Preparation method of atom self-doped porous material

A porous material and self-doping technology, which is applied in the field of catalysis and new energy material preparation, can solve the problems of precursor pore system shrinkage, weaken pore wall, destroy original pore system, etc., achieve high specific surface utilization and eliminate mass transfer Cliff, to achieve the effect of coupled mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: In this embodiment, seaweed is selected as the precursor, ethanol aqueous solution is the polar solvent, water is the freeze-swell liquid, and sodium citrate is the filler. The specific steps are as follows:

[0032] First put 5 grams of seaweed into 60 ml of ethanol aqueous solution, seal it in a hydrothermal reactor, heat it at 110°C for 12 hours, then take it out and soak it in water, pack it in a ziplock bag, and freeze it in liquid nitrogen for 2 hours , remove and dry.

[0033] Then soak in saturated sodium citrate aqueous solution for 24 hours, and then dry at 60°C for 8 hours. Put the obtained laver into a corundum boat and put it into a tube furnace. Raise the temperature to 850°C, keep it for 1 hour, and then cool down to room temperature to take out the sample;

[0034] First wash with distilled water 3 times, then soak in distilled water for 24 hours; take out and dry at 110° C. for 6 hours to obtain a porous material.

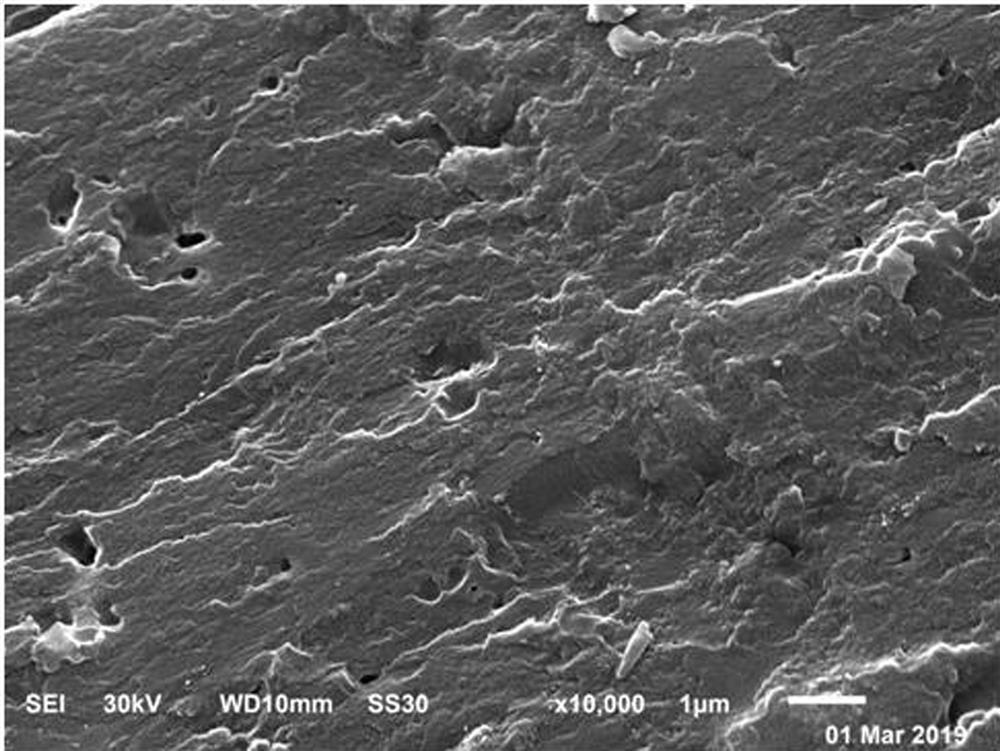

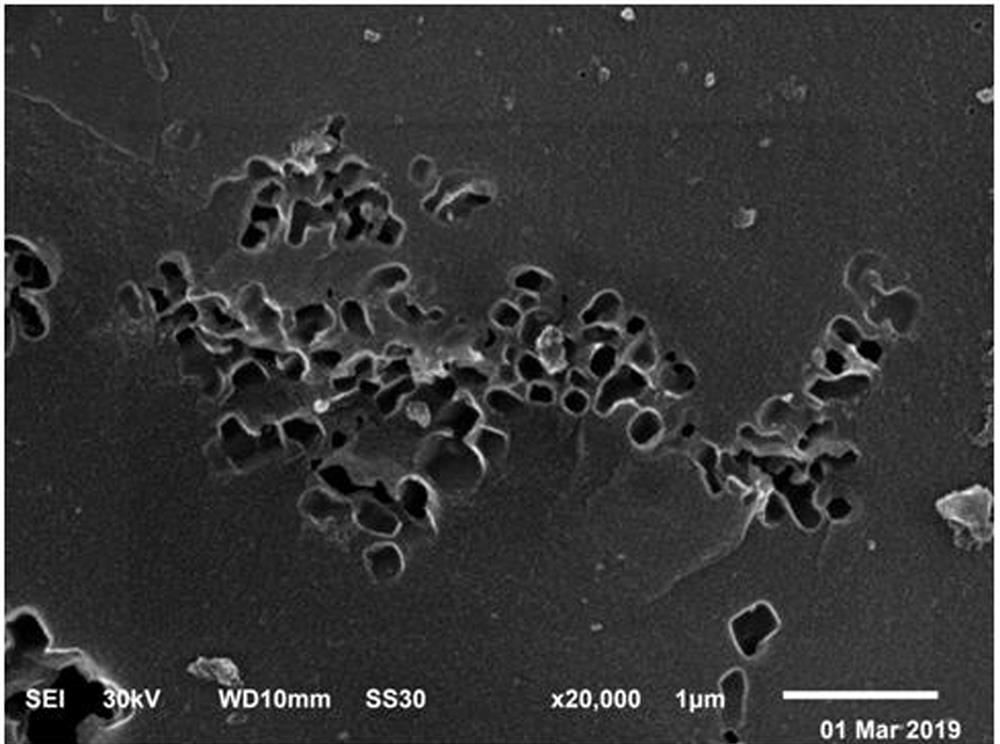

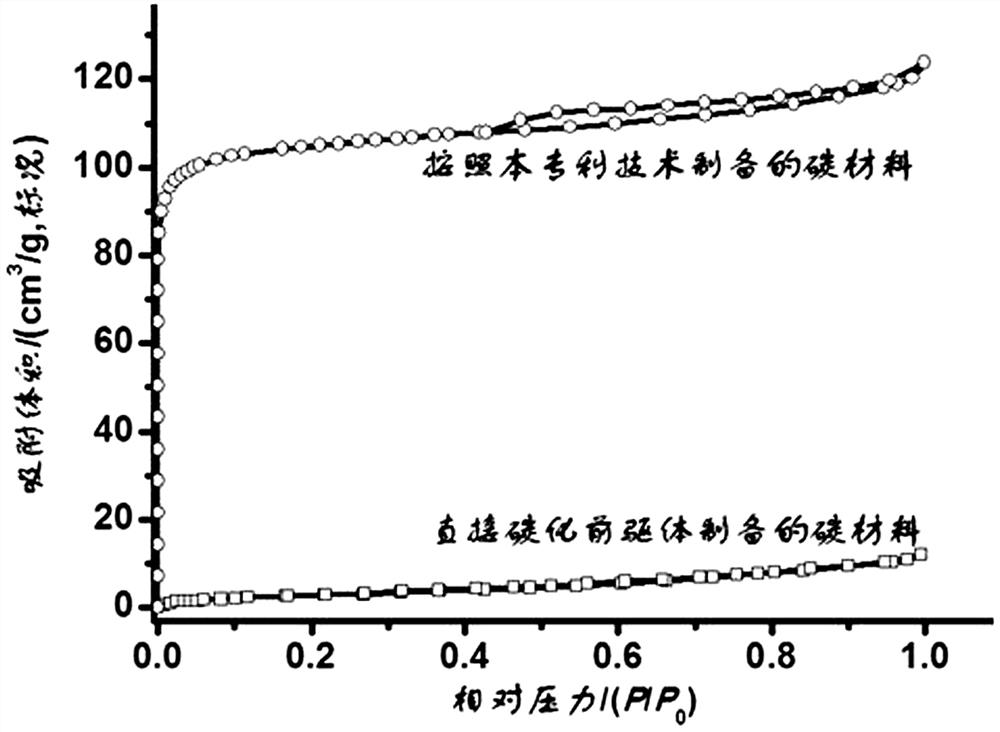

[0035] From attached f...

Embodiment 2

[0040] Embodiment 2: In the present embodiment, a kind of method for preparing the porous material of self-doping atom, select polymer material ion-exchange resin as precursor, distilled water is polar solvent, water is freeze expansion liquid, calcium bicarbonate is Filling, the specific steps are as follows:

[0041] First put 10 grams of ion exchange resin into 60 ml of distilled water, seal it in a hydrothermal reactor, heat it at 120°C for 12 hours, then wash and soak it with distilled water, pack it in a ziplock bag, and freeze it in dry ice for 5 hours; remove and dry.

[0042] Then soak in saturated calcium bicarbonate aqueous solution for 2 hours at 0°C, then dry at 90°C for 1 hour to convert it into calcium carbonate, soak in calcium bicarbonate aqueous solution for 2 hours and dry again, put the filled ion exchange resin into corundum Put the boat into a tube furnace, use argon flow as the inert atmosphere, raise the temperature from room temperature to 800 °C at 2...

Embodiment 3

[0045] Embodiment 3: In this embodiment, a mixture of laver and phenolic resin polymer is selected as the precursor, water is used as the polar solvent, saline is used as the freeze expansion liquid, and sodium hydroxide and hydrochloric acid are used as fillers. Specific steps are as follows:

[0046] First put 10 grams of seaweed and 5 grams of phenolic resin polymer into 120 ml of distilled water at the same time, seal it in a hydrothermal reaction kettle and heat it at 120°C for 10 hours, then wash and soak it with distilled water, and pack it in a ziplock bag. Place it in minus 50°C ethylene glycol aqueous solution and freeze it for 4 hours, take it out and dry it.

[0047] Then soak in saturated sodium hydroxide aqueous solution at 20°C for 2 hours, then dry at 50°C for 8 hours, then put it into the reaction kettle and fumigate it with concentrated hydrochloric acid to convert it into sodium chloride, and then put the obtained precursor into the corundum boat, Put it in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com