Continuous fiber agglomeration coarse-grain oil eliminator

A coarse-graining and degreasing technology, which is applied in the fields of grease/oily substance/float removal device, liquid separation, separation method, etc., can solve the problems of difficult elution and regeneration, difficult to put into use, and poor fiber hydrophilicity. , to achieve the effect of large processing capacity, easy elution and regeneration, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] First of all, the hydrophilic modification is carried out on the long fiber filter material to improve the regeneration ability of backwashing.

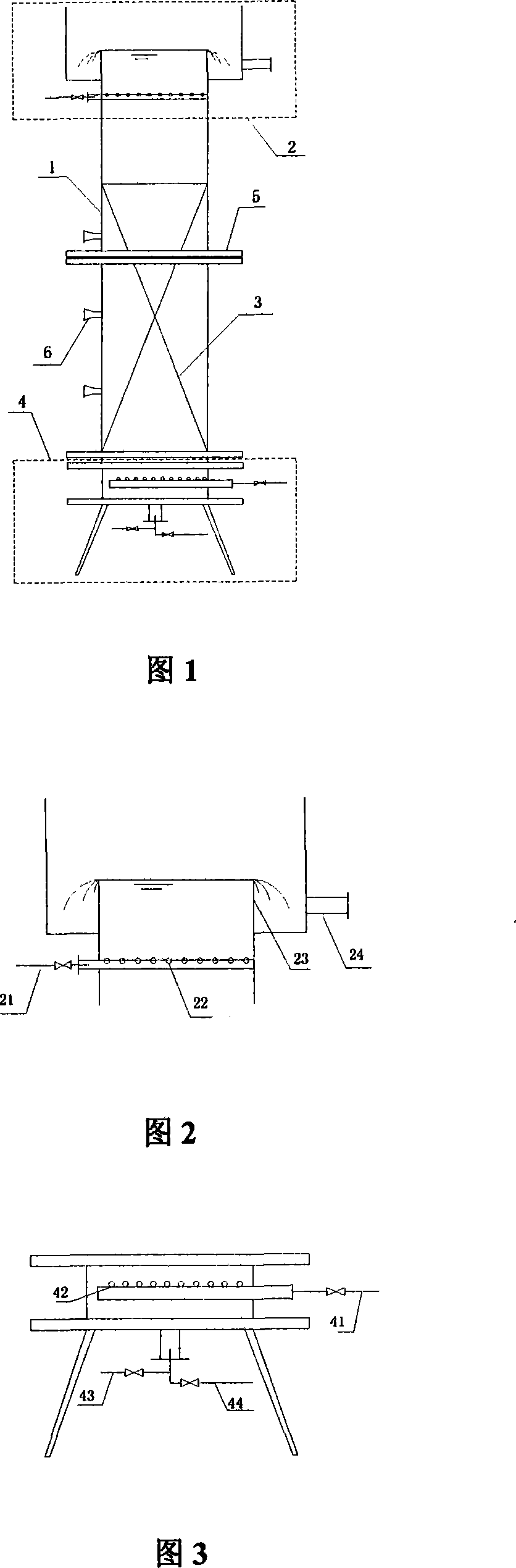

[0018] The degreaser includes degreasing reactor cylinder 1, water inlet and overflow device 2, modified fiber bundle assembly 3, water outlet and backwashing device 4, degreasing cylinder connector 5, sampling port 6; The hydrophilic modified fibers are woven into component units in the form of fiber bundles, installed in the oil removal reactor (as shown in the attached picture), the upper part is fed with water, and the lower part is aerated to realize the agglomeration and coarse graining of oil droplets in oily wastewater. Reach the purpose of oil-water separation; Based on the characteristics of relatively cheap price, the present invention uses polyester fiber as filter material, and preferably modifiers such as polyvinyl alcohol, sulfamic acid, and polyethylene glycol carry out hydrophilic modification to this fiber, ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com