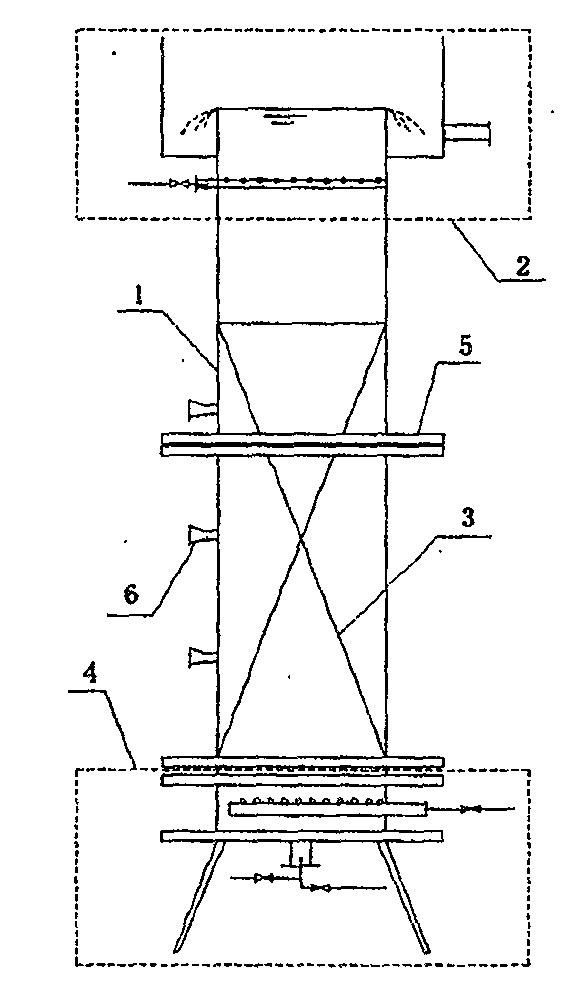

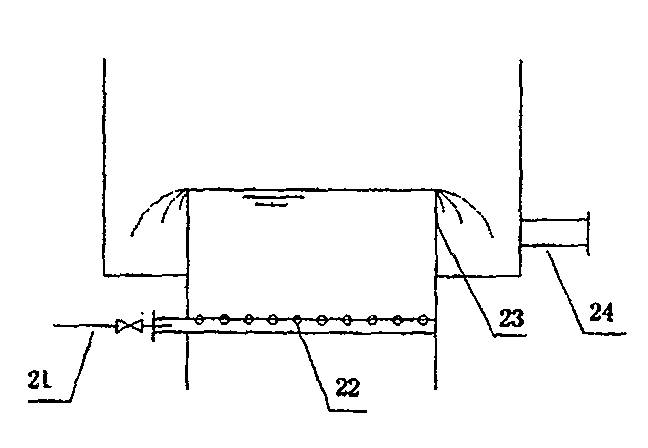

Continuous fiber agglomeration coarse-grain oil eliminator

InactiveCN101215021ALeave in timeEasy to elute and regenerateFatty/oily/floating substances removal devicesLiquid separationFiber bundleOil water

Disclosed is a thick granulating grease intercepter with filament agglomeration, which leads oil dripping to be capable of floating upward in time along a filtering layer by lifting of bubbles through a reasonable filtering layer framework, thereby achieving double goal of thick granulating and filtering degreasing. The grease intercepter comprises a degreasing reactor barrel (1), an inflowing and overflowing unit (2), a modified fiber bundle assembly (3), a water-yielding and backwash unit (4), a degreasing barrel connector (5) and a sample port (6), wherein the degreasing reactor barrel (1) is divided into an upper portion and a lower portion which are integrated via the degreasing barrel connector (5), the modified fiber bundle assembly (3) is arranged in the degreasing reactor barrel (1), the sample port (6) is arranged on the side surface of the degreasing reactor barrel (1), and the upper portion and the lower portion of the degreasing reactor barrel (1) are respectively provided with the inflowing and overflowing unit (2) and the water-yielding and backwash unit (4). The upper portion of the degreaser feeds water, the lower portion of that aerates, thereby achieving the agglomeration and thick granulating of the oil dripping in oily wastewater and reaching water-oil separating.

Owner:王世和

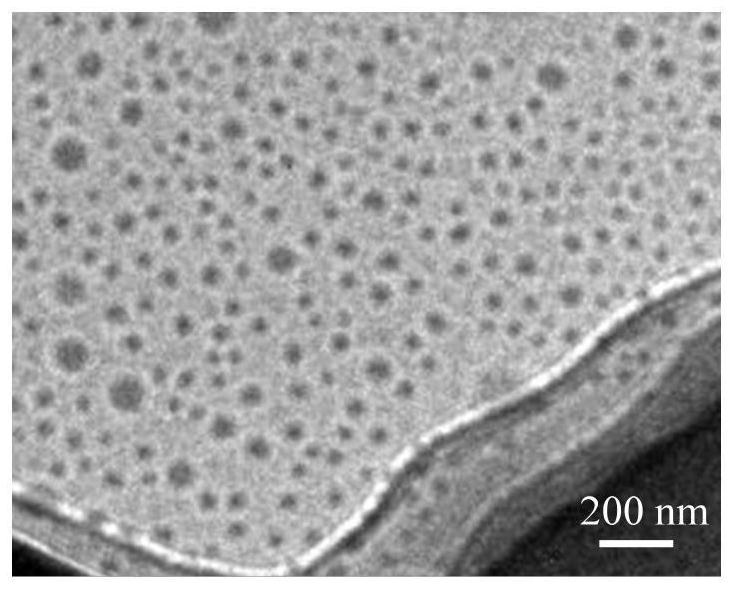

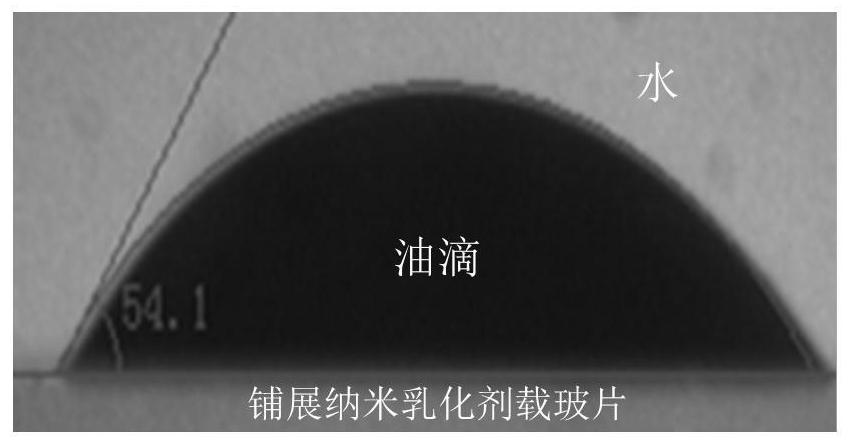

Preparation method of in-situ nano emulsifier and oil reservoir application method

ActiveCN112266775AGood injectionAchieve fluidityFluid removalDrilling compositionEnhanced oil recoveryWater saturation

The invention discloses a preparation method of an in-situ nano-emulsifier and an oil reservoir application method, the in-situ nano-emulsifier is successfully prepared, the property of the in-situ nano-emulsifier is weakly hydrophobic and oleophylic nano colloidal particles, and the nano-emulsifier provided by the invention is directly dispersed by injecting water into an oil field, is slightly higher than the injected water in viscosity, and is high in injectivity; under the condition that the water saturation of an oil reservoir is 25-85%, water-in-oil Pickering emulsion with stable dynamics is generated through the reverse phase bending effect of an oil-water interface and crude oil, the water-in-oil Pickering emulsion does not generate phase change in the range of the water saturationof the oil reservoir, and the viscosity of the Pickering emulsion is in direct proportion to the water saturation of a stratum and is in inverse proportion to the oil saturation. The viscosity of theemulsified liquid is 1.5-20 times that of crude oil, the viscosity of the emulsified liquid in a high-permeability area is higher than that of the emulsified liquid in a low-permeability area, the fluidity can be adaptively controlled, the displacement leading edge can be stabilized, intelligent oil displacement is achieved, and the crude oil recovery rate is increased to the maximum extent.

Owner:SOUTHWEST PETROLEUM UNIV

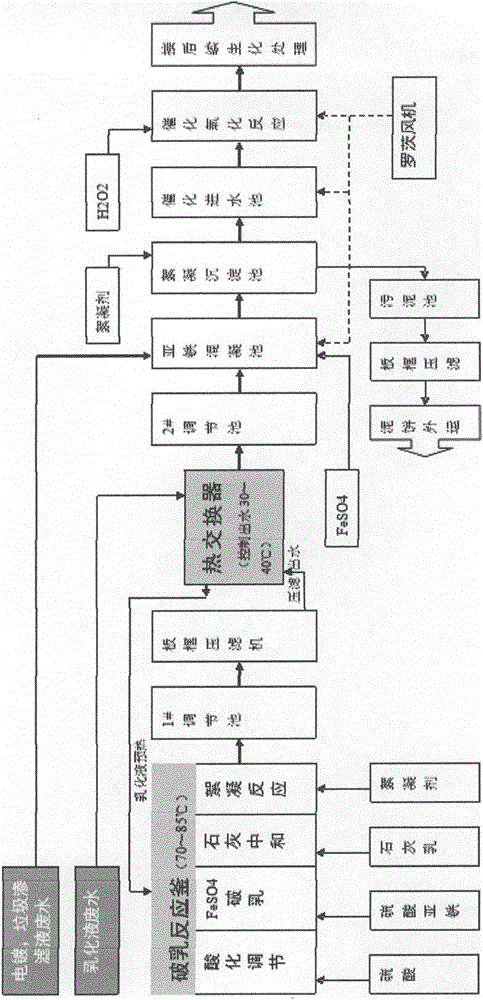

Integrated disposal technology for waste emulsion liquid, electroplating wastewater and landfill leachate

ActiveCN103819060ACompact equipmentLess investmentMultistage water/sewage treatmentEmulsionPre treatment

The invention discloses an integrated disposal technology for waste emulsion liquid, electroplating wastewater and landfill leachate. The integrated disposal of the waste emulsion liquid, electroplating wastewater and landfill leachate can be implemented by utilizing demulsification, oxidation pre-treatment and biological treatment. According to the integrated disposal technology for waste emulsion liquid, electroplating wastewater and landfill leachate, provided by the invention, the demulsification of various waste emulsion liquid with high COD can be implemented, the waste emulsion liquid, the electroplating wastewater and the landfill leachate can be disposed in the same disposal facility to reach the emission standard, the equipment is compact, and the investment is low.

Owner:QINGDAO NEW WORLD ENVIRONMENT PROTECTION CO LTD

Preparation method of magnetic nanometer water treatment agent for oil field sewage

InactiveCN106830248AEvenly dispersedGood superparamagneticWaste water treatment from quariesWater/sewage treatment by substance additionWater bathsFlocculation

The invention discloses a preparation method of a magnetic nanometer water treatment agent for oil field sewage. The preparation method includes firstly, soaking magnetic nanometer particles of Fe3O4 with water while regulating pH to 5-7 and then carrying out ultrasonic dispersion to obtain an aqueous solution containing magnetic nanometer particles of Fe3O4; stirring the aqueous solution containing magnetic nanometer particles of Fe3O4 in a container, placing the container in constant-temperature water bath for holding temperature, gradually dropwise adding sodium oleate solution, after that, continuing to stir for 20 to 40 minutes, and cooling the solution to the temperature of 45 to 55 DEG C to obtain a mixture; finally, adding block polyether modifier solution in the mixture while stirring at the temperature of 45-55 DEG C for 0.5 to 2 hours so as to obtain the magnetic nanometer water treatment agent. The water treatment agent has the advantages such as flocculation, demulsification and easiness in magnetic separation. The water treatment agent can be recovered so that consumption of the water treatment agent is lowered and water treatment cost is reduced.

Owner:YANGTZE UNIVERSITY

Oil-gas field oil-containing sludge treatment method

InactiveCN109250885AReduce oil contentReduce pollutionSludge treatment by oxidationWater contaminantsChemistryOil field

The invention relates to an oil-gas field oil-containing sludge treatment method. According to the method, the used oil-containing sludge treatment apparatus comprises a microwave reaction chamber, awaveguide pipe, a microwave generator and a power source; the stable emulsifying state of oil-containing pollution is destroyed by using a microwave catalytic oxidation method, and part of residual chemical agents in the oil-containing sludge can be subjected to a chemical reaction, such that demulsification and viscosity breaking are achieved, and the three-phase separation of oil, water and mudsand is achieved; the pollutants in the oil-containing sludge are mainly transferred into a water phase, the water is discharged into a sewage treatment system so as to be treated, and the crude oil is recycled; and the mud sand phase has extremely low oil content and extremely low content of other pollutants, can be used for paving various internal roads for oil field production, well sites and solid waste yards, and can be used as natural pit filling materials. According to the present invention, the method has advantages of simple treatment process, low treatment cost, safety, environmentalprotection, high recovery rate of crude oil, resource utilization of mud sand, and the like.

Owner:KARAMAY ZHONGKE OILFIELD SERVICES NEW TECH CO LTD

Treatment method of wastewater containing rubber latex

InactiveCN102826622AAchieve demulsificationEasy to handleWater/sewage treatment by flocculation/precipitationWater/sewage treatment by freezingEmulsionWater quality

The invention provides a treatment method of wastewater containing rubber latex. The method comprises a step that the wastewater is frozen and is then thawed. With the method provided by the invention, emulsion breaking can be effectively realized out upon the rubber-latex-containing wastewater with relatively low rubber latex content. With the method, solid substances in opalescent wastewater can be flocculated, water quality can be clarified, and wastewater can be decolorized. Therefore, subsequent wastewater treatment can easily be carried out upon the clarified liquid. No agent is adopted according to the invention, such that no secondary pollution is caused. Therefore, the method is environment-friendly.

Owner:CHINA PETROLEUM & CHEM CORP +1

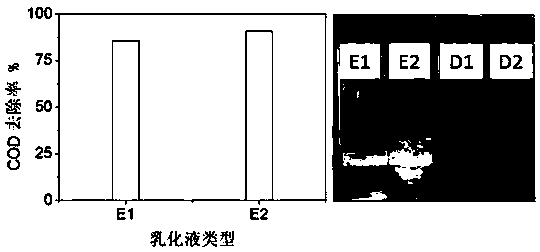

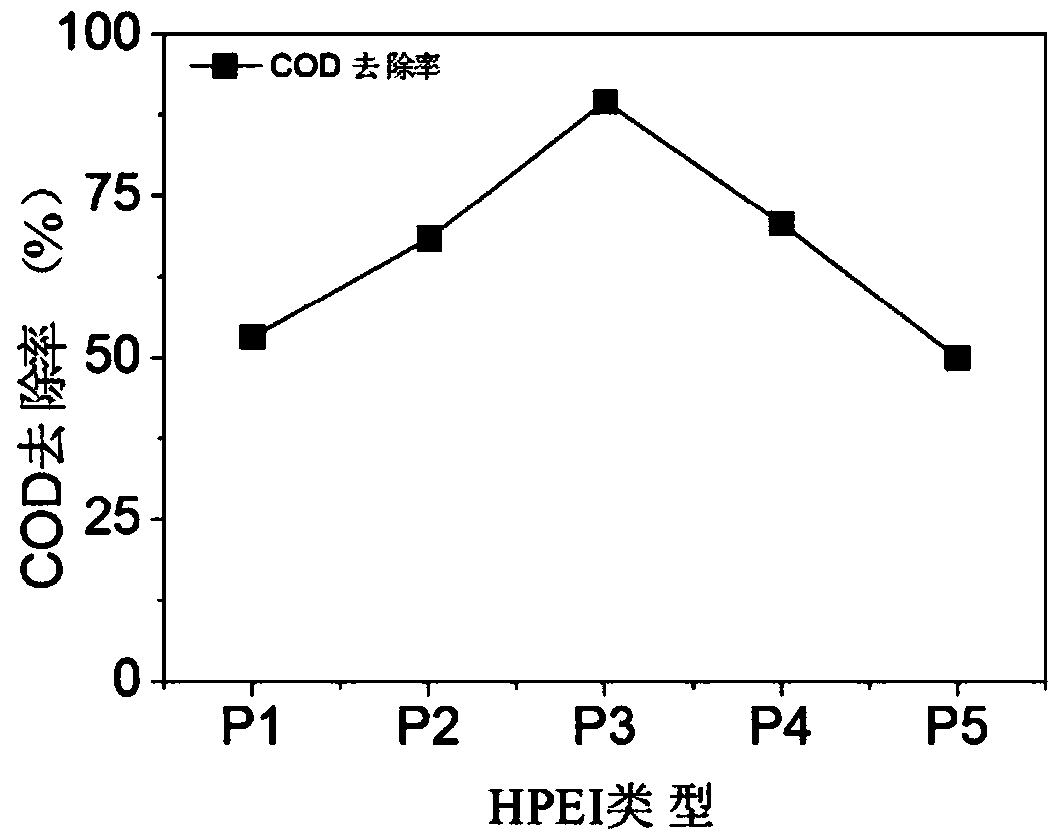

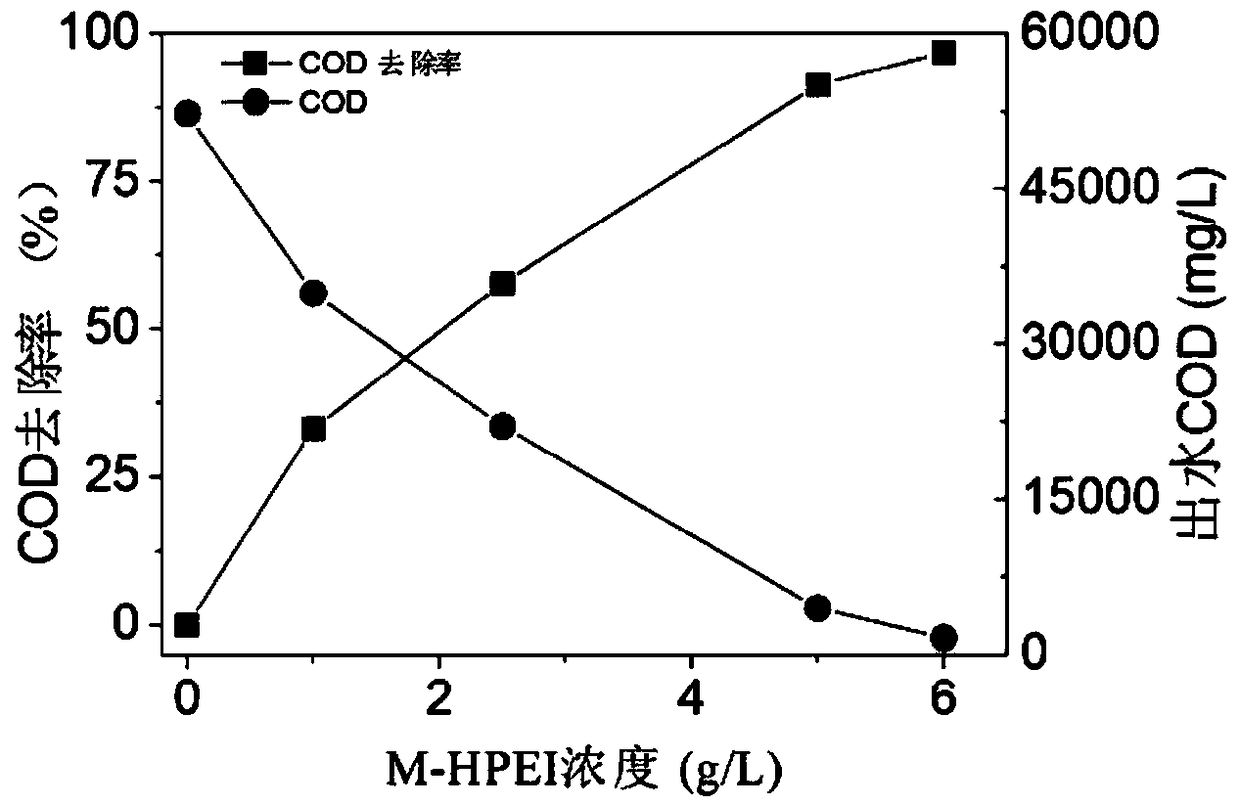

Amino-rich magnetic nanoparticle demulsifier preparation and application method thereof in treating waste emulsion

InactiveCN109350998AOvercoming rateOvercome the defect of large amount of sludge flocNon-miscible liquid separationDemulsifierEffective action

The invention relates to an amino-rich magnetic nanoparticle demulsifier preparation and an application method thereof in treating a waste emulsion. Magnetic nanoparticle demulsifier makes polyethyleneimine branched molecules fixed to the surface of a magnetic core, and a large number of effective action sites are provided for the emulsion. The method for treating the waste emulsion particularly comprises the steps that a magnetic nanoparticle demulsifier suspension is added in the waste emulsion, the mixture is fully mixed to be uniform, and oil-water separation is conducted by means of a magnetic field. By means of the simple method, the novel magnetic nanoparticle demulsifier is synthesized, efficient and rapid demulsification of emulsions with different compositions and properties is achieved, the operation condition is simple, the application range is wide, and industrial application is easy. The treatment scheme is particularly suitable for the waste emulsion generated in the machining process.

Owner:TONGJI UNIV

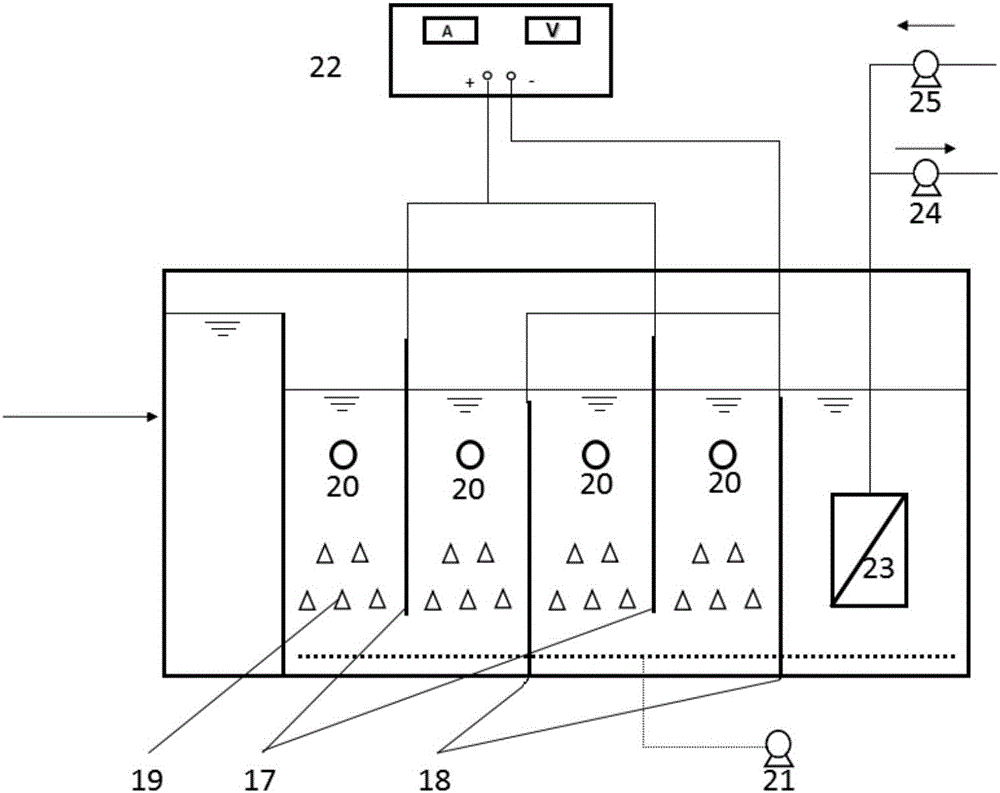

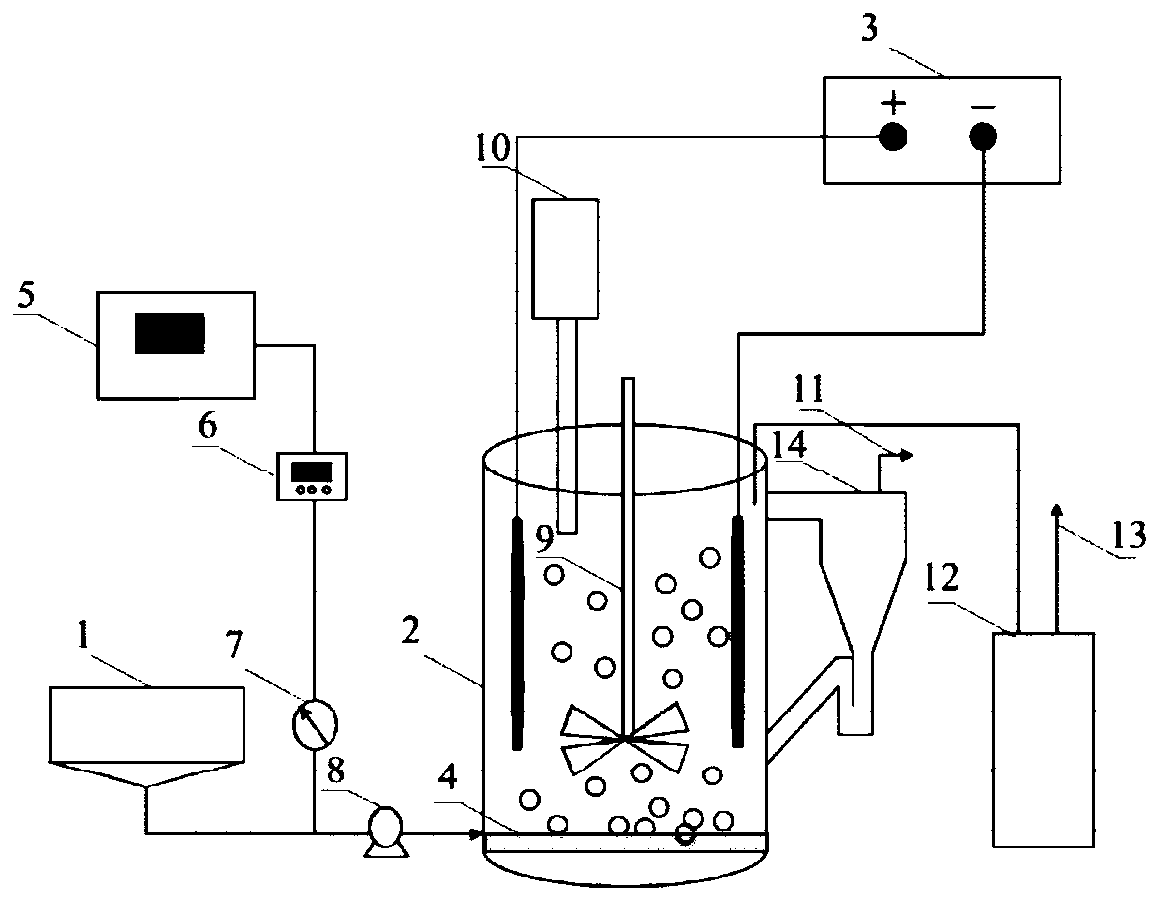

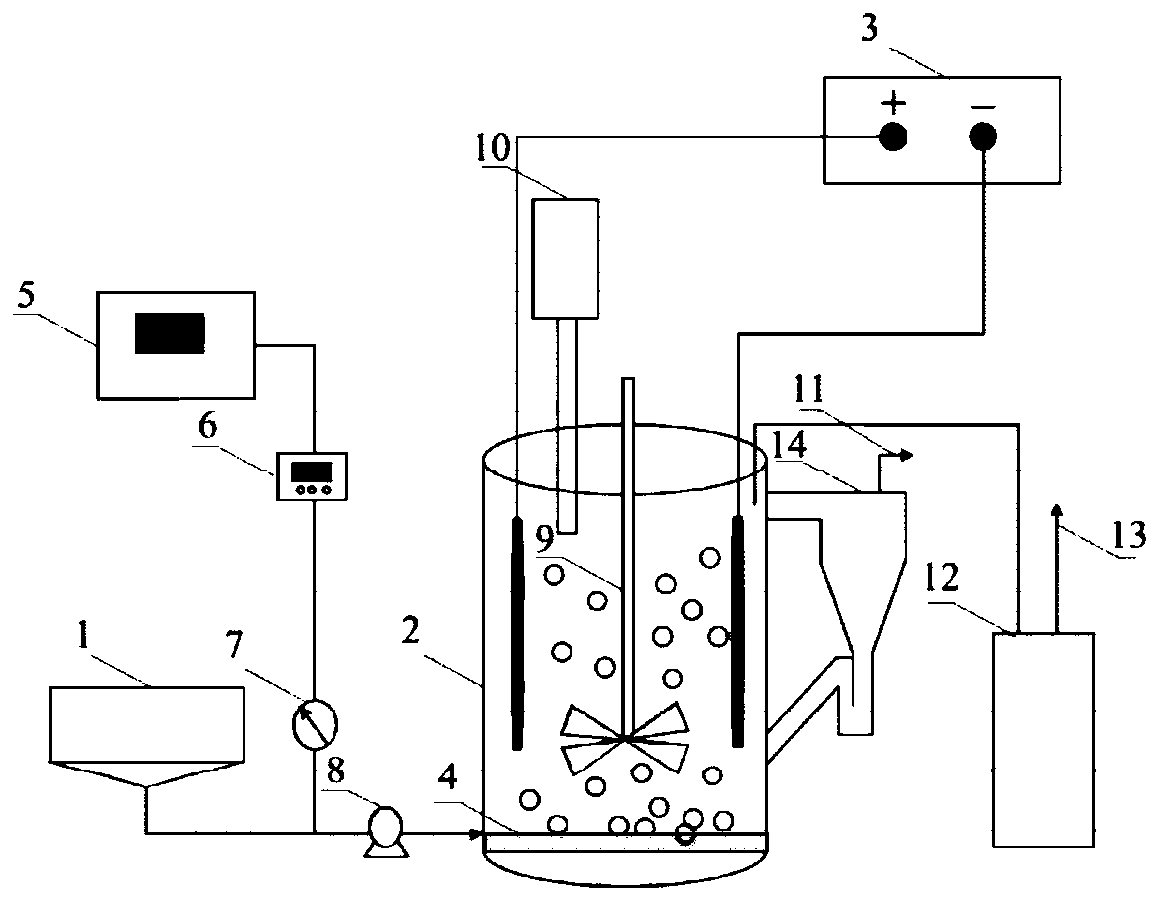

Device and method for advanced treatment of oily sludge by E<+>-micro-nano bubble ozone

ActiveCN111138057AAchieve demulsificationImprove adhesion efficiencySludge treatment by oxidationWater contaminantsMicro nanoElectrolysis

The invention discloses a device and a method for advanced treatment of oily sludge by E<+>-micro-nano bubble ozone. The device comprises a vibrating screen, an E<+>-micro-nano bubble ozone device anda power supply, the oily sludge treated by the vibrating screen enters an E<+>-micro-nano bubble ozone device, the emulsification structure of the oily sludge is destroyed through ozone oxidation, and demulsification is further conducted through E<+> electrolysis at the upper end of the device; the O2 entrained by the aeration process and O3 which cannot be consumed by organic matters in time areconverted into H2O2, .OH and the like under the coupling action of E<+>-micro-nano bubble ozone, so that deep oxidation of oil substances is realized, and the oil substances are converted into carbondioxide and water; the micro-nano ozone floating bubbles bring demulsified oil drops to the liquid level, and the demulsified oil drops are recycled through an oil scraper. According to the method, an E<+>-micro-nano bubble ozone coupling method is adopted, air floatation, ozone and electrochemical synergistic oxidation is achieved, and meanwhile the multiple effects of oily sludge recycling, reduction, harmlessness and the like are achieved.

Owner:SHANGHAI JIAO TONG UNIV

Composite emulsifier having magnetic-responsive performance

ActiveCN108686575AMagnetically responsiveInterface activeTransportation and packagingMixingWAS PROTEINRoom temperature

The invention discloses a composite emulsifier having magnetic-responsive performance and belongs to the technical field of colloid and interface chemistry. The emulsifier includes commercial nano Fe3O4 particles, which are not subjected to any modification, and enzyme; original particle size of the nano Fe3O4 particles is 20-200 nm, and application concentration, on the basis of a water phase, is0.05-5.0%; the lipases are protein enzymes and nucleic acid enzymes, and application concentration, on the basis of the water phase, is 0-20 mg / ml. An emulsion stabilized by the composite emulsifierbelongs to Pickering emulsion, wherein the composite emulsifier and the emulsion stabilized thereby have magnetic-responsive performance; at room temperature, as the emulsion passes through an area having certain magnetic field intensity, the composite emulsifier can leave from the interface of the Pickering emulsion and can be gathered, thus demulsifying the emulsion, but the composite emulsifierstill has interface activity; by homogenizing the separated system, the stable Pickering emulsion can be produced again.

Owner:JIANGNAN UNIV

Method for extracting oil from oil production microbes

InactiveCN104293474AHigh extraction rateReduce energy consumptionFatty-oils/fats productionOil and greaseOil phase

The invention discloses a method for extracting oil from oil production microbes. The method is characterized in that the method comprises the following steps: 1, adjusting the pH value of a water slurry containing the oil production microbes to 7.5-14; 2, stirring under hydrothermal conditions to dissolve out oil in the cells of the oil production microbes in order to obtain an oil production microbes dissolved slurry containing oil; and 3, adjusting the pH value of the oil production microbes dissolved slurry to 6.8-7.2 by using an acidic flocculating agent under stirring, allowing the obtained slurry to stand for layering, and separating the obtained upper layer oil, wherein the acidic flocculating agent is a flocculating agent which is acidic after dissolved in water. The method for extracting oil from oil production microbes allows the pH value of the oil production microbes dissolved slurry to 6.8-7.2 by using the acidic flocculating agent to successfully realize the demulsification of the oil production microbes dissolved slurry in order to thoroughly flocculate microbe residues, so an oil phase and a water phase can be well separate, the oil extraction rate is high, and the energy consumption is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pickering emulsion with CO2/double-response type surfactant and preparation method of Pickering emulsion

ActiveCN113292984ASimple preparation processUse low concentrationDrilling compositionActive agentCarboxylic group

The invention discloses a Pickering emulsion with a CO2 / double-response surfactant and a preparation method of the Pickering emulsion, which belong to the technical field of oil and gas field chemical agents. The preparation method comprises the following steps of firstly preparing carboxyl modified nano silicon dioxide particles, then preparing a CO2 / redox dual-responsive surfactant, finally mixing the carboxyl modified nano silicon dioxide particles and the CO2 / redox dual-responsive surfactant according to a certain proportion, adding the mixture into an oil phase and a water phase according to a certain proportion, and emulsifying through a vortex oscillator at a certain rotating speed to obtain the product. The emulsion has good stability, when the emulsion does not need to be kept in a stable state any more, the stable state of the emulsion can be broken and demulsification can be achieved only by introducing CO2 or adding an oxidizing agent into an emulsion system, on the other hand, the reversible emulsification process can be achieved by introducing N2 or adding a reducing agent into the emulsion, and the stable emulsion is obtained again.

Owner:DONGYING SPRING PETROLEUM ENG TECH +1

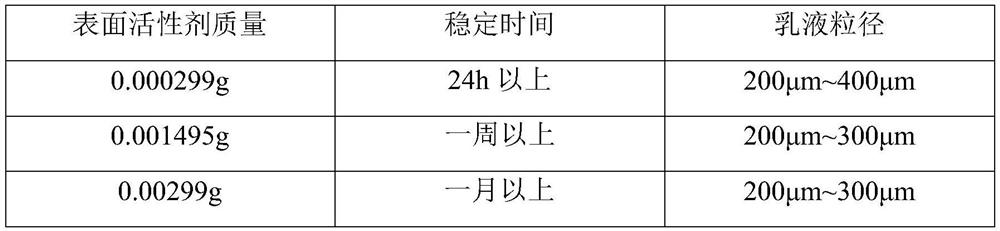

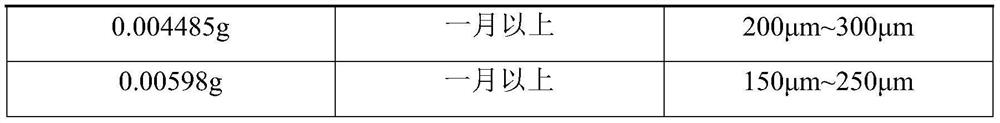

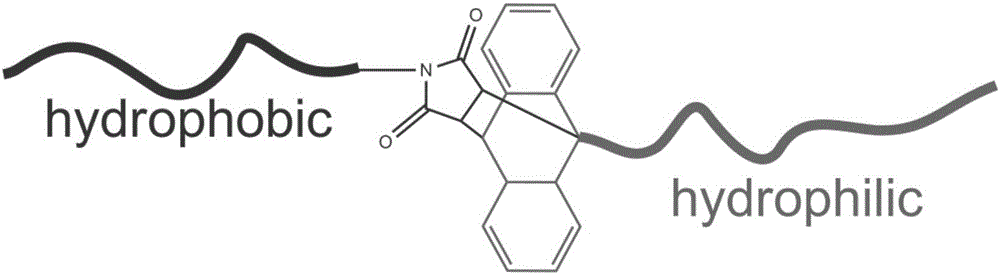

Preparation method of environment-friendly macromolecular emulsifier

The invention relates to a preparation method of an environment-friendly macromolecular emulsifier. The preparation method comprises the following steps: firstly, designing and synthesizing a functional potential hydrophilic chain segment and a hydrophobic chain segment by adopting a controllable living polymerization technology (ATRP (Atom Transfer Radical Polymerization) and SET-LRP (Single Electron Transfer-Living Radical Polymerization)); secondly, connecting the potential hydrophilic chain segment and the hydrophobic chain segment together by Diels Alder reaction, and hydrolyzing under acidic conditions to obtain an amphiphilic block copolymer, wherein the amphiphilic block copolymer can be self-assembled in water to form a micelle; enabling the hydrophilic chain segment and the hydrophobic chain segment of the micelle to be broken and generate Diels Alder reverse reaction under the action of an ultrasonic force. The hydrophilic chain segment of which an end group released by ultrasonic fracture is anthracene has a fluorescence effect which is detected by a fluorescence spectrophotometer. The macromolecular emulsifier can be used for preparing functional emulsion particles. Besides, the macromolecular emulsifier is the amphiphilic block copolymer and has sensitivity to the ultrasonic force, so the macromolecular emulsifier has potential applications in biomedicine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

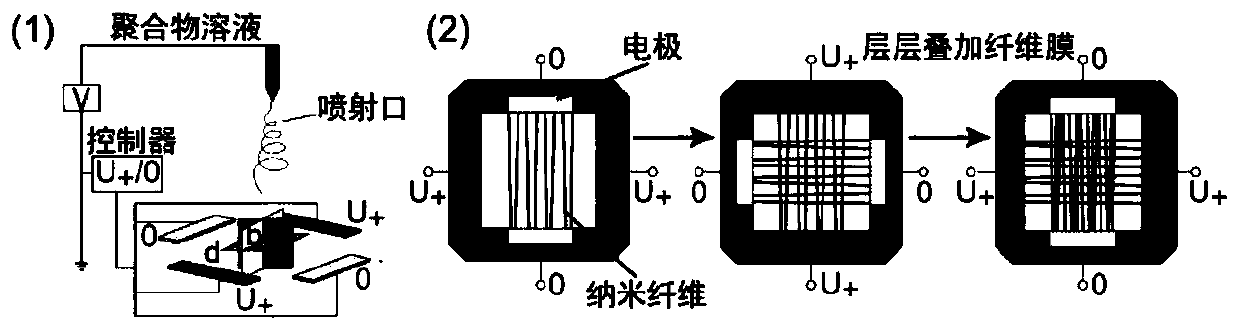

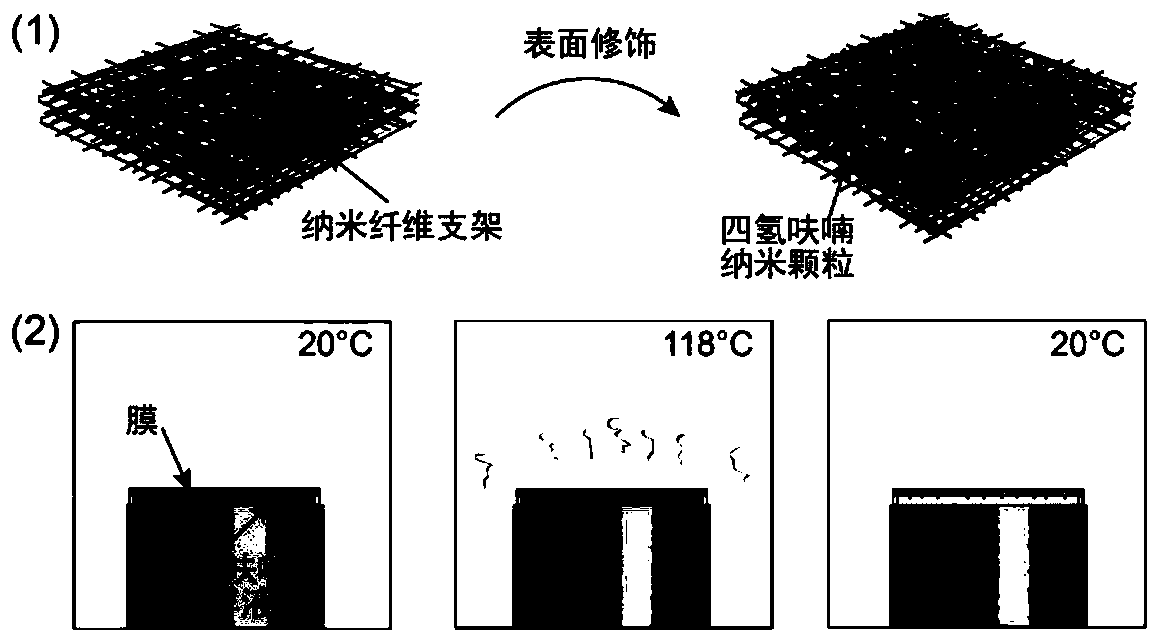

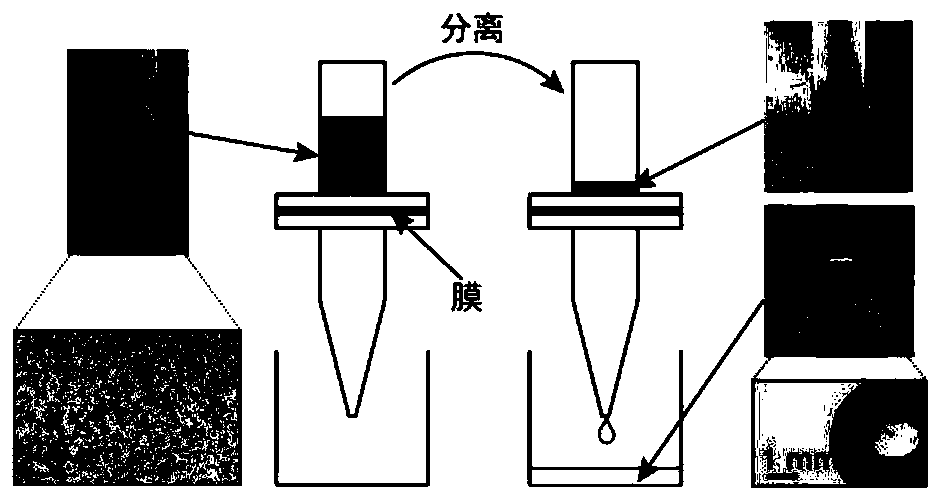

Nanofiber membrane, preparation method thereof and application of nanofiber membrane to oil-water separation

ActiveCN109876496AAchieve demulsificationEfficient separationNon-miscible liquid separationChemical compositionNanoparticle

The invention provides a nanofiber membrane, a preparation method thereof and application of the nanofiber membrane to oil-water separation. The nanofiber membrane comprises a cross-type nanofiber membrane body, and polytetrafluoroethylene nanoparticles for surface modification of the cross-type nanofiber membrane body. According to the nanofiber membrane, through the joint effect of a three-dimensional topology structure of the cross-type nanofiber membrane body and surface chemical component modification, a water-in-oil emulsion or an oil-in-water emulsion can be broken, and thus efficient oil-water separation is achieved; the membrane can be reused for multiple times, and the oil-water separation efficiency is stable; and experimental results show that the oil-water separation nanofibermembrane has no selectivity for the oil-in-water emulsion and the water-in-oil emulsion, the water-in-oil emulsion and the oil-in-water emulsion can both achieve the separation efficiency of 99% or above, and the separation efficiency is maintained at 98% or above after repetition for eight times.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

Method for demulsifying and extracting grease from oil-containing algae or fungal cell wall-broken liquid

PendingCN111690462AAchieve demulsificationHigh extraction rateFatty-oils/fats productionBiotechnologyOil and grease

The invention discloses a method for demulsifying and extracting grease from oil-containing algae or fungal cell wall-broken liquid. The pH of the wall-broken liquid is adjusted under the vacuum condition, a proper amount of inorganic salt is added, the stirring rotating speed and temperature in different time periods are regulated and controlled, oil, water, protein and fermentation extracellularproducts in the wall-broken liquid are completely separated, and the extraction yield of intracellular grease of algae and fungal cells is increased to 90%-96% from 85%-90%. When the method is used for demulsifying oil-containing emulsion, solvent residues caused by extraction and demulsification with an organic solvent and unsaturated fatty acid oxidation caused by high-temperature solvent recovery can be effectively avoided, meanwhile, various physicochemical indexes of the extracted crude grease are better, the quality of the crude grease is better, and the green, non-toxic and residue-free effects in the product extraction process are achieved.

Owner:XIAMEN HUISON BIOTECH

Supergravity sewage treatment device and supergravity sewage treatment technology

ActiveCN106830426AWell mixedImprove sufficiencyWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesDesalinationSewage

The invention relates to a supergravity sewage treatment device. Firstly, a filter and a membrane component are utilized for carrying out pretreatment on electro-desalting sewage, then alkali liquor in an alkali liquor tank is mixed with the sewage treated by the filter and the membrane component, the mixture enters a supergravity machine through a fluid channel of the supergravity machine, by virtue of a unique supergravity machine structure and a rotating channel which is formed between a hollow rotating shaft and a sleeve, is communicated with a filler region and is provided with a helical channel, spinning entrance of fluid through the rotating channel after passing the hollow rotating shaft is realized, intensive mixing of the sewage in the fluid and the alkali liquor is realized under the actions of a rotation acting force, a shearing force and a spinning acting force of the fluid at the moment that the fluid enters the filler region, and sufficient degree of liquid-liquid contact is improved, so that removal of the alkali liquor on oily substances and COD in the sewage is realized.

Owner:北京沃尔福环保科技有限公司

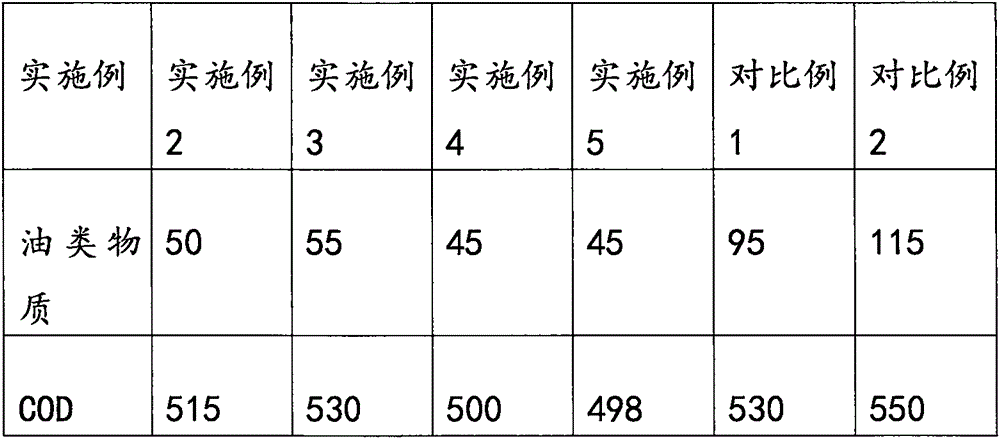

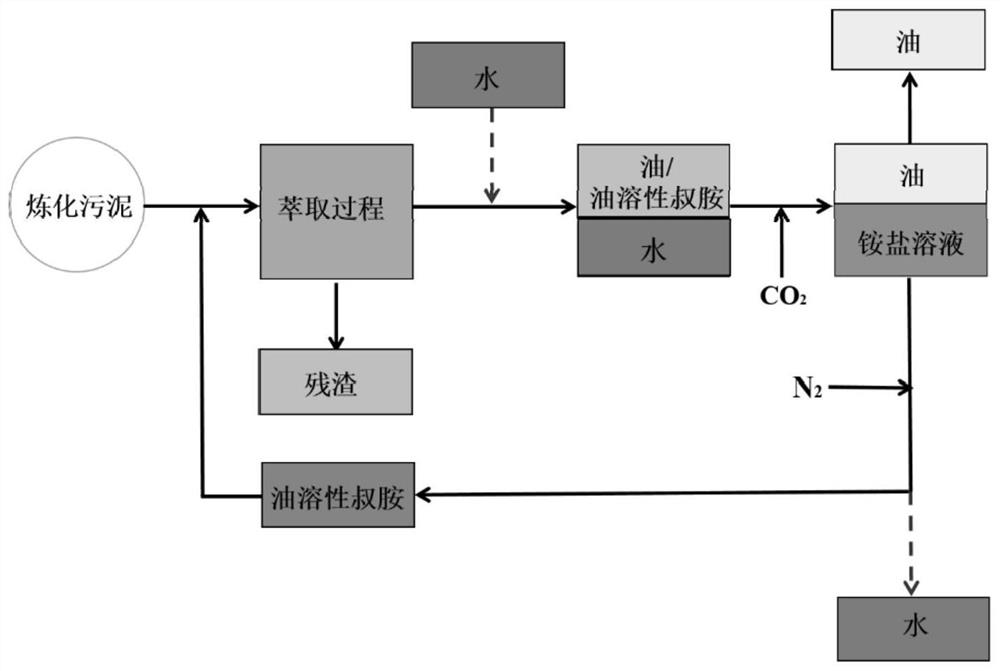

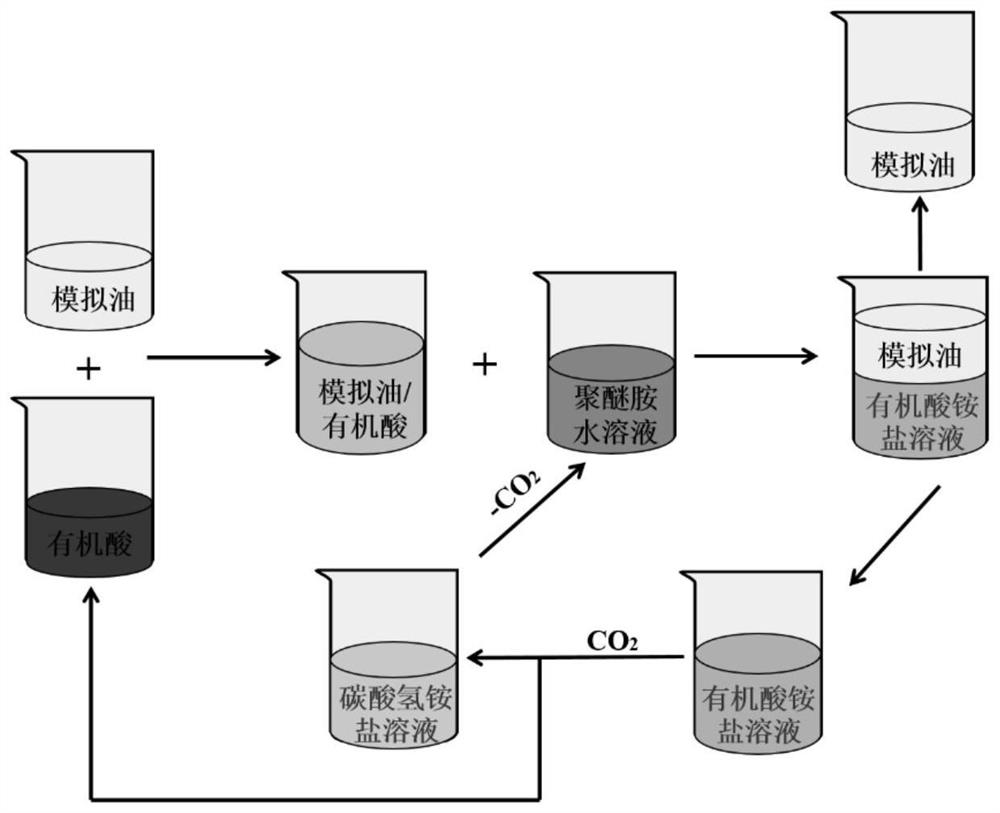

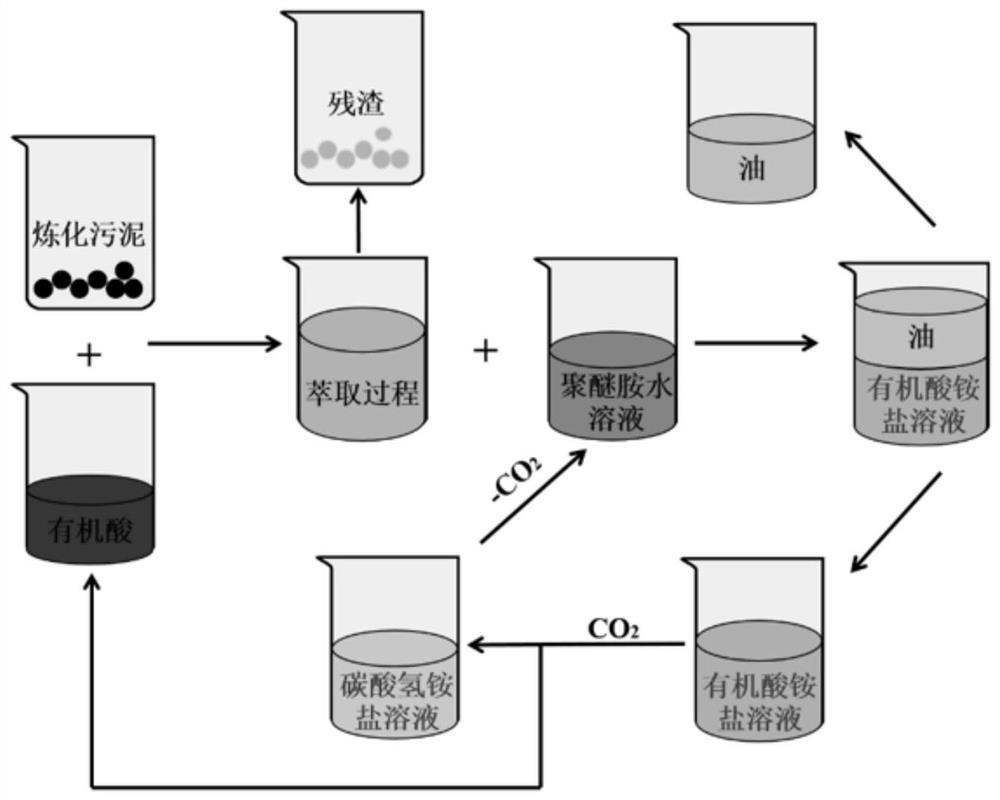

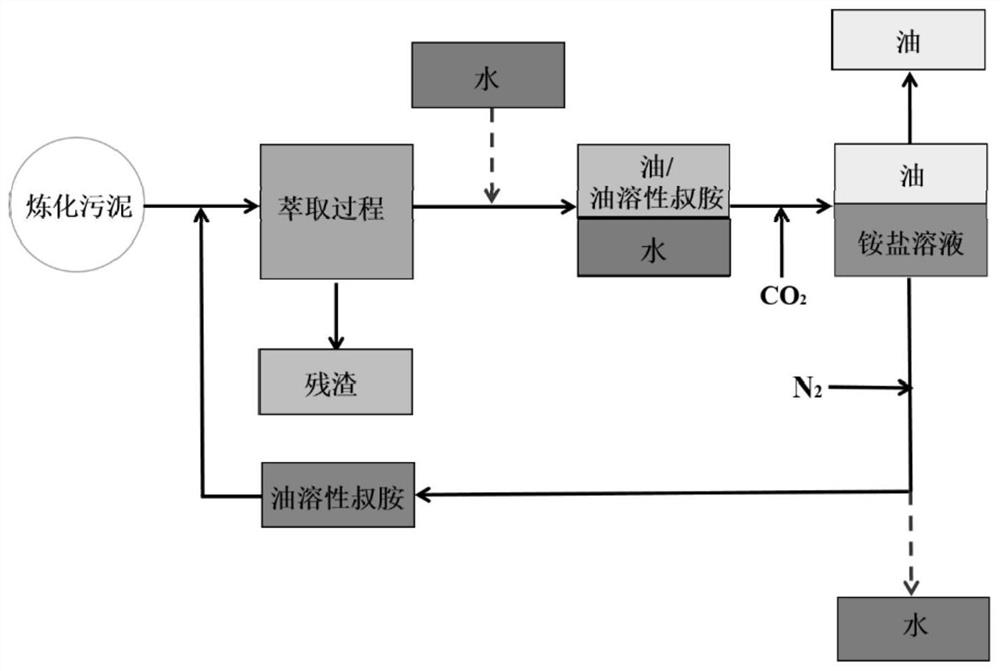

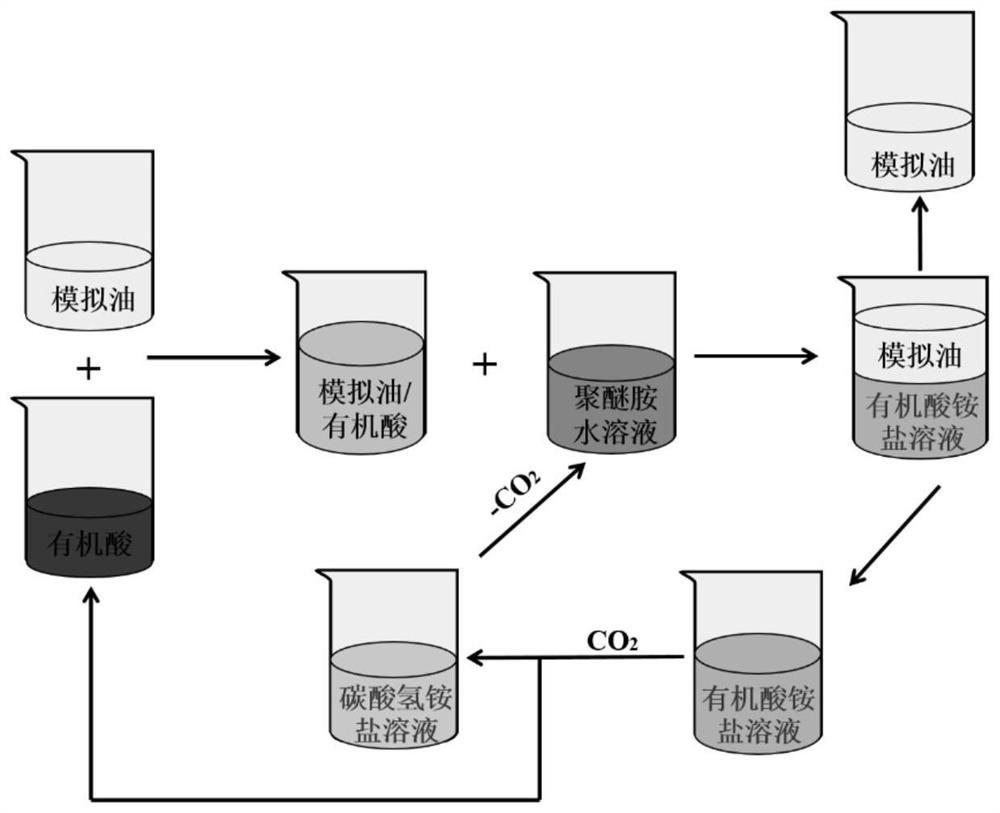

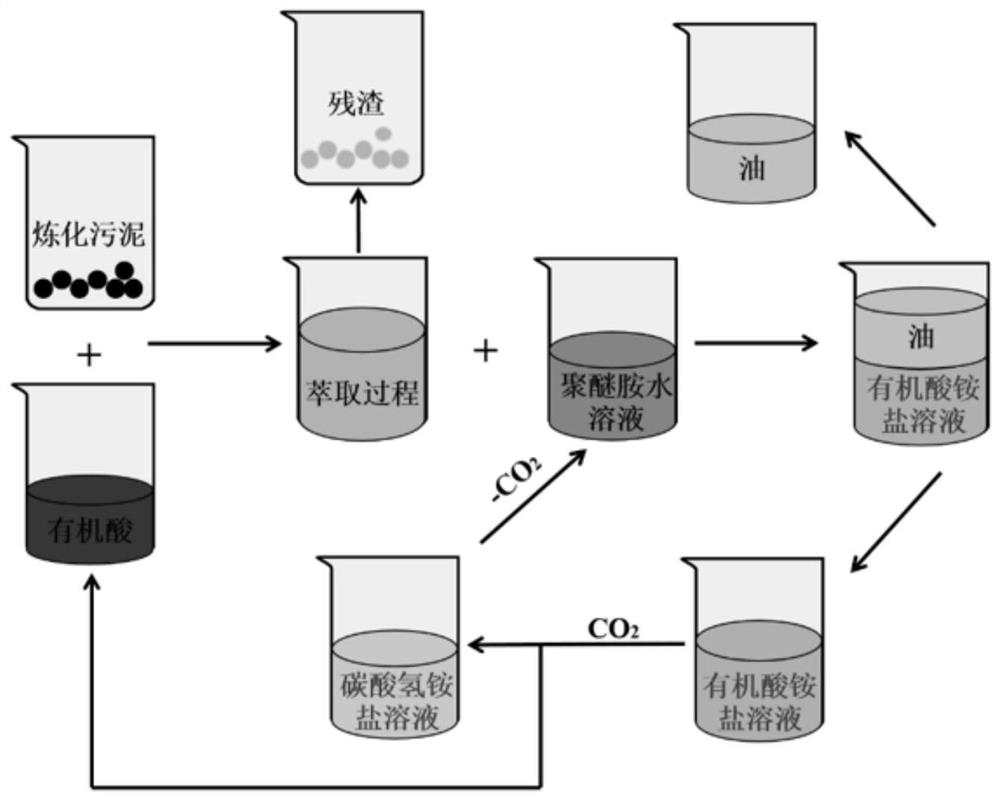

CO2/N2 switching type double-circulation extraction process and application thereof

ActiveCN112391190ANothing producedReduce usageSludge treatmentLiquid hydrocarbon mixture productionOrganic acidProcess engineering

The invention discloses a CO2 / N2 switching type double-circulation extraction process. The process comprises: mixing oil-containing solid waste and organic acid, separating to obtain mixed liquid A and solid waste, adding a polyetheramine aqueous solution into the mixed solution A, separating to obtain an oil phase and a mixed solution B, introducing CO2 into the mixed solution B, protonating, separating to obtain an organic acid and a mixed solution C, returning the organic acid to the oily solid waste, introducing N2 into the mixed solution C, deprotonating to obtain CO2 and a polyetheramineaqueous solution, returning the polyetheramine aqueous solution to the mixed solution A, and returning CO2 to the mixed solution B, wherein the temperature control range of the whole extraction process is 30-70 DEG C. The method has the advantages that (1) the organic acid aqueous solution and the polyether amine aqueous solution are combined for use, so that the purpose of oil removal is achieved, the organic acid aqueous solution and the polyether amine aqueous solution are recycled, the method is environment-friendly and safe to operate, and the oil removal cost is saved, the recovery rateof oil products is high, other impurities are not introduced, and the recovery rate of conventional oil products, especially heavy oil products, can reach 90% or above.

Owner:SOUTHWEST PETROLEUM UNIV

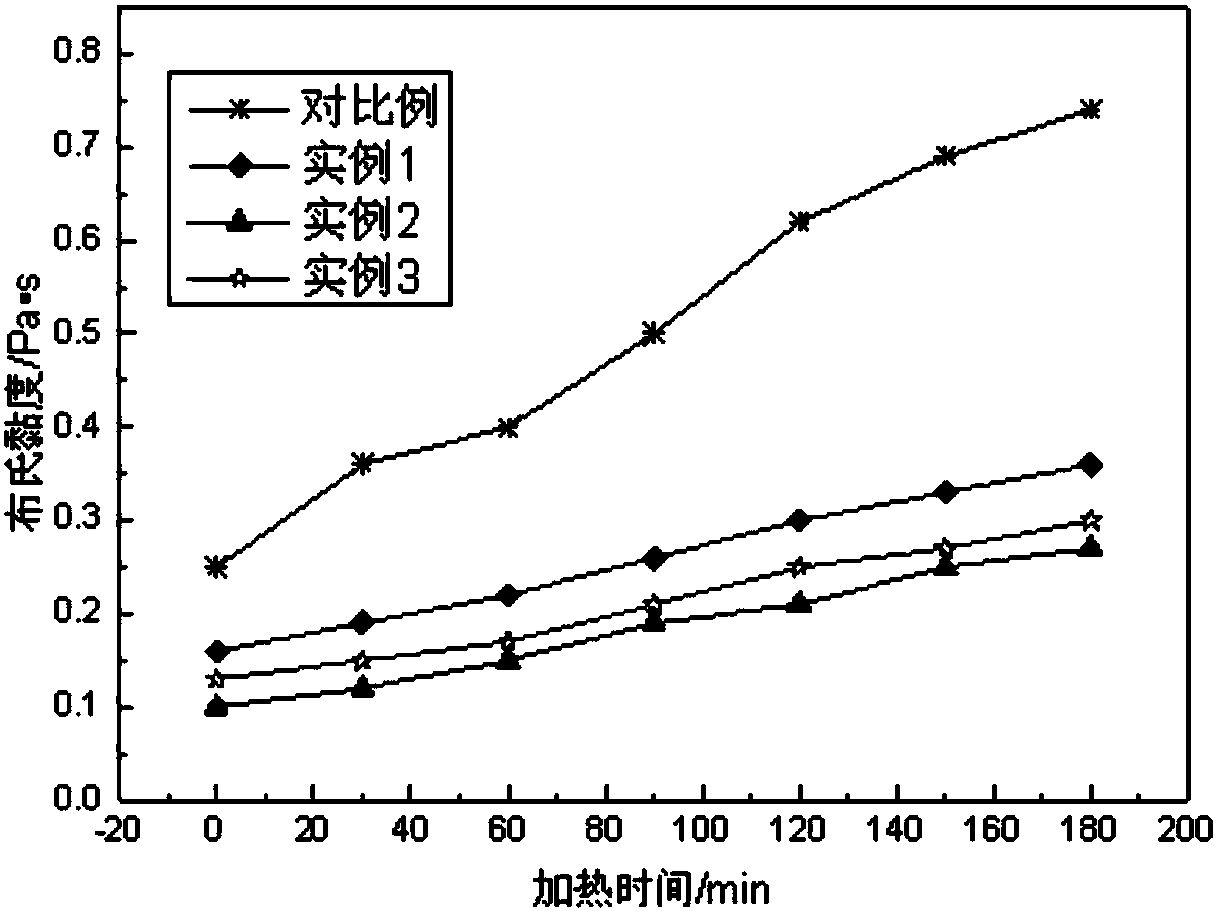

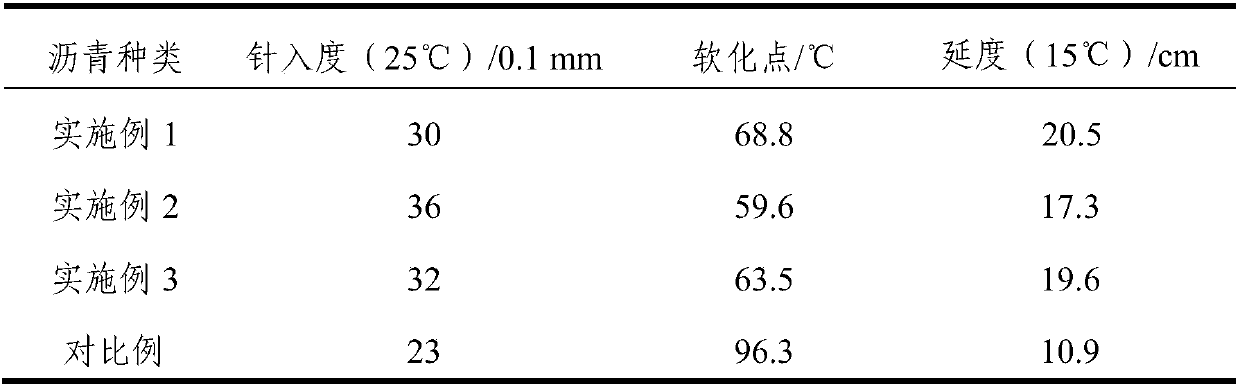

Biological asphalt and preparation method thereof

InactiveCN107916122AWide variety of sourcesLow costWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by thermal meansInorganic saltsDistillation

The invention relates to biological asphalt and a preparation method thereof. The preparation method comprises steps as follows: 1) inorganic salt is blended in biological oil and mixed uniformly; crude glycerin is added, and the mixture is mixed uniformly; 2) a product obtained in the step 1) is distilled under the normal pressure, and light components and mixed components comprising glycerin andlignin pyrolysis products are separated; 3) water is added to the mixed components, the mixture is mixed uniformly, left to stand and filtered, a water-glycerin mixed phase is removed, and a crude lignin pyrolysis product is obtained; 4) the crude lignin pyrolysis product is heated to the constant weight state, and the biological asphalt is obtained; the water-glycerin mixed phase is distilled under the normal pressure, and separated glycerin is recycled. The lignin pyrolysis product can be effectively separated through pretreatment of biomass pyrolysis oil, and meanwhile, the separation process of conventional distillation is improved, so that the asphalt components in the biomass pyrolysis oil can be sufficiently separated and have excellent usability and ageing resistance.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

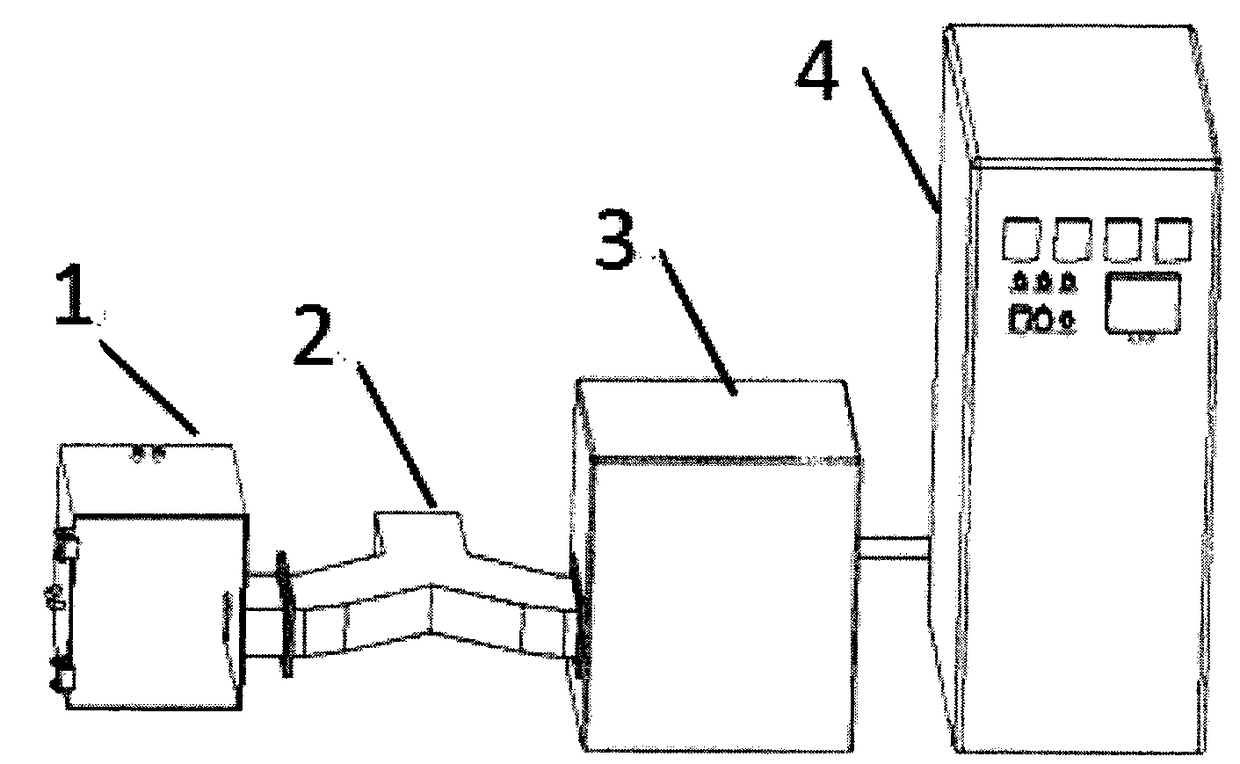

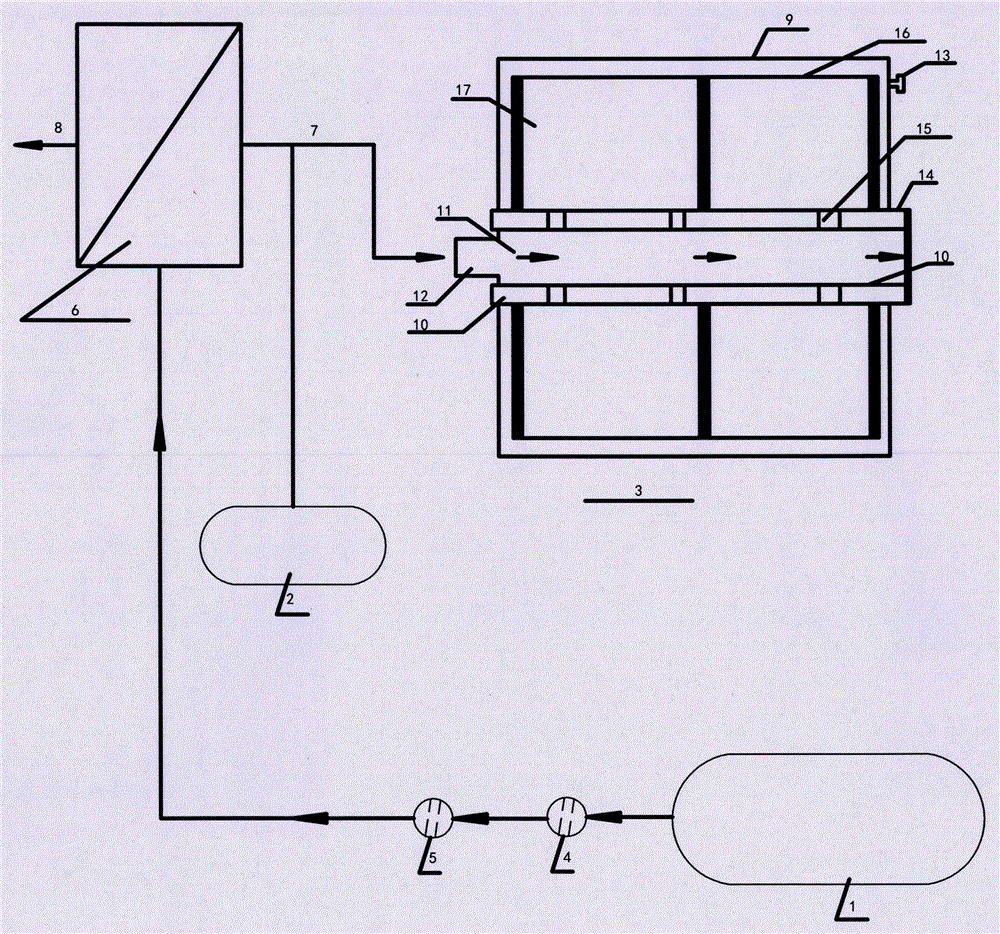

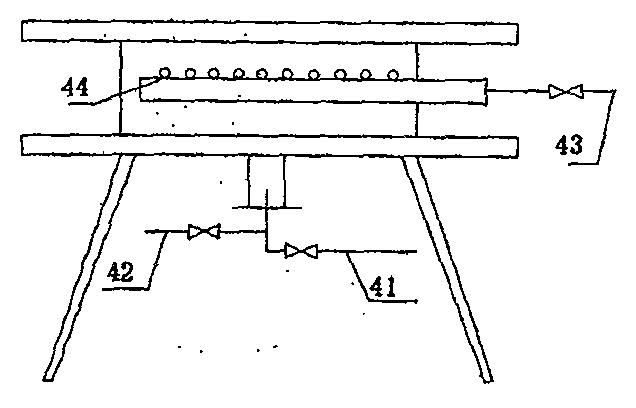

Continuous fiber agglomeration coarse-grain oil eliminator

InactiveCN100564269CAchieve demulsificationAchieve decentralizationFatty/oily/floating substances removal devicesLiquid separationFiber bundleWastewater

The long-fiber agglomeration coarse-grained degreaser enables oil droplets to float along the filter layer in time under the lift of air bubbles through a reasonable filter layer structure, achieving the dual goals of coarse-grained and filtered oil removal. The oil remover includes oil removal reactor column (1), water inlet and overflow device (2), modified fiber bundle assembly (3), water outlet and backwash device (4), oil removal column connector ( 5), sampling port (6); the deoiling reactor column (1) is divided into upper and lower parts, which are connected into one by the deoiling column connector (5), and the deoiling reactor column (1) A modified fiber bundle assembly (3) is installed inside, a sampling port (6) is provided on the side of the deoiling reactor cylinder (1), and a water inlet and overflow are provided on the upper part of the deoiling reactor cylinder (1). The flow device (2) is equipped with a water outlet and backwashing device (4) at the lower part of the oil removal reactor column (1); the upper part of the device is fed with water, and the lower part is aerated to realize the agglomeration of oil droplets in the oily wastewater, the coarse to achieve oil-water separation.

Owner:王世和

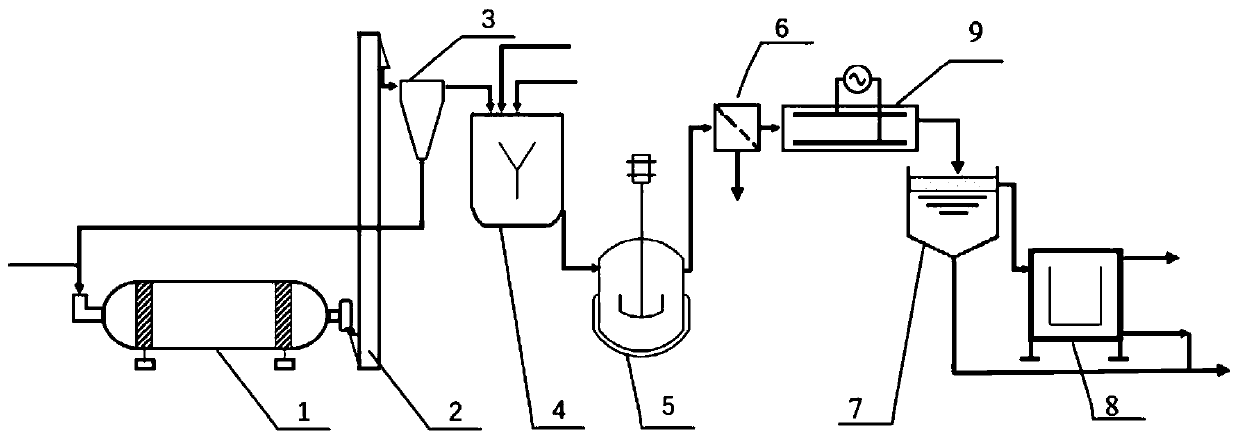

Process for extracting residual oil from oil-tea cake

PendingCN111187662AHigh extraction rateFix poor qualityFatty-oils/fats refiningFatty substance recoveryCamellia oleiferaEmulsion

The invention belongs to the technical field of tea oil extraction, and particularly relates to a process for extracting residual oil from a tea-oil cake. The process comprises the following steps: crushing oil tea cakes, carrying out sieving, and adding water to prepare a mixed solution for later use; carrying out ultrasonic stirring on the mixed solution obtained in the step (1), and conductingfiltering to obtain an emulsion; and carrying out demulsification and centrifugal separation on the emulsion to obtain an oil product. According to the method, ultrasonic stirring and demulsificationare matched for use, the tea oil cake with low oil content can be further extracted, and the extraction rate of residual oil in the tea oil cake is 75-80%; compared with a traditional method, the extraction rate of the residual oil is increased by 5-10%, and the method is short in extraction time, high in extraction efficiency and low in energy consumption. According to the method, water is used as a solvent, so the extracted oil product does not contain an organic solvent, the problem that the quality of oil products become poor due to the fact that hexane is used as the solvent in the priorart is solved, and the problems of environmental pollution and the like caused by separating hexane from the oil products in a later period are avoided.

Owner:JIANGXI UNIV OF SCI & TECH

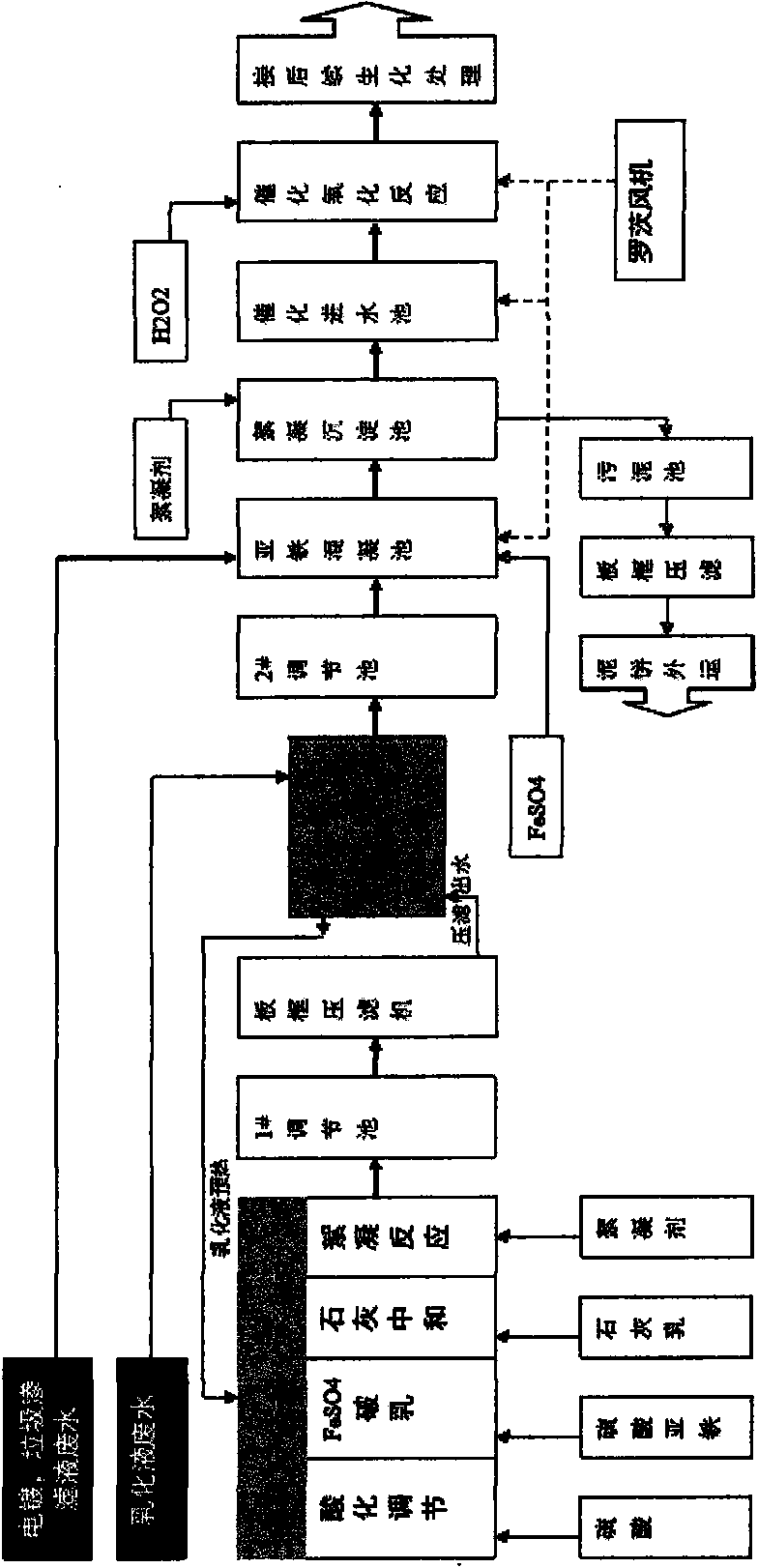

A comprehensive treatment technology for waste emulsion, electroplating wastewater and landfill leachate

ActiveCN103819060BAchieve demulsificationLess investmentMultistage water/sewage treatmentEmulsionEmission standard

The invention discloses an integrated disposal technology for waste emulsion liquid, electroplating wastewater and landfill leachate. The integrated disposal of the waste emulsion liquid, electroplating wastewater and landfill leachate can be implemented by utilizing demulsification, oxidation pre-treatment and biological treatment. According to the integrated disposal technology for waste emulsion liquid, electroplating wastewater and landfill leachate, provided by the invention, the demulsification of various waste emulsion liquid with high COD can be implemented, the waste emulsion liquid, the electroplating wastewater and the landfill leachate can be disposed in the same disposal facility to reach the emission standard, the equipment is compact, and the investment is low.

Owner:QINGDAO NEW WORLD ENVIRONMENT PROTECTION CO LTD

Environment-friendly fluorescent sewage treating agent

PendingCN110040810AAchieve demulsificationReduce demulsificationFatty/oily/floating substances removal devicesTreatment involving sedimentationChemical oxygen demandSludge

The invention relates to the technical field of sewage treatment and discloses an environment-friendly fluorescent sewage treating agent. The environment-friendly fluorescent sewage treating agent isprepared from the following raw materials in parts by weight: 85-95 parts of flocculating agent, 0.5-1.5 parts of coagulating agent, 1-3 parts of soap powder, 5-10 parts of activated clay, 0.5-1 partof settling agent and 0.5-1 part of decoloring agent. The environment-friendly fluorescent sewage treating agent disclosed by the invention is an green and environment-friendly agent, has no own oxidizability, has no hazard to human and equipment, and also cannot cause secondary pollution; the action mechanism of the environment-friendly fluorescent sewage treating agent is mainly adsorption, substances in the agent can adsorb organic molecules in sewage into the agent to form sludge due to large pores and surface areas so as to achieve the purpose of reducing the COD (Chemical Oxygen Demand)value; the purpose of meeting all discharging indexes of demulsification, decoloration, chain breaking by oxidation and COD reduction and the like of fluorescent waste water is achieved by adding onlyone agent, stirring, flocculating, filtering and mixing with ozone for oxidation.

Owner:扬州宏平精工设备有限公司

Method for treating wastewater containing rubber latex

ActiveCN102442721AAchieve demulsificationEasy to handleWater/sewage treatment by flocculation/precipitationLiquid layerEmission standard

The invention relates to a method for treating wastewater containing rubber latex, wherein the method comprises the steps of: mixing and standing the wastewater, water soluble alkali substances and water soluble metal halides. The method provided by the invention can effectively achieve demulsification of the wastewater containing the rubber latex with lower content, so that the wastewater is in milky wastewater layering to obtain a supernatant liquid layer, and the wastewater is decolored to facilitate the subsequent wastewater treatment of the supernatant liquid, so that the wastewater reaches the emission standard.

Owner:CHINA PETROLEUM & CHEM CORP +1

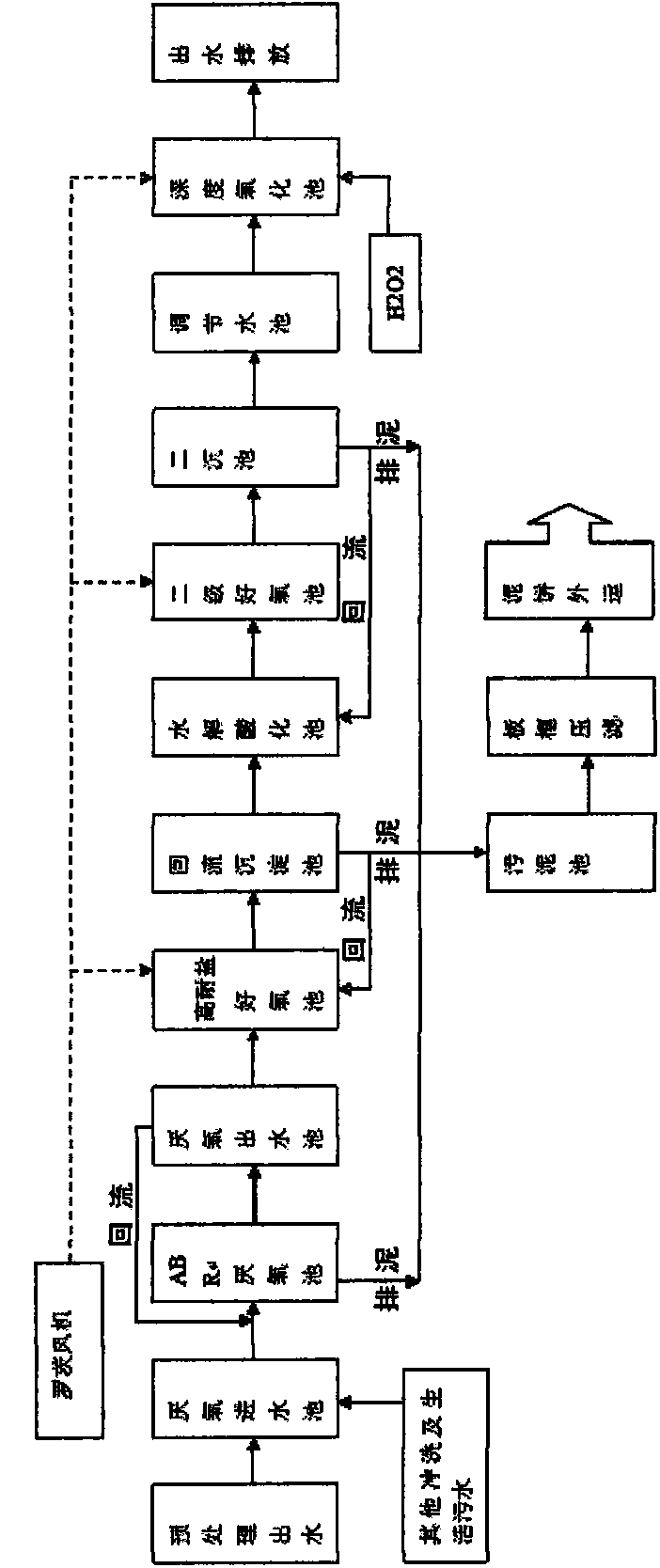

Device and method for treating ship black water and gray water

ActiveCN106430821BAchieve demulsificationRelieve pressureTreatment with aerobic and anaerobic processesSustainable biological treatmentSludgeWater quality

The invention provides a ship black water and ash water treatment device and method. The device comprises a pretreatment unit, a biological treatment unit, a photoelectrocatalytic reaction unit and a sludge treatment unit, wherein ash water is mixed together with simply treated black water after being subjected to ultrasonic enhanced coagulation and efficient gravity type solid-liquid separation treatment, and the mixture enters the biological treatment unit; sewage in the biological treatment unit is treated by an anaerobic pond, an anoxic pond and an MBR pond and enters a clear water tank, BOD and nitrogen and phosphorus pollutants in the water are removed in the biological treatment unit, and effluent of the clear water pond enters the photoelectrocatalytic reaction unit; organic pollutants difficult to degrade in the sewage and bacteria in water are degraded and removed under the synergistic action of photocatalysis and electrocatalysis, the sewage is filtered finally by a membrane assembly and discharged, and the quality of the discharged water meets the recycling standard; the sludge treatment unit simply dewaters sludge discharged from the biological treatment unit. The device and the method are simple and convenient to operate and efficiently treat ship black water and ash water, so that the black water and the ash water meet the recycling standard.

Owner:HARBIN ENG UNIV

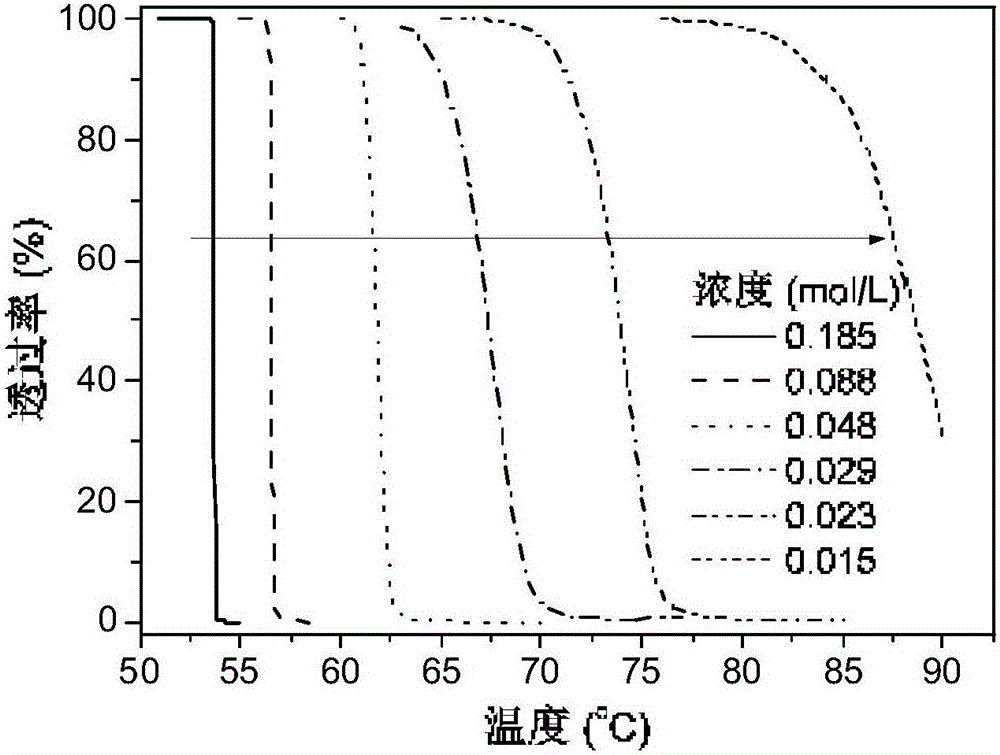

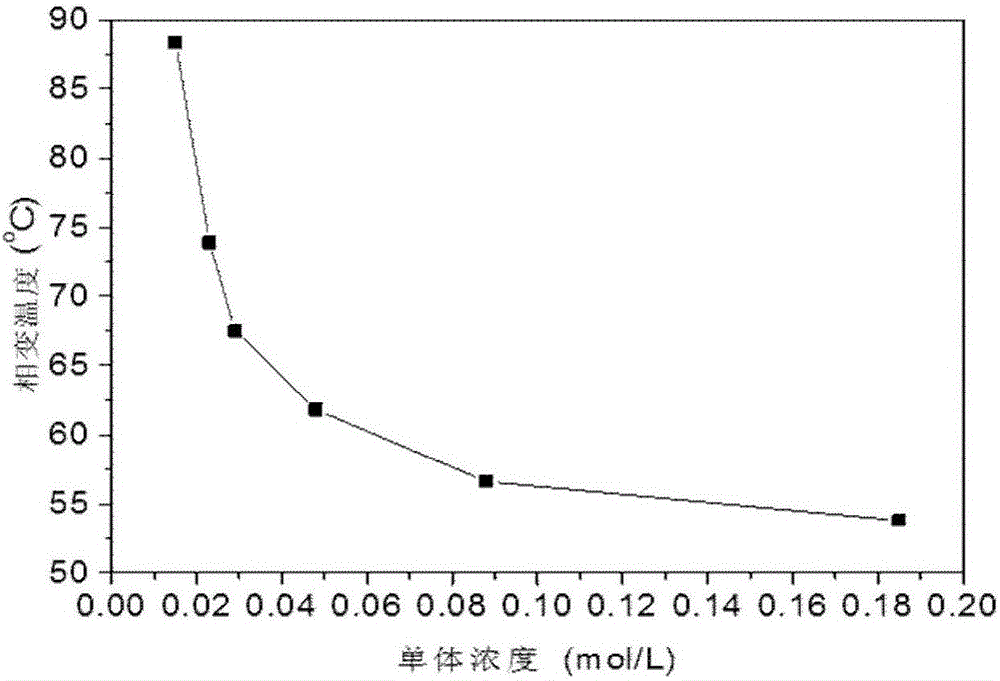

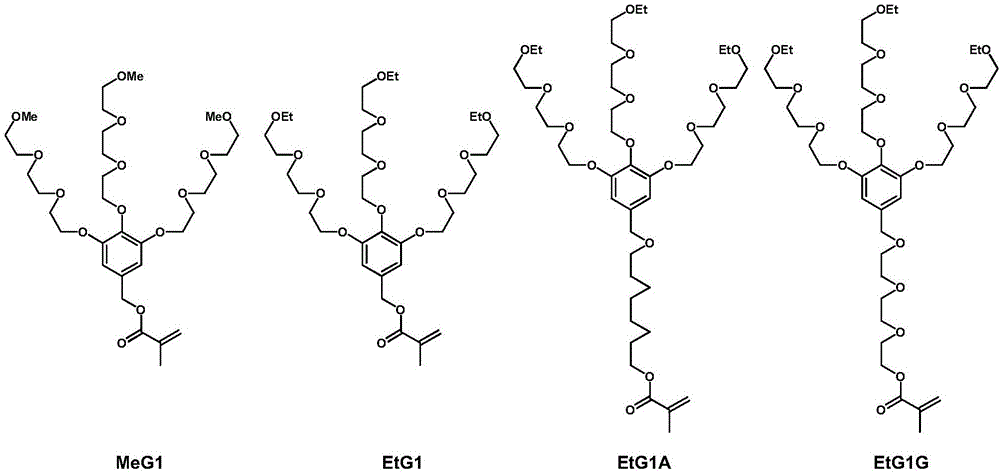

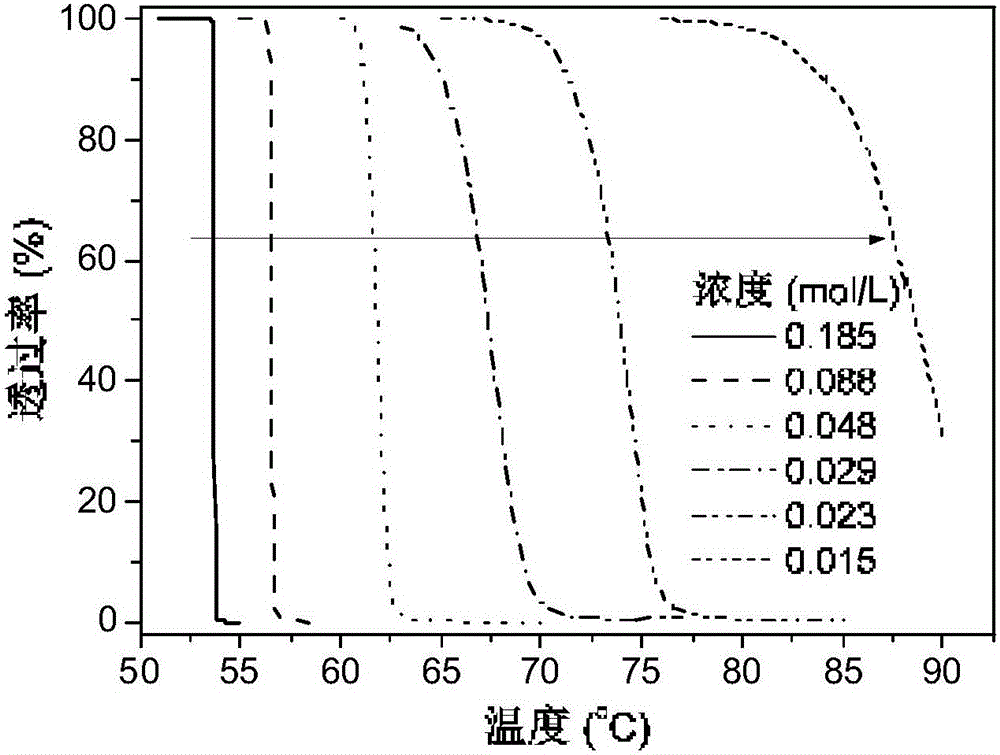

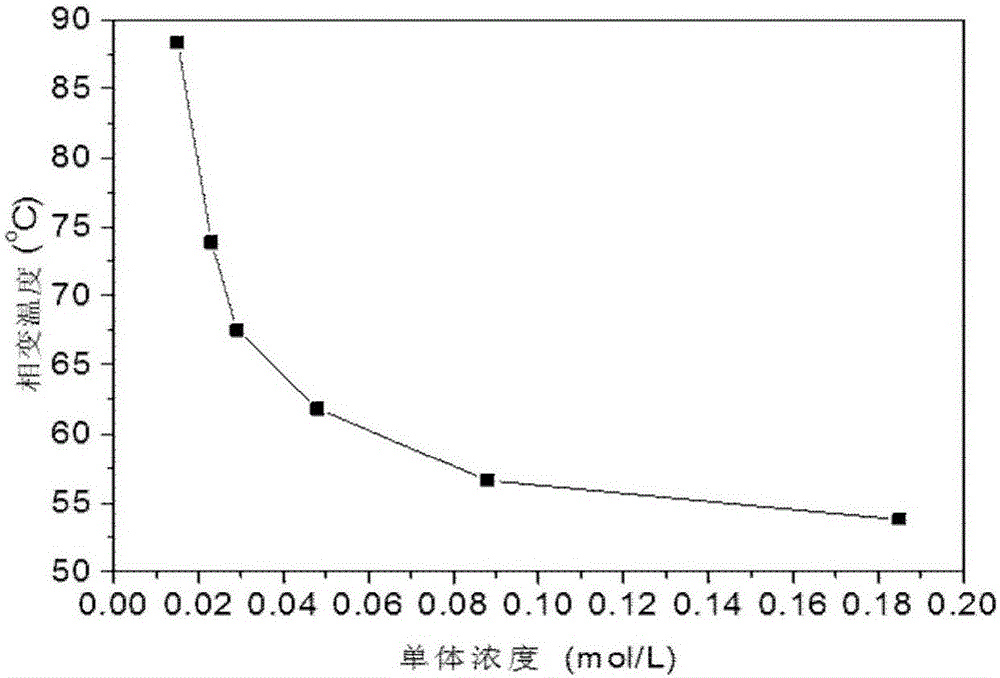

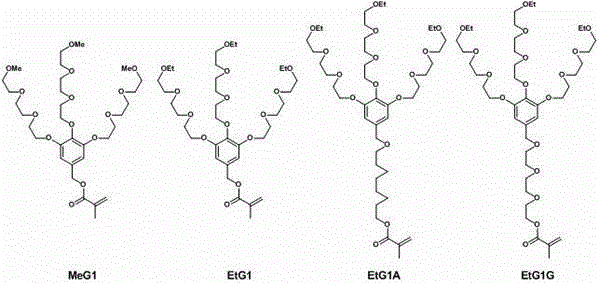

Temperature response monomer-based soap-free emulsion polymerization method

The invention provides a temperature response monomer-based soap-free emulsion polymerization method. According to the method, a temperature response monomer water solution is utilized; when the temperature of a system ascends to above a minimum critical solution temperature, the monomer is subjected to dehydration and phase change to generate an aggregate in water, the local concentration of the monomer is increased and the aggregate is similar to a micelle; and the monomer is subjected to polymerization reaction under existence of a water-soluble initiator. The emulsion is formed only through temperature increase under the condition of not adding an emulsifier, so that soap-free emulsion polymerization is achieved, and elusion polymerization can be achieved by the emulsion and a non-temperature response monomer. The temperature response monomer-based monomer soap-free emulsion polymerization method has the advantages that the influence of the emulsifier on the performance of a product can be avoided, and meanwhile, the complicated technology of the emulsifier is omitted.

Owner:SHANGHAI UNIV

Method for treating wastewater containing rubber latex

ActiveCN102442721BAchieve demulsificationEasy to handleWater/sewage treatment by flocculation/precipitationLiquid layerWastewater

Owner:CHINA PETROLEUM & CHEM CORP +1

Soap-free emulsion polymerization method based on temperature responsive monomer

InactiveCN106084107APolymerization conditions are mildAchieve aggregationEmulsionLower critical solution temperature

The invention provides a soap-free emulsion polymerization method based on a temperature responsive monomer. The method takes a temperature responsive monomer aqueous solution, when a system temperature rises above the lowest critical solution temperature, the monomer is subjected to dehydration phase change, an aggregate is produced in water, the monomer local concentration is increased, and the aggregate is similar to a micelle; in the presence of a water soluble initiator, the monomer is subjected to a polymerization reaction. Under a condition without addition of an emulsifier, the emulsion is formed only by increasing the temperature, soap-free emulsion polymerization is achieved, and emulsion copolymerization with a non-temperature-responsive monomer can be achieved. The method has the advantages that the influence of the emulsifier on the performance of the product can be avoided, and the complex process of removing the emulsifier is also omitted.

Owner:SHANGHAI UNIV

co2/n2 switch-type double-circulation extraction process and its application

ActiveCN112391190BReduce usageHigh puritySludge treatmentLiquid hydrocarbon mixture productionOrganic acidOil phase

The invention discloses a CO 2 / N 2 Switch-type double-cycle extraction process, oily solid waste and organic acid are mixed and separated to obtain mixed liquid A and solid waste; polyetheramine aqueous solution is added to mixed liquid A to separate oil phase and mixed liquid B, and CO is introduced into mixed liquid B 2 After protonation, the organic acid and the mixed solution C are separated, the organic acid is returned to the oily solid waste, and N is passed into the mixed solution C 2 CO is obtained after deprotonation 2 And polyetheramine aqueous solution, polyetheramine aqueous solution returns in the mixed solution A, CO 2 Returning to the mixed solution B, the temperature control range of the whole extraction process is 30-70°C; (1) The combination of organic acid and polyether amine aqueous solution not only achieves the purpose of oil removal but also realizes the separation of organic acid and polyether amine. The recycling of amine aqueous solution is environmentally friendly, safe in operation and saves oil removal costs; the recovery rate of oil products is high, and no other impurities are introduced. The recovery rate of conventional oil products, especially heavy oil products, can reach 90%. above.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com